Page 1

AE

SERVICES

STANDARD

AUTTIORISATION

SECTION

SERVICE

REVTSION:-

DATE:

14.03.2001

1

PROCEDURE

7

ЗЕ

Tec 4 Vaporizer

Section

1

Service

Manual

Page 1 of

Revision

18

7

Page 2

Page 3

AE

SERVICES

1.

Introduction

‘The

standard

Disassembly

Thorough

Inspection

Renewal

Lubrication

Tactile

Checks

Te-calibration

Unless

cleaning.

for

of

Wicks,

Tests.

of

the

otherwise

service

of

delivered

as

ol a Tec 4 Vaporizer

components

damage

and

wear.

Seals

and

concentration

necessary.

stated,

the

SECTION

RVICING

shall

as

required,

damaged

procedures

or

worm

under

closely

which

1

consist

components

follow

of

the

following:

as

defined

conditions

are

applicable

required.

and

to

all

Tec 4 vaporizers.

At

cach

stage

of

Service

generated

Record

by

the

testing,

AEOF-10.7.1/3

lascr

the

operator

shall

(filled-in

reltaciometer

and

CONTROLLED

record

the

by

hand)

and

laptop

computer.

DOCUMENT

test

results

on

the

on

Test

Certificate

Tee 4 Vaporizer

Service

Section

Manual

Page

20118

Revision

7

Page 4

Page 5

AE

SERVICES

2

21

211

ZII

2112

2.1.2

SERVICE

Draining

Method

Draining

a)

Drain

liquid

tilting

Drying-Out

a)

Mount

b)

Passa

hour

PROCEDURES

and

Drying

1

alt

the

free

can

be

scen

the

vaporizer

the

vaporizer

flow

of

5 litres/minute

until the

wicks

Alternatively:

a)

Block

the

outlet

of

the

vaporizer

flow)

Method

2

for

drain

one

hour

Out

liquid

from

the

in

the level

slightly

on

tube.

forwards,

the

test

air

have

dried

the

vaporizer,

to a vacuum

until the

vaporizer

vaporizer

Note.

stand

or

oxygen

out.

Lixhaust

tum

system

until

Draining

and

turn

through

to

the

dial

(between

îs

dry.

only a very

can

be

assisted

the

dial

to

its

the

vaporizer

suitable

to

its

maximum

10

and

a

gas

30

small

amount

by

maximum

for

scavenging

setting

litrestminute

of

carefully

setting.

at

Icast

one

system

and

connect

negative

FARA!

212

Agent

Draining

b)

e)

Drying

a)

b)

©).

Recovery

a}

Connect

into

the

Open

To

slightly

Ensure

Open

measuring

Condenser

Transfer

future purity check.

the

the

the

drain

clamp

screw.

the

drain

ensure

that

until

Out

that

the

drain

cylinder,

Record

the

Winchester

Condensers

vaporizer

port

screw

all

liquid

the

Condenser

valve,

to

of

the

and

liquid

can

and

Record

Form

agent

into

(Refer

bottle

in

the

vacuum

keyed

sct

the

is

drained

no

longer

is

switched

drain

the

system

filler

assembly

dial

to

its

maximum

from

the

be

scen

flowing

‘OFF.

olf

all

agent

quantity

of

anaesthetic

AEOF-10.6.1/1

the

appropriately

(0

TEST

the

designated

fabelled

EQUIPMENT

quarantine

by

inserting

and

vaporizer,

into the

into the

brown

drug

clamping

mark.

it

«itt

the

glass

appropriately

agent

recovered

Winchester

MANUAL

arca

of

the

Section

drug

specific

in

vaporizer

adaplor

position

with

farward

Mask

labelled

on

the

bottle

for

11).

Store

cupboard.

Teo 4 Vaporizer

Section

|

Service

Manual

[7

ROLLED

DOGUNENT

一

—

Page 3 of

Revision

18

7

Page 6

Page 7

AE

SERVICES

ENFLURANF

Close

the

Turn

on

the

out

of

the

‘Tum

off

the

NOTE:

may

In

be

set

ISOFLURANE

Close

the

pipe

“T

connection

aitting

Öpen

d)

Switch

(the

clapse

©)

During

pressure

action

£

_If

gun

the

on

green

in

drying-out

indicates

must

the

who

will

CONDENSFR

valve

on

the

outlet

drying-out

pump

system.

drying-out

order

to

in

the

pump,

speed

red-light

CONDENSER

valve

on

the

outlet

on

the

(0

force

out

any

outlet

valve

and

the

Condenser

lamp

will

be

illuminated)and

order

to

permit

monitor

thal

ice

be

taken

to

restore

specified

pressure

take

the

required

ONLY

lo

the

at

the

close

up the

Condenser

Condenser

time-switch

the

and

open

to

force

drain

valve,

thawing-out

position

ONLY

to

the

condenser

Condenser

remaining

re-fit

by

turning

the

"I"

the

inlet,

water

piece.

and

open

and

blow

[rom

switch

to

the

the

allow a period

the

correct

the

is

causing a restriction

is

operating

Condenser

the

Condenser's

exceeded,

pressure

inform

temperature

gauge.

to

optimum

the

action.

the

drain

valve.

any

temaining

and

open

the

process,

the

drain

through

the

water

outlet

the

heater

valve.

Detach

Condenser

system

cooling

the

Service/Test

position,

of

45

minutes

to

be

An

increase

gas

low,

operating

to

achieved.

in

and

that

condition.

Supervisor,

valve.

switch

the

using

an

22

2)

THEN:-

h)

i)

고

Recordthe

Blankofl'iheinict

Connect

Turn

dry out

quantity

the

vaporizer

the

dial

to

as

follows:

of

dricd-out

pori

with a plastic

to

the

maximum

the

evacuation

Halothane

Enflurane

vaporizers

on

AEQF-10.6.1/1

plug

system

calibration

/

Lsofluranc

mark

and

allow

the

40

minutes

30

minutes

vaporizers

to

Max.

Max

Tec 4 Vaporizer

Section

Service

Manual

Page 4 of

Revision

18

7

Page 8

Page 9

AE

SERVICES

23

24

25

INSPECTION/CITECK

With

the

exception

Interlock

carefully

vaporizer

Visually

damaged

Ensure

Block,

remove

using a cloth

examine

or

wom

that

the

satisfactorily

DIAL

ASSEMBLY

Remove

Loosen

the

the

three

of

the

and

the

all

other

moistened

the

vaporizer

parts

during

Locking

onto

the

Selectatec

(Figure

self

adhesive

cheese-head

Assembly.

Inspect

Renew

Check

NOTE:

the

that

the

Clicker

any

parts

DP

CONTROL

the

nylon Stop

If

the

stop

maximum

the

dial

dial

can

Plungers

which

arc

(Figure

Control

contro!

setting

reach

the

Serial

Number

vaporizer

self

Lever

type

label,

adhesivo

lor

the

operates

labels

with

Elecsol

signs

service.

positively

manifold,

1,

Page

8)

Dial

Cover

Label

screws

and

damaged

2,

for

has

to

may

maximum

(M3)

Springs

or

worn

Page

8)

damage

be

replaced,

have

to

he a adjusted

graduation

Label,

located

on

the

and

adhesive

ED

or

of

external

and

from

the

which

secure

and

also

the

and

wear

and

the

position

by

on

the

on the

font

similar

damage.

that

rear face

face

of the

residue

cleaning

Where

the

vaporizer

Dial

the

Dial

locking

catch

if

necessary

of

the

edge

culling

dial

or

of

the

Interlock

from

Block,

the

agent.

necessary,

renew

locks

and

remove

the

mechanism.

replace

of

the

stop

filing

the

stop

so

dial

at

2.6

REMOVING/REPLACING A ROTARY

Remove

Peel-off

hexagon

Plate.

Unscrew

Assembly.

It

may

damage

Carefully

Note.

Woodrult

Unscrew

Unscrew

Lift

off the

Spring

Remove

Pins,

Remove

Interlock

Note.

at

this

Tec 4 Vaporizer

Section

1

Service

the

Locking

the

self

adhesive

socket

head

completely

be

necessary

the

black

anodizing

remove

There

Key

and

the

the

are

two

and

the

remove

four

MS

Interlock

in

place

the

Pivot

Cam

and discard

Block.

If

it

is

necessary

point.

Manual

Lever serew (M3),

Label

from

the

screws

the

to

Woodruff

designs

the

Block,

(M4).

two

Pozi

lever

out

of

the

of

Rotary

later

one

three

M3

and

the

two

leaving

and

Retaining

the

black rubber

to

fit a new

[CONTROLLED

——

Remove

head

screws

these

assemblies

interlock

Key

and

Valve

has

an

integral

clamp

M4

serews

the

Rotary

Ring

Serial Plate,

(Figure

3,

Page 9 and

Figures 4 &

the

Locking

interlock

the

Block

two

Pozi

and

lift

but

Lever

head

out

care

Block.

put

to

one

side

for

in

use.

The

earlier

key.

screws

DOCUMENT

and

Clamp

that

secure

Valve,

from

the

Distributor

the

the

Washers

Block,

Seal

Interlock

1

5,

Page

and

the

to

expose

serews

the

Pivot

must

be

taken

later

use.

one

Tabs.

Interlock

and

lifting

over

from

the

Block

10)

Spindle

the

Bush.

heads

of

and

Top

the

Cover

Ann/Platform

not

to

uses a separate

Biock.

Compression

the

Spirol

bore

of the

should

be

drilled

Page 5 of

Revision

18

7

Page 10

Page 11

AE

SERVICES

b)

Carefully

the

Thrust

bft

the

Rotary

Washer(Thick),

Valve

off

Spring

the

Sump

and

Thrust

Cover

and

remove

Washer(

hin).

and

place

lo

one

side

NOTE:

and

The

great

handled.

¢)

Inspect and

Clean

the

taking

cloth,

on

removed

with a soft

clean,

Materials

d)

taking

dry

e)

Before

Service

1)

Very

particular

NOTE.

the

surface

by

dry

of a more

Thoroughly

care

cloth

fitting

Record,

carefully

positioned

Rotary

care

clean

Rotary

Valve

must

the

Valve

care

The

Rotary

of

the

gently

rubbing

cloth

moistened

cloth

abrasive

clean

the

nat

to

scratch

the

Rotary

place

to

the

right

and

be

taken

not

Rotary

not

Valve,

Valve

by

wiping

to

damage

Valve

which

with

with

nalure

Sump

Cover

or

damage

Valve,

the

Rotary

when

viewed

Sump

Cover

are

lo

damage

and

with a soft

the

must

are not

‘Duraglit’

Flecsol

must

with a sofi

the

write

the

Valve

[rom

them

Sump

lower

not

be

easily

Silver

FD,

Finally,

net

main

Valve

on

the

the

Cover

cloth

soaked

be

cloth

sealing

Sump

frant

very

important

when

they

checking

moistened

face,

then

polish

in

L'lecsol

removed

Polish

used.

by

Wadding

il

should

moistencd

face.

Then

Pressure

Reading,

Cover

of

with

the

vaporizer.

precision

are

being

for

with

components

worked

damage.

Elecsol

with a clean,

FD.

Any

marks

wiping,

be

should

and

then

polished

with

Eleesol

polish

with a clean

if

available,

the

key

or

keyway

with

on

or

FD,

dry

or

dirt

be

wiped

a

FD

on the

£)

Inspect

necessary

h)

Place

and

1)

‘Take

special

j)

Check

over

k)

Čarefully

and

‘Tec 4 Vaporizer

Section

|

the

ie.

the

thinner

then

the

anew

fitting

that

the

fitting

press

fully

lightening

Service

thinmer

Distributor

the

Thrust

if

damaged

Thrust

thicker

or

Washer

Thrust

‘U’

siceve

and

PTFE

O-Ring

sleeve

with

place

downwards

the

six ( Four

Washer

wom.

Washer.

Seal,

is

the

on the

Manual

and

also

the

over

the

stem

lubricate

the

sleeve

fitted

pointer

Interlock

MS

with

over

to

the

Interlock

to

the

Block

and

two

thicker

of

the

Valve,

Thrust

‘Fomblin’

the

valve

stem.

Block

front

and

hold

M4)

retaining

Washer

followed

UTI8

gecasc,

then

position

it

in

place

screws

and

replace

by

the

fit

the

whilst

Page 6 of

Revision

as

Spring

to

the

Block

fitting

18

7

Page 12

Page 13

AE

SERVICES

1)

Ensure

Grease

Rotary

that

the

Valve

adequately

Secure

evenly

Tin-up

m)

Fnsute

the

tightening

keyways

thal

assemblies

Secure

that

n)

Check

Plungers

M3

0)

Install

Knob

Install

Note

Inspection

the

there

is

that

and

screws.

the

Bush

the

that

the

there

is

sufficient

Pivot

Cam

as

required

spindle

lubricated

Retaining

there

and

assemblies

minimum

Spring

Springs

Lop

on

Lock/Unlock

Lock/Untock

stage.

into the

with

Fomblin

Ring

with

down

in

position.

in

Cam

and

is

sufficient

re-fit

the

Interlock

with

clcarance

is

in

position

are

in

Cover

Plate,

the

Locking

Lever

Knob

Label

Fomblin

Interlock

UT18

with

Fomblin

Block.

UTI8

the

three

Rotary

Valve

Fomblin

UT18

assembly.

two

M4

screws,

belween

then

re-fil

position

securing

and

re-fit

with

Spindle.

and sceure

may

be

fitted

grease

grease

M3

screws

then

grease

tightening

the

Pivot

Stop

two

with

on

UTI8

grease

Ensure

that

and

fit

and

fit

the

Woodrull

on

the

down

Bearings

Release

the

Dial

Assembly,

M4

screws,

one

M3

screw.

after

the

the

Button.

inal

Slip

Ring

and

then

the

retaining

into the

Clamp

Interlock

Tabs,

Key

Platform

in

position

and

Pivot

Check

sccuring

Install

the

Test

ai

and

replace.

fit

over

the

Ring

is

Black.

carefully

and

Pivot

but

and

Arm

ensuring

Arm.

that

Clicker

with

three

Lock/Unlock

the

Final

‘Tee 4 Vaporizer

Section

1

Service

Manual}

Page 7 of

Revision

18

7

Page 14

Page 15

AE

SERVICES

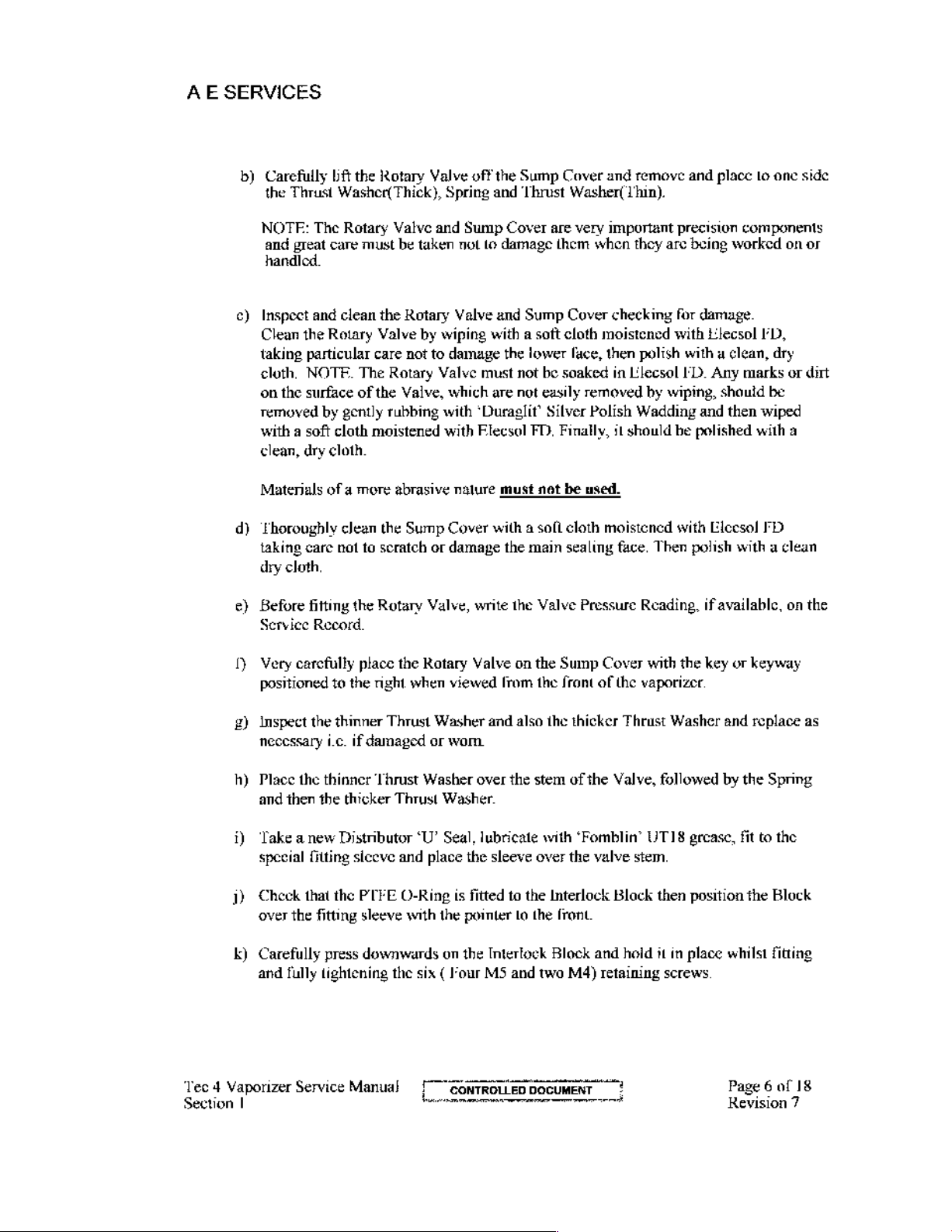

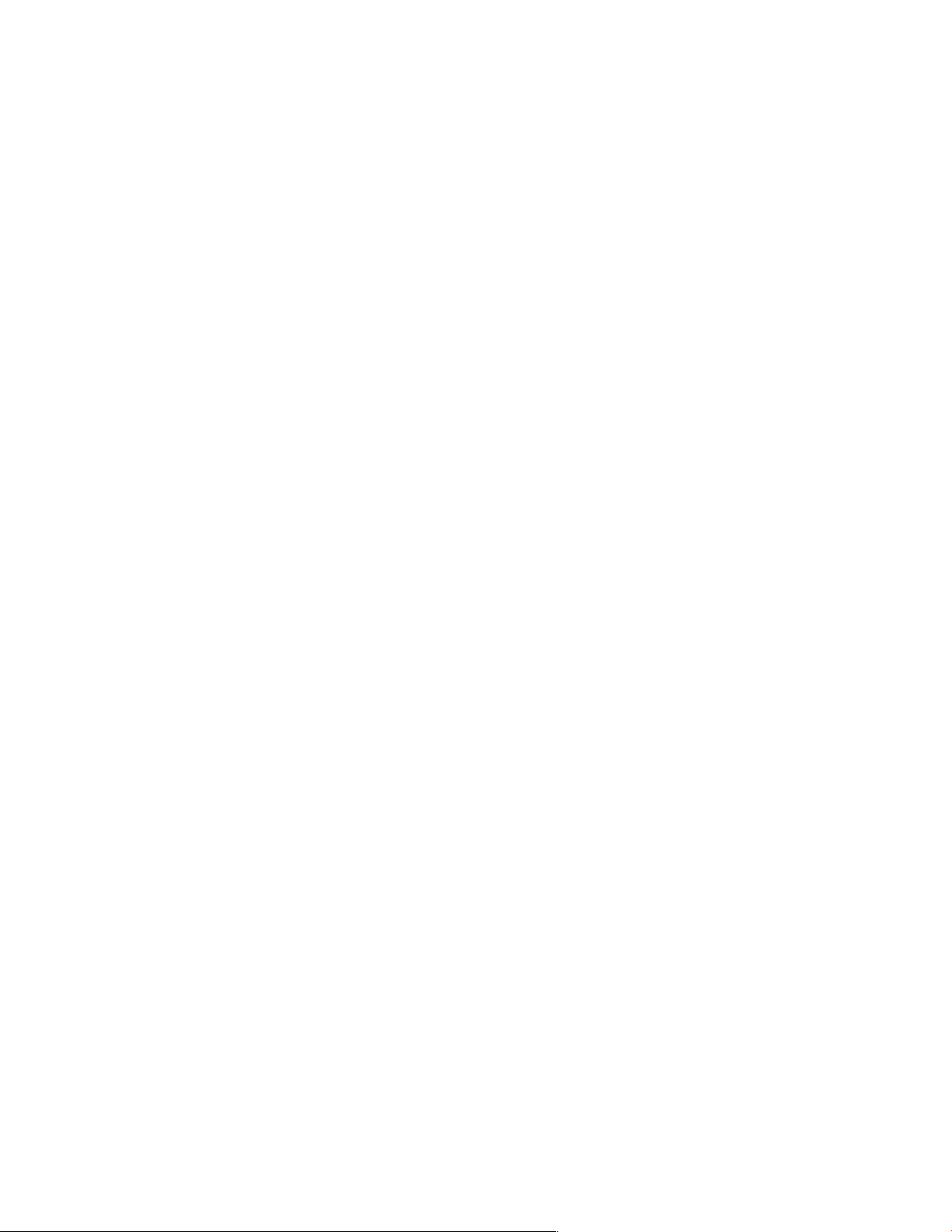

Figure 1 Dial

Assembly

Tec 4 Vaporizer

Section

I

Service

Manual

|

CONTROLLED

Figure 2 Dial

DOCUMENT

and

Stop

Control

Page 8 of

Revision

18

7

Page 16

Page 17

AE

SERVICES

E

.

+

n

品

i

na

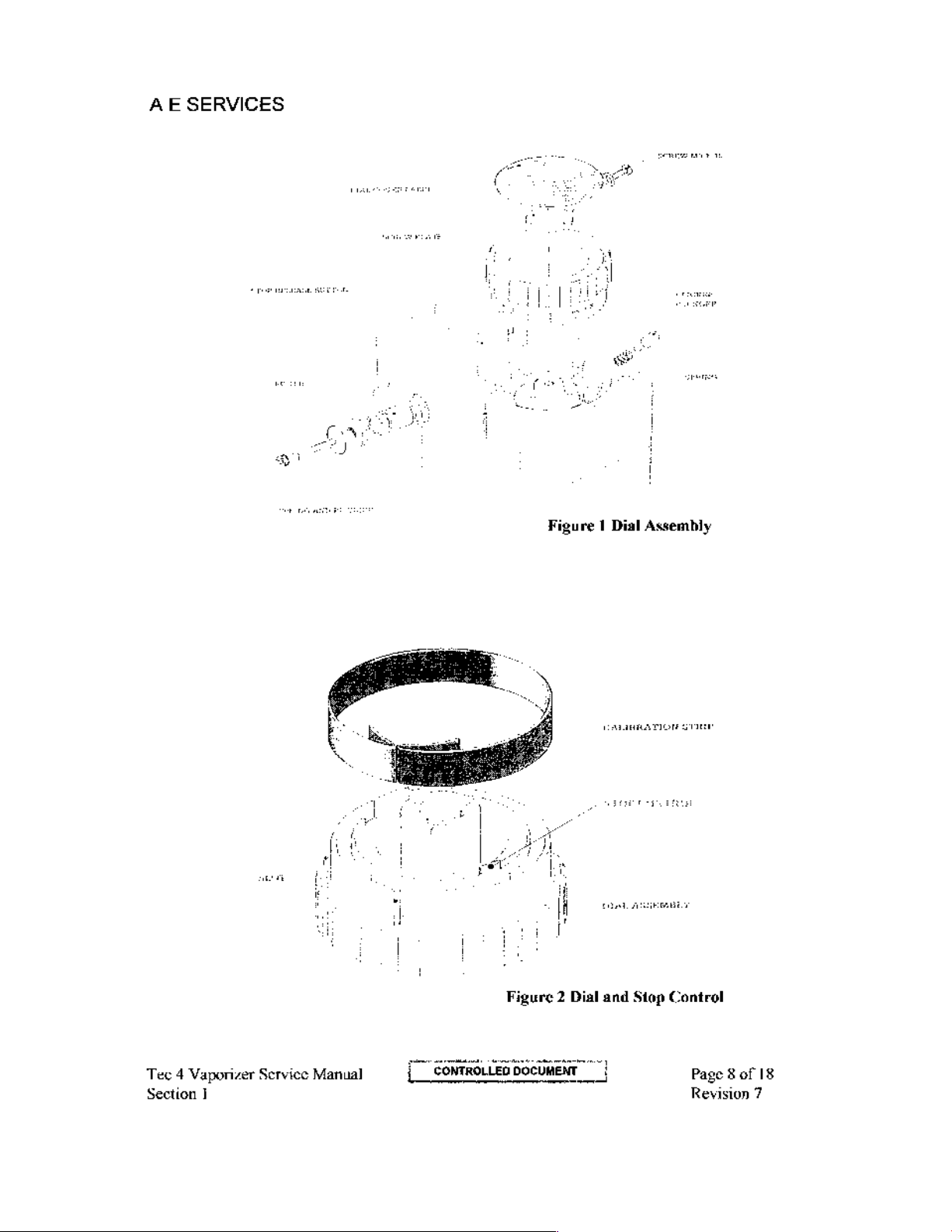

Tec 4 Vaporizer

Section

|

Service

Manual | CONTROLUFO

DOCUMENT";

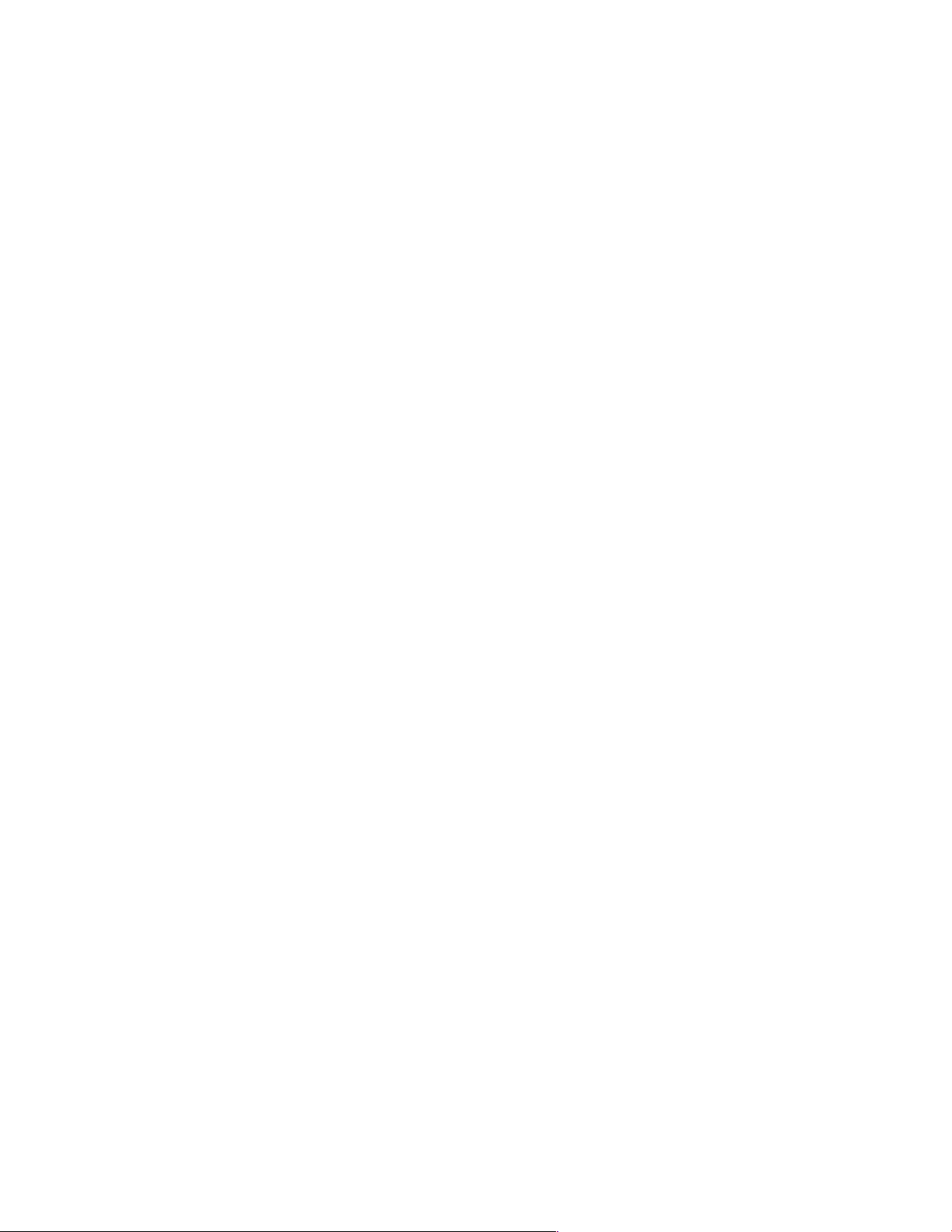

Figure 3 Mechanism

Page 9 of

Revision

18

7

Page 18

Page 19

AE

SERVICES

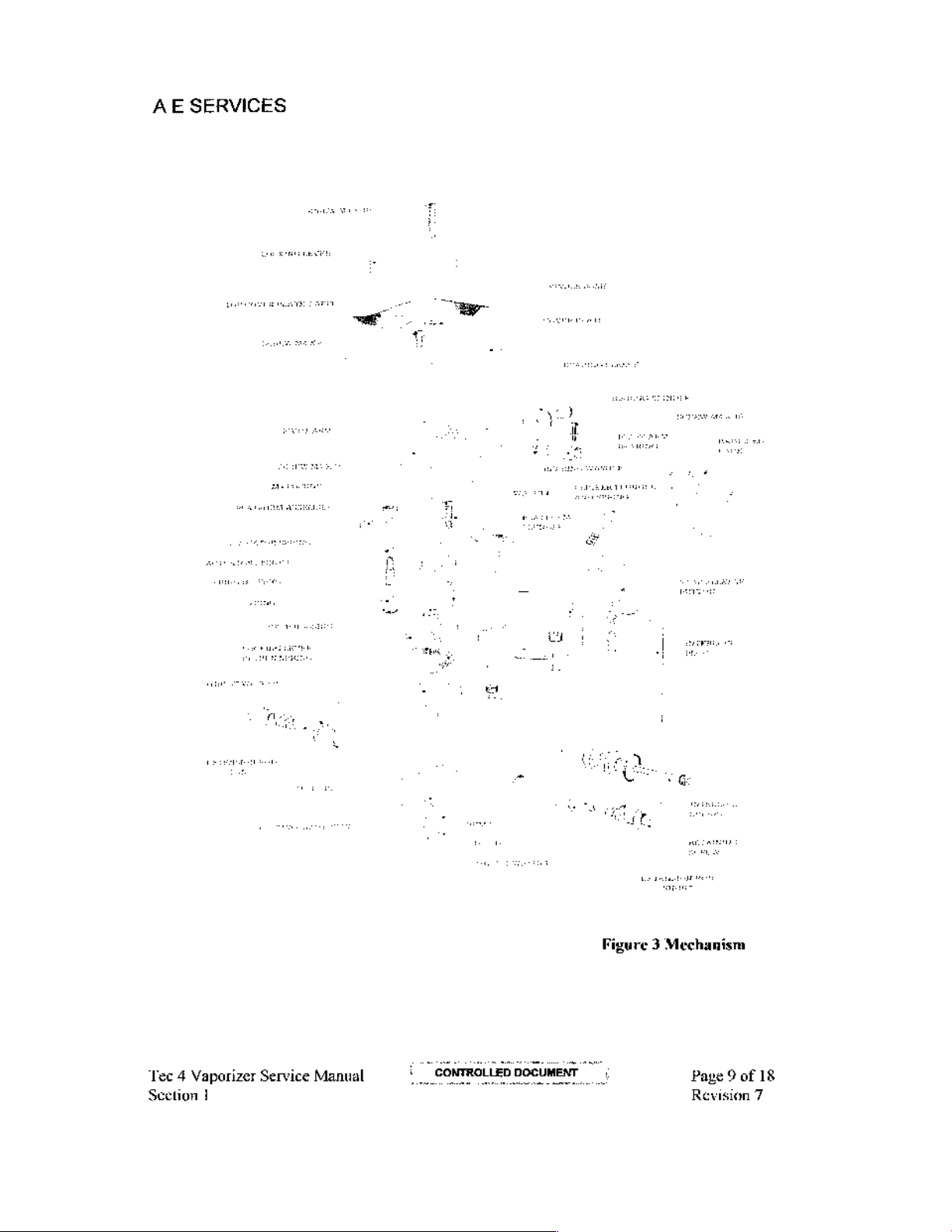

Figure 4 Rotary

Vaive

i

Tec 4 Vaporizer

Section

1

Service

fa

Manual

[CONTROLLED

DOCUMENT

ーーー

Figure 5 Pivot

|

|

|

Cam

Page

10

of

Revision

18

7

Page 20

Page 21

AE

SERVICES

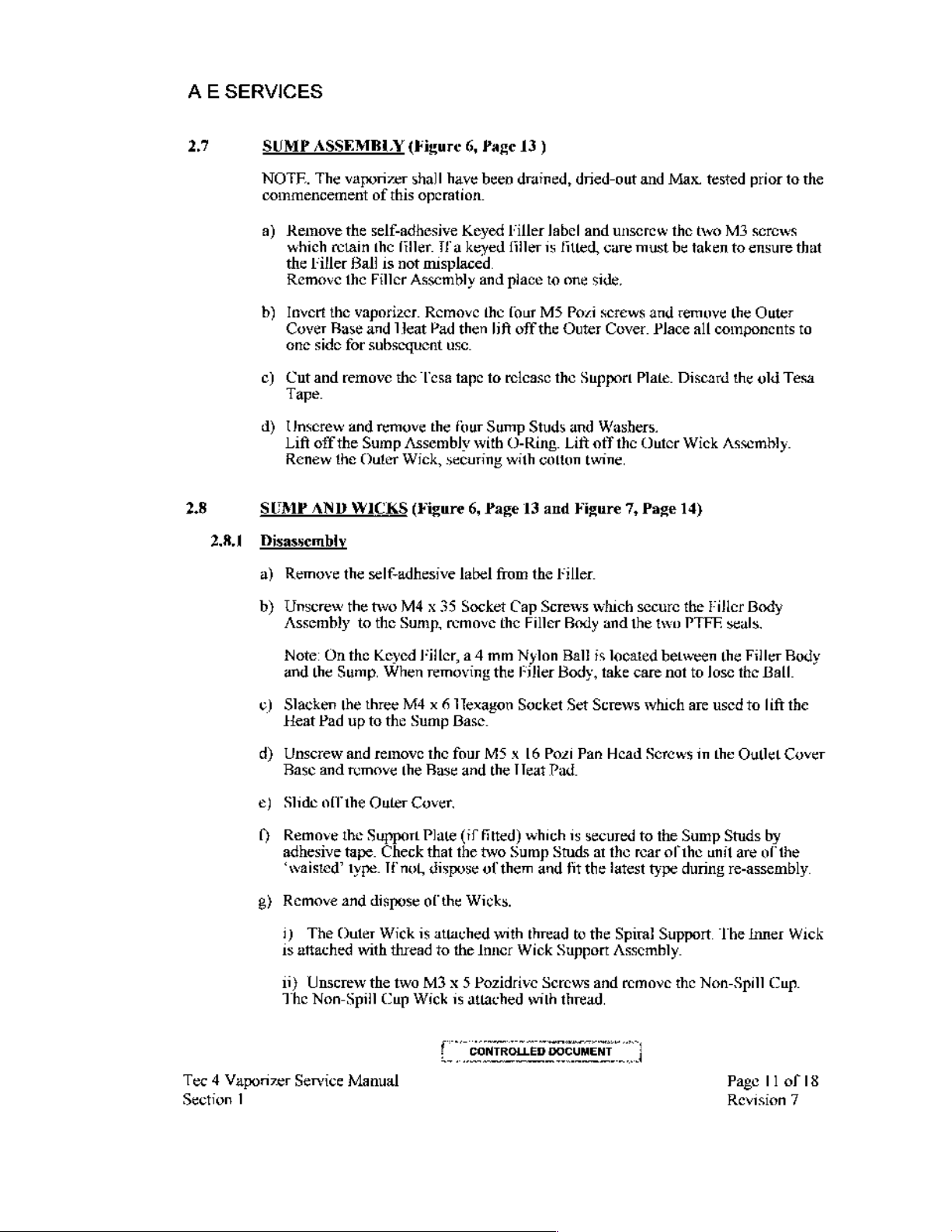

27

28

2.8.1

SUMP

NOTE.

commencement

a)

b)

©)

ASSEMBLY

The

vaporizer

Remove

which

the

Remove

Invort

Cover

one

Cutand

the

retain

killer

Ball

the Filler

the

vaporizer.

Base

side

for

remove

of

this

self-adhesive

the

is

and

Heat

subsequent

Tape.

d)

Unscrew

Lift

Renew

SUMP

off

the

the

AND

and

remove

Sump

Outer

WICKS

Disassembly

a)

Remove

the

self-adhesive

(Figure

shall

6,

Page

have been

operation.

Keyed

filler.

Tfa

keyed

not

misplaced

Assembly

Remove

Pad

and

{he

then

lift

use.

the

Tess tape

the

Assembly

Wick,

(Figure

to

four

Sump

with

securing

6,

Page

label

13)

drained,

I'iller

label

filler

is

fitted,

place

to

one

four

MS

off

the

Outer

release

the

Studs

O-Ring.

with

from

Lift

cotton

13

and

the

Filler.

dried-out

and

and

unscrew

cure

must

side.

Pozi

screws

Support

and

Washers.

off

and

Cover.

Place

Plate.

the

Outor

twine,

Figure

7,

Page

Max.

tested

the

two

M3

be

taken

to

remove

Discard

Wick

the

all

components

the

Assembly.

14)

prior

to

the

scrows

ensure

that

Outer

to

old

Tesa

b)

Unscrew

Assembly

Note:

On

and

the

©)

Slacken

Heat

Pad

d)

Unscrew

Base

and

e)

Slide

off

©

Remove

adhesive

‘waisted’

2)

Remove

i)

The

is

attached

ii)

Unscrew

The

Non-Spill

the

two

to

the

the

Keyed

Sump,

the

three

up

to

and

remove

When

the

remove

the

Outer

the

Support

tape.

Check

type.

If

and

dispose

Outer

Wick

with

thread

the

two

Cup

M4 x 35

Sump,

Socket

remove

Filler,

a 4 mm

removing

M4

x 6

Texagon

Sump

Base.

the

four

(he

Base

and

Cover,

Plate

(if

that the

nol,

dispose

of

the

is

attached

to

the

M3 x 5

Wick

is

Cap

Screws

the

Filler

Nylon

the Filler

Body,

Socket

MS x 16

the

fitted)

two

of

Pozi

Tleat

which

Sump

them

and

Pad.

Studs

Wicks.

with

thread

Inner

Wick

Support Asscmbly.

Pozidrive

attached

Screws

with

thread

which

Body

and

Ball

is

located

take

Set

Screws

Pan

Head

is

secured

at

the rear of

fit

the

latest

to

the

Spiral

and

secure

the

the Filler

two

PTFE

between

care

not

to

which

are

Screws

to

the

Sump

the

type

during

Support.

remove

the

Body

seals,

the

Filler

Body

lose

the

Ball

used

to

lift

the

in

the

Outlet

Studs

unit

are of the

Cover

by

re-assembly.

The

inner

Wick

Non-Spill

Cup.

Tec 4 Vaporizer

Section

1

Service

Manual

Page

11

of

Revision

7

18

Page 22

Page 23

AE

SERVICES

h)

Remove

Support

surfaces

i)

Note:

‘This

been

serviced

the

four

M4 x 10

Assembly

with

next

complete

Elecsol

ED

procedure

in

the

past

Cheese

or

only

three

lead

with

Thermostat

similar

needs

years.

Screws

and

Cover

cleaning

to

agent

be

carried

remove

Assembly.

out

the

Inner

Clean

if

the

vaporizer

Wick

the

external

has

not

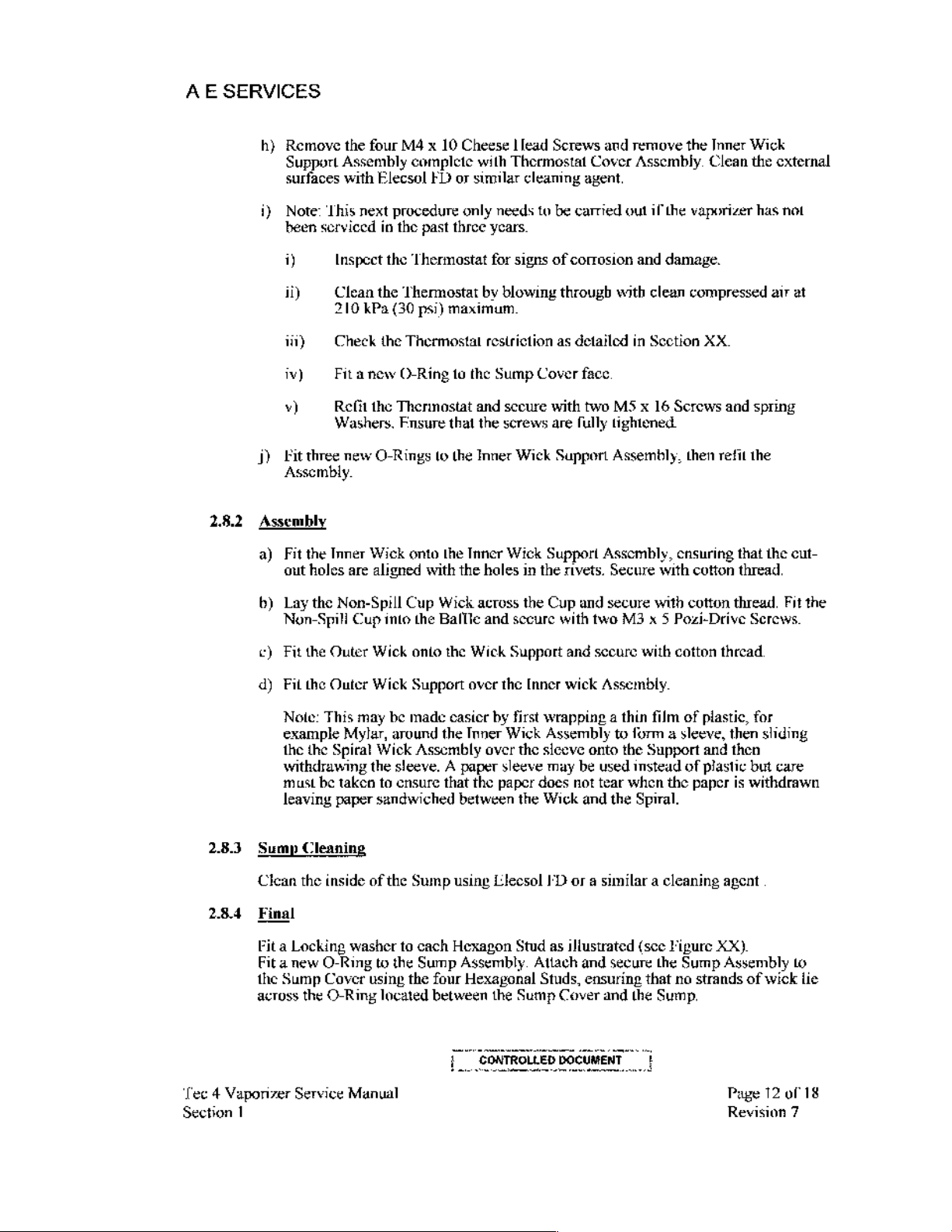

2.8.2

i)

ii)

iii)

iv)

у)

」)

Kit

three

Assembly.

Assembly

a)

Fit

the

Inner

aut

holes

b)

Lay

the

Non-Spili

«)

Fit

the

Outer

d)

Fil

the

Outer

Inspectthe

Clean

210

kPa

Check

Fita

Refît

Washers,

new

are

Non-Spill

Cup

Thermostat

the

‘Thermostat

(30

psi)

maximum.

the

Thermostal

new O-Ring

{he

Thermostat

Fnsure

O-Rings

Wick

aligned

Cup

into

Wick

Wick

to

that the

to

the

onto

the

with

the

Wick

the

Ballle

onto

the

Support

for

signs

of

by

blowing

restriction

the

Sump

and

secure

screws

Inner

Inner

Wick

holes

across

and

secure

Wick

Support

over

the

through

as

Cover

with

are

Wick

Support

Support

in

the rivets.

the

Cup

with

Inner

wick

corrosion

detailed

face.

two

fully

and

damage.

with

clean

in

Section

MS x 16

tightened.

Assembly,

Assembly,

and

two

and

secure

Secure

secure

with

with

M3 x 5

with

Assembly.

compressed

XX.

Screws

then

refit

ensuring

cotton

cotton

Pozi-Drive

cotton

thread.

air

and

spring

the

that

the

thread.

thread,

Screws.

at

cut-

Fit

the

Note:

This

example

the

the

withdrawing

must

be

leaving

283

284

Tec 4 Vaporizer

Section

Sump

Clean

Final

Fita

Fit a new

the

across

1

Cleaning

the

Locking

O-Ring

Sump

the

Service

may

be

Mylar,

Spiral

taken

paper

inside

around

Wick

the

sleeve. A paper

to

sandwiched

of

the

washer

to

the

Cover

using

O-Ring

located

Manual

made

casier

the

Inner

Assembly

ensure

that the

between

Sump

using

to

cach

Hexagon

Sump

Assembly.

the

four

Hexagonal

between

by

first

wrapping a thin

Wick Assembly

over

the

siceve

sleeve

paper does

the

Wick

Llecsol

Stud

Attach

Studs,

the

Sump

onto

may

be

not tear

and

FD

or a similar

as

illustrated

and

ensuring

Cover

film

of

plastic,

to

form a sleeve,

the

Support

used instead

when

the

Spiral.

a

(sce

secure

the

that

and

the

Sump.

and

of

plastic

the

paper

cleaning

Figure

Sump

no

strands

for

then

sliding

then

but

care

is

withdrawn

agent

XX).

Assembly

of

Page

Revision

to

wick

12

of

7

lie

18

Page 24

Page 25

AE

SERVICES

‘Tec 4 Vaporizer

Section

|

Service

Manual

i

R

al

Page

13

of

18

Revision

7

Page 26

Page 27

AE

SERVICES

NOLL.

the

restrict

The

knot

transfer

holes

fitting

of

must

are

the

Spiral

be

outside

not

obstructed,

Wick

of the

Assembly.

Inner

Tt

must

Wick

and

in a position

also

be

of a size

Figure 7 Wick

which

Renewat

where

does

not

‘Tec 4 Vaporizer

Section

I

Service

Manual

μα

DOCUMENT

Page

14

of

18

Revision

7

Page 28

Page 29

AE

SERVICES

29

THERMOSTAT

N.B. This

need

Unscrew

and

subsequent

procedure

of

adjustment

the

four

lift

off

the

assembly

use.

during

M4

Obtain a replacement

new

test

and

Secure

head

correctly

Invert

dì

Wrap

Wick

become

Note

Fit

e)

is

in

Secure

to

the

thermostat

sheet.

washers.

the

screws,

the

greaseproof

Support

tom

that

the

Sump

place.

the

sides

on the

Secure

the

Inner

Wick

ensuring

orientated.

vaporizer.

paper

into

position

and

that the

the leg

of

the

Assembly

Secure

Support

of

the

the

Sump.

Plate

needs

only

to

be

performed

calibration.

slotted

Thermostat

thermostat

that

Sump

head

screws

together

with

of

test

sheet.

Staple

to

the

Assembly

round

Inner

Spiral

over

in

to

the

the

three

O-Rings

the

Inncr

over

the

Inner

Wick

is

positioned

the

Wick

to

the

Sump

position

on

the

is

if

the

which

the

correct

the

Sump

Sump

Wick

Wick,

not

Assembly

Cover

the

secure

three

O-Rings,

type

thermostat

Cover

using

Cover

are

in

place

Assembly

ensuring

crumpled

at

the

bottom

ensuring

with

Sump

Studs

thermostat

the

Place

and

record

test

record

the

using

the

and

and

that the

into

the

of

the

that the

the

four

with

is

Inner

Wick

to

one

the

to

two

M5

[Dur

that the

slide the

paper

spiral.

Sump

Sump

Sump

Tesa

Tape

found

to

be

Assembly

side

for

number

the

M4

of

vaporizer

Pozi

screws

slotted

Wick

is

Spiral

has not

O-Ring

Studs

adhering

in

the

Fit

the

8)

Position

Base

M5

Secure

Cover

Tec 4 Vaporizer

Section

1

Service

Outer

the

into

position

Pozi

Pan

the

leat

Base

Manual

Cover

over

Heat

Pad

on

Head

screws.

Pad

to

the

Sump

on

the

base

the

Outer

Cover

the

Sump

CONTROLLED

Studs.

of the

Sump

and secure

with

the

three

DOCUMENT

Assembly.

to

M4

Fit

the

Sump

Grub

screws

the

Studs

Outer

Cover

with

the

in

the

Outer

Page

15

Revision

four

of

18

7

Page 30

Page 31

AE

SERVICES

2.10

2.10.1

FELLER

a)

b)

ASSEMBLIES

Keyed

inspect

black band,

two

When

marked

both

이

Filanew

over

d)

Unscrew

Cam.

open

<)

©

Remove

Spool

Remove

clean,

any foreign

Filler

Assembly

the

Level

Tube.

remove

triangles.

filting

the

new

bands

and

triangles

are

in

the

bottom

O-Ring

the

thread

and

‘This

the

Valve.

the

Valve

and

dry,

te

and

remove

aperation

Spool

Valve

using

a 2

dispose

compressed

matter.

(Figure

it

and

Level

If

il

is

fit

Tube,

8,

the

are

half

of

the

the

Level

then

to

compress

the

three

is

casier

if

from

mm

tommy-bar

of

the

Filler

air

to

the

Page

17)

an

earlier

type,

later

type

fit

two

towards

the

opening

‘Tube

Plug.

it

into

M2.5

x 6

the

Knob

the

Killer

Body.

to

Valve

Seal,

ports

at

which

which

now

in

It

Screws

is

unscrew

the

has

Scals

front

face

the

Block

is

necessary

the

groove.

which

tumed

fully

Fil

three

the

as

illustrated.

rear

of

the

incorporates a single

two black

and

ensure

of

the

to

secure

counter-clockwise

new

Piston

Filler

bands

and

that the

filler

and

that

stretch

the

O-Ring

the

Spool

seals

on

the

End,

Apply a jet

Bady

of

to

remove

black

Valve

lo

8

2.10.2

a)

b) | When

e)

d)

€)

fy

Fita

into

the Filler

Screw

Cap

Inspect

black

two

triangles.

marked

both

Fita

over

Unscrcw

Applya

Body

Fita

Body.

new

Valve

Seal

Body

Filler

Assembiy

the

Level

Tube. If

band,

remove

[tting

the

new

bands

and

triangles

arc

in

the

bottom

new O-Ring

the

thread

and

jet

to

remove

new

Seal

to

and

remove

of

clean,

any

Ring

then

as

illustrated

(Figure

it

is

an

earlier

it

and

fit

the

later

Level

Tube,

are

towards

half

of

the

opening

the

Level

Tube

to

compress

the

Filler

Plug and

dry,

compressed

foreign

to

matter.

the

Filler

Plug

CONTROLLED

and

then

carefully

9,

Page

17)

type,

type

which

fit

two

new

the

front

in

Plug.

Il

it

into

the

the

air

to

the

and

fil

DOCUMENT

refit

which

incorporates

has

two

black

Scals

and

ensure

facc

ol the

the

Block

is

necessary

to

groove.

Drain

Valve

Spindle

ports

at

the

the Filler

Plug

the

Spool Valve

a

single

bands

that

the

filler

and

stretch

the

Assembly.

rear

af

the

into the

Filler

and

black

that

O-Ring

Filler

Tec 4 Vaporizer

Section

|

Service

Manual

Page

16

Revision

of

18

7

Page 32

Page 33

AE

SERVICES

Figure 8 Keyed

Filler

Assembly

Tec 4 Vaporizer

Section

|

Service

7

Manual

i

CC

Figure 9 Screw

Cap

Filler

Assembly

Page

17

Revision

of

18

7

Page 34

Page 35

AE

2.11

SERVICES

a)

b)

ο)

d)

Fitihe

the

Support

Sump

Assembly.

Fit

thelleat

MS x 10

with

Screw

up

Fit

On

the

in

to

the

and

secure

the

Keyed

Pozi-Drive

Filler

and

Sump

Plate

and

Pad

and

Screws.

Body.

tighten

Base.

the

Filler

Filler

only,

secure

Cover

Base

Ensure

If

it

docs,

the

three

Ensure

that

Assembly

check

with

adhesive

and

secure

that the

fit

the

M4 x 6

the

Pad

to

the

that

the 4 mm

tape.

to

the

Cover

latest

type

Socket

is

in

Sump

Sel

firm

using

Ball

Fit

the

Outer

Texagon

base

does

with

cut-outs.

Screws

to

contact

is

with

new

scals.

in

position,

Cover

Studs

with

not

interfere

lift

the

Heat

the

over

four

Pad

Base.

Tec 4 Vaporizer

Section

I

Service

Manual

Page

18

Revision

of

18

7

Page 36

Page 37

AE

SERVICES

SECTION

LEAK

REVISION:

DATE:

TEST

14.03.01

AUTHORISATION.

2

2

APO

一

Vec 4 Vaporizer

Seetion

2

Service

Manual

Page 1 of

Revision

3

2

Page 38

Page 39

AE

SERVICES

VAPORIZER

1)

Connect

2)

Tum

Open

3

)

allow

Start

4

‘The

If

5

the

service

fluid,

Upon

6)

appropriate

SHOULD

Vaporizer

the

vaporizer

the

the

the

maximum

pressure

bench,

rectify

completion

CONTAIN

into

on

line

adjustment

pressure

timer

and

allowable

drop

locate

as

necessary

of a satisfactory

Service

VAPORIZER

NO

Leak

Test

and

set

the

valve

reading

after 30

to

stabilize.

seconds

pressure

is

outside

the

Record

the

source

and

repeat

together with

LEAK

LIQUID

circuit

dial

to

pressurize

drop

accepted

of the

leak

AGENT

(Figure

to

3%

Note

the

check

the

in

30

tolerance,

Icak

using a suitable

the

leak

test,

record

the

the circuit

pressure

seconds

test.

date

TEST

FOR

LEAK

1).

to

200

pressure

reading.

drop.

is 4 mm

return

the

brush

the

pressure

and

relevant

TEST

A’

to

220

mm

Hg

and

Lig

vaporizer

and

drop

to

leak

on

the

the

test

signature

7)

Disconnect

Tec 4 Vaporizer

Section

2

Service

the

vaporizer

Manual

from

the

CONTROLLED

t

Circuit.

DOCUMENT

^^

Page 2 of

Revision

3

2

Page 40

Page 41

AE

SERVICES

Air

Supply

Adjusiment

>———O——

Pressure

Gauge

Valve

mm

Vaporizer

Lg

2.5

Litre

OUT

Blank

a

Taper

on

‘Test

Reservoir

off

Outlet

Fitting

with

Tec 4 Vaporizer

Section

2

Service

LEAK

Manual

FIGURE

TEST

1

CIRCUIT

Page 3 of

Revision

3

2

Page 42

Page 43

AE

SERVICES

SECTION

MAX.

REVISION:

DATF:01.05.95

AUTHORISATION:

3

TEST

2

PSE

‘Tec 4 Vaporizer

Section

3

Service

Manual

Page 1 of

Revision

2

2

Page 44

Page 45

AE

SERVICES

Connect

Pass a [low

Tum

approximately

‘Measured

If

the

drying

Flowmeter

the

vaporizer

of 5 litres'min.

the

vaporizer

30

percentage

measured

out

cycle - see

F.A

Valve

into the

to

its

seconds

when

percentage

Section

Pressure

Regulator

da

REFERENCE

TEST

test

Air

through

maximum

or

more

establishing

is

more

1.

ab

CELL.

CELL

T

„I

SECTION

ST

PROCEDURE

circuit

as

shown

the

circuit.

percentage

note

than

mark.

refractometer

dryness

0.01%

should

the

AR

г

3

in

Figure

Maintain

reading

vaporizer must

1

not

exceed

fringes

F.A,

56-500

Flowmeter

500

lined

up

0.01%

be

anaesthetic

subjected

Valv

cc'm

set

+/-

50

ccim

and

after

agent

to a further

品

Exhaust

to

Room

Vaporizer

Tee 4 Vaporizer

Section

3

Service

[RL

Manual

Mixer

Dodi

0

TEST

ARRANGEMENT

FIGURE

I

Page 2 of

Revision

2

2

Page 46

Page 47

AE

SERVICES

SECTION

CALIBRATION

REVISION:-3

DATE:

AUTHORISATION:-

28,02,2001

4

TESTS

20096

一

一

一

二

_

Tec 4 Vaporizer

Section

4

Service

Manual

Page | of

Revision

4

3

Page 48

Page 49

AE

SERVICES

NOTE

‘The

Computer

Please

Portable

These

Setting

:TTING

Up

which

UP

refer

Refractometers.

CALIBRATION

procedures

and

has

PROCEDURE

to

the

Operating

are

use

of

the

special

SECTION

applicable

Laser

software

Instructions

to

all

Refractometer

installed.

for R & B Instruments

4

TESTS:

Tec 4 vaporizers.

is

facilitated

through a Laptop

Precision

and

Tee 4 Vaporizer

Section

4

Service

Manual

Page 2 of

Revision

4

3

Page 50

Page 51

AE

SERVICES

VAPORIZ,

NOTE

1

Prior

to

the

the

Testing

2

Place a thermometer

he

tested.

3

Install a vaporizer

4

Carry

the

5

Check

section

6 If

a

on

out the

Portable

the

or

the

vaporizer

self

adhesive

the

trolley

These

start

Department

test

Refractometer

test

results

in

the

appropriate

has

label

for

drying-out

procedures

of

testing,

fill

for a minimum

on

the

upper

on

the

test rig,

routine

us

and

against

passed

stuck

all

to

TE

И

are

applicable

the

vaporizer(s)

of 1 hour.

part

of

making

detailed

the

Wall

the

the

in

Section

print 2 copy

talerances

Chart

i.e.

calibration

top

face

of

y

PRO:

to

to

the

one

of

the

sure

that

2.3 of

of

the

results/test certificate,

given

for

AEOW-003

tests,

mark a ‘T°,

the

Interlock

E

all

ee 4 Vaporizers.

'Full’

mark

and

leave

vaporizers

it

is

properly

the

the

(See

Block and

in

the

batch

locked

Operating

relevant

Section

Instructions

vaporizer

10).

in

black

place

to

stand

which

in

place,

is

for

in

this

felt-tip

pen,

the

vaporizer

in

to

on

‘Tee 4 Vaporizer

Section

4

Service

Manual

CONTROLLED

DOCUMENT

Page 3 of

Revision

4

3

Page 52

Page 53

AE

SERVICES

ISOFLURANE

5% 5%

o 0 9

0.5

10 10

20 20

30 30

40 40

50

TINGS

HALOTHANE

05 92

50 20

FOR

TESTI

TEC 4 VAPORIZI

ENFLURANE

5% 7%

04

0.6

10

15

30

40 70

ENFLURANE

OFF

0.5

10

20

30

40

50

6.0

Tee 4 Vaporizer

Section

4

Service

Manual

Page 4 af

Revision

4

3

Page 54

Page 55

AE

SERVICES

SECTION

CURRENT

DATE;

AUTHORISATIO!

DIAL

REVISION:

14,03,01

5

STRIPS

0

Tee 4 Vaporizer

Section

5

Service

Manual

Page 1 of

Revision

2

0

Page 56

Page 57

AE

SERVICES

A

list

is

given

of

current

as

follow:

Dial

together

Strips

with

their

variation

for

each

specific

Vaporizer

Halothane

Isotivrane

Enflurane

Max

%

5

5

8

Dial

Strip

Part

No.

2400-0022/TA

2400-0022/A

2400-0022/A2

2400-0022/18

2400-0022/B

2400-0022/B2

2400-0022/TC

2400-0022/C

2400-0022/C2

2400-0022/D

2406-0022/D2

2400-0022/TB

2400-0022/B

2400-0022/B2

2400-0022/TC

2400-0022/C

2400-0022/C2

2400-0022/D

2400-0022/D2

2400-00227Y7A

2400-0022/Y6A

2400-0022/Y5A

2400-0022/Y4A

Calibration

Marked

Variation

Iighest Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Lowest

Highest

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Lowest

Jighest

Yes

Yes

Yes

Yes

Lowest

Yes

Enflurane

Tec 4 Vaporizer

Scetion

5

Service

7

Manual

2400-0022/57

2400-0022/17R

2400-0022/J6

2400-0022/16B

2400-0022/J5

2400-0022/15B

2400-0022/44

2400-0022/14C

2400-0022/J3C

Highest

Lowest

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Page 2 of

2

Page 58

Page 59

A E SERVICES

TEST

AUTHORISATIO!

TOLERANCES

REVISION:

DATE:

0

14.03.2001

„JE

Tee 4 Vaporizer

Section

6

Service

Manual

Page

Lofs

Revision

0

Page 60

Page 61

AE

SERVICES

Tec 4 Enfluratec

Room

Temperature

Table

gives % viv

Enfluranc

ated

Temperature

7%

Tolerances

in

air

Tolerances

(22°C)

(35°C)

Tec 4 Vaporizer

Section

6

Service

Manual

Table

Enflurane

Dial

0.50

1.00

2.00

3.00

4.00

5.00

6.00

7.00

gives % v/v

in

air

Max

0.58

1.10

2.20

3.30

4.40

5.50

6.60

7.70

Page 2 af

Revision

5

0

Page 62

Page 63

AE

SERVICES

Tec 4 Enfluratec

Room

Temperature

Table

Enflurane

Tolerances

gives

Ve

viv

in

air

Min

0.08

Max

0.05

030

0.50

0.70

110

1.70

220

3.30

5.50

5%

(220C)

Tec 3 Vaporizer

Section

6

Service

Elevated

‘Temperature

Dial

0,00

0.20

0.

1

1

24

34

44

5.

Manual

Tolerances

Table

gives % viv

Enflurane

in

2

€323

in

Min

0,00

8.18

0.36

0.54

0.90

135

1.80

2.70

3.60

4.50

air

Max

002

0.22

0.44

0.66

9.10

1.65

2.20

3.30

4.40

5.50

(35°C)

Page 3 of

Revision

5

0

Page 64

Page 65

AE

SERVICES

Tec 4 Isotec

Room

‘Temperature

Table

Diat

0.00

0.50

1.00

2.00

3.00

4.00

5.00

Elevated

Temperature

5%

Tolerances

gives % yy

Isoflurane

in

Min

0.00

0.35

0.85

1.80

2.70

3.60

4.50

air

Max

0.05

0.60

1.10

2.20

3.30

4.40

5.50

Toleranees

(22°C)

(359C)

Tec 4 Vaporizer

Section

6

Service

Manual

Table

gives

Isoflurane

Dial

000

0.50

1.08

2.00

Min

0.00

0.45

0.90

1.80

300 270

400 360

500 450

%

in

air

fe

Max

0.05

0.55

110

2.20

330

4.40

5.50

Page 4 of

Revision

5

0

Page 66

Page 67

AE

SERVICES

‘Room

Temperature

Tolerances

Table

gives

Fluothane

in

(22°C)

Dial

peeves

*(Fluotec

Elevated

4%

TemperatureTolerances

Table

Fluothane

Di

0.50

1.00

2.00

3.00

4.00

5.00

Min

0.35

0.85

1.80

270

3.60

888858

4.50

maximum

gives % viv

Min

0.45

0.90

1.80

2.70

3.60

4.50

in

air

dial

setting)

(35°C)

Max

0.55

AU

226

330

440

5.50

Tee 4 Vaporizer

Scetion

6

Service

Manual

Page 5 of

Revision

5

0

Page 68

Page 69

AE

SERVICES

SECTION

FINAL

INSPECTION

REVISION:

DATE:

20.07.95

AUTHORISATION:

7

2

Tec 4 Vaporizer

Section

7

Service

Manual

Page 1 of

Revision

2

Z

Page 70

Page 71

AE

SERVICES

1.

Examine

signature

2.

Tactile

a)

Tests-

Operate

place.

b)

Check

Tocked'

©)

Tum

resistance

d)

Tuming

e)

Examine

Where a product

test

sheets

ensuring

is

recorded

the

that

in

the

Lock/Unlock

the

vaporizer

position

Vaporizer

the

dial

fully

and

thal

the

vaporizer

the

Key

Filler

does

attention

course

of

the

of

action,

SECTION

nai

all

QA

Approved

lever

can

clockwise

'stop'

control

on

and

bridge

not

conform

Service/Test

Inspection

tests

have been

(o

check

only

be

and

functions

off

check

to

confirm

box.

turned

visually

at

Supervisor

7

Procedure

completed,

for

free

action

on

when

anti-clockwise

correctly.

that

that

il

is

a),b).c),d)

and

thai

and

that

the

Lock/Unlock

ensuring

both

interlock

correct.

or

e)

this

shall

who

shall

decide

the

an

authoritative

return

spring

Lever

that

there

rads

operate

be

brought

on

the

is

in

is

in

the

is

no

00046

correctly.

to

the

appropriate

3.

Thoroughly

4.

When

the

serial

QA

boxes

5.

Attach

6.

Check

the

correct

7.

Place

Tee 4 Vaporizer

Section

5

clean

cleaning

self

that

is

completed,

number

of

on

the

Test

adhesive

ail

labels

positions.

the

cleaned

and

Service

the

vaporizer.

the

Test

Certificate

labeis

to

are

correct

labeled

Manual

ensure

Sheet,

the

that a Serial

Write

the

and

Test

Record.

vaporizer

i.c

vaporizer

vaporizer

as

in a polythene

Number

date

and/or

required.

type,

agent

Plate

sign

type,

bag

is

fitted

the

Final

and

thal

and

record

Inspection

they

are

and

fitted

in

Page 2 of

Revision

2

2

Page 72

Page 73

A.

E.

SERVICES

SERVICE

MANUAL

TEC 4 VAPORIZERS

The

‘Tee 4 Vaporizer

words

Tec

Service

and

Selectates

Manual

are

registered

trade

marks

of

Datex-Ohmeda

Page 74

Page 75

AE

SERVICES

SECT

1

2

3

4

5

TEC 4 VAPORIZER

DOCUMENT

DESCRIYLION

Standard

Leak

Max.

Calibration

Current

Service

Fest

Test

Tests

Dial

Strips

Procedure

SERVICE

AEOM - 04.1

LIST

REV

7

2

2

3

0

140301

010595

280201

140301

MANUAL

DATE

14.03.01

-

RES

6

7

4

9

10

Tee 4 Servico

‘Lest

Final

Thermostat

‘Appendices

For

Manual

‘Tolerances

Inspection

Future Use

0

2

2

0

-

140301

200795

140301

140301

-

Page 76

Page 77

AE

SERVICES

SECTION

FAT

TTING

REVISION:-

DATE:

AUTHORISATION:

PROCEDURE

14.03.01

8

SERVICING

2

_

Tec 4 Vaporizer

Section

8

Service

Manual

Page 1 of

Revision

10

2

Page 78

Page 79

AE

SERVICES

Thermostat

NOTE: — Thermostats

Vaporizers

1

Clean

off

residual

NOTE:

2

3

Open

flapper

between

Whilst

thermostat

Segregate

Using

F-24.5

flapper

still

ffermostat

gauges

mm.

Servicing

covered

due

to

performance

shellac

Itis

not

necessary

that

may

with

fingers,

and

holding

via

inlet

TOI

and

and

(TO2)

Section

by

this

procedure

failure.

from

thermostat

to

remove

detach

flapper

hole.

as

thermostat

hold

up

thermastat

body

open,

RE-EXAMINE.

types

i.c.

E'

102,

check

E=

28.3mm

8

and

Setting

will

have

adjusting

all

traces

been

of

screws/nuts

to

light

source,

for

dirt

blow

clean

Enfluratec

the

effective

and

or

dust

air,

using

and

length

Procedure

removed

and

minimum

shellac,

are

adjusted.

examine

particles,

air-linc

from

stop

just

loose

arca

gun,

serews.

particles

through

Fluotec/lsotec

as

appropriate

(TO!)

4

Nolothat

being

deformed,

Remove

Detach

screws.

Position

spring,

Set

hinge gap

square

to

‘Tee 4 Vaporizer

Section

8

Service

this

stcp

as

the

two

Pozi

the

spring

hinge

Fit

new

hinge

flapper

secure

assembly.

loosely

using

the

thermostat

Manual

is

only

performed

indicated

HD

to

using

tool

by

instability

screws

from

(lapper

(103)

body

securing

the

flapper

and

onto

thermostat

two

Pozi

and

by fully

if

the

thermostat

on

setting

the

leaf

by

removing

secure,

pan

secure

ensuring

body

and

HD

screws.

flapper

tightening

and

the

spring

hinge

or

very

low

spring

and

the

two

hinge

is

fit

clamp

Icaf

spring

two

Pozi

is

suspected

resistance.

one

clamp

plate.

c/sk

Pozi

HD

square

to

plate

and

flapper.

leaf

assembly

pan

HD

screws

Page 2 of 10

Revision

2

of

Page 80

Page 81

AE

SERVICES

Thermostat

Setting

Procedure

Before

and

Passages,

Using a wad

strip,

backwards

as

Install

place

Place

Protect

Ensure

set

into

installing

thermostat

of

clean

potish

the

and

il

becomes

dirty

thermostats

(in

the

test

racks aside

from

dirt

that

the

any

thermostat.

one

of

the

nozzles

thermostats

body

for

paper

adjusting

forwards

or

worn)

(of

onto

dirt

particles,

inserted

screw

end

(approx,

same

type)

racks).

for

24

hours

to

particles

room

Monilor

with

polythene

temperature

thermostat

of

each

test

to

test

racks,

blowing

between

by

rubbing

15

times.)

onto

racks

allow

temperature

shocts

is

stable

at

temperature

rack.

visually

through

tbe

adjusting

(he

(Re-new

ensuring

229C

check

with

paper

wad

paper

'O'

rings

to

stabilize.

+/-

10€

using a thermometer

between

an

air-line

screw

flapper

to

and

Bi-metal

vigorously

wad

frequently

are

correctly

before

attempting

clear

in

to

inserted

Fee 4 Vaporizer

Section

8

Service

Manual

Page 3 of

Revision

10

2

Page 82

Page 83

AE

SERVICES

-M

i

Tec 4 Vaporizer

Section

8

Service

FIGURE

Manual

し

1

Thermostat

1

го

Test

Arrangement

1

Page 4 of

Revision

10

2

Page 84

Page 85

AE

SERVICES

FIGURE

2

Thermostat

AIT

e

Assembly

ΕΟΝ

CETTE

SETTING

DOME

Tee 4 Vaporizer

Section

8

Service

Manual

|

Page 5 of

Revision

2

10

Page 86

Page 87

AE

SERVICES

Minimum

Flow

a)

b

9

d

9)

В

Maximum

Flow

Stop:

Adjust

Ensure

Back-alf

Connect

(minimum

38

and

‘Tighten

Re-adjust

Record

Setting

Check

the

of

the

test

Adjust

5.0

litres/min

Tighten

Record

the

air

flow

to 5 Litres/Min

that

water

manometer

the

adjusting

air

supply

stop)

44

cms

water.

lock-nut

as

necessary

date,

pressure,

temperature

rack.

setting

screw

air

lock

nut.

date,

pressure

screw

to

nozzle

so

that

then

re-check

and

indicated

to

obtain a manometer

in

accordance

and

without a thermostat

indicates

so

that

of

test

the

indicated

pressure

temperature

with

temperature

zero.

it

is

rack

pressure

reading,

on

by

the

thermometer

tolerances,

on

in

clear

of

the

bi-metal

and

adjust

flow/temperature

is

between

AEQF-10.7.

1/4.

inserted

reading

ARQF-10.7,

at a flow

1/4,

circuit,

strip.

in

the

nozzle

of

stop

d)

e

‘Yee 4 Vaporizer

Section

8

Service

The

thermostat

impaired

if

instability.

careful

and

is a relatively

the unit

can

is

be

caused

(horough

bearing surfaces

Maintain

Observe

Using a finger,

screw

not

Record

Similar

serew

Record

If

the

for

air

flow

at

pressure

reading

apply a moderato

for

approx, | sec

altered

rectification,

from

its

date,

pressure,

to

(c)

but

instead,

and

releasing

date,

pressure,

thermostat

Fails

5.0

original

after

Manual.

delicate

roughly

cleaning

handled.

by

dirt

and,

Litres/Min

on

Manemcter.

then

release

setting

and

temperature

open

instrument

Alternatively,

or

dust.

if

necessary,

to

the

force

against

finger.

by

more

on

flapper

by

approx. | second.

and

temperature

the

'pustvpull

on

tests

and

the

stability

thermostat

Stability

thermostat.

ALOI-10.1.1/7.

pulling

is

usually

re-polishing

the

head

of the

Check

that the

than

approx.

at

pressure

1.0

head

of

restored

of

the

setting

cm

adjusting

AEQF-10.7.1/4

reject

thermostat

and

Page 6 of 10

Revision

may

be

by

has

water.

sogrogato

2

Page 88

Page 89

AE

SERVICES

A

final

check

on

the

thermostat

installation

in

the

vaporizer.

setting

As

follows:

shal!

be

carried

out

prior

to

1

2)

3)

41

3)

6)

Ensure

Set

Pass $ litres/min

Check

Record

Apply

temperature

manometer

to

through

pressure

date,

shellac

reading

pressure,

to

low

is

within

zero,

and

temperature

permitted

Airflow

at 5 litres/min.

tolerance,

thermostat.

to

tolerance

temperature

chart.

on

stop

and

AEQF-10.7.1/4,

setting

screws.

Tec 4 Vaporizer

Section

8

Service

77

como

Manual

Eb

Page 7 of 10

Revision

2

Page 90

Page 91

AE

SERVICES

Fee 4 Vaporizer

Enfluratec

Enlluratce

Enfluratec

Enfluratec

Fluotec

Fluotec

Fluotec

Fluotec

Isotec

Isoice

5%

4%

5%

5%

5%-

5%

-

5%

7%

5%

7%

-

-

-

-

-

-

-

-

Screw

Serew

Keyed

Keyed

Screw

Screw

Serew

Keyed

Screw

Keyed

‘Thermostat

Type

Ethrane

Fthrane

Lthranc

Ethrane

Fluotoe

Fluotee

Fluoteg

Fluotec

Huotec

Fluotec

Tec 4 Vaporizer

Section

8

Service

PEG

Manual

ecu

I

Page 8 of 10

Revision

2

Page 92

Page 93

AE

SERVICES

TOLERANCES

Temperature | Temperature | Nominal

°C

o

189

192

o

FOR

°F

660

66.5

670

“e

5

68.0

i

68.5

69.0

i

69.

5

m0

70.5

710

71.5

72.0

725

730 212

735

74.0

TAS

750

755

76.0

HALOTHANE

gm

30,3

29.3

|

283.

275 29.3

26.

26.0

254

24.8

|

7

we

23.6 24.8

23.0

-

225

221

ив

.

20

20.5

>

20.

19.8

19.

191

TO

7

8

т

4

THERMOSTATS

Maximum

em

HO

327

315

303

때

|

ーー

“ao

283

275

26.7

26.0

254

242

23.6

225

21

21.6

2

20.8

205

20.1

198

2

7

`

|

‘Yee 4 Vaporizer

Section

8

Service

Manual

Page 9 of 10

Revision

2

Page 94

Page 95

AE

SERVICES

TOLERANCES

Temperature

|

-

"C

189

193

194

197

209

203

206

ms

sm

214

23.3

239

22

244

|

|

|

|

Er

|

7

|

Temperature | Nominal | Maximum | Minimum

7

|

|

|

FOR

of.

66.0

66.5

670

675 282 302

680

685 265

690

65

700

705

71.0

715

720 218

ns

we

735

740

745

750

755

760

ENFLURANE

_

_

_

THERMOSTA’

em

HO

315

309 327 282

29.1

273

257

243

242 257

236 250 224

23.0

224 236

212

206 218

20.0

195

19.0

185

181

176 185

cm

lbO

338

314 273

292

382

273

26.5

243

23.0

224

212

20.6

20.0

19.5

190

m2

em

1,0

291

26.5

257

25.0

243

236

23.0

218

“312

206

200

195

190

185

“180

176

168

|

|

|

|

Tec 4 Vaporizer

Section

8

Service

Manual

Page

10

of

10

Page 96

Page 97

AE

SERVICES

SECTIO

APPENDICES

REVISION:

DATE-

AUTHORISATION:-_.

15.03.2001

0

Toc 4 Vaporizer

Section

9

Service

Manual

‘CONTROLLED

DOCUMENT}

Page

I

Revision

0

Page 98

Loading...

Loading...