Page 1

Giraffe

®

OmniBed

Service Manual

®

Page 2

Important

The information contained in this service manual pertains only to those models of products which are marketed by Ohmeda Medical as of the effective date of this manual or the latest revision thereof. This service

manual was prepared for exclusive use by Ohmeda Medical service personnel in light of their training and

experience as well as the availability to them of parts, proper tools and test equipment. Consequently,

Ohmeda Medical provides this service manual to its customers purely as a business convenience and for the

customer’s general information only without warranty of the results with respect to any application of such

information. Furthermore, because of the wide variety of circumstances under which maintenance and repair

activities may be performed and the unique nature of each individual’s own experience, capacity, and qualifications, the fact that a customer has received such information from Ohmeda Medical does not imply in

anyway that Ohmeda Medical deems said individual to be qualified to perform any such maintenance or

repair service. Moreover, it should not be assumed that every acceptable test and safety procedure or

method, precaution, tool, equipment or device is referred to within, or that abnormal or unusual circumstances,

may not warrant or suggest different or additional procedures or requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned to obtain and consult

the latest revision before undertaking any service of the equipment.

CAUTION w Servicing of this product in accordance with this service manual should never be undertaken

in the absence of proper tools, test equipment and the most recent revision to this service

manual which is clearly and thoroughly understood.

This static control precaution symbol appears throughout this manual. When this symbol appears

next to a procedure in this manual, static control precautions MUST be observed. Use the static

control work station (Stock No. 0175-2311-000) to help ensure that static charges are safely

conducted to ground and not through static sensitive devices.

Technical Competence

The procedures described in this service manual should be performed by trained and authorized personnel

only. Maintenance should only be undertaken by competent individuals who have a general knowledge of and

experience with devices of this nature. No repairs should ever be undertaken or attempted by anyone not

having such qualifications. Genuine replacement parts manufactured or sold by Ohmeda must be used for all

repairs. Read completely through each step in every procedure before starting the procedure; any exceptions

may result in a failure to properly and safely complete the attempted procedure.

Definitions

Note: A note provides additional information to clarify a point in the text.

Important: An Important statement is similar to a note, but is used for greater emphasis.

CAUTION: A CAUTION statement is used when the possibility of damage to the equipment exists.

WARNING: A WARNING statement is used when the possibility of injury to the patient or the operator exists.

m

x

y

~

Type B Electrical equipment

Protective ground

Functional Ground

Alternating Current (AC)

Static Control Precaution

European Union Representative

Page 3

Table of Contents

Chapter 1 – Functional Description

1.1 Control Board .............................................................................................1-1

1.2 Relay Board ...............................................................................................1-3

1.3 Display Driver Board/EL Display.................................................................1-4

1.4 LED Board .................................................................................................1-4

1.5 Power Supply .............................................................................................1-4

1.6 Peripheral Components..............................................................................1-4

1.61 Rail and Heater Door Switches ..........................................................1-5

1.7 DataLink Option .........................................................................................1-5

1.8 Servo Controlled Oxygen Option ................................................................ 1-6

Chapter 2- Service Checkout

2.1 Setup..........................................................................................................2-1

2.2 Mechanical checks.....................................................................................2-1

2.3 Controller checks .......................................................................................2-2

2.4 Humidity check...........................................................................................2-3

2.5 Servo Controlled Oxygen check .................................................................2-3

2.6 Accessory checks ......................................................................................2-4

2.5 Cable Connections and Mechanical Controls ............................................. 2-5

Chapter 3- Calibration and Maintenance

3.1 Maintenance schedule ...............................................................................3-1

3.2 Special tools...............................................................................................3-1

3.3 System Calibration .....................................................................................3-3

3.4 Line Volt age Calibration..............................................................................3-3

3.5 Humidifier Calibration .................................................................................3-4

3.6 Servo Controlled Oxygen Calibration .........................................................3-4

3.7 Scale Calibration ........................................................................................3-5

3.8 Leakage Current ........................................................................................3-5

3.9 Ground Resistance ....................................................................................3-5

Chapter 4- Troubleshooting

4.1 Service Screen...........................................................................................4-1

4.2 Alarm Messages ........................................................................................ 4-5

4.3 Error Codes................................................................................................4-8

4.4 Troubleshooting Table ................................................................................4-13

4.5 Additional Troubleshooting Tips..................................................................4-16

4.6 Servo Controlled Oxygen ...........................................................................4-19

Servo Controlled Oxygen Service Screen..................................................4-19

Servo Controlled Oxygen Alarm Messages ...............................................4-20

Servo Controlled Oxygen Troubleshooting Tips .........................................4-22

Chapter 5- Repair Procedures

5.1 Canopy removal for replacement ...............................................................5-1

5.1 1 Replacing the seals............................................................................ 5-2

5.12 Porthole Door Replacement...............................................................5-3

5.2 Canopy Lift Assembly Repair Procedures ..................................................5-4

5.21 Removing the right upright (motor side) ............................................. 5-4

5.22 Removing the left upright ...................................................................5-7

5.23 Right rail internal repairs ....................................................................5-8

5.231 Removing the inner rail assembly..............................................5-8

5.232 Replacing rollers and tension springs ........................................ 5-8

5.233 Replacing the micro-switches....................................................5-9

5.234 Separating the lift rail from the belt channel...............................5-9

5.235 Replacing the drive belt .............................................................5-10

5.236 Replacing the rail buoyancy springs ..........................................5-10

5.24 Re-assembling the right upright .........................................................5-11

5.25 Left rail internal repairs.......................................................................5-13

6600-0343-000 08/27/03 i

Page 4

Table of Contents

5.251 Removing the inner rail assembly..............................................5-13

5.252 Replacing the rail buoyancy springs ..........................................5-14

5.253 Replacing rollers, tension springs and cable carrier links ..........5-14

5.26 Re-assembling the left upright ...........................................................5-14

5.3 Radiant Heater Assembly Rep air Procedures ............................................5-16

5.31 Removing the Canopy/Heater Assembly............................................5-16

5.31 1 Re-aligning the canopy ..............................................................5-17

5.32 Heating Element ................................................................................5-17

5.33 Heater doors ......................................................................................5-18

5.34 Heater door cable adjustment............................................................5-18

5.4 Compartment Probe repairs .......................................................................5-19

5.5 Top rail end cap replacement .....................................................................5-20

5.6 Lower Unit Repairs.....................................................................................5-21

5.61 Removing the chassis cover with the storage door in place...............5-21

5.62 Incubator fan/motor/optical sensor.....................................................5-21

5.63 Cartridge heater replacement ............................................................5-21

5.64 Elevating base ...................................................................................5-23

5.65 Chassis replacement .........................................................................5-24

5.66 Elevating footswitch ...........................................................................5-25

5.67 Canopy footswitch..............................................................................5-25

5.68 Canopy finger switch..........................................................................5-25

5.69 Humidifier heater components ...........................................................5-25

5.7 Bed Tilt Brake Shoe Replacement..............................................................5-25

5.8 Castor Replacement ..................................................................................5-26

5.9 Humidifier Repairs......................................................................................5-27

5.10 Controller and Display Module repairs......................................................5-29

5.1 1 1 Display module ..........................................................................5-29

5.1 12 Probe panel ...............................................................................5-30

5.1 13 Controller components...............................................................5-31

Control Board ...................................................................................5-31

Relay Board......................................................................................5-32

Solid State Relays ............................................................................5-32

Power supply....................................................................................5-32

Battery..............................................................................................5-32

Transformers....................................................................................5-32

Circuit breakers, power switch and outlets .......................................5-33

5.1 14 Servo Controlled Oxygen Service Procedures...........................5-33

5.1 141 Inst alling oxygen sensors......................................................5-33

5.1 142 Replacing the vent screen .................................................... 5-33

5.1 143 Sensor housing rep airs.........................................................5-34

5.1 114 Valve housing repairs ............................................................5-35

5.1 115 Endcap Safety valve .............................................................5-36

Chapter 6- Illustrated Parts

6.1 Exploded Views..........................................................................................6-1

6.1 1 Probe housing, display module and electrical enclosure ....................6-1

6.12 Bed and side panels ..........................................................................6-8

6.13 Radiant heater and canopy ................................................................6-14

6.14 Chassis..............................................................................................6-19

6.15 Humidifier ..........................................................................................6-22

6.16 Elevating base ...................................................................................6-24

6.17 Uprights and lift rail components........................................................6-26

6.18 Compartment probe...........................................................................6-34

6.19 Servo Controlled Oxygen ...................................................................6-35

6.20 Storage drawer and shelves...............................................................6-39

6.2 Accessories................................................................................................6-44

6.3 Labels ........................................................................................................6-45

6.4 PCB layouts ...............................................................................................6-48

6.5 Wiring diagrams .........................................................................................6-52

ii 08/27/03 6600-0343-000

Page 5

Table of Contents

6600-0343-000 08/27/03 iii

Page 6

Appendix

Compartment and Skin Probe Characteristics .................................................A-1

Specifications...................................................................................................A-2

Power requirements...................................................................................A-2

Operating Environment..............................................................................A-2

Storage Conditions ....................................................................................A-2

User Control Settings.................................................................................A-2

Alarms .......................................................................................................A-2

Performance..............................................................................................A-3

System ................................................................................................A-3

Humidity ..............................................................................................A-3

Servo Controlled Oxygen ....................................................................A-3

Mechanical Specifications..........................................................................A-4

RS-232 Serial Data ..........................................................................................A-5

Data S tream...............................................................................................A-5

Nurse Call..................................................................................................A-6

List of Figures

1-1 Block Diagram ...........................................................................................1-2

2-1 Cable connections and mechanical controls..............................................2-5

3-1 Control board test points............................................................................3-2

4-1 First service screen ...................................................................................4-1

4-2 Second service screen ..............................................................................4-2

4-3 Status menu...............................................................................................4-2

4-4 Switch diagnostic diagram .........................................................................4-3

4-5 Pedal screen .............................................................................................. 4-3

4-6 First service screen- diagnostics................................................................4-4

4-7 Servo O2 service screen............................................................................4-19

5-1 Heater housing cover and soffit .................................................................5-1

5-2 Canopy , bracket and heater housing..........................................................5-2

5-3 Canopy seals and extrusions .....................................................................5-3

5-4 Disconnecting door cable...........................................................................5-4

5-5 Upright decorative strips, end caps and wire covers .................................. 5-5

5-6 Removing the lift motor ..............................................................................5-5

5-7 Display module disassembly ...................................................................... 5-6

5-8 Right upright assembly............................................................................... 5-8

5-9 Rollers and tensioning spring .....................................................................5-9

5-10 Replacing the drive belt............................................................................5-10

5-1 1 Replacing the buoyancy springs...............................................................5-11

5-12 Left inner rail ............................................................................................5-12

5-13 Left rail springs and spools ......................................................................5-13

5-14 Re-attaching the upright...........................................................................5-14

5-15 Radiant heater disassembly .....................................................................5-15

5-16 Canopy alignment ....................................................................................5-16

5-17Heater door cable adjustment ...................................................................5-18

5-18 Compartment probe disassembly.............................................................5-19

5-19 Top rail end cap........................................................................................5-19

5-20 Bed disassembly......................................................................................5-20

5-21 Fan motor ................................................................................................5-21

5-22 Heat sink and fan .....................................................................................5-22

5-23 Elevating base .........................................................................................5-23

5-24 Chassis bottom cover ..............................................................................5-24

5-25 Replacing the tilt brake............................................................................. 5-26

5-26 Humidifier parts........................................................................................5-28

iv 08/27/03 6600-0343-000

Page 7

5-27 Display module ........................................................................................5-30

5-28 Probe panel.............................................................................................. 5-30

5-29 Electronics enclosure...............................................................................5-31

5-30 Installing sensors ..................................................................................... 5-33

5-31 Sensor housing ........................................................................................5-34

5-32 V alve housing...........................................................................................5-35

5-33 Endcap safety valve .................................................................................5-36

6-1 Probe Panel Assembly...............................................................................6-1

6-2 Display Module...........................................................................................6-3

6-3 Electrical enclosure....................................................................................6-5

6-4 Humidifier Transformer and Rs232 option..................................................6-7

6-5 Bed ............................................................................................................6-9

6-6 Side panel (E/W)........................................................................................6-11

6-7 Rear (north) and front (south) panel...........................................................6-13

6-8 Radiant Heater...........................................................................................6-15

6-9 Canopy ......................................................................................................6-17

6-10 Heater doors ............................................................................................6-18

6-1 1 Upper chassis ..........................................................................................6-19

6-12 Lower chassis ..........................................................................................6-21

6-13 Humidifier................................................................................................. 6-23

6-14 Base and elevating column ......................................................................6-25

6-15 Right (East) upright, motor side................................................................6-27

6-16 Belt channel -1 (lift motor side).................................................................6-28

6-17 Belt channel -2 (lift motor side).................................................................6-29

6-18 Lift rail (both sides)...................................................................................6-30

6-19 Rail End caps...........................................................................................6-31

6-20 Left (west) upright ....................................................................................6-33

6-21 Compartment Air Probe............................................................................6-34

6-22 Servo Control Oxygen Sensor Housing assembly....................................6-35

6-23 Servo Control Oxygen V alve Housing ......................................................6-36

6-24 Expansion Chamber/Heatsink Vent..........................................................6-37

6-25 Servo Control Oxygen Cooling Fan..........................................................6-37

6-26 Servo Control Oxygen PC board ..............................................................6-38

6-27 Manifold Endcap Safety V alve..................................................................6-38

6-28 Strorage Drawer.......................................................................................6-39

6-29 Instrument Shelf.......................................................................................6-40

6-30 Monitor Shelf............................................................................................6-40

6-31 E Cylinder holder......................................................................................6-41

6-32 Tubing Management Arm.........................................................................6-41

6-33 Dovetail mount DIN rail ............................................................................6-42

6-34 Silo Support .............................................................................................6-42

6-35 Rotating IV Pole Assy. ..............................................................................6-43

6-36 Dovetail extension....................................................................................6-44

6-37 Control board ...........................................................................................6-48

6-38 Display driver board .................................................................................6-49

6-39 Relay board (Rev 10 or higher) ................................................................6-50

6-40 Relay board (Rev 9 or lower) ...................................................................6-51

6-41 Wiring Diagram Control Board .................................................................6-52

6-42 Wiring Diagram Elevating Base and Canopy Lift Rails.............................6-53

6-43 Wiring Diagram Electrical Enclosure........................................................6-54

6-44 Wiring Diagram Graphics Display ............................................................6-55

6-45 Wiring Diagram Incubator (Relay board rev 10 or higher) ........................6-56

6-46 Wiring Diagram Incubator (Relay board rev 9 or lower) ...........................6-57

6-47 Wiring Diagram Radiant heater (Relay board rev 10 or higher)................6-58

6-48 Wiring Diagram Incubator (Relay board rev 9 or lower) ...........................6-59

6-49 Wiring Diagram Servo Humidifier (Relay board rev 10 or higher)............. 6-60

6-50 Wiring Diagram Servo Humidifier (Relay board rev 9 or lower) ................6-61

6-51 Wiring Diagram Servo Control Oxygen .................................................... 6-62

6600-0343-000 08/27/03 v

Page 8

Precautions

wWarnings

Before using the OmniBed, read through this entire manual. As with all medical equipment, attempting to use

this device without a thorough understanding of its operation may result in patient or user injury. This device

should only be operated by personnel trained in its operation under the direction of qualified medical personnel

familiar with the risks and benefits of this type of device. Additional precautions specific to cert ain proce-

dures are found in the text of this manual.

Complete the “Pre-operative Checkout Procedures” section of the Operator’s manual before putting the unit

into operation. If the incubator fails any portion of the checkout procedure it must be removed from use and

repaired.

Do not use the OmniBed in the presence of flammable anesthetics; an explosion hazard exists under these

conditions.

Always disconnect the power before performing service or maintenance procedures detailed in this manual.

Apply power only if you are specifically instructed to do so as part of the procedure.

Thoroughly air dry the incubator after cleaning it with flammable agents. Small amounts of flammable agents,

such as ether, alcohol or similar cleaning solvent s left in the incubator can cause a fire.

wCautions

Only competent individuals trained in the repair of this equipment should attempt to service it as detailed in this

manual.

Detailed information for more extensive repairs is included in the service manual solely for the convenience of

users having proper knowledge, tools and test equipment, and for service representatives trained by Ohmeda

Medical.

vi 08/27/03 6600-0343-000

Page 9

Chapter1- Functional Description

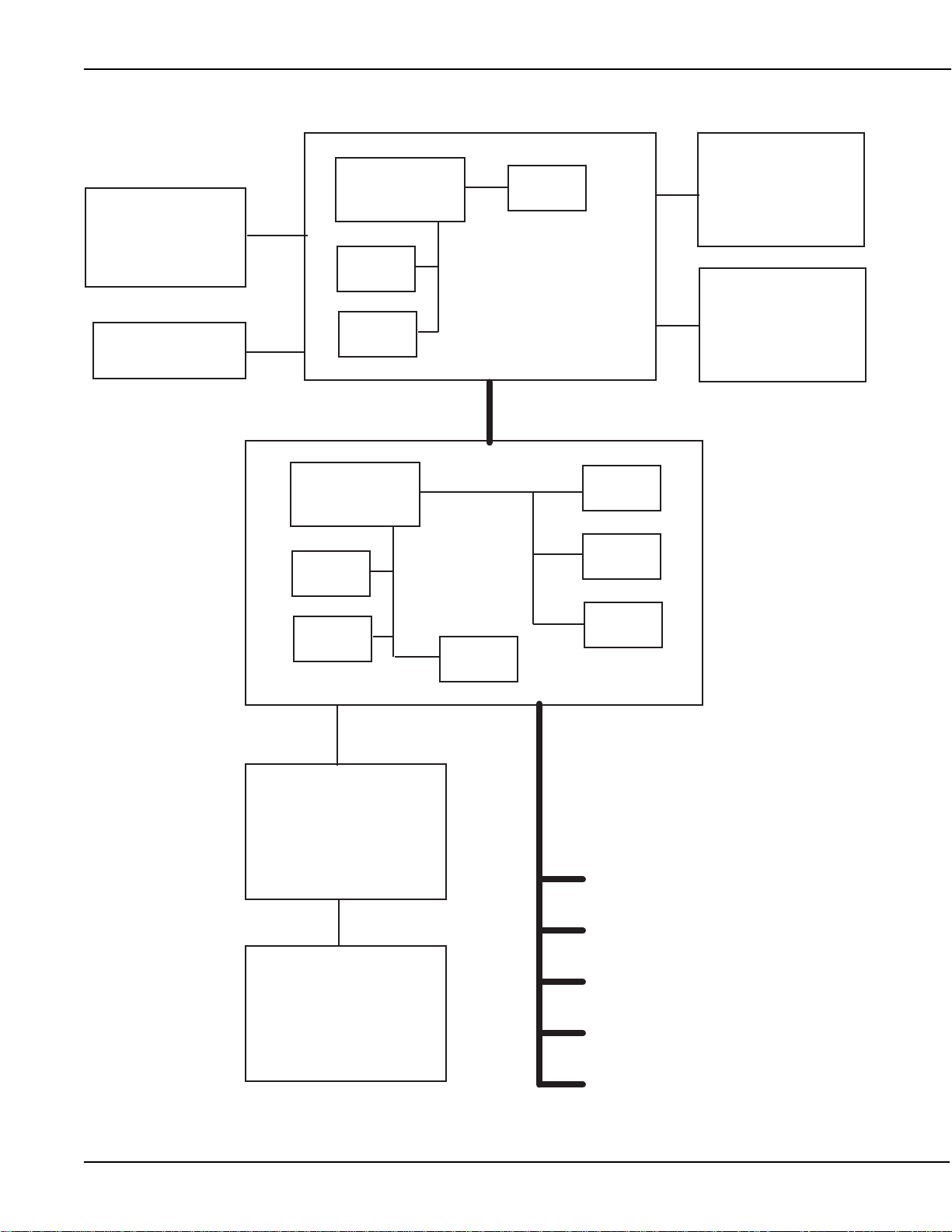

This functional description is divided into four sections representing each of the four boards. The reader

should also reference the block diagram and wiring diagram when studying this section.

1.1 Control Board

The Intel 80C188EC microcontroller is an enhanced X86 processor with many on-board peripheral features,

such as a interrupt controller, DMA controller, peripheral chip select driver, programmable timers, etc. The two

programmable timers are used to control the two heaters (bed and radiant). The input to these timers is line

frequency . This allows the control signal to be synchronized with the line frequency to better control the zerocrossing solid state relays. The on-board interrupt controller has several interrupts: analog-to-digital converter

(ADC) conversion ready signal, overtemperature comparator output, watchdog output, power fail signal, and

module interrupt signal from the system data bus. The microcontroller external bus is a multiplexed address

and data bus.

The system memory consists of a programmable read-only memory (PROM) and static random access

memory (SRAM). The EEPROM is used for calibration values and infrequently changing variables. This

memory holds the data even after power is turned off.

The RS-485 integrated circuit converts the RS-232 TTL signals from the microcontroller to RS-485 signals for

the bus. This bus is the main communications bus from the control board to all other boards with processors.

There are two isolation transceivers used to isolate the circuits powered by +5V and the circuits powered by

+5VSTBY (battery backup).

The board contains a 16 channel multiplexer. There are seven temperature measurement channels. These

channels measure the two patient probes with two thermistors each, the two air temperature thermistors used

for display and control, and an additional thermistor used to measure the heat sink temperature.

Additional channels include the humidity sensor (RHIN), LINE COMP & LINE COMP2, 5 V olt s, Motor current,

Vthref, VDAC, and 1.2Vind.

Attached to the environmental probe connection is the relative humidity signal conditioning circuitry. The 1V

reference that is used for the analog circuitry is also the maximum input voltage and the offset voltage for the

ADC. This yields a purely ratiometric system.

The overtemperature circuit compares the air temperature to a reference level, generates an interrupt, and

turns off the heat if the air temperature is higher than the reference level. The overtemperature circuit requires

varying its voltage levels to accommodate various thermistor measurements. This is because the calibration is

digital (no potentiometer).

The watchdog circuitry monitors the 80C188 microprocessor, and monitors the +5V and +5VSTBY voltages. It

generates the interrupt signal and power failure signal to the 80C188 microprocessors. The audio circuit

includes a 8752 microcontroller that reads a wavetable located in a PROM and sends the table to a digital

audio circuit and amplifier. The high priority (HP) and other alarm signal lines select an output at the correct

frequencies.

Three OR gates are combined to generate the error signal. The inputs to the circuit are overtemperature,

power failure, and system failure. This circuit generates an error signal that turns off the heater and sounds the

HP alarm. This circuit is independent of the microcontroller.

6600-0343-000 08/27/03 1-1

Page 10

Chapter 1- Functional Description

LED Board

EL Display

Microprocessor

PROM

SRAM

Microprocessor

PROM

SRAM

Audio

Time

Display Driver Board

Temp

Channels

Overtemp

Watch

Dog

Membrane Switches

Knob

Figure 1-1

Block Diagram

Control Board

Relay Board

RS485

Future Options

and

Modules

Power Supply

1-2 08/27/03 6600-0343-000

Page 11

Chapter1- Functional Description

1.2 Relay Board

The Relay Board includes 2 safety relays, which close to supply mains power to the heater and motor circuits.

Safety relay 1 is wired in series with the primary coil of the isolation transformer for the incubator and radiant

warmer heaters. Safety relay 2 closes the mains supply to the humidifier isolation transformer and the transformer for the e-base and canopy motors. Control signals for the two relays originate on the Control Board.

The Relay Board interfaces the DC control signals to the two chassis mounted solid-state relays (SSRs), which

control the incubator and radiant warmer heaters individually . The control signals for the two heater SSRs

originate on the Control Board.

The Relay Board includes a SSR for the humidifier. The SSR output is wired in series with the humidifier

heater. The humidifier SSR control signal originates on the Control Board.

There is one current sense circuit for the incubator and radiant warmer heaters and an additional one for the

humidifier heater. These circuits consist of a small signal transformer that produces a current proportional to

the current through the heater circuits. The current is rectified and measured. The subsequent comparator

then generates a digital level based on a specified current level. This results in a signal to the Control Board

representing the state of the heater (on or off).

The two line compensation circuits consist of a signal transformer connected to the mains voltage. The

secondary of this transformer feeds a full wave rectifier and capacitor . The resulting DC voltage is proportional

to mains voltage, and it is measured on the Control Board.

The line frequency circuit consists of a full wave rectifier and a comparator . This circuit generates a digit al

pulse with frequency twice that of the line frequency (50 or 60 Hz). The output signal is provide to the Control

Board.

The Relay Board provides the +5v standby power supply to the entire Giraffe system. A +5V regulator generates the +5V standby from the diode OR combination of the system +12V power supply or the backup battery .

If there is no mains power, then +12v is not present, and the battery will generate the +5V st andby. When

+12V is present, the battery is biased out of the circuit with the diode and is merely being trickle charged

though a resistor.

The motor driver circuit turns the DC motor coils in the incubator airflow fan motor on and off based on feedback from the hall effect position sensors. This integrated circuit can also vary the speed and brake the motor

based on input signals from the Control Board.

The airflow sensor consists of an opto-coupler that outputs a clocking pulse proportional to the fan movement.

The signal is AC coupled to eliminate of fset voltages and drif t s. The resulting pulse is half wave rectified and

stored in a capacitor to yield a DC voltage proportional to the fan speed. If the fan stops or there is no fan, this

DC voltage becomes zero. The output signal is provide to the Control Board to indicate proper airflow motor

operation.

The hood lift and elevating base circuit consists of a series of relays that apply voltage to the hood lift motor or

the elevating base motor. The hood lif t motor is driven at 30V going up and 15V going down. The e-base

motor is always driven at 30 volts. The motor current sense circuit consists of a small signal transformer that

produces a current proportional to the motor current. The transformer output current is converted to a voltage

and filtered. An output volt age indicative of the motor current amplitude is provided to the Control Board. A

subsequent comparator then generates a digital level based on a specified current level. This results in a

signal to the Control Board indicating whether or not the e-base motor is stalled.

The Relay Board interfaces the user and system status input switch signals to the Control Board. Switch

signals include, e-base & canopy activation, canopy and heater door position, and humidifier reservoir and

water level status.

6600-0343-000 08/27/03 1-3

Page 12

Chapter 1- Functional Description

1.3 Display Driver Board / EL Display

The Display Driver board contains the same Intel microcontroller as the Control board. The processor on the

display board is used to control the EL display contents and monitor user inputs received from the membrane

switch panel and rotary encoder knob.

There are two groups of digital inputs: membrane switch panel and rot ary encoder knob. The membrane

switches are pulled high; pressing the switch grounds the input. The encoder also has a switch, and two

optically isolated lines that pulse out of phase with each other. The number of pulses represents the number

of steps the knob rotates. The phase of the pulses represents the direction of the knob rot ation.

The display board system memory consists of a programmable read-only memory (PROM) and static random

access memory (SRAM).

The RS-485 integrated circuit converts the RS-232 TTL signals from the microcontroller to RS-485 signals for

the bus.

The timekeeping RAM has a battery integrated into the chip so that the time and date run are kept current

even with the power off. The battery has a minimum life of 10 years.

The graphics controller is an S-MOS VGA controller. The graphics controller interfaces the data from the video

RAM to the EL display. The controller also synchronizes the display using a horizontal pulse (LP) and a

vertical pulse for the whole display frame (YD). The controller handshakes with the 80C188 using the READY

line to eliminate any lost data during display refreshes.

1.4 LED Board

The LED Board contains five display banks and two display drivers. One of the display drivers controls the

patient temperature and air temperature display banks. The other driver controls the patient set temperature,

air set temperature, warmer bar graph, and the mode and override indicators.

This allows the two large displays (patient and air temperature) to be multiplexed at a slower rate than the

other LEDs. This results in brighter large displays. Each driver has a brightness potentiometer that is preset

at the factory and should not be adjusted in the field.

1.5 Power Supply

The universal input switching power supply converts the line voltage to +5V DC and +12V DC. This supply can

source up to 75 watts. The 5 volts powers the electronics and the 12 volts is used by the EL display and for

future boards.

1.6 Peripheral Components

There are several peripheral components. The isolation transformer isolates the radiant heater from the line

voltage.

The toroidal transformer bucks the line voltage to the range of the elevating base and the canopy lift drive

system.

The humidifier isolation transformer isolates the humidifier heater from the line voltage.

The solid state relays mounted to the chassis are used to control the radiant and bed heaters.

1-4 08/27/03 6600-0343-000

Page 13

Chapter1- Functional Description

1.61 Rail and Heater Door Switches

There are seven switches used to determine the position of the canopy and the heater doors.

Two normally open switches on each heater door determine the position of the doors. Each switch is wired in

series with the corresponding switch on the other door. One p air of switches closes only when the doors are

fully open and the other pair closes only when the doors are fully closed.

There are 3 normally open switches in the right upright which are used to determine the position of the canopy .

The top switch closes when the canopy reaches the upper position. The middle switch detects downward

movement of the canopy . The bottom switch closes when the lowest position is reached.

The radiant heater will turn on only if the two heater door open switches and the top rail switch are all closed.

The system will control as an incubator only if the bottom rail switch and the two heater door closed switches

are all closed.

As the canopy lowers the system senses the closure of the middle rail switch, then looks at the heater door

closed switches. If they are not closed the canopy will return to the highest position. This insures that the

canopy will not lower to the lowest position if the heater doors are not closed.

1.7 DataLink Option

The DataLink option allows direct output of serial data to various remote monitoring systems, such as a

computer or commercial RS-232 monitor. The Dat aLink option board cont ains the electronic circuitry necessary to provide a 2500 VRMS isolated serial interface to meet the logic levels specified by EIA RS-232D and

CCITTV.28.

The MAX250 and MAX251 (U1 and U2), together with two 6N136 optocouplers and transformer TR1, form an

isolated RS-232 transmitter and receiver. The MAX250 connect s to the non-isolated or “logic” side of the

interface, translating logic signals to and from the optocouplers, while the MAX251 resides on the isolated or

“cable” side, translating data between the optocouplers and RS-232 line drivers and receivers. In addition to

the optocoupler drivers and receivers, the MAX250 also contains isolation transformer drive circuitry which

supplies power to the isolated side of the interface, and the MAX251.

The transmit signal is input to the MAX250 driver (U1 pin 4) whose output (U1 pin 3) drives optocoupler U4.

The optocoupler output (U4 pin 6) is then fed into the MAX251 driver (U2 pin 3). The output of the MAX251

driver (U2 pin 12) is at the logic levels conforming to EIA RS-232D and CCITTV.28. Conversely, the receive

signal enters the MAX251 driver (U2 pin 10) and is stepped down to CMOS/TTL levels at U2 pin 5. This logic

level drives optoisolator input (U3 pin 3) whose output is fed into U1 pin 10. The output (U1 pin 9) signal is then

available to the control printed circuit board.

A slide switch SW1 is used as a “self test” for the RS-232 interface. In the closed position, the J30-1 transmit

signal is sent through the MAX250/MAX251 transmitter and back into the receiver portions. The signal can be

read at J30-2 and verified to be correct. Any external cable connection must be removed for this self test to

function. CR1 and CR2 provide transient protection for MAX251. In normal operation SW1 should be in the

open (OFF) position.

The nurse call signal is input at J30-5 as a TTL logic level. In the “no alarm” st ate, this signal is a logic high,

which turns on Darlington Q1, energizing relay K1. This results in contact closure between J31-1 and J31-2. In

the “alarm” state, J30-5 is a logic low , which turns of f Q1, de-energizes K1 and results in cont act closure

between J31-2 and J31-3. K1 provides 2500 VRMS isolation between the relay coil inputs and contact outputs.

6600-0343-000 08/27/03 1-5

Page 14

Chapter 1- Functional Description

1.8 Servo Controlled Oxygen Option

The Giraffe Servo Control Oxygen System consists of an oxygen sensing circuit, Servo Oxygen circuit board,

and an oxygen delivery system.

The sensing circuit is located beneath the bed and consists of a pair of fuel cell oxygen sensors, a three-way

solenoid calibration valve, and a calibration fan. In normal operation the calibration valve is closed and allows

the Giraffe fan to circulate gas from the infant compartment across the sensors.

The unit must be calibrated at least every 24 hours when servo oxygen is in use. Af ter 24 hours have elapsed

the system prompts the user to perform calibration. Once the operator initiates calibration, the calibration

valve opens and the calibration fan is turned on. This draws ambient air across the sensors until a stable

reading is obtained. This 21% oxygen reference value is then used to calibrate the measuring algorithm. After

calibration 100% oxygen is briefly delivered to the system to ensure there are no occlusions. When calibration

is complete the unit will resume controlling oxygen based on the last set point.

The system must have two sensors present to operate. One sensor is always used for control and the other is

used for a redundant check and display . The sensors generate a volt age of about 40 millivolt s at 21% oxygen

concentration and about 200 millivolts at 100% oxygen concentration. The voltage is directly proportional to

the concentration of oxygen. Humidity and temperature sensors located in the sensor plug are used for

voltage compensation. A fan mounted to the sensor-housing door is activated when the temperature reaches

50 degrees C. This fan circulates air to keep the sensors below the maximum allowable operating temperature, about 55 degrees C.

The Servo O2 board is located in the Giraffe controller enclosure. The microcontroller and integrated EPROM

on the board perform the following:

Convert sensor output from analog to digital

Activates oxygen alarm conditions.

Two-way communications via 485 bus with the Giraf fe control board.

Controls the calibration valve to select calibration mode.

Controls the two supply valves to maintain the desired oxygen set point.

Opens the safety relay , which removes power to the three-way valve and the supply valves in case of

a system failure.

The oxygen delivery system consists of two solenoid supply valves, and a regulator assembly . The preset

regulator regulates the oxygen supply to 345 kPa (50 psi). T wo supply valves, controlled by the Servo Oxygen

board, control flow to the infant compartment. Both valves are opened until the measured level gets close to

the desired set point then one valve is closed. One valve is then cycled on and off as needed to maintain the

desired oxygen levels in the infant compartment. The valve selected is alternated so both valves cycle about

the same number of times. There are 2 fuses between the Servo O2 board and the supply valves that prevent

high current from the board entering the valve housing should a short occur in the supply valves. A safety valve

that shuts off oxygen flow whenever the canopy is raised actuates mechanically by the movement of the

canopy support rail. When the canopy is down the valve is open (canopy up/valve closed). The safety valve

actuates independently of the solenoid type supply valves.

1-6 08/27/03 6600-0343-000

Page 15

Chapter 2- Service Checkout

2.1 Setup

The OmniBed is shipped with the canopy in the locked down position. Before the canopy can be raised the rail

shipping locks must be released. They are located in both sides of the OmniBed near the outside bottom of the

uprights. An orange tear-away label marks their location. The lock consists of a socket head cap screw in a

slot. Tightening the screw disengages the screw head from the slot and releases the lif t rail. Using the 4 mm

hex key provided with the unit, turn the screw clockwise about 8 rotations until the screw securely seats in its

hole. Remove the tear away label.

WARNINGS w Do not perform the preoperative checkout procedure while the patient occupies the

unit.

w Complete the preoperative checkout procedure section of this manual before

putting the unit into operation. If the equipment fails any portion of the checkout

procedure it must be removed from use and repaired.

2.2 Mechanical checks

1. Disconnect the power cord for the mechanical portion of the preoperative checkout procedure.

2. Examine the power cord for any signs of damage. Replace the cord if damage is evident.

3. Check that both plug retaining brackets are in place.

4. Examine the unit overall for any damaged or missing parts.

5. Check that all the casters are in firm contact with the floor and that the unit is stable. Lock the caster

brakes and check that they hold the unit in place. Release the brakes and check that the unit moves

smoothly.

6. Check the operation of the two side doors. Open the doors and check that they swing all the way down

and hang perpendicular to the bed. Check that the doors are securely attached to the unit and that the

hinge pins are properly seated. Check that the inner walls are securely fastened to the doors. Close the

doors and check that the latches hold the doors securely shut. The orange latch open indicators should

not be visible when the latches are engaged. Check that the top of the doors meet the canopy seal.

7. Check the portholes. Open the portholes by pressing on the latch. The cover should swing open. Close the

porthole and check that the latch holds the cover securely shut and that the cover seals tightly against the

porthole gasket. Check that all the porthole seals are in place and are in good condition.

8. Check that the tubing access covers in the four bed corners and the large slot grommet at the head of the

bed are in place and are in good condition.

9. Check the operation of the bed. The bed should rotate easily without binding. If the bed is properly seated

and locked in place, the mattress should be level. With the bed rotated back into the straight position,

check to see that the bed platform extends and stops when it is pulled out on either side. Check the

operation of the bed tilt mechanism. Squeeze the tilt control and push down on the foot of the bed. The

head of the bed should raise easily , and should stay in position at any angle along it s tilt p ath when the tilt

control is released. Push down on the head of the bed. The foot of the bed should raise easily, and should

stay in position at any angle along its tilt path when you the tilt control is released.

6600-0343-000 08/27/03 2-1

Page 16

Chapter 2- Service Checkout

2.3 Controller checks

WARNING w Do not use the OmniBed in the presence of flammable anesthetics: an explosion

hazard exists under these conditions.

1. Connect the OmniBed power cord to a properly rated outlet.

2. Connect the patient probe to jack 1 on the probe panel.

3. Switch on the power at the mains switch on the back of the unit, and at the standby switch on the jack

panel, while holding in the override button (>37) on the control panel during power up until the software

revision screen appears. Release the button and the first service screen will appear.

4. Scroll to “Down” and select it to bring up the second service screen. Select Status to see Status screen.

Check status of the software self tests. These include: incubator heater on (INCHTRON), warmer heater

on (WRMHTRON), incubator/warmer heater off (I/WHTROFF), humidifier heater on (RHHTR), remote

monitoring data stream (RS232LOOP), incubator fan on (F ANON), and incubator fan off (FANOFF). All

test should say P ASS except RS232 LOOP (the connector pins must be shorted to get the PASS message).

5. Using the standby switch turn off the unit, then turn it back on.

Verify the following:

➺ All the displays and indicators light

➺ The software revision appears

➺ The prompt tone begins

Note: If the unit has been used in the last 2 hours, the patient history query appears.

6. Adjust the set temperature to silence the prompt tone.

7. Check the patient probe. If the probe is below 30 C, the display will show -L-. Warm it by placing it between

your fingers, and verify that the baby temperature reading increases.

8. Unplug the patient probe and check that both visual and audio alarms trigger in the Baby control mode.

9. Check the canopy lift mechanism. Push the lift pedal and verify the canopy raises smoothly in one continuous movement to its upper limit, the heater doors open, and the unit shifts into warmer operation. Check

that the pedals on both sides of the unit raise the canopy .

10. With the canopy raised, check the operation of the panel at the foot of the bed. Check that after you lift up

on the panel, it swings down and hangs perpendicular to the bed. Check that the panel is securely attached. Check that it swings back up and seats in the closed position.

1 1 . Lower the canopy and verify that it stops when you remove your finger from the hand switch. Check that it

stops automatically at its lower limit, and that the canopy seal makes contact with all four bed sides, and

that the unit shifts into the incubator operating mode. Check that the raise and lower buttons at the head of

the bed on both sides of the unit raise and lower the canopy .

12. If so equipped, check the operation of the bed elevating system. Raise and lower the bed along its entire

travel range, checking that the mechanism operates smoothly . Check that the pedals on both sides of the

unit raise and lower the bed.

13. Check the power failure alarm and the battery backed up memory. Make note of the current control mode

and temperature settings and wait one minute, then unplug the OmniBed from the wall outlet. An alarm

2-2 08/27/03 6600-0343-000

Page 17

Chapter 2- Service Checkout

should sound and the power failure indicator should light. Wait one to two minutes and plug the OmniBed

back in. Verify that the alarm cancels and that the OmniBed returns to the same control mode and temperature settings it displayed before the power interruption.

Note: A fully charged battery should supply the power failure alarm for approximately 10 minutes. If the

alarm is tested for the full 10 minutes the OmniBed must be run at least two hours to recharge the battery

before it is used with a patient. Total recharge time is 8 to 10 hours.

14. Perform the Leakage Current and Ground Resistance checks in Chapter 3 of this manual.

2.4 Humidity check

Turn on the Giraffe unit and verify that the Servo Humidity icon is on the screen. Set the Humidity to 65%. Wait

for 4 minutes. If no alarms are seen (except for a possible “Add Water” message) the humidifier is operational.

Note: It is not necessary to have water in the reservoir to perform this test.

2.5 Servo Controlled Oxygen check

Leak Check

This test checks for leaks between the O2 sensors and the Heat sink vent fitting.

1. Remove translation deck, tilt platform, upper pan, and fan.

2. Cover the heat sink vent near the fan shaft with adhesive tape. Make sure the tape will not interfere with fan

rotation. Reinstall the fan, upper pan, tilt platform, and translation deck.

Note: If the conical shaped rubber grommet was removed with the fan, when reinstalling fan be sure that

rubber grommet clicks into groove on fan shaft.

3. Power up the unit, hold down the ‘Air curtain’ button and press the ‘Down’ button to force the Giraf fe into low

fan speed.

4. Set O2 set point to 21%; the display will show the actual concentration in the larger numerals next to the set

point. Open the doors until the actual concentration reaches 21% (ambient).

5. Run the Servo O2 calibration routine and wait for the calibration complete message. In approximately 20

seconds, the “Check O2 Supply” alarm should sound. If there is no alarm, the tubing between the sensor

housing and the heat sink vent fitting has a leak or is disconnected. Repair the leak and repeat steps 1

through 4 of this procedure.

6. After performing the test, power off the unit. Remove the translation deck, tilt platform, upper p an, and the

fan, and remove the adhesive tape. Be sure to remove any residue on the heat sink left by the tape.

7. Reassemble the system and run the calibration routine one final time.

Pre-use Checkout

This test checks for leaks between the chassis vent fitting and the O2 sensors.

1. Connect an acceptable hose from an oxygen supply to the oxygen inlet fitting on the unit. Supply pressure

should be between 310 kPa (45 PSI) and 586 kPa (85PSI).

2. Select wrench icon on display screen to bring up setup menu. Select Cal Oxygen on the setup menu to

initiate calibration.

6600-0343-000 09/09/03 2-3

Page 18

Chapter 2- Service Checkout

3. When calibration is completed, 100% oxygen is delivered for approximately 20 seconds to ensure there

are no occlusions in the system. Do not turn off the unit or disconnect the oxygen supply during this brief

period after the ‘Calibration Complete’ screen appears. Exit calibration screen.

4. Select O2 icon on display screen to bring up Servo Control Oxygen menu. Hold down the ‘Air curtain’

button and press the ‘Down’ button to force the Giraffe into low fan speed.

5. Set O2 set point to 65%. Start timer and verify that unit reaches 60% in less than 10 minutes. If rise time is

longer than 10 minutes check all tubing between the O2 sensors and the chassis vent fitting.

Note: The chassis vent may be identified by its mushroom cap shaped cover .

Supply Valve Leak Test

1. Connect oxygen supply to Servo Oxygen fitting.

2. Disconnect the 10mm hose from the expansion chamber .

3. Power up unit in Service Mode.

4. The canopy should be closed for this step and step 5. Scroll to Servo Oxygen service screen, and open V1

& V2 and verify that gas flows audibly .

5. Close V1 & V2 and place the 10mm hose in a cup of water. Verify that no more than 10 bubbles appear

over a one minute period. If unit fails, replace supply valves.

6. Raise the canopy a couple of inches and open V1 & V2. Verify that no more than 10 bubbles appear over

a one minute period. If unit fails replace two-way valve or spring assembly .

When test is completed, reattach 10 mm hose to expansion chamber.

2.6 Accessory checks

1. Check that all accessories are securely mounted and out of the path of the canopy .

2. Check the operation of any accessories with reference to their appropriate operation manuals.

3. Setup any required suction or gas supply systems. Check them for leaks as described in their respective

operation manuals.

2-4 08/27/03 6600-0343-000

Page 19

Chapter 2- Service Checkout

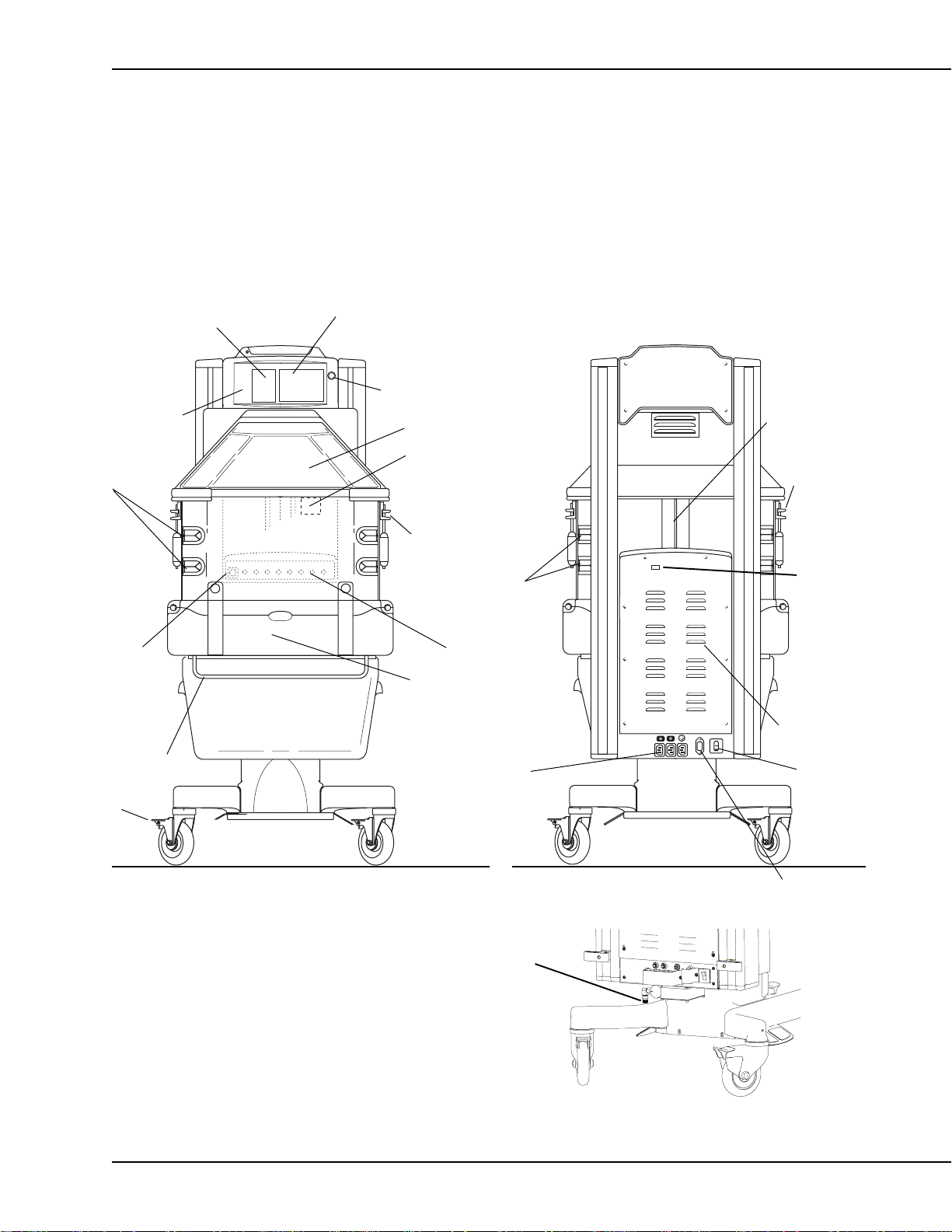

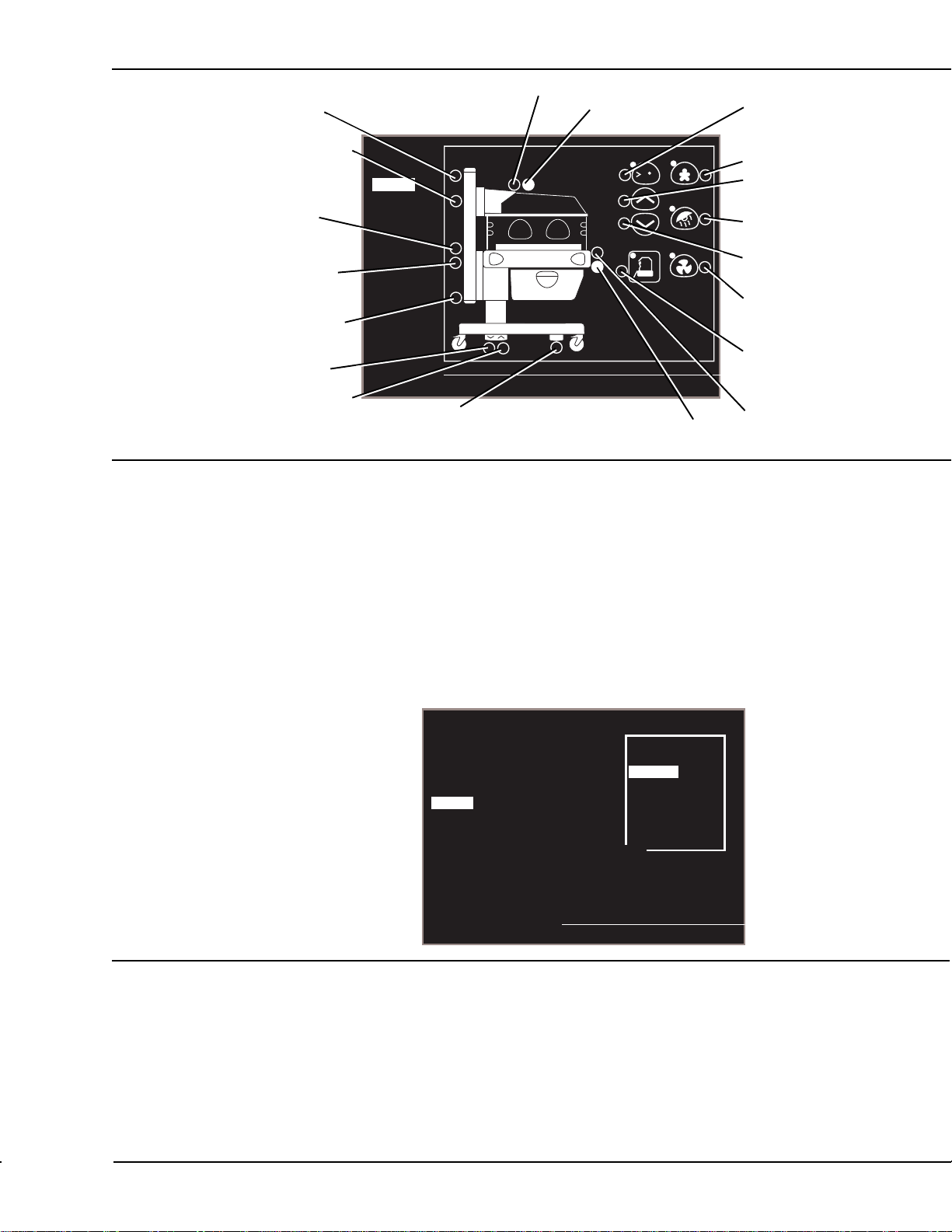

2.6 Cable Connections and Mechanical Controls

Numeric Temperature Displays

Temperature

Regulation

Controls

Tubing Grommets

Standby

Power

Switch

(I/O)

Drainage

Hanger

Caster

Brake

Graphics Screen

Control Knob

Canopy

Compartment Probes

Side Door Latch

Tubing Grommets

Humidifier Reservoir

(air intake filter located

behind reservoir)

Accessory

Power Outlets

Ventilator

Slot

Side Door

Latch

RS 232

Connector

Probe Jacks

Controller

Cover

Mains Power

Switch

FRONT

Figure 2-1

Connections and controls

6600-0343-000 08/27/03 2-5

O2 connection for

Servo Controlled Oxygen option

Plug retaining brackets

not shown for clarity

BACK

Power

Cord

Inlet

Page 20

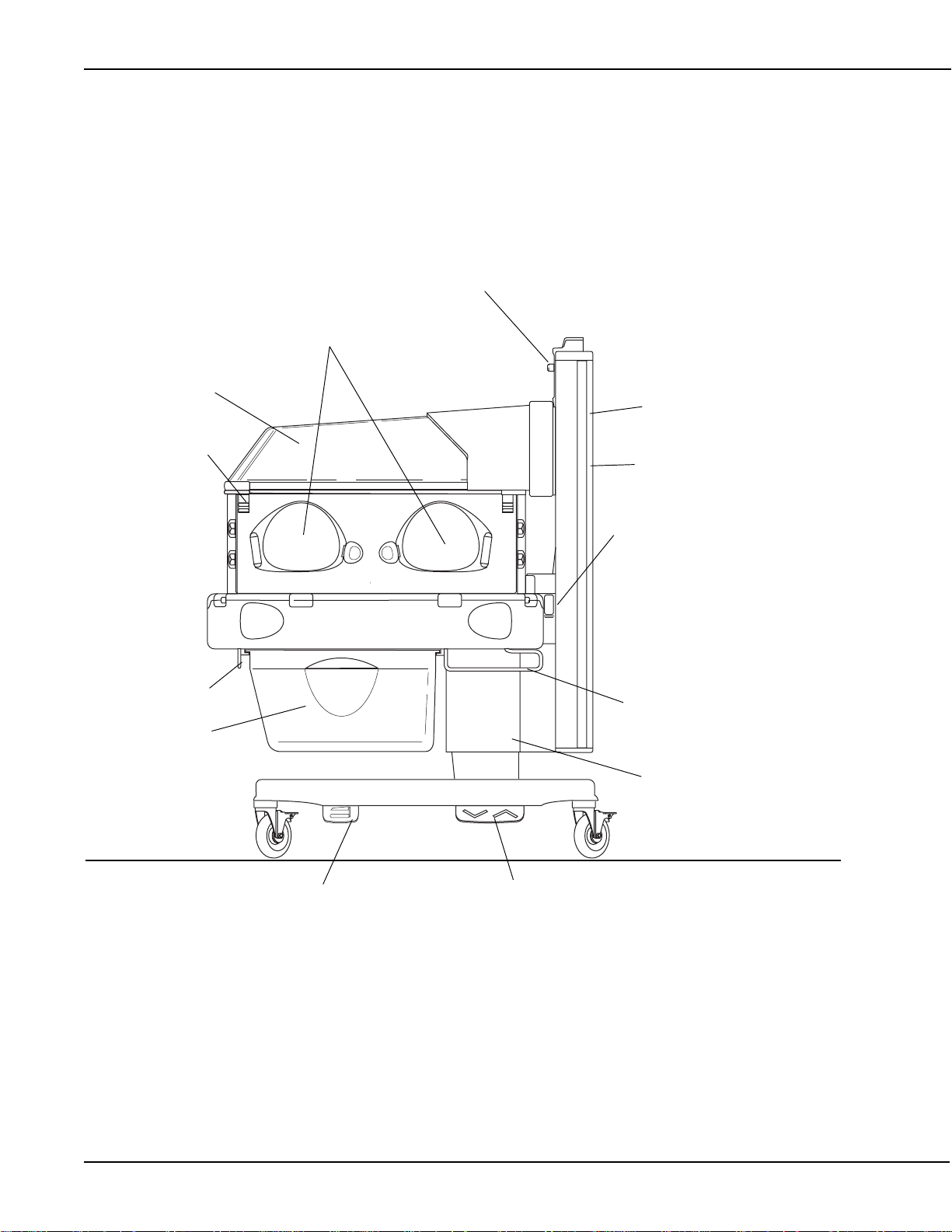

Chapter 2- Service Checkout

Portholes

Canopy

Control Panel

Upright

Side Door Latch

Drainage

Hanger

Storage Drawer

Raise Canopy Pedal

SIDE

Dovetail rail

Canopy Raise/Lower Switches

Pleural Drainage Hanger

Elevating Column

Bed Height Pedal

2-6 08/27/03 6600-0343-000

Page 21

Chapter 3- Calibration and Maintenance

Use Static Control W ork Station to help ensure static charges are safely conducted to ground.

The velostat material is conductive; do not place electrically powered boards on it. Whenever

this symbol appears beside a procedure, take static control precautions.

WARNING w Af ter performing any rep air or calibration, always perform the Service Checkout Proce-

dure before putting the unit back into service.

3.1 Maintenance schedule

The unit should be maintained in accordance with the procedures detailed in this manual. Service maintenance must be performed by a technically competent individual.

Service maintenance

This schedule lists the minimum frequencies. Always follow hospital and local regulations for required

frequencies.

Annually

Perform the electrical safety and calibration procedure as described in the service manual.

Calibrate the scale.

If unit is equipped with Servo Controlled oxygen:

Replace vent screen.

Perform supply valve leak test.

Replace sensors*. It’s recommended both sensors be replaced at the same time.

*

Sensor life of one year is approximate. If the sensor is used often at high oxygen concentrations, sensor life will decrease.

Every T wo Years

Replace the battery .

Note: The battery is used to sound the power failure alarm and to power memory circuits during a

power failure.

Every Three Y ears

Calibrate the humidifier.

3.2 Special Tools

The following tools (or their functional equivalents) are required to complete the recommended

service procedures:

Digital Multimeter , 4-1/2 digit

Leakage Current Tester

PLCC Extractor for removing socketed chips

Static Control Work Station (recommended)

Light gray touch-up paint (Munsell .16GY8.56-0.44 chroma)-18ml ........6600-0714-200

Servo Humidity Calibration Kit................................................................6600-0048-850

Scale calibration weight- 5kg .................................................................6600-0209-800

6600-0343-000 08/27/03 3-1

Page 22

Chapter 3- Calibration and Maintenance

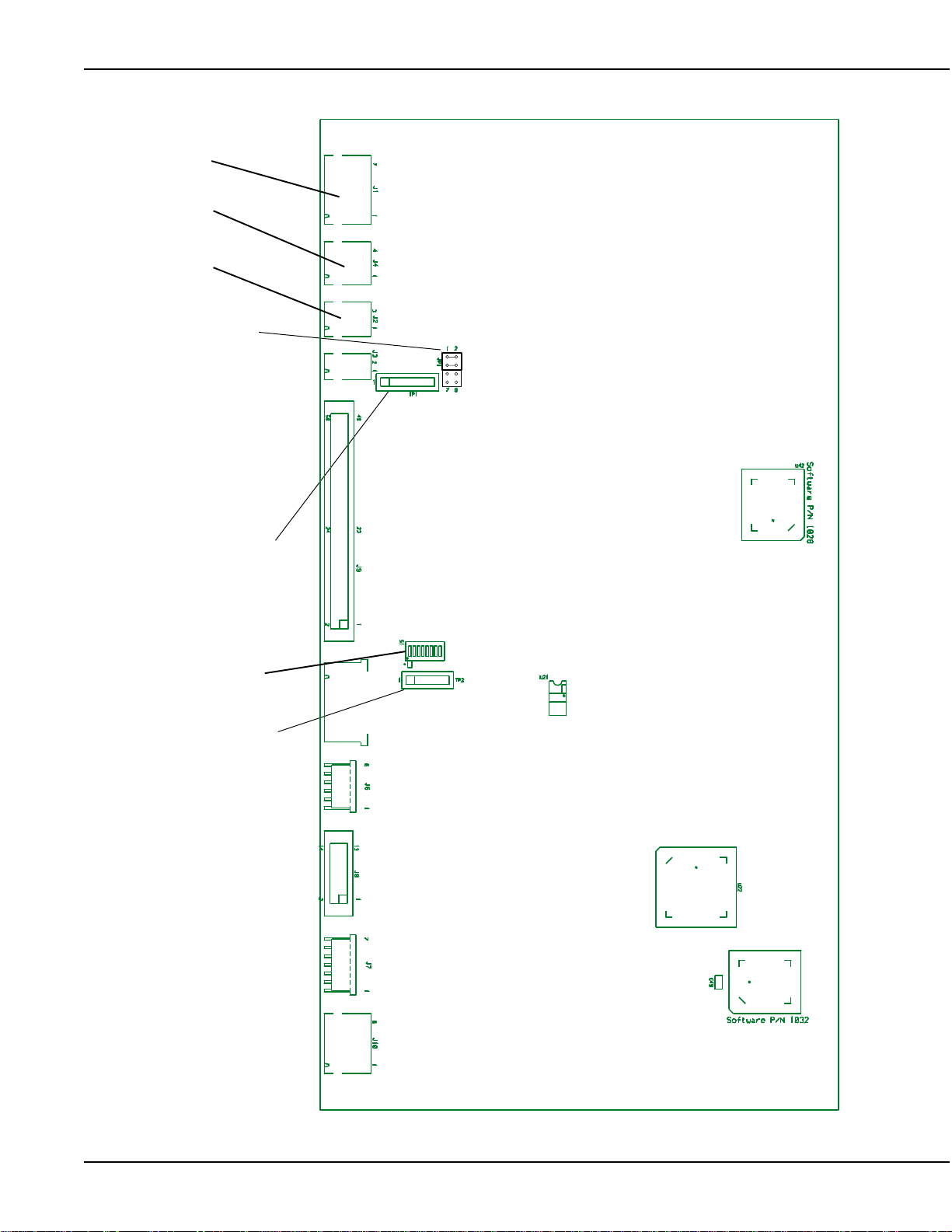

J1

J4

J2

Calibration jumper

NORMAL

MODE

CAL

MODE

Test Point 1

Dipswitch

Test Point 2

12345678

Figure 3-1

Control board test points

3-2 08/27/03 6600-0343-000

Page 23

Chapter 3- Calibration and Maintenance

3.3 System Calibration

Note: If Only performing line voltage calibration, follow instuctions in next section, 3.4.

Important: Be sure to perform System Calibration after replacing a control board.

1. Turn power off.

2. Remove electrical enclosure back panel.

3. Unplug the temperature sensors and from J1, J4 and J2 on the control board.

4. Move jumper JP1 to the CAL MODE position on the control board (see Figure 3-1). Be sure to orient the

jumper correctly so pins 5-6 and 7-8 are shorted.

5. Turn power on. After running the power-up testing INITIALIZING will be displayed and dots will move

across the top of the screen.

6. After about 90 seconds CALIBRATION MODE, Enter “VREF”, and Enter “Mains” will be displayed.

7. Using a 4 ½ digit DVM (capable of measuring to 0.1 millivolt) measure VREF at TP1, pins 1 and 6 (pin 6 is

ground) on the control board. Measure to the nearest 0.1 millivolt.

8. Dial in VREF using the control knob. Press the knob to enter the value.

9. Measure the Mains Voltage at the AC connectors at the bottom of the electronics enclosure cover .

10. Dial in the Mains voltage using the control knob. Press the knob to enter the value.

11. After a few seconds the dots will stop moving across the screen and DONE will appear on the top right of

the display . Do not shut of f the unit until the DONE message is displayed or the new calibration values will

not be stored.

If the message “Mains voltage calibration failed. Please enter the mains voltage again” appears this

indicates the dialed in line voltage is 20% different than the measured value (not the nominal value).

12. Power down the unit and move the calibrate jumper to the NORMAL MODE position. Be sure to orient the

jumper correctly so pins 1-2 and 3-4 are shorted. Reconnect J1, J4 and J2 on the control board.

3.4 Line Voltage Calibration

Important: Be sure to perform line voltage calibration after replacing a relay board.

1. Hold the overide button (>37) while powering up the unit to enter the service screen.

2. On the second service screen select CAL LV.

3. Measure the line voltage at the AC connectors located at the bottom of the electrical enclosure.

4. On the CAL LV screen, dial in the mains voltage value that you measured and push the knob to enter it.

5. When calibration is completed screen will say Mains Volt age Calibration Complete.

If the message “Mains voltage calibration failed. Please enter the mains voltage again” appears this

indicates the dialed in line voltage is 20% different than the measured value (not the nominal value).

6600-0343-000 08/27/03 3-3

Page 24

Chapter 3- Calibration and Maintenance

3.5 Humidifier Calibration

Important: Be sure to re-calibrate the humidifier whenever either the sensor or the control board is

replaced.

Important: In order for the water in the calibration bottle (6600-0048-850) to be completely saturated, most

of the salt should not be dissolved. There should be as little standing water above the salt line as possible

to minimize the response time. The salt in the calibration bottle may only be used for a period of one year

after it’s initial mix with water then the kit should be discarded.

1. Take the cap off the humidity calibration bottle and add one half cap full of distilled water to the bottle.

Shake the bottle to thoroughly mix the salt and water solution. Place the smaller end the elbow over the

bottle.

2. Slide the elbow over the humidity sensor (mounted on the back wall) until it stops. This creates a 75% RH

environment for the sensor.

3. Hold the override key while powering up to enter the service screen.

4. On the second service screen, select Cal RH. The screen will prompt “Push knob when RH reading is

stable.” Wait for 20 minutes or until the RH display st abilizes (does not change by more than 1% in 5

minutes).

5. Depress the control knob to complete the calibration. On software revision 1.3 and higher , you will have

the option to select ST ABLE, SET TO DEFAULT or EXIT. STABLE initiates calibration. SET T O DEFAUL T

resets calibration values back to factory default settings. If you started calibration by mistake (without the

calibration bottle in place, for example) you would select SET TO DEFAULT and then calibrate the unit. If

you have entered the calibration routine by mistake, select EXIT to leave without initiating calibration.

6. If “RH Sensor Calibration Completed.” is displayed the calibration is complete. Depress the knob to exit

the Cal RH routine.

7. If “RH Sensor Calibration Failed. Try Again.” is displayed verify your setup and press the knob to try the

calibration again. This message appears if the signal from the RH sensor is outside the values expected

from the sensor at 65-85% RH. If the failure persists it means the readings are out of this range and either

the calibration bottle or the RH sensor may be defective.

3.6 Servo Controlled Oxygen Calibration

1. Select Set Up icon (wrench) to bring up Set Up screen.

2. Scroll down and select Cal Oxygen to initiate calibration. Calibration is automatic and takes less than five

minutes. A bar graph indicates progress toward completing calibration. If for any reason you wish to

discontinue calibration before it is completed, turning the control knob in either direction will cause the

word Cancel to appear on the calibration screen. Pushing in the control knob will discontinue calibration.

When calibration is completed, 100% oxygen is delivered for approximately 20 seconds to ensure there

are no occlusions in the system. Do not turn off the unit or disconnect the oxygen supply during this brief

period after the ‘Calibration Complete’ screen appears.

Note: The servo control oxygen system prompts for calibration every 24 hours, but the system may prompt for

calibration if there is a large leak in the system (for example if a door is open) for half an hour.

CAUTION w The servo-control system must be calibrated at the same atmospheric pressure in which it is

to be used. Operation at atmospheric pressures other than that present during calibration may

result in readings outside the stated accuracy for the unit.

3-4 08/27/03 6600-0343-000

Page 25

Chapter 3- Calibration and Maintenance

3.7 Scale Calibration

NOTE: The scale is calibrated using a Class F calibration weight between 1 kilogram and 8 kilograms

(accuracy of 0.01%).

1. Place the test weight on the center of the bed.

2. Hold the override key while powering up to enter the service screen.

3. On the second service screen, select Cal Scale.

4. Remove the weight and push the knob at the screen prompt “REMOVE THE WEIGHT AND PUSH

KNOB”. The screen will prompt “INITIALIZING......” for a few seconds.

5. Replace the weight and push the knob at the screen prompt “PLACE TEST WEIGHT AND PUSH KNOB”.

The screen will prompt “MEASURING ....” for a few seconds

6. When the screen prompts “ENTER TEST WEIGHT” Dial in the test weight to the nearest gram. Press the

knob to enter. The screen will prompt “CALCULATING.” for a few seconds.

7. When the screen prompts:

SA VE AND EXIT

EXIT ONLY

RESTORE DEFAULT

Select and enter “SA VE AND EXIT”

8. Turn off the power to exit the service mode.

3.8 Leakage Current

Use approved equipment and techniques to test the unit’s leakage current and ground continuity. Follow the

directions supplied by the test equipment manufacturer to verify the following:

1. Less than 300 microamperes measured at any exposed metal surface for equipment rated at 120 Vac, 50/

60 Hz.

2. Less than 500 microamperes measured at any exposed metal surface for equipment rated at 220 Vac, 50/

60 Hz or 240 V ac, 50/60 Hz.

3.9 Ground Resistance Check

Measure the resistance between the ground pin on the line cord plug and exposed metal of the electronic

enclosure. The ground resistance must be less than 0.2 ohms.

6600-0343-000 08/27/03 3-5

Page 26

Chapter 3- Calibration and Maintenance

3-6 08/27/03 6600-0343-000

Page 27

Chapter 4-Troubleshooting

4.1 Service Screen

To access the service screen, hold in the override button (>37) during power up until the software revision

screen appears. Release the button and the first service screen will appear.

Figure 4-1

DAC Volt 0.000

Language English

Temp U C

Volume Maximum

Pat Alarm 1.0C

Elevate Enable

Pat Ctrl Both

Pat Algo Cascade

Preheat 25%

Canopy Enabe

Scale U gms

Scale R 10g

Comfort Enable

Set Time

View Mods

Down

HFS 1500

LFS 1000

RH 50

SR 1548

SC 21279

Last Cal: 1/1/02 Fri 3/3/03 9:54am

ADT 22.66

ACT 22.65

P11 327.67

P12 327.67

P21 327.67

P22 327.67

HSP 18208

LV1 117.4

LV2 117.8

LF 60

MC 0.001

TV 1.648

5V 5.059

VR 1.233

DV 0.000

BV 0.000

First service screen

Default options that may be selected from this screen appear along the left side of the screen

DAC Volt Digital/Analog Converter voltage. This is the over temperature voltage that is used by the

system to verify the computer independent circuitry is working. To manually test this circuit

enter voltages from 0 to .5 V. The DV value at the bottom right corner of the screen should

match this value within 10mV.

Language English is the default language that appears on the EL screen, but you can select French,

Spanish, etc., depending on what software is installed.

Temp U Changes temperature displays to show Fahrenheit, Celsius or Celsius Only so the

Fahrenheit option is not present on the user Set-up screen (Celsius is factory set default).

Volume Select one of four volume settings. 1 is minimum, 4 is maximum.

Pat Alarm Set the default Baby Hot/Baby Col alarm to activate when either 0.5ºC or 1.0ºC difference

is read between a set temperature and the baby probe temperature.

Elevate Disable or enable the elevating column foot pedal switches. If the pedals are disabled on

the service screen they cannot be enabled on the user setup screen (wrench icon).

Pat Ctrl Allows you to disable patient control.

Pat Algo To be used for future software options.

Preheat Select from 10 to 50% radiant heater power to preheat without alarms; 25% is the default.

NOTE: Reseting maximum preheat level to above 25% may result in noncompliance to

device standard IEC 601-2-21

Canopy Disable or enable the canopy foot pedal control; hand switches will remain active. If the

pedals are disabled on the service screen they cannot be enabled on the user setup

screen (wrench icon).

Scale U Select from Grams, Pounds or Grams Only so that the pounds option is not present

on the user Scale screen (grams is the factory default).

6600-0343-000 08/27/03 4-1

Page 28

Chapter 4- Troubleshooting

Scale R Select from 2 scale resolution settings; 10 grams or 5 grams (10 grams is the factory

default).

Comfort Allows you to remove the Comfort Screen feature.

Set Time Set real time clock for time, day and date. Choose how date is displayed (North American

or European). Choose a 12 hour (AM/PM) or 24 hour time display.

View Mods Display the current software revision of the options installed on this specific unit (Humidi-

fier, Scale, SPO2, etc.)

Down Go to second service screen.

Up Return to previous screen.

Figure 4-2

Second service screen

Up

Status

Switches

Errors

Hours Run

Cal LV

Man temp al Enable

Pedals

BatLoad Disable

Cal RH

ServO2

Cal Scale

HFS 1153

LFS 887

RH 20

Last Cal: 1/1/00 Fri 3/3/02 9:54am

ADT 22.66

ACT 22.65

P11 327.67

P12 327.67

P21 327.67

P22 327.67

HSP 18208

LV1 117.4

LV2 117.8

LF 60

MC 0.001

TV 1.000

5V 5.059

VR 1.233

DV 0.002

BV 0.000

Status Check status of all self test the software runs continuously. These include: incubator

heater on (INCHTRON), warmer heater on (WRMHTRON), incubator/warmer heater off

(I/WHTROFF), humidifier heater on (RHHTR), remote monitoring data stream

(RS232LOOP), incubator fan on (FANON), and incubator fan off (FANOFF).

If the RS232 option is not installed RS232LOOP will display N/A. To test the circuit if the

option is installed, short pins 2 & 3 on the 9 pin connector on the back of the electrical

enclosure.

Up

Status

Switches

Errors

Hours Run

Cal LV

Man temp al. Enable

Pedals

BatLoad Disable

Cal RH

ServO2

Cal Scale

HFS 1500

LFS 1000

RH 20

INCHTRON PASS

WRMHTRON PASS

I/WHTROFF PASS

RHHTR PASS

RS232LOOP N/A

FANON PASS

FANOFF PASS

TV 1.000

5V 5.059

VR 1.233

DV 0.002

BV 0.000

Figure 4-3

Status menu

Last Cal: 1/1/00 Fri 3/3/00 9:54am

Switches Select to bring up a diagnostic diagram of the unit that displays the status of all the

switches. If the circle next to the switch is lit, the switch is closed; if its not lit, the switch is

open. Also, while the switch status screen is active, you can hold down the alarm silence

button to light the alarm light, system failure light and all LED segments to test them.

4-2 08/27/03 6600-0343-000

Page 29

Chapter 4-Troubleshooting

Heater doors open

Canopy up

Heater doors closed

Overide

control

Canopy middle

Canopy hand

switch up

Canopy hand

switch down

Canopy down

Elevating base

pedal down

Elevating base

Figure 4-4

pedal up

Switch diagnostic diagram

Up

Status

Switches

Errors

Hours Run

Cal LV

Man temp al.

Pedals

BatLoad

Cal RH

ServO2

Cal Scale

Canopy pedal

c

37

LastCal: 1/1/02 Fri 3/3/03 10:10am