Ohmeda Ohio Service manual

Ohio@ Infant Warmer

Systems

All Models

I

and Maintenance Manual

User Responsibility

This Product will perform in conformity with the description thereof

contained in this operating manual and accompanying labels and/or

inserts, when assembled, operated, maintained and repaired in accor-

dance with the instructions provided. This Product must be checked

periodically. A defective Product should not be used. Parts that are

broken, missing, plainly worn, distorted or contaminated should be

replaced immediately. Should such repair or replacement become neces-

sary, Ohmeda recommends that a telephone or written request for

service advice be made to the nearest Ohmeda Regional Service Center.

This Product or any of its parts should not be repaired other than in

accordance with written instructions provided by Ohmeda and by

Ohmeda trained personnel. The Product must not be altered without the

prior written approval of Ohmeda’s Quality Assurance Department. The

user of this Product shall have the sole responsibility for any malfunction

which results from improper use, faulty maintenance, improper repair,

damage, or alteration by anyone other than Ohmeda.

!

A

CAUTION: Federal law in U.S.A. and Canada restricts this device to

sale by or on the order of a licensed medical practitioner.

6600-0194-000

11109/93

Model Descriptions v

Definitions vii

Precautions ix

l/Description l-l

Warnings ix

Cautions xiii

1.1

General l-l

1.2 Support Structure l-l

1.3 Heater Assembly l-l

1.4 Control Unit l-2

1.5 Bed Platform l-2

1.6

Bassinet l-2

1.7

Accessories

l-3

S/Setup and Checkout Procedure

2.1 Setup 2-l

2.2 Mechanical Checkout Procedure 2-l

A. Overall Appearance 2-l

B.

Heater Assembly Rotation 2-2

C. Mechanical Checks 2-2

D.

Warmer/Bassinet Interlock (model 3500 only)

E.

Warmer/Bassinet Unlock 2-3

F.

Accessory Checks 2-3

G. Wall Mount Checkout 2-4

2.3 Control Unit Checkout Procedure 2-4

A. Control Unit Check 2-5

B.

Elapsed Timer Check 2-6

Observation Light Check 2-6

C.

Raise and Lower Bed Switch Check (Elevating Models

D.

Only) 2-6

E.

Interlock Switch Check 2-7

F.

Power Failure, Memory and Battery Test (all models except the

2001 International) 2-7

3/0peration

3-1

2-1

2-3

3.1 Control Panel Operation 3-l

A. Displays 3-l

B.

Indicator Lights 3-2

C. Switches 3-2

D. Alarms 3-4

3.2

Manual and Servo Mode Operation

3.3

Elapsed Timer Operation 3-11

6600-0194-000

11/09/93

3-7

i

Table of Contents

3.4

Bassinet Operation (model 3500 only) 3-11

3.5

Bed Platform Operation 3-12

3.6

Side Panel Operation 3-13

3.7

X-ray Procedures 3-14

3.8

Oxygen Administration 3-16

3.9

Gas Cylinder Installation and Operation 3-16

3.10

Mounting Accessories 3-18

A.

Mounting and Releasing Procedure

B.

Adapter

C.

ECMO Adapter 3-20

3.11

ThermaLink

Using the Serial Data Interface

Using the Nurse

Nurse

3.12

Rotating Drawer Option 3-22

Plate Mounting and Releasing Procedure

Options 3-20

Call

checkout 3-22

CaII

System Interface

3-19

3-19

3-21

3-21

4KXeaning

and Disinfecting 4-1

Appendix A-l

4.1

Cleaning 4-l

4.2

Wood Surfaces (model 3500

4.3

Reusable Skin Temperature

Temperature Conversion Chart A-l

Servo Mode Algorithm A-2

Infant Warmer System Specifications

Electrical A-2

Controller A-3

Alarms

Environmental Specifications

Electromagnetic Compatibility

Mechanical (Without Accessories) A-6

3500 Bassinet A-7

Accessories A-8

Radiant Energy Distribution A-10

Thermalink

Serial data A-10

Nurse

Installing

Pre-Installation Preparation

Warmer Installation A-14

A-4

Option Specifications A-10

CaII

specifications

waII

mounted units

only)

Probe

A-5

A-12

A-13

A- 13

4-2

4-2

A-2

(EMC)

A-6

Warranty W-l

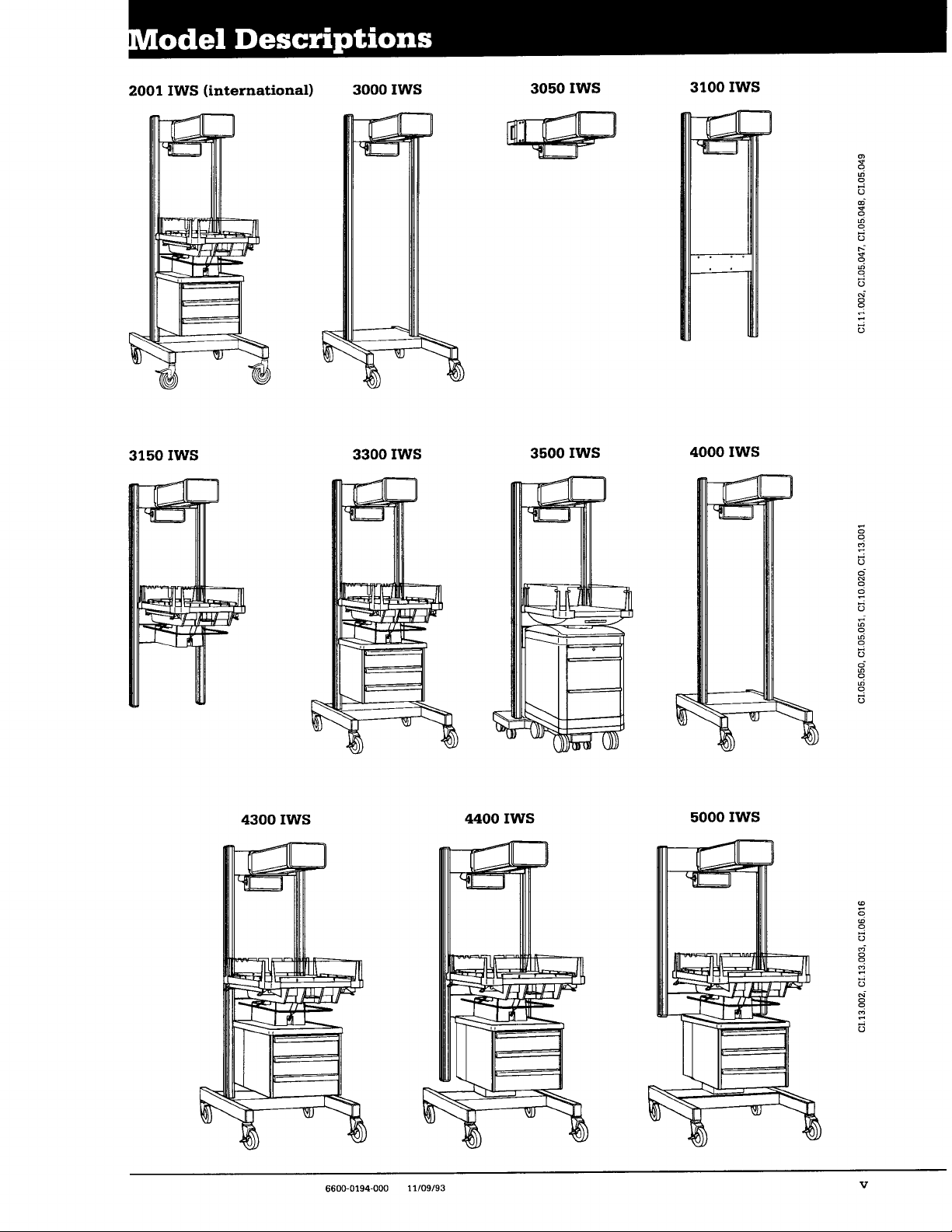

2001 IWS (international)

3000

IWS

6600-0194-000

11/09/93

V

Model Descriptions

All models of the Ohmeda Infant Warmer System provide a controlled

source of radiant heat for infants and pediatric patients. The control sys-

tem uses a microprocessor and provides both manual and servo modes of

operation (except for the 2001 International, which is manual mode only).

The model 2001 International has an integral infant bed and is a manual

mode only warmer designed for short term attended care in the OR and

L&D.

The wall mounted 3050, 3100 and 3150 models are available to accommo-

date specific architectural requirements in the NICU, L&D, LDR and LDRP

room

.

The 3050 is a heater head only, the 3100 is a heater and dove tail

rails, and the 3150 includes a heater, rails and integral bed.

The model 3300 has an integral bed for infants and is intended for proce-

dures and long term care in the Nursery and L&D.

The model 3000, 3500 and 4000 are free standing Warmers which can be

used over a variety of infant bassinets in the general nursery, over post-

operative patients, during patient feeding, and in any other application

where controlled radiant heat is required.

The 3500 System also has a detachable Bassinet for infants, and is in-

tended for procedures and long term care in the Nursery, L&D, LDR and

LDRP Rooms.

The model

4300,440O

and 5000 have a larger size bed than the model 3300

and are intended for surgical procedures and long term care in the Nursery

and L&D Rooms. Both the 5000 and 4400 have an elevating pedestal to

raise and lower the bed-to-floor height. The model 4400 has a narrower

foot print than the 5000 warmer. The model 4300 is a non-elevating

version of the 4400.

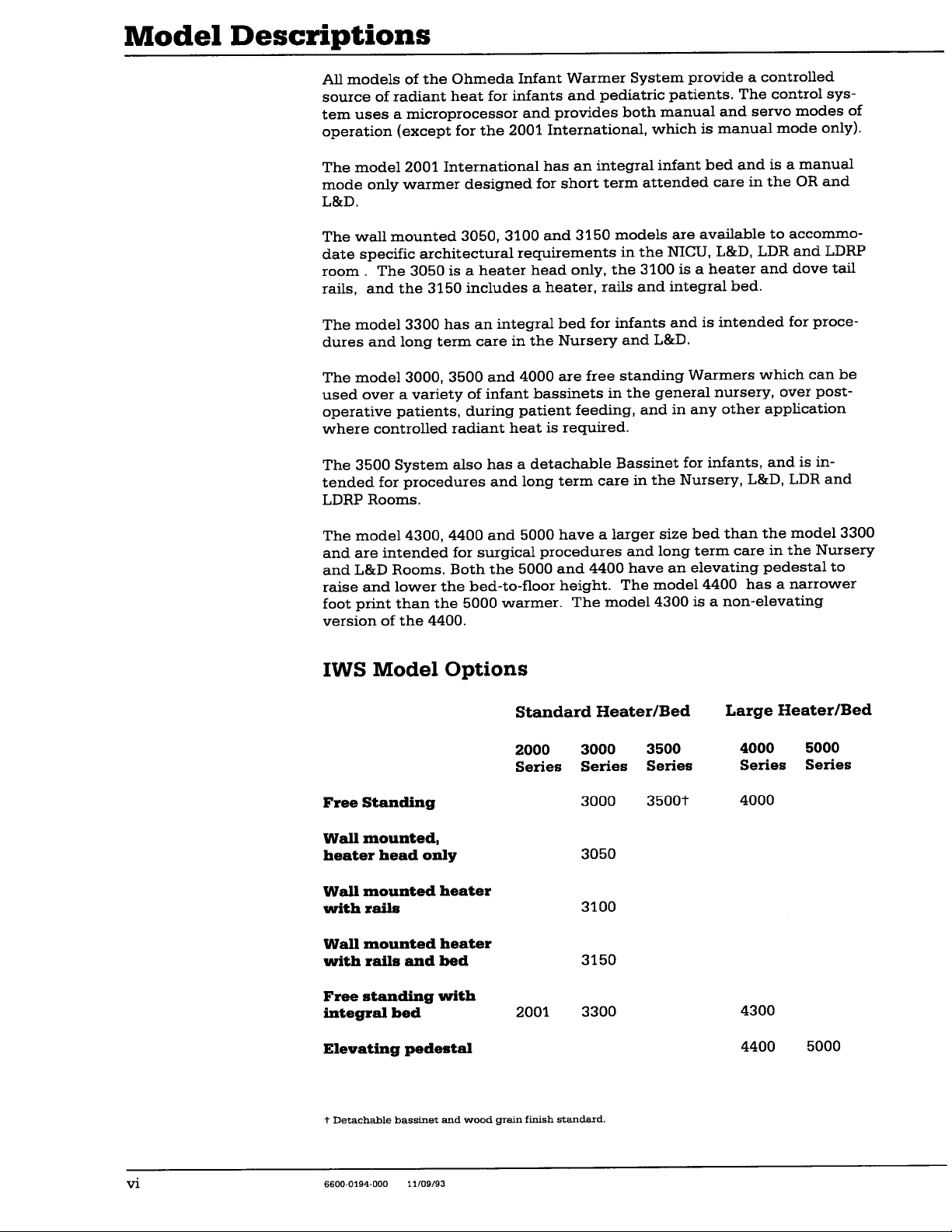

IWS Model Options

Large Heater/Bed

4000

5000

Series Series

4000

Free Standing

Wall mounted,

heater head only

Wall mounted heater

with rails

Wall mounted heater

with rails and bad

Standard Heater/Bed

2000 3000

3500

Series Series Series

3000

3500t

3050

3100

3150

vi

Free standing with

integral bed

Elevating pedestal

t Detachable bassinet and wood

6600-0194-000

11109/93

grain

2001

finish standard.

3300

4300

4400 5000

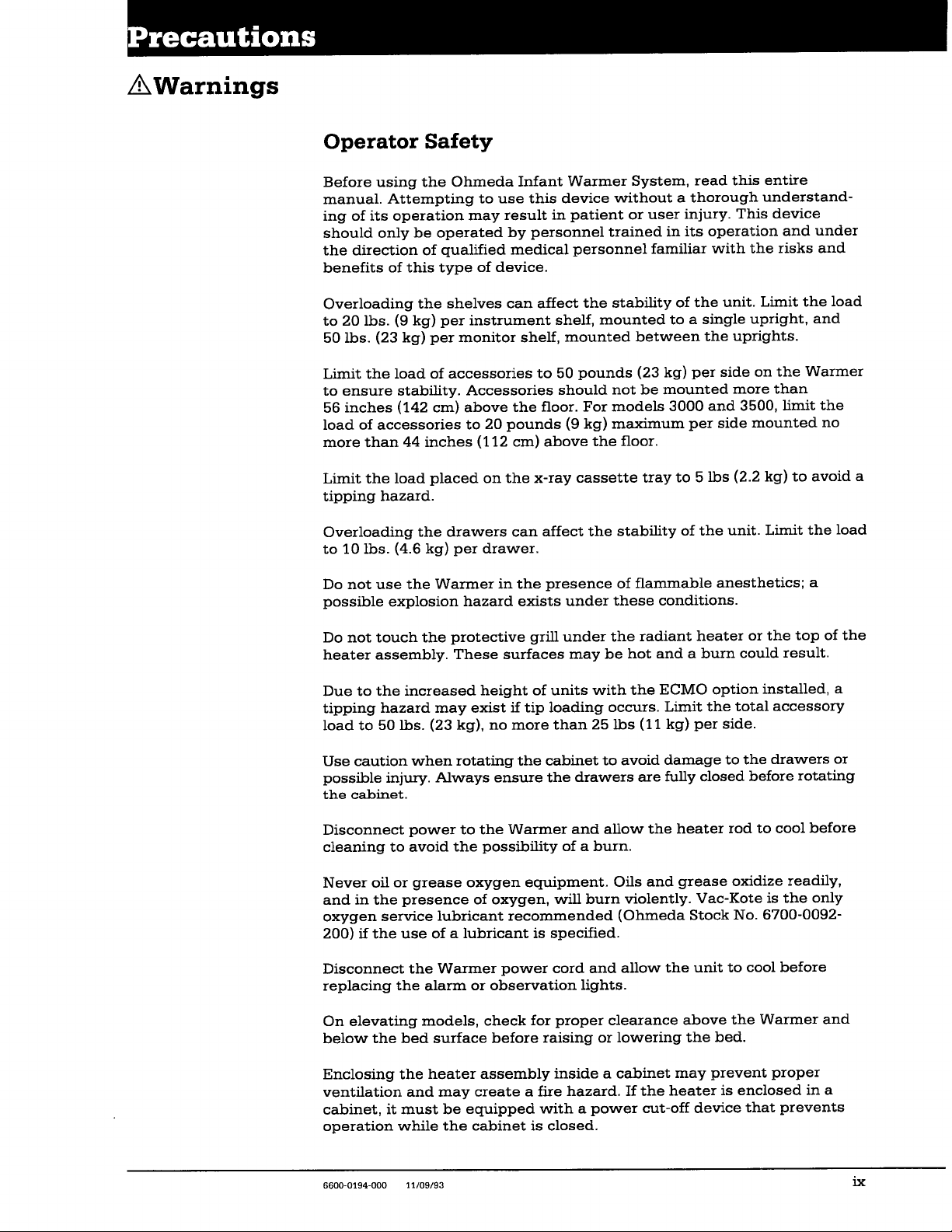

AWarnings

Operator Safety

Before using the Ohmeda Infant Warmer System, read this entire

manual. Attempting to use this device without a thorough understand-

ing of its operation may result in patient or user injury. This device

should only be operated by personnel trained in its operation and under

the direction of qualified medical personnel familiar with the risks and

benefits of this type of device.

Overloading the shelves can affect the stability of the unit. Limit the load

to 20 lbs. (9 kg) per instrument shelf, mounted to a single upright, and

50 lbs. (23 kg) per monitor shelf, mounted between the uprights.

Limit the load of accessories to 50 pounds (23 kg) per side on the Warmer

to ensure stability. Accessories should not be mounted more than

56 inches (142 cm) above the floor. For models 3000 and 3500, limit the

load of accessories to 20 pounds (9 kg) maximum per side mounted no

more than 44 inches (112 cm) above the floor.

Limit the load placed on the x-ray cassette tray to 5 lbs (2.2 kg) to avoid a

tipping hazard.

Overloading the drawers can affect the stability of the unit. Limit the load

to 10 lbs. (4.6 kg) per drawer.

Do not use the Warmer in the presence of flammable anesthetics; a

possible explosion hazard exists under these conditions.

Do not touch the protective grill under the radiant heater or the top of the

heater assembly. These surfaces may be hot and a burn could result.

Due to the increased height of units with the ECMO option installed, a

tipping hazard may exist if tip loading occurs. Limit the total accessory

load to 50 lbs. (23 kg), no more than 25 lbs (11 kg) per side.

Use caution when rotating the cabinet to avoid damage to the drawers or

possible injury. Always ensure the drawers are fully closed before rotating

the cabinet.

Disconnect power to the Warmer and allow the heater rod to cool before

cleaning to avoid the possibility of a burn.

Never oil or grease oxygen equipment. Oils and grease oxidize readily,

and in the presence of oxygen, will burn violently. Vat-Kote is the only

oxygen service lubricant recommended (Ohmeda Stock No. 6700-0092-

200) if the use of a lubricant is specified.

Disconnect the Warmer power cord and allow the unit to cool before

replacing the alarm or observation lights.

On elevating models, check for proper clearance above the Warmer and

below the bed surface before raising or lowering the bed.

Enclosing the heater assembly inside a cabinet may prevent proper

ventilation and may create a fire hazard. If the heater is enclosed in a

cabinet, it must be equipped with a power cut-off device that prevents

operation while the cabinet is closed.

6600-0194-000

11109/93

ix

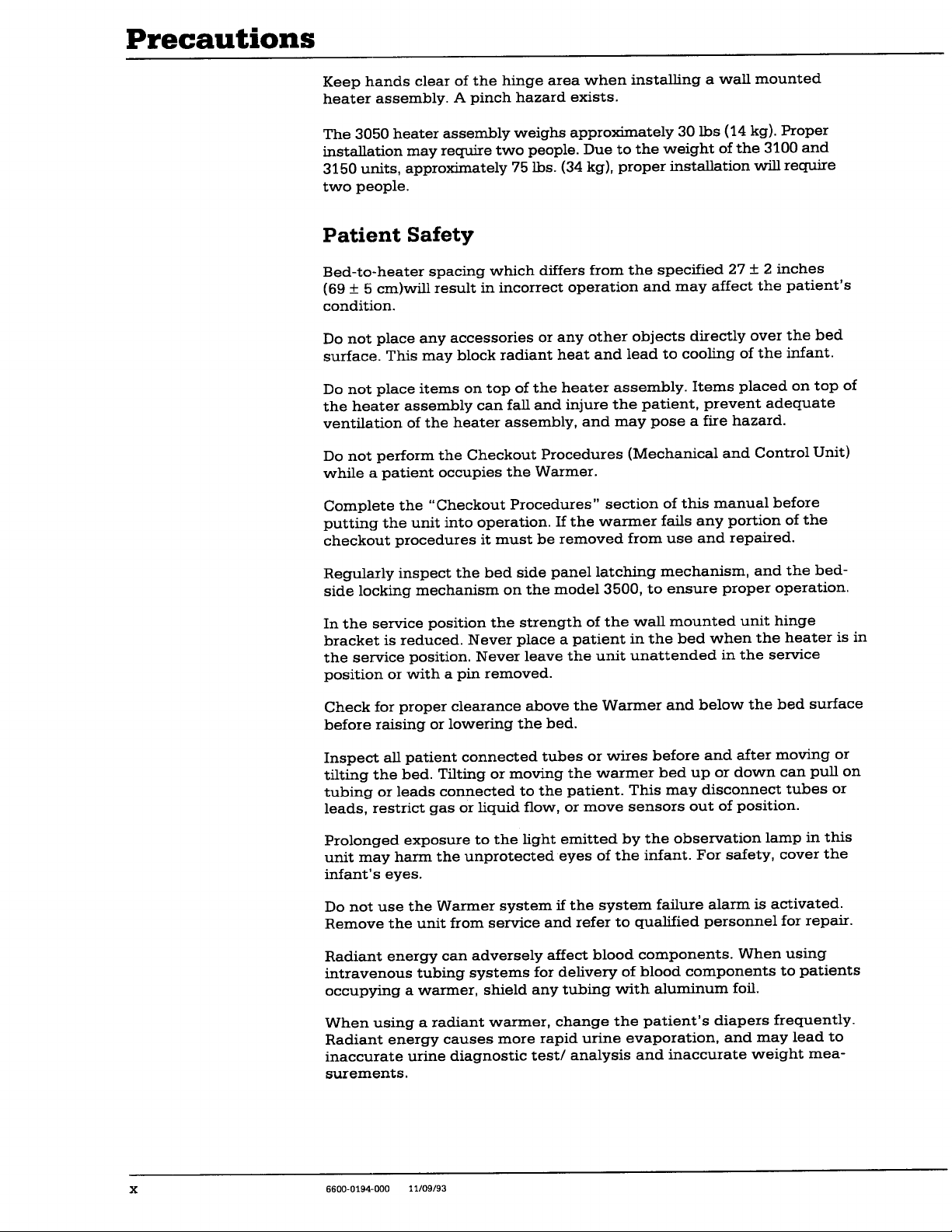

Precautions

Keep hands clear of the hinge area when installing a wall mounted

heater assembly. A pinch hazard exists.

The 3050 heater assembly weighs approximately 30 lbs (14 kg). Proper

installation may require two people. Due to the weight of the 3100 and

3150 units, approximately 75 lbs. (34 kg), proper installation will require

two people.

Patient Safety

f

Bed-to-heater spacing which differs from the specified 27

(69

&

5 cm)will result in incorrect operation and may affect the patient’s

condition.

Do not place any accessories or any other objects directly over the bed

surface. This may block radiant heat and lead to cooling of the infant.

Do not place items on top of the heater assembly. Items placed on top of

the heater assembly can fall and injure the patient, prevent adequate

ventilation of the heater assembly, and may pose a fire hazard.

Do not perform the Checkout Procedures (Mechanical and Control Unit)

while a patient occupies the Warmer.

2 inches

Complete the “Checkout Procedures” section of this manual before

putting the unit into operation. If the warmer fails any portion of the

checkout procedures it must be removed from use and repaired.

Regularly inspect the bed side panel latching mechanism, and the bed-

side locking mechanism on the model 3500, to ensure proper operation.

In the service position the strength of the wall mounted unit hinge

bracket is reduced. Never place a patient in the bed when the heater is in

the service position. Never leave the unit unattended in the service

position or with a pin removed.

Check for proper clearance above the Warmer and below the bed surface

before raising or lowering the bed.

Inspect all patient connected tubes or wires before and after moving or

tilting the bed. Tilting or moving the warmer bed up or down can pull on

tubing or leads connected to the patient. This may disconnect tubes or

leads, restrict gas or liquid flow, or move sensors out of position.

Prolonged exposure to the light emitted by the observation lamp in this

unit may harm the unprotected eyes of the infant. For safety, cover the

infant’s eyes.

Do not use the Warmer system if the system failure alarm is activated.

Remove the unit from service and refer to qualified personnel for repair.

Radiant energy can adversely affect blood components. When using

intravenous tubing systems for delivery of blood components to patients

occupying a warmer, shield any tubing with aluminum foil.

When using a radiant warmer, change the patient’s diapers frequently.

Radiant energy causes more rapid urine evaporation, and may lead to

inaccurate urine diagnostic test/ analysis and inaccurate weight mea-

surements.

X

*1109/936600-0194.000

Precautions

Do not install chest drainage tubes in the Tubing Organizer Rear Side

Panel.

Install tubing in the appropriately sized holes. Use of inappropriate holes

may cause kinking, pinching or restriction of flow through the tubes, and

may interfere with the proper operation of therapy equipment.

Do not lower the Tubing Organizer Rear Side Panel with tubing attached.

Lowering can pull on the tubing, causing the tubes to dislodge from the

patient.

Do not move the warmer by pushing or pulling on the bed side panels.

This action may lead to the deterioration and breakage of the compo-

nents which form a safety barrier around the infant.

Ensure that the bedside panels are locked in position when a patient

occupies the bed. Blankets or other foreign objects may prevent the

latches from fully engaging.

Do not leave the patient unattended when the side panels are lowered.

Never place an infant on the X-ray cassette tray.

Do not place any foreign objects on the warmer bed or in the under bed

cavity while performing X-ray procedures. Incompatible materials in the

path of the X-ray may adversely affect the quality of the X-ray image. Use

of mattress or bedding materials other than those supplied by Ohmeda

should be evaluated by a Neonatologist or Radiologist.

Do not leave the patient unattended when using the warmer. Check the

patient’s temperature regularly to ensure the comfort and the safety of

the patient. If the warmer is used for an extended time, it is recom-

mended that the servo mode of operation be used. When an alarm is

silenced, close monitoring of the patient’s condition is required.

Use the servo mode unless the manual mode is specifically prescribed.

While both modes require patient monitoring, the manual mode requires

constant attention. In the manual mode, you must take the

for detecting changes in the environment (drafts, direct sunlight,

therapy lamp usage, etc.) or the patient condition requiring heater

adjustments in response to these changes. In the servo mode, the infant

warmer automatically adjusts heater output to maintain the desired skin

temperature, reducing (but not eliminating) the need to monitor the

patient and make adjustments to the equipment.

Use of electrosurgical units or other electrical field radiating equipment

can affect the operation of the warmer. Keep the patient probe lead as far

away as possible from electrosurgical cables. Do not allow excess electri-

cal cables to be laid on the bed platform. Use of electrosurgical units or

other instruments which radiate electrical fields can cause indirect

heating, by several tenths of a degree of the skin temperature probe due

to absorbed electrical energy. When using these devices near the radiant

warmer, operate the Infant Warmer in manual mode for maximum safety.

The use of phototherapy equipment may raise the patient’s temperature.

responsibihty

photo-

Radiant warmers increase an infant’s insensible water loss. Take appro-

priate measures to maintain the patient’s fluid balance while caring for

them in a radiant warmer.

Use only the Reusable Ohmeda skin temperature probe (Stock No. 0208-

0697-700) and heat reflective patches (Stock No. 0203-1980-300,

6600-0194-000

11/09/93

50/pkg)

xi

Precautions

or the disposable probe (Stock No. 6600-0208-700,

6600-0196-700.

other manufacturer’s probes may affect the accuracy of warmer opera-

tion and the electrical safety of the patient.

The skin temperature probe should be located on the patient’s skin in an

area which is directly in the path of the radiant heat. It should not be

attached to an area which is shielded from the radiant heat or between

the patient and the mattress. Large temperature gradients and very long

servo response times will result from improper probe placement.

Rectal temperatures must never be used to servo control a patient’s

temperature.

Intimate contact between the skin temperature probe tip and the

patient’s skin must be maintained for accurate skin temperature mea-

surement. Underheating or overheating may result from poor contact

between the skin temperature probe and the patient. Verify that the skin

temperature probe is securely attached to the patient at least once every

half hour.

In the servo mode, verify that the patient temperature probe is securely

attached to the patient at least once every half hour. A dislodged probe

may not trigger an alarm. If the probe becomes dislodged, the warmer

can over or under heat the infant.

50/pkg)

to monitor the patient’s skin temperature. Use of

lO/pkg;

Stock No.

Oxygen concentrations higher than 40% can increase the risk of

tal fibroplasia (retinopathy or prematurity). It is probable that even

concentrations of 40% or less oxygen (formerly considered safe) could be

dangerous to some infants. Therefore, arterial blood gas measurements

are extremely important for regulation of the concentration of inspired

oxygen when an oxygen-enriched environment is considered necessary.

(See current edition of “Standards and Recommendations for Hospital

Care of Newborn Infants” prepared by the Committee of Fetus and

Newborn of the Academy of Pediatrics.)

Do not leave both cylinder valves open. Leaving both oxygen cylinder

valves open at the same

cylinders with no reserve oxygen supply available.

Use only one cylinder gasket per yoke. Use of more than one gasket could

cause leakage of the cylinder gas

Do not leave gas cylinder valves open if the pipeline supply is in use.

Pressures from both oxygen cylinders may become equal, and if simulta-

neously used, cylinder supplies may be depleted, leaving no reserve

supply in case of pipeline failure.

The patient probe is not isolated from earth ground. Any additional

equipment used with the Ohmeda Infant Warmer System must comply

with UL 544, CSA 22.2, IEC 601 and VDE 750.

time will allow simultaneous depletion of both

retrolen-

Xii

The computer or RS-232 monitor’s user program must continuously check

the data link. The program should constantly verify connection to the

warmer controller and check for updated data.

Remote monitoring does not replace the need for direct patient

6600-0194-000

11109/93

observa-

Precautions

ACautions

tion by qualified medical personnel.

If you connect the Nurse Call output to a system which uses a normally

open connection, a disconnected Nurse Call cable will not trigger an

alarm.

When installing a wall mounted unit, to achieve adequate structural

strength all four holes of each mounting bracket must engage tracks.

Should the hole saw miss a track do not proceed. Consult the project

engineer for further direction.

To prevent the drawers from opening unintentionally while moving the

3500 Bassinet, move it from the front only.

On elevating models, do not continue to run the motor at the upper and

lower limit positions; equipment damage may result.

Yoke check valves are not intended to provide a leak-free seal; always

use a yoke plug and a fresh cylinder gasket to seal an unused cylinder

port.

Open cylinder valves S-L-O-W-L-Y to avoid damaging the regulators.

Use cleaning solution sparingly on a cloth when cleaning the Warmer. Do

not saturate the unit

components.

Use of cleaning/disinfecting solutions containing chemicals that are not

listed in the table on page 4-2 (i.e. alcohol, acetone, etc.), or chemicals in

greater concentrations than those listed, may damage the patient probe

or other material being cleaned.

Do not autoclave or gas sterilize the skin temperature probe. Do not

immerse the probe in liquid cleaner. Avoid placing excessive strain on

the probe lead. Always remove the probe by grasping the plug at the

panel. Do not pull on the probe lead. These precautions will help avoid

damage to the probe.

Do not autoclave or gas sterilize the mattress.

Only competent individuals trained in the repair of this equipment should

attempt to service it as detailed in the service manual. The Service

Manual provides detailed information solely for use by individuals having

proper knowledge, tools and test equipment, and for service representa-

tives trained by Ohmeda.

-

excessive solution causes damage to internal

6600-0194-000

11/09/93

. .

Xlll

In this section

1.1 General

1.1

General l-l

Support Structure

1.2

Heater Assembly

1.3

Control Unit l-2

1.4

Bed Platform l-2

1.5

Bassinet (3500 Series) l-2

1.6

Accessories l-3

1.7

All models of the Ohmeda Infant Warmer System provide a controlled

source of radiant heat for infants and pediatric patients. The control

system uses a microprocessor and provides both manual and servo

modes of operation (model 2001 International is manual mode only). The

patient temperature, control temperature, and elapsed time displays are

digital for ease of viewing. The control panel includes a one hour elapsed

timer with time displayed in minutes and seconds. The timer features

optional audible tones for use during Apgar scoring. A complete audio

and visual alarm system is included on the control panel.

l-l

l-l

The optional

232 serial data is provided for use with customized research software or

compatible vital signs monitors. The Nurse Call connection lets you

integrate the Warmer into your current or future remote alarm systems.

1.2 Support Structure

The support structure provides excellent stability for the radiant heater

and optional accessories. On free standing units, the support structure

consists of the base assembly and the uprights with an integral rail

system. The rails provide a means for mounting accessories and ancillary

equipment to the unit. Refer to Section 1.7 for a description of the acces-

sory items.

1.3 Heater Assembly

The warmer is designed to warm infants on a bed surface located 27

!

A

inches

WARNING: Bed-to-heater spacing which differs from the specified 27

2 inches

patient’s condition.

For your convenience, on Model

bed-to-heater spacing is indicated by a label located on the right alumi-

num upright (as viewed from the front).

f

2 inches

(69+5

ThermaLink feature simplifies charting and monitoring.

(69+5

cm) beneath the heater assembly.

cm) will result in incorrect operation and may affect the

3000,3100,3500, and 4000 the proper

RS-

f

6600-0194-000

11/09/93

l-l

l/Description

The heater assembly consists of a radiant heater, parabolic reflector,

observation light, and a visual alarm light. The parabolic reflector focuses

radiant energy on the bed surface, minimizing energy loss due to scatter-

ing and providing an even field of radiant heat over the bed surface. The

observation light provides intense light for procedures. The alarm light is

located on the end of the heater assembly for ease of viewing. The entire

heater assembly rotates to the side for X-ray procedures and for observa-

tion lamp replacement.

1.4

Control Unit

The control unit contains the electronic circuits and controls used to

operate the radiant heater and the observation light. The control unit

performs regular self checks during its operation including failure diag-

nostics.

Either manual or servo mode of operation may be selected. In the manual

mode of operation,

the % power display on the control panel. The control circuit then main-

tains the selected level of radiant heat. The manual mode has a preheat

setting which allows the Warmer to be preheated. In the servo mode of

operation, select the patient’s control temperature. A skin temperature

probe is used to monitor the patient skin temperature. The control

system modulates the radiant heat to maintain the patient at the se-

lected control temperature. The patient’s skin temperature is continu-

ously displayed.

select the level of radiant heat output as indicated by

Alarms activate to alert the operator of a low or high patient tempera-

ture, a skin temperature probe failure, a power failure, equipment failure

or a check patient prompt.

1.5 Bed Platform

Warmers with beds include a mattress and transparent side panels. The

side panels fold down for easy access to the patient and can be removed

for cleaning. The X-ray cassette tray (located in an opening beneath the

bed when installed) pulls out for insertion of X-ray cassettes and allows

X-rays to be taken without moving the patient. * Markings located along

the side panels allow easy location of the cassette in the X-ray tray

relative to the position of the patient on the warmer bed.*

bed platform allows Trendelenburg and Fowler positioning. The hydrau-

lic system for the

avoid disturbing the patient. * A chest drainage hanger attached to the

bed and rear cross bar extrusion provides a convenient location to hang

chest drainage devices. *

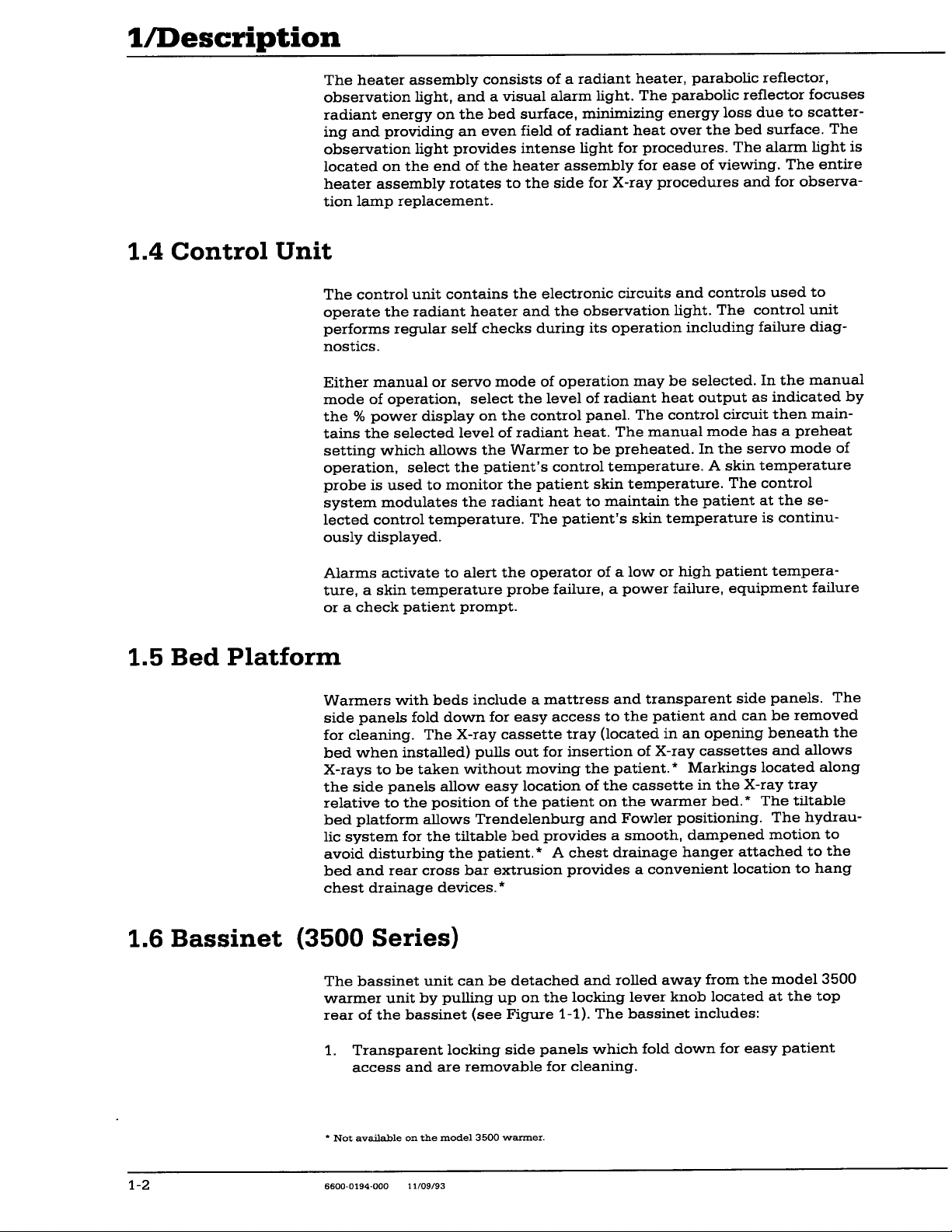

1.6 Bassinet (3500 Series)

The bassinet unit can be detached and rolled away from the model 3500

warmer unit by pulling up on the locking lever knob located at the top

rear of the bassinet (see Figure l-l). The bassinet includes:

tiltable

The

tiltable bed provides a smooth, dampened motion to

l-2

1.

Transparent locking side panels which fold down for easy patient

access and are removable for cleaning.

l

Not available on the model 3500 wanner

6600-0194-000

11/09/93

l/Description

2. A mattress.

3.

4.

5. Front locking casters.

Figure l-l

Operating the

bassinet

locking lever knob

A tiltable, positive-lock bed platform which allows Trendelenburg

and Fowler positioning at 4” and 8“ tilt positions

Three drawers which open from the front (or from the side in an

optional configuration) for storing equipment or supplies. The top

drawer is provided with a key lock.

.

1.7 Accessories

The rail mounting system is the basis for most of the accessories for the

Warmer. This patented design consists of a dovetail shaped aluminum

extrusion and a positive locking mounting block. Mounting blocks are

attached to various accessories for mounting to the rail system. The

mounting blocks are produced in two standard lengths and are machined

to accommodate each specific accessory.

Accessories which mount on a single upright are interchangeable be-

tween all model Warmers.

Accessories can only be mounted to the inside dovetail rail on each

upright of the 3500 Warmer.

6600-0194-000

11/09/93

l-3

In this section

2.1 Setup 2-l

2.2 Mechanical Checkout Procedure 2-l

A.

Overall Appearance 2-l

B.

Heater Assembly Rotation 2-2

C. Mechanical Checks 2-2

D.

Warmer/Bassinet Interlock (model 3500 only)

E.

Warmer/Bassinet Unlock (model 3500 only)

F.

Accessory Checks 2-3

G. Wall Mount Checkout 2-4

2.3 Control Unit Checkout Procedure 2-4

A.

Control Unit Check 2-5

B.

Elapsed Timer Check 2-6

C.

Observation Light Check 2-6

Raise and Lower Bed Switch Check (Elevating Models

D.

Only) 2-6

E.

Interlock Switch Check 2-7

F.

Power Failure, Memory and Battery Test (all models except the

2001 International) 2-7

2-3

2-3

2.1 Setup

Refer to the setup instructions shipped with the warmer for initial unpack-

ing and setup of the unit after shipment. For model 3050, 3100 and 3150

wall mounted units, refer to the mounting instructions in the Appendix.

After removal from the shipping containers, inspect the Ohmeda Infant

Warmer System and all accessory items for any signs of damage which

may have occurred during shipment. File a damage claim with the ship-

ping carrier if damage has occurred. Also confirm the presence of all

accessory items or factory installed options as listed on the packing slip.

Mechanical Checkout Procedure

2.2

WARNING: Before using the Ohmeda Infant Warmer System, read this

entire manual. Attempting to use this device without a thorough under-

standing of its operation may result in patient or user injury.

WARNING: Do not perform the Checkout Procedures (Mechanical and

Control Unit) while a patient occupies the warmer.

WARNING: Complete the “Checkout Procedures” section of this manual

before putting the unit into operation. If the warmer fails any portion of

the checkout procedures it must be removed from use and repaired.

A

A

A

!

!

!

A.

Overall Appearance

Disconnect the power cord from the ac power source for the mechani-

1.

cal checks portion of this procedure.

Check the overall appearance of the Infant Warmer/ Bassinet System.

2.

There should be no obvious damage.

6600-0194-000

11/09/93

2-l

2/Setup

and Checkout Procedures

For the model 3500, separate the warmer from the bassinet.

3.

For units with casters, check that all casters are in firm contact with

4.

the floor and that the warmer is stable and moves freely.

For the model 3500, check that all six casters on the warmer move freely.

Note: On the model 3500, it is possible that the two center casters may

not be in contact with the floor at all times.

5.

Lock the two front casters and check that the warmer is held in place.

On the model 3500, lock the two rear casters and check that the

warmer is held in place.

6.

For the model 3500, place the bassinet on a level surface. Check that

all four casters are in firm contact with the floor and that the Bassinet

moves freely.

7.

For the model 3500, lock the two front casters and check that the

Bassinet is held in place.

8.

Examine the power cord for damage. Replace the power cord if dam-

age is evident.

Examine the unit for objects placed on top of the heater assembly.

9.

!

A

!

A

!

A

WARNING: Do not place any accessories or other objects directly

over the bed surface. This may block radiant heat energy and lead to

cooling of the infant.

WARNING: Do not place items on top of the heater assembly. Items

placed on top of the heater assembly can fall and injure the patient,

prevent adequate ventilation of the heater assembly, and may pose

a fire hazard.

B. Heater Assembly Rotation

Rotate the Heater Assembly to the side and then back to the normal

position. Check for a smooth rotation.

C. Mechanical Checks

1.

Check the operation of the bed sides. The bed sides should operate

smoothly.

WARNING: Regularly inspect the bed side panel latching mecha-

nism, and the bedside locking mechanism on the model 3500, to

ensure proper operation.

2.

Check the operation of the tilt mechanism. Verify that the bed plat-

form operates smoothly and locks in normal, Trendelenburg and Fowler

positions.

!

A

2-2

3.

If the drawer package is installed, check that all the drawers open and

close freely. On units with the rotating drawer package, make sure the

drawers rotate from front to 90” left and right and firmly stop in the

detented positions.

WARNING Overloading the drawers can affect the stability of the

unit. Limit the load to 10 lbs. (4.6 kg) per drawer.

4.

For the model 3500 bassinet, remove the keys from the top drawer and

lock it. Check that the drawer is securely held closed.

6600-0194-000

11/09/93

2Betup

and Checkout Procedures

D. Warmer/Bassinet Interlock

Lock the 3500 warmer’s two rear casters.

1.

Align the rear of the bassinet with the warmer’s base.

2.

Push the bassinet into the alignment/locking track of the warmer’s

3.

base.

Continue pushing the bassinet until its locking pin drops into the

4.

socket at the end of the alignment track. There should be an audible

click when the pin drops into position.

Lightly push and pull the bassinet to verify that the two units are

5.

securely held together.

6.

Unlock the two rear casters on the warmer and check that the com-

bined unit moves smoothly.

Warmer/Bassinet Unlock

E.

1.

Verify that the two bassinet front casters are unlocked and the two

warmer rear casters are locked

With the locking pin handle (located at the rear of the bassinet)

2.

raised, pull the bassinet forward until it is fully detached from the

warmer

.

.

(model 3500 only)

(model 3500 only)

!

A

!

A

!

A

CAUTION: To prevent the drawers from opening unintentionally

while moving the detached bassinet, move it from the front only.

Accessory Checks

F.

Perform these checks if they are applicable.

1.

Check that all accessories are mounted securely and that the load

limits are not exceeded.

2.

Check that all gas accessories are installed and operating properly

(refer to Section 3.9).

3.

Where applicable, perform the checkout procedures detailed in the

Operation and Maintenance Manuals for the accessories.

the

WARNING: Limit

side

on the Warmer to ensure stability. Accessories should not be

mounted more than 56 inches (142 cm) above the floor. For models

3000 and 3500, limit the load of accessories to 20 pounds (9 kg)

maximum per side mounted no more than 44 inches (112 cm) above

the floor.

WARNING: Due to the increased height of units with the ECMO

option installed, a tipping hazard may exist. Limit the total acces-

sory load to 50 lbs. (23 kg), no more than 25 lbs. (11 kg) per side.

load of accessories to 50 pounds (23 kg) per

6600-0194-000

11/09/93

2-3

2/Setun

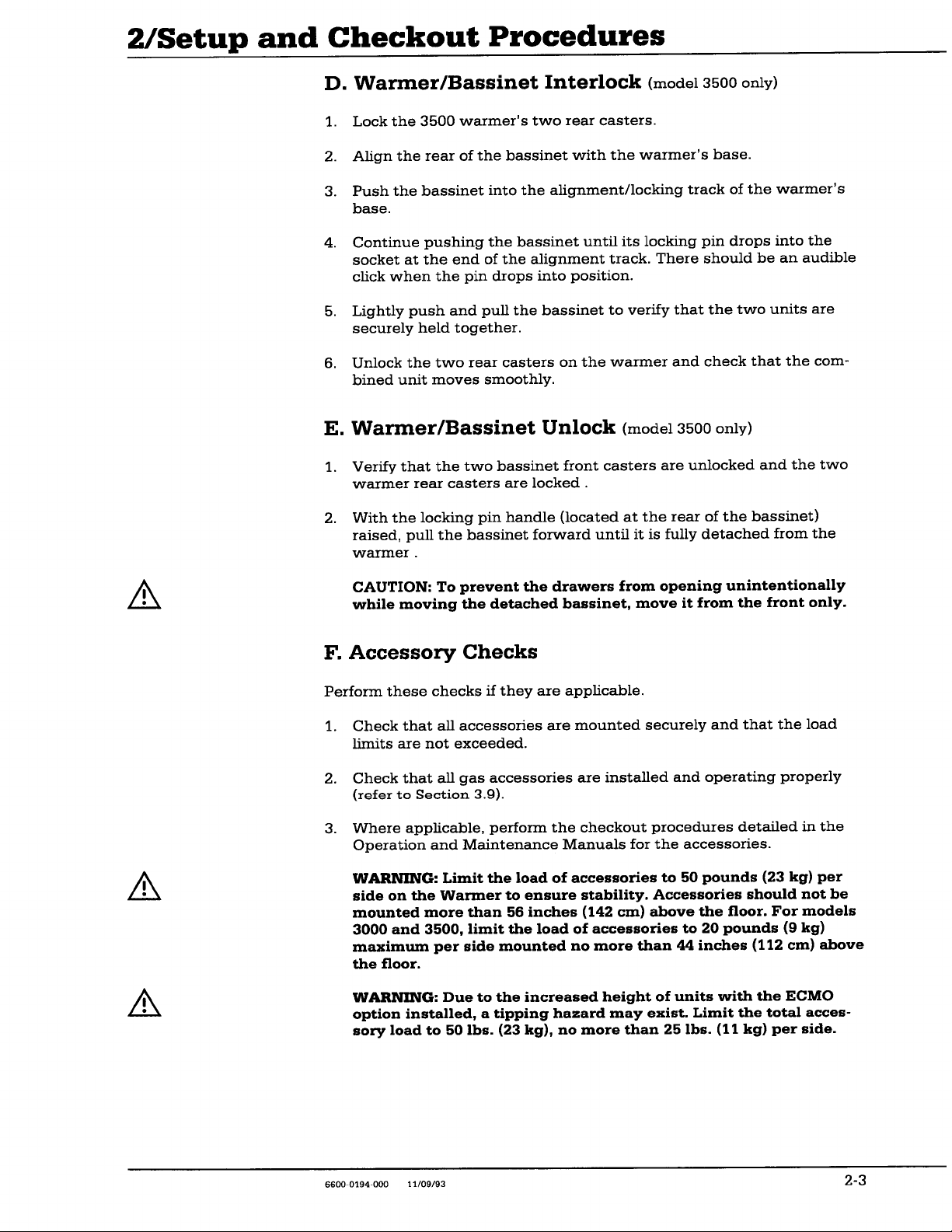

Figure 2-1

Wall mount pin

insertion

and Checkout Procedures

G. Wall Mount Checkout

1.

Verify that the warmer is rigidly secured to the wall and the heater

assembly is level.

!

A

Note: To

procedures, either hinge pin may be removed, allowing the warmer

to pivot away from the wall.

2.

Check that both hinge pins are in place and fully inserted with the

pin heads at the top of the hinge.

WARNING: In the service position the strength of the hinge

bracket is reduced. Never place a patient in the bed when the

heater is in the service position. Never leave the unit unattended

in the service position

access the control unit and display module for service

or with either pin removed.

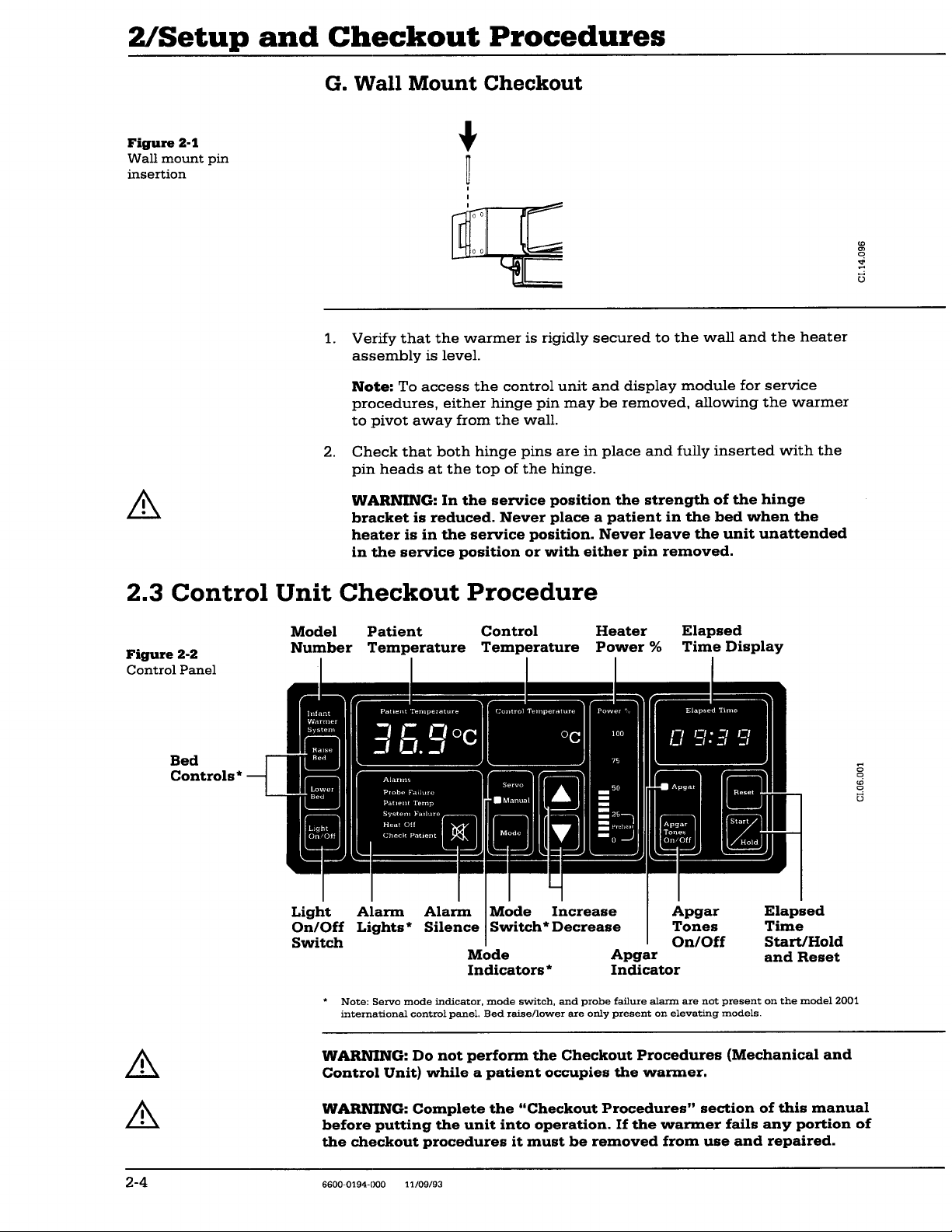

2.3 Control Unit Checkout Procedure

Control

I

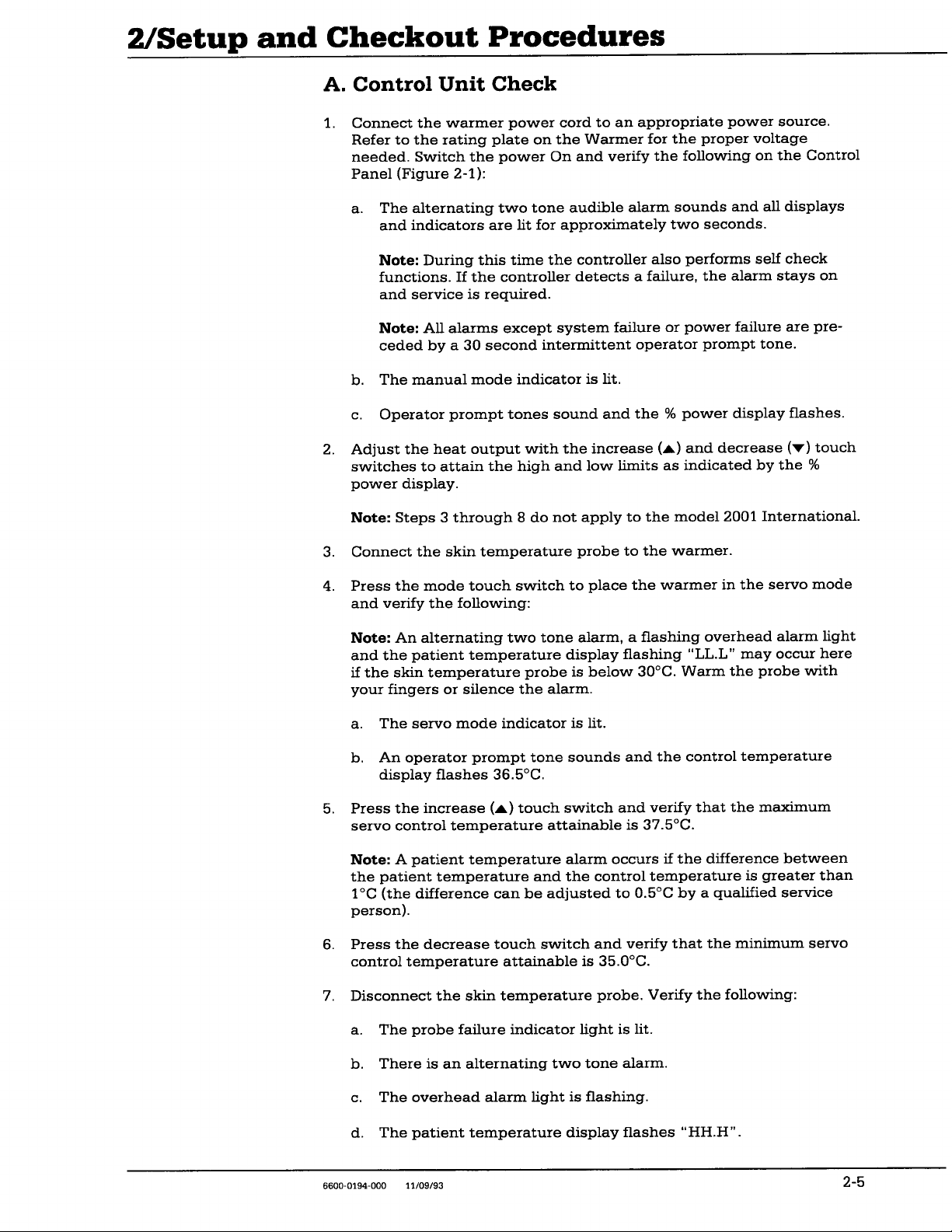

Figure 2-2

Control Panel

Bed

Controls

Model Patient

Number Temperature Temperature Power % Time Display

II

Heater

I

Elapsed

I

!

A

!

A

2-4

Light

On/Off Lights* Silence Switch* Decrease

Switch

Alarm Alarm Mode

Mode

Indicators

*

Note: Servo mode indicator, mode switch, and probe failure

international control panel. Bed

WARNING: Do not perform the Checkout Procedures (Mechanical and

Control Unit) while a patient occupies the warmer.

WARNING: Complete the “Checkout Procedures” section of this manual

before putting the unit into operation. If the warmer fails any portion of

the checkout procedures it must be removed from use and repaired.

6600-0194-000

11/09/93

Increase

*

raise/lower

are only present on elevating models.

Apgar

Indicator

alarm

Apgar

Tones

On/Off

are not present on the model 2001

Elapsed

Time

Start/Hold

and Reset

2/Setup

and Checkout Procedures

A. Control Unit Check

1.

Connect the warmer power cord to an appropriate power source.

Refer to the rating plate on the Warmer for the proper voltage

needed. Switch the power On and verify the following on the Control

Panel (Figure 2-l):

a.

The alternating two tone audible alarm sounds and all displays

and indicators are lit for approximately two seconds.

Note:

During this time the controller also performs self check

functions. If the controller detects a failure, the alarm stays on

and service is required.

Note:

All alarms except system failure or power failure are pre-

ceded by a 30 second intermittent operator prompt tone.

b.

The manual mode indicator is lit.

c.

Operator prompt tones sound and the % power display flashes.

2.

Adjust the heat output with the increase (A) and decrease

switches to attain the high and low limits as indicated by the %

power display.

(v)

touch

Note: Steps 3 through 8 do not apply to the model 2001 International.

3.

Connect the skin temperature probe to the warmer.

4.

Press the mode touch switch to place the warmer in the servo mode

and verify the following:

Note:

An alternating two tone alarm, a flashing overhead alarm light

and the patient temperature display flashing

if the skin temperature probe is below 30°C. Warm the probe with

your fingers or silence the alarm.

a.

The servo mode indicator is lit.

b.

An operator prompt tone sounds and the control temperature

display flashes

5.

Press the increase (A) touch switch and verify that the maximum

servo control temperature attainable is

Note:

the patient temperature and the control temperature is greater than

person).

6.

Press the decrease touch switch and verify that the minimum servo

control temperature attainable is

A patient temperature alarm occurs if the difference between

1°C (the difference can be adjusted to

36.5”C.

0.5”C

35.O”C.

“LL.L”

may occur here

37.5”C.

by a qualified service

7.

Disconnect the skin temperature probe. Verify the following:

a.

The probe failure indicator light is lit.

b.

There is an alternating two tone alarm.

C.

The overhead alarm light is flashing.

d.

The patient temperature display flashes

6600-0194-000

11/09/93

“HH.H”.

2-5

Loading...

Loading...