Page 1

[О

АСТИ

BiliBlanket®

Phototherapy

Operation,

Maintenance

Plus

System

and

W

=

Service

Manual

—

\

Page 2

General

Precautions

Care

PLEASE

of

the

IMPORTANT

READ

Skin

The

skin

insults.

a

route

intensive-care

small,

premature

coupled

problems

Please

1.

Please

literature?

given

*

Observe

+

Clean

CAREFULLY

serves

The

skin

of

water

techniques

with

excessive

for

the

read,

evaluate

refer

when

to

sanitation

color,

skin

CLINICAL

as a protective

is

also

important

excretion,

infants.

nursing

to

the

with

especially

has

been

The

immaturity

instrumentation

care

of

and

implement

following

utilizing

rashes,

warm

and

skin

water

this

excoriation

INFORMATION

BEFORE

barrier

integrity.

against

in

the

regulation

in

premature

associated

and

these

infants’.

the

standard

device

with

USING

chemical,

with

of

the skin

handling,

following

of

skin

care

all

infants.

THIS

mechanical,

of

body

temperature

infants.

the

recommendations

The

introduction

increased

of

the

very

low

poses

previously

recommendations

Special

attention

DEVICE

and

biological

and

survival

weight

of

infants,

unrecognized

as

appropriate:

as

should

serves

of

new

very

given

be

in

ο

as

the

*

Clean

perineal

e

Change

This

device

this

device

recommended.

studies

prophylactic

NAACOG(1992),

ibid

have

area

infant's

position

is

intended

for

prophylactic

These

produced

phototherapy

OGN

Nursing

after

stooling

every 2 hours

only

for

treatment,

infants

inconsistent

treatment

Practice

Resource,

the

treatment

have

extremely

conclusions

45.

Neonatal

of

existing

particularly

of

fragile

concerning

Skin

Care,

NAACOG.

hyperbilirubinemia.

premature

skin?

infants,

and various

the

effectiveness

Use

is

not

clinical

of

©

of

Rutter,

N.,

The

immature

Curtis-Cohen,

of

Pediatrics,

Brown,

February , 1988

6600

0228

A.,

000

et

M.,

July,

al,

04/22/96

et

al,

Randomized

1985

Efficacy

skin,

British

of

Phototherapy

Medical

trial

of

in

Bulletin,

Vol.

prophylactic

Prevention

and

44,

No.

4,

phototherapy

Management

1988

in

the

infant

of

Neonatal

with

very

low

birth

Hyberbilirubinemia,

weight,

Pediatrics,

TheJoumal

Page 3

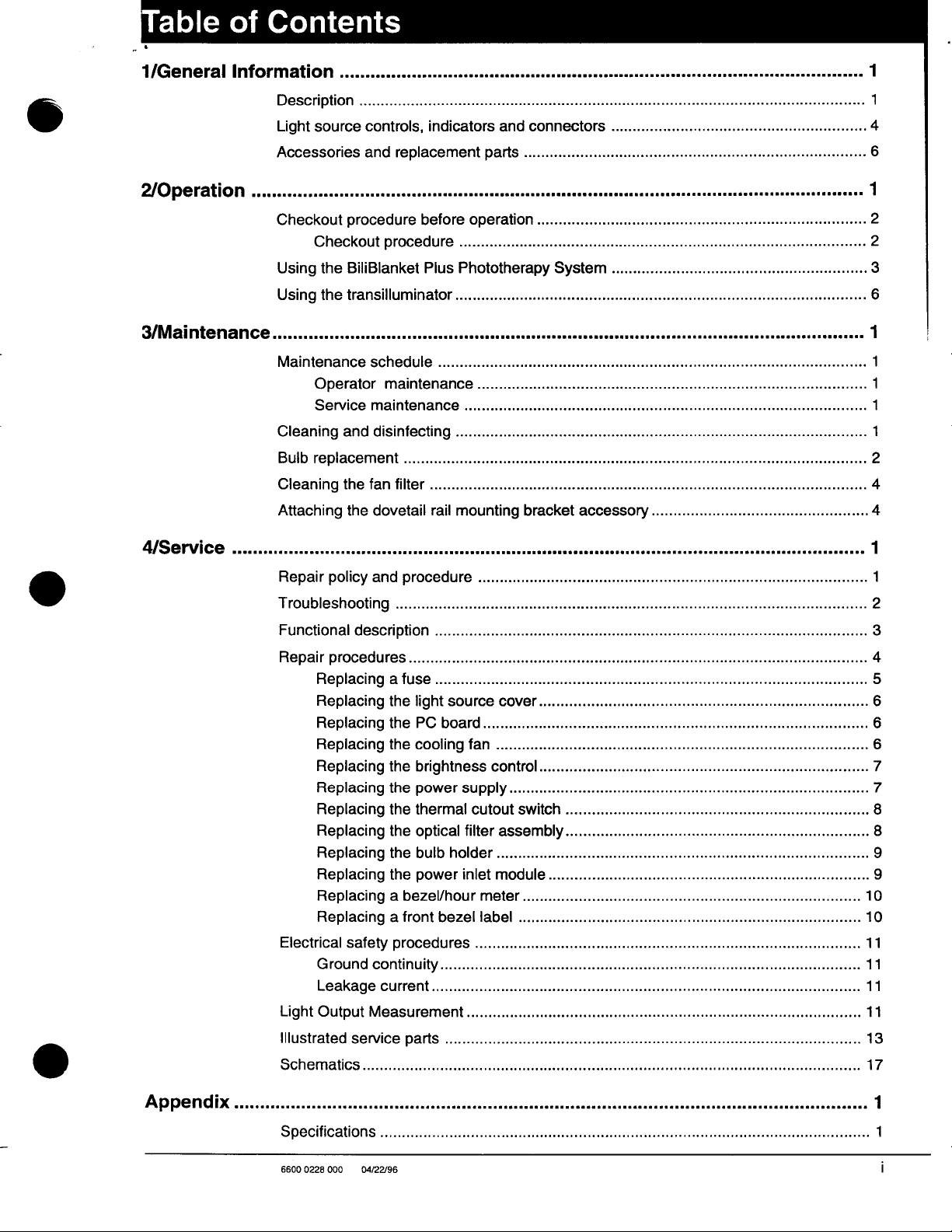

Table

of

Contents

©

1/General

2/Operation

3/Maintenance..............

Information

Description

Light

Accessories

......mmnccccnccnonnccanononennannnconnnnasnaconononennanne

source

controls,

and

.........................

Checkout

UsingtheBiliBlanketPiusPhototherapySystem......................................................

Using

procedure

Checkout

the

procedure

transilluminator

ee

Maintenance

Operator

Service

Cleaning

Bulb

replacement

Cleaning

Attaching

schedule

Maintenance

maintenance

and

disinfecting

the fan

the

dovetail

nro

rnonanancnoocnarsaananaanananons

nen non

non

coran

indicators

replacement

and

parts

connectors

ii

…...........................

ee

before

Operation

ii

.............ocomooononnonoconncccnnnnannaconnonancnna

ee

.................................................

.............

fe

rail

mounting

iii

ee

bracket

нии

ини

accessory

имении

нити

ananana

nora

ee

nano

ーーー

|

nc

cn

cana

cnnacnn

non

1

ss.

4

6

1

nanonocananancas

ee

nen

линнеяжннния

и

ити

i

トーーーー…ー…

2

n

2

3

6

1

renee

1

1

тотнннииа

1

1

2

renge 4

4

©

4/Service

.ee

Repair

Troubleshooting

Functional

Repair

Electrical

Light

ee

PA

policy

and

procedure

… せ

description

DrocedureS

Replacing a fuSe

Replacing

ReplacingthePCboard...........................................

Replacingthecoolingfan...........................................

Replacing

Replacing

Replacingthethermalcutout

Replacing

Replacing

Replacing

Replacing a bezel/hour

Replacing a front

Ground

Leakagecurrent..........................................

Output

the

the

the

the

the

the

зау

ргоседигез

continuity

Measurement

light

brightness

power

optical

bulb

power

pe

.es

source

SUpply

filter

holder

inlet

bezel

...........

rie

cover...

sise

CONtrol..............

iii

switch...

assembly...

eee

module

Meter

label

..................

ии

ини

иляшин

ини

ii

ини

ии

тии

AREA

ининин

нелли

nerne

ини

REP

een een

sis

ss

nen e nn

нана

KAP KOP a Ke

ena

AR

i

ли

ниниининни

rese

kranse

tn

Ranné

es

nen

enes

nen n nn

krans

1

1

2

3

4

5

6

6

6

gene

7

7

8

8

9

9

10

10

11

11

11

11

ο

Appendix

lllustrated

Schematics

.es

Specifications

6600 0228

000

service

DaS

.es

...............

04/22/96

oo...

ii

ee

iii

ee

13

17

1

1

i

Page 4

General

Precautions

Definitions

Next

What

symbo!

the

attention

means

to

accompanying

of

these

When

the

it

means

each

warning

documents”

important

A

attention

that

the

or

caution,

symbol

statements.

symbol

text

appears

is

elaborated

we

to

This

upon

have

alert

is

the

in

front

placed

you

to

attention

of

text that

in

the

operation

an

“attention,

the

presence

symbol:

is

printed

manual.

read

on

the

system

itself,

WARNINGS

WARNING: A Warning

the

operator

CAUTION: A Caution

ment

exists.

Indicates

Indicates

This

letter

Important:

sis.

Note: A Note

The

following

certain

exists.

alternating

IEC

Type B equipment.

appearing

An

Important

provided

are

general

procedures

current.

before a fuselink

are

A

statement

statement

statement

additional

Warnings

found

in

is

used

when

is

used

when

value

is

similar

information

and

Cautions.

the

text

of

the

possibility

the

possibility

indicates a time

to a note

to

clarify a point

the

but

Precautions

manual.

of

delay

is

used

of

injury

damage

fuselink.

for

in

the

text.

specific

to

the

to

the

greater

to

patient

or

equip-

empha-

CAUTIONS

Do

not

use

the

BiliBlanket

anesthetics; a possible

Service

individual

extensive

personnel

representatives.

described

as

described

repairs

having

in

this

are

included

proper

A

Servicing

undertaken

service

6600 0228

of

without

manual

000

04/22/96

this

product

the

which

Plus

explosion

manual

in

this

knowledge,

in

accordance

proper

is

clearly

Phototherapy

hazard

must

manual.

in

this

tools,

and

exists

be

Detailed

manual

tools

with

test

equipment

thoroughly

System

under

performed

drawings

solely

and

test

equipment,

this

service

understood.

in

the

presence

these

conditions.

by a technically

and

procedures

for

the

convenience

or for

and

manual

the

most

should

recent

of

flammable

competent

for

more

of

qualified

Ohmeda

never

service

be

revision

of

this

出

Page 5

1/General

In

this

Section

Information

WARNING

Description

Light

source

Light

Light

Accessoriesandreplacementparts...............................................

ZX

Do

the

exists

General

This

manual

Plus

Phototherapy

to

service

Before

*

Read

*

Pay

+

Read

scribes

+

Read

defect.

controls,

source

source

not

turn

presence

under

Information

describes

the

BiliBlanket

using

the

through

special

the

User

what

the

Warranty;

attention

is

indicatorsandconnectors

and pad

back

on

of a flammable

these

System.

BiliBlanket

sections

Responsibility

expected

eserinin

panel

or

operate

conditions.

how

Plus.

one

to

the

it

describes

..................

to

checkout,

It

also

Plus

through

Warnings

of

the

ii

sssssissicersssneeeeneennenneessecesesssesseneessenneenee

...................................

iii

the

BiliBlanket

anesthetics; a possible

operate

describes

Phototherapy

three

and

statement

user

Ohmeda's

located

to

maintain a safe

Plus

and

for

the

technically

System

of

this

manual.

Cautions

on

responsibility

Phototherapy

maintain

which

the

the

competent

appear

inside

and

accurate

in

case

eee

System

explosion

Ohmeda

in

the

front

cover;

product.

of a

functional

in

hazard

BiliBlanket

person

manual.

it

how

de-

1-1

1-4

1-4

1-5

1-5

Keep

Description

The

light

disposable

ideal

On

through a flexible

from

pneumothoraces.

The

with a four

a

tion

The

The

transmitted.

Although

mately

this

Ohmeda

from a high

400

units

with

the

cable

BiliBlanket

variable

near

light

reflector

the

manual

BiliBlanket

cover

to

550

the

is

Plus

foot

long

power

the

lamp.

source

is

coated

This

there

will

same

available

intensity

that

nanometer

transilluminator

light

used

fiber

supply

lamp

bulb

be a slight

light

for

answering

Plus

Phototherapy

lamp

to a woven

is in

contact

range

pipe

to

appear

to

facilitate

Phototherapy

optic

cable.

for

the

light

is a high

with a dichroic

is

intensity

intensity,

specifically

degradation

throughout

option,

guestions

System

fiber

optic

with

the

patient.

for

phototherapy

unfiltered

at

the

tip

of

vascular

system

source, a cooling

manufactured

sticks

consists

The

light

tungsten

surface

over

its

source

which

time,

life.

which

may

uses a fiber

pad.

The

pad

The

patient

treatment.

light

in

the

visible

the

transilluminator

or

injections.

of a

light

unit

system

halogen

reduces

for

use

the

It

source

contains a lamp,

and

bulb

the

with

the

bulb

will

arise.

optic

cable

to

is

placed

is

exposed

is

also

overheating

with a built-in

infrared

BiliBlanket

maintain

to

spectrum

cable.

The

used

unit

and a light

light

energy

approxi-

deliver

in

a

light

in

the

travels

light

to

find

pad

filters,

protec-

reflector.

Plus.

6600

0228

000

04/22/96

1-1

Page 6

1/General

A

eter

allowed

Any

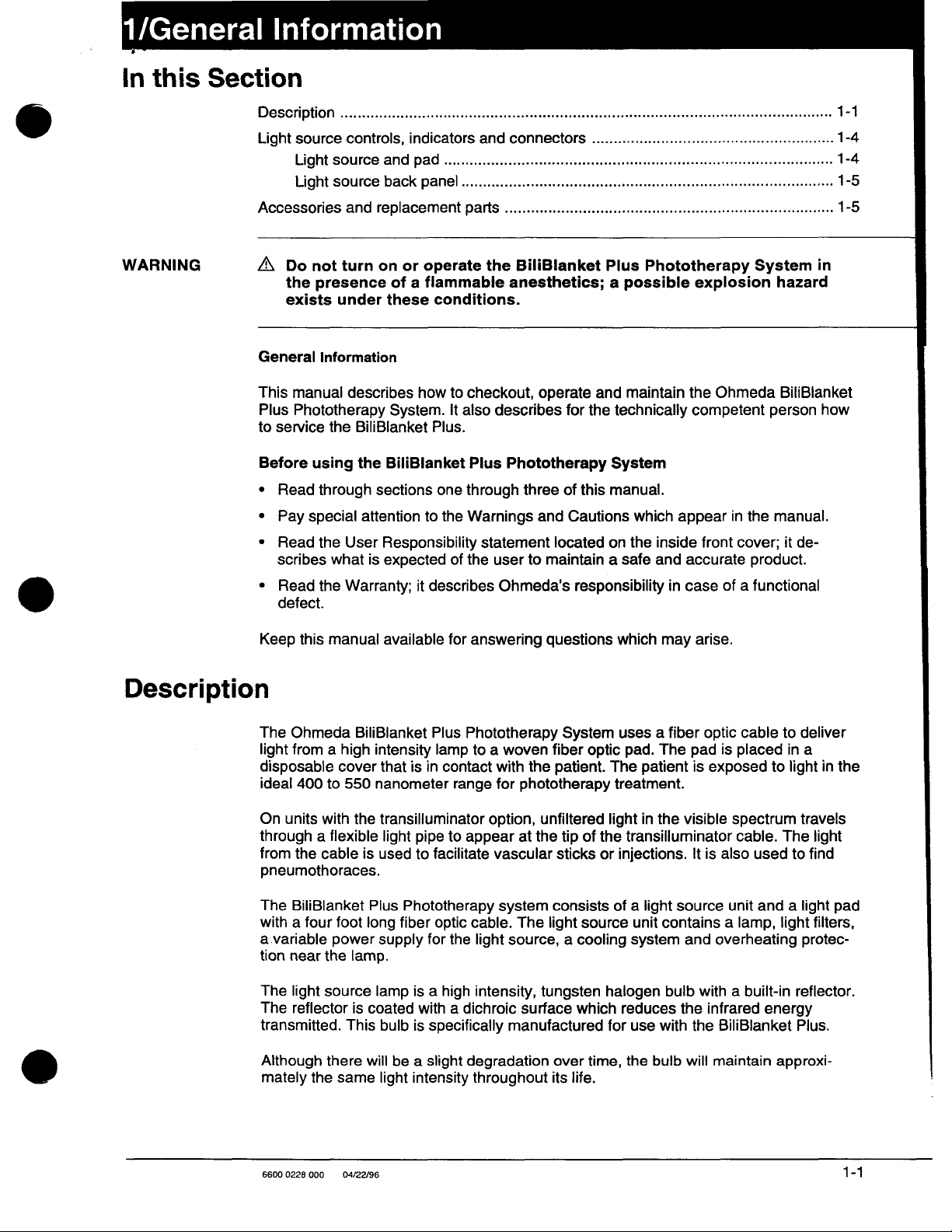

1-1

Information

light

filter,

range.

to

light

shows

Low

Medium

.

High

*

For

Meter

positioned

This

filter

pass.

intensity

the

light

more

precise

and

follow

blocks

This

filtered

may

be

output

Brightness

Rotary

EN

©

se

control

Light

in

front

selected

values

Control

== | Clockwise

of

light

Output

of

the

nearly

all

light

is

focused

by

at

the

Full

Counter

Clockwise

Center

Detent

Full

output,

use

Measurement

lamp,

rejects

ultra-violet

on

the

the

front

panel

low,

center

(pW/cm?/nm)

the

Ohmeda

Procedures

BiliBlanket®

in

light

outside

and

infrared

inlet

of

brightness

and

high

Output

15+3.75

2046.25

*

*

*

35 + 8.75"

Section

4.

the

light;

the

fiber

rotary

positions.

400

only

optic

control.

to

550

the

cable.

nanom-

blue

Table

light

is

Table

1-1

BiliBlanket

Mode

Selects

transilluminator

transilluminator.

Supply

Power

source

Power

Cooling

A

fan

protects

Fiber

The

the

light

into a mat.

These

to

bulb

uniform,

reduce

select

the

power

for

at

enters

cools

the

optic

fiber

optic

source

fibers

hot

continuous

the

Plus

phototherapy

operating

light

the

light

either

50

the

the

light

light

source

cable

cable

to

This

patented

are

randomized

spots,

risk

of

light

dust

cross-contamination

light

output

mode ; phototherapy

pipe,

the

BiliBlanket

source

or

the

unit

60

Hz

source

source

contains

blanket

unit. A thermal

unit

light

pad.

process

on

the

can

be

that

have

through a receptacle

and

fiber

2400

The

produces a pad

in

the

filter,

dust

of

light. A disposable

values

or

transillumination.

Plus

supplied

voltages

cutout

optic

cable

individual

light

cable

pad

to

on the

and

plastic

is

eliminate

make

System

by

in

cable

can

any

standard

the

range:

that

has

switch

or

transilluminator

fibers

constructed

with

light

any

end,

protective

the

patient

Using

be

used

AC

90 - 132

an

integral

located

which

by

weaving

over

local

intensity

etc.

This

pad

more

the

Ohmeda

as

a

mains

power

or

180 - 264.

power

next

to

the

from

overheating.

transmit

the

cover

comfortable.

these

entire

gradients

allows

is

the

the

provided

switch.

light-filter

light

from

fibers

surface.

due

nearly

to

Disposable

The

disposable

infant

between

6600

0228

lies

directly

the

000

cover

pad

04/22/96

cover

on

and

is

designed

the

disposable-covered

the

infant.

for

use

with

pad

both

without

premature

any

and

full-term

method

infants.

of

attachment

The

Page 7

1/General

Information

Disposable

A

disposable

disposable

phototherapy

and

full-term

Transilluminator

The

transilluminator

source

to

the

vest

vest

vest,

treatment.

infants

tip.

is

designed

it

is

possible

who

light

The

disposable

can’t

pipe

to

secure

to

hold

and

tolerate

contains

the

fiber

nurse

cover

having

plastic

optic

the

infant

should

the

vest

fibers

pad

be

used

secured

which

to

the

while

continuing

for

around

transmit

infant.

With

premature

the

light

from

the

infants

midsection.

the

light

6600 0228

000

04/22/96

1-3

Page 8

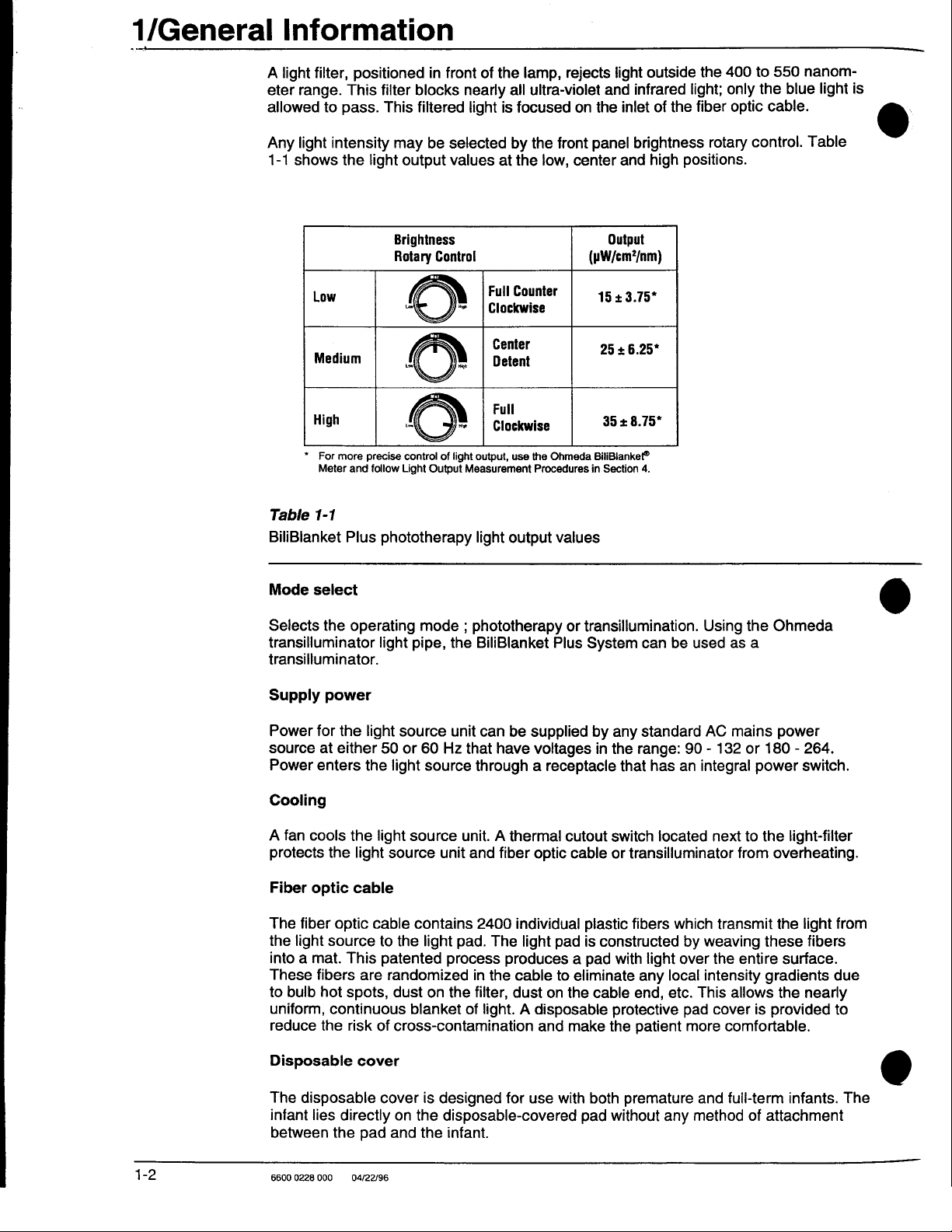

1/General

Information

Light

source

controls,

indicators

and

connectors

Nontransilluminator

Phototherapy

4.

Wernlag:

Connect

Pad

intense

Light

Prior

to

to

Unit

Syste:

Operation

C1.17.019,020,016

1-4

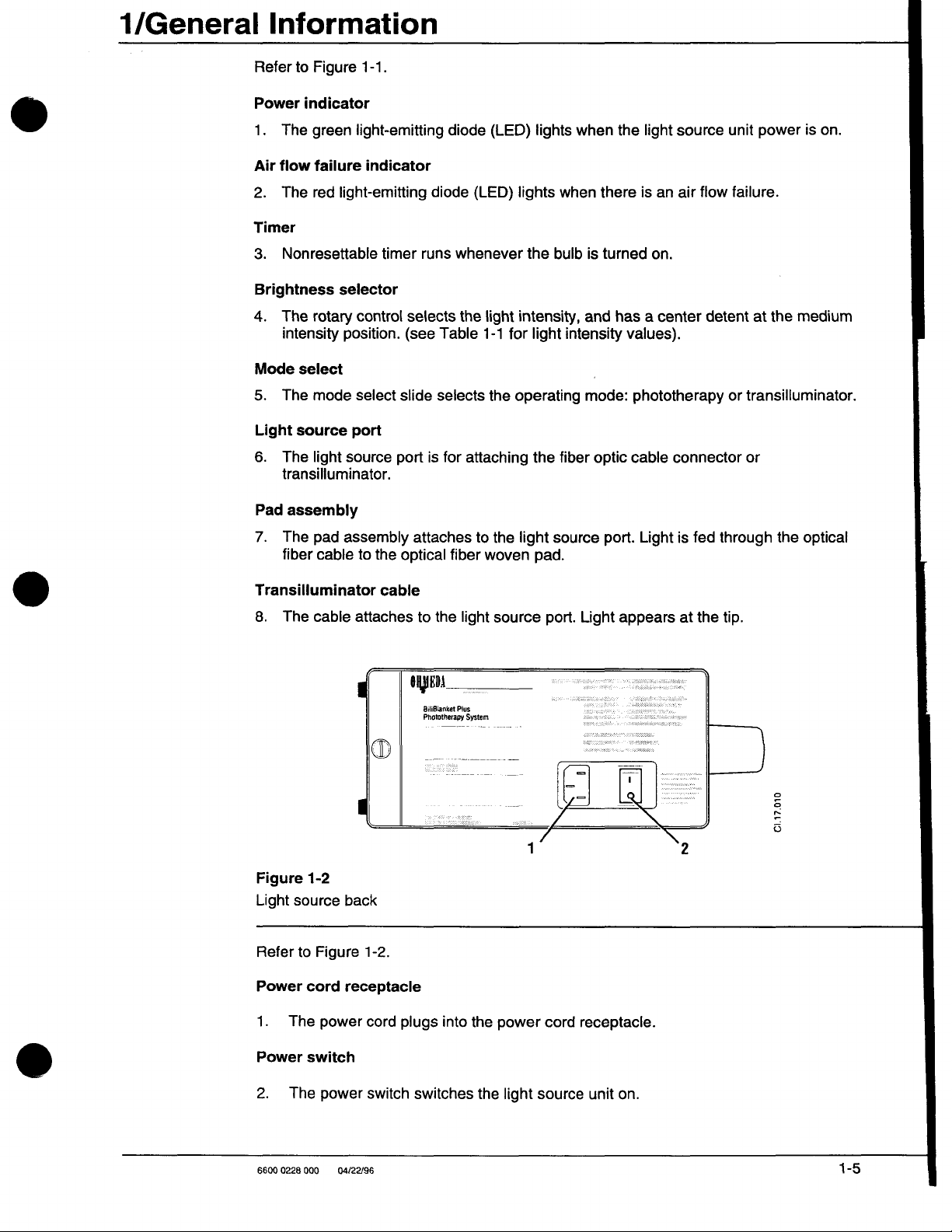

Figure

Light

source,

6600

0228

1-1

000

pad

and

04/22/96

transilluminator

cable

Page 9

1/General

Information

Refer

to

Figure

1-1.

Power

1.

Air

2.

Timer

3.

Brightness

4.

indicator

The

green

flow

failure

The

red

light-emitting

Nonresettable

selector

The

rotary

intensity

Mode

select

5.

The

mode

Light

source

6.

The

light

transilluminator.

Pad

assembly

7.

The

pad

fiber

cable

light-emitting

indicator

diode

timer

runs

control

position.

select

port

source

assembly

to

port

the

selects

(see

slide

is

attaches

optical

diode

(LED)

whenever

the

Table

selects

for

attaching

to

fiber

(LED)

lights

light

intensity,

1-1

for

the

operating

the

light

woven

tights

when

the

bulb

light

the

fiber

source

pad.

when

the

there

is

turned

and

has a center

intensity

values).

mode:

optic

port.

light

source

is

an

air

flow

on.

detent

phototherapy

cable

connector

Light

is

fed

unit

power

failure.

at

the

medium

or

transilluminator.

or

through

the

optical

is

on.

Transilluminator

8.

The

cable

attaches

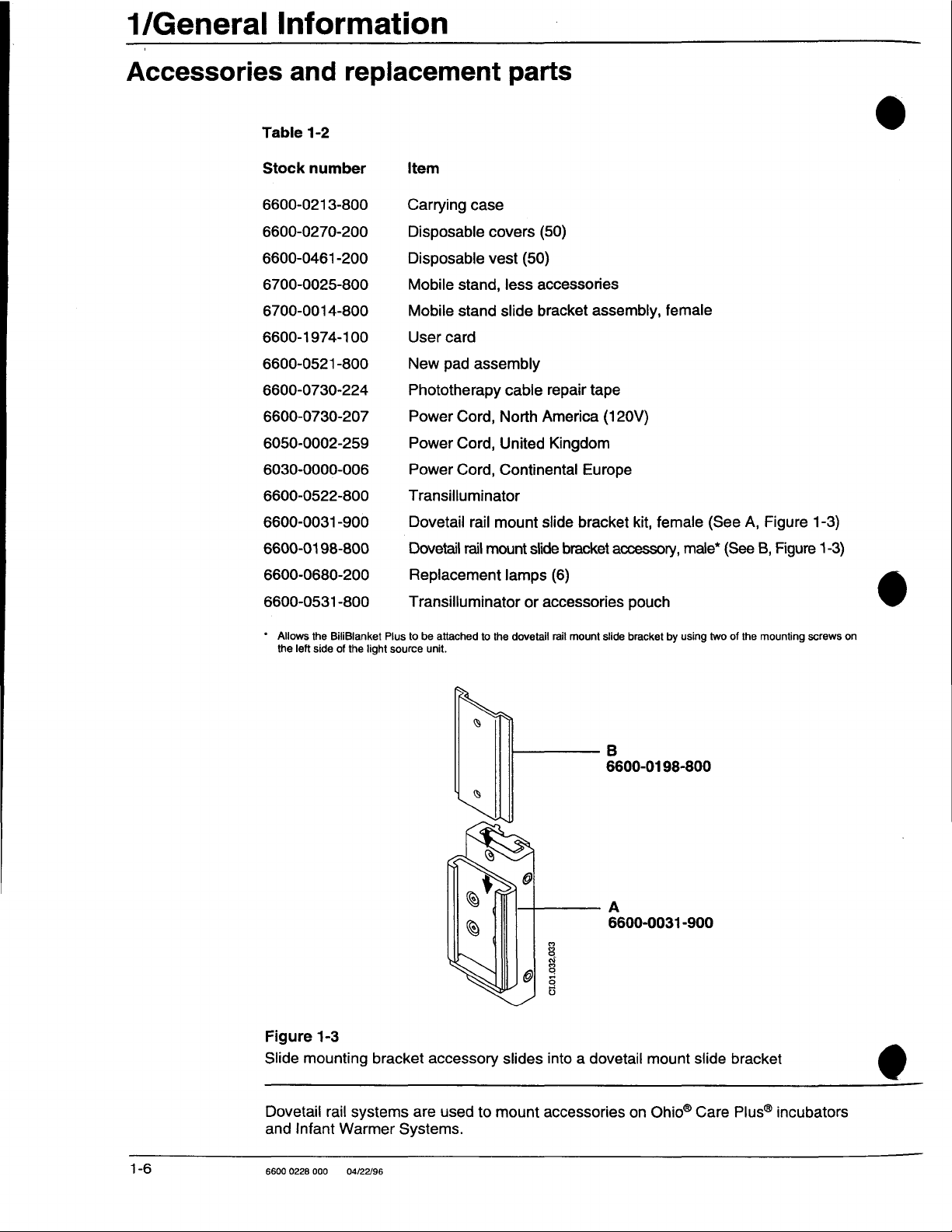

Figure

Light

Refer

Power

1.

1-2

source

to

Figure

cord

The

power

back

receptacle

cable

1-2.

cord

to

AED

BiliBlanket

Phototherapy

plugs

the

into

light

Plus

System

the

source

power

port.

cord

receptacle.

Light

appears

at

the

tip.

C1.17.010

Power

2.

6600

The

0228

switch

power

000

04/22/96

switch

switches

the

light

source

unit

on.

1-5

Page 10

1/General

Information

Accessories

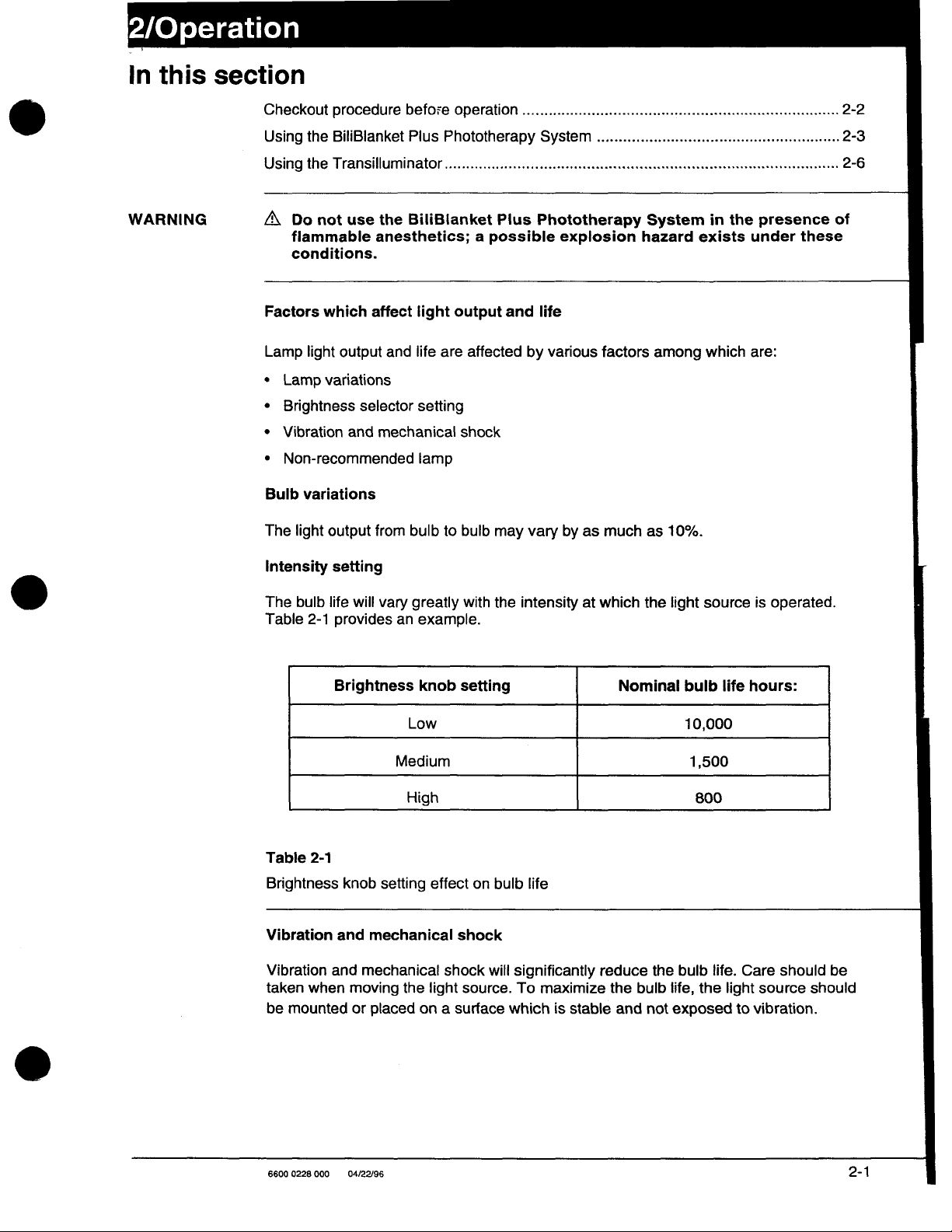

Table

Stock

6600-0213-800

6600-0270-200

6600-0461-200

6700-0025-800

6700-0014-800

6600-1974-100

6600-0521-800

6600-0730-224

6600-0730-207

6050-0002-259

6030-0000-006

6600-0522-800

6600-0031-900

and

1-2

number

replacement

Item

Carrying

Disposable

Disposable

Mobile

Mobile

User

New

Phototherapy

Power

Power

Power

Transilluminator

Dovetail

case

stand,

stand

card

pad

assembly

Cord, North

Cord,

Cord,

rail

parts

covers

vest

(50)

(50)

less

accessories

slide

bracket

cable

repair

America

United

Continental

mount

slide

assembly,

tape

Kingdom

Europe

bracket

(120V)

kit,

female

female

(See

A,

Figure

1-3)

6600-0198-800

6600-0680-200

6600-0531

*

Allows

the

left

the

side

-800

BiliBlanket

of

the

Dovetail

Replacement

Transilluminator

Plus

to

source

be

unit.

light

rail

mount

slide

bracket

lamps

attached

to

the

or

accessories

dovetail

(6)

rail

mount

C1.01.032,033

accessory,

pouch

slide

bracket

B

6600-0198-800

A

6600-0031-900

male*

by

using

two

(See

of

the

B,

Figure

mounting

1-3)

screws

9

on

1-6

Figure

Slide

mounting

Dovetail

and

Infant

6600 0228

000

1-3

rail

bracket

systems

Warmer

04/22/96

accessory

are

used

Systems.

to

mount

slides

into a dovetail

accessories

on

mount

Ohio“

slide

Care

bracket

Plus®

incubators

0

Page 11

In

this

section

WARNING

Checkout

Using

Using

A

procedure

the

BiliBlanket

the

Transilluminator

Do

not

use

flammable

conditions.

Factors

Lamp

*

e

e

*

Bulb

The

which

light

output

Lamp

variations

Brightness

Vibration

and

Non-recommended

variations

light

output

before

operation

Plus

Phototherapy

eee

the

BiliBlanket

anesthetics; a possible

affect

light

and

life

are

selector

setting

mechanical

output

affected

shock

Plus

and

lamp

from

bulb

to

bulb

may

i

System

Phototherapy

explosion

life

by

various

vary

by

as

ss.

factors

much

System

hazard

among

as

10%.

in

the

exists

which

presence

under

are:

σος

these

2-2

2-3

이

2-6

of

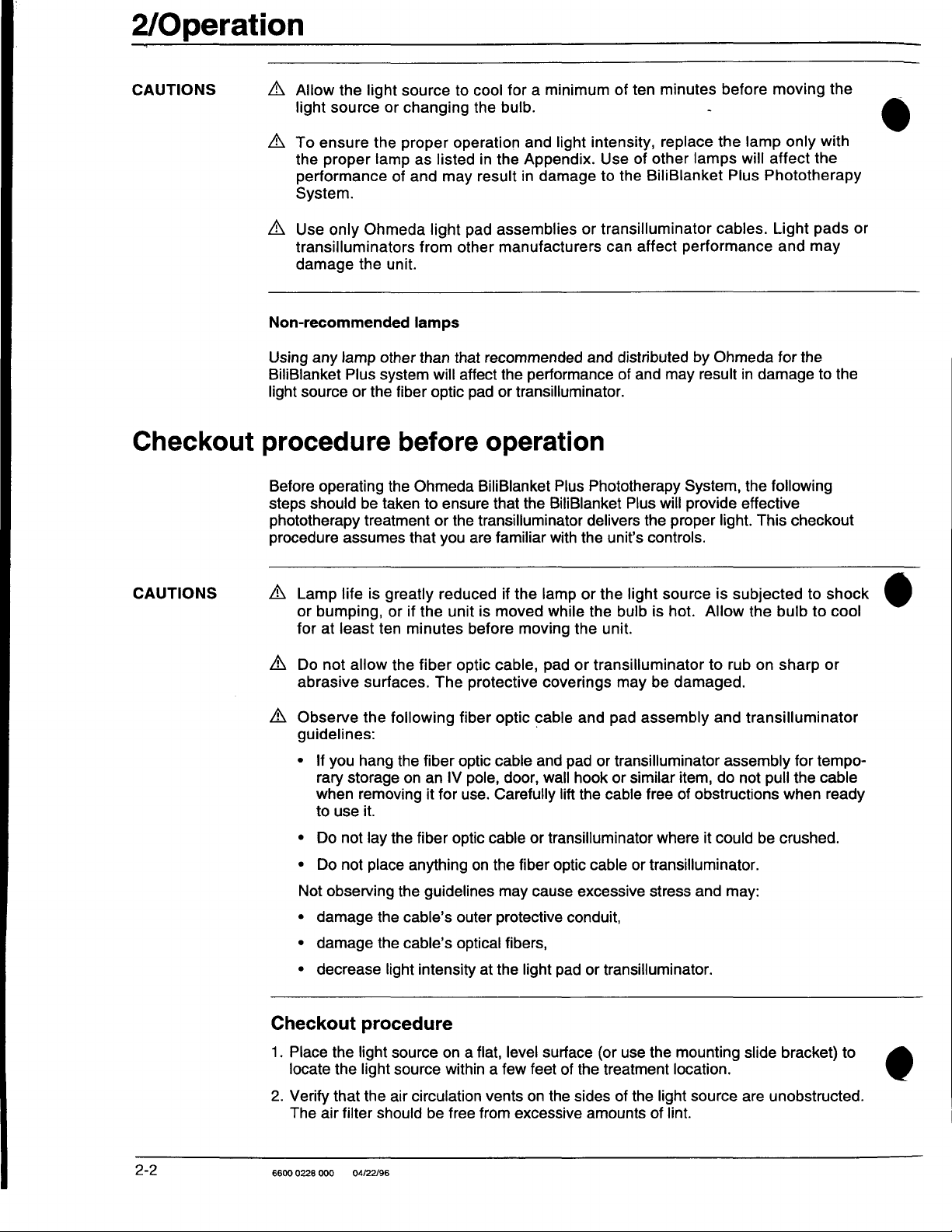

Intensity setting

The

bulb

life

will

vary

Table

2-1

provides

Brightness

Table

2-1

Brightness

Vibration

Vibration

taken

be

mounted

when

knob

and

mechanical

and

mechanical

moving

or

placed

greatly

an

example.

knob

Low

Medium

High

setting

effect

the

light

on a surface

with

setting

on

shock

shock

source.

the

intensity

bulb

life

will

significantly

To

maximize

which

is

at

which

the

light

Nominal

source

bulb

10,000

life

hours:

is

operated.

1,500

the

life,

exposed

800

bulb

the

life.

Care

light

to

should

source

vibration.

should

be

reduce

the

bulb

stable

and

not

6600 0228

000

04/22/96

2-1

Page 12

2/Operation

CAUTIONS

Checkout

À

Allow

the

light

light

source

ZX

To

ensure

the

proper

performance

System.

À

Use

only

Ohmeda

transilluminators

damage

Non-recommended

Using any

BiliBlanket

light

source

the

lamp

Plus

or

the

procedure

Before

steps

phototherapy

procedure

operating

should

assumes

be

treatment

source

or

changing

the

proper

lamp

as

of

and

from

unit.

lamps

other

than

system

fiber

before

the

Ohmeda

taken

to

that

to

operation

listed

may

light

other

that

will

affect

optic

ensure

or

the

you

cool

for a minimum

the

bulb.

and

light

in

the

Appendix.

result

in

damage

pad

assemblies

manufacturers

recommended

the

performance

pad

or

transilluminator.

operation

BiliBlanket

that

transilluminator

are

familiar

Plus

the

BiliBlanket

with

of

ten

minutes

intensity,

Use

to

or

transilluminator

can

and

Phototherapy

delivers

the

unit’s

replace

of

other

the

BiliBlanket

affect

performance

distributed

of

and

may

Plus

will

the

proper

controls.

before

-

the

lamps

Plus

cables.

by

Ohmeda

result

System,

provide

light.

moving

lamp

only

will

affect

Phototherapy

Light

and

for

the

in

damage

the

following

effective

This

checkout

the

with

the

pads

may

to

or

the

CAUTIONS

A\

Lamp

or

bumping,

for

at

A

Do

not

abrasive

ZA

Observe

guidelines:

e

İf

you

rary

when

to

use

+

Do

+

Do

Not

observing

¢

damage

*

damage

+

decrease

Checkout

life

is

greatly

or

least

ten

allow

the

surfaces.

the

following

hang

storage

removing

it.

not

lay

the

not

place

the

the

light

procedure

reduced

if

the

minutes

fiber

The

the

fiber

on

an

it

for

fiber

anything

the

guidelines

cable’s

cable’s

intensity

unit

is

moved

before

optic

cable,

protective

fiber

optic

optic

cable

IV

pole,

use.

Carefully

optic

cable

on the

may

outer

protective

optical

at

the

if

the

lamp

moving

pad

coverings

cable

and

door,

wall

or

fiber

cause

fibers,

light

or

the

light

source

while

the

bulb

is

the

unit.

or

transilluminator

may

be

and

pad

assembly

pad

or

transilluminator

hook

or

similar

lift

the

cable

free

transilluminator

optic

cable

excessive

conduit,

pad

or

transilluminator.

where

or

transilluminator.

stress

is

hot.

Allow

to

damaged.

and

item,

do

of

obstructions

it

could

and

subjected

the

rub

on

transilluminator

assembly

not

be

to

bulb

sharp

for

pull

the

when

crushed.

may:

shock

to

cool

or

tempo-

cable

ready

2-2

1.

Place

locate

2.

Verify

The

6600 0228

the

the

that

air

000

light

light

the

filter

should

04/22/96

source

source

air

on

within a few

circulation

be

free

a flat,

level

vents

from

surface

feet

of

the

on

the

sides

excessive

(or

use

treatment

of

the

amounts

the

mounting

location.

light

of

lint.

source

slide

bracket)

are

unobstructed.

to

Page 13

2/Operation

CAUTION

CAUTION

WARNING

ZX

Do

not

3.

Examine

signs

of

4.

Connect

5.

Fully

engage

port.

A

Do

not

sharp

6.

Select

will

light.

7.

Using

the

ensure

8.

Select

A A hot

the

light

light

block

the

damage.

the

power

scratch

or

heavy

“|”

on

the

brightness

that

light

“O”

on

surface

source

source

the

power

the

fiber

or

power

is

the

is

port

air

intake

cord,

Replace

cord

to

optic

soil

the

objects

switch

selector

being

power

switch

exposed

port.

whether

or

outlet.

fiber

optic

them

the

light

cable

light-input

on

the

to

switch

emitted

to

when

Do

not

the

cable and

if

they

are

source

connector

end

fiber

optic

turn

the

on

from

the

turn

the

the

insert

lamp

transilluminator

damaged.

first

and

or

transilluminator

of

the

pad,

power

on.

the

front

pad.

power

fiber

optic

fingers

is

on

or

then

connector

vest

or

The

panel,

off.

cable

or

foreign

off.

cable

to

the

line

into

cable.

connecting

green

select

any

is

disconnected

objects

power

the

power

light

for

obvious

supply.

light

Do

not put

cable.

indicator

intensity

into

source

light

and

from

the

Using

WARNING

the

BiliBlanket

The

disposable

infant

lies

pad and

А

If

there

cover

System

with

Plus

1.

When

2.

When

3.

When

or

The

disposable

term

infants

disposable

The

infant,

will

continue

covered,

cover

directly

the

on

infant.

is a concern

the

patient’s

to

shield

conventional

may

not

using

the

pad

the

patient

abdomen.

vest

who

cannot

cover

should

along

with

to

receive

light-emitting

Plus

is

designed

the

covered

eyes

them

phototherapy

be

necessary

the

vest.

is

kept

is

secures

tolerate

be

the

light

effective

section

Phototherapy

for

use

with

both

pad

about

when

or

when

against

clothed

the

having

used.

pad,

phototherapy

of

without

exposure

using

under

the

after

fiber-optic

may

the

pad

any

to

the

the

BiliBlanket

lights.

these

patient’s

applying

pad

the

vest

be

covered

treatment

remains

System

premature

method

direct

BiliBlanket

Eye

conditions:

to

the

secured

in

of

light

Plus

patch

back.

the

pad

infant.

around

or

wrapped

as

contact

and

full-term

attachment

from

the

Plus

is

used

use

with

to

the

patient’s

For

premature

the

in a blanket.

long

as the

with

the

infants.

between

light

pad,

Phototherapy

in

conjunction

the

BiliBlanket

chest

and

full-

midsection,

The

disposable-

skin.

The

the

the

infant

The

disposable

pad and

with a new

6600 0228

the

000

cover

infant's

cover.

04/22/96

should

skin.

The

disposable

If

the

be

the

only

disposable

cover

material

cover

should

also

between

becomes

be

the

light-emitting

soiled,

replaced

it

should

between

side

of

be

replaced

patients.

the

2-3

Page 14

2/Operation

Important:

The

Pad

scribed

must

above.

тт

I

| I

b 4

|!

1.

Inserting

pad

be

Do

4

into

covered

not

use

LI)

i

JD

the

light

the

cover.

with the

the

Pad

disposable

without

the

cover

or

disposable

disposable

2.

Adhesive

fastened

cover

tabs

around

the

vest

or

vest.

optic

as

de-

cable.

Figure

Inserting

2-1

1.

Inserting

pad

the

light

=

into

pad

~

the

light

the vest.

into

the

cover

or

vest

2.

Adhesive

fastened

optic

tabs

around

cable.

C1.01.007,008,009,010

the

WARNINGS

2-4

ZA

ZA

6600

The

light

exposed

an

electric

Never

warmer

0228

000

source

to

shock

place

or

bassinet;

04/22/96

unit

liquids.

hazard.

the

light

is

not

Liquids

source

these

waterproof.

that

enter

inside

conditions

the

Locate

the

infant

expose

the

unit

can

compartment

the

unit

damage

infant

where

it

it

and

of a incubator,

to

possible

will

not

create

injury.

be

Page 15

2/Operation

1.

source

the

Mount

the

place

it

so

can

Insert

the

fiber-optic

disposable

pad

all

BiliBlanket

that

it

sits

on a flat,

be

placed

pad

vest

goes

the

way

in

Plus

System

flat

on

into a new,

over

the

to

the

solid

its

clear

end

side

of

on a radiant

surface

or

within a few

upright.

disposabie

illuminating

the

vest/cover.

warmer,

cover

side

of

See

incubator,

feet

of

or

vest.

the

pad.

Figure

the

The

Be

2-1.

or

stand,

baby.

white

sure

The

side

to

insert

or

light

of

the

Secure

2-1.

Connect

outlet.

Firmly

there

light

knocked

Lay

(side

side

at

*

*

‧

When

hold

Set

prescribed.

9.

Turn

the

the

place

is

no

source

over

the

covered

without

of

the

the

infant's

as

much

pad

as

is

there

is

disposable

the

baby’s

using

the

pad

the

brightness

the

power

cover

or

power

cord

the

fiber-optic

pressure

as a safety

when

the

light

label)

facing

pad

with

the

feet.

See

of

the

infant’s

possible

nothing

the

cover

eyes

vest,

in

position

between

are

variable

switch

vest

around

to

the

cable

or

strain on the

precaution

cable

pad

on the

up.

tip

of

the

Figure

skin

(diapers

the

(clothing

not

directly

wrap

the

and

secure

intensity

to

on.

the

light

source

connector

to

is

pulled

mattress

Place

pad

2-2.

is

in

may

infant's

may

be

exposed

strap

pad

cable

cable.

help

beyond

the

infant’s

at

the

Ensure

direct

be

worn)

skin

worn

section

it

with

knob

on

with

and

plug

into

the

The

cable

prevent

its

or

other

back

baby’s

that:

contact

and

over

the

to

the

snug

the

tape

the

front

the

adhesive

into a grounded

light

source

disconnects

the

light

source

length

during

flat

surface

or

chest

shoulders

with

the

lighted

the

light

pad

pad)

covered

around

tabs.

light

the

See

panel

tabs.

port.

easily

from

treatment.

with

illuminating

directly

and

the

section

other

pad.

infant’s

Figure

to

the

intensity

See

Figure

electrical

Ensure

from

being

on

the

pad’s

cable

of

the

than

the

mid

section

2-3.

level

that

the

side

white

to

The

baby

may

be

clothed

phototherapy

the

skin

results

hold

and

Important:

patient's

Figure

Placing

6600 0228

treatment

(it

is

light

in

the

isomerization

nurse

Be

skin.

2-2

the

infant

000

04/22/96

from

the

sure

onto

as

the

infant

while

that

the

the

or

bundled

long

pad

of

the

in a blanket

as

the

lighted

penetrating

bilirubin

molecule).

continuing treatment.

maximum

pad

with

area

cover

and

section

the

outer

of

illumination

will

continue

of

the

few

millimeters

Using

is

pad

the

in

contact

to

remains

vest,

receive

in

of

skin

it

is

possible

with

effective

contact

which

to

the

with

С1.01.028

2-5

Page 16

2/Operation

1.

Place

infant

with a disposable

on

light

vest.

pad

covered

2.

Secure

disposable

vest

around

σι.01.027,029

infant.

CAUTION

Using

WARNING

the

Figure

Placing

A\

10.

2-3

the

Lamp

or

bumping,

for

at

When

remove

infant

life

is

least

the

treatment

the

onto

greatly

or

if

the

ten

minutes

pad and

the

pad

reduced

unit

is

completed,

vest.

transilluminator

A\

Light

from

the

tip

of

the

heating

particularly

sider

heat

.

Remove

=

.

Using

©

.

Insert

AR

.

Turn

の

.

Adjust

DO

.

When

of

the

if

you

lowering

burn.

the

phototherapy

the

mode

the

transilluminator

power

switch

the

light

intensity

the

transilluminator

skin.

notice

the

tight

select

on.

Reposition

slide

with

vest

if

the

lamp

is

moved

before

Remove

tranilluminator

redness

output

fiber

switch,

light

using

is

no

moving

switch

with

optic

pipe

the

variable

longer

while

and

the

of

cable

select

into

or

the

light

source

the

bulb

is

hot.

the

unit.

off

the

light

source

discard

tip

the

light

needed,

the

disposable

is a form

of

the

transilluminator

the

skin.

In

this

intensity

from

the

light

transilluminator.

port.

intensity

knob.

return

to

is

subjected

Allow

power

vest.

of

energy

case

you

control

source.

phototherapy

knob

the

bulb

switch

and

often,

may

to

to

and

can

avoid

mode.

shock

to

cool

cause

con-

@

2-6

.

Turn

off

the

power

switch.

© a

.

Disconnect

0

.

Using

一

o

.

Connect

6600

0228

000

the

the

04/22/96

mode

the

transilluminator

selector

phototherapy

switch,

light

cable

pipe.

select

to

the

phototherapy.

light

port.

0

Page 17

3/Maintenance

In

this

section

Maintenance

Naintenance

Operator

Service

Cleaning

Bulb

Cleaning

Attaching

and

replacement

the

the

schedule

Maintain

Operator

After

Weekly

Quarterly:

the

each

or

schedule........................................

maintenance

maintenance

disinfecting

.9

fan

filter

dovetail

unit

in

accordance

.................

ii

RARA

ee

.................

rail

bracket

sise

with

the

information

ии

RAR

ecenin

линии

RRE

below:

RARE R RR

maintenance

patient:

after

each

patient:

Replace

Clean

the

the

light

source

the

unit.

accumulation

Clean

the

air

the

phototherapy

cables.

disposable

Check

(see

and

vacuum

filter.

and

RRA

RR RR

RR

RR

nr re

naU

cover

or

vest.

the

air

filter

Figure

4-6)

for

clean

if

Clean

the

light

transilluminator

ини

naa

rc

nanananones

ss

on

the

side

lint

and

dust

necessary.

input

end

of

connector

3-1

3-1

3-1

3-1

3-2

3-4

3-4

of

Cleaning

WARNING

CAUTIONS

Note:

This

it

appears

ronment.

Service

Annually

According

care

institution

electrical

and

disinfecting

À

Make

source

А

Never

circuited,

ZN

Never

is

the

minimum

dirty,

depending

maintenance

to

your

health

protocol

equipment

sure

the

before

immerse

causing

immerse

cleaning

on

for

light

source

cleaning

the

light

permanent

the

pad, vest

frequency.

the

concentration

Perform

described

Ensure

emitted.

Measurement

power

and

that

source

in

damage.

or

connecting

the

that

Refer

cord

the

unit

liquid.

The

air

filter

of

lint

and

electrical

in

section

the

required

to

Light

Procedures.

is

disconnected

is

completely

The

electronic

cable

must

dust

in

safety

4/Service.

light

Output

circuitry

in

liquid.

be

cleaned

the

operating

procedures

output

from

dry

is

the

before

can

whenever

envi-

being

power

using

be

short-

it.

А

Z\

6600

Use

light

light

Do

not

0228

000

the

cleaning

source.

source

autoclave

04/22/96

solution

Do

not

causing

or

sparingly

saturate

damage

gas

sterilize

on a cloth

the

unit - excessive

to

internal

the

BiliBlanket

when

solution

components.

Plus

cleaning

the

may

Phototherapy

exterior

flow

into

System.

of

the

the

3-1

Page 18

3/Maintenance

3.

4.

cord

power

the

or

not

the

pad

both

the

outside

sponge.

allow

light

assembly

hospital

use

an

rinse

of

Agueous

may

liguids

to

source

and

agent

disinfectants

abrasive

the

Unplug

Clean

cloth

mycobactericides

Do

Dry

The

using a disinfecting

are

Never

transilluminator.

Thoroughly

the

allow

and

source

light

the

solutions

be

used.

seep

into

the

surface

pad

with a clean,

transilluminator

safe

for

and

cleaner

to

remove

on

source

light

using

which

housing.

soft,

must

use

on

the

mycobactericides

the

pad,

any

cleaning

to

detergent

mild

a

are

both

cloth.

be

cleaned

materials.

the

cable,

for

cool

hospital

without

Aqueous

may

by

the

connector

solution

residue.

minutes.

ten

least

at

a

solution

disinfectants

used.

on

immersing

solutions

or

the

damp

and

by

which

|

CAUTIONS

A\

Do

not

been

A\

Exposing

ultra-violet

ing

solutions

pad’s

solutions,

The

following

Table

3-1

Cleaning

use a phenolic

associated

the

fiber-optic

light

that

light

output.

strong

table

lists

Generic Formulation:

Hydrogen

Sodium

Cavicide®

and

disinfecting

compound

with

elevated

can

cause

discolor

Do

not

acids,

some

peroxide

hypochlorite

solutions

pad’s

plastic

premature

the

pad,

place

strong

alkali,

cleaning

based

bilirubin

cover

breakdown

such

the

pad

or

solutions:

cleaner.

levels

in

to

strong

as

iodine

in

direct

bleach

Maximum

Phenolic

infants.

cleaning

of

the

plastic

solutions,

sunlight.

solutions

concentration

6%

100

parts/million

100%

spray

compounds

solutions

material.

will

Do

not

to

clean

reduce

use

the

level:

have

or

Clean-

the

iodine

pad.

Bulb

WARNINGS

CAUTION

3-2

replacement

A\

Disconnect

bulb

access

4\

Allow

move

Â

To

ensure

the

Ohmeda

will

affect

Phototherapy

6600

0228

000

the

it.

04/22/96

the

door.

bulb

the

proper

bulb

the

performance

System.

power

to

cool

listed

cord

from

for

at

operation

in

Specifications

of,

least

and

and

the

ten

light

may

power

result

source

minutes

intensity,

in

the

in

before

before

replace

Appendix.

damage

opening

attempting

the

bulb

Use

of

other

to,

the

BiliBlanket

to

only

the

re-

with

bulbs

Plus

0

Page 19

3/Maintenance

Note:

tamination

during

clean,

hot.

Refer

1.

Switch

source.

2.

Turn

and

3.

Gently

the

Move

5.

Firmly

Connect

6.

Close

clockwise.

Do

not

touch

of

the

bulb

installation

soft

cloth.

Also,

to

figure

3-1

off

the

the

screw

open

the

door.

move

the

bulb

outward.

the

lever

slide

the

the

pins

the

lamp

the

center

may

or

if

stains

take

light

source

on

the

lever

Disconnect

back

bulb

of

access

result

bulb

next

to

all

the

glass

are

noted,

care

not

and

access

to

its

original

the

way

new

bulb

panel

bulb

or

in

reduced

clean

to

let

the

disconnect

door

the

bulb

the

connector,

position.

into

the

into

the

and

turn

the

the

lamp

the

bulb

the

one

from

socket

bulb

panel

mirror

surface

performance.

bulb

with

wires

touch

power

cord

quarter

right

turn

to

left,

remove

connector.

the

until

it

screw a quarter

with

your

fingers.

If

the

bulb

alcohol

moving

“clicks”

and

dry

the

reflector

from

the

power

counter-clockwise

the

lever

bulb,

and

discard.

into

position.

turn

is

touched

with

when

and

Con-

a

it

is

WARNING

À

Do

lamp

7.

Bulb

ulb

not

operates

Perform

connector

Lever - ㅡ

operate

the

checkout

n

|

the

lamp

with

the

under

pressure

procedure

protective

and

high

detailed

in

compartment

temperature

section

2/Operation.

|

|

door

and

may

Bu

Compartment

一

Bulb

open. The

shatter.

8

CAUTION

Figure

Bulb

replacement

A

Lamp

or

for

6600

0228

3-1

life

is

bumping,

at

least

000

04/22/96

greatly

or

if

the

ten

minutes

reduced

unit

is

before

if

the

moved

moving

lamp

while

or

the

the

the

light

bulb

unit.

source

is

hot.

is

subjected

Allow

the

bulb

to

to

shock

cool

3-3

Page 20

3/Maintenance

Cleaning

Attaching

the

The

checked

The

counter

the

The

sory

stand.

Attach

shown

lamp

the

fan

filter

fan

filter

on

the

and

cleaned

filter

can

be

clockwise.

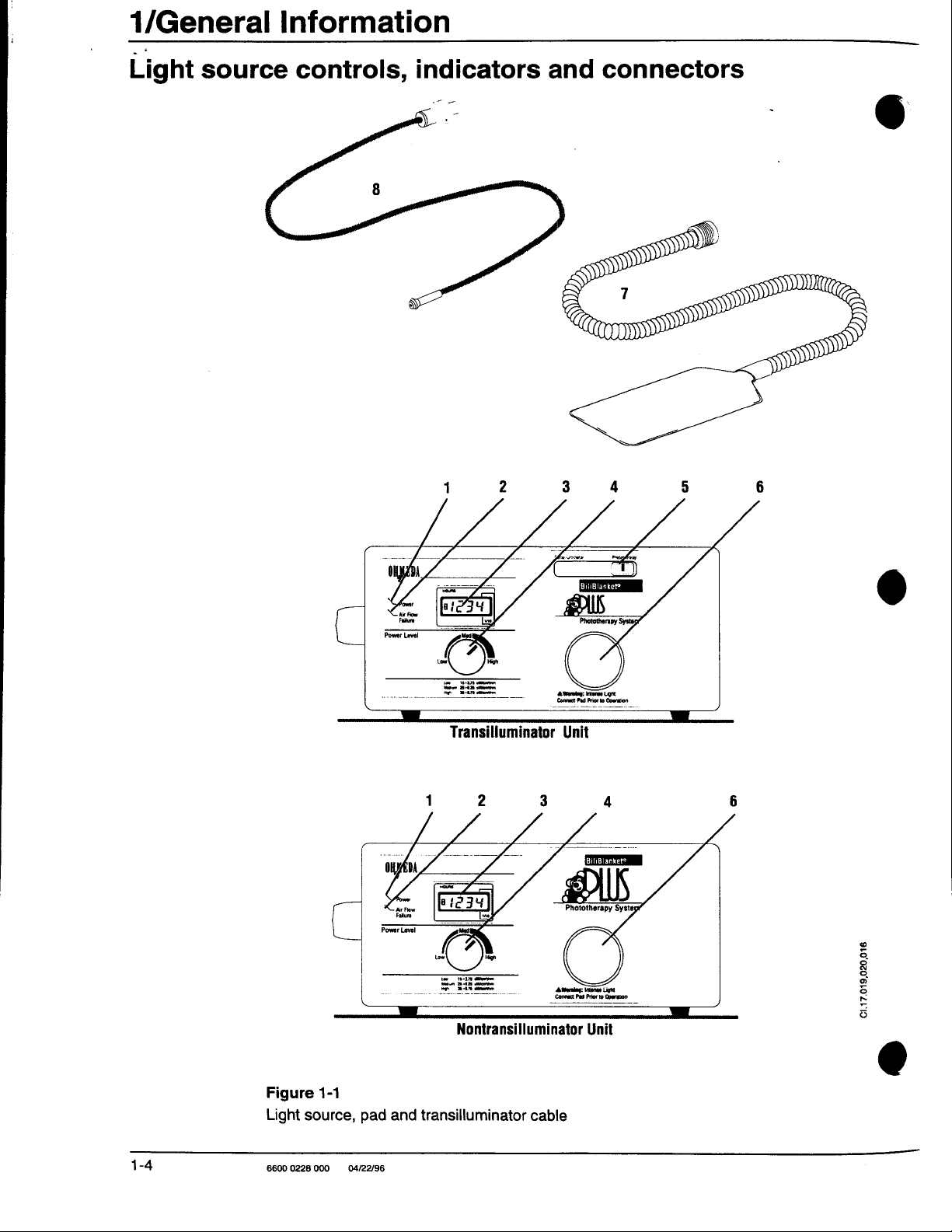

dovetail

dovetail

rail

compartment

unit

rail

system

Refer

the

in

figure

horizontally

to

male

of

the

mounting

3-2.

side

of

if

needed

removed

The

for

filter

rail

mounting

an

“Accessories

side

bracket

Ohmeda

bracket

Use

two

of

the

or

vertically.

the

light

source

to

prevent

cleaning

may

be

cleaned

by

mounting

allows

incubator,

and

replacement

accessory

of

the

three

light

source,

(see

Figure

air

blockage

turning

by

vacuuming

bracket

the

light

infant

warmer

to

the

Phillips

depending

the

screw

source

parts”

left

head

on

4-6)

should

that

may

on

the

it.

accessory

to

be

or

Multi-Purpose

section

side

of

the

screws

already

whether

be

cause

filter

mounted

for

stock

light

you

visually

over

heating.

one

quarter

on

the

Therapy

numbers.

source

attached

wish

to

as

mount

turn

|

acces-

to

the

0

3-4

Figure

Dovetail

6600

0228

3-2

000

rail

mount

04/22/96

bracket

attachment

(male

bracket

mounting

on

light

source)

C1.17.013

Page 21

In

this

section

In

this

Repair

Troubleshooting

section

policy

i

and

procedure

rei

aran

rerann

nan

nc o AKA P RKK KKK

|

4-1

4-1

4-2

Functional

Repair

Electrical

Light

Illustrated

SchematieS

description

prOCOdUTeS

Replacing a fuse

Replacing

ReplacingthePCboard.............................................

Replacing

Replacing

Replacingthepowersupply.....................................

Replacing

Replacing

Replacingthebulbholder............................................

Replacing

Replacing a bezel/hour

Replacing a front

safety

Ground

KARTS

Output

continuity… せ ee

Measurement

service

e

..oooooccccoccconaccnanconannnanocanonnnnnano

the

light

source

the

cooling

the

brightness

the

thermal

the

optical

the

power

bezel

procedures

parts

1…..u..ssenvsvsessersssensesenn

이 나 나 이 아

아 아

COVeT

.Re

fan

control...

cutout

switch

filter

asseMmbly

inlet

MOdUlE

meter

label

1...

.0.1.101. 이 니 이 이 아 이

아 아

아 아 아 아 마 며 아 마 아 마 아 아 이 아

.......................

eee

.................

nono

nroarcncnann

i

0

eee

아 이 나 어 마 아 아 아 아 아 아 아 아

nes

tsk

아 어 아 아 아 아 아

nro

sense

아 아 아 아

ncnnnn

iii

eee

eee

아 마

마 아 아 아

Renere

아 아 아 아 아 아

rencor

eee

eee

emen

near

nrona

RR RP

oeeoee000eene

아 아 이 이 아 아 나 아 아 이 아 아 이 이 4-11

ener enes

아 아

nana

ronncrnnerannes

RR

RR

πι

υυ-ν

n

nn

n

nné

ss

one

onen

een

ooo

nee n nen

4-10

4-10

i

4-11

4-11

4-11

nens

esse

es

4-13

아 아 아 아

애 애 아 아 이 이 4-17

4-3

4-4

4-5

4-6

4-6

4-6

4-7

4-7

4-8

4-8

4-9

4-9

Г

Repair

WARNING

policy

Do

not

determined

facility.

À

Service

competent

procedures

for

tools

In-Warranty

Repair

Service

personnel

Out-of-Warranty

To

promote

and

parts

having

and

Distribution

listed

procedure

use

malfunctioning

by

the

described

individual

for

the

convenience

and

test

and

service

and

Distribution

may

void

full

reliability,

Center.

in

this

experience

equipment.

equipment

in

more

of

equipment,

of

eguipment

Center.

the

warranty.

have

If

this

manual

in

the

may

repair

warranty

this

manual

as

described

extensive

qualified

or

for

under

Service

Refer

all

repairs

is

not

possible,

be

undertaken

of

devices

Perform

status

and

must

in

repairs

personnel

Ohmeda

warranty

performed

to

the

and

of

this

the

appropriate

normal

be

this

are

service

should

warranty

service

replacement

by

trained

nature.

service

performed

manual.

included

having

be

or

attempted

statement

performed

and

To

repair

procedure

procedures

by a technically

Detailed

in

proper

representatives.

performed

and

maintenance

competent

ensure

drawings

this

manual

knowledge,

at

the

by

unauthorized

for

further

by

Ohmeda

personnel

performance

of

your

and

solely

Ohmeda

details.

Service

of

those

to

6600

0228

000

04/22/96

4-1

Page 22

4/Service

factory

specifications,

manufactured

perform

tion

All

price

Ohmeda

When

clean

in

1. A letter

2.

3.

The

Center

the

pre-operative

and

compliance

out-of-warranty

for

replacement

Service

sending

the

equipment.

the

original

describing

Al

warranty

must

be

included.

Purchase

the

Ohmeda

Return

Contact

address

person

equipment

listed

it

is

recommended

or

sold

by

Ohmeda.

checkout

with

published

repairs

and

equipment

shipping

performed

parts,

labor

Distribution

to

the

Include

container

in

detail

information. A copy

order

Service

should

on

the

number

and

(name

back

and

bill-to

and

then

be

cover

to

that

After

all

procedure

specifications.

by

Ohmeda

charges

Center

Onmeda

the

light

(if

the

difficulties

cover

Distribution

information.

telephone

shipped

of

this

Service

source,

possible)

of

the

the

repair

Center

prepaid

manual.

all

replacement

repair

actions

in

this

will

and

shipping

and

pad

and

and

include:

experienced

invoice

of

or

any

for

number)

to

the

and

manual

reflect

charges

Distribution

power

with

other

applicable

unit

not

details.)

for

operational

Ohmeda

parts

be

tests

are

to

ensure

Ohmeda’s

where

Center

cord.

Package

the

unit.

under

warranty.

inquiries.

Service

those

either

complete,

proper opera-

then

current

applicable.

for

service,

it

securely

documentation

(Contact

and

Distribution

.

ὐ

list

Service

If

your

light

available.

Troubleshooting

CAUTION

А

Insulation

deteriorated

Table

4-1

Troubleshooting

Symptom:

Unit

overheats

automatically

of

pad

pad

Contact

or

assemblies

should

on

become

the

Ohmeda

electrical

insulation

Guide

and

shuts

cycles

on

wiring

on

off

and

damaged,

Service

can

power

off.

cord

1.

2.

3.

both

new

and

Distribution

deteriorate

and

all

other

Recommended

Check

not

Inspect

Check

power

that

blocked.

the

that

switch

the

fan

and

re-manufactured

Center

with

age.

Check

electrical

Action:

air

intake

filter.

Clean

the

fan

is

running

on.

for

details.

wiring.

and

or

pads

for

brittle

outlet

are

replace

with

the

are

or

if

clogged.

@

4-2

6600 0228

000

04/22/96

4.

Turn

5.

Check

being

temperature

6.

Check

light

source.

off

the

that

the

operated

that

the

power

and

environment

in

does

above

35°C

correct

(Part

number

allow

the

unit

that

the

not

have

ambient

(95°F).

lamp

is

installed

6600-0680-200).

to

unit

in

cool.

is

the

Page 23

4/Service

Symptom:

Power

switch

but

the

fan

light

source

does

not

Power

the

but

light

Low

switch

green

no

light

source

light

is

turned

does

not

power

light.

is

turned

power

indicator

is

emitted

port.

intensity

on

operate

indicator

on,

is

from

from

the

and

on,

the

pad.

Recommended

1.

Check

2.

Check

and

properly

and

the

3.

Check

Replace

1.

Disconnect

supply.

Open

the

is

installed

Replace

1.

Check

the

proper

2.

Remove

source

for

dirt

with a soft,

that

vents

that

the

power

connected

line

power

the

fuses

if

necessary.

the

power

Allow

the

bulb

access

and

fully

the

bulb

that

the

brightness

setting.

the

fiber

port.

Check

or

obstructions.

damp

Action:

are

not

cord

source.

in

the

power

cord

bulb

to

door.

connected.

if

the

problem

optic

cable

the

cable

Wipe

cloth.

blocked.

is

in

good

at

both

inlet

from

cool

for

Check

rotary

from

end

cable

condition

the

light

source

module.

the

power

ten

minutes.

that a bulb

persists.

control

the

and

end

is

light

the

clean

at

pad

Functional

Pad

has

developed a hole

plastic

cover.

description

The

BiliBlanket

flexible

source

The

system.

The

one

of

cable

Using

The

mined

light

light

pad

end

the

design

pad.

cable.

at

light

is

covered

patented

by

assembly

and

Pius

The

either

50

source

the

consists

the

light

source.

with a protective

technology,

distributes

power

consists

light

source

or

60

Hz.

of a lamp,

consists

pad

Light

is

light

of

the

in

the

of

the

can

operate

of a bundle

on

the

other

transmitted

plastic

the

pad’s

over

the

light

source,

3.

Check

light

4.

Check

discolored

agents.

1.

Check

pad.

solutions

2.

light

light

end.

through

light

entire

that

source.

that

the

Use

Replace

source

from

filters, a variable

of

optical

The

outer

jacket.

fibers

surface

the

length

the

correct

(Part

the

plastic

by

non-recommended

type

of

only

recommended

on

the

pad.

pad.

and

the

light-emitting

90-132 V or

fibers

with

inlet

end

the

length

are

woven

of

the

of

the

light

bulb

number

pad

cleaning

180-

power

is

of

pad.

supply

an

inlet

located

the

cable

into a flat

Light

cable

is

installed

6600-0680-200).

cover

agent