Page 1

List

Parts

Model

Anesthesia

Oxygen

Portable

National

Defense

and

4

Stock

Personnel

885A

Apparatus,

Volatile

Cylinder Capacity

Number

6515-01-185-8446

Support

Center

Gas,

Liquid

Nitrous

Anesthetics,

Oxide,

Illustrated

with

Manual

Service

and

Ohmeda

A

Division

Madison

BOC

Stock

09/90 — Revised

Wisconsin

Health

Number

of

The

Care

BOC

Group

53707

0178-1683-000

Inc

Instruction

Page 2

Table

List

of

Illustrations . .................

Künt

СЕТА

User

Responsibility

Precautions

Warnings

.

of

Contents

m

.............

.

sus.

Cautions

1/Specifications............

2/Description

2.1

General

2.2

Items

and

A.

Gas

Supply

B..

Control

C.

Breathing

D.

Additional

E.

Protective

Head

3/Setup . .

3.1

General

3.2

Breathing

Adult

A.

B.

3.3

4/Checkout

4.1

A.

B.

4.2

A.

B.

C.

4.3

A.

B.

C.

4.4

5/Routine

5.1

A.

B.

C.

5.2

A.

В.

C.

D.

5.3

A.

B.

C.

D.

5.4

A.

B.

C.

D.

E.

F.

5.5

5.6

A.

B.

C.

D.

Rebreathing

Pediatric

Draining

Theory

The

The

Preoperative

Non-Adjustable

Zeroing

Pressure

Leak

and

of

Delivery

Breathing

the

Test

Troubleshooting

Vaporizer

TotalFlowVapor

UseoftheFlowCalculator...........

Use

of

the

Volatile

PreoperativeCheckout

Maintenance

Preventive

ChangingSodaLimeinCanisters.......

CheckValveMaintenance

APL

(Adjustable

Valve

Maintenance

Cleaning

Flowmeters

Absorber

Vaporizer

Rubber

Sterilization

General

Rubber

Absorber

Apparatus

Field

Goods

Repair/Service

Regulators

Flow

Control

Flowmeters

Inhalation

Vaporizer

Non-Adjustable

Repacking

Repair/Service

Depot

Vaporizer

Glass

Sight

Complete

Control

.............

Components . .............

Equipment . .............

|..

Circuit

Items. . ...........

Items

Closure

Devices...........-

.

Circuit

Partial

Vaporizer

and

Setups

Circuit

Rebreathing

....:...........

Operation . .....,..,.,....

Operation

Circuit

Circuits . ............

Tests

and

Relief

Breathing

Gauge . ................

Procedures

Operation

................

Formulas

AnestheticsChart

Maintenance

and

Pressure

.

.......

.

..................

........:..........

Procedures . ..............

Goods

Head

..................

Check

and

Associated

and

.

Valves

...................

Exhalation

and

Funnel

Service

Service

and

Relief

Storage

for

. .

Replacement

and

Assembly

e

eee

ee

6...»

. È

Kuga

・・

eee

-©

<

の

9

and

Checkout

...........

Circuit

.....

..............

..............

Procedures

“Pop-Off"

Circuit

Guides . .........

.....

Valve...

.............-

...........

.............

..............

............

...........

Limiting)

..............

e

Valves

Components

ㄴㄴ

..............

Check

Drain

Valve.........-

Shipment

or

el

..........

ㄴㄴ ㄴㄴ ㄴㄴ

Valves

Plugs..-...-

.....

..............

.........:.:....

..........

.

.

Cleaning

Parts

........

.......

.

.

keme

ㄴㄴ

seli

ーー

ンー:

...

...

..

-

.

.

a

31

.

2

2

2

3

B

6

8

8

9

12

13

17

17

19

20

22

22

22

22

23

23

23

24

25

25

26

28

30

31

31

32

32

33

33

33

34

34

34

35

35

35

35

35

35

36

36

36

36

39

40

5.7

External

5.8

Flow

5.9

5.10

6/Model

Oxygen

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7/Parts

Capacity

Absorber

Gasket

Canister

885A

Monitor

Description

Unpacking . ..

Setup

Checkout

Oxygen

Routine

for

the

Repacking

Replaceable

Illustrations

Leak

Test

Test

Control

Replacement

Gasket

with

an

Using

the

Flow

Verification

Maintenance

Oxygen

Monitor

for

Storage

Parts..........--

for

the

for

the

Head

Body

..............

Replacement

Ohmeda

Oxygen

Vaporizer . .

Vaporizer

5120

. .

........

Monitor:

...........

.

.

„M

.

.

40

42

43

43

44

44

46

47

Page 3

Table

List

Figure

with

Figure

Lower

Figure

Breathing

ана

Figure

Adult

Figure

Apparatus

Figure

Stored Items and

Figure

into

Figure

Figure

into

Figure

Figure

Upright

Figure

Control

Figure

Figure

Small

Figure

Large

Figure

Figure

Circuit

Figure

Figure

Figure

Circuit:

Figure

Example

Figure

Example

Figure

Temperature

Figure

the

Gas

Figure

Figure

Figure

Figure

Figure

Figure

Loop

Figure

Batteries

Figure

Mounting

Figure

SOS

Figure

Mounting

Figure

in

the

Figure

Figure

0309-2002-800..........

Figure

Detail

Figure

0306-1480-800 . .

Figure

0306:14832800

of

of

Illustrations

1:

Apparatus

Glides

Заре

an

an

10:

11:

12:

13:

14:

15:

16:

17:

18:

19:

20:

21:

22:

23:

24:

25:

26:

27:

28:

29:

30:

Fastening

31:

32:

33:

34:

35:

36:

37:

38:

39:

40:

Installed

2:

Upper

Carrying

Carrying

3:

Apparatus

Circuit,

НОВО

4:

Apparatus

Rebreathing

5:

Lower

Case

Collapsed

6:

Upper

Case

7:

Pulling

Upright

8:

Caster

9:

Pulling

Upright

Hinged

Front

Control

Compartments

Head

Floor

Supply

Cylinder

Supply

Cylinder

Adult

Pediatric

Anesthetic

Adult

Pediatric

i i u S

Flow

Flow

Anesthetic

Removing

Machine

Anesthetic

Site

Control

External

Flow

Opening

Removing

.

Oxygen

Sensing

TOS

Mounting

Placing

Tee

Control

Anesthetic

Anesthetic

for

O,

N,0

Location

View

Stand. . ..............

of

Use

or

Rebreathing

Rebreathing

Calculator,

Probleml

Calculator,

Problem

Chart

Glass

Capacity

Bracket . .

is

Bracket. . ...............

Figure

Regulator

Regulator

Contents

Carrying

Case . .

Assembled

Cylinders,

Assembled

Circuit

with

Within............

with

Components

the

Control

Position

the

Control

Position

Thumb

of

Head.

..............

Lower

Hose

Connections

. : : .:

Hose

Connections

Primary/Backup

Partial

Vaporizer

Partial

................

HT.

.:............

Vapor

......

the

.....

Vaporizer

Assembly

Head

Assembly

Leak

the

Hook

Strap.

..............

the

Monitor

...............

Cable

the

the

Sensor

Head

Vaporizer,

Vaporizer,

37

................

Assembly,

cus

Case

©. 5 2...

Case,

..............:

еее

.............

Head

..............

and

Glide

Head

Bolt

.

at

Base

Case

..........

:....:,..,...,

Circuit

Rebreathing

..........

Circuit

Rebreathing

Solution

Solution

Pressure

Vaporizer

-< + <<

Assembly . . . . 38

..........

Test

...........«

Test...........-

and

Monitor

Assembly

Oxygen

and

Monitor

Probe

.............

ce

game

ROD

ec

ews

without

Stand

Removal.

for

for

Use

. . .

.......

.......

нана»

to

to

vs

see

s%

........

and

ese

анны

with

..........

of

© © ©

from

rr

MEO

1...

νο.

nie

..

4

os

. .

20

21

21

27

27

29

37

38

41

41

42

44

45

45

46

48

49

50

50

51

6

6

A

7

7

8

9

9

11

12

13

15

16

17

Figure

41:

Pressure

02078277801...

Figure

Figure

Figure

Figure

Figure

List

Table 1 —

Table 2 —

Table 3 —

Table 4 —

User

CAUTION:

stricts

licensed

This

scription

and

bled,

ance with

must

should

plainly

replaced

ment

telephonic

made

This

other

provided

written

user

for

faulty

ation

Note:

units

vals,

Preoperative

Note:

service

Preoperative

Note:

units

formed

unit

Procedures

and

42:

Limiting

Exploded

Valve

43:

Control

44:

Items

45:

Items

46:

Head

of

Tables

Flowmeter

Items

Storage

Locations.................

Control

Recommended

Responsibility

Federal

these

devices

medical

Product

accompanying

operated,

be

become

to

Product

than

of

any

maintenance,

by

Storage

in

Use

Perform

Storage

with

sample

the

will

thereof

maintained

the

instructions

checked

not

be

used.

wom,

distorted

immediately.

necessary,

or

written

the

nearest

or

any

in

accordance

by

Ohmeda,

approval

this

Product

malfunction

anyone

Inspection

storage

quarterly

should

MIL-STD

Checkout

preventative

Checkout

Inspection

oxygen

at

12

month

size.

in

Section 4 for

Oxygen

Sensor

View

Shutoff

of

Valve,

Adjustable

Pressure

(APL) . ..............

Head

Stored

Stored

Assembly,

Furnished

and

practitioner.

perform

contained

labels

periodically. A defective

of

of

Ohnmeda's

shall

which

other

105D

(every 4 months).

monitor

Follow

Monitor

..............

in

Lower

in

Upper

Case

Case

......

......

0216-6057-801

Information

and

Indicators

Sterilization

law

in

U.S.A.

to

sale

in

in

and/or

and

provided.

Parts

that

or

contaminated,

Should

Ohmeda

request

Ohmeda

its

parts

with

or

altered

have

results

improper

than

Ohmeda.

Requirements — Inspection

be

performed

for

unit

Procedures

maintenance

Procedures

Rquirements — Inspection

sensors

intervals.

the

the

Flow

..........

their

. . . .......

Methods

and

by

or

on

the

conformity

this

operation

inserts,

repaired

This

are

broken,

such

repair

recommends

for

service

Regional

should

written

Safety

the

repair,

sample

Use

Preoperative

Oxygen

Ratio

Service

not be

instructions

without

Department.

sole

responsibility

from

improper

damage,

at

30

size.

in

Section

Foliow

in

Section

should

MIL-STD

Monitor

Checks.

Canada

order

with

when

in

Product

Product

should

or

advice

the prior

month

Follow

for

the

be per-

Checkout

a

52

52

53

54

55

. . . .

56

5

14

17

.

33

re-

of

a

the

de-

manual

assem-

accord-

missing,

be

replace-

that

a

be

Office.

repaired

The

use,

or

alter-

of

inter-

the

4.

units

in

4.

of

105D

for

Check

Page 4

Precautions

Notice:

a

indicates a condition

damage

The

various

inform

Warnings

When

urely,

bly

Never

filling

adverse

could

ways

before

Never

container.

the

e.g.,

Halothane

Forane.

Do

the

the

removing

Always

inadequate

is

be

Make

condition

tightened.

result

Do

ition

so

of

The

of

patient

Leakage

the

tient

may

to

each

duced

If

specifications,

and

Do

the

been

Proceed

elevations

THRU

centrations

tions

As

used

in

potentially

following

raising

life

or

malfunction.

WARNINGS

places

throughout

the

reader

the

otherwise

pinching

fingers

mix

two

or

or

cleaning.

effect on the

result

in

an

drain,

then

adding

drain

liquid

another

liquid

To

prevent a serious

into a container

drain a Halothane

anesthetic

not

attempt

“O,

vaporizer

make

to

for

Vaporizer"

control

the

funnel

sure

(less

present,

delivered.

not

might

anesthetic

APL

the

anesthesia

determine

the

repaired,

not

leak

the

sure

the

funnel

and

that

Any

in

loss

of

turn

the

vaporizer

until

the

flow

expose

agent

valve

must

pediatric

gases

of

metabolic

pollute

use

to

apparatus

use

test

purged

partial

may

of

gases

apparatus

the

possible

of

the

an

acceptable

and

do not

the

anesthesia

procedure

with

desired

leaks

vapor

the

atmosphere.

apparatus,

circuit

cautiously

above

VERNI-TROL

of

agent

above

sea

level

this

threatening

of

apparatus

the

more

The

unpredictable

dry

anesthetic

fill

that a liquid

than

the

of

diluting

patient

vapor.

be

occur.

and

oxygen

the

oxygen.

when

sea

flow

vapor

manual, a WARNING

that

possible

apparatus

situation; a CAUTION

may

lead

and

CAUTIONS

this

manual

hazards

hold

the

will

and hands.

agents

vapor

patient.

in

the

delivered

Also,

vaporizer

liquid

agent

agent.

agent

accident,

labelled

designated

bottle,

the

vaporizer

flow

knob

to

for

etc.

with

when

control

the

OFF

plug.

50

vapor

plug

funnel

from

and

control

completely

rebreathing

vapors

circuits

leakage

level.

does

problem

use

the

level

ml)

amount

concentration

sealing

plug

around

gas

to

knob

gas has

to a lethal

to

the

may

and

anesthetic

It

is

important

be

and

that

not

conform

cannot

apparatus.

the

the

closed

circuit.

performed

apparatus

until

the

vaporizer

using

the

flow

level.

The calculated

rate

will

provide

in

the

total

than

at

sea

level.

indicates

to

equipment

are

to

and

control

fall

forward

vaporizer

could

mixing

used

appropriately

problems.

head

possi-

when

have

of

agents

output.

from

the

vaporizer

into

an

unmarked

always

the

same

vaporizer

Ethrane

valve,

position

is

of

O-ring

is

securely

funnel

agent,

into

in

use.

Close

and

tum

before

visible.

liquid

agent

may

is

in

good

hand

plug

and

If

atmosphere.

to

the

ON

pos-

been

set.

Todo

concentration

during

The

loss

atmosphere

deprive

the

agent,

that

from

tests

before

leakage

after

be

to

stated

be

identified

performing

circuit

calculator

FLOW

higher

flow

Use

con-

at

eleva-

lower

in

sec-

an

Al-

drain

a

an

not

can

use

of

pa-

and

re-

has

at

“oxygen

until

higher

Proceed

atile

The

concentrations

vations

“oxygen

until

higher

Do

verifying

of

should

supplies

Do

system,

Ensure

ation

If

the

checks

service

required

Never

unless

this

oxidize

will

Cello-Seal*

mended

Talc,

which

rubber

ory

Follow

age

Do

sterilization

check

Never

unless

this

oxidize

will

lubricant

Never

of

fabric

cause

tant

Do

flowmeter

will

If

the

drained

mentally

»

Cello-Seal

0220-5160-300.

*

Vac

for

flow

vaporizer”

rates.

experience

cautiously

Anesthetics

calculated

flowmeter

of

above

sea

for

vaporizer”

experience

flow

rates.

not

begin

to

use

its

correct

all

associated

be

that

not

use a damaged

patient

that

when

5120

do

not

and

to

oil

or

the

type

of

readily,

burn

violently.

for

zinc

may

articles

tract.

equipment.

performed

will

injury

there

performing

Oxygen

attempt

repair,

bring

it

grease

lubricant

service.

and

is

the

the

APL

stearate,

have

been

could

sterilization

to

components.

not

steam

sterilize

could

valves

from

oil

or

grease

the

lubricant

type

of

service.

readily,

burn

cover

static

fire

not

operate

not

operate

or

or

and

violently.

recommended

the

anesthesia

plastic

electricity

explosion.

the

tube

is

properly.

sight glass

agent

should

acceptable

is a trademark

Kote

is a registered

has

has

be

calibrate

covering.

of

flow

rates

than

justified

when

at

vapor

level

than

using

elevations

Chart

agent

flow

justified

See

Section

this

anesthesia

operation

before

used

for

or

malfunctioning

could

is

proper

the

Monitor

to

use

and

up

to

published

any

anesthesia

used

is

In

general,

in

the

presence

oxygen

service

Valve.

calcium

used

confidence

the

setting

in

the

at

sea

rates

confidence

4.3.

and

the

Preoperative

each

case

that

result.

ventilation

following

fails

the

it.

Remove

checkout

made

oils

carbonate,

to

prevent

calculated

in

formula

above

will

provide

total

flow

level.

than

calculated

in

machine

correct

checkouts

and

with

specific

case.

anesthesia

for

gas

check.

preceding

the

monitor

the

monitor

specifications.

oxygen

and

lubricant

equipment

approved

and

greases

of

oxygen,

or

corn

tackiness

contaminate a patient's

procedures

the

warp

functioning

any

anesthesia

used

In

general,

in

the

Vac

with

anesthesia

broken,

the

be

carefully

check

valve

the

discs

and

properly.

oxygen

is

made

and

oils

presence

Kote*

is

the

for

use.

apparatus

Removal

the

possibility

apparatus

The

anesthesia

vaporizer

disposed

is

of

in a safe,

to

avoid

discs.

prevent

equipment

approved

and

greases

of

oxygen,

oxygen

with

of

the

cover

if

apparatus

broken,

manner.

of

Fisher

Scientific.

trademark

of

the

Ohmeda

Ball

Corporation.

using

and

Vol-

sea

level.

higher

at

ele-

Use

lower

using

without

operation

the

gas

evacu-

initial

from

as

for

they

recom-

starch

of

respirat-

dam-

Steam

the

for

they

service

any

type

may

of a resul-

any

the

environ-

Stock

No.

Page 5

Precautions

It is

very

the

Do

Knob-Assembly

requires

Improper

reassembly

patients

Do

operation.

the

Do

Scotch-Grip*

1357

losively

only

Cautions

When

tridges,

canisters,

breathing

All

not

internal

Use

than

improper

Do

not

sorber

to

warp

No

repair

anyone

this

Do

not

maximum

could

Do

not

vaporizer

could

Always

ing

Before

sure

adequate

ition

making

Do

not

valve.

developing

rapidly

chatter

sleeve

important

order

that

they

not

attempt

special

if it

not

use

vaporizer

not

use a damaged

is

extremely

and

with

using

remove

seals

should

in

use.

parts.

only

one

one

gasket

to

(see

and

orientation

will

render

is

used.

the

vaporizer

This

test

has

3M

High

cause

cross-ventilation.

Pre-Pak*

the

otherwise

circuit

be

This

will

cylinder

could

engagement

overtighten

crossbar.

Overtightening

resulting

should

not

nature.

allow

having

the

on

the

ever

gauge

occur.

depress

the

output

is

occur.

open

the

that the

at

This

cylinder

regulators.

connecting

remaining

for

the

case

the

end

of

the

vent

helps

in

the

the

diaphragm.

last

after

estimate

obstruct

past

or

vibrate,

with a light

that

all

were

disassemble

item

intricate

items

disassembled.

3,

Figure

and

alignment

the

vaporizer

alignment

without

should

been

be

disassembled

or

malfunctioning

Performance

flammable.

flash

screens

the

may

in

place

help

cause

the

in

gas

be

experience

Vapors

fire.

Vapors

factory

be

prefilled

from

resistance

too

high.

whenever

prevent

gasket

per

cylinder

with

the

clamp

screw

leakage.

undertaken

pressure

gauge

scale.

Damage

O,

Flush

occluded.

the

absorber

at

use.

air

spring

lubricate

film

Valve

Damage

valves

slowly

capacity

hand

judged

Color

rest

unreliable.

vent

in

prevent a pump

sleeve

If

the

the

of

Cello-Seal*

be

reassembled

the

Control

27).

This

procedures.

of

parts

dangerous

verifying

performed

its

when

or

repaired.

vaporizer.

Contact

may

ignite

are

harmful,

absorbant

the

base

of

in

the

patient

the

machine

contamination

yoke.

Use

gas

index

under

cause

or

attempted

build

beyond

to

button

to

to

avoid

patient

the

soda

by

the

during

knob

of

action

gas

valve

begins

of

leakage

the

devices

the

while

the

color

the

is

the

safety

could

repairing

to

to

each

of

recedes

the

when

outside

in

Head

assembly

during

to

correct

ever

Adhesive

exp-

Use

car-

the

is

of

of

more

and

pins.

ab-

canisters

by

of

the

gauge

the

gauge

damag-

make

lime

is

pos-

rest,

APL

from

flowing

to

spring

Following

should

allow

sorbed

ation

Aeration

devices

dations

Do

not

residue

in

the

affect

Do

not

temperatures

detrimental

Do

not

of

the

tape

gen

Do

not

This

sterilization

be

quarantined

dissipation

by

the

period

of

time

are

used.

for

specific

cold

sterilize

will

be

valve

internal

proper

steam

to

use

organic

oxygen

or

thread

Systems, 4 oz.

move

the

alignment

with

in

of

rubber

seven

can

be

Follow

a

residual

and

plastic,

days

decreased

manufacturer's

aeration

the

both

in

gauge

the

left

components

operation

sterilize

and

particular

regulator.

compound,

is

of

these

the

anesthesia

residual

components.

based

thread

Use

Anti-seize

Tube,

NSN

Control

vital

Knob

for

proper

ethylene

well

ethylene

or

more

oxide,

ventilated

area

oxide

In

some

cases,

may

when

be

special

parts

gas

required.

aeration

recommen-

periods

or

the

gauge

mechanism

and

required.

APL

valve.

this

residue

devices.

water

sealants

only

teflon

apparatus.

condensate

on

thread-sealing

and

Sealing,

High

may

any

portion

Oxy-

8030-00-243-3284.

from

the

ON

position.

reassembly.

to

ab-

aer-

A

and

may

be

Scotch-Grip

Sealers

*

Pre-Pak

Cello-Seal

0220-5160-300.

is a registered

Division/3M.

is a registered

is a trademark

trademark

trademark

of

Fisher

of

Scientific.

of

Adhesives,

W.R.

Grace

Onmeda

Coating

& Co.

Stock

and

No.

Page 6

1/Specifications

Closed

13”

Weight

115

Weight

86

Vaporizer

maximum,

Vaporizer

O

Breathing

dual

+100

Oxygen

depressing

flow

Regulator

40

Pressure

shuts

in

Gas

range 2 to

Non-Adjustable

opens

Absorber

holds

Carrying

wide,

20"

in

lbs.

without

lbs.

to

50°C

range

calibrated

cm

H,0

Flush

Case

long,

18”

shipping

container:

shipping

Liquid

Thermometer:

Circuit

250

mL

with + 1°C

from

Anesthetic

Pressure

—10

with +0.5

Valve:

pushbutton

of

40

LPM

psig

off

the

circuit

Outlet

nominal

Sensor

nitrous

Pressure

Shutoff

oxide

drops

to

Evacuator/Relief

70

mm

Hg

Relief

between

60

and

Canister:

2.5 — 3 lbs.

of

soda

Dimensions:

high

(4680

container:

Agent

accuracy

Range:

to

70

mm

allows a minimum

Setting:

Valve:

flow

when

approximately

Valve:

Valve:

80

mm

lime

cubic

inches)

Capacity:

mm

Hg

and

-20

Hg accuracy

oxygen

pressure

20

of

oxygen

psig

Hg

(bulk

or

prepackaged)

to

O,

Cylinder

40

psig

3000

psi;

N,O

Cylinder

40

psig

psi;

blue

Gas

Supply

two

114” long

hoses

discs

are

discs

are

Case

Relief

nominal

885A

Anesthesia

Regulator

regulator;

white

regulator;

with

Hoses:

have

color

white

blue

Valve:

relief

with

Regulator

white

hoses,

with

with

pressure

Charateristi

Operating

Temperature:

104°F)

Storage

Temperature : -28°C

130°F)

Long

Term

Storage

(-20

to

130°F)

Note:

To

life,

the

Manual

should

Temperature:

Humidity:

5120

Operating

to

Temperature

(59°F

Sensor

O,

maximize

when

refrigeration

5120

Oxygen

Ohmeda

be

stored

55% + 5%

Oxygen

Temperature

104°F)

to

104°F)

Life:

equal

to

+20°C

Monitor

Compensation

12

months,

50%

Assembly:

gauge

is

calibrated

green

symbol

Assembly:

gauge

is

calibrated

symbol

一

coded

silver

silver

Apparatus

coded

two

40”

long

identification

characters;

characters

rating

of

Environmental

+5°C

to + 40°C

to

Temperature:

the

oxygen

Monitor

Stock

No.

in a clean

(68°F)

monitor

is

not

available

Operation

0178-1757-000)

and

dry

+2°C

Characteristics:

Range:

+5°C

Range:

at

typical;

+25°C

assumes

(+77°F).

from 0 to

coded

tee

from 0 to

tee

handle

hoses;

1.6

disc,

nitrous

psig

all

oxygen

(41°F

+54°C

(-20°F

-28°C

to

+54°C

sensor's

(as

and

noted

Maintenance

the

environment

to + 40°C

+15°C

to + 40°C

average

handle

3000

supply

oxide

to

to

shelf

in

sensor

at:

(41°F

%

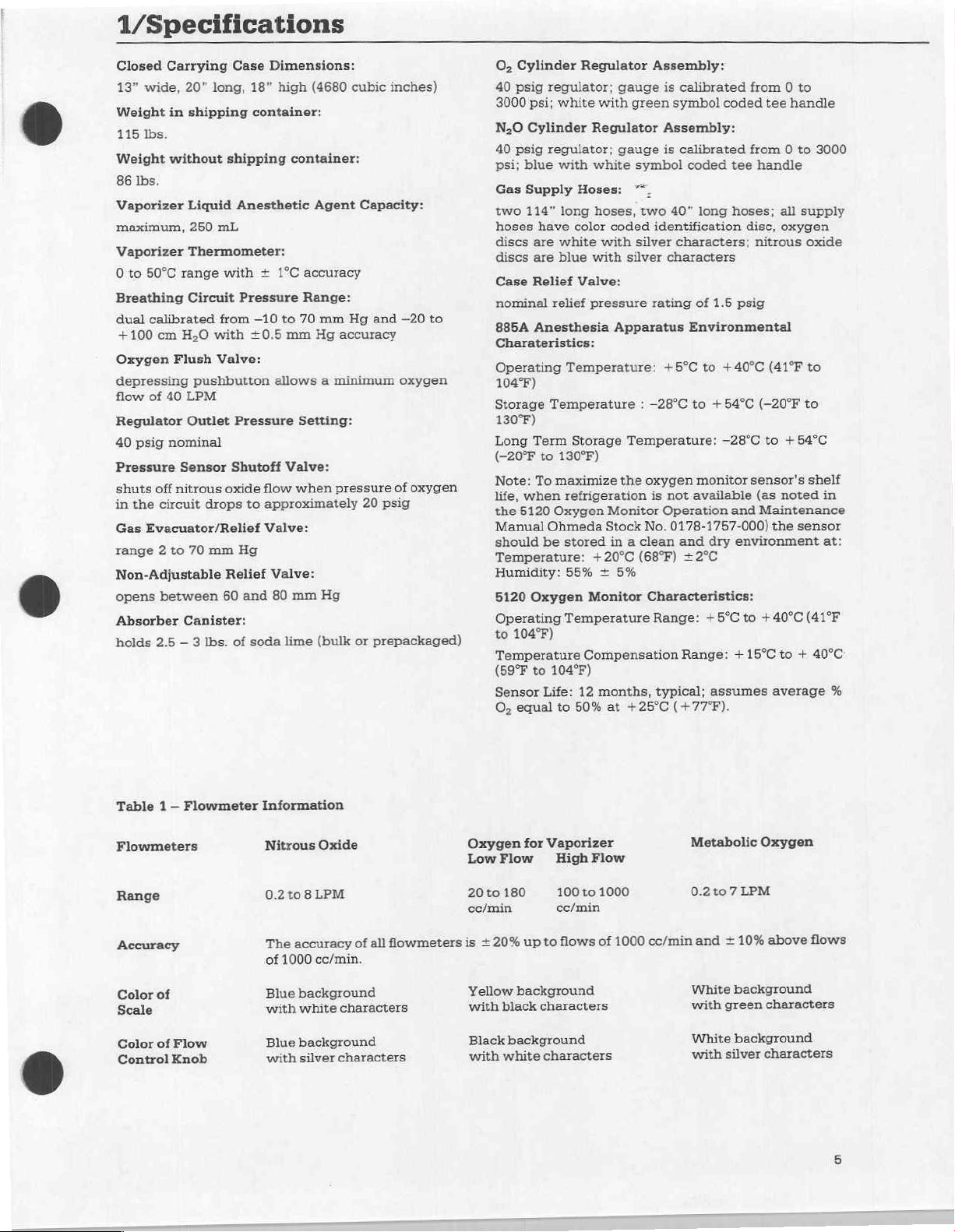

Table 1 —

Flowmeter

Flowmeters

Range

Accuracy

Colorof

Scale

Flow

of

Color

Control

Knob

Information

Nitrous

Oxide

0.2t08LPM

accuracy

The

of

1000

cc/min.

background

Blue

‘with

Blue

with

characters

white

background

characters

silver

flowmeters

all

of

Oxygen

Low

for

Flow

20t0180

cc/min

up

+20%

is

Yellow

with

Black

with

background

black

background

white

Vaporizer

High

Flow

1000

to

100

cc/min

1000

of

flows

to

characters

characters

Metabolic

0.2t07LPM

cc/min

and

White

with

White

with

Oxygen

above

10%

+

background

characters

green

background

characters

silver

flows

Page 7

2/Description

2.1

General

The

Model

885A

Anesthesia

within a 18" x 20" x 18"

assembled,

administration

pediatric

eguipment

cluded).

accommodates

E

size)

Note:

case.

Note:

supplied

The

carrying

case

The

upper

draw

regulator

circuit

(see

Figures 3 and

provides

of

anesthesia

partial

The

cylinder

Push

See

Cylinders

with

rebreathing

and

expendable

apparatus

large

gas

the

Pressure

Figure

1

(oxygen

the

case

(smaller)

bolts

and

case

is

(see

Figures 1 and

assemblies,

items

necessary

all

the

is

(M

and G size)

supplies

Relief

885A

Anesthesia

consists

the

lower

secured

supply

4).

When

Apparatus

carrying

minimum

by

adult

technigues

supplies

designed

Button

and

nitrous

of

two

case

to

the

2).

hoses,

for

use

the

anesthesia

is

contained

case

and,

essentials

rebreathing

(tracheal

are

not

in-

for

field

use

and

small

(D

prior

to

opening

oxide)

are

Apparatus.

sections:

the

(larger).

lower

case

It

contains

and

of

the

by four

cylinder

other

apparatus

apparatus

when

for

and

and

and

not

upper

breath-

is

assembled

serve

as a stool

The lower

sockets

pending

glides

the

absorber,

necessary

The

items

885A

packing

sections

while

ing

tion

tempted.

The

ence

A

summary

tions

case

in

the

on

or

the

lower

case.

vaporizer,

items

following

and

components

Anesthesia

and

so

its

description

these

preliminary

sections

schematics

when

within

and

being

used,

the

for

the

anesthetist.

has a carrying

bottom

which

set

for

is

being

of

four

The

apparatus

cylinder

are

also

sections

handle

either

glides

used,

either

casters

are

stand,

adapters, and

stored

within

provide

descriptions

which comprise

Apparatus.

setup instructions

that an

item

is

Some

or

component

being

read.

are

instructions,

before

reading

of

the

from

items

carrying

further

this

furnished

page

21

manual.

case

setup

may

and

is

provided

upper

case

can

on

each

end and

or

casters.

the

set

of

retained within

control

head,

other

the

lowercase.

of

the

the

Model

preliminary

included

may

Other

read

or

operation

in

be

viewed

than

follow-

the

descrip-

is

be a helpful

their

storage

on

loca-

page

De-

four

un-

these

at-

refer-

14.

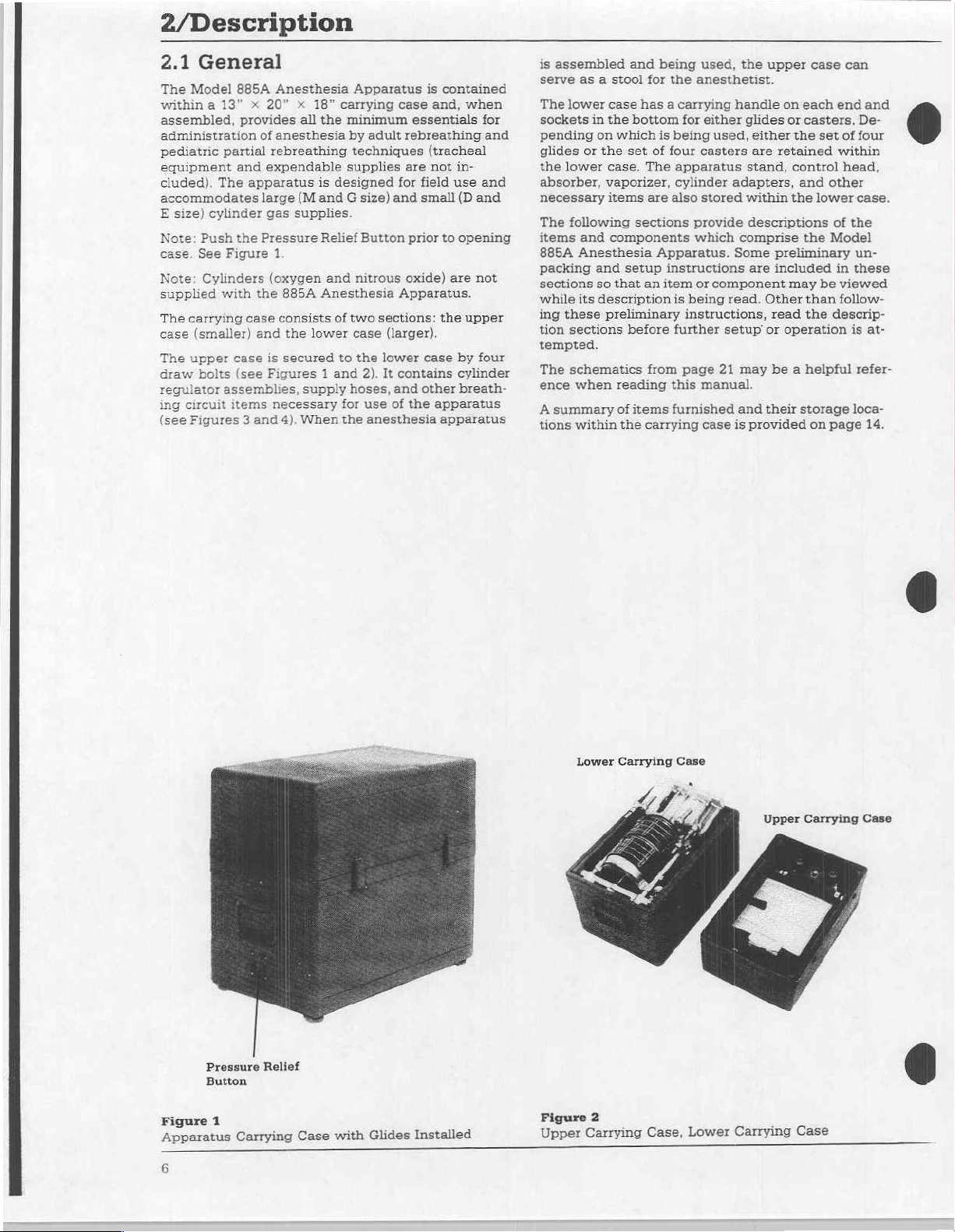

Pressure

Button

Figure

Apparatus

6

1

Carrying

Relief

Case

with

Glides

Installed

Lower

Figure

Upper

2

Carrying

Carrying

Case

Case,

Lower

Upper

Carrying

Carrying

Case

Case

Page 8

2/Description

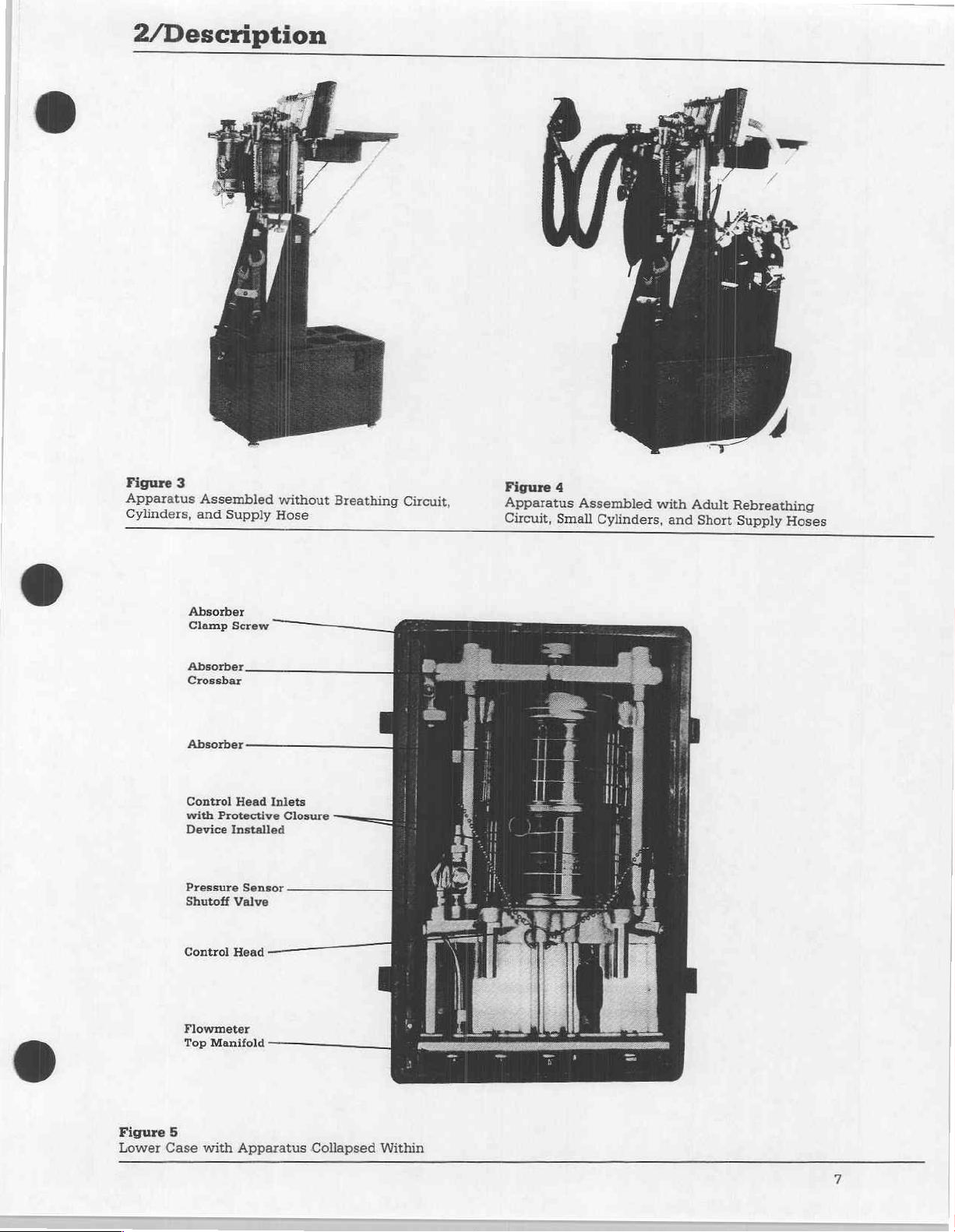

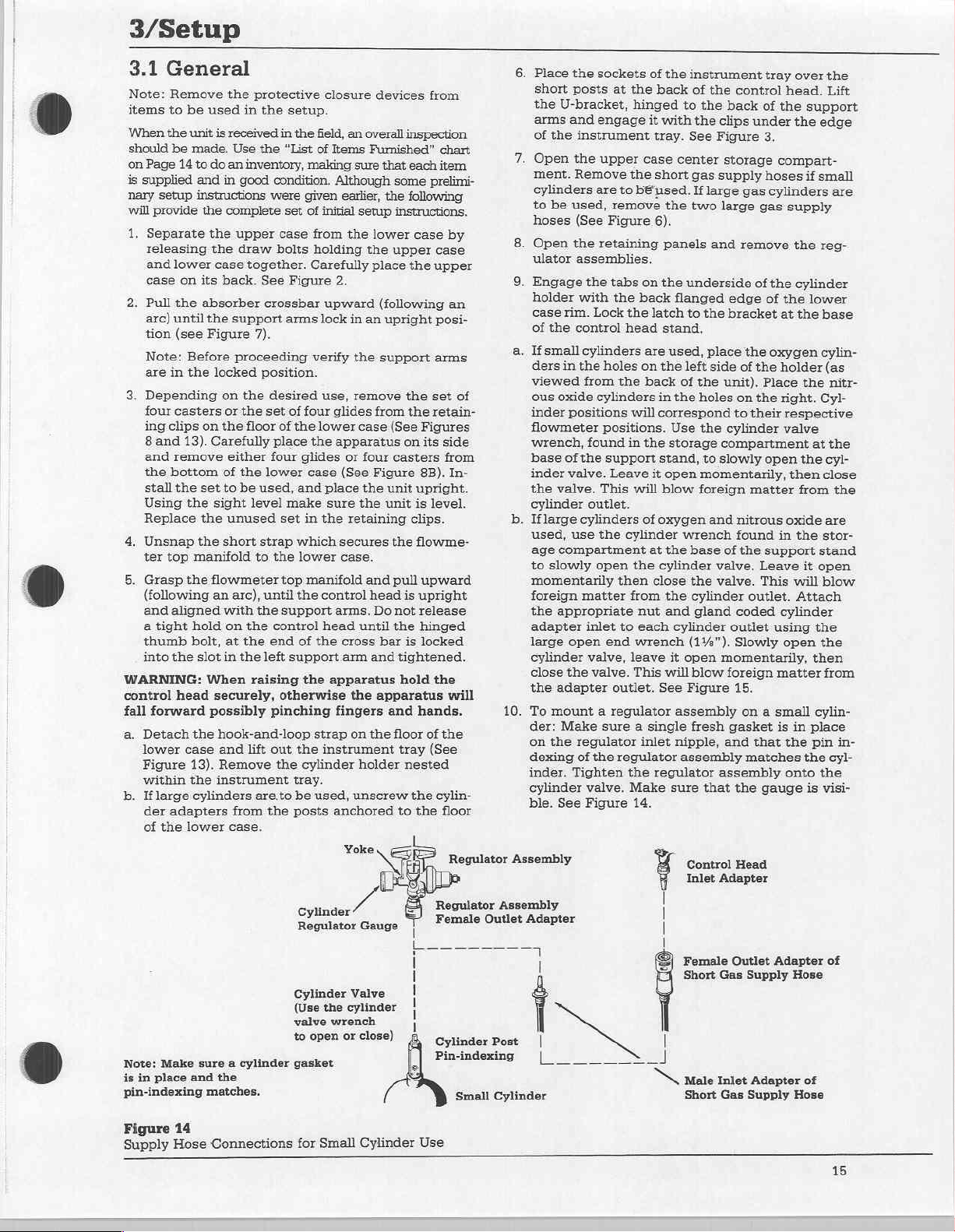

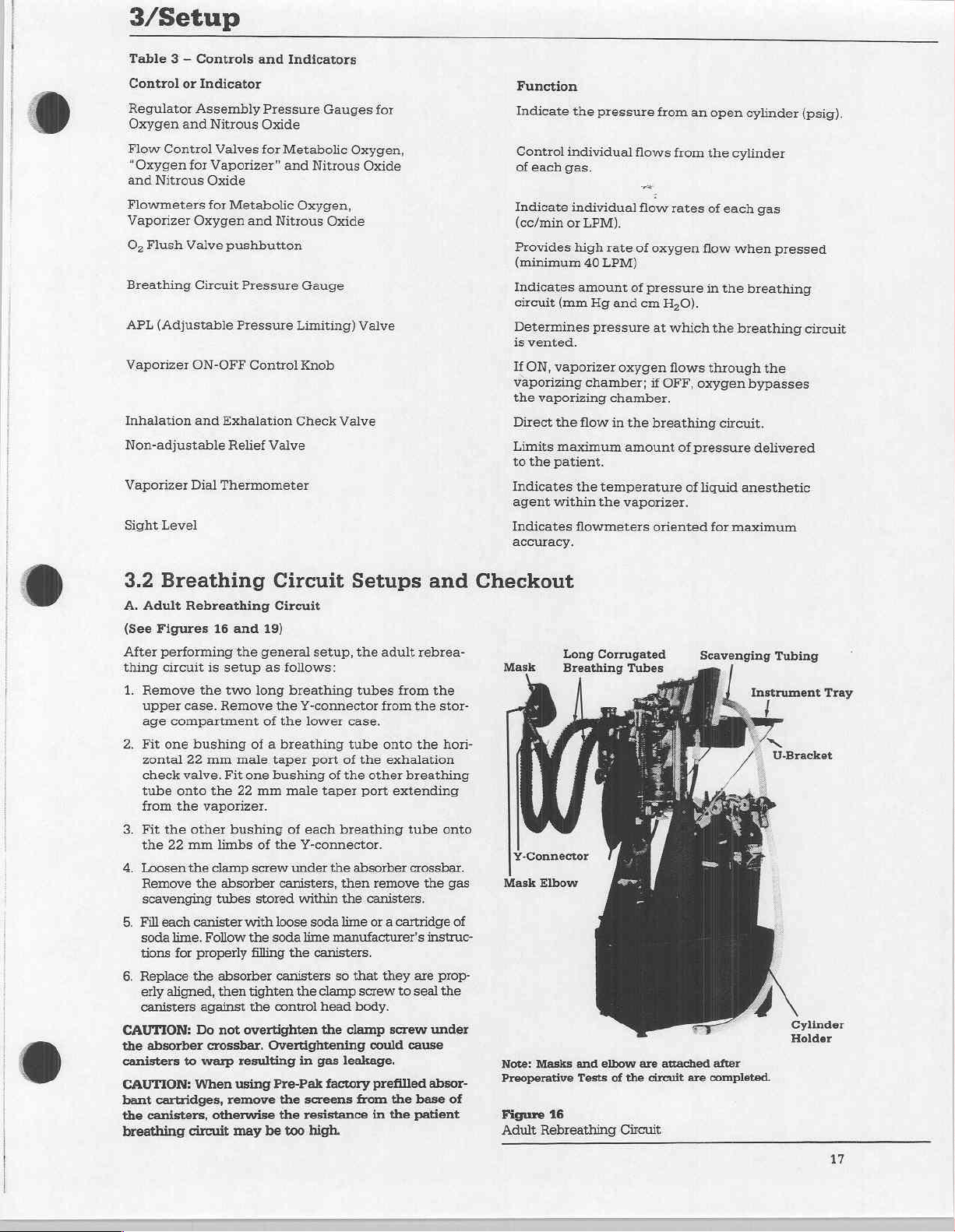

Figure

Apparatus

Cylinders,

3

Assembled

and

Absorber

Clamp

Absorber,

Crossbar

Control

with

Device

Pressure

Shutoff

Supply

Protective

without

Hose

Screw

Head

Inlets

Installed

Sensor

Valve

Closure

Breathing

Circuit,

Figure

Apparatus

Circuit,

4

Assembled

Small

Cylinders,

with

and

Adult

Rebreathing

Short

Supply

Hoses

Figure

Lower

5

Case

Control

Flowmeter

Top

Head

Manifold

with

Apparatus

Collapsed

Within

:

Page 9

2/Description

2.2

Items

A.

Gas

Supply

To

view

the

paragraphs,

and

lower

upper

case

1.

Cylinder

oxide

cylinder

posts

anchored

case

(see

for

mounting

threaded

have

nut

pin

indexed

help

prevent

tions

(e.g.,

not

fit a nitrous

oxygen

regulator

2,

Cylinder

regulator

and

two

blies

are

held

securely

gure

6).

pin

indexed

pin

indexed

indexed

and

Equipment

components

release

cases

on

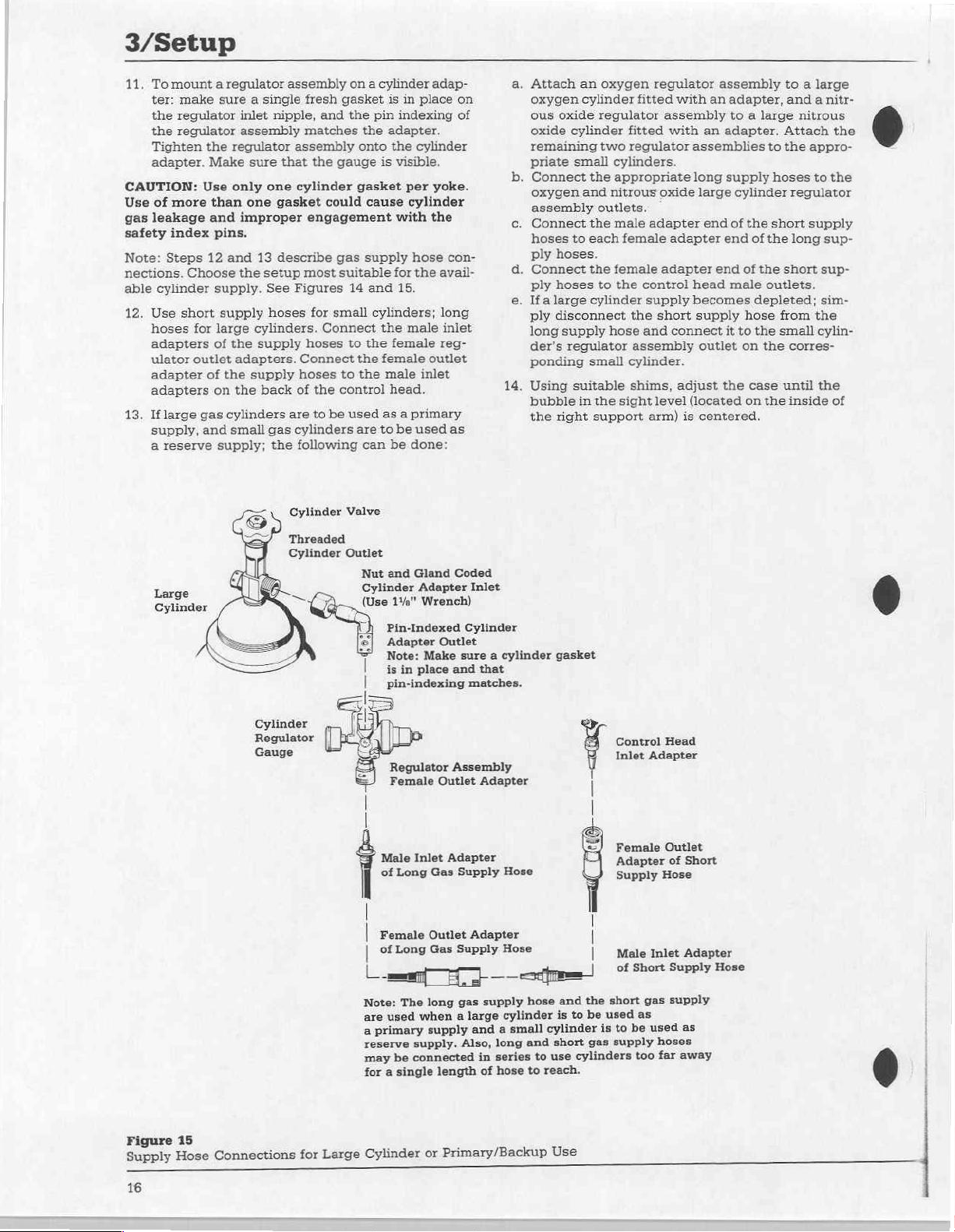

Adapters:

Figure

outlet

and gland

cylinder

assembly

Regulator

assemblies

for

stored

Each

cylinder

the

together

its

back

adapter

to

the

12).

yoke-type

cylinder

outlet

connections.

accidental

an

oxygen

oxide

adapter

nitrous

oxide.

in

the

by

latched

regulator

inlet

which

cylinder

adapter.

Components

draw

as

One

The

coded

inlet).

Assemblies:

are

valve,

described

and

shown

oxygen

are

inside

in

bolts

holding

carefully

in

Figure

and

stored

bottom

adapters

regulator

valves.

Cylinder

inlet

connections

These

interchange

cylinder

cylinder

outlet

adapter

outlet,

fit a

Four

provided:

All

four

regulator

upper

case

retainer

assembly

attaches

Pin

panels

has a yoke-type,

to a post-type,

or to

the

indexing

the

following

the

upper

place

the

2.

one

nitrous

on

threaded

of

the

lower

provide a means

assemblies

of

the

nor

nitrous

two

where

outlet

to

adapters

and

features

connec-

inlet

will

will

an

oxide

cylinder

for

oxygen

assem-

they

are

(see

Fi-

of a pin

helps

pre-

vent

the

accidental

tween

the

regulator

Each

regulator

sure

gauge, a relief

let

adapter

connect

outlet

accidental

outlets

.

Gas

supply

stored

two

each

The

center

stored

To

of

Each

adapter,

adapter

inlets

for

will

are

the

supply

and

Supply

hoses

in

long

for

both

long

storage

within

gain

access

the

storage

hose

with

will

which

fit

only

intended.

cross

hoses.

the

(114")

hoses

and a keyed

connections

interchange

cylinders

assembly

or

inlets.

assembly

valve,

with

an

integral

adapters

interchange

the

supply

Hoses:

Four

with a fabric

upper

case

and

two

oxygen

are

wrapped

and

compartment;

the

compartment.

to

the

hoses,

compartment.

has a keyed

an

fit

only

they

the

This

quick

integral

the

regulator

are

intended;

control

keying

of

of

connections

cylinder

adapters

also

has a cylinder

and a quick

check

valve.

are

keyed

of

the

hose

to

regulator

inlets

conductive

reinforced

(see

Figure

short

(40")

nitrous

oxide

around

the

short

unlatch

quick

connect

connect

check

valve.

assembly

supply

head

inlets

system

oxygen

helps

and

connect

The

help

prevent

assembly

rubber

core

6).

There

hoses;

delivery.

the

upper

hoses

the

hinged

male

female

Supply

hose

for

which

prevent

nitrous

be-

and

the

pres-

out-

quick

gas

are

one

case

are

lid

inlet

outlet

hose

outlets

outlets

they

oxide

are

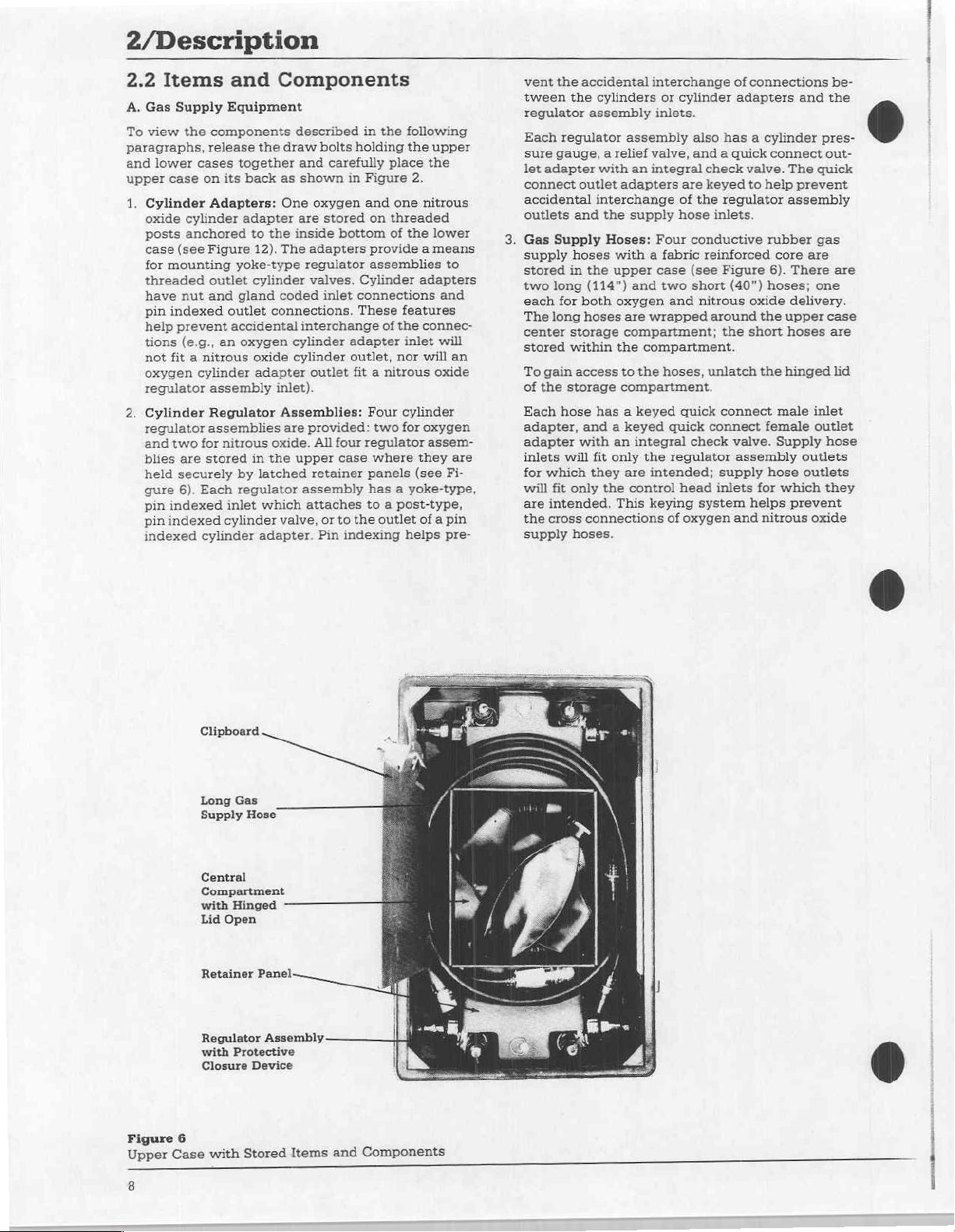

Figure

Upper

Case

Clipboard

Long

Gas

Supply

Hose

Central

Compartment

with

Hinged

Lid

Open

Retainer

Regulator Assembly.

with

Closure

Panel.

Protective

Device

6

with

Stored

Items

and

Components

8

Page 10

2/Description

B,

Control

See

The

lower

scribed

head.

the

back

See

1.

Gas

adapters

ible

inlet

on

See

2.

Pressure

sor

ous

normally

ery

decreases

the

stricted.

(cylinder

nitrous

To

paragraphs,

head

complish

a,

Pull

port

Note:

in

the

b.

Depending

casters

clips

Carefully

move

bottom

the

Using

(see

taining

c.

Unsnap

ter

d.

Grasp

until

the

control

end

left

Note:

apparatus

trol

head;

apparatus

(see

Figure

Head

Figures 5 and

control

Figure

Figure

head

carrying

in

When

case.

the

following

resting

of

the

5

Inlet

Connections:

for

oxygen

with

their

adapters

the

lower

5

Sensor

shutoff

oxide

inlet

valve

closed

circuit;

so,

to

valve

closes,

In

the

pressure

oxide

view

the

components

it

and

its

stand

this,

the

absorber

arms

lock

Before

proceeding

locked

position.

on

or

the

on the

floor

place

either

four

of

the

set

to

be

the

sight

Figure

top

support

of

support

References

12).

clips.

the

short strap

manifold

the

flowmeter

the

control

arm.

head

the

cross

arm

are

made

that

is,

where

11).

until

11

and

The

within

control

respective

are

located

control

Shutoff

is

adapter.

valve,

when

30

psig

the

event

falling

flow

will

do

the

crossbar

in

an

desired

set

of

of

the

glides

lower

used,

level

Replace

to

head

Do

the

bar,

and

to

the

with

the

the

flowmeter

its

stand

collapse

items

sections

head

and

head

and

comprise

the

lower

faces

The

control

nitrous oxide

supply

behind

body.

Valve:

located

will

directly

It

is

diaphragm

which

is

the

oxygen

the

valve

nitrous

oxide

of

an

oxygen

to

approximately

be

completely

described

be

necessary

out

of

the

following:

upright

four

the

apparatus

and

the

front

upward

position

verify

the

use,

remove

glides

lower

case

or

four

case

(see

place

the

make

sure

the

unused

which

secures

lower

case.

top

manifold

is

upright

not

release a tight

hinged

is

tightened

left,

thumb

locked

right,

respect

refers

panel

within

components

the

carrying

upward.

head

are

hose

outlets.

the

flowmeters,

The

pressure

above

located

in

cylinder

begins

to

flow

is

supply

shut

in

the

to

lift

lower

the

case.

until

(see

Figure

support

the

from

on

casters

Figure

into

(see

front

to

to

set

the

retaining

(see

Figure

its

side

from

8B).

unit

upright.

the

unit

set

the

and

pull

and aligned

hold

bolt,

the

slot

Figure

or

back

the

upright

the

side

can

be

the

de-

control

case,

gas

inlet

compat-

The

sen-

the

nitr-

operated,

the

deliv-

pressure

close.

As

re-

failure

20

psig)

off.

following

control

To

ac-

the

sup-

7).

arms

are

of

four

8A).

and

re-

the

Install

is

level

in

the

re-

flowme-

upward

with

on the

at

the

in

the

10).

of

the

con-

of

the

viewed

Figure

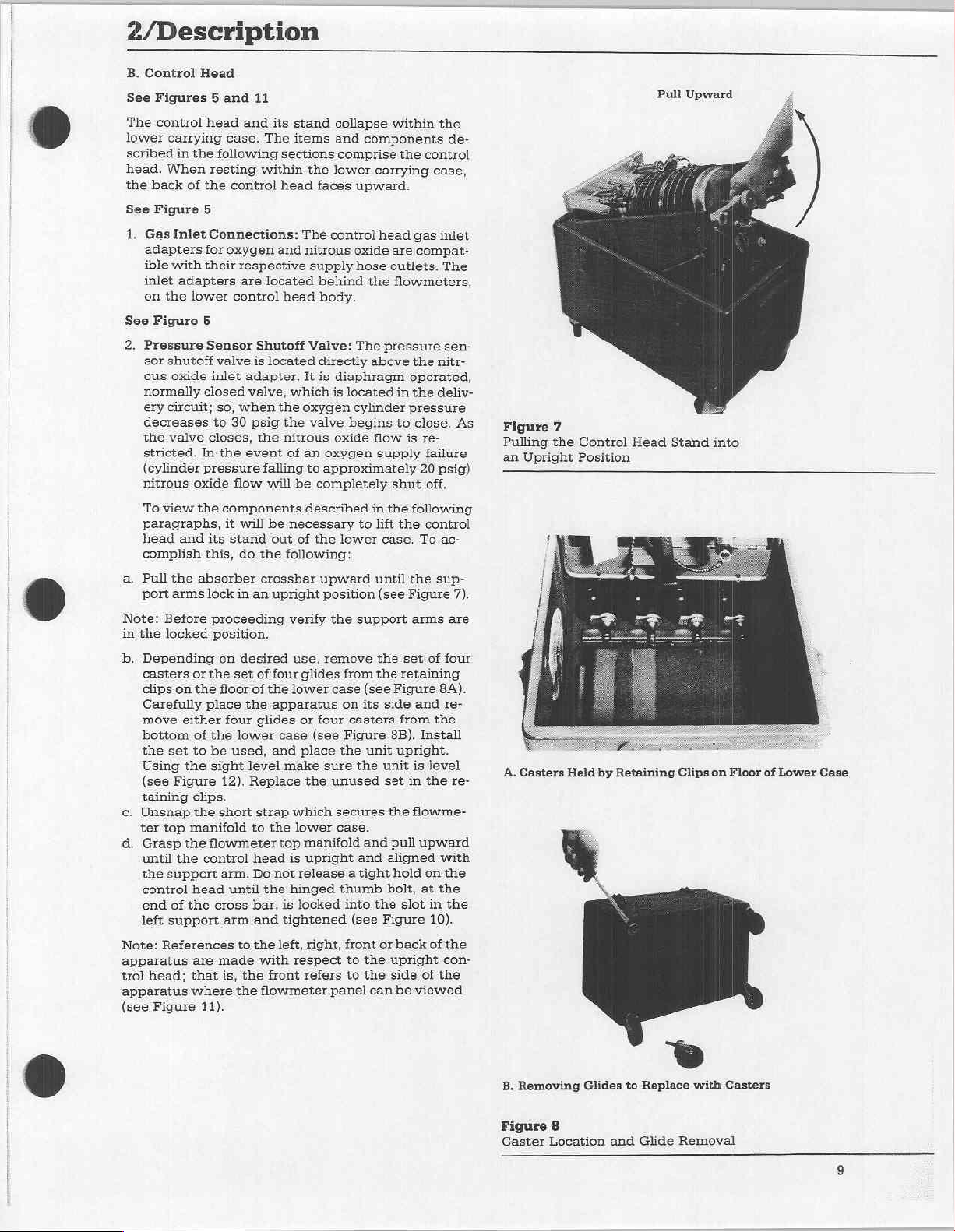

Pulling

an

A.

7

the

Upright

Casters

Control

Position

Held

by

Retaining

Pull

Head

Upward

Stand

into

Clips

on

Floor

of

Lower

Case

B.

Removing

Figure

Caster

Glides

8

Location

to

and

i

Replace

Glide

Removal

with

Casters

Page 11

2/Description

Lock

Bolt

into Slot

and

Tighten

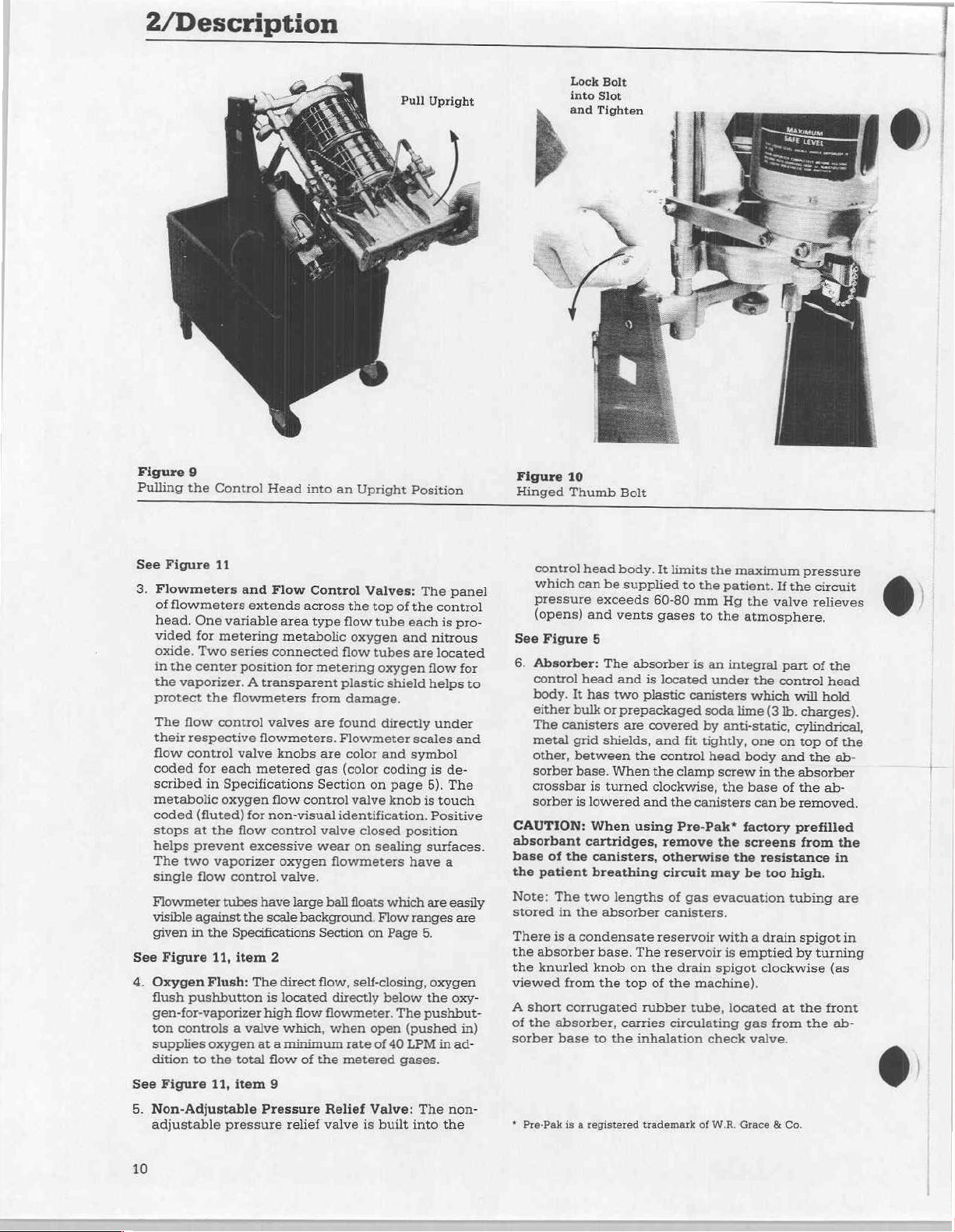

Figure

Pulling

See

3.

See

4.

See

5.

9

the

Control

Figure

11

Flowmeters

of

flowmeters

head.

One

vided

for

metering

oxide.

Two

in

the

center

the

vaporizer. A transparent

protect

The

their

flow

coded

scribed

the

flow

control

respective

control

for

each

in

metabolic

coded

(fluted)

stops

at

helps

The

single

the

prevent

two

vaporizer

flow

Flowmeter

visible

against

given

in

the

Figure

Oxygen

flush

gen-for-vaporizer

ton

supplies

dition

Figure

Non-Adjustable

adjustable

11,

Flush:

pushbutton

controls a valve

oxygen

to

the

11,

Head

and

extends

variable

series

position

flowmeters

valves

flowmeters.

valve

metered

Specifications

oxygen

for

non-visual

flow

excessive

control

tubes

have

the

scale

Specifications

item

The

is

high

at a minimum

total

item

Pressure

pressure

into

an

Flow

Control

across

area

type

flow

metabolic

connected

for

flow

metering

plastic

from

damage.

are

found

Flowmeter

knobs

are

color

gas

(color

Section

flow

control

identification.

control

valve

wear

oxygen

flowmeters

valve.

large

ball

background.

Section

2

direct

flow,

located

which,

flow

9

flow

of

the

relief

directly

flowmeter.

when

rate

metered

Relief

valve

Upright

Position

Valves:

the top

of

the

tube

oxygen

each

and

tubes

are

oxygen

shield

directly

scales

and

symbol

coding

on

page

valve

knob

closed

on

floats

self-closing,

sealing

which

Flow

on

Page

below

The

open

of

40

gases.

Valve:

is

built

position

have

ranges

(pushed

LPM

into

The

panel

control

is

pro-

nitrous

located

flow

for

helps

to

under

and

is

de-

5).

The

is

touch

Positive

surfaces.

a

are

easily

are

5.

oxygen

the

oxy-

pushbut-

in)

in

ad-

The

non-

the

Figure

Hinged

10

Thumb

control

which

pressure

(opens)

See

Figure

6.

Absorber:

control

body.

either bulk

The

canisters

metal

other,

sorber

crossbar

sorber

CAUTION:

absorbant

base

of

the

the

patient

Note:

The

stored

in

There

is a condensate

the

absorber

the

knurled

viewed

A

of

sorber

*

from

short

corrugated

the

absorber,

base

Pre-Pak

is a registered

Bolt

head

body.

can

be

supplied

exceeds

vents

and

5

The

head

and

It

has

two

or

prepackaged

are

grid

shields,

between

base.

When

is

tumed

is

lowered

When

cartridges,

canisters,

breathing

two

lengths

the

absorber

base.

knob

on

the top

carries

to

the

It

limits

to

the

60-80

mm

to

gases

absorber

is

plastic

is

located

canisters

soda

covered

the

the

by

and

fit

tightly,

control

clamp

clockwise,

and

the

canisters

using

Pre-Pak*

remove

otherwise

circuit

of

gas

canisters.

reservoir

The

reservoir

the

drain

of

the

machine).

rubber

inhalation

trademark

tube,

circulating

of

the

maximum

patient.

Hg

the

an

integral

under

anti-static,

head

screw

the

the

may

evacuation

with a drain

is

spigot

located

check

W.R.

If

the

the

valve

atmosphere.

part

the

control

which

(3

will

lb.

lime

cylindrical,

one

on top

body

and

in

the

base

of

can

be

factory

screens

the

be

emptied

gas

Grace & Co.

prefilled

resistance

too

high.

tubing

by

clockwise

at

from

valve.

charges).

absorber

the

removed.

from

spigot

the

pressure

circuit

relieves

of

the

head

hold

of

the

the

ab-

ab-

the

in

are

in

turning

(as

front

the

ab-

10

Page 12

2/Description

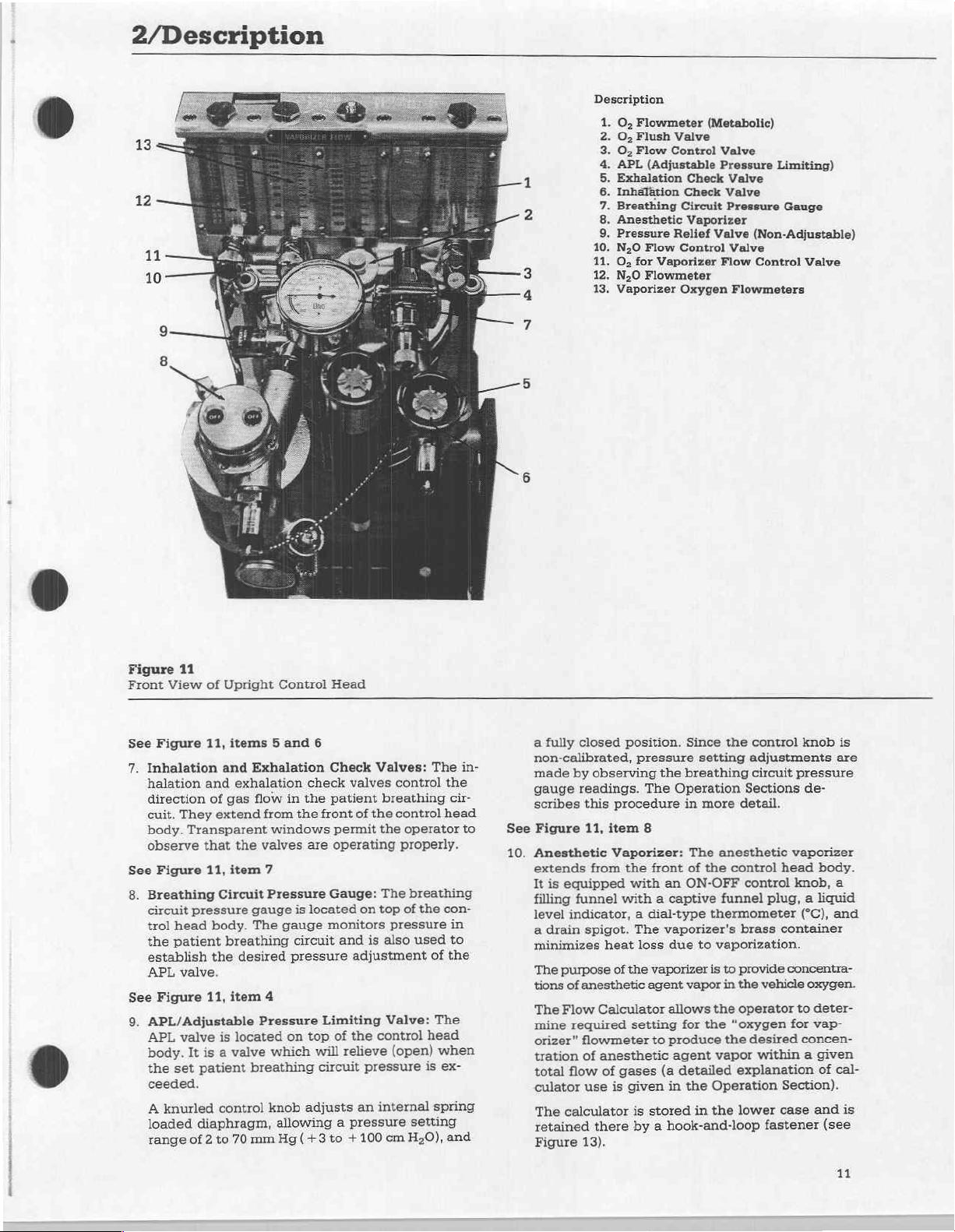

Description

1.

O,

Flowmeter

2.

O,

Flush

3.

O,

4.

APL

5.

Exhalation

6.

Inhalation

7.

Breathing

8.

Anesthetic

9.

Pressure

10.

№0

11.

Оз

12.

N20

13,

Vaporizer

Valve

Flow

Control

(Adjustable

Check

Circuit

Relief

Flow

Control

for

Vaporizer

Flowmeter

Oxygen

(Metabolic)

Valve

Pressure

Check

Valve

Valve

Pressure

Vaporizer

Valve

(Non-Adjustable)

Valve

Flow

Control

Flowmeters

Limiting)

Gauge

Valve

Figure

Front

See

7.

See

8.

11

View

Figure

Inhalation

halation

direction

cuit.

They

body.

Transparent

observe

Figure

Breathing

circuit

trol

head

the

patient

establish

APL

valve.

See

Figure

9.

APL/Adjustable

APL

valve

body.

It

the

set

ceeded.

A

knurled

loaded

range

of 2 to

of

Upright

11,

items 5 and

and

Exhalation

and

exhalation

of

gas

flow

extend

that

11,

pressure

body.

from

windows

the

valves

item

7

Circuit

Pressure

gauge

The

breathing

the

desired

11,

item

4

Pressure

is

located

is a valve

patient

control

which

breathing

knob

diaphragm,

70

mm

Control

Head

6

Check

Valves:

check

valves

control

in

the

patient

the front

permit

are

operating

Gauge:

is

located

gauge

monitors

circuit

pressure

Limiting

on

top

of

will

circuit

adjusts

allowing a pressure

Hg

(+3

to + 100

breathing

of

the

control

the

operator

properly.

The

on

breathing

top

of

pressure

and

is

also

used

adjustment

Valve:

the

control

relieve

(open)

pressure

an

internal

setting

em

H,0),

the

The

the

head

con-

of

The

head

when

is

ex-

spring

and

in-

cir-

to

in

to

the

a

fully

closed

non-calibrated,

made

by

gauge

scribes

See

Figure

10.

Anesthetic

extends

It

filling

level

a

minimizes

The

tions

The

mine

orizer”

tration

total

culator

The

retained

Figure

observing

readings.

this

11,

from

is

equipped

funnel

indicator, a dial-type

drain

spigot.

purpose

of

anesthetic

Flow

required

flowmeter

of

flow

use

calculator

13).

position.

pressure

the

The

procedure

item

8

Vaporizer:

the front

with

an

with a captive

The

vaporizer's

heat

loss

due

of

the

vaporizer

agent

Calculator

anesthetic

of

gases

is

there

allows

setting

to

produce

(a

given

in

is

stored

by a hook-and-loop

Since

the

setting

breathing

Operation

in

more

The

anesthetic

of

the

control

ON-OFF

funnel

thermometer

to

vaporization.

is

to

vapor

in

the

for

the

“oxygen

vapor

detailed

the

Operation

in

the

the

explanation

agent

control

knob

adjustments

circuit

Sections

detail.

pressure

de-

vaporizer

head

control

brass

provide

the

operator

lower

knob,

plug, a liquid

(°C),

container

concentra-

vehicle

to

for

desired

concen-

within a given

Section).

case

fastener

is

are

body.

a

and

oxygen.

deter-

vap-

of

cal-

and

is

(see

11

Page 13

2/Description

C.

Breathing

1.

Breathing

rugated,

Y-connector

the

case;

partment

Figure

Y-connector

breathing

rebreathing

Tubing

is

also

ment

ductive

taper

taper

hose

end

2.

Breathing

are

stored

The

liter

female

ing

Circuit

Tubes

conductive

are

central

and a tee

large 3 liter

bag

vent

compartment

the

Y-connector

at

the

12).

The two

fit

tubes.

circuit

for

the

stored

and

in

includes: a short

rubber

connector

connector

with a 15

connector

Bags

in

the

is

for

taper

connector

valve

Items

and

rubber

provided.

base

of

22

the

22

These

pediatric

the

upper

breathing

at

one

at

the

mm

female

and

Fittings:

upper

bag

is

pediatric

at

the

Fittings:

is

the

mm

mm

items

Two

breathing

The

tubes

of

the

upper

stored

in

control

male

taper

bushings

are

partial

rebreathing

case

central

(12”)

tube with a 15mm

end and a 15

other,

and a pediatric

taper

at

the

other.

Two

case

central

for

adult

use

and

at

one

end,

other

end

long

(32")

tubes

are

stored

carrying

the

latched

head

stand

limbs

of

the

long

used

in

the

compart-

corrugated

mm

female

connector

breathing

compartment.

use.

The

has a 15

and a scaveng-

small

mm

cor-

and

a

in

com-

(see

of

the

adult

circuit

con-

male

supply

at

one

bags

1

3.

Masks

and

posts

in

the

one

adult,

inflatable

inflated

tours

Each

The

a.

the

b.

the

с.

the

d.

the

Placement

breathing

Y-connector

the

Each

bushing.

conductive

case

rated

the

control

mask

and

cushions

the

of a patient's

mask

has a 22

other

end

pediatric

short

pediatric

adult

of

circuit

is

base

of

the

adult

mask

The

rubber

central

compartment.

legs

which

each

large

breathing

circuit

hooks

Fittings: Five

uncovered

head

stand

in

adult

masks

mm

of

the

mask

tee

female

breathing

Y-connector.

the

mask

being

stored

control

face

compartment

(see

newborn,

sizes.

so

that

will

fit

securely

face.

bushing

elbow

connector

tube

female

bag

elbow

used.

in

the

covered

head

has a four-hook

are

used

to

head

strap

The

fasten

to

the

four

masks

Figure

infant,

Both

when

for

(15

female

will

When

stand.

ring

retain

is

stored

strap

hooks

are

at

the

12).

child,

adult

masks

they

are

against

the

mask

mm

male)

connector

connector

depend

not

in

compartment

around

the

mask.

in

the

has

four

on

the

stored

on

base

There

of

is

medium

have

properly

the

con-

elbow.

will

fit:

or

on

the

use,

the

at

the

22

mm

One

upper

perfo-

mask.

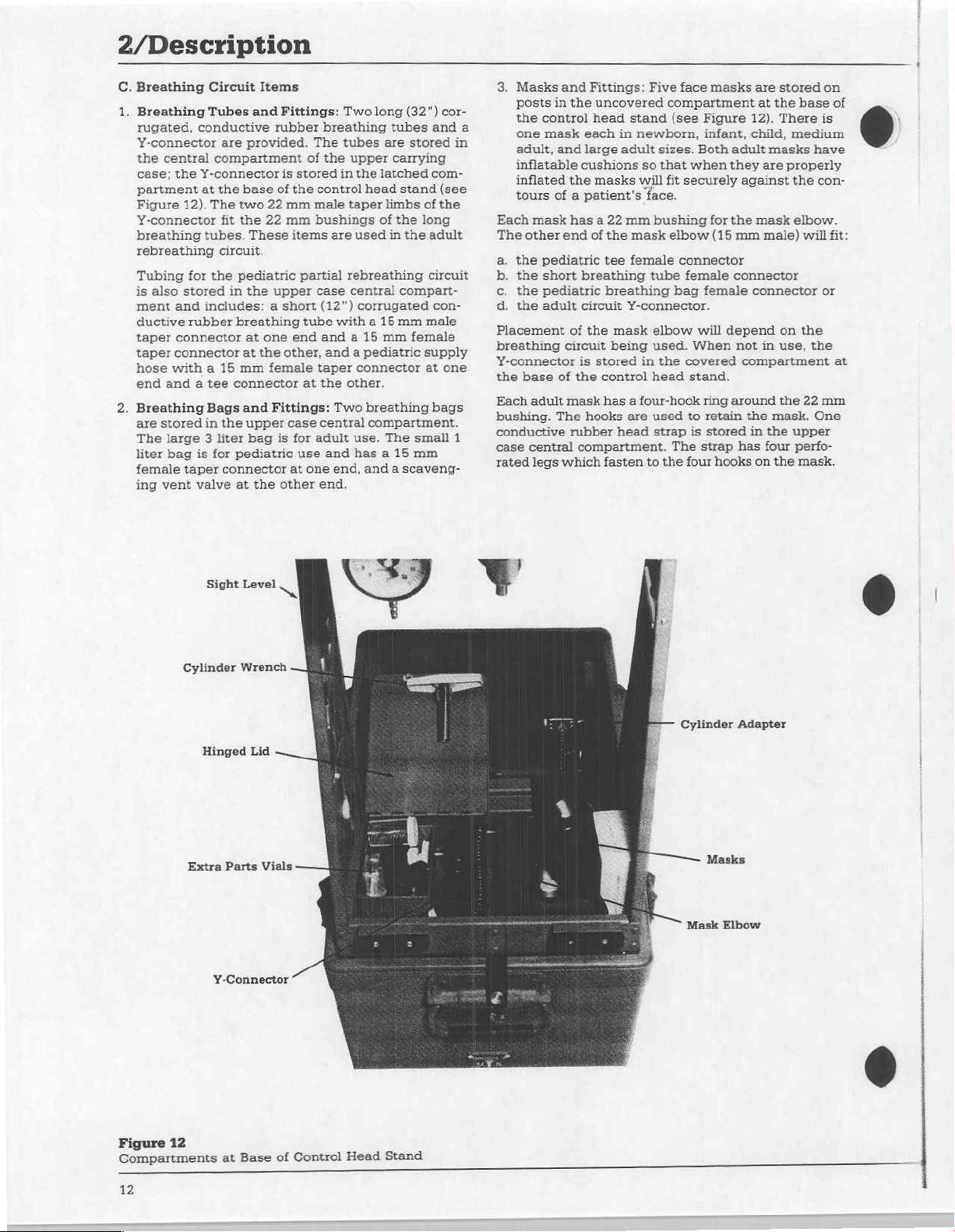

Sight

¡gl

Cylinder

Wrench

Hinged

Extra

Parts Vials

Y-Connector

Level

ES

Lid

Cylinder

Adapter

Masks

Mask

Elbow

Figure

Compartments

12

12

at

Base

Control

of

Head

Stand

Page 14

2/Description

D.

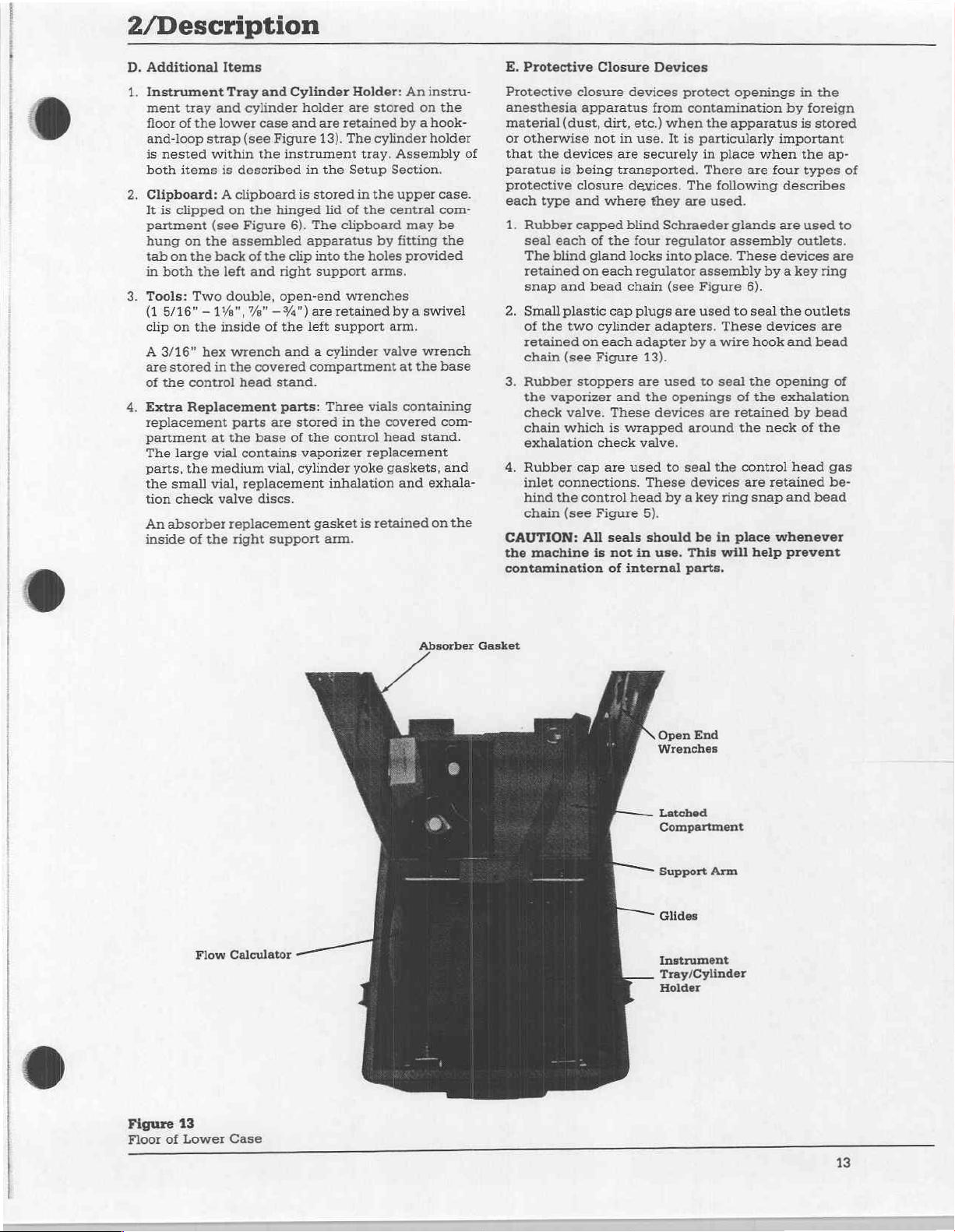

Additional

1.

Instrument

ment

floor

and-loop

is

nested

both

2.

Clipboard: A clipboard

It is

partment

hung

tab

on the

in

both

3.

Tools:

(1

5/16" — 18",

clip

on the

A

3/16"

are

stored

of

the

4.

Extra

replacement

partment

The

large

parts, the

the

small

tion

An

absorber

inside

Items

Tray

tray

and

of

the

lower

strap

within

items

is

clipped

(see

on the

back

the

left

Two

double,

on the

assembled

inside

hex

wrench

in

the

control

Replacement

parts

at

the

vial

medium

vial,

check

valve

replacement

of

the

and

cylinder

case

(see

Figure

the

instrument

described

hinged

Figure

of

the

and

right

open-end

7" — 3%")

of

the

and a cylinder

covered

head

stand.

parts:

are

base

contains

vial,

replacement

discs.

right

support

Cylinder

holder

and

are

retained

13).

in

the

is

stored

lid

6).

The clipboard

apparatus

clip

into

the

support

are

retained

left

support

compartment

Three

stored

in

of

the

control

vaporizer

cylinder

inhalation

gasket

arm.

Holder:

are

stored

The

cylinder

tray.

Setup

in

the

of

the

by

holes

arms.

wrenches

valve

vials

the

covered

head

replacement

yoke

gaskets,

is

retained

An

instru-

on the

by a hook-

holder

Assembly

Section.

upper

case.

central

com-

may

be

fitting

the

provided

by a swivel

arm.

wrench

at

the

base

containing

com-

stand.

and

and

exhala-

on

of

the

E.

Protective

Protective

anesthesia

material

or

otherwise

that

paratus

protective

each

1.

Rubber capped

seal

The

retained

snap

2,

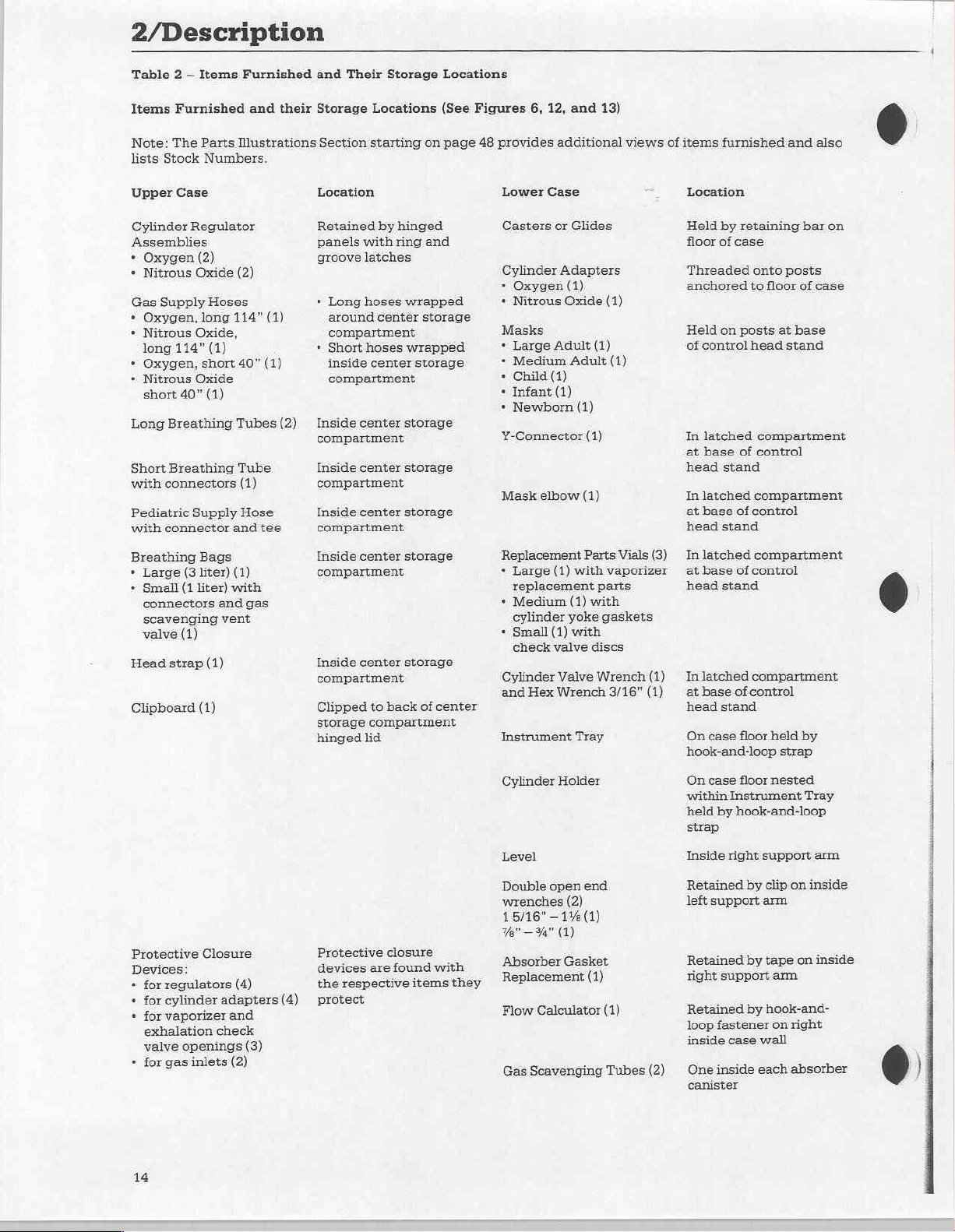

Small

of

retained

chain

3.

Rubber

the

check

chain

closure

apparatus

(dust,

the

devices

is

being

closure

type

and

each

blind

on

and

plastic

the

two

on

(see

stoppers

vaporizer

valve.

which

exhalation

4.

Rubber

inlet

hind

chain

CAUTION:

the

contamination

connections.

the

(see

machine

cap

control

All

Closure

Devices

devices

from

dirt,

etc.)

not

in

use.

are

securely

transported.

devices.

where

they

blind

of

the

four

gland

locks

each regulator

bead

chain

cap

plugs

cylinder

each

Figure

adapters.

adapter

13).

are

and

the

These

devices

is

wrapped

check

valve.

are

used

These

head

Figure

is

seals

not

of

internal

5).

should

in

use.

protect

openings

contamination

when

the

apparatus

It is

particularly

in

place

There

The

following

are

used.

Schraeder

regulator

into

(see

are

glands

assembly

place.

assembly

Figure

used

These

to

These

by a wire

used

to

openings

to

by a key

seal

are

around

seal

the

devices

ring

be

in

This

will