Page 1

e

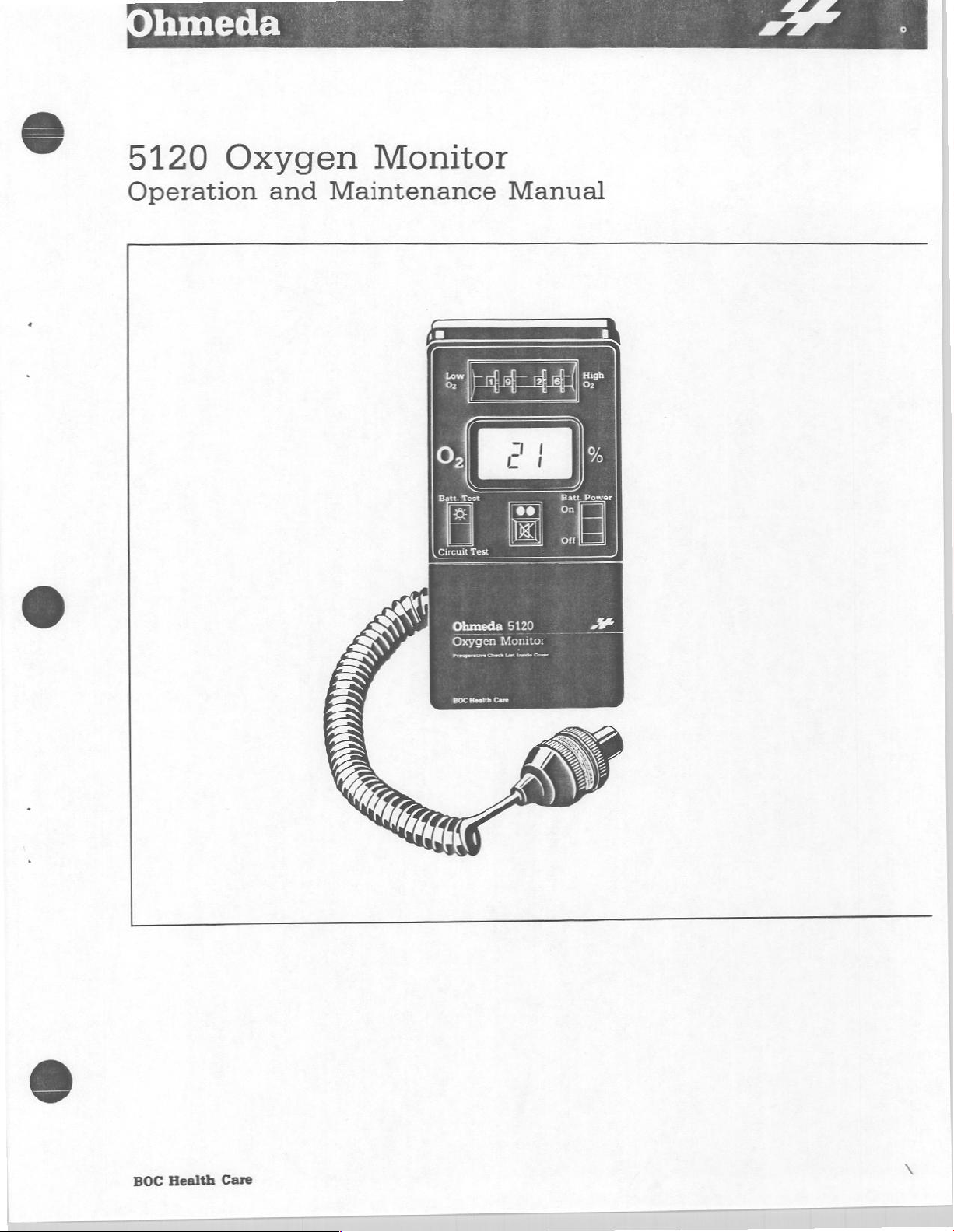

5120

Oxygen

Monitor

Operation

and

Maintenance

Manual

BOC

Health

Care

Page 2

USER

RESPONSIBILITY

This

contained

inserts,

accordance

checked

that

should

become

request

Service

repaired

by

altered

Department.

responsibility

faulty

other

TRACEABILITY:

this

registration

Ohmeda.

6050-0000-134.

Product

periodically.

are

be

necessary,

for

Center.

Ohmeda

without

maintenance,

than

equipment.

when

broken,

other

If

will

in

this

assembled,

with

replaced

service

than

and

by

The

for

Ohmeda.

Federal

card

additional

perform

operating

the

instructions

missing,

immediately.

Ohmeda

advice

This

in

Ohmeda

the

prior

user

any

improper

Please

included

in

operated,

A

defective

plainly

recommends

Product

accordance

trained

written

of

this

malfunction

law

fill

cards

conformity

manual

be

made

or

any

personnel.

Product

repair,

in

the

out

with

this

are

and

accompanying

maintained

provided.

Product

worn,

Should

that

to

the

of

its

with

approval

U.S.A.

the

required,

written

shall

which

damage,

self-addressed

product

with

distorted

such

the

and

This

should

repair

a

telephonic

nearest

parts

The

of

Ohmeda's

have

results

or

requires

and

order

description

labels

repaired

Product

not

be

or

contaminated

or

replacement

or

Ohmeda

should

instructions

Product

the

from

alteration

traceability

return

Stock

not

must

Safety

sole

improper

traceability

Number

thereof

and/or

in

must

used.

written

Regional

be

provided

not

by

it

to

be

Parts

be

use,

anyone

of

CAUTION:

sale

by

Federal

or

on

the

law

order

in

U.S.A.

a

of

and

licensed

Canada

medical

restricts

practitioner.

this

device

to

Page 3

Addendum

Operation

to

0178-1757-000

For

Contract

the

and

Number

5120

Maintenance

(04

Oxygen

87

RB)

DLA120-87-C-4281

Monitor

Manual

Number

NOTE:

should

sample

NOTE:

(every

tion

NOTE:

monitor

105D

in

NOTE:

Storage

be

size.

Perform

4

3.

Storage

for

Section

The

enviroment

B).

NOTE:

eration

dry

To

enviroment

performed

months).

sensors

unit

3.

5120

with

maximize

is

not

Inspection

at

Follow

the

preventative

Follow

Inspection

should

sample

Oxygen

temperatures

the

available,

at:

Temperature:

Requirements

30

month

Preoperative

the

Requirements

be

performed

size.

Monitor

oxvgen

the

Humidity:

intervals.

Checkout

maintenance

Preoperative

-

at

Follow

not

monitor

sensor should

should

to

the

exceed

sensor

-20'C

55%

+/-

-

Inspection

Use

for

units

Checkout

Inspection

12

month

Preoperative

be

stored

-28'C

s

be

(68

F)

+/-.2°C

5%

of

MIL-STD

Procedure

in

Procedure

of

intervals.

Checkout

to

+54°C

shelf

stored

life,

3

units

105D

in

service

units

in

a

(-20'F

in

a

in

for

Section

quarterly

with

Use

Procedure

clean

when

clean

storage

in

oxygen

MIL-STD

to

refrig-

unit

3.

Sec-

dry

130

and

Addendum

No.

0178-1759-000

(01

88)

Page 4

LIST

OF

ILLUSTRATIONS

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Fioure

Figure

Figure

Figure

Figure

LIST

Chart

Chart

LIST

Table

OF

OF

の

Ohmeda:

Standard

oO

Optional

5120

me

Probe

Universal

の

aa

Oxygen

Oxygen

oo

Oxygen

10.

Battery

115

Rear

12:

Replacing

134

Battery

14.

Replacement

15.

Rear

CHARTS

1.

Operation:

2.

Troubleshooting

TABLES

ES

Remote

5120,

Accessories.

Accessories

Oxygen

Holder

Monitor,

Monitor,

Monitor,

Compartment

View

Replacement

View

Alarm

Oxygen

Monitor

Mounting

ее

Sensor

Parts

ee

Summarv

Guide:

Pulse

Monitor

Block

|.

»

Clamp

Front

Front

Front

cartridge

ee

of

Codes

.

so

.

.

Diagram

ο

View

View

View

ev

s

e

ae me

e

des

Displays,

i

ον

2.

το

-555

ενος

=

a

sl

ο

οσο

ο

.

.

. .

(continued)

(continued)

be

çi

еее

ее

es

e

Alarms

Sad

eo:

ее:

ο

e

ο

ο

ee

and

ος τα

e

ο»

ее

>

.

ος

a

o

Page 5

TABLE

OF

CONTENTS

PRECAUTIONS

Introduction

System

1.0

GENERAL

151

Description

1.2

'ACCessorlesı

1.3

Theory

1.4

Specifications

+0

SETUP

Del

Setup.

2.2

Mounting

2.3

Controls

2.4

Alarms

255

calibrations

3.0

OPERATION

3.1

Preoperative

3%

2"

Operation

4.0

OPERATOR

4.1

Cleaning

(Warnings

..

Installation

INFORMATION

of

Operation.

AND

CALIBRATION

se

e

and

оо

<...

2

MAINTENANCE

and

and

Cautions)

. .

(Modulus

. .

“iile,

5...

e ο ο ο e

・

3

sc

ooo

. . . . .

ο

ος

λος

Components

oie

Checkout

Sterilization

desto

wipe

We

S

AO

II

Anesthesia

aile

οσο

ο ο

. . .

e

e e

ae

Procedure

e e

ko

Maleta

«de

cite

3

.

.

.

ο

System)

dd

ロロ

5.0

SERVICE

5.1

5.2

5.3

5.4

APPENDIX

APPENDIX

WARRANTY

PROCEDURES

Repair

Policy

Troubleshooting

Parts

Replacement

Replacement

A - Output

B - System

さる We

로 6 고

and

Procedure

Guide

Procedures

Parts

ον ος ο κος

List

Connector

Test Mode

....

da

. . .

. .

ον

ο ο ες

oe

oii

39

.

39

40

43

o

48

49

.

52

53

Operation

and

Maintenance

Manual

Page

i

Page 6

PRECAUTIONS

A

WARNINGS:

e

Connect

the

that

monitor.

If

the

Checkout

corrected.

A

When

moisture

Use

immerse

or

Do

not gas

Do

not

Following

(front

only

output

is

lower

See

monitor

Procedure,

caurions:

in

use,

build-up

the

recommended

autoclave

sterilization

half

quarantine

absorbed

recommendations

by

a

high

connector.

than

page

fails

Pages

See

the

sensor

monitor.

the

sterilize

the

only)

parts

the

to

material.

for

impedance

the

24,

to

do

29

its

on

cleaning

the

monitor.

of

the

allow

procedure

Improper

corresponding

respond

not use

36.

and

should

sensing

solution

Page

See

monitor.

See

with

tee

ethylene

manifold,

dissipation

Follow

and

device

loading

as

it

until

always

surface.

36.

See

Page

sterilizer

aeration

(at

least

will

value

described

the

be

pointing

sparingly;

Page

36.

oxide

or of

of

residual

10

result

displayed

in

the

malfunction

Page

See

do

36.

of

the

the

sensor

manufacturer's

period.

K

ohms)

in

an

output

by

the

Preoperative

has

down

31.

not

probe

to

saturate

housing

cartridge,

ethylene

See

Page

to

pin

oxygen

been

reduce

oxide

37.

5

of

voltage

gas

©

Only

should

Detailed

service

knowledge,

competent

trained

After

the

the

replacing

Preoperative

monitor

stabilize

After

fresh

Procedure

properly.

Page

ii

individuals

attempt

information

manual solely

by

the

in

See

to

tools

Ohmeda.

the

is

working

sensor;

batteries

Section

Page

and

Checkout

service

for

for

test

See

sensor

refer

are

3.1

46.

trained

it.

more

the

equipment,

Page

properly.

39.

cartridge

Procedure

to

installed,

to

verify

in

See

Page

extensive

convenience

and

or

in

Allow

the

NOTE

perform

that

the

39.

repairs

for

the

Section

at

on

the

repair

of

users

service

sensor

least

page

the

monitor

of

this

is

included

having

assembly,

3.1

to

five

28.

See

Preoperative

is

equipment

in

the

proper

representatives

perform

verify

minutes

Page

that

to

43.

Checkout

working

5120

Oxygen

Monitor

6

Page 7

INTRODUCTION

This

manual

prepare,

Read

through

attention

manual

Read

the

it

The

life

statement

to

Keep

concerning

case

the

user

lists

oxygen

affected

realize

this

of

operate,

to

and

are

User

to

Ohmeda's

sensor

(on

maximum

manual

the

failure,

contains

and

the

entire manual

the

Warnings

summarized

Responsibility

maintain

responsibility

cartridge

by

several

page

5)

service

available

monitor's

its

information

maintain

and

in

a

safe

and

is

factors.

about

proper

life.

for

operation,

repair.

that

the

Ohmeda

before

Cautions

the

PRECAUTIONS

statement;

accurate

in

case

a

consumable

Read

handling

answering

its

will

guide

5120

using

the

which

it

lists

instrument.

of

a

item

the

Sensor

and

questions

maintenance,

you

Oxygen

monitor.

appear

section.

what

functional

with

Life

storage

which

to

properly

Monitor.

Pay

throughout

is

expected

Read

the

defect.

a

limited

Expectancy

of

the

may

in

or

special

this

of

Warranty;

service

sensor

arise

System

The

carried

size

such

except

footnotes,

stand-alone

Consult

Manual

the

monitor

Installation

5120

Oxygen

from

makes

as

the

for

the

for

Monitor

place

it

an

Modulus

a

few

the

or as

to

ideal

considerations

operation

a

Modulus

information

and the

(Modulus

is

place

module

II

Anesthesia

of

system

II

Anesthesia

regarding

rest

of

II

Anesthesia

a

stand-alone

as

required.

for

explained

the

monitor

unit.

the

system.

use

in a larger

System.

is

System

the

interconnection

System)

unit

However,

which

In

either

in

referenced

identical

Operation

can

its

compact

system

case,

as

and

between

be

a

Maintenance

Operation

and

Maintenance

Manual

Page

1

Page 8

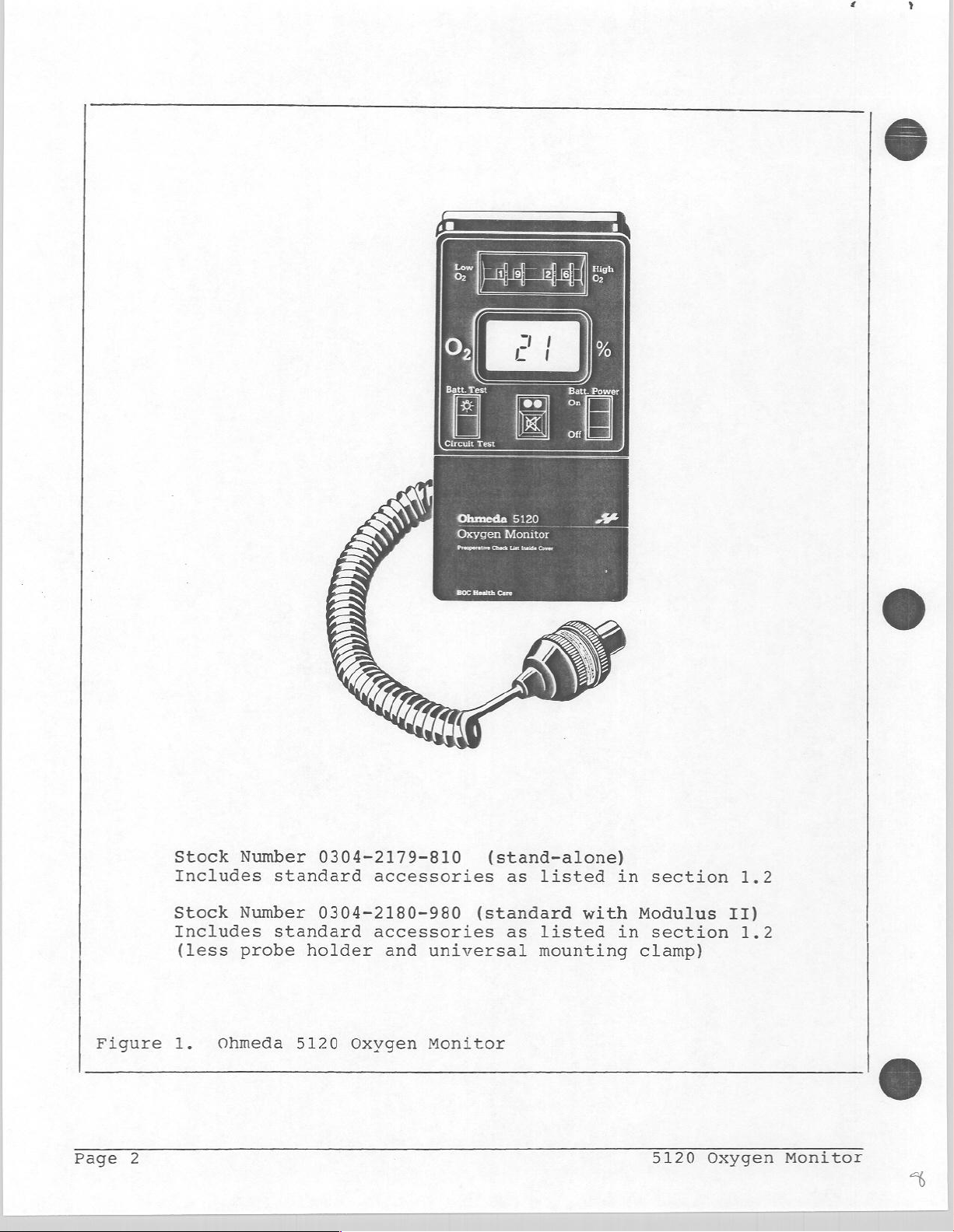

Stock

Includes

Stock

Includes

(less

Number

standard

Number

standard

probe

0304-2179-810

accessories

0304-2180-980

accessories

holder

and

Oxygen

(stand-alone)

(standard

universal

Monitor

as

listed

as

listed

mounting

with

in

Modulus

in

clamp)

section

section

1.2

II)

1.2

Figure

Page

2

1.

Ohmeda

5120

Oxygen

Monitor

5120

Oxygen

Monitor

a

も

Page 9

1.0

GENERAL

INFORMATION

This

illustrates

of

1.1

The 5120

throughout

nursery,

The

(LCD)

100

easy

section

operation

Description

Oxygen

or

5120

Oxygen

that

percent.

viewing.

describes

the

(1.3),

the

hospital:

wherever

indicates

The

Additional

- A switch-operated

- A digital

set

points.

Setting

tones

does

alarm

switch

the

and

not

accept

whenever

regardless

the

accessories

and

Monitor

a

measurement

Monitor

oxygen

digits

backlight

to

select

Low

02

a

continuous

low

the

of

how

general

supplied

lists

(refer

in

anesthesia,

features

concentrations

are

large

features

High

alarm

visual

alarm

displayed

far

below

features

detailed

to

Figure

of

a

LIQUID

(1.3

include:

for

viewing

02

limit

limits

02

18%

with

it

specifications

1

on

in

respiratory

oxygen

CRYSTAL

from

cm,

in

and

Low

below

indicator

18%

below

reading

the

Low

of

the

monitor

(1.2),

page

concentration

2)

digital

zero

0.5

inches,

subdued

O2

alarm

results

(vellow).

18%.

is

02

The

below

alarm

includes

(1.4).

can

therapy,

to

high)

light(*).

limit

in

The

monitor

18%

limit

(1.1),

a

be

used

is

required.

DISPLAY

for

three

monitor

will

02

is

theory

in

the

beep

set.

Setting

High

procedures.

-

Visual

concentration.

concentration

For

silenced

than

Alarm

duration

remain

The

(*)

external

General

the

O2

alarms,

and

audible

a

Low

for

Low

02,

Silence

of

active

backlight

source;

Information

High

alarms

The

is

less

O2

alarm

approximately

the

switch,

the

throughout

always

is

example,

for

02

a

feature

alarms

than

condition,

audible

alarm

alarm

to

warn

respond

or

alarm

and

condition.

any

when

on

a

limit

useful

of

greater

the

30

seconds.

will

alarm

the

Modulus

switch

during

a

low

whenever

than

audible

mav

he

remain

The

condition.

monitor

II

to

"00"

100%

or

a

the

the

selected

alarm

For

conditions

silenced

silenced

visual

is

Anesthesia

disables

oxygen

high

displayed

oxygen

can

with

for the

indicators

powered

System.

the

flush

oxygen

limits.

be

other

the

an

by

Page

3

Page 10

-

-

-

A

that

A

sensor

A

sensor

assembly

extends

long-life

assembly

The

sensor

compensation.

when

used

humidity

exposed

anesthesia

non-condensing).

hinged,

front

to

approximately

oxygen

without

includes

to

when

cover

which

attaches

cartridge

tools.

an

The

sensor's

carbon

gases.

monitoring

that

6

feet.

which

internal

accuracy

dioxide,

The

sensor

a

humidified

opens

to

the

can

thermistor

nitrous

for

easy

monitor

be

is

is

also

easily

not

oxide

insensitive

gas

stream

access

with

a

replaced

for

temperature

noticeably

or

other

(95%

to

coiled

in

affected

normally

to

R.H.

cable

the

&

a

--

the

--

and,

--

-

Two

modes

a

--

and

--

which,

life

-

useful

- A front

a

sensor

(88

to

The

displayed

are

- A modular

the

following

Preoperative

calibration

replacement,

for

for

testing

test

as

(LOW.

level,

test

applicable,

BATT),

switch

manual

a

panel

signal

102

%).

circuit

test

messages,

functional.

connector

for

Checklist,

control,

the

initiated

performed

‘or,

halts

(CIRCUIT

simulating

verifies

and

(Output)

remote

batteries.

the

internal

the

by

automatically

either

the

if

operation

TEST)

a

high

that

the

visual

at

the

monitoring

batteries

operator,

by

indicates

batteries

until

the

which

concentration

the

digital

alarm

back

equipment.

of

(*).

monitor,

the

limited

discharged

are

batteries

remaining

electronically

of

oxygen

display,

indicators

the

monitor

below

are

replaced.

substitutes

the

(LEDs)

provides

battery

a

©

-- an

-- a digital

--

(*)

The

external

Anesthesia

Page

4

analog

an

external

battery

source;

System.

signal

output

alarm

tests

for

See

proportional

signal

silence

are

not

example,

item

indicating

valid

when

3

on

input

if

installed

page

to

for

the

18.

the

an

oxygen

alarm

remote

monitor

in a Modulus

concentration

condition

silence

is

capability.

powered

II

by

Section

an

©

One

\b

Page 11

ATTENTION

SENSOR

LIFE

EXPECTANCY

The

oxygen

time

percent

to

This

approximately

For

one

at

to

life

This

atmosphere

Do

prior

This

which

conditions.

increased

prevent

and,

Placing

refrigerator

should

DO

service

and

while

sensor

example,

year

100%

C02

of

sensor

not

to

sensor

will

thus,

NOT

sensor

oxygen

oxygen.

may

the

puncture

the

unopened

extend

FREEZE.

life

is

conditions,

the

in

service.

will

438,000

it

at

50%

also

sensor.)

STORAGE

is

packaged

to

maximize

or

placing

has

vary

relative

enhance

depending

Reduced

sensor

(Temp.

the

of

this

affected

as

sensor

typically

percent

would

oxygen

(Continuous

shorten

the

a

finite

sensors

shelf-life.

typically

or

shelf-life.

open

sensor

temperatures

humidity

from

its

shelf-life.

6 C +/- 3 C)

high-quality

by

storage

well

the

in

the

shelf-life

drying

in

as

is

exposed

function

hours.

6

months

exposure

expected

an

inert

package

in

on

storage

will

a

the

last

service.

and

help

out

for

for

General

Information

Page

5

\\

Page 12

1.2

Accessories

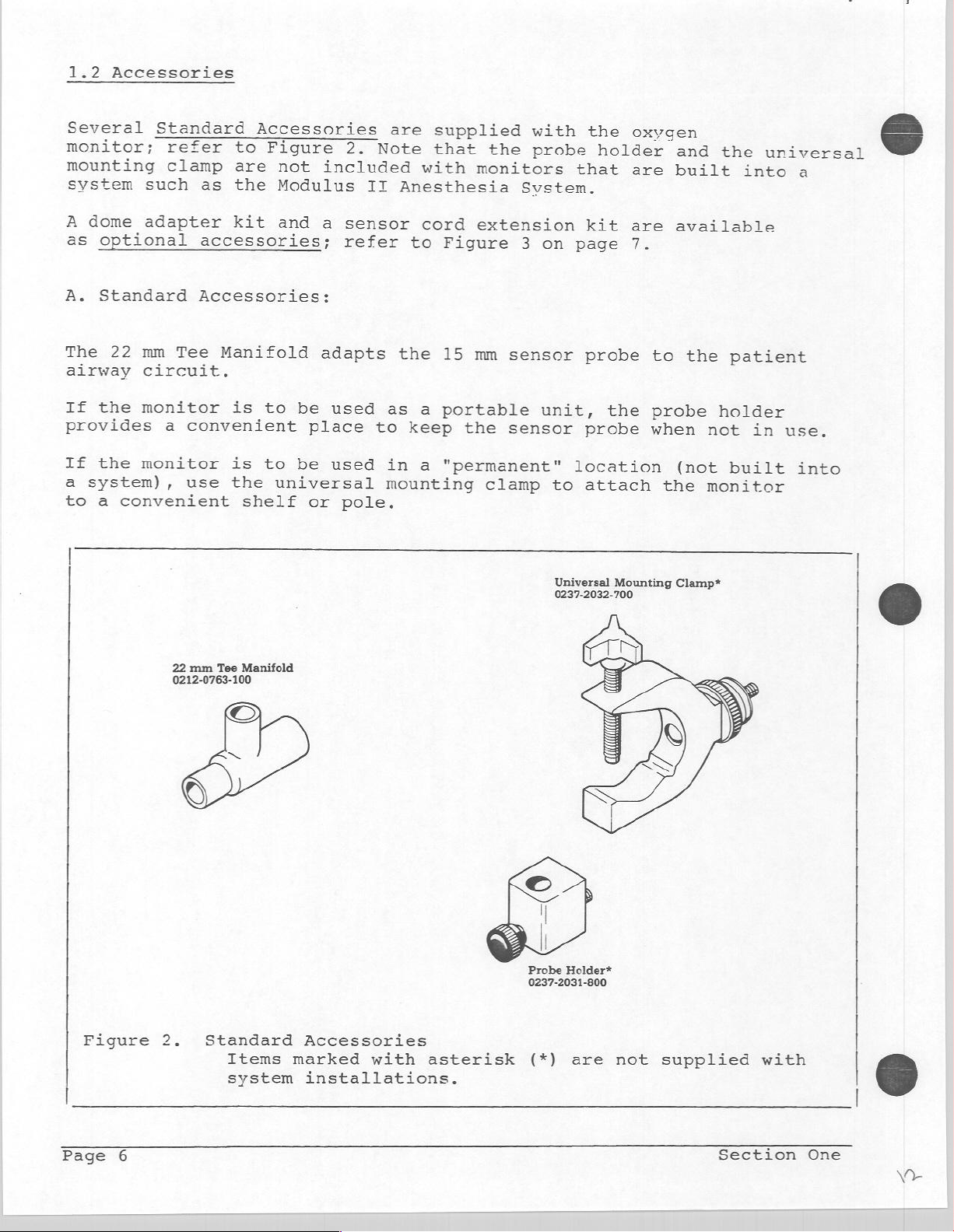

Several

monitor;

mounting

system

A

dome

as

optional

A.

Standard

The

22

airway

If

the

provides

If

the

a

system),

to

a

convenient

Standard

refer

clamp

such

adapter

mm

circuit.

monitor

monitor

as

accessories;

Accessories:

Tee

a

convenient

use

Accessories

to

Figure

are

the

Modulus

kit

Manifold

is

to

is

to

the

universal

shelf

not

and

be

be

2.

included

a

sensor

refer

adapts

used

place

used

or

pole.

are

Note

II

Anesthesia

to

the

as

to

keep

in

mounting

supplied

that

with

cord

a

a

monitors

extension

Figure

15

mm

portable

the

"permanent"

the

sensor

sensor

clamp

with

probe

Svstem.

3

on

unit,

to

the

oxygen

holder

that

page

probe

probe

location

attach

kit

are

are

7.

the

and

built

available

to

the

probe

when

(not

the

the

into

patient

holder

not

in

built

monitor

&

universal

a

use.

into

22

mm

Tee

0212-0763-100

Manifold

©

6)

Universal

0237-2032-700

Probe

Holder*

0237-2031-800

Mounting

Clamp*

©

Figure

Page

2.

6

Standard

Items

system

Accessories

marked

installations.

with

asterisk

(*)

are

not

å

supplied

Section

with

6

|

One

V

と

Page 13

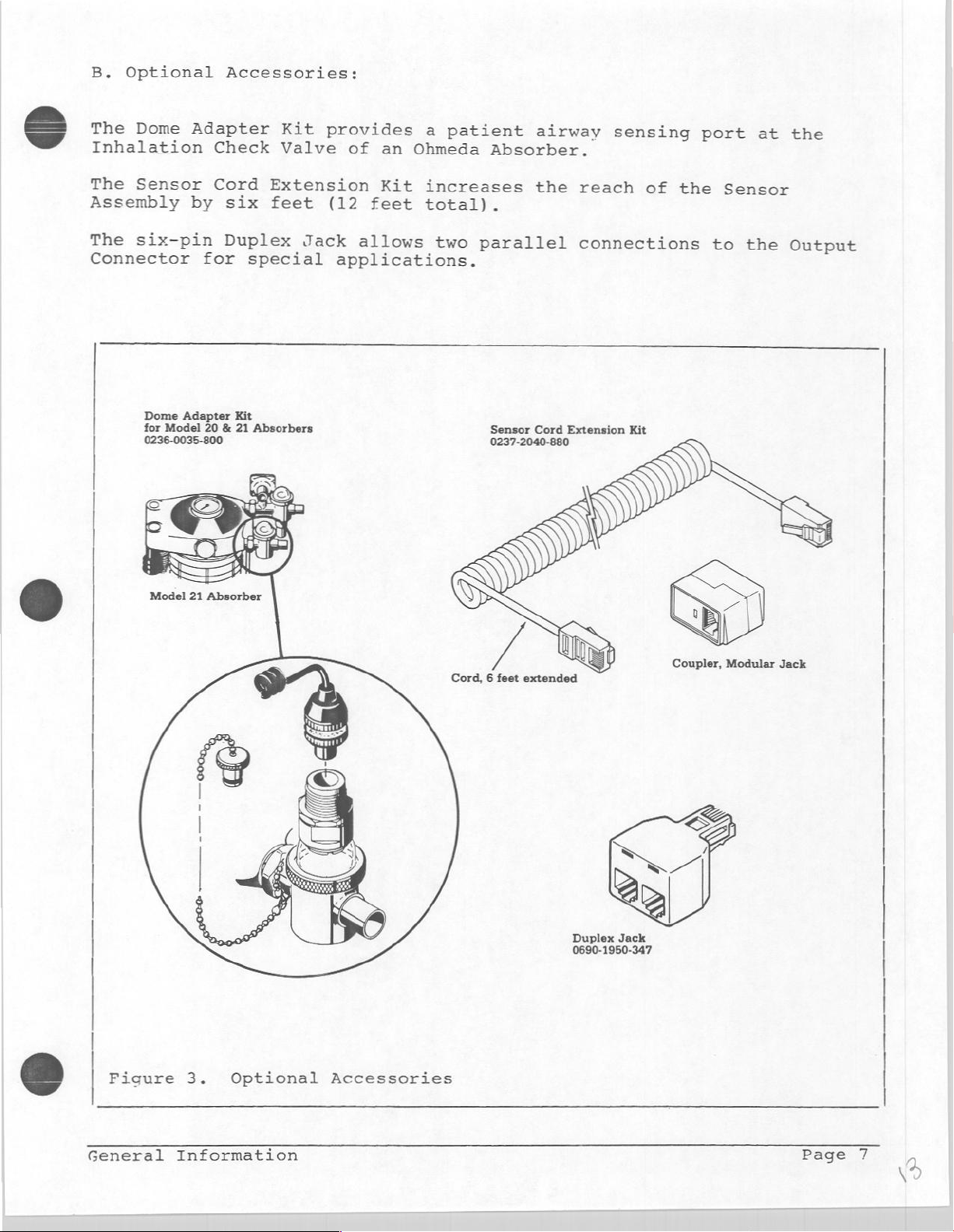

B.

Optional

The

Dome

Inhalation

Accessories:

Adapter

Check

Kit

Valve

provides

of

an

a

patient

Ohmeda

airway

Absorber.

sensing

port

at

the

The

Assembly

The

Connector

Sensor

six-pin

Dome

for

0236-0035-800

by

for

Adapter

Model

Cord

six

Duplex

special

Kit

20 & 21

Extension

feet

Jack

Absorbers

Kit

(12

feet

allows

applications.

increases

total).

two

parallel

Sensor

0237-2040-880

the

reach

connections

Cord

Extension

of

Kit

the

Sensor

to

the

Output

Figure

3.

Optional

Accessories

Cord, 6 feet

extended

È

Duplex

0690-1950-347

Jack

Coupler,

Modular

Jack

General

Information

Page

7

vd

Page 14

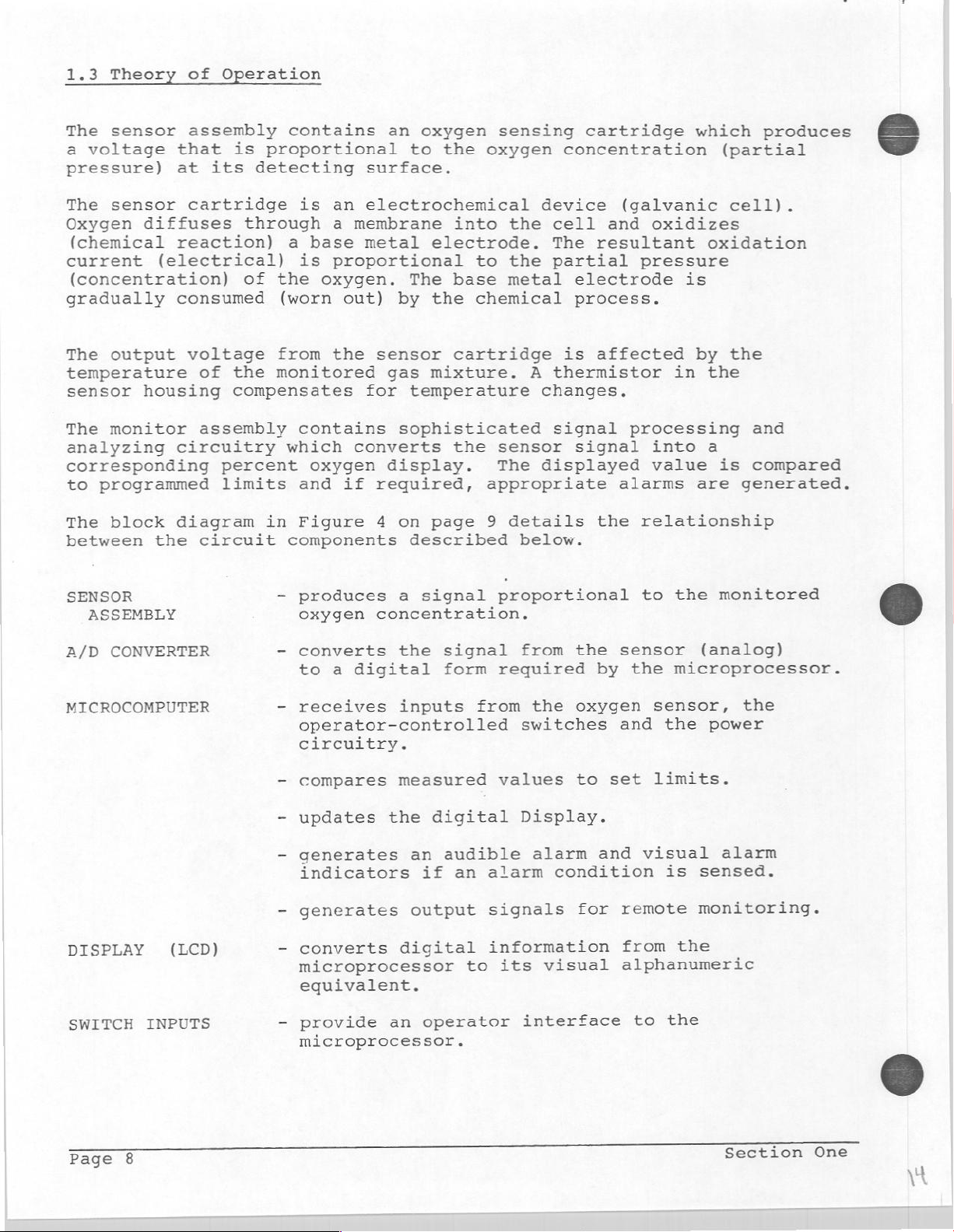

1.3

Theory

of

Operation

The

Oxygen

sensor

a

voltage

pressure)

The

sensor

(chemical

current

that

at

diffuses

reaction)

(electrical)

(concentration)

gradually

The

output

consumed

temperature

sensor

The

analyzing

housing

monitor

circuitry

corresponding

to

programmed

The

block

between

diagram

the

assembly

is

its

cartridge

through

of

voltage

of

the

compensates

assembly

percent

limits

circuit

contains

proportional

detecting

is

an

a

a

base

is

proportional

the

oxygen.

(worn

from

out)

the

monitored

contains

which

oxygen

and

in

Figure

components

an

oxygen

to

surface.

electrochemical

membrane

metal

electrode.

The

by

the

sensor

gas

mixture.

for

temperature

sophisticated

converts

display.

if

required,

4

on

page

described

sensing

the

oxygen

into

to

base

chemical

cartridge

the

sensor

The

appropriate

9

concentration

device

the

cell

The

the

partial

metal

is

A

thermistor

changes,

signal

displayed

details

below.

cartridge

(galvanic

and

resultant

pressure

electrode

process.

affected

processing

signal

alarms

the

relationship

which

oxidizes

oxidation

is

by

in

the

into

a

value

are

produces

(partial

cell).

the

and

is

compared

generated.

6

SENSOR

ASSEMBLY

A/D

CONVERTER

MICROCOMPUTER

DISPLAY

SWITCH

INPUTS

(LCD)

-

produces

oxygen

-

converts

to

-

receives

operator-controlled

circuitry.

-

compares

-

updates

-

generates

concentration.

a

digital

measured

the

indicators

-

generates

converts

-

microprocessor

equivalent.

provide

-

an

microprocessor.

a

signal

the

signal

form

inputs

digital

an

audible

if

an

output

digital

operator

proportional

from

required

from

the

switches

values

Display.

alarm

alarm

signals

information

to

its

interface

the

by

oxygen

to

and

condition

for

visual

to

the

sensor

the

microprocessor.

sensor,

and the

set

limits.

visual

is

remote

from

the

alphanumeric

the

to

monitored

(analog)

the

power

alarm

sensed.

monitoring.

Page

8

Section

One

M

Page 15

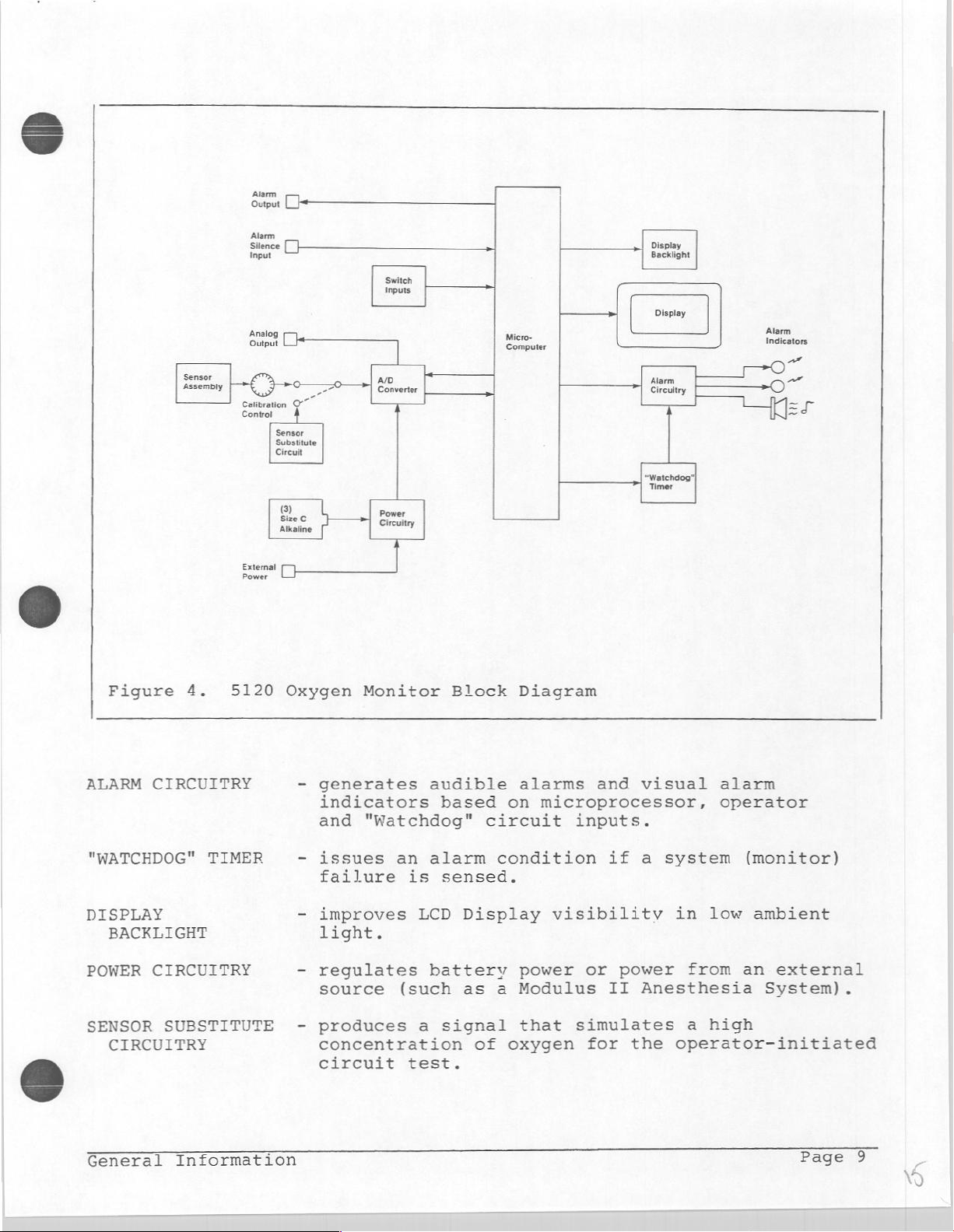

나

(7

—

Switch

Inputs

Display

Backlight

Suyu

Alarm

Silence

Sensor

Assembly

Figure

>

scemi,

4.

5120

Analog

Eri

тя

Foa

Calibration

Control

sm

hr.

=

O”

Sensor

Substitute

Circuit

©

b

Size

Alkaline

Oxygen

Converter

Power

ve

Monitor

Ao

Circuitry

Block

a

Miro

Diagram

Alarm

Circuitry

watchdog"

Timer

Alarm

z

~

0

ALARM

"WATCHDOG"

DISPLAY

POWER

SENSOR

General

CIRCUITRY

BACKLIGHT

CIRCUITRY

CIRCUITRY

TIMER

SUBSTITUTE

Information

-

generates

indicators

and

"Watchdog"

=

issues

failure

-

improves

light.

-

regulates

source

produces

-

concentration

circuit

an

is

LCD

(such

a

test.

audible

based

alarm

sensed.

Display

battery

as

signal

of

alarms

on

microprocessor,

circuit

condition

power

a

Modulus

that

oxygen

and

inputs.

if

visibility

or

power

II

simulates

for

the

visual

a

system

Anesthesia

alarm

operator

in

low

from

a

high

operator-initiated

(monitor)

ambient

an

external

System).

Page 16

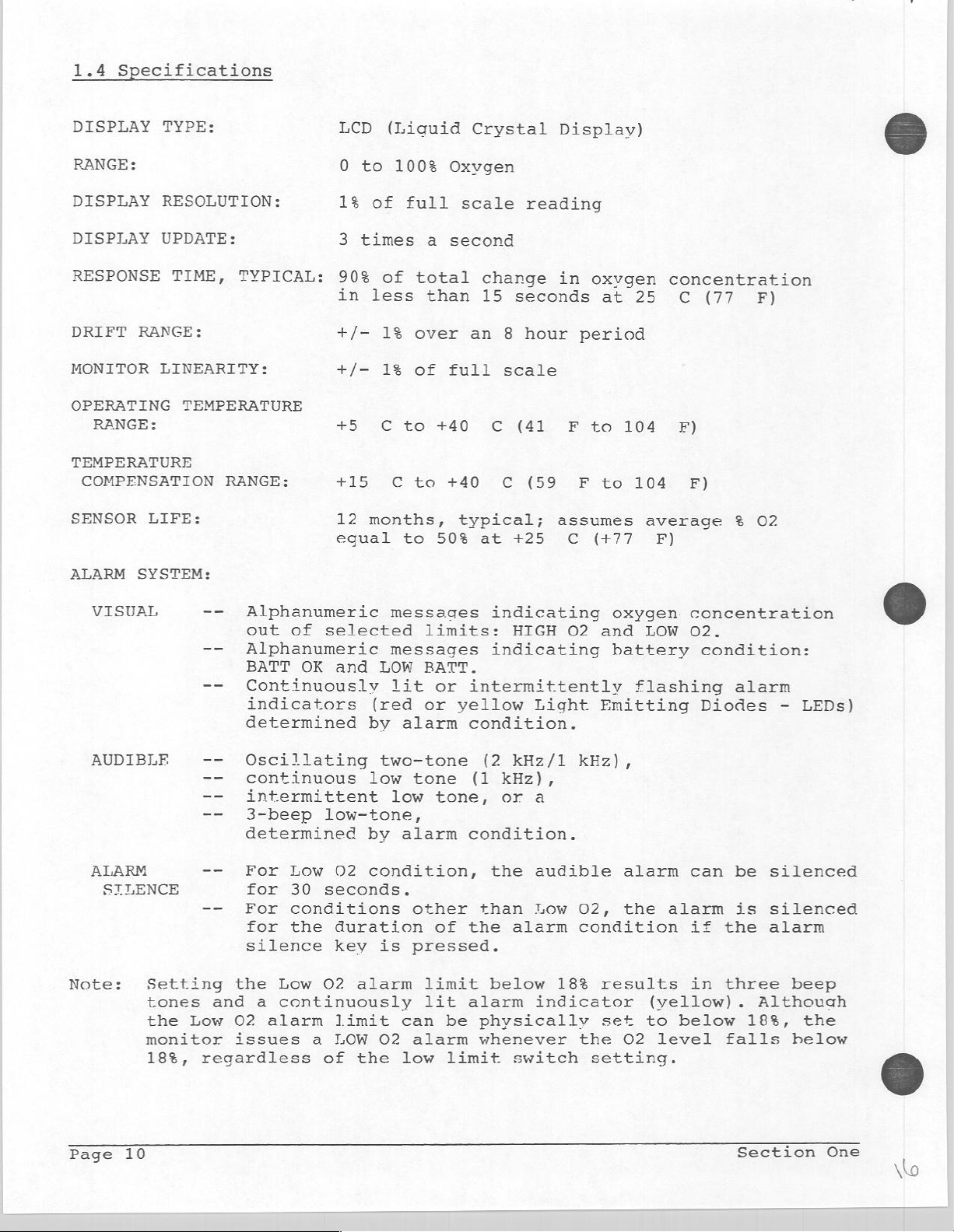

1.4

Specifications

DISPLAY

RANGE:

DISPLAY

DISPLAY

RESPONSE

DRIFT

MONITOR

OPERATING

TEMPERATURE

COMPENSATION

SENSOR

ALARM

RANGE:

RANGE:

LIFE:

SYSTEM:

TYPE:

RESOLUTION:

UPDATE:

TIME,

LINEARITY:

TEMPERATURE

TYPICAL:

RANGE:

LCD

0

to

1%

3

times

90%

in

+/-

+/-

#9

415

12

egual

(Liquid

100%

of

full

of

less

1%

1%

C

to

€

months,

to

a

total

than

over

of

110

to

50%

Crystal

Oxvgen

scale

second

change

15

an 8 hour

full

40

typical;

scale

С

ς

at

Display)

reading

in

seconds

т

(9ο

assumes

+25

oxvgen

at

period

во

r

to

G

(77.

concentration

25

104

-1045

average

E)

©

e)

F)

(77

%

E)

02

VISUAL

AUDIBLE

ALARM

Note:

SILENCE

Setting

tones

the

monitor

18%,

--

Alphanumeric

out

--

Alphanumeric

BATT

--

Continuously

indicators

determined

ーー

--

continuous

--

intermittent

--

3-beep

determined

--

For

for

--

For

for

silence

the

and

Low

02

issues

regardless

of

OK

lating

Low

30

conditions

the

Low

a

continuously

alarm

a

selected

and

LOW

(red

by

two-tone

low

low-tone,

by

02

condition,

seconds.

duration

key

is

O2

alarm

limit

LOW

02

of

the low

messages

limits:

messages

BATT.

lit

or

or

alarm

tone

low

tone,

alarm

other

of

pressed.

limit

lit

can

be

alarm

limit

indicating

HIGH

indicating

intermittently

yellow

condition.

(2

(1

Light

kHz/1

kHz),

or

a

condition.

the

audible

than

the

alarm

physically

whenever

Low

alarm

below

indicator

switch

O2

and

Emitting

kHz),

02,

condition

18%

results

set

the

setting.

oxygen

LOW

battery

flashing

alarm

the

(yellow).

to

02

level

concentration

O2.

condition:

alarm

Diodes

can

be

alarm

below

if

in

is

the

three

falls

-

silenced

silenced

alarm

beep

Although

18%,

helow

LEDs)

the

Page

10

Section

One

No

Page 17

POWER

REQUIREMENTS:

Three

size

C

alkaline

batteries

S

DRAIN:

BATTERY

BATTERY

ANALOG

DIMENSIONS:

WEIGHT:

LIFE,

TEST:

OUTPUT:

NOMINAL:

Typical

(assumes

1300

hours

hours;

a

backlight)

Manual

10

load

Depth:

and

mV/%02

impedance

Width:

Height:

0.6

kg

current,

no

day);

Automatic

at

6

cm

9

cm

17

cm

(1.3

alarms

eight

(assumes

10

(2.25

(3.50

(6.75

lbs)

3.5

or

weeks

K

ohms

inches)

inches)

without

milliamps

use

continuous

no

minimum

inches)

of

alarms

sensor

at

4.5

backlight)

use

or

use

volts

(24

of

General

Information

Page

11

Page 18

Page

12

Section

Two

Page 19

2.0

SETUP

AND

CALIBRATION

This

receive

universal

section

components

describes

conditions

regularly

2.1

Setup

As

received,

batteries

to

the

monitor.

the

monitor

Note:

Read

before

1.

Install

as

outlined

it

(2.1),

mounting

you

the

(2.4),

to

must

the

three,

tells

will

alarms

ensure

the

be

If

should

operating

using

in

you

shows

clamp

be

the

and

the

5120

installed

the

be

the

size

Section

how

to

you

(2.2),

using

monitor

includes

accuracy

Oxygen

monitor

ready

instructions

monitor.

C,

alkaline

5.3C,

set

how

while

a

Monitor

and

is

for

up

the

to

attach

identifies

operating

generates

calibration

the

of

is

the

sensor

part

of a Modulus

operation.

in

batteries

omitting

monitor

the

probe

the

the

warn

to

procedure

displayed

fully

Section

Step

assembled,

assembly

3.

when

holder

controls

monitor

you

readings

must

II

3.2

you

first

or

and

(2.3),

specific

of

follow

to

(2.5).

however,

be

attached

Anesthesia

the

System,

NOTE:

convenience.

guarantee

Replace

2.

Attach

as

described

3.

Install

as

described

Three,

can

with

the

the

Size

Since

be

fresh,

sensor

in

sensor

in

C,

all

made

Size

assembly

Section

cartridge

Section

alkaline

batteries

as

to

C,

to

5.3A.

5.3B.

batteries

their

alkaline

the

into

have

service

batteries.

monitor

the

sensor

are

a

limited

life.

included

shelf-life,

assembly

for

probe

your

no

housing

Setup

Calibration

and

Page

13

A

Page 20

2.2

The

on

Two

A.

a

Mounting

5120

post

Oxygen

or

accessories

PORTABLE:

If

the

monitor

is

provided

is

not

in

bar

Refer

use.

Monitor

(shelf)

are

provided,

to

is

to

protect

can

Figure

used

in

be

the

as

the

used

area

one

for

5.

a

stand-alone

sensor

as

a

portable

of

intended

each

situation.

probe while

unit,

instrument

use

(*).

a

holder

the

monitor

or

mounted

Align

mounting

Screw

MOUNTED:

If

the

built

described

4

cm

(1-5/8

in

diameter.

The

monitor

ball

joint

Tighten

Screw

the

monitor;

housing.

Attach

used.

Position

large

the

probe

hole

the

bolt

Refer

monitor

into

a

below.

which

the

the

mounting

the

clamp

Loosen

the

retaining

holder

in

the

in

firmly

to

Figure

is

to be

system),

The

inches)

attachment

can

large

ensure

the

retaining

to

large

monitor

nut

back

attach

clamp

thick

be

clamp

a

the

to

to

with

the

of

(finger-tight);

6.

placed

can

or a pole

and the

swiveled

nut

into

firm

grip

shelf

retaining

the

desired

hold

the

retaining

the

monitor.

in a permanent

the

universal

be

attached

up

clamp

to

the

between

or

are

25

degrees

lock

threaded

pole

nut

where

to

viewing

monitor

pin and

do

not

mounting

to

to 5 cm

held

in

the

ball

hole

the

clamp

the

free

angle.

in

place.

the

use

location

a

shelf

(2

inches)

together

any

direction.

joint

in

the

and

monitor

the

ball

threaded

tools.

(not

clamp

up

to

by

in

back

the

is

joint.

Tighten

as

a

place.

of

monitor

to

be

the

The

(*)

Modulus

Page

14

oxygen

Anesthesia

II

monitor

can

System.

also

be

Refer

installed

the

to

systems:

in

System's

manuals

such

as

details.

for

Section

the

Two

10

Page 21

Figure

5.

Probe

Holder

Shelf

Mount

Pole

Mount

Figure

Setup

and

6.

Universal

Calibration

Mounting

Clamp

Page 22

2.3

Controls

and

Components

This

during

Functions

section

the

described.

(Refer

1.

to

BATTery

to

Note:

Modulus

set

the

the

power

will

left

prevent

Normally

is

sensor

sensor

stabilize

identifies

operation

are

Figure

turn

If

to

the

external

BATTery

source

sound,

on

turned

assembly

cartridge

and

defined

7

POWER

the

the

II

Anesthesia

OFF

and

on

page

Switch:

monitor's

monitor

position

power

POWER

is

then

indicating

battery

this

the

on;

power.

alarm.

monitor

no

warm-up

has

has

sensor. Refer

the

controls

maintenance

their

17)

This

battery

is

installed

System,

if

source

switch

turned

that

Turn

is

ready

is in

or

been

disconnected

been

to

and

of

effects

is a two

power

the

the

monitor

provided

the

off,

the

monitor

the

BATTery

for

standby

replaced,

the

note

components

the

5120

on

the

total

position

on

and

in a system,

battery

is

by

the

ON

position

an

intermittent

has

POWER

operation

is

required.

from

allow

on

page

encountered

Oxygen

off.

power

to be

system

been

switch

as

the

at

least

28.

Monitor.

system

rocker

such

as

switch

operated

connection.

and

the

low

tone

inadvertently

OFF

soon

as

However,

monitor,

five

are

switch

the

must

from

external

alarm

to

the

or

minutes

used

be

If

power

if

if

6

the

the

to

1A.

Automatic

switch

condition

corresponding

an

a.

b.

(*)

If

the

Anesthesia

switch

should

powered

determine

To

manual

Page

battery

16

is

audible

If

the

batteries

operates

backlight);

a

day,

the

of

When

operation.

condition

continuous

the

monitor

indicator,

should

(assumes

to

continue

ensure

monitor

System,

be

external

an

by

the

test

Battery

first

of

alarm

for

turned

the

batteries

messages

is

at

this

of

operation.

batteries

displays

and

sounds

no

use

uninterrupted

is

installed

the

internal

left

in

source)

condition

described

as

Test:

on

is

generated(*).

are

fresh

least

is

the

1,300

equal

The

batteries

reach

a

"LOW

3

to

operate

of

backlight),

Off

the

the

of

Whenever

(and

displayed;

periodically

is

tested

(size

hours

to

eight

monitor

the end

BATT"

low-tone

message,

properly

monitoring.

in

a

system,

batteries

position

not

are

internal

item

in

the

monitor's

automatically

and

C,

alkaline)

(assuming

weeks

displays

will

replace

allow

of

their

beeps.

for

(because

whenever

tested

batteries,

on

3

Battery

thereafter)

if

required,

the

.no

of

continuous,

a

"BATT

more

useful

lights

Although

approximately

the

such

the

batteries

as

the

the

the

automatically.

perform

page

18.

and

monitor

alarms

OK"

message

than

life,

yellow

the

Modulus

battery

monitor

Power

the

a

an

or

24

8

hours

the

monitor

6

hours

power

is

the

Section

use

hour

(LED)

II

©

of

if

@

Two

Page 23

c.

If

the

battery

monitor

-

an

-

the

1

the

-

the

goes

audible

yellow

LOW

digital

BATT

power

into

alarm

alarm

message

display

is

a

"shutdown"

sounds

indicator

appears

is

below

blank.

an

(intermittent

(LED)

acceptable

mode:

flashes,

on

the

low-tone)

display,

threshold,

,

and

the

Figure

Setup

7.

and

Oxygen

Calibration

Ohmeda

Oxygen

Monitor,

5120

Monitor

Front View

Page

17

Page 24

2.

a.

b.

DISPLAY:

to

show

also

battery

displays

The

monitor

oxygen

Messages

-

The

LOW

concentration

refer

-

The

HIGH

oxygen

limit

-

The

BATT

require

this

-

The LOW

the

section.

batteries;

The

oxygen

the

concentration

alphanumeric

status.

displays

in

1%

increments.

appear

02

message

is

to

item

02

4

message

concentration

selected;

OK

message

attention

BATT

message

on

less

of

refer

at

refer

monitor

of

oxygen

the

display

appears

than

this

section.

appears

is

greater

to

indicates

this

indicates

to

items

uses

a

oxygen

messages

concentrations

to

whenever

the

low

whenever

than

item

4

of

that

time;

refer

a

1A

Liquid

in

for

indicate

the

02

the

this

the

low

voltage

and

Crystal

numeric

alarm

displayed

alarm

the

displayed

high

section.

batteries

to

items

3b

of

Display

form.

conditions

from

various

"00"

limit

02

alarm

do

1A

condition

this

section.

The LCD

and

to

"100"%

conditions.

oxygen

selected;

not

and

3b

of

(LCD)

of

3.

a.

b.

BATTery

position

display

and

to

are

operational.

A

Liquid

depends

visible.

difficult

activates

display.

to

turn

Note:

System,

The

condition

the

top

circuitry

is

displayed,

monitoring

Note:

System,

of

power

TEST

switch'used

in

subdued

verify

Crystal

on

When

to

an

The

the

If

the

the

half

(along

If

the

the

is

(CÔ-)

that

ambient

the

read.

internal

light

backlight

monitor

backlight

of

of

the

replace

of

the

monitor

batteries

off and

and

CIRCUIT

to

turn

lighting,

the

display

Display

light

room

Pressing

light

remains

off.

is

is

the

batteries

switch

with

the

the

patient.

is

can

the

TEST

on

the

to

perform

circuitry

(LCD)

to

make

light

installed

always

installed

BATTery

is

the top

that

on

until

(BATT

backlight).

batteries

only

Switch:

backlight

does

can

be

not

the

digits

low the

half

continuously

the

in a Modulus

on

whenever

be

TEST)

to

in a Modulus

tested

POWER

This

a

manual

and

the

produce

display

of

switch

checked

activates

If

the

ensure

if

switch

is a three-

for

viewing

battery

alarms

light.

(characters)

may

the

switch

illuminates

is

again

II

Anesthesia

the

system

manually.

battery

LOW

BATT

uninterrupted

II

Anesthesia

the

external

is

on.

the

test,

It

be

pressed

is

Pressing

test

message

source

the

on.

Page

18

Section

Two

AM

Page 25

The

electronic

periodically

messages,

functional.

(Circuit

a

high

messages

are

turned

If

any

sequence,

and

Test)

concentration

are

of

the

the

circuitry

to

verify

the

Pressing

electronically

displayed

on

(along

monitor

monitor

visual

of

with

of

that

alarm

the

bottom

oxygen

and

the red

one

functions

must

not

the

monitor

the

digital

indicators

portion

substitutes

(88

short

fail

be

used

to

and

audio

to

should

display,

of

102

yellow

alarm

operate

until

(see

the

a

voltage

%).

repairs

be

the

item

switch

All

alarm

beep).

during

tested

displayed

6)

are

simulating

alarm

indicators

the

are

HIGH

test

made.

02

[00

Oxygen

Oxygen

Figure

Setup

8.

and

Calibration

Monitor

Monitor,

Front

View

(continued)

Page

19

25

Page 26

Alarm

and

Limit

the low

concentration

Low

02

and

with

LOW

than

LOW

flashes

corresponding

02:

02

the

message

Whenever

value

and

Switches:

oxygen

is

High

set

is

an

oscillating

alarm

less

02

alarm

alarms.

the

by

displayed,

Use

these

limits.

than

or

limit

displaved

the

Low

two-tone

switches

When

greater

switch,

oxygen

02

alarm

the red

to

the

displayed

than

the

concentration

limit

alarm

audible

set

the

values

monitor

switch,

indicator

alarm

the

oxygen

will

sounds.

high

set

is

the

(see

oxygen

by

the

respond

less

item

6

6)

5.

NOTE:

yellow

beeps.

monitor

regardless

is

set.

HIGH

than

02

02:

the

message

flashes

Note:

the

HIGH

flush

Alarm

procedures.

Indicators

Emitting

The

red

the

value

The

yellow

--

the

High

--

the

--

the

Setting

alarm

If

the

will

of

Whenever

value

is

and

an

Setting

02

alarm;

Diodes

LED

set

LED

displayed

O2

switch,

sensor

batteries

the

Low

indicator

displayed

issue

how

displayed,

set

a

far

a

by

intermittent

the

High

this

(00):

(LEDs)

flashes

by

the

flashes

%02

is

disconnected

have

02

limit

(LED)

concentration

high

displayed

below

the

the

priority

High

02

mode

The

to

visually

whenever

Low

02

whenever

is

greater

discharged

on,

18%

oxygen

02

yellow

low-tone

alarm

is

alarm

the

switch.

or

switch

accompanied

the

alarm

below

falls

alarm

Low

02

concentration

limit

alarm

(same

indicator

alarm

limit

useful during

switch

silence

indicate

displaved

than

the

defective,

below

value

a

useable

18%

by

below

as

alarm

switch,

sounds.

to

100%

switch

an

alarm

02

is

or

turns

three

18%,

LOW

limit

"00"

oxygen

includes

less

set

level.

the

low-tone

the

02

alarm)

switch

is

greater

the

HIGH

(see

item

disables

condition.

than

by

the

two

6)

Light

Alarm

6.

"alarm

visual

than

for

In

continuously

period.

Page

The

yellow

-- a LOW

-

the

BATTery

Low

-- a system

Silence

silence"

alarm

02

Low

the

duration

either

20

case,

LED

is

02

limit

(monitor)

Switch

switch

indicators

alarm

of

a

(not

continuously

condition

switch

failure

Xx):

(

turns

remain

conditions,

the

alarm

flashing

flashing)

occurs,

is

set

is

During

off

active

the

condition.

alarm

for

lit

whenever

below

sensed.

a

alarm

the

audio

indicator

duration

the

18,

or

alarm,

02

Low

for

throughout.

alarm

switches

of

30

is

the

pressing

seconds;

other

For

silenced

to

Alarm

being

Silence

Section

the

the

on

G

Two

20

Page 27

HIGH

02

|

IDO

LI

LI

LOW

02

Figure

7.

Sensor

housing

and the

The

be

Setup

9.

Assembly:

sensor

installed

and

Calibration

connector

Oxygen

(probe)

cartridge

before

Monitor,

The

for

the

which

is

use

Front

sensor

oxygen

joins

not

(refer

View

assemblv consists

sensor

the

part

to

(continued)

sensor

of

the

section

cartridge,

assembly

sensor

of

5.3.B).

the

the

to

assembly;

coiled

the

monitor.

it

cable,

must

Page

21

2

Page 28

11

O

VOLTS

1.5

CAES

bt,

VOLTS

1,5

ere

VOLTS

15

3

Preoperative

See

Operation & Maintenance

1,

Depress

displayed,

alkaline

"Batt,

Depress

and

Calibrate

“Low

*Low

20%.

Calibrate

minutes

minutes

If

the

cartridge.

replacement

Checklist

and

hold

immediately

"C"

size.

Power”

on

“Circuit

102.

to

21%

O,"

alarm

O;”

to

below

Alarm

must

to

99% once each

to

stabilize.

after

returning

unit

will

not

See

Operation & Maintenance

instructions

“Batt.

Retest.

and external

Test”

switch.

in

room

adjustment

21%

and

sound

Display

calibrate

CT

PTP

NY

Manual

Test”

change

“Batt.

air,

to

turn

to

room

for

switch.

all

three

Test”

must

power

Display

allow 2 minutes

22%.

Alarm

“High

month,

or

must

return

air.

to

either

21%

detailed

If

off.

must

O,“

as

instructions.

“Low

Batt.”

batteries,

must

alarm

required.

or

Manual

using

be

performed

(e.g.

Modulus

read

between

tostabilize.

sound.

adjustment

to

21%21%

99%,

replace

for

message

fresh

with

II)

88

Tum

Set

to

allow

2

within

3

probe

test

and

is

Figure

Page

22

10.

Battery

Compartment

Section

Two

Page 29

(Refer

8.

Front Cover:

for

and the

to

easy

Figure

access

calibration

10

The

on

to

page

lower

the

control.

22)

portion

Preoperative

of

the

front

Checklist,

panel

the

flips

down

batteries,

Preoperative

brief

monitor

monitor

Refer

πο,

Batteries:

alkaline

a

Section

1%

CALibration

is

calibration

the

in

Similar

diminishes

change.

Check

oxygen

Section

procedure

a

is in

to

manual

5.3C

proportional

monitored

the

Preoperative

to

the

to

2.5

Checklist:

to be

new

patient.

operating

section

The

3.1

oxygen

batteries(*).

battery

Control:

test

describes

to

control

oxygen

batteries,

with

monitor

assure

time.

periodically

the

details

The

followed

Follow

order.

for

the

monitor

The

monitor

described

how

to

The

oxygen

the

oxygen

is

used

concentration.

Checkout

the

output

The

CALibration

monitor's

the

calibration

inside

daily

this

Preoperative

is

procedure

powered

includes

in

items

replace

sensor

concentration

to

set the

Procedure.

from

with

specified

of

the

front

or

whenever

Checkout

by

1A

spent

produces

displayed

Room

a

air

the

sensor

adjustment

"100%"

accuracy.

procedure.

cover

preparing

to

ensure

Procedure.

three,

an

automatic

and

batteries.

monitored.

3b

a

size

of

current

reading

(21%

02)

cartridge gradually

compensates

concentration

contains

that

C,

and

this

The

to

is

specified

a

to

the

section.

that

match

for

of

the

The

against

calibration

(*)

monitor

the

POWER

calibration

the

If

switch

inadvertent

is

monitor

should

Off)

to

control

movement,

required.

installed

is

operated

be

conserve

to

is

housed

but

in

from

the

behind

provides

Modulus

a

the

monitor's

the

II

system's

front

easy

internal

access

Anesthesia

power

panel

when

System,

source

batteries.

to

guard

(BATTery

Setup

and

Calibration

Page

23

Page 30

(Refer

12

Sensor

the

13.

Output

to

--

WARNING:

to

result

value

Refer

description

MOUNTING:

14,

probe

be

clamp

to

three

an

- a

- a

pin

used

Figure

(Input)

back

of

the

Connector:

features

analog output

digital

connection

Connect

5

of

the

in an

displayed

to

Appendix

of

If

holder

in

a

instead.

11

on

page

Connector:

monitor

The

of

output

for

only

analog

output

on

the

A

each

the

monitor

to

this

"permanent"

Refer

25)

The

through

output

the

5120

of

the

displayed

indicating

remote

a

high

output

alarm

voltage

oxygen

for the

feature.

is

threaded

location,

to

section

sensor

an

connector

Oxygen

a

impedance

connector.

that

monitor.

pin

connections

intended

insert;

1.2,

assembly

8-pin

Monitor:

percentage

sensed

silencing.

is

lower

for

if

attach

Accessories.

modular

provides

alarm

device

Improper

than

and

portable

the

monitor

the

cable

connects

jack.

remote

of

oxygen,

condition,

(at

least

loading

the

corresponding

a

detailed

use,

is

universal

to

access

and

10 K ohms)

will

attach

to

mounting

the

e

Page

24

Section

Two

20

Page 31

14

13

Figure

11.

Rear

View

À

Caution:

device

to

sale

Output

Federal

by

cr

on

Setup

and

Calibration

Page 32

2.4

Alarms

The

5120

present

limits,

changed

of

alarm.

summarized

Oxygen

at

its

sensor.

alarms

and

condition.

The

alarms

in

Chart

Monitor

messages

The

1

displays

If

severity

are

on

the

sensed

are

described

page

38.

the

percent

values change

generated

of

the

in

to

condition

the

following

of

oxygen

alert

concentration

beyond

the

operator

determines

paragraphs

selected

the

and

of

the

level

NOTE:

and,

(not

In

30

alarms,

Pressing

if

flashing)

the

seconds

condition.

1.

If

limit

2.

If

alarm

3.

As

generates

flashing,

case

the

the

of

(if

alarm

detected

set

Audible

Red

Low

the

detected

limit

Audible

Yellow

HIGH

the

batteries

the

for the

a

the

point

alarm

02

message

set

Alarm

02

two

"Alarm

causes

Low

02

Low

remains

oxyaen

or

alarm

indicator

oxygen

point,

alarm

message

reach

levels

Silence"

the

duration

alarm,

02

alarm

silent

concentration

below

concentration

a

indicator

the

of

alarm:

alarm

of

the

condition

18%,

(LED)

less

end

switch

indicator

the

alarm

for

a

urgent

(LED)

of

Alarm

the

high

-

oscillating

-

flashing

-

displayed

-

intermittent

-

flashing

-

displayed

their

turns

to

Silence

will

again

still

duration

falls

priority

rises

alarm

useful

off

be on

exists);

of

below

alarm

above

is

generated:

life,

the

audible

continuously

period.

sound

the

the

after

for

current

Low

is

two-tone

the

High

low-tone

the

alarm

the

other

alarm

O2

alarm

generated:

(high/low)

02

monitor

1st

LEVEL

LOW

Yellow

Audible

Although

approximately

replace

2nd

LEVEL

Display

Audible

Yellow

LOW

The

must

-

CAUTION:

BATT

alarm

alarm

the

-

SHUTDOWN:

-

alarm

alarm

BATT

monitor

replaced

be

message

indicator

monitor

the

6

batteries

Blank

indicator

message

indicates

hours

before

(LED)

should

(assumes

ensure

to

(LED)

a

high

the

-

displayed

-

lit

-

three

continue

no

uninterrupted

-

intermittent

flashing

-

-

displaved

priority

monitor

(continuously)

(3)

low-tone

operate

to

backlight),

of

use

alarm;

be

can

monitoring.

low-tone

the

used.

beeps

properly

hatteries

Section

for

Two

Page 33

4.

If

the

Low

O2

alarm

limit

switch

is

set

below

18%:

о

을

5.

If

disconnected:

6.

If

a

The

the

7.

When

Power

the

set

is in

is

under

Audible

Yellow

the

sensor

Audible

Yellow

Display

the

System

"Watchdog"

Fail

Audible

Yellow

Display

monitor

troubleshooting

used

batteries.

to

turned

in a Modulus

switch should

the

On

use,

the

off,

battery

Alarm

alarm

assembly

alarm

alarm

alarm

alarm

alarm

cannot

If,

position

monitor

indicating

power.

indicator

is

indicator

circuitry

is

generated:

indicator

be

used

guide

II

be

set

however,

while

will

(LED)

interrupted

(LED)

detects

(LED)

until

repairs

(section

Anesthesia

to

the

the

monitor's

the

Modulus

generate

that

the

-

three

-

lit

(continuously)

by

-

intermittent

-

flashing

-

shows

a

computer

-

continuous

-

lit

(continuously)

-

blank

5.2) for

System,

Off

position

an

alarm

monitor

(3)

low

component

00

failure,

low-tone

are

made,

details.

the

to

Batt

II

Power

Anesthesia

when

remains

tone

failure

low-tone

refer

monitor's

conserve

switch

the

turned

beeps

to

System

system

on,

or

Batt

is

is

Audible

Display

alarm

-

intermittent

-

shows

oxygen

low-tone

concentration

Setup

Calibration

and

Page

27

2

る

Page 34

2.5

Calibration