Ohmart Vega W-4510 Technical Reference Hardware Manual

Technical Reference

MANUAL

W-4510 WEIGH SCALE WITH GEN 2000

®

ELECTRONICS MODEL W-4510 WITH

FREQUENCY OUTPUT

W-4510 Weigh Scale

with GEN2000® Electronics

Technical Reference Manual

Model W-4510

with

frequency output

Manual part number 31559-US

Version 1.0

Preface

Revision history

Table 1: Revision history

Manual version Description Date

1.0 Initial release. Formerly 241818. 051201

Copyright © 2001-2005 Ohmart/VEGA Corporation, Cincinnati, Ohio. All rights reserved.

This document contains proprietary information of Ohmart Corporation. It shall not be reproduced in whole or in part,

in any form, without the expressed written permission of Ohmart/VEGA Corporation.

The material in this document is provided for informational purposes and is subject to change without notice.

®

is a registered trademark of The HART® Communication Foundation.

HART

GEN2000 ® is a registered trademark of the Ohmart/VEGA Corporation.

ISO 9001 approval by Lloyd’s Register Quality Assurance Limited, to the following Quality Management System

Standards: ISO 9001:1994, ANSI/ASQC Q9001-1994, Approval Certificate No. 107563.

Ohmart/VEGA Corporation

4241 Allendorf Drive

Cincinnati, Ohio 45209-1599 USA

Voice:

(513) 272-0131

FAX:

(513) 272-0133

Web site

www.ohmartvega.com

Field service email

fieldservice@ohmartvega.com

WARNING

Use this equipment only in the manner that this manual describes. If you do not use the

equipment per Ohmart/VEGA specifications, the unit is not CE compliant, and may be

damaged or cause personal injury.

ii W-4510 Weigh Scale Technical Reference Manual

Contents

Contents iii

Tables vii

Figures ix

Procedures xi

Procedures xi

Explanation of symbols xiii

Your comments xv

CHAPTER 1 : INTRODUCTION 1

Nuclear materials notice 1

Unpacking the equipment 2

Storing the equipment 3

Storing the source holder 3

Storing the detector 3

Specifications 4

Typical applications 5

Belt loading 5

Loading rate 5

Where to find help 6

Ohmart Customer Service 6

System overview 7

Principles of operation 9

Communicating with the gauge 10

Smart Pro software 10

Step-by-step method 10

Direct access method 10

Smart listing 10

Sample Smart Listing 11

Preface

CHAPTER 2 : INSTALLATION 13

Location considerations 13

Avoid source cross-talk 13

Blending applications 13

Prevent process accumulation 13

Re-cal considerations 14

Restrict air gap access 14

Weigh scale assembly 15

Source on/off lights 16

Securing the weigh scale assembly 18

Mounting the electronics console 18

Smart Pro mounting 18

Pro Pac mounting 20

Rack mount computerized electronics 21

On/Off switch with circuit breaker and pilot light 22

CPU board 22

I/O termination board 23

Case 23

Power supply 23

Hinged front panel 23

Processor select circuit board 23

Key pad assembly 23

LCD display interface circuit board 23

Operator display/interface 23

W-4510 Weigh Scale Technical Reference Manual iii

Preface

Display window 24

Data entry keys 25

Function keys 27

Access keys and indicators 28

Wiring the equipment 29

Smart Pro and Pro Pac connections 32

Power 35

Switch for CE compliance 35

Conduit 35

Auxiliary and optional equipment 36

Tachometer 36

Line down contacts 37

Commissioning the gauge 38

Can you remove the source holder lock? 38

Field service commissioning cal checklist 40

CHAPTER 3 : SETUP 41

Detailed screen description 41

Setup menus 41

Time and date 42

Time 42

Date 42

Memory functions 43

Upper Ram transfers 44

EEPROM transfers 45

Upload and download configuration program 46

Password functions 47

Analog output setup 48

Measurement span setup 54

Measurement units setup 57

Custom units 57

Comm port setup 60

Temperature compensation setup 62

Operator 63

Input channel setup 64

520 Frequency input channel #1, primary sensor signal (frequency only) 64

521 Frequency input Channel #2, tachometer/speed input 64

Output channel setup 65

Product codes 66

Channel#1 product codes 66

Channel #2 product code 66

Get linearizer data points 68

Data Collect Setup 71

Data collection interval 71

Measurement cutoff 72

Filtering 73

Type (RC exponential or rectangular window) 73

RC exponential 73

Rectangular window filtering 73

Diagnostic RC filter 73

Damping 74

Fast response cutoff 74

Selecting the filter type 75

Selecting a filter type, damping, and fast cutoff 75

Adaptive filter 76

Totalizer menu 77

Minus sign configuration 80

iv W-4510 Weigh Scale Technical Reference Manual

CHAPTER 4 : CALIBRATION 81

Process calibration 82

Calibration main menus 82

Product code screen 82

Initial calibration overview 83

Step 1: Verifying the proper measurement units 84

Step 2: Verifying the proper measurement span entries 84

Step 3: Determine the linearization 85

Step 4: Collecting data for the zero and span 86

Calibrate zero—low on process channel #1 86

Calibrate high on process—channel #1 88

Step 5: Calculating the calibration 90

Two point calibration 90

Step 6: Setting the absorber value 92

Step 7: Saving the calibration information to EEPROM 93

Periodic calibration—channel #1 functions 94

Periodic calibration overview 94

Step 1: Simple cal on low 95

Step 2: Cal Hi on absorber 96

Step 3: Simple data collect 97

Simple data collect 97

Step 4: Absorber value setup 98

Step 5: Saving the calibration information to EEPROM 98

Calibration—channel #2 functions 99

Step 1: Collecting data for the zero and span 99

Cal Lo on process 99

Calibrate zero—low on process Channel #2 100

Calibrate high on process—Channel #2 101

Step 2: Calculating the calibration 103

Step 3: Saving the calibration information to EEPROM 103

Current loop (analog output) calibration 104

Analog output 104

Calibration of the analog output signal 104

Preface

CHAPTER 5 : DIAGNOSTICS AND REPAIR 109

Communication diagnostics 109

Bi-level input 109

Hardware diagnostics 121

Jumpers 122

LED indicators 122

LED summary table 123

Maintenance and repair 124

Periodic maintenance schedule 124

Spare parts 124

Field repair procedures 125

Requesting field service 126

Requesting field service 126

Returning equipment for repair to Ohmart 126

Returning equipment for repair 127

APPENDIX I: PARAMETER BLOCKS 129

Screen 520 Frequency Input Block 129

Screen 522 Frequency Output Block 132

Screen 524 Auto Zero Log 133

Screen 525 Totalizer Block 134

Screen 527 Product Code Block 135

W-4510 Weigh Scale Technical Reference Manual v

Preface

Screen 528 Linearizer Block 137

APPENDIX II: AUTO ZERO FEATURE 139

Auto zero log 142

INDEX 143

vi W-4510 Weigh Scale Technical Reference Manual

Tables

Table 1: Revision history ii

Table 2: Explanation of symbols xiii

Table 3: Specifications list 4

Table 4: Contact information 6

Table 5: Sample Smart Listing 11

Table 6: Function key descriptions 27

Table 7: Terminal names and descriptions 30

Table 8: W-4510 interconnect to Smart Pro or Pro Pac—Measure signal 32

Table 9: W-4510 interconnect to Smart Pro or Pro Pac—tachometer signal 32

Table 10: Tachometer interconnect to Smart Pro or Pro Pac—line down signal 32

Table 11: Access levels and passwords 47

Table 12: Smart Pro CPU board jumper information 50

Table 13: Smart Pro CPU board test point information 51

Table 14: Linearizer curve chart 70

Table 15: Screen 092 minus sign configuration 80

Table 16: Calibration records 107

Table 17: Bi-level inputs, terminals, grounds, addresses, and LEDs 109

Table 18: Power supply board test points and labels 122

Table 19: CPU board test points and labels 122

Table 20: Jumper division values 122

Table 21: Power supply board LED summary table 123

Table 22: CPU board LED summary table 123

Table 23: Maintenance schedule 124

Table 24: Spare part numbers 124

Table 25: Screen 520 OR 521 Frequency input block 130

Table 26: Screen 522 Frequency Output block Channel #1 132

Table 27: Screen 522 Frequency Output block Channel #2 132

Table 28: Screen 524 Auto zero log 133

Table 29: Screen 525 Totalizer block #1 134

Table 30: Screen 525 Totalizer block #2 134

Table 31: Screen 527 Product code block 136

Table 32: Screen 528 Linearizer block 137

Table 33: Screen 529 Auto Zero feature 140

Table 34: Screen 529 Auto Zero feature 142

Preface

W-4510 Weigh Scale Technical Reference Manual vii

Preface

Notes

viii W-4510 Weigh Scale Technical Reference Manual

Figures

Figure 1: System overview 7

Figure 2: Typical source holder shutter mechanism 8

Figure 3: W-4510 assembly 15

Figure 4: Typical W-4510 detector outline 16

Figure 5: Typical W-4510 source holder outline 17

Figure 6: Typical Smart Pro dimensions 19

Figure 7: Typical Pro Pac dimensions 20

Figure 8: Rack mount interface components 21

Figure 9: Simplified CPU board 22

Figure 10: Data entry/function keys 26

Figure 11: Rack mount displays 28

Figure 12: Typical interconnect diagram 29

Figure 13: W-4510 terminal illustration 31

Figure 14: Typical interconnect diagram for Smart Pro 33

Figure 15: Typical interconnect diagram for Pro Pac 34

Figure 16: Setup screens 1–4 41

Figure 17: Time and date screen 42

Figure 18: Memory areas EEPROM vs. RAM 43

Figure 19: Memory backup screen 43

Figure 20: SmartPro upload and download application 46

Figure 21: Communication cable 46

Figure 22: Password function screens 47

Figure 23: Analog output setup screens 48

Figure 24: Smart Pro/Pro Pac CPU board jumper and test information 49

Figure 25: Simplified Smart Pro circuit board 50

Figure 26: Set gauge span screens 54

Figure 27: Measurement units setup screen 57

Figure 28: Comm port setup screen 60

Figure 29: Temp comp setup screen 62

Figure 30: Operator setup screens 63

Figure 31: Input channel setup screens 64

Figure 32: Output channel setup screen 65

Figure 33: Data collect setup screens 71

Figure 34: Totalizer menu screen 1of 3 77

Figure 35: Totalizer menu screens 2 and 3 of 3 77

Figure 36: Screen 092 main screen display 80

Preface

W-4510 Weigh Scale Technical Reference Manual ix

Preface

Figure 37: Cal menu screens 82

Figure 38: Product code screens 82

Figure 39: Graphical representation of the calibration curve 83

Figure 40: Cal Lo on process screen 86

Figure 41: Cal Hi on process screen 88

Figure 42: Two point calibration screen 90

Figure 43: Simple re-cal on low screen 95

Figure 44: Cal on absorber screen 96

Figure 45: Simple data collect screen 97

Figure 46: Absorber value setup screen 98

Figure 47:Cal Channel #2 function screen 99

Figure 48: Cal Lo on process screen 99

Figure 49: Cal Hi on process screen 101

Figure 50: Example of a bi-level input open circuit 109

Figure 51: Smart Pro power supply flow chart – part 1 110

Figure 52: Smart Pro power supply flow chart – part 2 111

Figure 53: Smart Pro TTL/Relay flow chart 112

Figure 54: Smart Pro frequency input 113

Figure 55: Smart Pro analog output (mA/mV) flow chart 114

Figure 56: Smart Pro analog input-2 flow chart 115

Figure 57: PRO PAC Frequency input 116

Figure 58: Pro Pac Analog Input-2 117

Figure 59: PRO PAC TTL/Relay flow chart 118

Figure 60: PRO PAC Analog Output (mA/mV) flow chart 119

Figure 61: PRO PAC AC voltage and power supply flow chart 120

Figure 62: CPU board simplified component layout 121

Figure 63: GEN2000 LED indicators 122

Figure 64: Frequency input Channel #1 screen 129

Figure 65: Frequency input Channel #2 screen 129

Figure 66: Frequency output channel screen 132

Figure 67: Totalizer screen 134

Figure 68: Product code table screen 135

Figure 69: Linearizer curve screen 137

Figure 70: Auto zero screen 140

Figure 71: History index screen 142

x W-4510 Weigh Scale Technical Reference Manual

Procedures

Procedure 1: Change time and date 42

Procedure 2: Transfer to upper RAM 44

Procedure 3: Transfer to RAM 44

Procedure 4: Upload to EEPROM 45

Procedure 5: Input password 47

Procedure 6: Change password 47

Procedure 7: Select output type 51

Procedure 8: Setup analog output Channel #1 52

Procedure 9: Setup analog output Channel #2 53

Procedure 10:Setup gauge span—Channel #1 55

Procedure 11:Setup gauge span—Channel #2 56

Procedure 12: Setup units of measurement for Channel #1 and #2 58

Procedure 13: Setup communication port 61

Procedure 14: Setup operator screen 63

Procedure 15: Setup product code 67

Procedure 16: Take datapoints for linearizer curve 69

Procedure 17: Selecting a filter type, damping, and fast cutoff 75

Procedure 18: Setting up an adaptive filter 76

Procedure 19: Setup totalizer #1 78

Procedure 20: Setup totalizer #2 78

Procedure 21: Setup totalizer #1&2 total units 79

Procedure 22: Verify units of measurement 84

Procedure 23: Verify proper measurement span entries 84

Procedure 24: Verify the curve is loaded into Smart Pro 85

Procedure 25: Collect data for zero Channel #1—low on process 87

Procedure 26: Collect data for span Channel #1—high process 89

Procedure 27: Calculate calibration—Channel #1 91

Procedure 28: Set absorber value 92

Procedure 29: Save calibration information to EEPROM 93

Procedure 30: Simple re-cal Channel #1 95

Procedure 31: Cal Hi on absorber—Channel #1 96

Procedure 32: Simple data collect—Channel #1 97

Procedure 33: Absorber value setup—Channel #1 98

Procedure 34: Collect data for zero Channel#2—low on process 100

Procedure 35: Collect data for span Channel#2—high process 102

Procedure 36: Calculate calibration—Channel #2 103

Preface

W-4510 Weigh Scale Technical Reference Manual xi

Preface

Procedure 37: Calibrate the analog output signal—Channel#1 105

Procedure 38: Calibrate the analog output signal—Channel#2 106

Procedure 39: Returning equipment for repair 127

Procedure 40: Auto Zero feature 141

xii W-4510 Weigh Scale Technical Reference Manual

Explanation of symbols

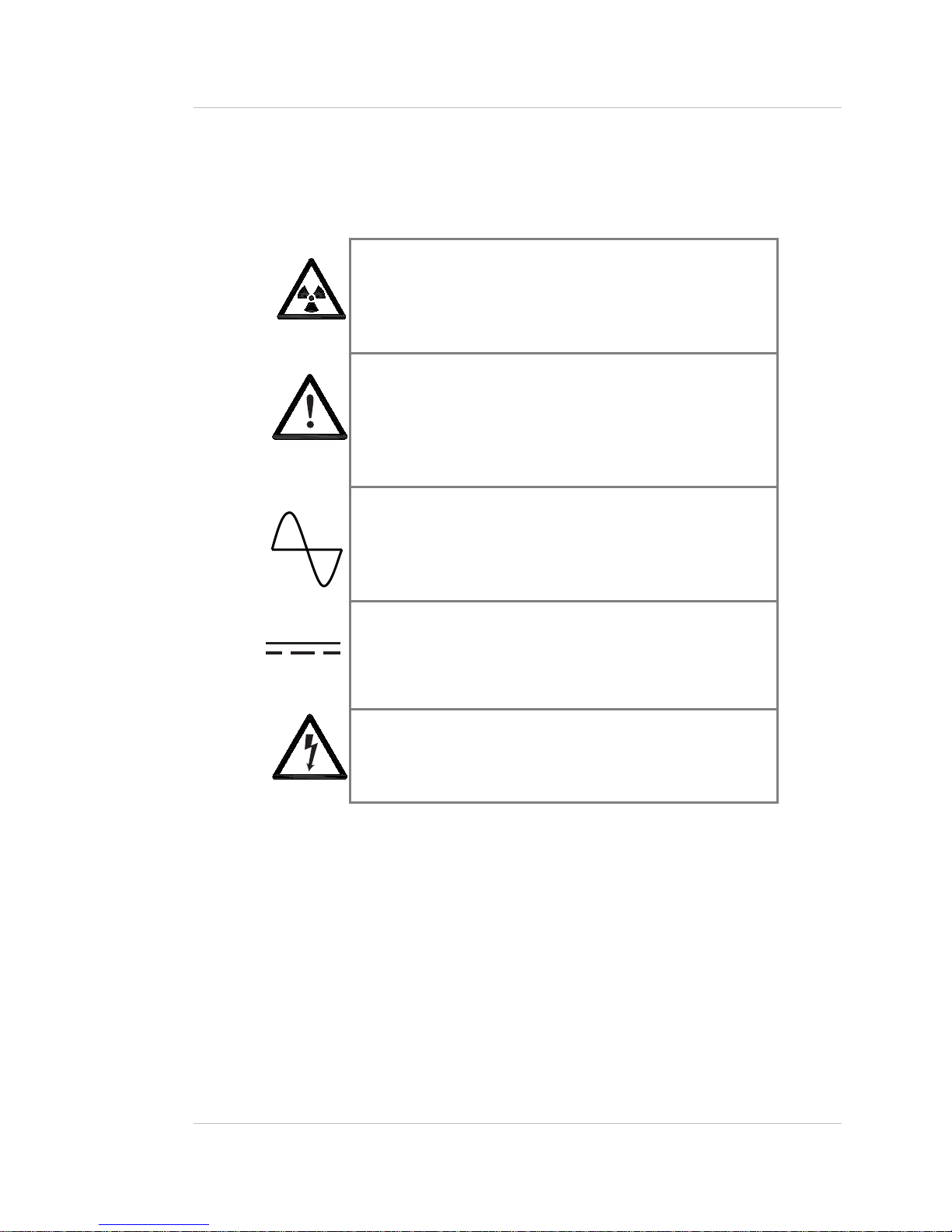

Table 2 lists the symbols that the manual and instrument use.

Table 2: Explanation of symbols

Preface

Radiation notice

In the manual, information concerning radioactive materials

or radiation safety information is found in the accompanying

text.

Caution! The text next to this symbol contains the warning

of potential damage to equipment or people.

Attention! Le texte apparaissant près de ce symbole vous

informe d’un danger possible pour l’équipement ou pour

l’usager.

AC current or voltage

On the instrument, a terminal to which or from which an

alternating (sine wave) current or voltage may be applied or

supplied.

DC current or voltage

On the instrument, a terminal to which or from which a

direct current voltage may be applied or supplied.

Potentially hazardous voltages

On the instrument, a terminal on which potentially

hazardous voltage exists.

W-4510 Weigh Scale Technical Reference Manual xiii

Preface

Notes

xiv W-4510 Weigh Scale Technical Reference Manual

Preface

Your comments

Ohmart values your opinion! Please fill out this page so that we can continually improve our

technical documentation.

Manual: W-4510 Weigh Scale with GEN2000 Electronics Technical Reference Manual

Date: ______________

Customer Order Number: ___________________

How we can contact you (optional if you prefer to remain anonymous):

Name: _________________________

Title: _________________________

Company: __________________________

Address: __________________________

__________________________

__________________________

Did you find errors in this manual? If so, specify the error and page number.

Did you find this manual understandable, usable, and well organized? Please make

suggestions for improvement.

Was information you needed or would find helpful not in this manual? Please specify.

Please send this page to:

Ohmart Corporation

Director of Engineering

4241 Allendorf Drive

Cincinnati, OH 45209-1599

W-4510 Weigh Scale Technical Reference Manual xv

Preface

Notes

xvi W-4510 Weigh Scale Technical Reference Manual

Chapter 1: Introduction

Nuclear materials notice

This equipment contains radioactive source material that emits gamma radiation. Gamma

radiation is a form of high-energy electromagnetic radiation. Only persons with a specific

license from the U.S. NRC (or other regulating body) may perform the following to the source

holder:

• Dismantle

• Install

• Maintain

• Relocate

• Repair

• Test

Ohmart Field Service engineers have the specific license to install and commission nuclear

gauges, and can instruct you in the safe operation of your density gauge. To contact Ohmart

Field Service, call 513-272-0131. Users outside the U.S. and Canada may contact their local

representative for parts and service.

Note: Special instructions concerning your source holder are found in

the envelope that was shipped with the source holder and the

“Radiation Safety for U.S. General and Specific Licensees, Canadian

and International Users” and the “Radiation Safety Manual Reference

Addendum” CD. Please refer to this document for radiation safety

information.

W-4510 Weigh Scale Technical Reference Manual 1

Introduction

Unpacking the equipment

CAUTION!

Make sure that you are familiar with radiation safety practices in

accordance with your U.S. Agreement State, U.S. NRC, or your

country’s applicable regulations before unpacking the equipment.

5 Unpack the unit in a clean, dry area

5 Inspect the shipment for completeness, by checking against the packing slip

5 Inspect the shipment for damage during shipment or storage

5 If the detector is included as a separate package in the shipment, inspect the assembly for

damage that may have occurred during shipment or storage

5 If there was damage to the unit during shipment, file a claim against the carrier and report

the damage in detail. Any claim on the Ohmart Corporation for shortages, errors in

shipment, etc., must be made within 30 days of receipt of the shipment

5 If you need to return the equipment, see the section “Returning equipment for repair to

Ohmart” in the “Diagnostics and Repair” chapter

5 After you unpack the equipment, inspect each source holder in the shipment to assure that

the operating handle is in the OFF position. In the event that you find the handle in the ON

position, place it in the OFF position immediately and secure it.

Note: Most source holder models accept a lock. Call Ohmart Field Service

immediately for further instructions, at 513-272-0131, if the source holder

has one of the following conditions:

• Does accept a lock and there is no lock on it

• The lock is not secured

• You are unable to secure the lock

• The operating handle does not properly move into the off position

2 W-4510 Weigh Scale Technical Reference Manual

Introduction

Storing the equipment

Storing the source holder

If you must store the source holder, adhere to the following guidelines:

• Store in a clean, dry area.

• Verify that the source holder shutter is in the OFF or CLOSED position.

• Check the current local regulations (U.S. NRC, Agreement State, or other) to determine if

this area must have any restrictions.

Storing the detector

If you must store the detector, adhere to the following guidelines:

• Avoid storage at temperatures below freezing.

• Store the detector indoors in an area that has temperature-control between 50 ºF and 95

ºF (10 ºC and 35 ºC) and less than 50% relative humidity.

• Store equipment in dry conditions until installation.

W-4510 Weigh Scale Technical Reference Manual 3

Introduction

Specifications

Table 3: Specifications list

System

Accuracy

Typical

Sources

Requirements*

Signal Cable Maximum length 5,000 feet (1,500 meters)

Source

Housing

W-4510

Detector

Housing

Input Signal input channels Two digital (frequency) 0–32kHz opto-isolated

Analog inputs Voltage or current, 0–0.1VDC into 1megaohm, 0–1.0VDC into 1megaohm,

TTL Logic level input

Output Relay 4 SPDT (4 form C) contacts: 2A–120VAC, 2A–28VDC, 1A 250VAC, CSA

TTL logic level Five open-collector transistor type capable of sinking 300mA (max) and

Analog channels Two 0–20mA into 0-1,000ohms, or 4–20mA into 0–1,000ohms, 0–

Serial ports Serial ports for local display and keypad, remote displays, and host

Signal Processing

Electronics On-board memory EEPROM and battery-backed RAM

Real-time clock Maintains time, date, and source decay compensation. Y2K compliant

Diagnostics LED indication +5V, Memory Corruption, CPU Active, Auxiliary, and High Voltage

±1% of span typical Accuracy depends on specific application parameters

Cesium-137 0.66MeV gamma radiation emitter, 30.2 year half life

AC 115VAC ±10% 50 or 60Hz, at 65 Watts maximum power consumption Power

Wiring #14–#22AWG (1.63–0.643mm)

Indicator On/Off light indicator

Calibration absorber Self-contained calibration absorber

Material Steel construction

Weight 450lbs

Paint Epoxy Powder Coat

Enclosure rating NEMA 4X

Ambient temperature –40°F to 140°F (–40°C to 60°C)

Humidity 0–95%, non-condensing

Material Aluminum

Weight ≅100lbs

Paint Epoxy Powder Coat

0–10VDC into 1megaohm, 0–1.0mA into 10kohm, 1–5mA into 2kohm,

4–20mA into 500ohm, 10–50mA into 200ohm

channels

capabilities

Six TTL input channels, voltage-free contacts from relay or switch, contact

loading 5V at 5milliamperes, maintain contact for one second (minimum)

version ratings: 0.6A–125VAC, 0.6A–110VDC, 2.0A at 30VDC

30V (max) resistive load, or 20V (max) inductive load and one

configurable to be isolated. If using a TTL for a totalizer, the max rate is 10

pulses per second.

100mVDC into 20kohms (min). Both sides of output are isolated from input

and ground. Ground either side. Meets ISA Standard 50.1: Type 4, Class

U isolated current loop transmitters.

interface. Two full and two partial RS-232C ports, or one partial RS-232C

port and one partial RS-422/485 port, and individual settings from 300

baud–19,200 baud.

Capabilities include: Linearization, display process measurement in

product units, generate high and low process alarms, filtering digital or

classic RC time constant, source decay compensation, and temperature

compensation.

4 W-4510 Weigh Scale Technical Reference Manual

Introduction

Typical applications

Belt loading

The W-4510 Weigh Scale can measure the belt loading (weight per linear distance) of

product on the belt. This signal can combine in the DCS/PLC with the belt speed to calculate

the mass flow (weight per unit time). This is essential for blending operations, as in OSB or

MDF/particleboard application to match the amount of resin to the weight of wood present.

Loading rate

The W-4510 Weigh Scale can measure the loading rate of product on the belt. This uses a

tachometer directly connected to the W-4510 to measure the belt speed. The output signal

data calibrates directly to the mass flow units (weight per unit time).

W-4510 Weigh Scale Technical Reference Manual 5

Introduction

Where to find help

If you need help finding information, check the Index and Table of Contents within this

manual. Also, refer to the Smart Pro Reference manual for information on calibration and

operation with the Smart Pro.

Ohmart Customer Service

Ohmart Customer Service has Field Service Engineers located across the U.S. for on-site

service to the U.S. and Canada. In many cases, a Field Service Engineer is at your plant for

the start up of your gauge. In addition, Field Service Engineers regularly assist customers

over the phone.

If you have a question or need help, call Customer Service during office hours. If your

problem is an emergency (for example, line shut down because of Ohmart equipment), you

can reach us 24-hours a day.

Table 4: Contact information

Ohmart Phone 513-272-0131

Ohmart FAX 513-272-0133

Ohmart Field Service E-mail fieldservice@ohmartvega.com

In addition, Ohmart provides field service for customers outside the U.S. and Canada.

Customers outside the U.S. and Canada can contact their local Ohmart representative for

parts and service.

When calling with a question, if possible, please have the following information ready:

5 Ohmart Customer Order (C.O.) Number—Locate on the engraved label on the source

holder

5 Sensor serial number—Locate on the sensor housing inside the external housing

6 W-4510 Weigh Scale Technical Reference Manual

Introduction

System overview

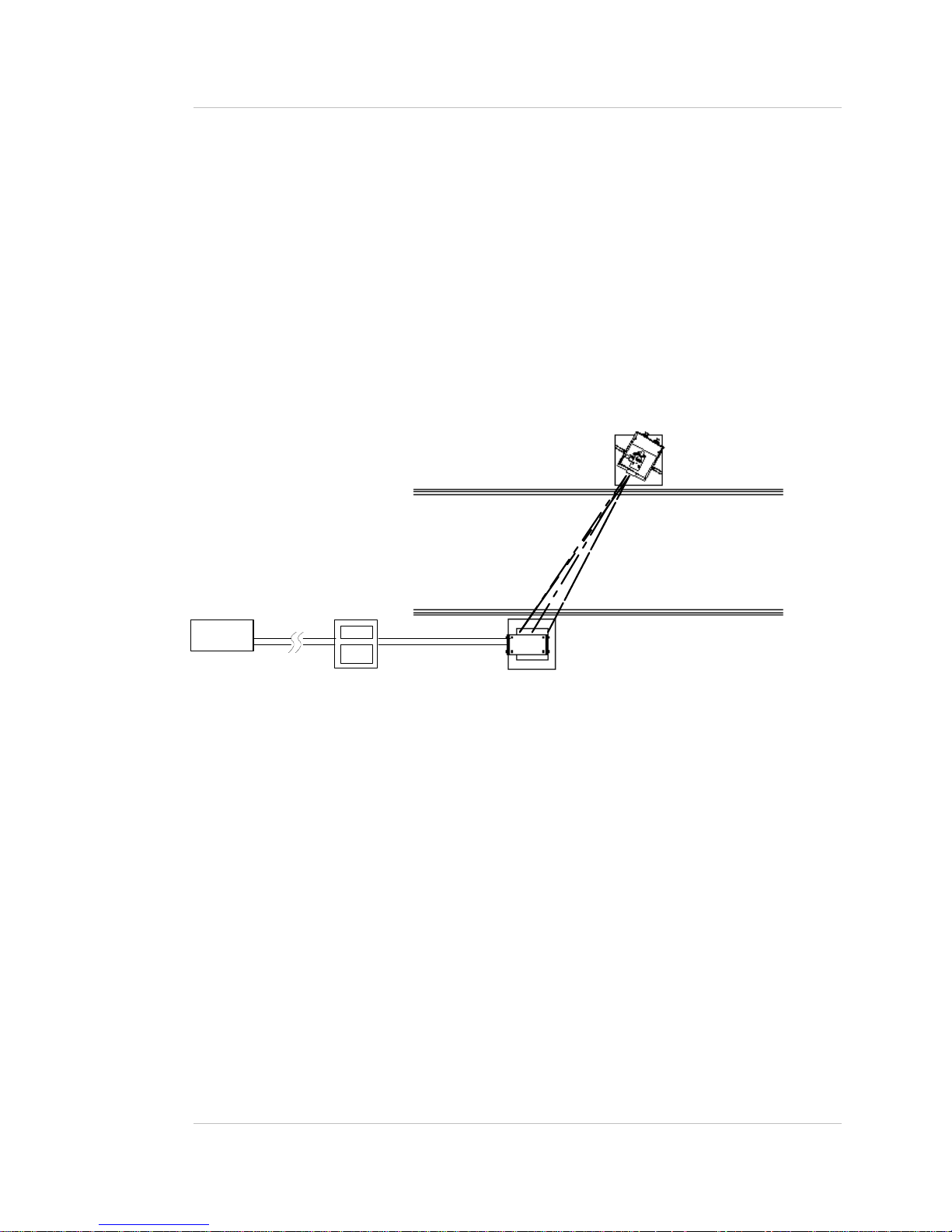

The W-4510 Weigh Scale detector uses Ohmart’s GEN2000 electronics. The W-4510 Weigh

Scale system consists of three main components:

• Source holder

• W-4510 Weigh Scale detector assembly (includes GEN2000 sensor and GEN2000 power

supply and communications)

• Smart Pro or Smart Pro Pac electronics

Source

Conveyor

4-20 mA

current loop

DCS

Smart

Pro

Frequency

output

Detector

Figure 1: System overview

The following statements describe the source holder:

• A cast or welded steel and lead enclosure that houses a radiation-emitting source

capsule

• Directs the radiation in a narrow collimated beam through the process material

• Shields the radiation elsewhere

• A shutter on the source holder either completely shields the radiation (source off) or

allows it to pass through the process (source on)

• Self-contained calibration absorber for performing a Two-point calibration on an empty

belt.

W-4510 Weigh Scale Technical Reference Manual 7

Introduction

Figure 2: Typical source holder shutter mechanism

The following statements describe the functions of the W-4510 Weigh Scale detector

assembly:

• Mounts opposite the source holder

• Inside the housing is a scintillation material

• The scintillation material produces light in proportion to the intensity of its exposure to

radiation

• A photomultiplier tube detects the scintillator’s light and converts it into voltage pulses

• The microprocessor receives these voltage pulses after amplification and conditioning by

the photomultiplier tube

• The microprocessor and associated electronics convert the pulses into a calibratable

output to the Smart Pro electronics

• The Smart Pro electronics receives and reads the input and converts it into process units

• Several outputs are available on the Smart Pro, including a 4–20mA output of the

process variable. Refer to the Smart Pro Reference manual for more information.

8 W-4510 Weigh Scale Technical Reference Manual

Introduction

Principles of operation

Ohmart’s W-4510 Weigh Scale is a nuclear gauge that mounts outside the conveyor

footprint. The detector receives a narrow beam of radiation, through the process material,

from the source holder.

The amount of radiation that the detector senses is in proportion to the amount of the

material’s mass. Since the radiation source and detector are always the same distance apart,

the only possible change in signal is directly a measure of the loading belt. A belt with a light

load allows more radiation to pass through to the detector. A belt with a heavier load allows

less radiation to pass through to the detector.

The Smart Pro calibrates the W-4510 Weigh Scale output and associates the digitized

detector readings, known as counts (the detector frequency output), with the loading of the

belt, in engineering units. The output range of the Smart Pro with the W-4510 Weigh Scale

are two

4–20mA current loop signals, in proportion to either the loading (pounds per linear foot), or

weight transfer rate (pounds per hour). In addition to the analog outputs, there are up to four

process relays available to convey totalization or other configurable alarm conditions.

W-4510 Weigh Scale Technical Reference Manual 9

Introduction

Communicating with the gauge

Use either a Smart Pro or Smart Pro Pac to enable the following:

• Initial setup

• Calibration

• Operation

Smart Pro software

The Smart Pro software is accessible through the Smart Pro wall mount or rack mount units.

You can use step-by-step method of screen selection for pre-programmed routines or direct

access to screens.

Step-by-step method

The step-by-step method takes you from the Main menus to the sub-menus by moving the

cursor to your choice and pressing SELECT and ENTER. You can press the NEXT SCREEN

and PREVIOUS SCREEN to take you back and forth between menus.

Direct access method

Use direct access to bypass the step-by-step progression of screens and go directly to your

chosen screen. You enter the screen number in the number field in the left hand corner and

press ENTER. For more information concerning function and data entry keys, refer to page

27.

Smart listing

The Smart Listing is a table of RAM addresses that lists the data that is stored at each

address.

This listing contains the software settings that configure each system for individual and

unique applications. You do not normally need this list, since all necessary information for

normal operation is accessible through user-friendly screens.

The top line of the listing’s label is Filename. It displays the following information:

• Shop order name

• Shop order number

• Date of printout

• Time of printout

10 W-4510 Weigh Scale Technical Reference Manual

Introduction

The first column down the left side is the base number. The base number represents the

address. The first row across the top is the displacement

from the base (incremental value).

Each address location is itemized by adding the displacement to the base.

Address location = base + displacement

For example, find 40 going down the first column and follow it across to the 12 located in the

top row. This represents address location 52 (40+12) and contains data 17196.

The LOW process value used to calibrate the gauge at the factory is at address location 153

(140+13). In this sample, that data value is 8427.

Sample Smart Listing

Table 5: Sample Smart Listing

Filename: A.B.C., Inc. (BJCX-0020-12133) 1-10-2001 16:17:18 Page 1

ADDR 0 1 2 3 4 5 6 7 8 9 10 11 12 13…

0 8191 16668 . 10 11 . 1668 . . . . . . 65153

20 534 37121 . . . 5500 1644 110 1991 . . . . 21760

40 16896 . 16946 . 16996 . 17046 . 17096 . 17146 . 17196 .

60 . . . . . . . . . . . . . .

80 . . . . . . . . . . . . . .

100 . . . . . . . . . . . . . .

120 . . . . . . . 1000 1 . . . . .

140 11103 11103 1807 . . . . . . 500 . . . 8427

160 . 6500 7657 7410 1 60 110 8427 5920 . . . 109 9000

…

…

…

Note: This example shows only a partial listing. The actual listing has 20 displacement fields.

In addition, a dot (.) represents the zeros (0) in this example, to enhance readability.

W-4510 Weigh Scale Technical Reference Manual 11

Introduction

Notes

12 W-4510 Weigh Scale Technical Reference Manual

Chapter 2: Installation

Location considerations

When you ordered the W-4510 Weigh Scale, the source was sized for optimal performance.

Notify Ohmart prior to installation of the gauge if the location of the gauge is different from the

original order location. Proper location of the density gauge can sometimes mean the

difference between satisfactory and unsatisfactory operation.

Note: Try to locate the source holder in such a place that process

material will not coat it. This ensures the continuing proper operation

of the source ON/OFF mechanism. Many regulatory agencies (for

example, the U.S. NRC) require periodic testing of the ON/OFF

mechanism. Refer to the “Radiation Safety for U.S. General and

Specific Licensees, Canadian and International Users” and the

“Radiation Safety Manual Reference Addendum” CD that came with

the source holder and the appropriate current regulations for details.

Avoid source cross-talk

When multiple adjacent conveyors have nuclear gauges, you must consider the orientation of

the source beams so that each detector senses radiation only from its appropriate source.

The best orientation, in this case, is for the source holders to be on the inside with radiation

beams pointing away from each other.

Blending applications

Place the scale on a flat or trough conveyor. The scale can also accommodate any conveyor

inclination angle. However, you must determine the exact location of the scale when ordering

the scale and adhere to the original location as ordered. A changing profile causes unwanted

measurement error. Some rotary feed systems tend to cause loading variations with time.

Prevent process accumulation

Prevent process material or dirt from accumulating between the source and the detector.

Such accumulation can cause the gauge to indicate a higher weight than actual.

W-4510 Weigh Scale Technical Reference Manual 13

Loading...

Loading...