0

RM10C

HYBRID RECORDER

COMMUNICATION COMMAND

INSTRUCTION MANUAL

HXPRM10mnC0005E

Jan. 2016 (2nd Edition)

All Rights Reserved, Copyright © 2004-2016, Ohkura Electric Co., Ltd.

― ―

HXPRM10mnC0005E

1

For safety using

Symbols used on the instrument

This shows “Caution for handling”. This symbol is used on the parts need to

reference the instruction manual for saving human body and the instrument.

This shows “Protective grounding”. Be sure to provide protective grounding prior

to operate this instrument.

This shows “Risk of electric shock”. This symbol is used on the parts, which has

a risk of electric shock.

Be sure to observe the following warnings/cautions and those provided in the text

in order to secure safety in handling the instrument.

WARNING

In order to prevent electric shock; be sure to disconnect this instrument from

the main power source when wiring it.

(1) In order to prevent an electric shock; be sure to provide protective

grounding prior to turning on this instrument.

(2) Do not cut a protective grounding conductor or disconnect protective

grounding.

(1) Make sure that the supply voltage for this instrument conforms to the

voltage of the supply source.

(2) Attach a protective cover prior to turning on this instrument.

Do not operate this instrument in the environment where it is exposed to a

combustible/explosive/corrosive gas or water/steam.

Provide input and output wiring after turning off the power.

全般

General

全般

Protective Grounding

全般

Power Source

全般

Working Environment

全般

Input and Output Wiring

Thank you for purchasing our RM10C Hybrid Recorder.

In order to this instrument to exhibit all of its functions effectively and correctly, read and understand this

instruction manual thoroughly before using the instrument.

The symbols below are used on this instrument for the cautioning information.

― ―

HXPRM10mnC0005E

2

CAUTION

Do not use empty terminals for other purposes such as relaying, etc.

When transporting this instrument or the equipment with this instrument

incorporated in it, take measures to prevent opening the door and falling out the

inner module.

Do not touch the switches, etc. inside this instrument. Also, do not replace the

main unit or PRINTed circuit boards. When this is neglected, we cannot

guarantee functioning of the instrument. Contact our dealer where you

purchased the instrument, or our sales representative.

[Note]

(1) Deliver this instruction manual to an end user.

(2) Prior to handling this instrument, be sure to read this manual.

(3) If you have any questions on this manual or find any errors or omissions in

this manual, contact our sales representative.

(4) After reading this manual, keep it carefully by the instrument.

(5) When the manual is lost or stained, contact our sales representative.

(6) It is prohibited to copy or reproduce this manual without our permission.

(1) When installing this instrument, put on a protective gear such as safety

shoes, helmet, etc. for your safety.

(2) Do not put your foot on the installed instrument or get on it, because it is

dangerous.

Only our serviceman or persons authorized by our company are allowed to

remove and take the inner module, the main unit and PRINTed circuit boards

apart.

(1) Dispose the replaced batteries in a correct way.

(2) Do not incinerate plastics of maintenance parts and replacement parts. A

harmful gas may be produced.

(1) Use dry cloth to clean the surface of this instrument.

(2) Do not use any organic solvent.

(3) Cleaning the instrument after turning off the power.

This instruction manual is subject to change without prior notice.

全般

Input and Output Wiring

全般

Transportation

全般

Inside of Instrument

全般

Instruction Manual

全般

Installation

全般

Maintenance

全般

Disposal

全般

Cleaning

全般

Revisions

― ―

HXPRM10mnC0005E

3

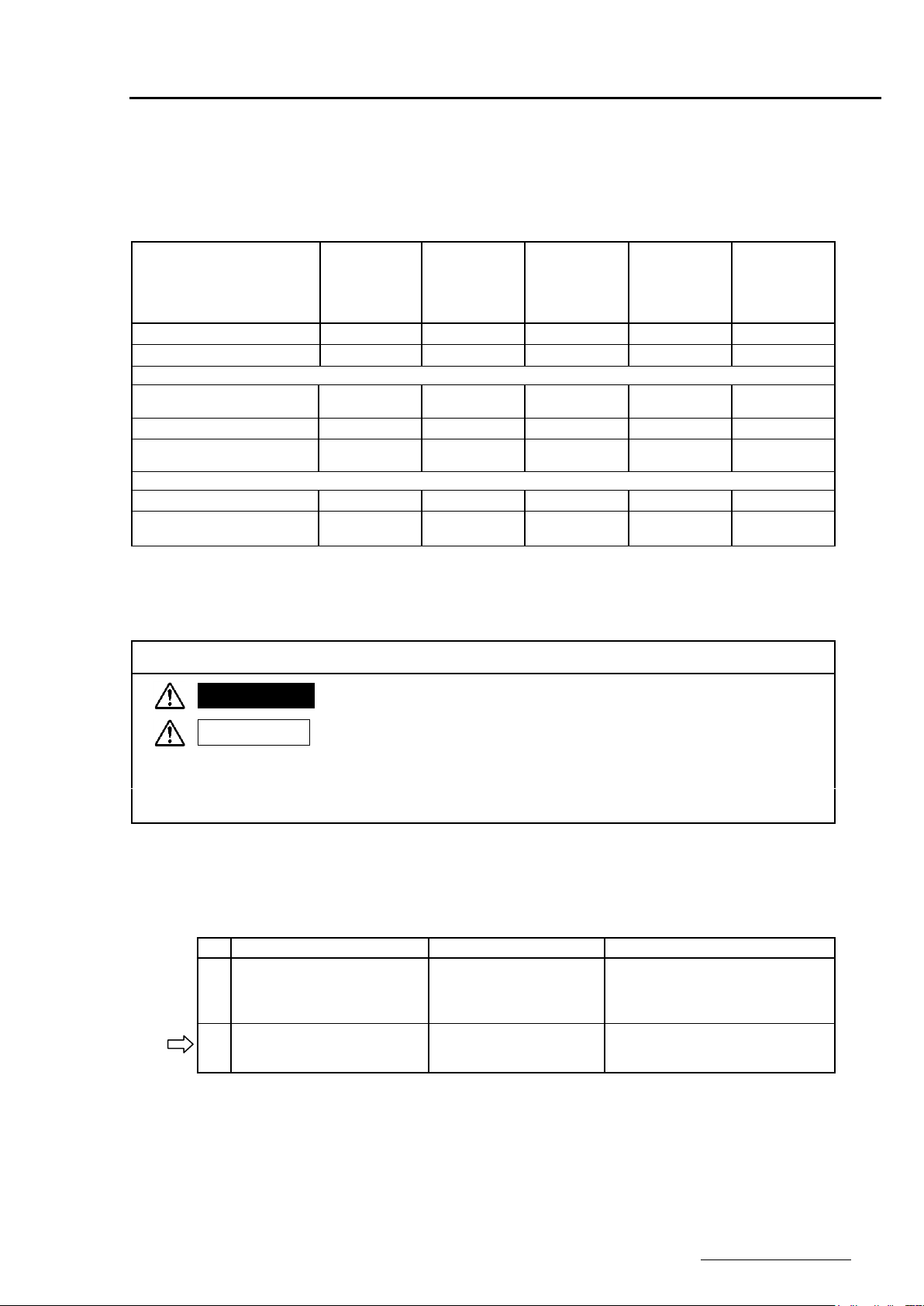

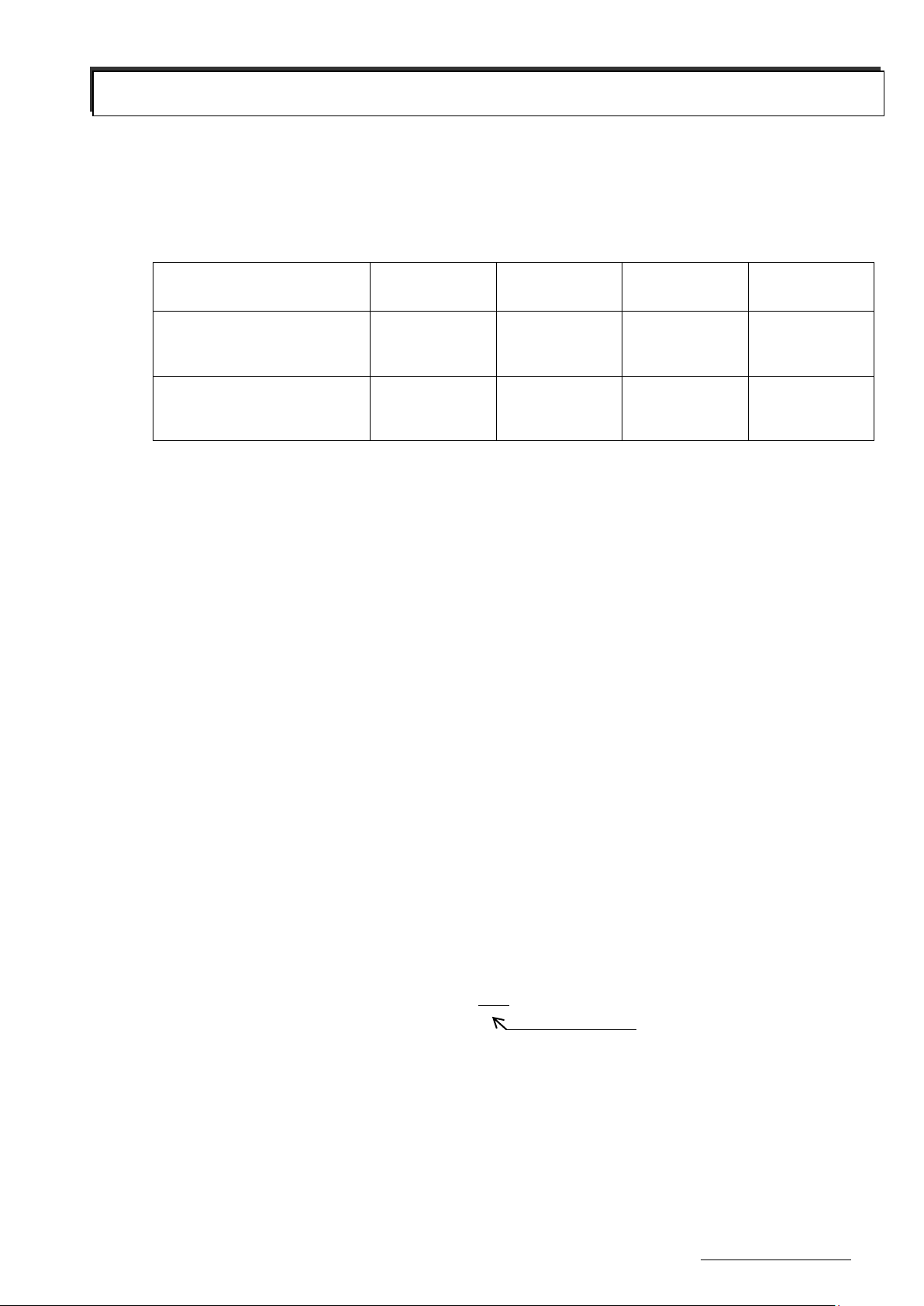

Using procedure for this manual

Chapter and TITLE

For purchase

and install

For initial

setting and

change setting

For daily

operation

For using

communication

For

maintenance

and

trouble-shootin

g

For safety using (page 1)

◎ ◎ ◎ ◎ ◎

1. INTRODUCTION

◎

◎

Original protocol

2. THE RECEPTION OF

DATA

○ ◎ ○

3. DATA TRANSMISSION

○

◎

○

4. NOTE OF DATA

COMMUNICATION

○ ◎ ○

ModbusRTU protocol

5. OVERVIEW

○

◎

○

6. DATA TRANSMISSION

AND RECEPTION

○ ◎ ○

Symbols used on this manual

WARNING

Failure to observe this information could result in death or injury.

Be absolutely certain to read this.

CAUTION

Failure to observe this information could damage the instrument.

Be certain to read it.

[Note]

This is cautionary information for correct use of the instrument.

Be certain to read it.

[Reference]

This is information to help you use the functions of this instrument more

effectively.

Name

Part No.

Outline

1

RM10C Hybrid Recorder

instruction manual

HXPRM10mnC0001E

HXPRM10mnC0002E

Explanation for installing, wiring,

standard operation. And setting

or operation for using this

instrument.

2

RM10C Hybrid Recorder

Communication Command

instruction manual

HXPRM10mnC0005E

Explanation for reading and

writing data of the recorder by

communication function.

This

manual

1.Using procedure

This instruction manual consists of “For safety using”, “Contents” and “Chapter 1 to Chapter 6” as bellow.

Read the applying sections for your purpose to use this instrument.

◎ :Be absolutely certain to read this.

○ :Be certain to read this if you need.

The symbols below are used on the warning and cautioning information in this manual.

2.Guide of Instruction manual

The instruction manuals of this instrument are as the table below.

― ―

HXPRM10mnC0005E

4

CONTENTS

1. INTRODUCTION ......................................................................................................................... 5

1.1 General Description ............................................................................................................. 5

1.2 Difference in RS-485, RS-232C ........................................................................................... 5

1.3 Original Protocol - Basic item about the command .............................................................. 5

1.4 Basic item about the Modbus RTU protocol ......................................................................... 6

2. ORIGINAL PROTOCOL - THE RECEPTION OF THE DATA ..................................................... 7

2.1 Setup command ................................................................................................................... 7

2.1.1 Setup command list .................................................................................................. 7

2.1.2 Setting of INPUT RANGE/RECORD SPAN .............................................................. 8

2.1.3 Setting of Alarm ...................................................................................................... 11

2.1.4 Setting of the Unit ................................................................................................... 11

2.1.5 Setting of the 1st chart speed ................................................................................. 11

2.1.6 Setting of the date/time ........................................................................................... 12

2.1.7 Copying the Setting Data of the channel ................................................................ 12

2.1.8 Setting of the Printing cycle(Multipoint type only) ................................................... 12

2.1.9 Setting of the Zone Recording ............................................................................... 12

2.1.10 Setting of the Partial Compression/Expansion ........................................................ 13

2.1.11 Setting of the Digital Print ON/OFF ......................................................................... 13

2.1.12 Setting of the Tag Character ................................................................................... 13

2.1.13 Setting of the Comment Character ......................................................................... 14

2.2 Control command............................................................................................................... 15

2.2.1 Control command list .............................................................................................. 15

2.2.2 Recording Start/Stop .............................................................................................. 16

2.2.3 Manual Print Start/Stop ........................................................................................... 16

2.2.4 List Print Start/Stop ................................................................................................. 16

2.2.5 Engineering list Print Start/Stop .............................................................................. 16

2.2.6 Choice of the display contents. ............................................................................... 17

2.2.7 Communication comment print out ......................................................................... 17

3. ORIGINAL PROTOCOL - DATA TRANSMISSION ................................................................... 18

3.1 Getting the Set Value ......................................................................................................... 18

3.2 Data Reception Example ................................................................................................... 18

4. ORIGINAL PROTOCOL - NOTES OF COMMUNICATION ....................................................... 19

4.1 Half-Duplex Transmission .................................................................................................. 19

4.2 Multiple access .................................................................................................................. 19

4.3 Continuation of Opening the Link ....................................................................................... 19

4.4 Outputting the Status ......................................................................................................... 19

5. MODBUS RTU PROTOCOL - OVERVIEW ............................................................................... 20

5.1 Modbus RTU Protocol ........................................................................................................ 20

5.2 Add new items and Map version ........................................................................................ 20

6. MODBUS RTU PROTOCOL - DATA TRANSMISSION AND RECEPTION ............................... 21

6.1 Communication Protocol .................................................................................................... 21

6.2 Function codes .................................................................................................................. 21

6.3 Error response ................................................................................................................... 21

6.4 Reading of input register area ............................................................................................ 22

6.4.1 Reading of input register area ................................................................................ 22

6.4.2 Input Register Area Map ......................................................................................... 23

6.5 Reading and writing of the holding register area ................................................................ 26

6.5.1 Reading of the holding register area ....................................................................... 26

6.5.2 Writing of the holding register area (Single) ............................................................ 27

6.5.3 Writing of the holding register area (Continuation) ................................................. 28

6.5.4 Holding register area map ...................................................................................... 29

6.5.5 Holding register area setting range detail ............................................................... 35

― ―

HXPRM10mnC0005E

5

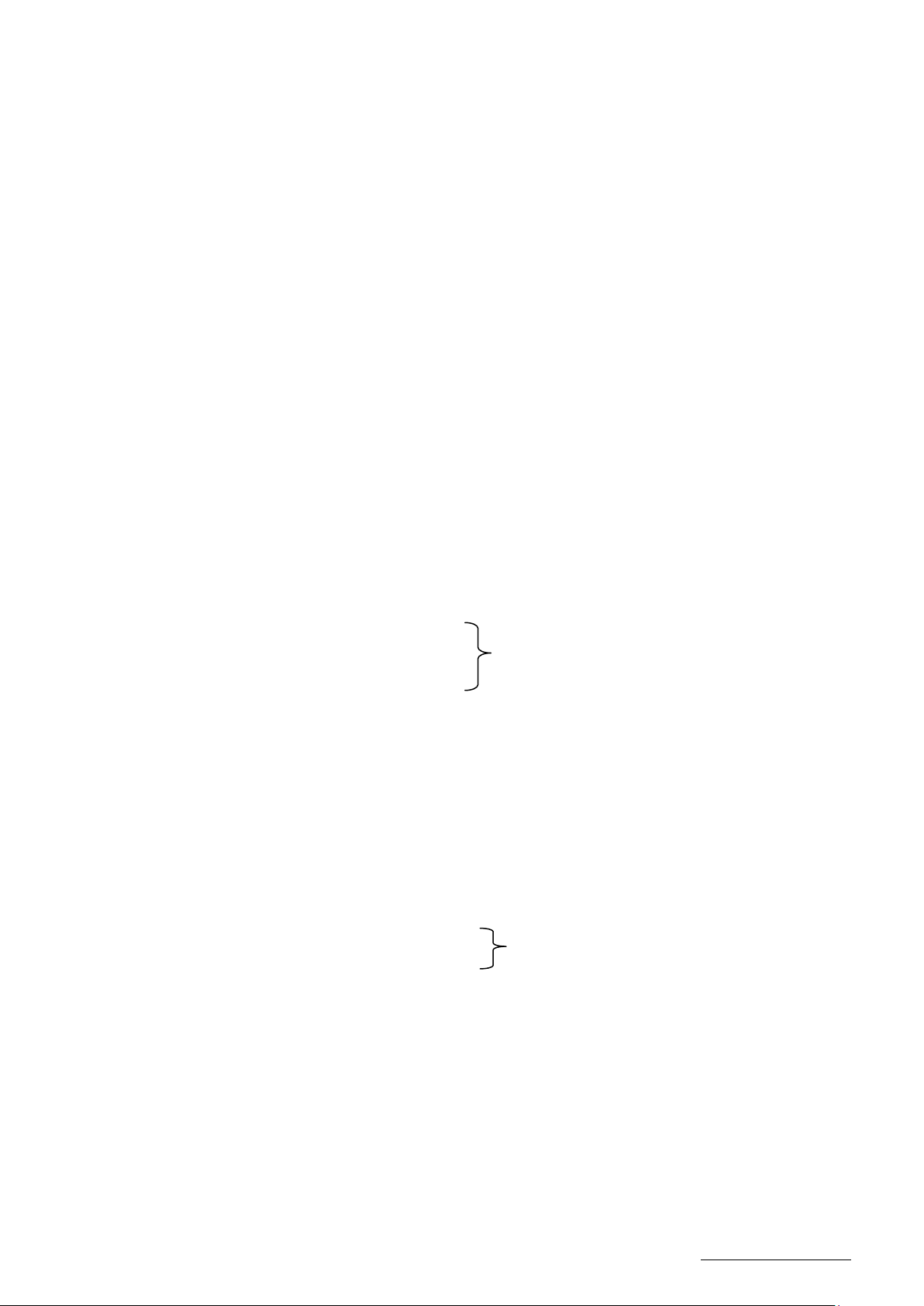

1. INTRODUCTION

Omission is possible

contents

Wiring and

communication

procedure

Request

measurement

value

Setting of the

recorder

Control of the

recorder

RM10C Hybrid Recorder

instruction manual

(HXPRM10mnC0001E,

HXPRM10mnC0002E)

○

○

RM10C Hybrid Recorder

Communication Command

instruction manual

(HXPRM10mnC0005E)

○

○

1.1 General Description

This instruction manual describes the communication command of the RM10C Recorder. Please refer to the

instruction manual (HXPRM10mnC0001E, HXPRM10mnC0002E) for the transmission of the measurement

data, a setup of communication and wiring.

1.2 Difference in RS-485, RS-232C

There is no difference between RS-232C and RS-485 about the communication command in this Recorder.

But, wiring and signal level are different.

1.3 Original Protocol - Basic item about the command

The communication command consists of a command distinction code, a parameter, delimiter(comma),

and terminator. The format of the command is as follows.

(Example) SR02 VOLT,200mV,0,20000 (terminator)

Command distinction code:

This code is defined by two characters the capital letter. (Exp. SR)

If the command needs a channel number, a channel number is described behind the

distinction code.

Parameter: Each parameter is divided with comma.

All the setting value is shown with the integer. (The plus sign can be omitted.)

The space character in the input parameter is ignored. The other side, the space

character in the unit code, the comment printout code and the tag printout code isn't

ignored. The parameter can be omitted unless the parameter is varied. But, a comma(,)

can't be omitted. Comma which is in front of the terminator can be omitted.

(Example)SR02,VOLT,,,(CR)(LF)

― ―

The date parameter, the time parameter and the channel number parameter have fixed

length. When that parameter length is different, these data induce errors.

(1) Date YY/MM/DD (8 characters)

(2) Time HH:MM:SS (8 characters)

(3) Channel Number: CHXX (2characters)

HXPRM10mnC0005E

6

1.4 Basic item about the Modbus RTU protocol

Modbus protocol is a Modicon Inc. (AEG Schneider Automation International SAS) is a communication

protocol that was developed for the PLC, are listed in the protocol specification (PI-MBUS-300 Rev.J).

Please refer to the same specification for the specification of the Modbus protocol.

In this manual, we describe the function code and data content of mainly Modbus protocol that can be used

in the present equipment.

― ―

HXPRM10mnC0005E

7

2. ORIGINAL PROTOCOL - THE RECEPTION OF THE DATA

Table 2.1 Setup command list

Command

Setting item

The number of

the parameters

Contents of a parameter

SR

Setting the range

MAX 7

Channel,Mode,Range(Reference

Channel)

Span lower limit value.

Span higher limit value.

Scaling lower limit value.

Scaling higher limit value

SA

Setting the Alarm

7

Channel,

Alarm level

Alarm on/off

Alarm type,Alarm set point

Relay on/off、Relay No.

SN

Setting the Unit

2

Channel, Unit

SC

Setting

the Chart Speed

1

1st Chart speed

SD

Setting the Date/Time

2

Date, time

SF

Setting

the Digital Print

2

Channel

Digital print on/off

ST

Setting the Tag

2

Channel, Tag characters

SG

Setting the Comment

2

Comment number,

Comment characters

SZ

Setting

the Zone recording

3

Channel, Left position,

Right position

SP

Setting the Partial

Compression/Expansion recording

4

Channel, Partial on/off

Compression

Expansion

SE

Setting

the Chart Speed

1

2nd chart speed

SY

Copying

the Setting data

2

Copy-from channel

Copy-to channel

SS

Setting

the recording cycle

1

Recording Cycle

(Multipoint type only)

2.1 Setup command

2.1.1 Setup command list

― ―

HXPRM10mnC0005E

8

2.1.2 Setting of INPUT RANGE/RECORD SPAN

Refer to table 2.2.

The input range and record span of each channel is set up as follows.

<Format>

SR(CH),(Mode),(Pr1),(Pr2),(Pr3),(Pr4),(Pr5),(Pr6),(Pr7)(CR)(LF)

CH: Specify the channel number to set.

Mode: The input mode is set up.

PrN: The number of PrN varies depend on the contents of Mode.

(1) Setting of the record skip.

The record of the channel, which specified with CH is stopped.

(The pen of pen type recorder is fixed on the zero point.)

CH:Setting Channel 01~06(The pen type is 01~02.).

Mode:SKIP

Example)SR05,SKIP(CR)(LF)

The 5th channel doesn't record.

(2) Setting of the Voltage, the Current, the Thermocouple or the RTD input range.

CH:Setting Channel 01~06(The pen type is 01~02.).

Mode:VOLT,TC or RTD

Pr1:Range

Pr2:Left end(Zero Input Value) Refer to table 2.2.

Pr3:Right end(Span Input Value)

Example)SR02,TC,K,0,3000(CR)(LF)

The input of 2nd channel is recorded in Thermocouple type K 0.0-300.0 ℃

(3) The setting of Difference/Sum/Mean operation.

CH:Setting Channel 01~06(The pen type is 01~02.).

Mode:DELT,SIGM or MEAN

Pr1:Refference Channel

・Choose a smaller channel than CH.

・The reference channel must be VOLT, TC, RTD or SCL mode.

Pr2:Left end(Zero Input Value)

Pr3:Right end(Span Input Value)

― ―

Example)SR05,02,DELT,0,3000(CR)(LF)

The output of the 5th channel shows a difference between the input of the 5th channel and

the 2nd channel (CH5-CH2). In this case, the input range of 5th channel becomes the

same as 2nd channel.

HXPRM10mnC0005E

9

(4) The setting of Scaling.

[CAUTION]

Pr5 - 7 can be omitted. If you omit the parameters, three parameters must be omitted

simultaneously.

[CAUTION]

Pr5 - 7 can be omitted. If you omit the parameters, three parameters must be omitted

simultaneously.

Refer to table 2.2.

Refer to table 2.2.

Refer to table 2.2.

CH:Setting Channel 01~06(The pen type is 01~02.).

Mode:SCL

Pr1:VOLT, TC, RTD

Pr2:Scaling Mode

Pr3:Left End(Zero Input Value)

Pr4:Right End(Span Input Value)

Pr5:Scaling Left End

Pr6:Scaling Right End

Pr7: Decimal point position(0~4)

Example)SR04,SCL,RTD,PT,0,3000,0,30000,2(CR)(LF)

[CAUTION]

Pr5 - 7 can be omitted. If you omit the parameters, three parameters must be omitted

simultaneously.

(5) The setting of Square Root

CH:Setting Channel 01~06(The pen type is 01~02.).

Mode:SQRT

Pr1:Range(Only VOLT Input)

Pr2:Left End(Zero Input Value)

Pr3:Right End(Span Input Value)

Pr4:Scaling Left End

Pr5:Scaling Right End

Pr6:Decimal point position(0~4)

Example)SR03,SQRT,mA,400,2000,0,10000,2(CR)(LF)

※Pr5 - 7 can be omitted. If you omit the parameters, three parameters must be omitted

simultaneously.

(6) The setting of Decade

CH:Setting Channel 01~06(A pen type is 01~02.).

Mode:DECAD

Pr1:Range(Only VOLT Input)

Pr2:Left End(Zero Input Value)

Pr3:Right End(Span Input Value)

Pr4:Scaling Left End

Pr5:Scaling Right End

Example)SR01,DECAD,10mV,0,1000,10E+01,10E+06(CR)(LF)

― ―

HXPRM10mnC0005E

10

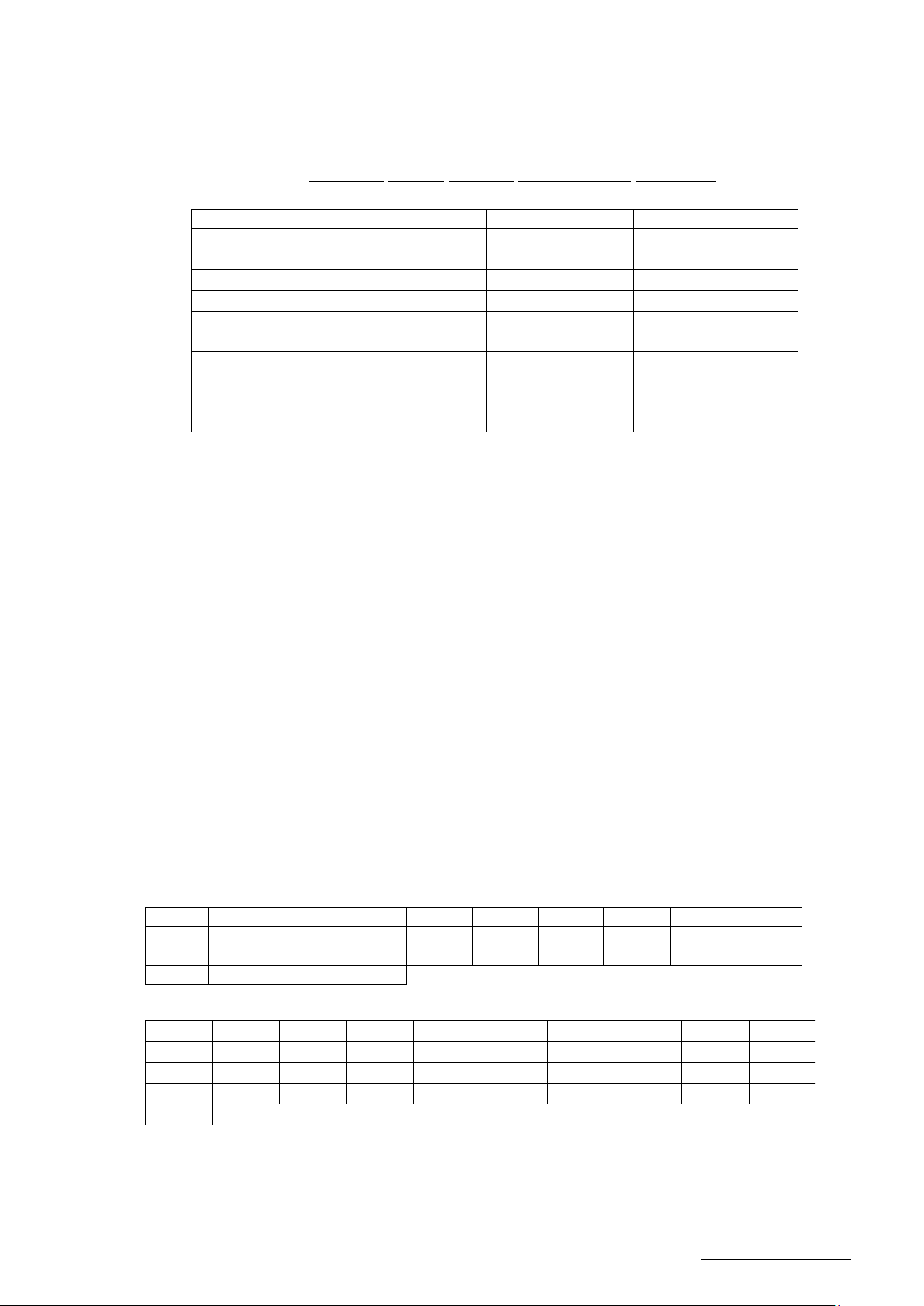

Table 2.2 Setting range

Input

Range

Range or

Scaling

Mode

Zero Input

Value

(Left End)

Span Input

Value

(Right End)

Decimal

Point

(Fixation)

Note

VOLT

10mV

-1000

1000

2

±10mV

20mV

0

2000

2

0~20mV

50mV

0

5000

2

0~50mV

200mV

-2000

2000

1

±200mV

1V

-1000

1000

3

±1V

5V

0

5000

3

0~5V

10V

-10000

10000

2

±10V

mA

400

2000

2

4~20mA

TC

B

0

18200

1

0~1820℃

320

33080

1

32~3308゚F

R

0

17600

1

0~1760℃

320

32000

1

32~3200゚F

S

0

17600

1

0~1760℃

320

32000

1

32~3200゚F

K

-2000

13700

1

-200~1370℃

-3280

24980

1

-328~2498゚F

E

-2000

8000

1

-200~800℃

-3280

14720

1

-328~1472゚F

J

-2000

11000

1

-200~1100℃

-3280

20120

1

-328~2012゚F

T

-2000

4000

1

-200~400℃

-3280

7520

1

-328~752゚F

C

0

23200

1

0~2320℃

320

42080

1

32~4208゚F

Au-Fe

10

3000

1

1~300K

N

0

13000

1

0~1300℃

320

23720

1

32~2372゚F

PR40-20

0

18800

1

0~1880℃

320

34160

1

32~3416゚F

PLII

0

13900

1

0~1390℃

320

25340

1

32~2534゚F

U

-2000

4000

1

-200~400℃

-3280

7520

1

-328~752゚F

L

-2000

9000

1

-200~900℃

-3280

16520

1

-328~1652゚F

RTD

Pt100

-2000

6500

1

-200~650℃

-3280

12020

1

-328~1202゚F

JPt100

-2000

6300

1

-200~630℃

-3280

11660

1

-328~1166゚F

Example)When decimal point position is "1", the input value "1000" is recognized as "100.0".

― ―

HXPRM10mnC0005E

11

2.1.3 Setting of Alarm

Item

Contents

Setting Range

Note

CH

Channel number

01~06(multi)

01~02(pen)

LEVEL

Alarm Level

1~4

ON/OFF

Alarm ON/OFF

ON or OFF

It can be omitted.

TYPE

Alarm Type

H:Upper-limit

L:Lower-limit

It can be omitted.

VALUE

Set Value

It can be omitted.

RLY ON/OFF

Relay ON/OFF

ON or OFF

It can be omitted.

RLY No.

Relay No.

I01~I06(multi)

I01~I03(pen)

It can be omitted.

0 1 2 3 4 5 10

15

20

25

30

40

50

60

75

80

90

100

120

150

160

180

200

240

300

360

375

450

600

720

750

900

1200

1500

5

10

15

20

25

30

40

50

60

75

80

90

100

120

150

160

180

200

240

300

360

375

450

600

720

750

900

1200

1500

1800

2400

3000

3600

4500

4800

5400

6000

7200

9000

10800

12000

The Alarm of each channel is set up as follows.

<Format>

SA(CH),(LEVEL),(ON/OFF),(TYPE),(VALUE),(RLY ON/OFF),(RLY No.)(CR)(LF)

Part of underline can be omitted.

2.1.4 Setting of the Unit

The Unit of each channel is set up as follows.

<Format>

SN(CH),(UNIT)(CR)(LF)

CH:Setting Channel 01~06(The Pen type is 01~02.).

UNIT:The Unit is set up with the code as shown in table 2.3.( Within 6 characters.)

When you use the code beyond 7F

Please refer to the chapter 7.2.7 of the instruction manual (HXPRM10mnC0001E,

HXPRM10mnC0002E) for the data length setting.

2.1.5 Setting of the 1st chart speed

The 1st chart speed is set up as follows.

<Format>

SC(CHART SPEED)(CR)(LF)

The chart speed is chosen from the following table.

CHART SPEED (Multipoint type)

, the data length must be used as 8 bit.

HEX

― ―

CHART SPEED (Pen type)

HXPRM10mnC0005E

12

2.1.6 Setting of the date/time

The date/time of the internal watch of the recorder is set up as follows.

<Format>

SD(DATE),(TIME)(CR)(LF)

DATE:YY/MM/DD

(YY)Year 00~99

(MM)Month 01~12

(DD)Day 01~31

TIME:HH:MM:SS

(HH)Hour 00~23

(MM)Minute 00~59

(SS)Second 00~59

2.1.7 Copying the Setting Data of the channel

The setup data of the channel can be copied on other channels.

<Format>

SY(CHS),(CHD)(CR)(LF)

CHS:Copy-from Channel 01~05(The Pen type is 01 only.)

CHD:Copy-to Channel ( CHS < CHD )

The copy-to channel must set larger value than copy-from channel.

2.1.8 Setting of the Printing cycle(Multipoint type only)

The Printing cycle of the recorder is set up as follows.

<Format>

SS(PRINTING CYCLE)(CR)(LF)

PRINTING CYCLE: 10,20,30 and 60 (sec)

2.1.9 Setting of the Zone Recording

The Zone Recording of each channel is set up as follows.

<Format>

SZ(CH),(LEFTPOSITION),(RIGHTPOSITION)(CR)(LF)

CH:Setting Channel 01~06(The Pen type is 01~02.).

LEFTPOSITION:0~95%

RIGHTPOSITION:5~100%

Part of underline can be omitted. The original setup is inherited when it omits.

― ―

HXPRM10mnC0005E

13

2.1.10 Setting of the Partial Compression/Expansion

The Partial Compression/Expansion recording of each channel is set up as follows.

<Format>

SP(CH),(ON/OFF),(BOUNDARY POSITION),(BOUNDARY VALUE)(CR)(LF)

CH:Setting Channel 01~06(The Pen type is 01~02.).

ON/OFF:Partial Compression/Expansion function ON or OFF

BOUNDARY POSITION: 1~99%

BOUNDARY VALUE:

CH is VOLT,TC,RTD,DELT,SIGM or MEAN mode: In the span data

CH is SCALE,SQRT,DECAD mode: In the scale data

Part of underline can be omitted. The original setup is inherited when it omits.

2.1.11 Setting of the Digital Print ON/OFF

The Digital Print ON/OFF of each channel is set up as follows.

<Format>

SF(CH),(ON/OFF)(CR)(LF)

CH:Setting Channel 01~06(The Pen type is 01~02.).

ON/OFF: ON or OFF

2.1.12 Setting of the Tag Character

The Tag Character of each channel is set up.

<Format>

ST(CH),(TAG)(CR)(LF)

CH:Setting Channel 01~06(The Pen type is 01~02.).

TAG:The Tag Character is set up with the character code shown by the table 2.3.

( Multipoint type is within 7 characters. Pen type is within 5 characters.)

When you use the character code beyond 7F

function must be used as 8 bit. Please refer to the chapter 7.2.7 of the instruction manual

(HXPRM10mnC0001E, HXPRM10mnC0002E) for the data length setting.

, the data length of communication

HEX

― ―

HXPRM10mnC0005E

14

2.1.13 Setting of the Comment Character

2*

3*

4*

5*

6*

7*

A*

B*

C*

D*

E*

F*

*0

SP 0 @

P p

0

0

Π

π

*1 ! 1 A Q a q

1

1

Α Ρ α

ρ

*2 ″ 2 B R b r

2

2

Β Σ β

σ

*3 # 3 C S c s

3

3

Γ Τ γ

τ

*4 $ 4 D T d t

4

4

Δ Υ δ

υ

*5 % 5 E U e u

5

5

Ε Φ ε

φ

*6 & 6 F V f v

6

6

Ζ Χ ζ

χ

*7 ′ 7 G W g w

7

7

Η Ψ η

ψ

*8 ( 8 H X h x

8

8

Θ Ω θ

ω

*9 ) 9 I Y i y

9

9

Ι ι

*A * : J Z j z

Κ κ

*B + ; K [ k {

+

+

Λ λ

*C , < L ¥ l |

± Μ μ

*D

- = M ] m

}

Ν ν

*E

. > N ^ n

̄

-

-

Ξ ξ

*F / ? O _ o

o

o

Ο ο

The Comment Character to print by the Digital Input is set up.

<Format>

SG(Cn),(COMMENT)(CR)(LF)

Cn:Comment Number(1~3)

COMMENT:A Comment Character is set up with the character code shown by the table 2.3.

(Multipoint type is within 16 characters. Pen type is within 12 characters.)

When you use the character code beyond 7F

function must be used as 8 bit. Please refer to the chapter 7.2.7 of the instruction

manual (HXPRM10mnC0001E, HXPRM10mnC0002E ) for the data length setting.

Character Code Table

, the data length of communication

HEX

Table 2.3 Character Code Table

Example)The character code "43

― ―

" represents as the character "C".

HEX

HXPRM10mnC0005E

15

2.2 Control command

Table 2.4 Control command list

Command

Control Item

The number of

parameter

The explanation of operation

PS0

Recording Start

-

This command is the same as RUN key.

PS1

Recording Stop

-

MP0

Manual Print starting

-

This command is the same as key

operation of "Manual Print".

MP1

Manual Print stop

-

LS0

List Print starting

-

This command is the same as key

operation of "List Print".

LS1

List Print stop

-

SU0

Engineering List Print starting

-

This command is the same as key

operation of "Engineering List Print".

SU1

Engineering List Print stop

-

UD0

Chooses an Auto Display

-

When choosing the manual display,

channel number can be set.

But, the channel number can be omitted.

Exp.)Display the measurement value of

5th channel.

UD

1,05

(CR)(LF)

UD1

Chooses a Manual Display

1

UD2

Chooses a Date Display

-

UD3

Chooses a Time Display

-

UD4

Chooses a Display OFF

-

PR0

Communication comment print

out (Sync printout)

2

The printout of characters which is

received by the communication.

The parameter consist of printout colors

and the printout characters.

PR1

Communication comment print

out (Async printout)

2

BO0

Byte output order

(High byte earlier)

2

This command only affects the binary

mode.

(Please refer to the chapter 8 of the

instruction manual for details.)

(HXPRM10mnC0001E,

HXPRM10mnC0002E)

BO1

Byte output order

(Low byte earlier)

2

TS0

Chooses of the measurement

value output

-

This command chooses send data.

The send data actually uses

LF command, FM command.

(Please refer to the chapter 8 of the

instruction manual for details.)

(HXPRM10mnC0001E,

HXPRM10mnC0002E)

TS1

Chooses of the setting value

output.(Refer to Chapter 3)

-

TS2

Chooses of the decimal point

position and the unit character

output.

-

FM0

The ASCII output of the

measurement data.

2

This command outputs a measure-ment

value. The parameter consists of the

output starting channel and output

ending channel.

(Please refer to the chapter 8 of the

instruction manual for details.)

(HXPRM10mnC0001E,

HXPRM10mnC0002E)

FM1

The Binary output of the

measurement data.

2

LF

The output of the setting value,

the unit character and the

decimal point position.

2

This command outputs a setting value.

The parameter consists of the output

starting channel and output ending

channel.

(Please refer to the chapter 8 of the

instruction manual for details.)

(HXPRM10mnC0001E,

HXPRM10mnC0002E)

2.2.1 Control command list

― ―

HXPRM10mnC0005E

16

2.2.2 Recording Start/Stop

This command starts or stops recording of the recorder.

<Format>

PS0(CR)(LF) ・・・The recorder starts the record.

PS1(CR)(LF) ・・・The recorder stops the record.

2.2.3 Manual Print Start/Stop

This command starts or stops printing of the "Manual print".

<Format>

MP0(CR)(LF) ・・・The manual print is started.

MP1(CR)(LF) ・・・The manual print is stopped.

2.2.4 List Print Start/Stop

This command starts or stops printing of the "List print".

<Format>

LS0(CR)(LF) ・・・The list print is started.

LS1(CR)(LF) ・・・The list print is stopped.

2.2.5 Engineering list Print Start/Stop

This command starts or stops printing of the "Engineering list print".

<Format>

SU0(CR)(LF) ・・・The Engineering list print is started.

SU1(CR)(LF) ・・・The Engineering list print is stopped.

― ―

HXPRM10mnC0005E

17

2.2.6 Choice of the display contents.

This command chooses the display mode of the recorder.

The Auto Display, the Manual Display, the Date Display, the Time Display and Display OFF can be chosen.

When receiving this command, the display of recorder changes automatically.

<Format>

UD0(CR)(LF) ・・・・・Auto Display

UD1,(CH)(CR)(LF) ・・・・・Manual Display

UD2(CR)(LF) ・・・・・Date Display

UD3(CR)(LF) ・・・・・Time Display

UD4(CR)(LF) ・・・・・Display OFF

CH:The manual display channel 01~06(The Pen type is 01~02.).

The underline part can be omitted.

2.2.7 Communication comment print out

This command prints the character strings, which is received by the communication.

Please refer to table 2.3 for the character code. When you use the character code beyond 7FHEX,

the data length of communication function must be used as 8 bit. Please refer to the chapter 7.2.7

of the instruction manual (HXPRM10mnC0001E, HXPRM10mnC0002E ) for the data length setting.

<Format>

PR0,(COLOR),(TEXT)(CR)(LF) ・・・・・The Sync printout.

PR1,(COLOR),(TEXT)(CR)(LF) ・・・・・The Async printout.

COLOR:Choose a printout color. (The Pen type is only PRP.)

PRP:Purple RED:Red BLK:Black GRN:Green BRN:Brown BLU:Blue

TEXT:Maximum character number of Multipoint type is 47.

Maximum character number of Pen type is 21.

― ―

HXPRM10mnC0005E

18

3. ORIGINAL PROTOCOL - DATA TRANSMISSION

Order

Command

Description

1

PS

Recording/Stop

2

SR

Input range, recording span

3

SN

Unit 4 SA

Alarm

5

SC

1st chart speed

6

SS

Analog printing period

7

SZ

Zone recording

8

SP

Partial compression/expansion recording

9

SF

Digital printing

10

ST

Tag character

11

SG

Comment character

12

SE

2nd chart speed

13

UD

Display indication mode

14

EN

End

Send the set value in this order

Open command

Open the link

Set value data output

designation

command(TS1)

Prepares for

the set value

data output

Data update

command(ESC T)

Prepares for

the update

data

Data output request

command(LF)

Sends the

update data

Close command

Close the link

Send the command to the

recorder to which you want to

start data transmission.

When you want to get the set

value from same recorder

continuously, this is

unnecessary.

Send the command to the

recorder each time.

Send the command when you

want to send to other recorder.

3.1 Getting the Set Value

When the recorder receives "(TS1)+(ESC T)+(LF)", the recorder sends the setting value continuously

according to the following table 3.1.

The output formats of each command are as same as that of format when it set up.

Table 3.1 Order of the set value transmission

3.2 Data Reception Example

― ―

HXPRM10mnC0005E

19

4. ORIGINAL PROTOCOL - NOTES OF COMMUNICATION

4.1 Half-Duplex Transmission

The recorder side is the half-duplex transmission. The recorder cannot receive the data while sending

the data. When the host computer sends the next data, all the receiving data must be completed.

4.2 Multiple access

Don't open another recorder when one recorder is opened on the same line.

4.3 Continuation of Opening the Link

Don't take interval for a long time, after sending the open command.

The syntax error may occur when not sending data some time.

Be sure to send the close command "ESC C" when you do not use the communication.

If the syntax error occurs, send the status output command "ESC S" to reset the error.

(※ The close command cannot reset the syntax error.)

4.4 Outputting the Status

When the open-link recorder has a data error on its link, the recorder saves the error in the internal status

area as a communication error. The "ESC S" command can reads this status.

Issuing this command clears the on-going error. Refer to chapter 8.5 in the instruction manual.

(HXPRM10mnC0001E, HXPRM10mnC0002E)

Be sure to reset the error when data set to recorder. When no error reset, you may not be able to judge

command, which the error specify.

― ―

HXPRM10mnC0005E

20

5. Modbus RTU PROTOCOL - OVERVIEW

Item

Specification

Interface

RS-485/RS-232C

Protocol

Modbus RTU

Communication speed

1200 /2400 /4800 /9600 /19200/ 38400 [bps]

Parity

None/Even/Odd

Data length

8bit(※)

Stop bit

1bit / 2bit

Slave address

1~247(0 invalid)

Body version

Map version

Contents

Note

before Ver4.00

-

ModbusRTU is not available.

Ver4.00

01

The first release of the Modbus

RTU function.

[CAUTION]

In the old version, you can’t use features added in the new version.

In that case, there is a possibility that it does not work properly when reading / writing to

the address of the newly added function.

5.1 Modbus RTU Protocol

※ Please use in 8bit data length When using the ModbusRTU protocol.

Can’t be performed successfully communication If you using 7bit.

5.2 Add new items and Map version

Depending on the version up of the recorder, there is that the contents of the Modbus map is hanged.

If the Modbus map is modified, Modbus map version (address 30025) will also be updated.

Newly added setting items are available in the corresponding version or later. (Table below)

― ―

HXPRM10mnC0005E

21

6. Modbus RTU PROTOCOL - DATA TRANSMISSION AND RECEPTION

Slave address

(1byte)

Function code

(1byte)

Data

(variable)

CRC

(2byte)

Code

Function

Maximum

data length

Modbus original function (reference)

03H

Setting data read

123 words

Data read from holding register

04H

Input data read

123 words

Data read from input register

06H

One-time setting data write

1 words

Data write to holding register

10H

Continuous setting data writes

123 words

Data write to holding register

Configuration

Data length

Data

Slave address

1

-

Function code + 80H

1

86H

Error code

1

10H

Error check (Only for Modbus RTU)

2

CRC

Total number of bytes

5

-

Error

code

Description

Occurrence condition(s)

01H

Invalid function code

An unsupported function code is specified.

02H

Invalid register address

The relative address range exceeds "9999."

03H

Invalid number of registers

- The length of the accessed data is "0" or the sum of the

relative address and data length exceeds the limit.

- It is assumed that two or more function codes, each

executable for one area, are involved.

- Data longer than 2 words is specified for a one-time write

command.

- The data length exceeds 123 words.

04H

Device error

The received data is shorter than the predefined data length.

10H

Command error

An attempt at a write over an area exceeding the writable range.

6.1 Communication Protocol

This equipment is compatible with Modbus RTU protocol.

Data format of the protocol is as below. It is composed of slave address, function code,

data, and CRC section.

Modbus RTU Data format

6.2 Function codes

Function code that can be used in this equipment is as follows.

6.3 Error response

In accordance with the communication protocol for the pertinent function code, if an error occurs during

command transmission, an error response is returned in the fixed format described in this section.

■ Example of slave response (function code = 06H, command error = 10H)

●Error codes and their occurrence conditions.

― ―

HXPRM10mnC0005E

22

6.4 Reading of input register area

Component

Data

length

Data

Slave address

1

-

Function code

1

04H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

32H

Read data count (high-order)

1

00H

Read data count (low-order)

1

02H

Error check

2

CRC (16 bits)

Total number of bytes

8

Component

Data

length

Data

Slave address

1

-

Function code

1

04H

Data

Number of data bytes

1

04H

Data 1 (high-order)

1

00H

Data 1 (low-order)

1

09H

Data 2 (high-order)

1

00H

Data 2 (low-order)

1

0AH

Error check

2

CRC (16 bits)

Total number of bytes

9

The input register area is a read-only area.

The current measured value and the current time are mapped. Specify the start

address (relative) and data count (assuming that one word is two bytes) of the data to be read.

6.4.1 Reading of input register area

Function code :04H

■ Example of master transmission (with a start address of 0032H and a data count of 2 words)

■ Example of slave response (with a start address of 0032H and a data count of 2 words)

― ―

HXPRM10mnC0005E

23

6.4.2 Input Register Area Map

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

30001

0

Model type(1/8)

1

ASCII

Multipoint type :"MULTI"

30002

1

Model type(2/8)

2

Pen type :"PEN"

30003

2

Model type(3/8)

3

After the blank

30004

3

Model type(4/8)

4

30005

4

Model type(5/8)

5

30006

5

Model type(6/8)

6

30007

6

Model type(7/8)

7

30008

7

Model type(8/8)

8

30009

8

Software version(1/16)

1

ASCII

Version information on a system.

30010

9

Software version(2/16)

2

30011

A

Software version(3/16)

3

30012

B

Software version(4/16)

4

30013

C

Software version(5/16)

5

30014

D

Software version(6/16)

6

30015

E

Software version(7/16)

7

30016

F

Software version(8/16)

8

30017

10

Software version(9/16)

9

30018

11

Software version(10/16)

10

30019

12

Software version(11/16)

11

30020

13

Software version(12/16)

12

30021

14

Software version(13/16)

13

30022

15

Software version(14/16)

14

30023

16

Software version(15/16)

15

30024

17

Software version(16/16)

16

30025

18

Modbus map version

1

Binary

30026

19

Reserve

30027

1A

Reserve

30028

1B

Reserve

30029

1C

Reserve

30030

1D

Reserve

30031

1E

Reserve

30032

1F

Reserve

30033

20

Reserve

30034

21

Reserve

30035

22

Reserve

30036

23

Reserve

30037

24

Reserve

30038

25

Reserve

30039

26

Reserve

30040

27

Reserve

30041

28

Reserve

30042

29

Reserve

30043

2A

Reserve

30044

2B

Reserve

30045

2C

Reserve

30046

2D

Reserve

30047

2E

Reserve

30048

2F

Reserve

30049

30

Reserve

【Input Register Area Map】Function code: 04H

― ―

HXPRM10mnC0005E

24

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

30050

31

Reserve

30051

32

Year

0~99

Every second update

30052

33

Month

1~12

30053

34

Day

1~31

30054

35

Hour

0~24

30055

36

Minute

0~59

30056

37

Second

0~59

30057

38

Recording status

0~1

0:Recording not in progress

1:Recording in progress

30058

39

Chart sensor status

0~1

0:With chart

1:Without chart

30059

3A

Manual print status

0~1

0:Print stops

1:During printing

30060

3B

List print status

0~1

0:Print stops

1:During printing

30061

3C

Engineering

list print status

0~1

0:Print stops

1:During printing

30062

3D

Reserve

30100

63

Reserve

30101

64

Channel status

CH01

00bit:

Alarm 1 1= ON 0= OFF

01bit:

Alarm 2 1= ON 0= OFF

02bit:

Alarm 3 1= ON 0= OFF

03bit:

Alarm 4 1= ON 0= OFF

30102

65

CH02

30103

66

CH03

30104

67

CH04

30105

68

CH05

30106

69

CH06

30107

6A

Measurement data(BIN)

CH01

-32000~32000

Data of more than±32000,

the minus side will be 8181H,

the plus side will be 7E7EH.

30108

6B

CH02

30109

6C

CH03

30110

6D

CH04

30111

6E

CH05

30112

6F

CH06

30113

70

Decimal point position

CH01

0~4

30114

71

CH02

30115

72

CH03

30116

73

CH04

30117

74

CH05

30118

75

CH06

30119

76

Measurement data(Float)

CH01

Float (high-order 2 byte)

Float (low-order 2 byte)

30120

77

30121

78

CH02

30122

79

30123

7A

CH03

30124

7B

30125

7C

CH04

30126

7D

30127

7E

CH05

30128

7F

30129

80

CH06

30130

81

― ―

HXPRM10mnC0005E

25

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

30131

82

Unit (1/4)

CH01

Current unit

30132

83

Unit (2/4)

30133

84

Unit (3/4)

30134

85

Unit (4/4)

30135

86

Unit (1/4)

CH02

Current unit

30136

87

Unit (2/4)

30137

88

Unit (3/4)

30138

89

Unit (4/4)

30139

8A

Unit (1/4)

CH03

Current unit

30140

8B

Unit (2/4)

30141

8C

Unit (3/4)

30142

8D

Unit (4/4)

30143

8E

Unit (1/4)

CH04

Current unit

30144

8F

Unit (2/4)

30145

90

Unit (3/4)

30146

91

Unit (4/4)

30147

92

Unit (1/4)

CH05

Current unit

30148

93

Unit (2/4)

30149

94

Unit (3/4)

30150

95

Unit (4/4)

30151

96

Unit (1/4)

CH06

Current unit

30152

97

Unit (2/4)

30153

98

Unit (3/4)

30154

99

Unit (4/4)

30155

9A

Reserve

・・・

・・・

Unused or later.

39999

270E

― ―

HXPRM10mnC0005E

26

6.5 Reading and writing of the holding register area

Component

Data

length

Data

Slave address

1

-

Function code

1

03H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

C8H

Read data count (high-order)

1

00H

Read data count (low-order)

1

02H

Error check

2

CRC (16 bits)

Total number of bytes

8

Component

Data

length

Data

Slave address

1

-

Function code

1

03H

Data

Number of data bytes

1

04H

Data 1 (high-order)

1

00H

Data 1 (low-order)

1

05H

Data 2 (high-order)

1

00H

Data 2 (low-order)

1

00H

Error check

2

CRC (16 bits)

Total number of bytes

9

The holding register area is a read-write area. Parameter settings and the start and stop command of the

recording state are mapped. For read, specify the start address (relative) and data count (assuming that one

word is two bytes) of the data to be read. For write, specify the start address and the data to be written.

6.5.1 Reading of the holding register area

It is used when calling the parameters that are currently set.

Also, it can not be read in the case of the operation command system. It becomes writing only.

Function code (Reading): 03H

■ Example of transmitting master(starting address=00C8H, data length=2words)

■ Example of slave's responding (starting address=0032H, data length =2words)

― ―

HXPRM10mnC0005E

27

6.5.2 Writing of the holding register area (Single)

Component

Data

length

Data

Slave address

1

-

Function code

1

06H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

C8H

Write data (high-order)

1

00H

Write data (low-order)

1

05H

Error check

2

CRC (16 bits)

Total number of bytes

8

Component

Data

length

Data

Slave address

1

-

Function code

1

06H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

C8H

Write data (high-order)

1

00H

Write data (low-order)

1

05H

Error check

2

CRC (16 bits)

Total number of bytes

8

It is used when carrying out a set of command operations or parameters.

In the case of operation command, it will take effect immediately when you send.

In the case of parameter settings, it is reflected by sending a separate "settings save"

command (address 40104 (relative address 0067H)).

Function code(Writing): 06H

■ Example of transmitting master(starting address=00C8H, data =5)

■ Example of slave's responding (starting address=00C8H, data =5)

― ―

HXPRM10mnC0005E

28

6.5.3 Writing of the holding register area (Continuation)

Component

Data length

Data

Slave address

1

-

Function code

1

10H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

6EH

Number of write register

(high-order)

1

00H

Number of write register

(low-order)

1

07H

Cut the number of bytes

1

0EH

Write data 1 (high-order)

1

AAH

Write data 1 (low-order)

1

01H

Write data 2 (high-order)

1

00H

Write data 2 (low-order)

1

0FH

Write data 3 (high-order)

1

00H

Write data 3 (low-order)

1

01H

Write data 4 (high-order)

1

00H

Write data 4 (low-order)

1

02H

Write data 5 (high-order)

1

00H

Write data 5 (low-order)

1

17H

Write data 6 (high-order)

1

00H

Write data 6 (low-order)

1

1EH

Write data 7 (high-order)

1

00H

Write data 7 (low-order)

1

00H

Error check

2

CRC(16bit)

Total number of bytes

23

-

Component

Data length

Data

Slave address

1

-

Function code

1

10H

Data

Relative start address (high-order)

1

00H

Relative start address (low-order)

1

6EH

Number of write register

(high-order)

1

00H

Number of write register

(low-order)

1

07H

Error check

2

CRC(16bit)

Total number of bytes

8

-

Time setting command and the like, and then used when the data needs to send in succession.

In the case of operation command, it will take effect immediately when you send.

In the case of parameter settings, it is reflected by sending a separate "settings save" command

(address 40104 (relative address 0067H)).

Corresponding to that memory map is part. Please refer to Section 6.5.4 for the area which is

corresponding.

Function code(Writing): 10H

■ Master transmission example (Start address =006EH, Number of data =7words

Data =AA01H,000FH,0001H,0002H,0017H,001EH,0000H)

( Clock set command January 2, 2015 23:30:00 )

■ Slave response example(Response of Start address =006EH, Number of data =7words)

― ―

HXPRM10mnC0005E

29

6.5.4 Holding register area map

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40001

0

Reserve

Unused

…

40100

63

Reserve

Operation command

40101

64

Recording start / stop

AA01:Start

AA00:Stop

Invalid except left.

The disabled in selecting DI.

40102

65

Reserve

40103

66

Reserve

40104

67

Save the settings

AA01:Save

Invalid except left.

40105

68

Manual print

AA01:Start

AA00:Stop

40106

69

LIST print

40107

6A

ELIST print

40108

6B

Comments 1 print

AA01:Sync

AA02:Async

40109

6C

Comments 2 print

40110

6D

Comments 3 print

40111

6E

Clock set

AA01:Run

AA01 ignored except

7 words continuous writing only

valid

Clock sets in the received values.

When isn’t time has come ignored

(month = 0, etc.).

40112

6F

Year(00~99)' 2 digits

40113

70

Month(01~12)

40114

71

Day(01~31)

40115

72

Time(00~23)

40116

73

Minute(00~59)

40117

74

Second(00~59)

40118

75

Reserve

40119

76

Reserve

40120

77

Reserve

40121

78

Communication printing

set

AA01:Sync

AA02:Async

AA01 and AA02 ignored except

Multipoint type:3~26 words

Pen type:3~13 words

Continuous writing only valid

40122

79

Printing color

0~5

Pen type recorder is invalid.

40123

7A

Printing character (01/24)

ASCII

Multipoint type:0~47 character

40124

7B

Printing character (02/)

Pen type:0~21 character

40125

7C

Printing character (03/)

40126

7D

Printing character (04/)

40127

7E

Printing character (05/)

40128

7F

Printing character (06/)

40129

80

Printing character (07/)

40130

81

Printing character (08/)

40131

82

Printing character (09/)

40132

83

Printing character (10/)

40133

84

Printing character (11/)

40134

85

Printing character (12/)

40135

86

Printing character (13/)

40136

87

Printing character (14/)

40137

88

Printing character (15/)

40138

89

Printing character (16/)

40139

8A

Printing character (17/)

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

― ―

HXPRM10mnC0005E

30

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40140

8B

Printing character (18/)

40141

8C

Printing character (19/)

40142

8D

Printing character (20/)

40143

8E

Printing character (21/)

40144

8F

Printing character (22/)

40145

90

Printing character (23/)

40146

91

Printing character(24/24)

40147

92

Reserve

…

40200

C7

Reserve

Setup mode parameters(channel)

40201

C8

Mode

CH1

0~6 , 8 ( 7: Error )

(※1)Mode

40202

C9

Input type

0~34

(※2)Range code

40203

CA

Reference channel

0~4

CH1 configurable value:

None(Setting disable)

CH2 configurable value:0

CH3 configurable value:0~1

CH4 configurable value:0~2

CH5 configurable value:0~3

CH6 configurable value:0~4

40204

CB

Measurement range (L)

depends on the range

(※2) Measurement range

40205

CC

Measurement range (H)

depends on the range

(※2) Measurement range

40206

CD

Scaling range (L)

-32000~32000

(※3) Depends on the Scaling

40207

CE

Scaling range (H)

-32000~32000

(※3) Depends on the Scaling

40208

CF

Decimal point position

0~4

Only when a Scaling is “ON” , this

setting is enable.

40209

D0

Unit (1/3)

ASCII

Units at the time of

the scaling "ON" (Note.1)

40210

D1

Unit (2/3)

40211

D2

Unit (3/3)

40212

D3

Reserve

40213

D4

Tag (1/4)

ASCII

Multipoint type:7 character

Pen type:5 character

40214

D5

Tag (2/4)

40215

D6

Tag (3/4)

40216

D7

Tag (4/4)

40217

D8

Digital print ON/OFF

0~1

0:OFF

1:ON

40218

D9

Paritial compression /

expansion ON/OFF

0~1

0:OFF

1:ON

40219

DA

Zone L

0~99

40220

DB

Zone H

1~100

40221

DC

Partial compression

boundary point position.

1~99

40222

DD

Partial compression

boundary point

measurements.

depends on the range

Scaling "ON":Depends on the scaling

Other : measurement range.

(※3) Scaling dependent

(Note 1) The setting of the unit is enabled, the range setting is only case of "SCALE","SQRT","DECAD",

"DELT","SIGM","MEAN".

(However, "DELT" "SIGM" "MEAN" is valid only when the range setting of the reference channel is "SCALE".)

Otherwise the range setting, the unit is automatically determined according to the range.

― ―

HXPRM10mnC0005E

31

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40223

DE

Alarm 1 action ON/OFF

CH1

0~1

0:OFF

1:ON

40224

DF

Alarm 1 type

0~1

0:H

1:L

40225

E0

Alarm 1 Set value

-32000~32000

(※3) Depends on the Scaling

40226

E1

Alarm 1 RLY output

ON/OFF

0~1

0:OFF

1:ON

40227

E2

Alarm 1 DO No.

0~5

Multipoint type:0~ 5(RLY1~RLY6)

Pen type:0~ 2 (RLY1~RLY3)

40228

E3

Alarm 2 action ON/OFF

0~1

0:OFF

1:ON

40229

E4

Alarm 2 type

0~1

0:H

1:L

40230

E5

Alarm 2 Set value

-32000~32000

(※3) Depends on the Scaling

40231

E6

Alarm 2 RLY output

ON/OFF

0~1

0:OFF

1:ON

40232

E7

Alarm 2 DO No.

0~5

Multipoint type:0~ 5(RLY1~RLY6)

Pen type:0~ 2 (RLY1~RLY3)

40233

E8

Alarm 3 action ON/OFF

0~1

0:OFF

1:ON

40234

E9

Alarm 3 type

0~1

0:H

1:L

40235

EA

Alarm 3 Set value

-32000~32000

(※3) Depends on the Scaling

40236

EB

Alarm 3 RLY output

ON/OFF

0~1

0:OFF

1:ON

40237

EC

Alarm 3 DO No.

0~5

Multipoint type:0~ 5(RLY1~RLY6)

Pen type:0~ 2 (RLY1~RLY3)

40238

ED

Alarm 4 action ON/OFF

0~1

0:OFF

1:ON

40239

EE

Alarm 4 type

0~1

0:H

1:L

40240

EF

Alarm 4 Set value

-32000~32000

(※3) Depends on the Scaling

40241

F0

Alarm 4 RLY output

ON/OFF

0~1

0:OFF

1:ON

40242

F1

Alarm 4 DO No.

0~5

Multipoint type:0~ 5(RLY1~RLY6)

Pen type:0~ 2 (RLY1~RLY3)

40243

F2

Reserve

・・・

40250

F9

Reserve

40251

FA

Scaling range (L)

(float)

2 words continuous writing only

40252

FB

is valid. (※4)float Format

40253

FC

Scaling range (H)

(float)

2 words continuous writing only

40254

FD

is valid. (※4)float Format

40255

FE

Alarm1 set value (float)

2 words continuous writing only

40256

FF

Alarm1 set value (float)

is valid. (※4)float Format

40257

100

Alarm2 set value (float)

2 words continuous writing only

40258

101

Alarm2 set value (float)

is valid. (※4)float Format

40259

102

Alarm3 set value (float)

2 words continuous writing only

40260

103

Alarm3 set value (float)

is valid. (※4)float Format

40261

104

Alarm4 set value (float)

2 words continuous writing only

40262

105

Alarm4 set value (float)

is valid. (※4)float Format

― ―

HXPRM10mnC0005E

32

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40263

106

Reserve

CH01

…

40300

12B

Reserve

40301

12C

Mode

CH02

Input channel

…

40400

18F

Reserve

40401

190

Mode

CH03

Input channel

…

40500

1F3

Reserve

40501

1F4

Mode

CH04

Input channel

…

40600

257

Reserve

40601

258

Mode

CH05

Input channel

…

40700

2BB

Reserve

40701

2BC

Mode

CH06

Input channel

…

40800

31F

Reserve

Setup mode parameters(Other)

40801

320

Recording paper feed

speed (1st)

Multipoint:0~33

(※5) Recording paper feed speed

40802

321

Recording paper feed

speed (2nd)

Pen type:0~40

40803

322

Recording period

0~3

(Multipoint Type only)

0:10sec

1:20sec

2:30sec

3:60sec

40804

323

Reserve

40805

324

Comment (1/8)

Cmt1

ASCII

Multipoint type:0~8 Words

Pen type:0~6 Words

40806

325

Comment (2/8)

40807

326

Comment (3/8)

40808

327

Comment (4/8)

40809

328

Comment (5/8)

40810

329

Comment (6/8)

40811

32A

Comment (7/8)

40812

32B

Comment (8/8)

40813

32C

Reserve

40814

32D

Reserve

40815

32E

Comment (1/8)

Cmt2

ASCII

Multipoint type:0~8 Words

Pen type:0~6 Words

40816

32F

Comment (2/8)

40817

330

Comment (3/8)

40818

331

Comment (4/8)

40819

332

Comment (5/8)

40820

333

Comment (6/8)

40821

334

Comment (7/8)

40822

335

Comment (8/8)

40823

336

Reserve

40824

337

Reserve

― ―

HXPRM10mnC0005E

33

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40825

338

Comment (1/8)

Cmt3

ASCII

Multipoint type:0~8 Words

Pen type:0~6 Words

40826

339

Comment (2/8)

40827

33A

Comment (3/8)

40828

33B

Comment (4/8)

40829

33C

Comment (5/8)

40830

33D

Comment (6/8)

40831

33E

Comment (7/8)

40832

33F

Comment (8/8)

…

40900

383

Reserve

Engineering parameters

40901

384

Burnout

CH1

0~1

0:OFF 1:ON

40902

385

Offset

±32000

40903

386

Offset DP

0~4

40904

387

RJC setting

0~2

0:INT

1:EXT

2:CH

40905

388

RJC EXT fixed value

-32000~32000

Uv

40906

389

RJC CH destination

Multipoint type

:0~5

Pen type:0~1

40907

38A

Printing color

0~5

(Multipoint type only)

(※6)Printing color

40908

38B

Digital filter

0~10000

(Pen type only)

Decimal point:4-digit fixed

40909

38C

Reserve

40910

38D

Reserve

40911

38E

Burnout

CH2

Same as CH1

…

40920

397

Reserve

40921

398

Burnout

CH3

Same as CH1

…

40930

3A1

Reserve

40931

3A2

Burnout

CH4

Same as CH1

…

40940

3AB

Reserve

40941

3AC

Burnout

CH5

Same as CH1

…

40950

3B5

Reserve

40951

3B6

Burnout

CH6

Same as CH1

…

40960

3BF

Reserve

40961

3C0

Hysteresis setting

0~1

0:OFF

1:ON

40962

3C1

Alarm printing function

0~2

0:OFF

1:Alarm printing 1

2:Alarm printing 2

40963

3C2

RUN trigger setting

0~1

0:INT

1:EXT

40964

3C3

CH / TAG printing

switching

0~1

0:CH

1:TAG

― ―

HXPRM10mnC0005E

34

【Holding register area map】Fanction Code:03H(Reading),06H(Writing),10H(Continuous writing)

Address

Relative

address

(HEX)

Name

Array

Content

Remarks

40965

3C4

Logging print ON/OFF

0~1

0:OFF

1:ON

40966

3C5

Logging print interval

0~11

(※7) Logging print interval

40967

3C6

Logging print reference

time

0~23

Unit:Hour

40968

3C7

Logging print criteria

minute

0~59

Unit:Minute

40969

3C8

Logging print

Sync/Async

0~1

0:Sync

1:Async

40970

3C9

Record start/end print

presence or absence

0~2

0:OFF

1:Sync

2:Async

40971

3CA

Host address

1~32

40972

3CB

Communication speed

(Note.1)

0~5

0:1200 bps

1:2400 bps

2:4800 bps

3:9600 bps

4:19200 bps

5:38400 bps

40973

3CC

Data length

(Note.2)

0~1

0:7bit

1:8bit

40974

3CD

Parity

(Note.2)

0~2

0:Even

1:Odd

2:OFF

40975

3CE

Stop bit

(Note.2)

0~1

0:1bit

1:2bit

40976

3CF

Communication protocol

0~1

0:Original

1:ModbusRTU

40977

3D0

Logging print scale

presence or absence

0~1

(Multipoint type only)

0:OFF

1:ON

40978

3D1

Printing gap setting

0~1

(Pen type only)

0:OFF

1:ON

40979

3D2

DI1 function

0~12

(※8)DI function

Can’t select the same function in

DI1,2,3.

40980

3D3

DI2 function

0~12

(※8)DI function

40981

3D4

DI3 function

0~12

(※8)DI function

40982

3D5

Reserve

Unused later

…

49999

270E

Reserve

― ―

HXPRM10mnC0005E

35

6.5.5 Holding register area setting range detail

Value

Content

Remarks

0

Scaling OFF

1 Scaling ON

2

Square root

calculation (SQRT)

It can be set only when the range code is 0 to 7 (voltage current

range).

3

exponent display

(DECAD)

It can be set only when the range code is 0 to 7 (voltage current

range).

4

Difference

calculation (DELT)

Change of input width after calculation, please change by entering

a value in the "measurement range".

5

Sum calculation

(SIGM)

Change of input width after calculation, please change by entering

a value in the "measurement range".

6

Average

calculation (MEAN)

Change of input width after calculation, please change by entering

a value in the "measurement range".

7

Disable

If you select this, it will result in an error.

8

Skip

Code

Input type

Measurement range ※

0

DC voltage

±10mV

(-10.00 to 10.00)

1

0-20mv

(0.00 to 20.00)

2

0-50mV

(0.00 to 50.00)

3

±200.0mV

(-200.0 to 200.0)

4

±1V

(-1.000 to 1.000)

5

0-5V

(-0.000 to 5.000)

6

±10V

(-10.00 to 10.00)

7

DC current

4-20mA

(4.00 to 20.00)

8

TC

(Unit:℃)

(Au-Fe is K)

B

(0.0 to 1820.0)

9

R1

(0.0 to 1760.0)

10

R2

(0.0 to 1200.0)

11 S (0.0 to 1760.0)

12

K1

(-200.0 to 1370.0)

13

K2

(-200.0 to 600.0)

14

K3

(-200.0 to 300.0)

15

E1

(-200.0 to 800.0)

16

E2

(-200.0 to 300.0)

17

E3

(-200.0 to 150.0)

18

J1

(-200.0 to 1100.0)

19

J2

(-200.0 to 400.0)

20

J3

(-200.0 to 200.0)

21

T1

(-200.0 to 400.0)

22

T2

(-200.0 to 400.0)

23 C (0.0 to 2320.0)

24

Au-Fe

(1.0 to 300.0)

25 N (0.0 to 1300.0)

26

PR40-20

(0.0 to 1880.0)

27

PL2

(0.0 to 1390.0)

28 U (-200.0 to 400.0)

29 L (-200.0 to 900.0)

30

RTD

(Unit:℃)

Pt100-1

(-200.0 to 650.0)

31

Pt100-2

(-200.0 to 200.0)

32

JPt100-1

(-200.0 to 630.0)

33

JPt100-2

(-200.0 to 200.0)

Setting range of register on the map written in the ※ are listed below.

※1 Mode

※2 Range code, Measurement range.

― ―

HXPRM10mnC0005E

36

※3 Depends on the Scaling

Value

Speed

(mm/h)

Value

Speed

(mm/h)

Value

Speed

(mm/h)

Value

Speed

(mm/h)

0 0 10

30

20

160

30

750 1 1

11

40

21

180

31

900 2 2

12

50

22

200

32

1,200 3 3

13

60

23

240

33

1,500 4 4

14

75

24

300 5 5

15

80

25

360 6 10

16

90

26

375 7 15

17

100

27

450 8 20

18

120

28

600 9 25

19

150

29

720

Value

Speed

(mm/h)

Value

Speed

(mm/h)

Value

Speed

(mm/h)

Value

Speed

(mm/h)

Value

Speed

(mm/h)

0 5 10

80

20

360

30

2,400

40

12,000 1 10

11

90

21

375

31

3,000 2 15

12

100

22

450

32

3,600 3 20

13

120

23

600

33

4,500 4 25

14

150

24

720

34

4,800 5 30

15

160

25

750

35

5,400 6 40

16

180

26

900

36

6,000 7 50

17

200

27

1200

37

7,200 8 60

18

240

28

1500

38

9,000

9

75

19

300

29

1800

39

10,800

Scaling range, the alarm set value, partial compression boundary point measurement is depends on

the holding register address 40201 "mode" and 40208 "decimal point position".

The set value is reflected in the form that is dependent on the "decimal point position" if the mode is

scaling ON ( “SCALE” and “SQRT” ). In the case of OFF will reflect decimal point position of

the range .

Example 1: "Scaling range (L)" set to 123.45 at Scaling "ON".

Holding register address "40208 (decimal point position)" : Set the value to 2.

Holding register address "40206(scaling range (L))" : Set the value to 12345.