Ohio Medical P25-M, P30-M Operation Manual

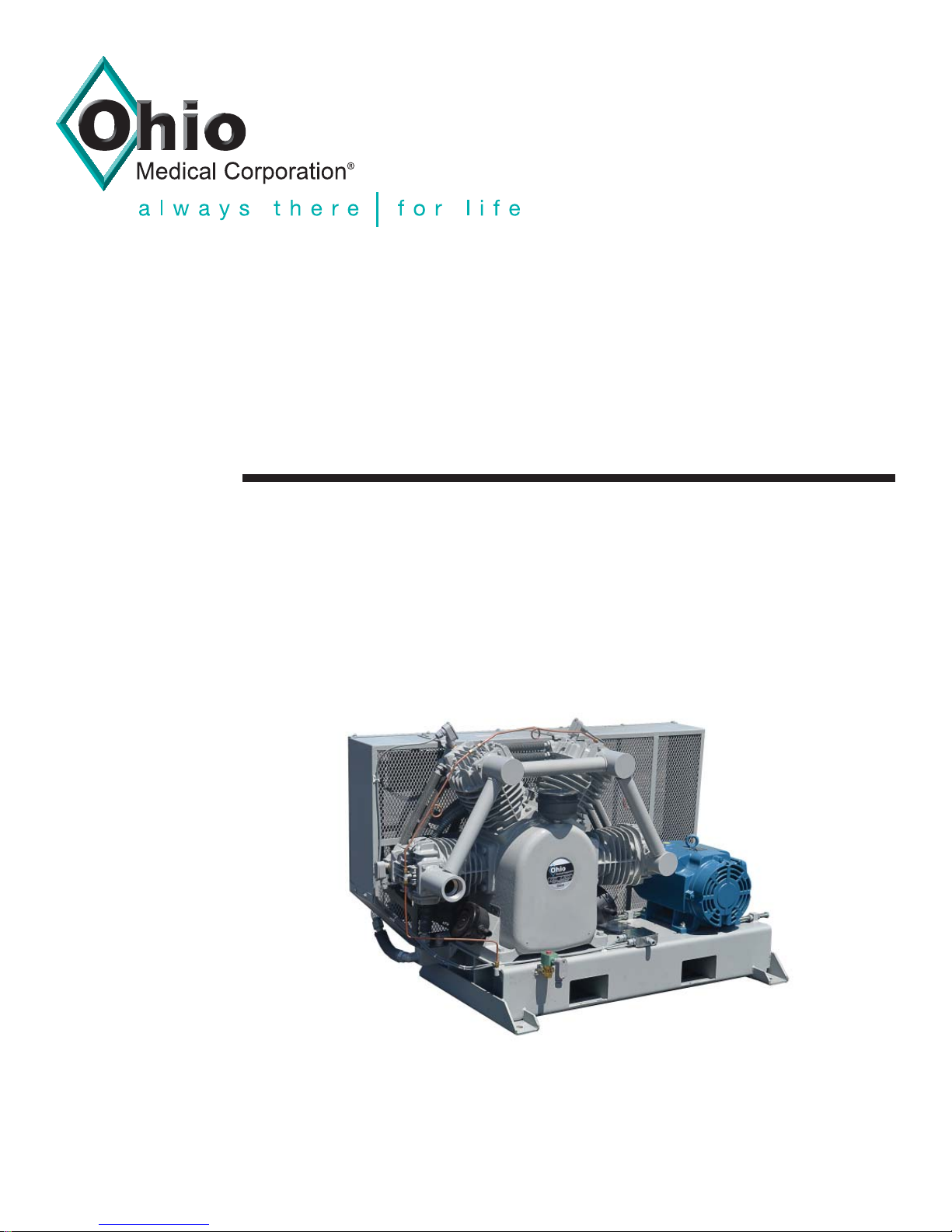

Air Compressor

Operation Manual

P20-M / P25-M / P30-M

255549 Rev.1

01/2014

PREFACE

Thank you for purchasing an Ohio Medical air compressor . This manual introduces our Oil-less

Air Compressors to users about all the information required for air compressor installation,

operation and maintenance to ensure the most effi cient and trouble-free operation.

In any situation of the product being tampered or repaired with parts not supplied by Ohio

Medical Corporation, serviced by unauthorized personnel, or where recommended maintenance

procedures have not been followed, etc, the warranty is void.

This compressor is intended for compressing atmospheric air only and is strictly prohibited from

compressing any other gas.

Ohio Medical compressors incorporate the latest design of technology and use only components

selected for their high quality and durability to ensure more effi cient and durable operation.

We constantly strive to meet the best quality and durability standards and reserve the right to

change specifi cations if required. Thank you again for your interests and continuous support to

of Ohio Medical products.

“Proper Maintenance Leads To Long Service Life”

Safety Precautions:

1. Risk of Hot Surfaces

NEVER touch the discharge tube, cylinder and cylinder head while in operation.

2. Risk of Danger

Do not remove, make adjustment to, or substitute the protection devices. Any adjustment

against the factory setting will automatically void the warranty.

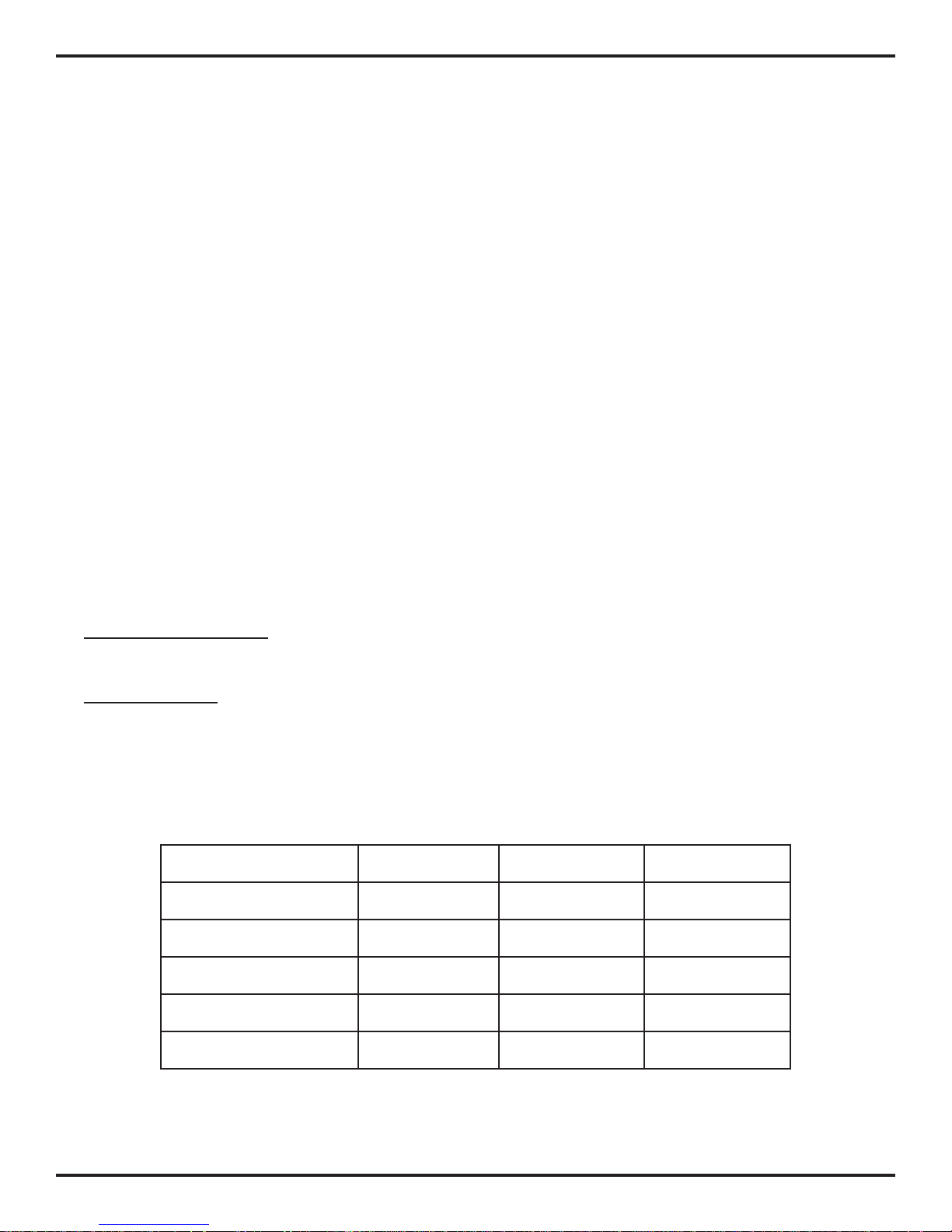

Product Specifi cations

MODEL P20-M P25-M P30-M

PART # 100-0225 100-0226 100-0227

HORSEPOWER 20 25 30

CFM @ 50 PSI 75 90 106

CFM @ 100 PSI 62 76 92

MAX PRESSURE 115 115 115

2 255549 (Rev.1) 01/2014

INDEX

1. General Description --------------------------------- 3

2. Installation --------------------------------------------- 3

3. V-Belt Adjustment ------------------------------------ 4

4. Safety Device ----------------------------------------- 4

5. Operation ---------------------------------------------- 5

6. Daily Maintenance ----------------------------------- 5

7. Periodical Maintenance ---------------------------- 6

8. Trouble Shooting ------------------------------------- 8

Appendix I Maintenance Record ----------------- 9

9. Spare Parts List --------------------------------------11

10. Replacement Parts ---------------------------------14

1. General Description

1.1 This is an Oil-Less air compressor.

1.2 The cylinder is uniquely designed with W-type arrangement; the high rigid structure

guarantees low-vibration, stable and reliable operation.

1.3 Suction/Discharge valve assembly is made of high strength stainless steel alloy,

which allows quick heat dissipation; low noise level; high effi ciency; and longer

working life.

1.4 The well-designed ductile iron crankshaft integrated with counterweight is precisely

balanced for smooth, and long-term operation.

1.5 The cylinder is made of aluminum alloy material with cooling fi n design and special

coating to ensure durable operation.

1.6 Compression ring and guide ring are made of Tefl on

and smooth operation.

1.7 Bearing is totally enclosed with heat resistant grease to ensure long working life.

1.8 Special design on Air Outlet Connectors, for easy maintenance.

®

material to ensure anti-friction

2. Installation

2.1 The unit must be located in an area with good ventilation and enough space for

maintenance work.

2.2 Never place the compressor in an area where the atmosphere is dusty, damp or

where corrosive vapors may enter the unit.

255549 (Rev.1) 02/2014 3

2.3 The machine must be leveled in all directions and must be fi rmly mounted.

2.4 The fl ywheel, which is also a fan for circulating air over the cylinder, should never be

placed closer than 12” against the wall, so there is plenty of cooling air circulation.

2.5 Improper installation and maintenance may result in abnormal conditions such as:

1) Insuffi cient cooling, higher ambient temperature, insuffi cient cooling space, and

incorrect rotation direction all may easily result in over heating the compressor,

electric motor and compressed air.

2) Placing the unit in a damp and dusty environment may fi ll the compressed air

with high moisture and create damage to the control system.

3) Severe vibrations will happen when feet are uneven or mounted on a non-solid

fl oor or nuts and bolts are not securely tightened.

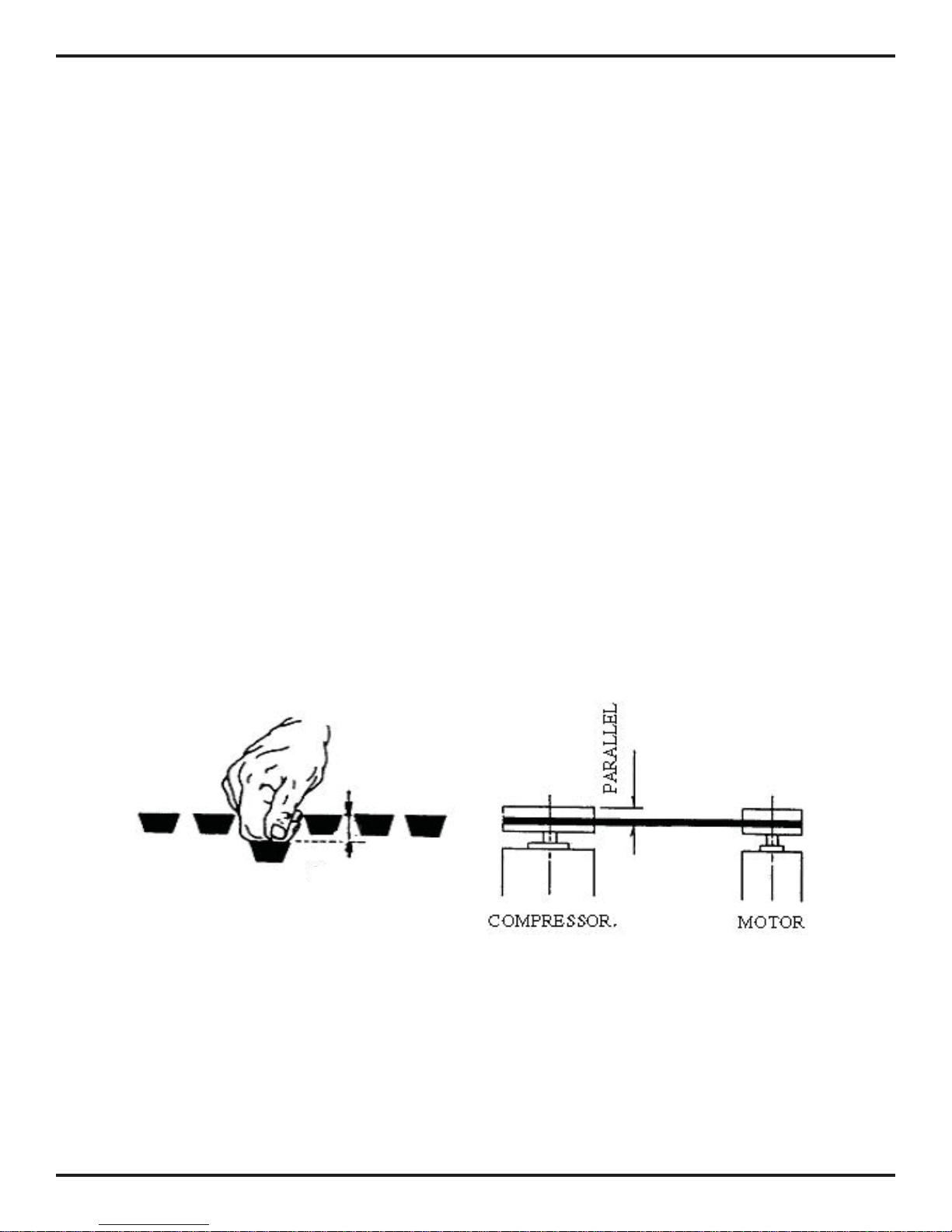

3. V-Belt Adjustment

3.1 Keep the grooves of fl ywheel and motor pulley clean.

3.2 Align fl ywheel with pulley groove when installing the V-belts.

3.3 Over tightened belts can cause extra load and shorten the life of the motor bearings.

Overly loose belts can cause V-belt slippage, reduce effi ciency and break V-belt.

3.4 Maintain the proper belt tension.

1) Use belt adjuster to correct belt tightness (adjust the tightness according to belt

type, center distance and belt length).

2) Push the belt at its central point by hand to check the belt tightness as below:

Press down fi rmly on each individual belt and check the defl ection to be .8” as

shown on the following picture.

.8”

4. Safety Device

4.1 Besides Automatic pressure switch and Automatic unloader as standard protective

components, the following optional safety accessories are also available.

4.2 The air compressor should be equipped with a relief valve to avoid any danger

from excess pressure. The relief valve is designed according to Pressure Vessel

regulations.

4 255549 (Rev.1) 01/2014

4.3 Motor should follow regulations to be equipped with Magnetic switch and Overload

relay to avoid the motor current over pre-setting limit.

5. Operation

5.1 Checks before starting

1) Make sure that electrical connections comply with local electrical regulations.

2) Check set bolts and nuts to be securely tight.

3) Check V belt for proper tension.

4) Check that electrical cables are correct and securely tight.

5) Check that voltage is correct.

5.2 Checks under operation

1) If rotating direction of compressors is right.

2) If compressed air pressure rises normally while running.

3) If current of the motor remains within standard level under loading condition.

4) Stay away from extremely hot components.

6. Daily Maintenance

6.1 Clean the Belt Guard and the ventilation area of the air compressor frequently to

ensure proper cooling.

6.2 Inspect if there is unusual noise or if temperature is too high.

6.3 Check if there is abnormal vibration.

6.4 Check if voltage & current of the power supply are correct.

255549 (Rev.1) 02/2014 5

Loading...

Loading...