Ohio Medical Area, Master, Combo Maintenance Manual

OHIO MEDICAL CORPORATION

Medical Gas Alarms

Installation and

Maintenance Manual

Area Alarm

Combo Alarm

Master Alarm

P/N 255098 (Rev.8) 07/08

Page 2

NOTES

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 3

SQUIRE-COGSWELL COMPANY WAS FORMED IN 1916 AS A SUPPLIER OF RAILWAY AND FOUNDRY

EQUIPMENT IN CHICAGO. IT CONTINUED ALONG THIS BUSINESS PATH UNTIL 1951 WHEN WALTER F.

DEVEREUX PURCHASED THE COMPANY. AT THAT TIME THE COMPANY BEGAN TO CONCENTRATE ITS

EFFORTS ON A LINE OF NON-LUBRICATED AIR COMPRESSORS AND VACUUM PUMPS AND A NICHE

WAS FOUND SERVICING THE PRINTING PRESS INDUSTRY. UTILIZING THIS EXPERTISE, THE COMPANY

BEGAN TO SUPPLY CUSTOM PUMPING PACKAGES FOR A VARIETY OF APPLICATIONS AND IN THE

EARLY 1950’S SQUIRE-COGSWELL SOLD ITS FIRST HOSPITAL VACUUM PUMP PACKAGE, THE

CORNERSTONE OF TODAY’S BUSINESSES AND PRODUCT LINES.

IN 1962, MR. HERBERT SCHIFTER, MR. DEVEREAUX’S SON-IN-LAW TOOK OVER AS PRESIDENT.

MR. SCHIFTER WAS THE ORIGINAL INVENTOR OF THE “DIAMOND ONE” GAS OUTLET WHICH HE

PATENTED IN 1959. THE BUSINESS GREW SIGNIFICANTLY AS A SUPPLIER OF CUSTOM DESIGNED

AND CONSTRUCTED VACUUM AND AIR COMPRESSOR SYSTEMS FOR MEDICAL AND INDUSTRIAL USE.

TO DATE, SQUIRE-COGSWELL HAS MANUFACTURED OVER 15,000 HOSPITAL AIR COMPRESSOR AND

VACUUM PUMPING SYSTEMS THAT HAVE BEEN INSTALLED AROUND THE WORLD BEARING A VARIETY

OF VERY WELL-KNOWN TRADE NAMES.

TODAY IN THE THIRD GENERATION OF FAMILY OWNERSHIP AND MANAGEMENT, SQUIRE-COGSWELL

COMPANY CONTINUES TO SERVE THE WORLDWIDE NEEDS FOR HOSPITAL VACUUM PUMPING AND AIR

COMPRESSOR PACKAGES ALONG WITH THE COMPLETE HEALTHCAIR® MEDICAL GAS PIPELINE

OFFERING.

IN 1962, THE SUBSIDIARY COMPANY, AEROS INSTRUMENTS, INC., WAS FORMED TO MANUFACTURE

SUCTION AND OXYGEN THERAPY EQUIPMENT FOR THE MEDICAL COMMUNITY. TODAY AEROS

CONTINUES TO MANUFACTURE ALL OF THE SALES REQUIREMENTS FOR ONE OF THE LARGEST

SUPPLIERS OF SUCH EQUIPMENT IN THE WORLD. AT THE SAME TIME, AEROS INSTRUMENTS

PRODUCES AND SELLS IT’S OWN LINE OF PORTABLE SUCTION MACHINES UNDER THE WELL-KNOWN

NAMES OF MOBLVAC ®, INSTAVAC ®, CARE-E-VAC ® AND TOTE-L-VAC ®.

HE AEROS INSTRUMENTS SUBSIDIARY, WHICH IS AN ISO 13485 REGISTERED COMPANY AND IS A

T

GOVERNMENT REGISTERED MEDICAL DEVICE MANUFACTURER, PRODUCES THE HEALTHCAIR®

S

ERIES OF MEDICAL GAS PIPELINE EQUIPMENT INCLUDING THE MEDICAL GAS OUTLETS AND

EDICAL GAS ALARM SYSTEMS.

M

SQUIRE-COGSWELL/AEROS INSTRUMENTS INC. ARE THE ONE SOURCE FOR ALL MEDICAL GAS

PUMPING, MEDICAL GAS PIPELINE EQUIPMENT AND MEDICAL ASPIRATION EQUIPMENT. FROM

CUSTOM DESIGNED PUMPING SYSTEMS TO THE MOST MODERN LINE OF ASPIRATION EQUIPMENT

AND MEDGAS PIPELINE AVAILABLE ANYWHERE, SQUIRE-COGSWELL–AEROS DOES IT ALL. NO

OTHER SUPPLIER SURPASSES OUR CONTINUITY OF EXPERIENCE AND LEADERSHIP IN THE MEDICAL

GAS PUMPING, PIPELINE AND ASPIRATION MARKETS.

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 4

T A B L E O F C O N T E N T S

1.0 Responsibilities................. .......... .......... ......... .......... .......... .................... .......... 5

1.1 Installer .. .................... .......... .......... ......... .......... .......... .................... .......... 5

1.2 User ....... .................... .......... .......... ......... .......... .......... .................... .......... 5

2.0 System Description & Function .... .......... ......... .......... .......... .................... .......... 5

2.1 Sensor Module........... .......... .......... ......... .......... .......... .................... .......... 7

2.2 Annunciator Panel...... .......... .......... ......... .......... .......... .................... .......... 8

2.3 Area Alarm Module .... .......... .......... ......... .......... .......... .................... .......... 9

2.4 Master Alarm Module. .......... .......... ......... .......... .......... .................... .......... 9

3.0 Labeling ....... .................... .......... .......... ......... .......... .......... .................... .......... 10

3.1 Area Alarm Module Labeling. .......... ......... .......... .......... .................... .......... 10

3.2 Master Alarm Module Labeling ........ ......... .......... .......... .................... .......... 10

4.0 Installation.... .................... .......... .......... ......... .......... .......... .................... .......... 12

4.1 Mounting Instructions Prior to Drywall & Plaster Installation ................. .......... 12

4.2 Installation & Wiring Instructions After Drywall & Plaster Installation .... .......... 13

4.3 Area Alarm Remote Output Signal Connections... .......... .................... .......... 16

4.4 Master Alarm Connections From Source Equipment....... .................... .......... 17

4.5 Dry Contacts Master Alarm Output Connections .. .......... .................... .......... 18

4.6 Remote Audible Alarm Installation... ......... .......... .......... .................... .......... 19

4.7 Initial Start-Up Checks .......... .......... ......... .......... .......... .................... .......... 20

5.0 Programming .................... .......... .......... ......... .......... .......... .................... .......... 20

5.1 Programming Chart.... .......... .......... ......... .......... .......... .................... .......... 21

5.2 Default Settings Tables......... .......... ......... .......... .......... .................... .......... 22

5.3 Calibration Precautions......... .......... ......... .......... .......... .................... .......... 23

5.4 Programming Change Example....... ......... .......... .......... .................... .......... 24

5.5 Review Area Alarm Programming Parameters ..... .......... .................... .......... 24

5.6 Master Alarm Programming Mode ... ......... .......... .......... .................... .......... 24

6.0 LonWorks® Capabilities ... .......... .......... ......... .......... .......... .................... .......... 25

7.0 Specifications.................... .......... .......... ......... .......... .......... .................... .......... 25

8.0 Troubleshooting ................ .......... .......... ......... .......... .......... .................... .......... 26

9.0 Cleaning....... .................... .......... .......... ......... .......... .......... .................... .......... 27

10.0 Service Item List ............... .......... .......... ......... .......... .......... .................... .......... 27

11.0 Warranty ...... .................... .......... .......... ......... .......... .......... .................... .......... 29

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 5

1.0 Responsibilities

The information contained in this Installation and Operation Maintenance Manual, pertains only to the

Ohio Medical Corporation medical gas alarm system. The medical gas alarm system will operate in

conformance with the descriptions outlined in this manual only when it is operated, maintained and

serviced properly and in compliance with the instructions contained herein.

1.1 Installer Responsibilities

All contents of the alarm are shipped in ISTA approved packaging. The alarm should be handled,

installed, and tested per the recommended practices in this manual. Should such repair or

replacement become necessary, contact Ohio Medical Customer Service (800-448-0770) for original

equipment replacement parts.

1.2 User Responsibilities

The alarm should be tested and examined periodically. Any parts which are found to be damaged,

corroded, contaminated, etc. should be replaced. Possible replacement items are listed on pages 26

to 27 in this manual. Should such repair or replacement become necessary, contact Ohio Medical

Customer Service (800-448-0770) for original equipment replacement parts.

2.0 System Description & Function

The Ohio Medical Corporation Medical Gas Alarm System is designed to continuously monitor the

status of source equipment and gas line pressure of medical gases. The system is comprised of Area

Alarm Modules which monitor and indicate the gas pressure or vacuum level of a specific gas at a

specific point in the hospital and Master Alarm Modules which monitor source equipment such as

oxygen systems, air compressors or vacuum pumps.

The Alarm System monitors gas line pressure with sensors. The Alarm’s Annunciator determines the

status of the pressure and the pressure is displayed on an area alarm module. The alarm module also

has trend light LED’s to show that the displayed pressure is either in a normal, caution, or a high or

low alarm condition.

The Alarm System also has a master alarm module to monitor 10 condition points from source

equipment. Each point represents a condition that the source equipment might have. A dry contact

version of the master alarm is also available to relay conditions of the source equipment to a building

management system.

More detailed descriptions of each module is explained on pages 5 through 8.

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 8

2.2 Annunciator Panel

The Annunciator Panel is the main processing board for the Medical Gas Alarm System. The

Annunciator Panel accepts information by two different means. For gas pressure, the input

signal comes from the Sensor Module and goes to the annunciator to evaluate the pressure

being observed. This information is then transmitted directly to the corresponding Area Alarm

Module where the pressure or vacuum is displayed via the ribbon cable. For source

equipment, a condition is relayed to a point on a master alarm module first and then

transferred to the Annunciator via the ribbon cable. In normal operation, the Annunciator

continuously monitors all pressure, vacuum, and source equipment for alarm conditions.

When an alarm condition is detected, an audible alarm (approximately 80 decibels measured

at 3 feet) will sound and the appropriate red LED will illuminate from the corresponding Area

or Master Alarm Module. The audible alarm will sound under one of the four conditions listed

below.

■ When the pressure input increases above a specified high set-point

□ When the pressure or vacuum decreases below a specified low set-point

■ When an alarm condition is detected on the Master Alarm Module

■ When one of the Sensor Module’s wiring has become disconnected

There are two momentary push buttons on the Annunciator Panel, which are labeled as

“TEST” and “ALARM SILENCE/RESET”. To stop the audible alarm from sounding, press the

“ALARM SILENCE” button. However, the alarm will re-sound again after the specified repeat

time has elapsed unless the alarm condition has been cleared. When a new alarm condition

is detected from another alarm panel, the audible alarm will sound again. Each time the

“Alarm Silence” button is pressed the alarm repeat time will reset. To review if the alarm’s

displays and audible alarm are in working order, press the “TEST” button for approximately 3

seconds. While testing, all display segments and independent LED’s will be illuminated and

the audible alarm will sound.

The Annunciator has a relay for wiring an external buzzer to a remote location. This relay

energizes the external buzzer when the audible alarm sounds.

A communications port is provided on the Annunciator Panel that allows for integration with a

LonWorks® network system allowing the medical gas alarm system to communicate with a

LonWorks® capable building management system.

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 9

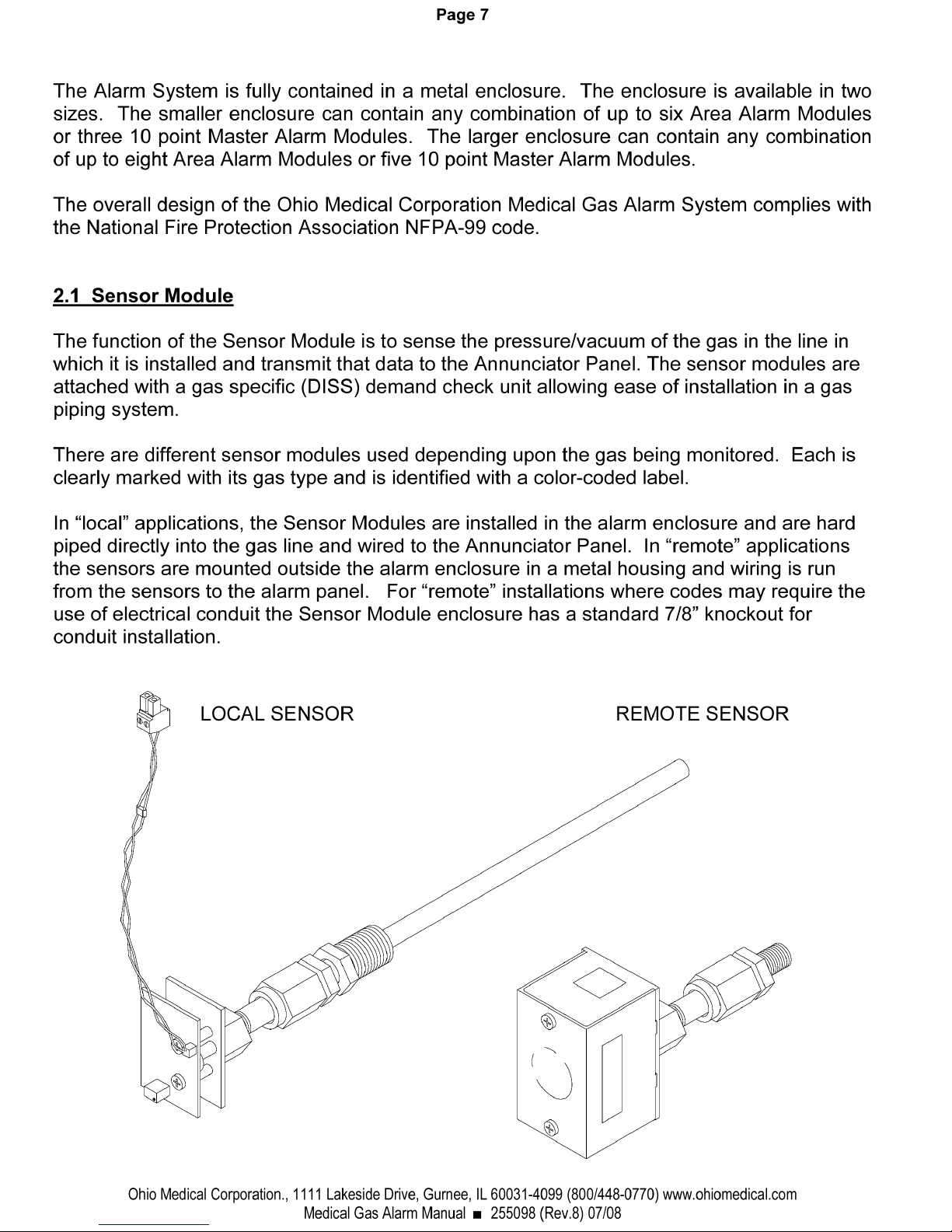

2.3 Area Alarm Panel

The Area Alarm Panel provides a digital display of the actual gas

line pressure or vacuum being monitored. The module has three

different color trend lights to indicate three different conditions of

the gas pressure. These colors are green, yellow and red for

normal, caution, and high or low pressure indications

respectfully. The trend lights and how they correspond to range

in pressure is explained in more detail while programming in

Chapter 5.2 on page 21. When an alarm detects a “LOW” or

“HIGH” condition the corresponding red LED on the Area Alarm

Panel will be illuminated and an audible alarm will sound from

the Annunciator Panel. The red LED will stay illuminated until the

alarm condition has been corrected and the “Reset” button is

pressed.

The two LED’s above the colored trend lights indicates which

unit of measure is being displayed. The units are English

(Standard) or Metric units for pressure or vacuum accordingly

and can be changed to whichever units when programming.

The Area Alarm Module has dry contacts on the backside to

connect to a pair of contacts on a Master Alarm Module for

remote monitoring purposes.

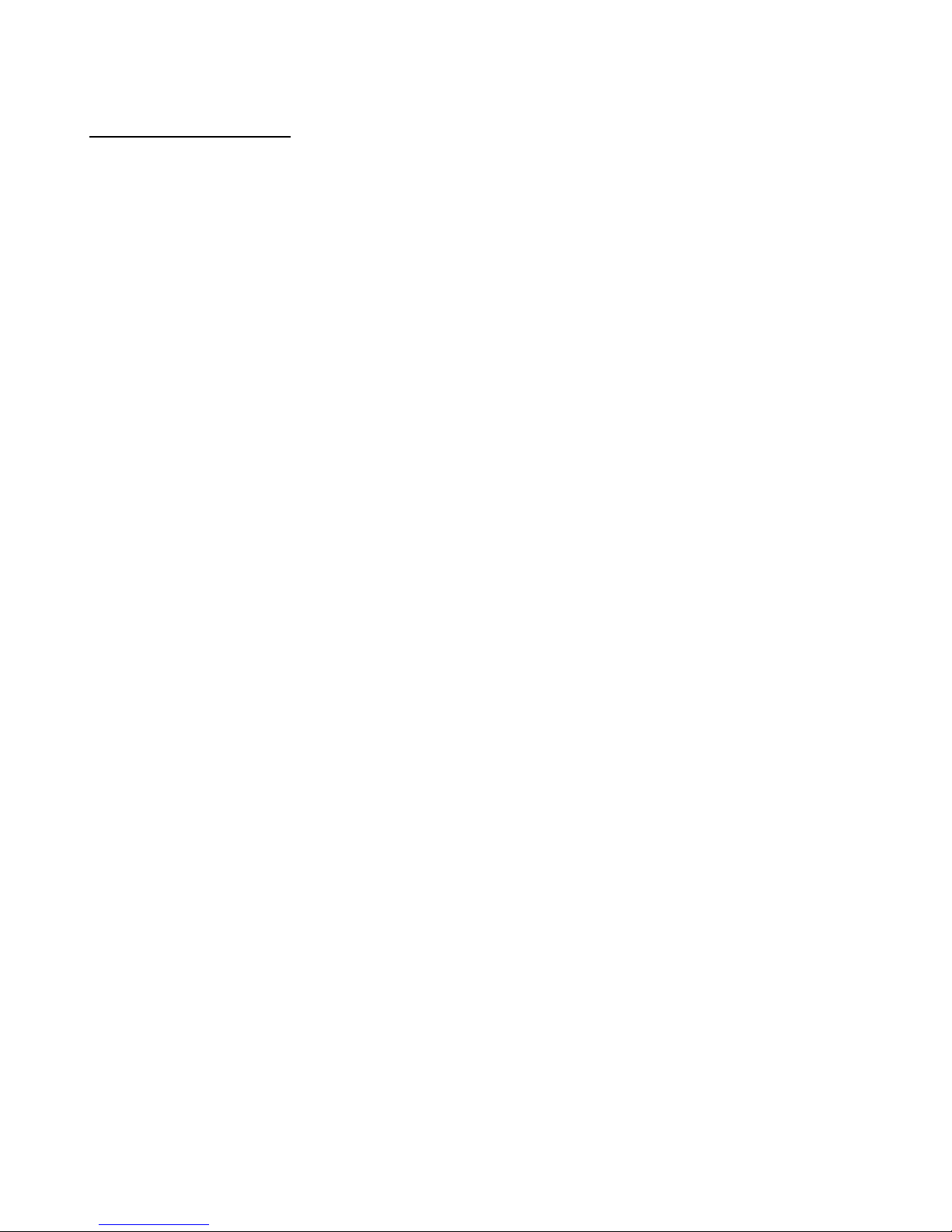

2.4 Master Alarm Panel

The Master Alarm Panel monitors dry contacts from source

equipment or area alarm panels. Each individual Master Alarm

Panel can monitor up to 10 signals. Each pair of contacts is

either configured for normally open or normally closed operation.

The default mode is normally closed per NFPA code. The

Master Alarm panel may be easily labeled to indicate each of the

conditions being monitored. A Dry Contact Master Alarm Module

is also available for computer interface or service to a building

management system.

In operation, the unit continuously monitors for alarm conditions.

Except for the green “POWER” indicator, all Master Alarm Panel

LED lamps will be off when there are no alarm conditions

present. When an alarm condition is detected, the

corresponding LED on the Master Alarm Panel will flash and the

audible alarm from the Annunciator Panel will sound. The LED

will continue to flash until the alarm condition has been corrected

and the alarm has been reset. If two or more alarm condition

occur at the same time, the most recent alarm will flash and the

other existing alarms will remain in constant illumination. Any

alarm will remain lighted until the respective alarm condition has

been corrected and the alarm has been reset.

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Page 10

3.0 Labeling Alarm Modules

Each application needs to describe the medical gas conditions and locations that are unique

to each installation. To provide clear and precise representation of this information, the area

and master alarm modules allocate a sufficient size area on their displays to label this

Information. To simplify in labeling the area or master alarms, please try to label these

assemblies prior to connecting leads to the dry contacts.

3.1 Labeling Area Alarm Modules

For ease of referencing what specific location the area alarm is representing, a window on

the bottom of each alarm is provided to label this information. See Labeling Module

Diagram on figure 3.

1. Make sure the alarm assembly is turned off prior to servicing.

2. Referencing figure 9, disconnect the cable ribbons leading to and from adjacent PCB/

Weldment assemblies.

3. Unfasten top and bottom hex nuts only. Do not unscrew the button head screws

attaching the circuit board to the weldment plate.

4. Extract the area alarm PCB/Weldment assembly from the front panel assembly.

5. Either slide required label through pocket provided in mylar screen or affix required label

directly over screen per Figure 3.

6. Refasten the master alarm assembly to the front panel with the hex nuts.

7. Reconnect cable ribbons as demonstrated in figure 6 on page 14 of your manual.

3.2 Labeling Master Alarm Modules

For ease of referencing what specific alarm conditions are present, each LED on the master

alarm module can be labeled to identify what condition it is represent. See Labeling Module

Diagram on figure 3.

1. Make sure the alarm assembly is turned off prior to servicing.

2. Disconnect cable ribbons from master alarm board.

3. Unfasten top and bottom hex nuts only. Do not unscrew the button head screws

attaching the circuit board to the weldment plate.

4. Extract master alarm PCB/Weldment assembly from the front panel assembly

5. Either slide required label through pocket provided in mylar screen or affix required

label directly over screen per Figure 3. Note that the “MA 1” dry contact will activate

the top LED, the “MA 2” contact activates the second from the top, and then follows

on down in that consecutive order.

Ohio Medical Corporation., 1111 Lakeside Drive, Gurnee, IL 60031-4099 (800/448-0770) www.ohiomedical.com

Medical Gas Alarm Manual ■ 255098 (Rev.8) 07/08

Loading...

Loading...