Ohio Medical 6700-1277-901, 6700-1275-901, 6700-1276-901, 6700-1278-901 User Manual

Thoracic Vacuum

Regulators

Service Manual

O(O)

|(On)

35

30

40

25

20

_

15

10

5

N

I

cmH O

E

R

C

45

2

50

55

60

A

S

E

40

50

5

60

4

High Flow

Low Vacuum

6

30

3

20

2

1

10

a

P

k

-

O

2

H

m

c

-

Thoracic

Thoracic

6700-0011-000 (Rev. 8.1) 08/19

Table of Contents

Safety Instructions ......................................................... 2

Receiving / Inspection.................................................... 2

User Responsibility ....................................................... 3

1/Precautions .................................................................. 4

1.1 Denitions ................................................................... 4

1.2 Warnings ....................................................................4

1.3 Cautions ..................................................................... 5

1.4 Intended Use .............................................................. 5

2/Scope ............................................................................ 6

2.1 North American Thoracic Vacuum Regulator ............. 6

2.2 English Thoracic Vacuum Regulator ..........................6

2.3 French Thoracic Vacuum Regulator ........................... 6

2.4 Spanish Thoracic Vacuum Regulator ......................... 6

3/Description and Specications .................................. 7

3.1 Description................................................................. 7

3.2 Specications ............................................................ 8

3.2.1 Technical Specications ................................... 8

3.2.2 Environmental Specications ........................... 8

3.2.3 Standards ......................................................... 8

4/Operation...................................................................... 9

4.1 Equipment Set-Up ...................................................... 9

4.1.1 Attaching the Overow Safety Trap (OST) ......10

4.2 Operation .................................................................. 10

4.2.1 Mode Selection .............................................. 10

4.2.2 Setting the Suction Level ............................... 10

4.2.3 Pre-use Checkout Procedure ......................... 10

4.2.4 Patient Set-Up ................................................ 11

8/Service Checkout Procedure.................................... 21

8.1 Set-Up ...................................................................... 21

8.2 Flow Test .................................................................. 21

8.3 Gauge Test ............................................................... 21

8.4 Regulation Test ......................................................... 21

8.5 Vacuum Limit Test .................................................... 21

8.6 Positive Pressure Relief Test .................................... 22

8.7 Leak Test .................................................................. 22

9/Maintenance ............................................................... 23

9.1 General Maintenance of Suction Equipment ............ 23

9.2 Recommended Maintenance.................................... 23

9.3 Repair Policy ............................................................ 24

9.4 Technical Assistance ................................................ 24

9.5 Return Instructions ................................................... 24

9.6 Installation Procedure for Adapters/Probes .............. 24

9.7 Disposal Instructions ................................................ 24

Safety Instructions

This manual provides you with important information about the

Thoracic Vacuum Regulators. To ensure the safe and proper

use of this device, READ and UNDERSTAND all of the safety

and operating instructions. IF YOU DO NOT UNDERSTAND

THESE INSTRUCTIONS, OR HAVE ANY QUESTIONS,

REFER TO THIS SERVICE MANUAL, CONTACT YOUR

SUPERVISOR, DEALER OR THE MANUFACTURER

BEFORE ATTEMPTING TO USE THE DEVICE.

Receiving / Inspection:

Remove product from package and inspect for damage. If

product is damaged, DO NOT USE and contact your dealer

or equipment provider.

5/Cleaning, Disinfection and Sterilization .................. 13

5.1 Cleaning ................................................................... 13

5.1.1 Routine Exterior Cleaning & Disinfection ........ 13

5.1.1.1 Approved Cleaning Solutions .............13

5.1.2 Internal Component Cleaning & Disinfection .. 13

5.1.2.1 Approved Flush Solutions ................... 13

5.1.3 Cold Flush Procedure .................................... 13

5.2 Sterilization ............................................................... 13

6/Troubleshooting ........................................................14

7/Service – Disassembly and Assembly ....................15

7.1 Service Tools and Equipment ................................... 15

7.2 Disassembly ............................................................. 15

7.2.1. Part Numbers ................................................ 16

7.3 Assembly ..................................................................20

2 6700-0011-000 (Rev. 8.1) 08/19

WARNINGS

⚠ This device is to be used ONLY by persons who

have been properly trained on the operation of the

device. Incorrect use of this device may cause

serious injury to a patient.

⚠ DO NOT operate this device in the presence of

ammable anesthetics. Static charges may not

dissipate and a possible explosion hazard exists

in the presence of these agents.

⚠ Thoracic Vacuum Regulator vacuum pressures

used should not exceed the recommendations of

the Chest Drainage System Manufacturer. Use of

excessive vacuum pressure may render the Chest

Drainage System ineective and may result in

patient harm.

User Responsibility

This Product will perform as described in this operating

manual and accompanying labels and/or inserts, when

assembled, operated, maintained and repaired in accordance

with the instructions provided. This Product must be checked

periodically. A defective product should not be used. Parts that

are broken, missing, worn, distorted or contaminated should

be replaced immediately. Should such repair or replacement

become necessary, see the Ohio Medical service manual for

service or repairs to this product. For service advice, Ohio

Medical recommends that a telephone request be made

Technical Competence

The procedures described in this service manual should

be performed by trained and authorized personnel only.

Maintenance should only be undertaken by competent

individuals who have a general knowledge of and

experience with devices of this nature. No repairs should

ever be undertaken or attempted by anyone not having such

qualications.

to the nearest Ohio Medical Regional Service Center. This

product and any of its parts should only be repaired using

written instructions provided by Ohio Medical or by Ohio

Medical trained personnel. The Product must not be altered

without the prior written approval of Ohio Medical’s Quality

Assurance Department. The user of this Product shall have

the sole responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage,

or alteration by anyone other than Ohio Medical.

Genuine replacement parts manufactured or sold by Ohio

Medical must be used for all repairs.

Read completely through each step in every procedure

before starting the procedure; any exceptions may result

in a failure to properly and safely complete the attempted

procedure.

Abbreviations used in this manual

O OFF

| ON (Regulate)

CCW Counter-clockwise (decrease)

CW Clockwise (increase)

in Inches

kPa Kilopascals (kPa x 7.50 = mmHg) (kPa x 10.197 = cmH2O)

LPM Liters per minute

mm Millimeters

mL Milliliters

mmHg Millimeters of mercury (mmHg x 0.133 = kPa ) (mmHg x 1.3595 = cmH2O)

cmH2O Centimeters of water (cmH2O x 0.098 = kPa) (cmH2O x 0.7355= mmHg)

°C Degrees Celsius

°F Degrees Fahrenheit

N-m Newton-Meter (N-m x .737 = ft-lb)

ft-lb Foot-Pound Force (ft-lb x 1.356 = N-m)

oz Ounces

NPTF National Pipe Thread Female (USA)

MPTS Multi-Purpose Therapy Stand

g grams

m meters

6700-0011-000 (Rev. 8.1) 08/19 3

1/Precautions

1.1 Denitions

Note: A Note provides additional information to clarify a

point in the text.

Important: An Important statement is similar to a note but of

greater emphasis.

⚠ CAUTION: A CAUTION statement is used when the

possibility of damage to the equipment exists.

⚠ WARNING: A WARNING statement is used when the

possibility of injury to the patient or the operator exists.

1.2 Warnings

This device is to be used only by persons who have been

adequately instructed in its use.

After patient use, regulators may be contaminated. Handle

in accordance with your hospital’s infection control policy.

Clean and disinfect all suction equipment before shipment

for service to ensure transportation personnel and/or service

personnel are not exposed to any hazardous contamination.

Clamping the tubing between the patient and the collection

bottle may result in pressure buildup in the catheter and

tubing.

Connect the vacuum regulator to the vacuum source only.

Connection to positive pressure sources, even momentarily,

could injure the patient or operator and damage the

equipment.

Always connect the regulator to the vacuum source and

check its operation before attaching the patient connection.

Do not use this device in the presence of ammable

anesthetics. Static charges may not dissipate and a possible

explosion hazard exists in the presence of these agents.

Following sterilization with ethylene oxide, quarantine parts

in a well ventilated area to allow dissipation of residual

ethylene oxide gas absorbed by the material. Aerate for 8

hours at 130°F (54°C).

If the vacuum regulator is repaired or disassembled in any

manner, the service checkout procedure (Section 8 Service

Checkout Procedure) must be performed before using the

equipment on a patient.

The pre-use checkout procedure (Section 4.2.3 Pre-use

Checkout Procedure) must be performed before using this

equipment on each patient. If the regulator fails any part of

the pre-use checkout procedure, it must be removed from

service and repaired by qualied service personnel.

When using a disposable chest drainage system, the

atmospheric vent at the top of the suction control chamber

must be occluded for proper suction regulation with the

Thoracic regulator.

The patient port of the regulator must be occluded when

setting the prescribed suction level so that the patient does

not receive higher than required suction levels.

A water seal system must be used with the Thoracic

Regulator to prevent atmospheric air from entering the

pleural cavity, and to show the presence of air movement

into the collection system.

The vacuum relief valve must be tested to ensure compliance

with the manufacturer’s specications before the unit is

placed in service. Remove the unit from service if it fails

the test, otherwise, excessive suction can cause injury to

a patient. Excess Loctite® may seal the steel ball to the

seat. This will disable the vacuum relief valve and may allow

suction to exceed the pre-set limit.

With the patient tubing occluded, all the bubbling in the water

seal system should stop. If bubbling does not stop, check all

connections to troubleshoot and eliminate leaks.

When a leak-free collection system connected to a patient

is turned on, after initial air in the system is eliminated, only

patient air will produce bubbles in the water seal.

4 6700-0011-000 (Rev. 8.1) 08/19

1/Precautions

1.3 Cautions

Cleaning the gauge may cause damage which will result in

inaccurate readings.

Do not steam autoclave or liquid sterilize the regulator.

Severe impairment of the operation of the regulator will

result. The only acceptable method of sterilization is with gas

(ethylene oxide).

To help prevent aspirate from entering the regulator, the

Thoracic Vacuum Regulator should always be used as part

of a water seal drainage system. If as a result of misuse,

water or aspirate gets into the regulator, it may impair the

regulator’s operation.

Do not use any Loctite® products, or any products which

contain methacrylate ester as an active ingredient to seal

the threads on the adapter/probe and ttings.

Only competent individuals trained in the repair of this

equipment should attempt to service it.

Sterilization with ethylene oxide mixtures may cause crazing

(minute supercial cracking) of some plastic parts. Crazing

will be more pronounced when mixtures containing Freon

are used.

1.4 Intended Use

The Ohio Medical® Thoracic Vacuum Regulator is a vacuumpowered suction apparatus that is intended for use with Chest

Drainage Systems in Thoracic, Cardiovascular, Trauma and

Critical Care applications.

®

Prior to placing the unit back into service, after disassembly

or cleaning, perform the service checkout procedure (Section

8 Service Checkout Procedure).

The gauge assembly must be handled with utmost care to

retain its precision. If the lens is removed, do not rest the

gauge on its face.

Use care when unhooking the tension spring from the

regulator. Excessive tension on the spring can crack the

plastic at the base of the mounting post.

To prevent stripping of the plastic threads, place the screw

in the hole and turn counter-clockwise until it drops into the

original threads, then tighten the screw.

Use of lubricants other than those recommended may

degrade plastic or rubber components (Section 7.1 Service

Tools and Equipment).

Not for eld or transport use*.

* The categories of Field and Transport Use are specically dened in ISO

10079-3 (Section 5.1.2), “Field” means use at accidents or emergencies

outside a hospital. “Transport” means use in ambulances, cars or airplanes.

These situations may expose the equipment to uneven support, dirt,

water, mechanical shock and temperature extremes. Ohio Medical suction

equipment has not been tested to comply with the specic requirements of

these categories.

6700-0011-000 (Rev. 8.1) 08/19 5

2/Scope

This service manual contains service, maintenance and

parts information for four models of the Thoracic Vacuum

Regulator.

Note: Parts numbers are for vacuum regulators without

adapters/probes.

2.1 North American

Thoracic Vacuum Regulator

O(O)

35

30

40

25

45

20

_

cmH O

2

15

10

5

50

55

60

E

A

R

S

C

E

N

I

2.3 French

Thoracic Vacuum Regulator

|(On)

30

40

3

4

High Flow

50

Low Vacuum

5

6

60

Thoracique

6700-1277-901

20

2

1

10

a

P

k

-

O

2

H

m

c

-

Thoracic

6700-1275-901

2.2 International

Thoracic Vacuum Regulator

|(On)

30

40

3

4

High Flow

50

Low Vacuum

5

6

60

20

2

1

10

a

P

k

-

O

2

H

m

c

-

2.4 Spanish

Thoracic Vacuum Regulator

|(On)

30

40

3

4

High Flow

50

Low Vacuum

5

6

60

Thorácico

6700-1278-901

20

2

1

10

a

P

k

-

O

2

H

m

c

-

Thoracic

6700-1276-901

6 6700-0011-000 (Rev. 8.1) 08/19

3/Description and Specications

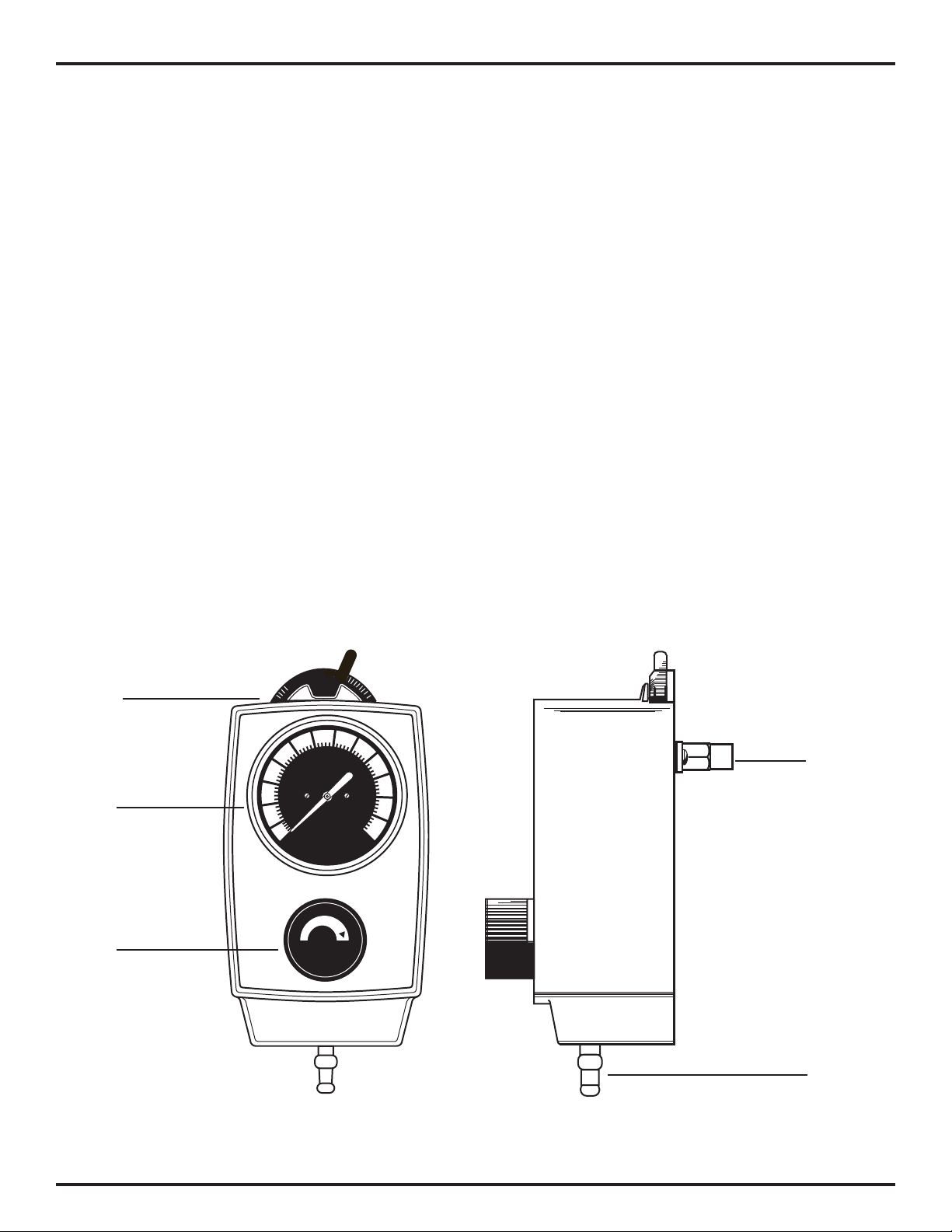

3.1 Description

⚠ WARNING: Do not use this device in the presence

of ammable anesthetics. Static charges may not

dissipate and a possible explosion hazard exists in

the presence of these agents.

The Thoracic Vacuum Regulator is a lightweight, compact

unit used throughout the hospital for chest and mediastinal

drainage.

Each regulator contains a vacuum gauge which indicates

suction supplied by the regulator.

The Thoracic Vacuum Regulator operates only in a regulated

vacuum mode. The unit has a diaphragm-type regulator

which provides an adjustable vacuum of 0 to 50 cmH2O (0 to

4.9 kPa). The regulator has a vacuum gauge with increments

to 60 cmH2O (5.9 kPa) and is housed in impact-resistant

plastic for durability.

A vacuum limiting valve is incorporated which limits the

maximum vacuum between 50 and 60 cmH2O (4.9 and 5.9

kPa). If positive pressure is applied to the patient port (e.g.

patient coughing) a positive pressure relief valve operates to

relieve the pressure.

In the | (ON) mode, the vacuum source is connected through

the regulator module which functions as an automatic valve.

Turning the suction control knob adjusts the position of the

regulator module and allows selection of a predetermined

level of suction.

During use, as the ow requirement increases, the valve

automatically opens to maintain suction at the pre-set level.

Conversely, when the ow requirement decreases, the valve

automatically closes to maintain suction at the pre-set level.

The same mechanism compensates for changes in supply

vacuum and automatically maintains the pre-set suction

level.

1. Suction Control Knob - Allows adjustment of suction to

the patient.

2. Mode Selector Switch - Allows quick mode changes.

a. | (ON) - Suction can be adjusted with the suction

control knob.

b. O (OFF) - No suction is supplied to the patient.

3. Vacuum Gauge - Displays the suction level to the patient

during use.

Mode

Selector

Switch

Vacuum

Gauge

Suction

Control

Knob

O(O)

30

25

20

_

cmH O

15

10

5

R

C

N

I

Thoracic

35

40

45

2

50

55

60

E

A

S

E

Probe

Port

Patient

Port

Adapter/

6700-0011-000 (Rev. 8.1) 08/19 7

3/Description and Specications

3.2 Specications

3.2.1 Technical Specications

Gauge: Accuracy ± 3 cmH2O (± 0.3 kPa)

Flow Rate: 0 to 40 LPM without ttings at full increase setting

depending on the supply vacuum and open air ow

Positive Pressure Safety Relief Valve: Located in patient circuit to prevent pressurization of

patient chest cavity in excess of 10 cmH2O (1.0 kPa)

Regulated Suction Range: 0 to 50 cmH2O (0 to 4.9 kPa)

Vacuum Relief Valve: 55 cmH2O ± 5 cmH2O (5.4 kPa ± 0.5 kPa)

Weight: 24 oz (680 g)

(less ttings)

Dimensions Height: 7.2 in (185 mm)

(less ttings) Width: 3.5 in (90 mm)

Depth: 4.3 in (108 mm)

Latex tubing 0 to full vacuum

0.25 in (6.4 mm) ID Flow dependent on source and set-up

Disposable tubing 0 to full vacuum

(available separately in some markets; Flow dependent on source and set-up

6 mm ID x 450 mm, 750 mm and 2 m) to connect regulator and collection bottle

Disposable Suction Filter: 0 to full vacuum

0 to 100 LPM @ 650 mmHg (86.7 kPa)

3.2.2 Environmental Specications

Operating Temperature Range: 40°F to 120°F (4°C to 49°C)

Storage Temperature Range: 0°F to 160°F (–18°C to 71°C)

Operating and Storage Relative Humidity: 5 to 95%

3.2.3 Standards

ISO 10079-3 (Section 5.1.2)

8 6700-0011-000 (Rev. 8.1) 08/19

Loading...

Loading...