Ohio Medical 263748-C, 263748-B, 263748-E, 263748, 263748-CB Service Manual

...

®

12.1” Touchscreen Master Alarm

Service Manual

Master Alarm Service Manual

Table of Contents

1.0 Responsibilities ............................................................................................................... 3

1.1 Installer Responsibilities ......................................................................................................... 3

1.2 User Responsibilities .............................................................................................................3

2.0 Alarm System Description & Functions ............................................................................. 3

2.1 Description of Basic Alarm & Functions ................................................................................... 3

2.2 Normal, Alarm & Maintenance Mode Condition Views ...............................................................4

2.3 Alarm Banners & Silence Alarm Conditions .............................................................................. 5

2.4 Testing The Alarm .................................................................................................................5

3.0 Installation ...................................................................................................................... 6

3.1 Box Assembly ....................................................................................................................... 6

3.2 Internal View of Master Alarm ................................................................................................. 6

3.3 Installation Instructions Prior To Drywall Plaster .......................................................................7

3.4 Box Wiring & Drywall/Plaster Preparation ................................................................................8

3.5 Instructions After Drywall & Plaster ......................................................................................... 9

3.6 Sensor Connections To Master Alarm Input Terminal(s) ........................................................... 10

3.7 Master Alarm Outputs .......................................................................................................... 12

4.0 Set-Up & Programming .................................................................................................. 13

4.1 Important Electrical Safety Notice Prior To Set-Up .................................................................. 13

4.2 Initial Set-Up ........................................................................................................................14

4.3 Programming, Conguration & Setting Up Alarm Points .......................................................... 15

Alarm Event Log

View All Events & History

View Single AP Log

Information

Test Alarms Points

Other Settings (Display, Factory Reset, Scroll Time)

5.0 Specications ................................................................................................................ 19

6.0 Dimensions ................................................................................................................... 20

7.0 Part Numbers ................................................................................................................ 20

8.0 Battery Replacement ..................................................................................................... 21

9.0 Troubleshooting ............................................................................................................. 22

10.0 Wiring Diagram ........................................................................................................... 23

2

550731 (Rev. 2.1) 11/19

Master Alarm Service Manual

1.0 Responsibilities

Information contained in this Installation and Operation Maintenance Manual pertains to the Ohio Medical Color LCD Touch

Screen Master Alarm (MA) System. The Master Alarm System will operate as described in this manual when operated and

serviced in compliance with the instructions.

1.1 Installer Responsibilities

The alarm should be handled, installed, and tested per the recommended practice as described within this manual.

Should any repair or replacement become necessary, contact Ohio Medical Customer Service (800-448-0770) for original

equipment, replacement parts.

1.2 User Responsibilities

The alarm should be tested and examined periodically according to facility codes. Any parts which are found to be

damaged, corroded, contaminated, etc. should be replaced.

2.0 Alarm System Description & Function

PLEASE NOTE THE FOLLOWING DEFAULT PASSWORD (PW) = “1111”

Note: The unit’s password may be changed anytime. Please contact Ohio Medical Customer Service if your password is forgotten. A Factory

Reset will need to be performed. Upon a Factory Reset, ALL user-customized information/settings will need to be re-entered. Given this,

please store your password in a secure location.

2.1 Description of Basic Alarm & Functions

The alarm is designed to monitor and display the status of up to 30 Alarm Points (APs). When an alarm condition occurs,

a signal is sent to the MA and is displayed on the Liquid Crystal Display (LCD). The unit is capable of relaying alarm

conditions to a Building Management System (BMS) via Dry Contacts, Modbus (or BACnet) or, via Ethernet connection.

Custom alarm labels may be created or chosen in the preprogrammed menu. Examples of alarm conditions include: High/

Low Gas Pressure, Low Vacuum, Manifold Reserve Tank In-Use, High Temperature Shutdown, Reserve Pump Running.

Alarm Events may be viewed/cleared per an individual alarm condition or, collectively as a group. The unit is also

equipped with a Maintenance Mode to permanently silence the audible portion of the alarm until the condition(s) causing

the alarm are xed. Visual Indicators always remain.

Other Key Functions Include:

Universal 100V-240V AC Power Input with Circuit Breaker Protection

Normally Open (N.O.) or Normally Closed (N.C.) alarm point set-up

Alarm Condition Communications (to BMS): Via BACnet, Modbus, Ethernet or Dry Contacts

Up-To 30 Dry Contact Outputs

12.1” Full Color LED Screen; Password Protection

Adjustable Screen-Scroll and Audible Alarm Silence Options

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE PROCEEDING

2.2 Normal Alarm & Maintenance Mode Condition Views

HAZARD OF ELECTRICAL SHOCK OR BURN. TURN OFF POWER

BEFORE WORKING ON THIS EQUIPMENT.

WARNING! SOME EDGES MAY BE SHARP, HANDLE WITH

CAUTION.

550731 (Rev. 2.1) 11/19

3

Master Alarm Service Manual

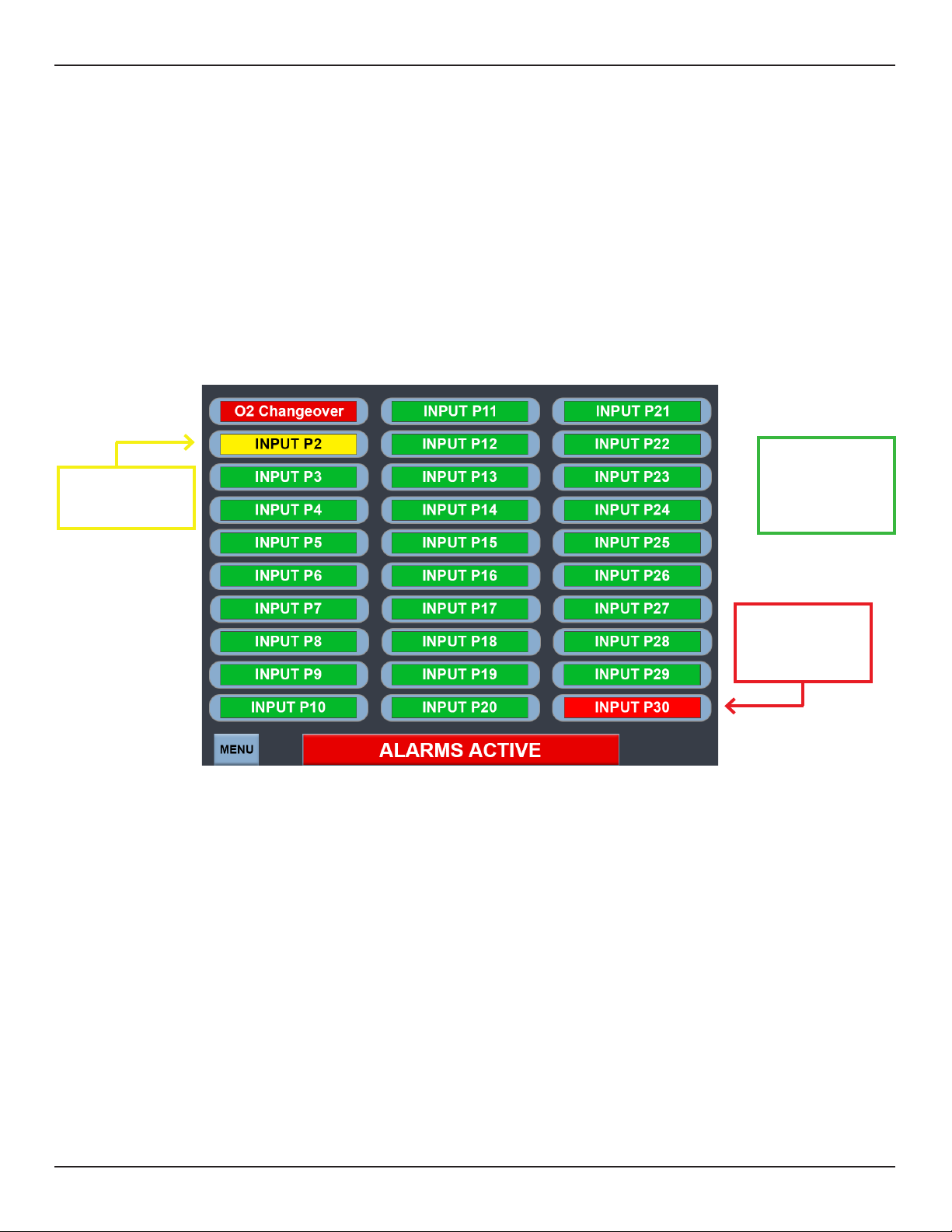

An AP will be displayed in three different ways:

1. Normal Alarm Condition: An AP will display with a green background and white text (as shown below) if

conditions on the source equipment are operating within normal operating parameters.

2. Alarm Condition: An AP in an alarm condition will display with a red background and white text (as shown

below) if conditions on the source equipment are operating outside normal operation.

3. Maintenance Mode: An AP in maintenance mode will display with a yellow background with black text (as

shown below) …. When the AP is manually placed in Maintenance Mode.

Figure 2.2 Below represents a 30 alarm points (APs) set-up. Two APs are in an alarm condition (red), one is in

maintenance mode (yellow) – with the rest seen as operating normally (green).

[FIGURE 2.2]

1. Normal Alarm

Condition

3. Maintenance Mode

Alarm Point Inputs, such

as INPUT P2

Alarm Point Inputs, such

as INPUT P3 thru INPUT

P29

{

Figure 2.2 Showing Master Alarm Front LCD Touch Screen

Note: Alarm Point Input titles (i.e. O2 Changeover) are customizable by the user.

2. Alarm Condition

Alarm Point Inputs, such

as O2 Changeover and

INPUT P30

4

550731 (Rev. 2.1) 11/19

Master Alarm Service Manual

2.3 Alarm Banners & Silence of Audible Alarm Conditions

The audible alarm will sound under any of the following key conditions:

1. An alarm condition exists for one or more APs.

2. The user adjustable Silence Duration time elapsed and any alarm condition is still present.

3. An alarm input on the MA is congured as Normally Open (N.O.) and the dry contacts for the AP (associated with

the Source Equipment) are congured as Normally Closed (N.C.).

4. An AP is congured, but no actual physical connection to the source equipment is made.

Silencing the Alarm

The Audible Alarm may be silenced in three ways. If the originating cause is not corrected, the following options will not x

the alarm condition.

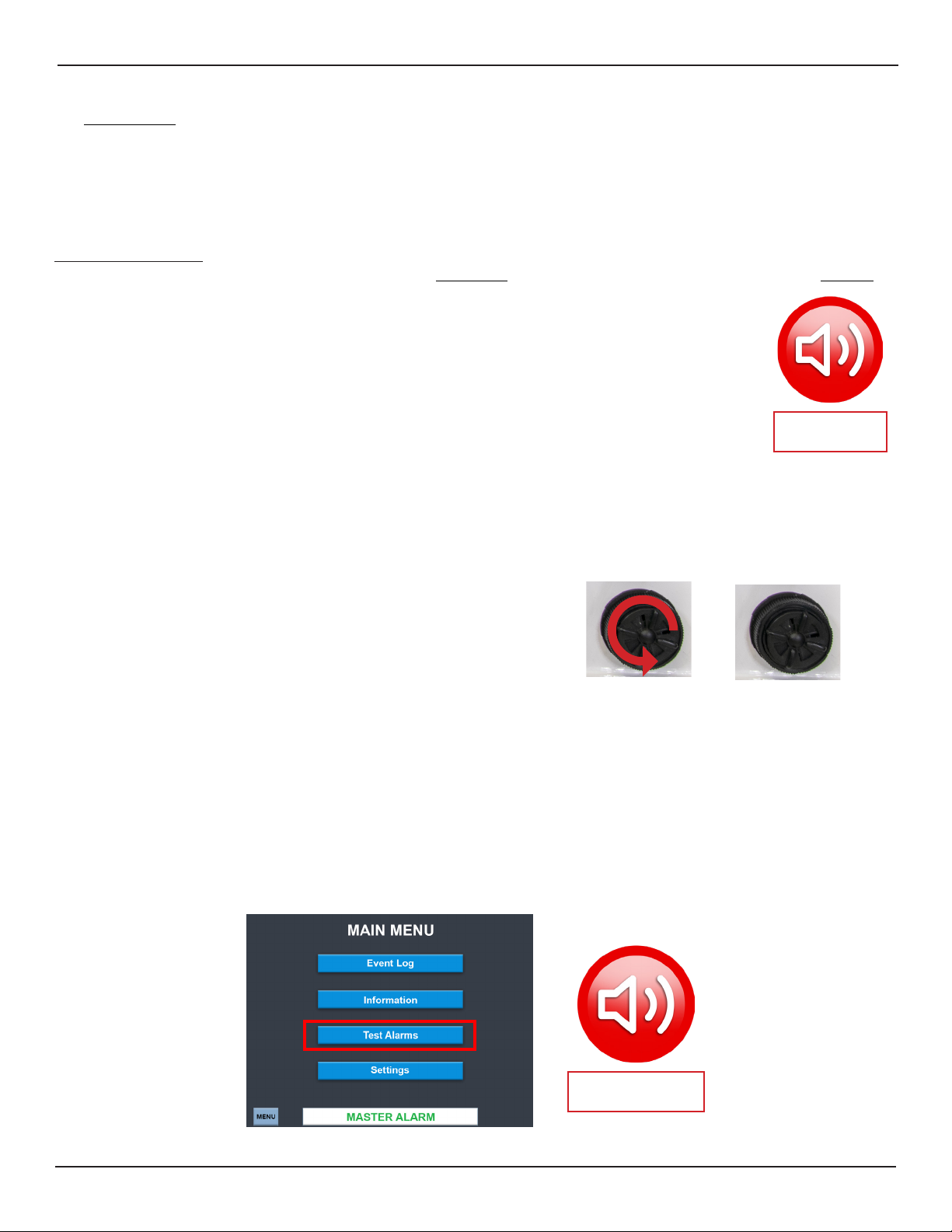

1. Silencing Button: The audible alarm may be temporarily silenced at any time by pressing

the Master Alarm Silencing Button (right) in the lower right portion of

the screen, regardless of the screen. Each time the alarm is silenced,

the user selected silence duration time will restart.

2. Silencing Duration: The default silencing duration time is 5 minutes. The silence duration can

be user set to a maximum of 59 minutes & 59 seconds. Silencing duration

Master Alarm

Silencing Button

must be set greater than 0.

3. Maintenance Mode: Any AP can be manually placed into maintenance mode. This will silence the audible alarm.

Visual alarm indicators remain.

[FIGURE 2.B]

Figure 2.B The volume of the alarm may be adjusted by rotating

the volume control located in the lower right corner of the box

(Reference Figure 3.2).

Bafes fully open for

loudest alarm

Bafes fully closed for

softest alarm

2.4 Testing the Alarm Points (APs) [Visual & Audible]

The MAIN MENU screen contains a Test Alarms button. Press and hold the button for approximately ve seconds. The

alarm will sound for 10 seconds along with red and white ashing visual indicators for all Inputs. See Figure 3.C

[FIGURE 3.C]

550731 (Rev. 2.1) 11/19

Master Alarm

Silencing Button

5

Master Alarm Service Manual

3.0 Installation

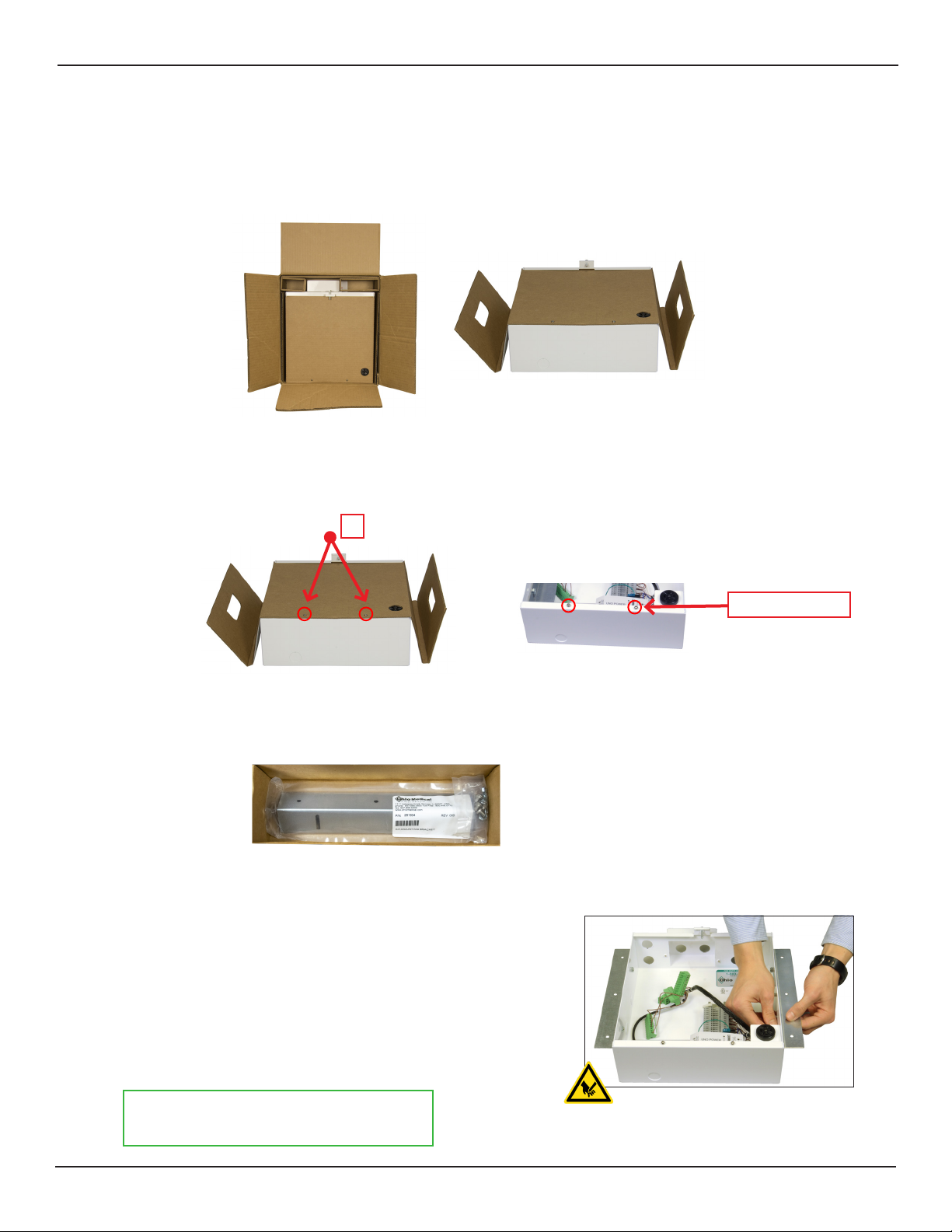

The alarm is shipped fully wired, tested and calibrated. For ease of assembly in walls, the alarm is shipped in two sections;

the Box and Front Panel assemblies. The box is installed in the drywall, then the front panel is attached. Finally, box wiring

and sensor inputs/outputs are congured.

3.1 Box Assembly

All sides of the enclosure have knock outs for the power supply

wiring and the input/output terminal blocks. Use a hammer and at

headed screwdriver to punch through the knockouts as shown in

Figure 3.1.

[FIGURE 3.1]

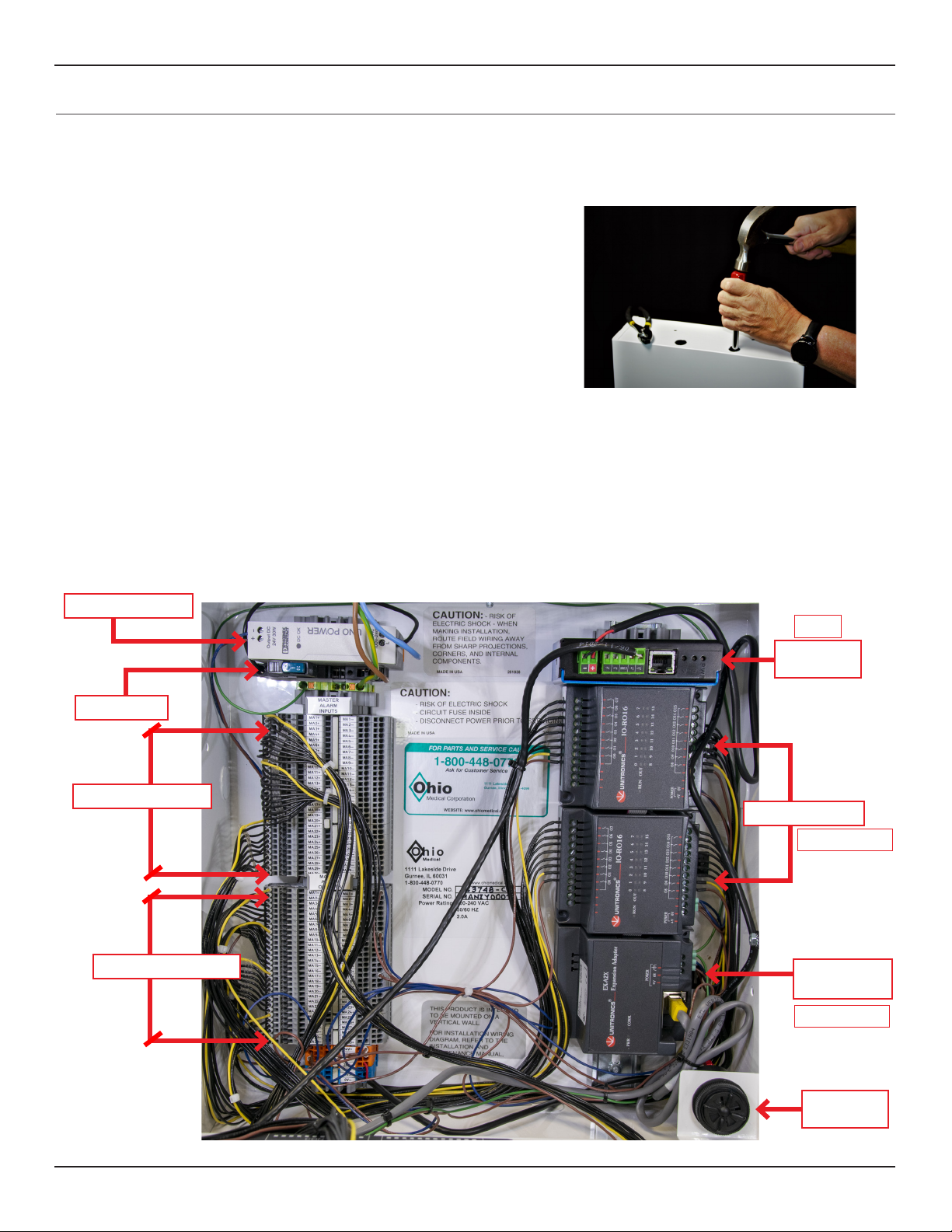

3.2 Internal View of Master Alarm

Primary components integrated within the Box Assembly include what is shown in Figure 3.2 below.

Primary Power Supply

Circuit Breaker

1. Input Terminal Blocks

2. Output Terminal Blocks

[FIGURE 3.2]

Optional

BACnet

Module

IO for Alarm Outputs

Depending on model

Expansion

Adapter

Depending on model

Volume

Control

6

550731 (Rev. 2.1) 11/19

Master Alarm Service Manual

3.3 Installation Instructions Prior to Drywall Plaster

It is important to mount the box between the wall studs at the required height for its intended use. Check all federal, local,

and building codes prior to installation. Adjustable wall-mounted brackets are provided to accommodate for wall thickness

after dry walling, plastering, or other means of wall nishing.

Figure 3.3.1 Remove the metal alarm box assembly from the carton.

[FIGURE 3.3.1]

Figure 3.3.2 Remove the cardboard dust cover from the metal box via the two screws (X). Re-insert the screws into the

box; they will be used later to hold the cardboard cover in place during drywalling/plastering, and ultimately

used for the front panel hinge assembly.

X

[FIGURE 3.3.2]

Reinsert screws

Figure 3.3.3 Remove the metal wall brackets and hardware from the box located inside the primary box the unit has

shipped in.

[FIGURE 3.3.3]

Figure 3.3.4 Install the brackets to the left and right sides of the box.

[FIGURE 3.3.4]

3.3.5 Adjust the brackets so that the front edge of the box assembly

[as shown without the hinged cover] is ush with the nished wall.

3.3.6 Once positioned & square, tighten the hardware securing the

mounting brackets to the alarm box assembly and wall supports.

Do not FULLY tighten hardware at this time.

Keep lightly snug to adjust to wall conditions.

550731 (Rev. 2.1) 11/19

7

Master Alarm Service Manual

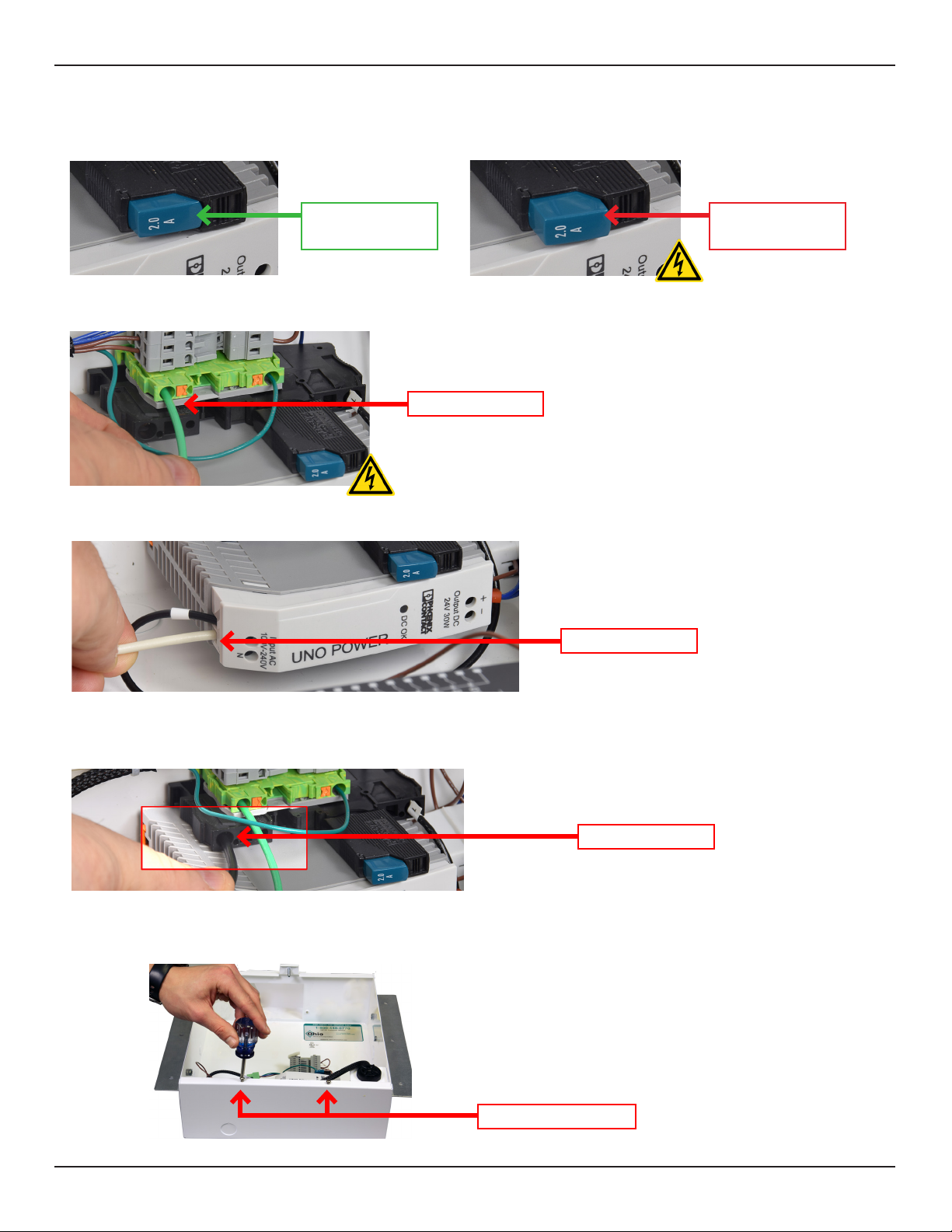

3.4 Box Wiring & Drywall/Plaster Preparation

For safety, the circuit breaker must be in the OFF position prior to electrical connections.

ON Position

pushed and locked in

Strip ½” of insulation and connect the ground wire to the green ground terminal block.

Ground Lead Location

Strip ½” of insulation, connect the neutral lead wire to the power supply terminal labeled “N”.

Neutral Lead Location

OFF Position

fully extended out

Strip the insulation and connect the live lead wire to the circuit breaker.

If not already removed, remove the two screws from the enclosure and set aside.

Note: For clarity, the product is shown removed from the wall.

Remove the Two Screws

8

550731 (Rev. 2.1) 11/19

Live Lead Location

Loading...

Loading...