Page 1

6700-0078-000 Rev1 06/2009

Continuous Vacuum

Regulators

Service Manual

E

D

M

100

80

120

-mmHg

60

W

O

40

L

20

F

140

H

I

G

H

160

180

200

U

C

L

A

V

L

600

400

500

50

60

70

High Flow

High Vacuum

80

90

100

700

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

Page 2

6700-0078-000 Rev1 06/2009

User Responsibility

This Product will perform in conformity with the description thereof contained in this manual and accompanying

labels and/or inserts, when assembled, operated, maintained and repaired in accordance with the instructions

provided. This Product must be checked periodically. A

malfunctioning Product should not be used. Parts that

are broken, missing, plainly worn, destroyed or contaminated, should be replaced immediately. Should such

repair or replacement become necessary, Ohio Medical

recommends that a telephonic or written request for service advice be made to the nearest Ohio Medical Service

Office. This Product or any of its parts should not be

repaired other than in accordance with written instructions provided by Ohio Medical, or altered without the

prior written approval of Ohio Medical’s Safety

Department. The user of this Product shall have the sole

responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage, or alterations by anyone other than Ohio Medical

Corporation.

Important: Federal law in the U.S.A. and Canada

restricts this device to sale by or on the order of a

licensed medical practitioner. This device is to be used

only by persons who have been adequately instructed in

its use.

Important: This document is not to be reproduced in any

manner, nor are the contents herein to be disclosed to

anyone without the express authorization of Ohio

Medical Corporation.

The procedures described in this service manual should

be performed by competent individuals who have a general knowledge of and experience with devices of this

nature. No repairs should ever be undertaken or attempted by anyone not having such qualifications.

Genuine replacement parts manufactured or sold by

Ohio Medical must be used for all repairs.

Read completely through each step in every procedure

before starting the procedure; any exceptions may result

in a failure to properly and safely complete the attempted procedure.

CCW Counterclockwise (Anti-clockwise)

MAX Full Line Vacuum

in Hg Inches of mercury

kPa Kilo pascals (kPa x 7.50 = mm Hg)

LPM Liters per minute

mm Hg Millimeters of mercury (mm Hg x .133 = kPa)

°C Degrees Celsius

°F Degrees Fahrenheit

N-m Newton-Meter (N-m x .737 = ft-lb)

ft-lb Foot-Pound Force (ft-lb x 1.356 = N-m)

oz Ounces

DISS Diameter Index Safety System

OES Oxequip Suction

NCG National Compressed Gases (Chemetron)

NPT National Pipe Thread (USA)

NPTF National Pipe Thread Female (USA)

MPTS Multi-Purpose Therapy Stand

gal Gallon

PTFE Teflon®

User Responsibility

User Responsibility

Page 3

6700-0078-000 Rev1 06/2009

Table of Contents

1/Precautions

1.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2/Scope

2.1 North American Vacuum Regulators. . . . . . . .2-1

2.2 International Vacuum Regulators . . . . . . . . . .2-2

3/Description and Specifications

3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4/Operation

4.1 Equipment Set-up . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Attaching the Safety Trap . . . . . . . . . . . . . . .4-2

4.3 Mode Selection . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Setting the Suction Level . . . . . . . . . . . . . . . .4-4

4.5 Pre-Use Checkout Procedure . . . . . . . . . . . .4-4

4.6 Patient Set-up . . . . . . . . . . . . . . . . . . . . . . . .4-7

5/Cleaning and Sterilization

5.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1.1 Routine Exterior Cleaning . . . . . . . . . . .5-1

5.1.2 Internal Component Cleaning . . . . . . . .5-1

5.2 Sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6/Troubleshooting

7/Service - Disassembly and Assembly

7.1 Service Tools and Equipment . . . . . . . . . . . .7-1

7.2 Continuous Vacuum Regulators (All Models)7-1

7.2.1 Disassembly . . . . . . . . . . . . . . . . . . . . .7-1

7.2.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3 Suction Level Limit Setting - Low

Models ONLY . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3.1 Low Vacuum Limiting Screws . . . . . . . .7-3

7.3.2 Vacuum Relief Valve Adjustment . . . . .7-4

7.4 Regulator Module . . . . . . . . . . . . . . . . . . . . . .7-4

7.4.1 Disassembly . . . . . . . . . . . . . . . . . . . . .7-4

7.4.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . .7-5

8/Service Checkout Procedure

8.1 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.2 Flow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.3 Gauge Test . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.3.1 High Vacuum Gauges ONLY . . . . . . . .8-2

8.3.2 Standard and Low Vacuum

Gauges ONLY . . . . . . . . . . . . . . . . . . .8-2

8.4 Regulation Test . . . . . . . . . . . . . . . . . . . . . . .8-2

8.5 Low Vacuum Regulators ONLY . . . . . . . . . . .8-2

8.6 Bleed Test . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.7 Leak Test - Supply Side . . . . . . . . . . . . . . . . .8-3

8.8 Leak Test - Patient Side . . . . . . . . . . . . . . . . . . .8-4

9/Maintenance

9.1 General Maintenance of Suction Equipment .9-1

9.2 Recommended Maintenance Schedule . . . . .9-1

9.2.1 Maintenance Schedule . . . . . . . . . . . . . . . . . .9-1

9.3 Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.4 Technical Assistance . . . . . . . . . . . . . . . . . . .9-2

9.5 Return Instructions . . . . . . . . . . . . . . . . . . . . .9-2

10/Ordering Information

10.1 Illustrated Parts . . . . . . . . . . . . . . . . . . . . . .10-1

10.2 Service Kits . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10.3 Fittings and Adapters . . . . . . . . . . . . . . . . . .10-2

10.4 International . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10.4.1 Regulator Options . . . . . . . . . . . . . . .10-3

10.4.2 Other Options . . . . . . . . . . . . . . . . . .10-4

Appendix

Installation procedure for Adapters/Probes and Fittings.

A-1

Page 4

6700-0078-000 Rev1 06/2009

1/Precautions

1.1 Definitions

Note: A Note provides additional information to clarify a point in the text.

Important: An Important statement is similar to a note but of greater emphasis.

CAUTION: A CAUTION statement is used when the possibility of damage to the equipment exists.

WARNING: AWARNING statement is used when the possibility of injury to the patient or the operator

exists.

= Attention. Alerts you to a warning or caution in the text.

MAX = maximum

High Flow

High Vacuum = high flow, high vacuum

High Flow

Low Vacuum = high flow, low vacuum

I (On) = on

O (Off) = off

= European Union Representative

1.2 Warnings

The Pre-Use Checkout Procedure must be performed

before using this equipment on each patient. If the regulator fails any part of the Pre-Use Checkout Procedure, it

must be removed from service and repaired by qualified

service personnel.

Connect the Vacuum Regulator to the vacuum source

only. Connection to pressure sources even momentarily

could injure the patient or operator and damage the

equipment.

Always connect the regulator to the vacuum source and

check its operation before attaching the patient connection.

The fitting port of the regulator must be occluded when

setting the prescribed suction level. This prevents the

patient from receiving higher than required suction levels.

Do not use this device in the presence of flammable

anesthetics. Static charges may not dissipate and a possible explosion hazard exists in the presents of these

agents.

After patient use, regulators may be contaminated.

Handle in accordance with your hospital’s infection control policy.

Clean and sterilize all suction equipment before shipment or service to ensure transportation personnel

and/or service personnel are not exposed to any hazardous contamination.

Clean and sterilize all suction equipment if contaminated

before disassembly, to ensure service personnel are not

exposed to hazardous contamination.

Following sterilization with ethylene oxide, parts should

be quarantined in a well ventilated area to allow dissipation of residual ethylene oxide gas absorbed by the

material. Aerate parts for 8 hours at 130oF (54oC).

If the Vacuum Regulator is repaired or disassembled in

any manner, the Service Checkout Procedure must be

performed before using the equipment on the patient.

The Low Vacuum Limit Setting Procedure must be followed when repairing Low Vacuum Regulators. Failure

to do this may result in suction exceeding the prescribed

level.

1-1

Page 5

6700-0078-000 Rev1 06/2009

Precautions/1

1.3 Cautions

Do not lubricate any internal components of the regulator

module.

Do not use any Loctite® products to seal the fitting and

adapter port threads (or products which contain

Methacrylate Ester as an active ingredient).

Only competent individuals trained in the repair of this

equipment should attempt to service it.

To help prevent aspirate from entering the regulator, as a

result of misuse, an Overflow Safety Trap and suction filter should be attached prior to its use. Aspirate in the regulator will impair the operation. The use of the Overflow

Safety Trap and suction filter will help prevent this and

extend the life of the suction equipment.

Use of lubricants other than recommended may degrade

plastic or rubber components.

Prior to placing the unit back into service after repair or

dissassembly , perform the Service Check-out Procedure.

Not for Field or Transport use**

®Loctite is a registered trademark of the Loctite Corp.

** The categories of Field and Transport Use are specifically defined in ISO

10079-3. "Field" means use at accidents or emergencies outside a hospital.

"Transport" means use in ambulances, cards and airplanes. These situations

may expose the equipment to uneven support, water, dirt mechanical shock and

temperature extremes. Ohio Medical suction equipment has not been tested to

comply with the specific requirements of these categories.

1-2

Page 6

6700-0078-000 Rev1 06/2009

2/Scope

This service manual contains service, maintenance and parts information on all models of the Continuous Vacuum

Regulator.

North American

International

2.1 North American Vacuum Regulators.

Note: Part numbers given are for Vacuum Regulators without fittings or adapters.

2.2 International Vacuum Regulators

Important: International Vacuum regulators comply with the requirements of EN ISO 10079-3 and are CE marked.

Note: Part numbers given are for Vacuum Regulators without fittings or adapters.

Standard Three Mode

Continuous

0-200 mmHg-FULL VAC

Low Continuous

0-135 mmHg

High Three Mode

Continuous

0-760 mmHg

Standard Two Mode

Continuous

0-200 mmHg-FULL VAC

Two Mode High Continuous

CCW

0-760 mmHg/0-100 kPa

Two Mode Low Continuous

CCW

0-135 mmHg/0-18 kPa

Three Mode High Continuous

CCW

0-760 mmHg/0-100 kPa

2-1

D

E

E

D

M

100

80

120

-mmHg

60

W

O

40

L

20

140

H

I

G

H

160

180

200

F

U

C

L

A

V

L

M

100

H

mm Hg

I

G

120

H

140

160

80

Low Vacuum

60

W

O

40

L

20

400

60

70

High Vacuum

100

50

High Flow

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

80

90

700

400

60

70

High Vacuum

100

50

High Flow

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

80

90

700

100

80

120

16

140

18

20

Low Vacuum

14

High Flow

60

12

10

8

40

6

4

2

20

a

P

k

-

g

H

m

m

-

Page 7

6700-0078-000 Rev1 06/2009

Description and Specification/3

3.1 Description

WARNING

Do not use this device in the presence of flammable anesthetics. Static

charges may not dissipate and a possible explosion hazard exists in the

presence of these agents.

The Continuous V acuum Regulator is a lightweight, compact unit used throughout the hospital primarily for pharyngeal/tracheal suctioning (airway management).

Various models provide regulated or full-line vacuum for

hospital suction procedures.

There are several models of the Continuous Vacuum

Regulators. All models contain a vacuum gauge which

indicates suction supplied by the regulator. Each has a

positive pressure safety relief valve to prevent pressurization by either failed injector vacuum (venturi) units or

inadvertent cross connection to pressurized gasses. In

addition, the Low Continuous models include a vacuum

relief valve to limit maximum suction.

Some models operate in a regulated or non-regulated

(MAX) mode. Others operate only in the regulated (limited) mode.

In the non-regulated (MAX) mode, the vacuum source is

connected directly to the fitting port. The regulator module is bypassed and full-line vacuum is provided.

In the regulated (limited) mode, the vacuum source is

connected through the regulator module which functions

as an automatic valve. Turning the suction control knob

adjusts the position of the regulator module and allows

selection of a predetermined level of suction when set

according to instructions.

During use, as the flow requirement increases, the valve

automatically opens to maintain suction at the preset

level. Conversely , when the flow requirement decreases,

the valve automatically closes to maintain suction at the

preset level. The same mechanism compensates for

changes in supply vacuum and automatically maintains

the pre-set suction level when set according to instructions.

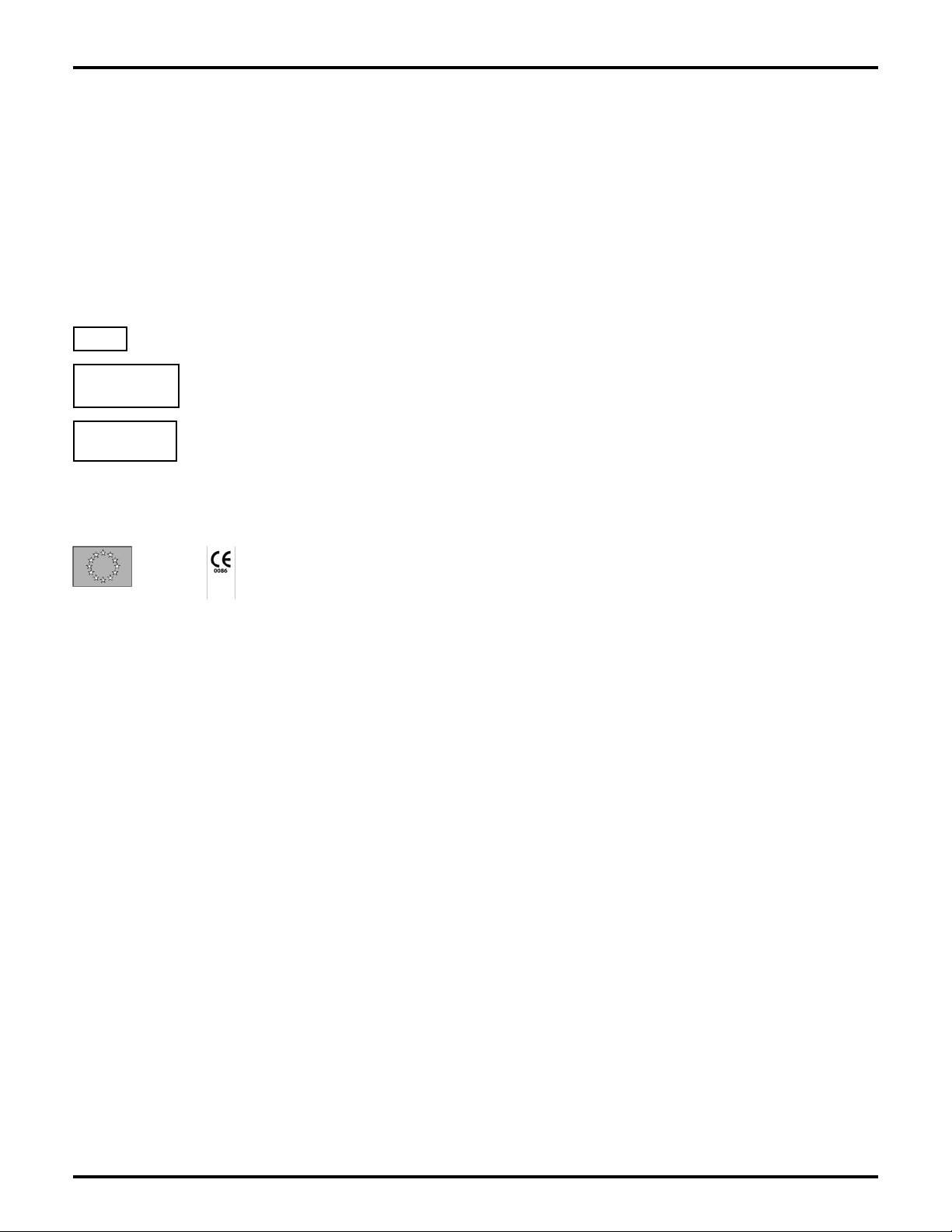

1. Suction Control Knob - Allows easy adjustment of

suction to the patient.

2. Mode Selector Switch - Allows quick and easy mode

changes.

a. | (On) - Suction can be adjusted with the suction

control knob.

b. O (Off) - No suction is supplied to the patient.

c. MAX - Maximum full-line vacuum is supplied to

the patient.

3. Vacuum Gauge - The suction level to the patient is

displayed during use.

Mode

Selector

Switch

Front and Side View

Fitting Port

Adapter

Port

Suction

Control

Knob

Vacuum

Gauge

3-1

400

50

60

High Flow

High Vacuum

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

70

600

80

90

100

700

Page 8

6700-0078-000 Rev1 06/2009

3/Description and Specifications

3.2 Specifications

Gauge: Accuracy: ±5% of full scale deflection

Flow Rate: 0 to 80 LPM without fittings at full increase setting depending on supply vacuum and open

air flow

Positive Pressure Safety Located in the vacuum supply line to prevent pressurization of the patient connection by

Relief Valve: failed injector vacuum (venturi) units, or inadvertent cross connection to pressurized

gases

Ranges: Gauge Range Regulated Suction

Standard Models 0 to 200 mm Hg/0 to 26 kPa 0 to 760 mm Hg/0 to 100 kPa

High Models 0 to 760 mm Hg/0 to 100 kPa 0 to 760 mm Hg/0 to 100 kPa

Low Models 0 to 160 mm Hg/0 to 21 kPa 0 to 135 mm Hg/0 to 18 kPa*

* When measured with an independent measuring device.

Vacuum Relief Valve 140 mm Hg ± 5 mm Hg/18.7 kPa ± 0.7 kPa

(Low Vacuum models ONLY):

Weight: 11 oz/312 grams

(Less fittings)

Weight

Low Vacuum models: 12 oz/340 grams

(Less fittings)

Dimensions: Height: 5.7 inches/145 mm

(Less fittings) Width: 3.0 inches/76 mm

Depth: 3.8 inches/96 mm

Latex tubing, 0.25 in (6.4 mm) I.D. X 0 to full vacuum

12 in (30 cm) supplied: Flow dependent on source and setup

Disposable tubing (Available 0 to full vacuum

separate in some markets; Flow dependent on source and setup

6 mm I.D. X 450 mm, 750 mm

and 2M) to connect regulator

and collection bottle

Disposable Suction Filter: 0 to full vacuum

0 to 100 Lpm @ 650 mmHg (-87 kPa)

Environmental Specifications

Operating Temperature Range: 40oF (4oC) to 120oF (49oC)

Storage Temperature Range: 0oF (-18oC) to 150oF (71oC)

Operating and Storage Relative Humidity: 5 to 95%

3-2

Page 9

6700-0078-000 Rev1 06/2009

Operation/4

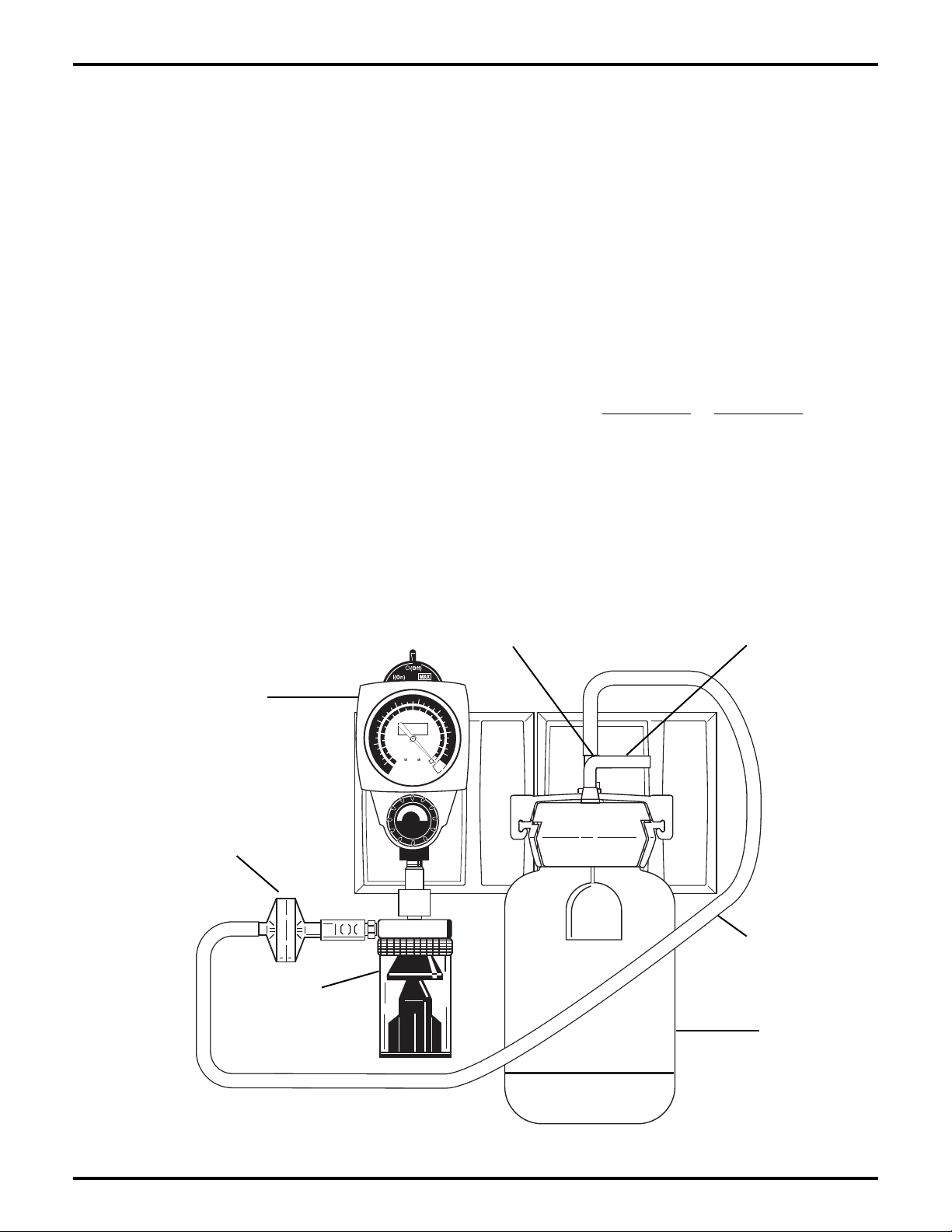

4.1 Equipment Set-up

Insert the probe into the vacuum wall outlet. If the regulator is mounted elsewhere, connect a vacuum supply

hose between the regulator’s probe adapter and the wall

outlet.

WARNING

Connect the vacuum regulator to the

vacuum source only and check its

operation before attaching the patient

connection. Connection to pressure

sources, even momentarily, could

injure the patient or operator and

damage the equipment.

Note: For proper installation of Adapters/Probes and

Fittings see Appendix.

Connect the collection bottle's vacuum port to the regu-

lator's fitting port or Overflow Safety Trap with the appropriate suction filter and vacuum tubing.

Use hospital-supplied suction tubing between the end

piece and the collection container, and between the

patient port and the patient (minimum inside diameter is

6 mm [0.25 in.]).

ISO 10079-3 (BS 7259: Part 2, section 5.1.2) states that

“the usable volume of the collection container shall not

be less than 500 ml.”

An Ohio Medical High Flow Suction Filter should be

used between the collection container and regulator to

prevent contamination of the regulator. Hospital-supplied suction tubing must be used between the catheter

and the collection bottle. Recommended minimum

inside diameter is 0.25 in (6 mm).

Suction Filters - Hydrophilic

Pkg of 20 6730-0350-800

Pkg of 200 6730-0351-800

Suction Filters - Hydrophobic

Tubing x 1/8 NPT x

tubing nipple

tubing nipple

Pkg of 3 6730-0570-800 6730-0580-800

Pkg of 10 6730-0571-800 6730-0581-800

Pkg of 100 6730-0572-900 6730-0582-800

Vacuum

Regulator

Overflow

Safety Trap

Equipment Set-Up

Collection

Bottle

Connective Tubing

Patient Port

Vacuum Port

Disposable

Suction Filter

4-1

400

80

90

70

100

50

60

High Flow

High Vacuum

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

700

Underwater Seal Line 2 cm H2O

Made in USA

Page 10

6700-0078-000 Rev1 06/2009

4/Operation

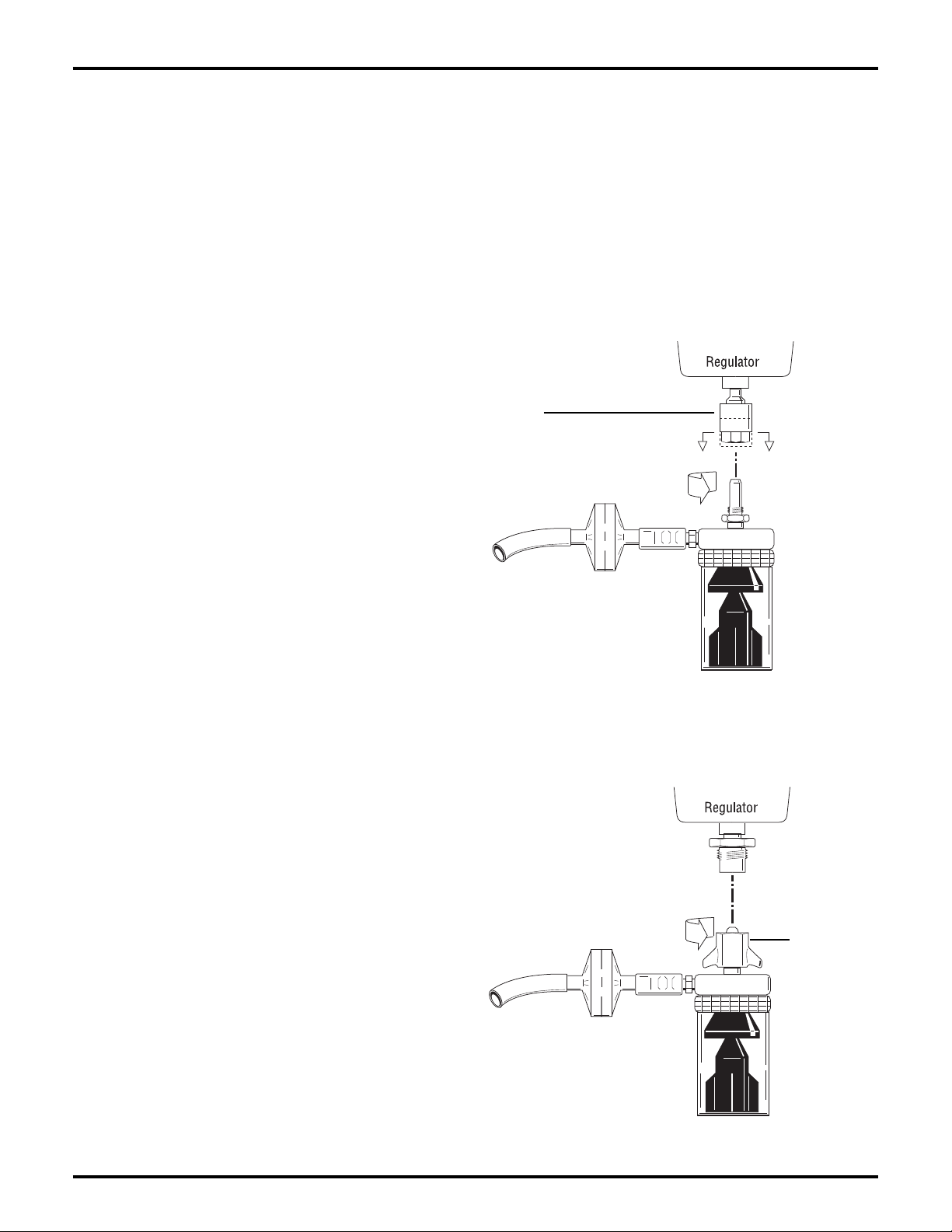

4.2 Attaching the Safety Trap

CAUTION

To help prevent aspirate from entering

the regulator, wall outlet and pipeline

system as a result of misuse, an

Overflow Safety Trap should be

attached prior to its use. Aspirate in the

regulator, wall outlet and pipeline system

may impair their operation. The use of

the Overflow Safety Trap and suction filter will help prevent this and extend the

life of suction equipment.

Standard fitting

1. Raise the sleeve and insert the trap into the regulator fitting.

2. Turn the trap clockwise about one and a half turns to

engage the threads. The trap does not need to be

screwed tight; an O-ring in the regulator fitting provides a vacuum seal. The trap should rotate freely to

allow the desired tubing positioning.

3. Lower sleeve to lock trap in position.

DISS fitting

1. Insert trap into the regulator fitting. Situate the tubing

in the desired position.

2. Turn the DISS wing nut clockwise to engage threads

and tighten (there is no O-ring, so the vacuum seal

depends on a tight connection).

Sleeve

Wing nut

4-2

Page 11

6700-0078-000 Rev1 06/2009

Operation/4

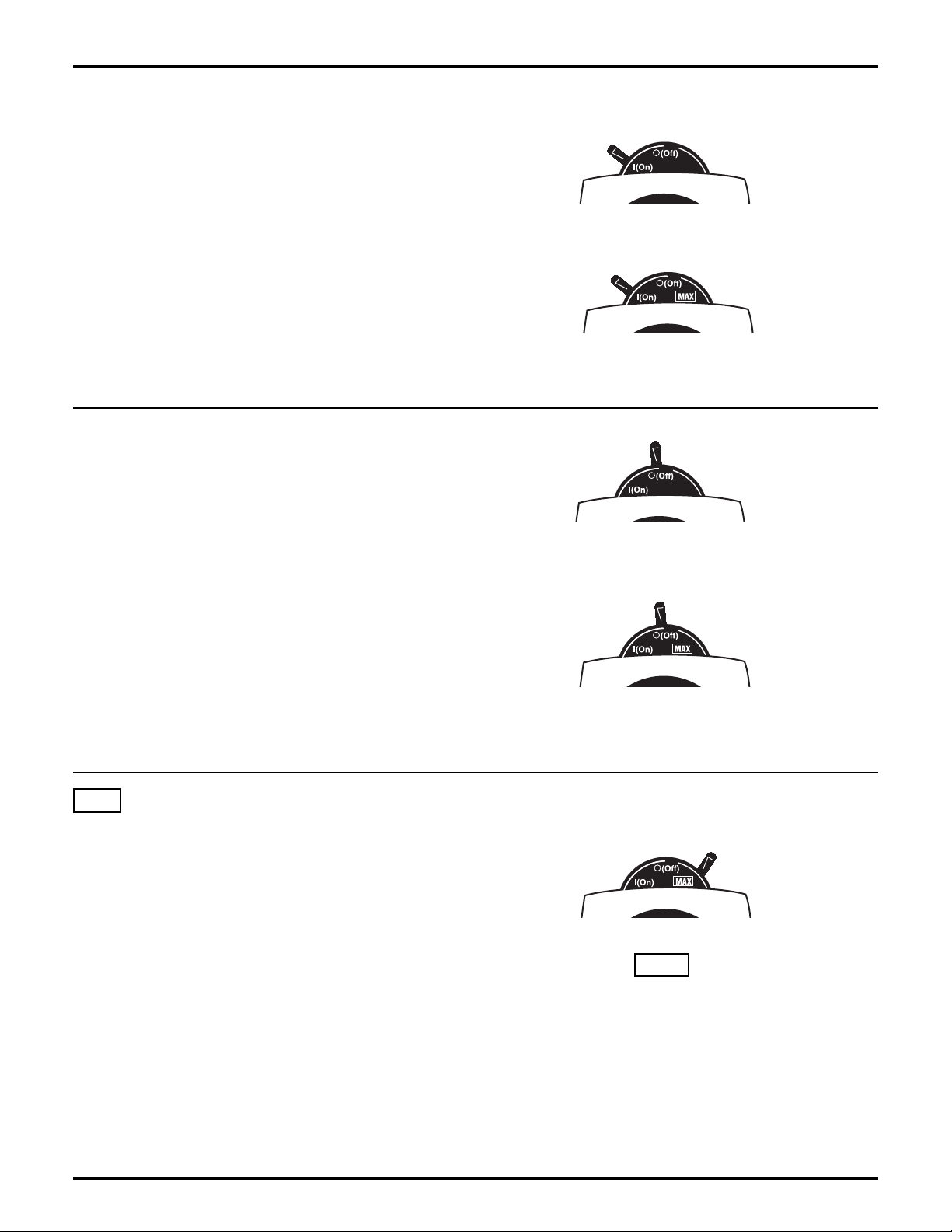

4.3 Mode Selection

| (On) - Suction can be adjusted with the suction control

knob.

O (Off) - No suction is supplied to the patient.

MAX - Maximum, full-line vacuum is supplied to the

patient.

Note: available on three mode vacuum regulators only.

2 - Mode Switch

3 - Mode Switch

I/(On)

2 - Mode Switch

3 - Mode Switch

O/(Off)

3 - Mode Switch

MAX

4-3

Page 12

6700-0078-000 Rev1 06/2009

4/Operation

4.4 Setting the Suction Level

1. Turn the mode selector switch to I (On).

2. Occlude or clamp tubing

3. Rotate the suction control knob until the vacuum

gauge indicates the required setting.

WARNING

The regulator fitting port or patient

connector must be occluded when

setting the prescribed suction level

so that the patient does not receive

higher than required suction.

4.5 Pre-Use Checkout Procedure

WARNINGS The Pre-Use Checkout Procedure

must be performed before using the

equipment on each patient. If the regulator fails any part of the Pre-Use

Checkout Procedure, it must be

removed from service and repaired

by qualified service personnel.

Connect the vacuum regulator to the

vacuum source only and check it's

operation before attaching the patient

connection. Connection to pressure

sources, even momentarily, could

injure the patient or operator and

damage the equipment.

All tests must be performed with supply vacuum of 380

mm Hg (51 kPa) minimum.

1. Turn the mode selector switch to O (Off).

Rotate the suction control knob one full turn clock-

wise (increase).

Clamp tubing to occlude the fitting port. The gauge

needle should not move.

Clamp

Clamp

4-4

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

Page 13

6700-0078-000 Rev1 06/2009

Operation/4

2. Turn the mode selector switch to I (On).

Rotate the suction control knob fully anti-clockwise

(decrease).

Clamp tubing. The gauge needle should not move.

3. Clamp tubing.

Regulator Setting

Standard & Low: increase the suction to 100 mm Hg

(13 kPa)

High: increase the suction to 300 mm Hg

(40 kPa)

Slowly open and close the clamped tubing to create various flow rates through the regulator. Check that the suction level is maintained when the tubing is clamped.

For Standard 2 Mode Continuous, go to step 5.

Clamp

Clamp

Release

Clamp

4-5

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

Page 14

6700-0078-000 Rev1 06/2009

4/Operation

4a. High and Standard 3 Mode Continuous

Turn the mode selector to MAX. Clamp tubing and

check that the gauge needle indicates the maximum

available suction.

Turn the mode selector to I (On).

4b. Low Continuous

Clamp tubing and rotate knob fully clockwise

(increase) to verify the suction level does not exceed

150 mm Hg (20 kPa).

Clamp

Clamp

4-6

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

100

80

120

60

12

14

10

16

140

8

18

40

6

20

4

2

20

a

P

k

-

m

High Flow

m

-

Low Vacuum

Page 15

6700-0078-000 Rev1 06/2009

Operation/4

5. Reduce the suction level to zero and set the mode

selector switch to O (Off).

4.6 Patient Setup

1. Make sure the Pre-Use Checkout Procedure has

been performed.

2. Turn the mode selector switch to I (On) and clamp

tubing.

3. Set the prescribed suction level.

WARNING

The regulator must be occluded when

setting the prescribed suction level

so that the patient does not receive

higher than required suction.

Clamp

4-7

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

Underwater Seal Line 2 cm H2O

Made in USA

Page 16

6700-0078-000 Rev1 06/2009

4/Operation

4. Turn the mode selector switch to O (Off).

5. Attach tubing to the vacuum port of the collection

container.

6. Turn the mode selector switch to I (On).

Important: The Low models do not

deliver suction in excess of 150

mm Hg (20 kPa).

Patient

Connective

Tubing

4-8

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

20

80

90

700

100

10

100

a

P

k

-

g

H

m

m

-

Underwater Seal Line 2 cm H2O

Made in USA

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

Underwater Seal Line 2 cm H2O

Made in USA

Page 17

6700-0078-000 Rev1 06/2009

Cleaning and Sterilization/5

5.1 Cleaning

WARNING After patient use, regulators may be

contaminated. Handle in accordance

with your hospital’s infection control

policy.

5.1.1 Routine Exterior Cleaning

Routine cleaning of the regulator is recommended as a

standard procedure after each use.

Wipe all exterior surfaces with a solution of water and

mild detergent.

5.1.2 Internal Component Cleaning

CAUTION Cleaning the gauge may result in damage.

The regulator requires cleaning if it becomes flooded with

patient fluid as a result of misuse.

1. Refer to the Service - Disassembly and Assembly

instructions.

2. All internal components, with the exception of the

gauge, may be cleaned with a solution of warm water

and mild detergent, preferably an enzymatic cleaner.

3. Dry all components with a lint free cloth before

assembly.

5.2 Sterilization

Should misuse occur, resulting in accidental flooding of

the regulator, the regulator may be sterilized using

Ethylene Oxide (ETO). After sterilization, follow the service checkout procedures in Section 8.

WARNING

Following sterilization with ethylene

oxide, parts should be quarantined in

a well ventilated area to allow dissipation of residual ethylene oxide gas

absorbed by the material. Aerate

parts for 8 hours at 130oF (54oC).

CAUTION

Do not steam autoclave or liquid sterilize

the Continuous Vacuum Regulator.

Severe impairment to the operation of

the regulator will result. The only acceptable method of sterilization is with gas

(ethylene oxide).

CAUTION

Sterilization with ethylene oxide mixtures may cause crazing (minute superficial cracking) of some plastic parts.

Crazing will be more pronounced when

mixtures containing Freon® are used.

Note: The Vacuum Regulator should only be sterilized if

it is contaminated or maintenance is to be performed.

1. The regulator should be sterilized with the mode

selector switch in the | (On) position.

2. The only acceptable method of sterilization is with

ethylene oxide. Ethylene oxide mixtures can be used

at temperatures of 125 to 135 °F (52 - 57 °C). If this

temperature cannot be obtained, room temperature

sterilization with 100% ethylene oxide can also be

used. Sterilization is not recommended as a standard procedure after each use.

3. After each sterilization, check the condition of the

internal filter. If the filter appears to have shrunk,

replace it before placing the regulator back in service.

4. Adequately aerate the regulator prior to disassembly,

shipment or use. Aerate parts prior to reassembly.

®Freon is a registered trademark of the DuPont Company.

5-1

Page 18

6700-0078-000 Rev1 06/2009

6/Troubleshooting

Problem

A. No gauge indication and no suc-

tion in any setting

B. No gauge indication but suction

is being delivered

C. Gauge indication but no suction

is being delivered

D. Suction level cannot be adjusted

E. Insufficient flow through regula-

tor

Possible Causes

1. No supply vacuum

2. Kinked tube

3. Poor connection

4. Blocked adapter port

5. Blocked backplate

6. Blocked adapter

7. Blocked wall outlet

1. Blocked gauge pressure sensing

orifice

2. Gauge mechanism locked by

debris

3. Gauge mechanism damaged

1. Blocked fitting port

2. Overflow Safety Trap shut-off

3. Blocked external filter

4. Blocked fitting

1. Mode selector switch in MAX

position

2. Regulator module small o-ring

failure

3. Regulator module diaphragm

rupture

4. Regulator module stem screw

loose

1. Partial blockage in wall supply

2. Partial blockage in regulator

Remedy

1. Correct supply problems

2. Straighten tube

3. Check all connections and seals

4. Unblock port

5. Clean with soap and water and

pipe cleaner

6. Replace adapter

7. Unblock outlet

1. Clean or replace gauge

2. Clean or replace gauge

3. Replace gauge

1. Clean port

2. Reset flow and/or empty trap

3. Replace filter

4. Clean fitting

1. Switch to I(On)

2. Replace rubber components with

regulator module replacement kit

3. Replace rubber components with

regulator module replacement kit

4. Tighten stem screw

1a. Confirm wall supply open air flow

meets minimum hospital requirements

1b. Unblock if necessary

2a. Perform the Flow Test in the

Service Checkout Procedure

Section of this manual

2b. Clear blockage if necessary

6-1

Page 19

6700-0078-000 Rev1 06/2009

Troubleshooting/6

Problem

F. Inaccurate gauge reading

Note: All gauge needles should

come to rest within the zero

range bracket or return to the

stop pin when no suction is

being supplied.

G. With the fitting port occluded,

unable to decrease the suction

level and gauge needle does not

return to zero when switched to

O (Off)

H. No suction in any setting and

whistling noise from inside the

regulator

Possible Causes

1. Damaged gauge

1. Blocked filter and/or orifice

2. Damaged gauge

1. Positive pressure safety relief

valve failure

2. Vacuum relief valve failure (low

models ONLY)

Remedy

1. Replace gauge

1. Clear orifice and replace filter

2. Replace gauge

1. Replace positive pressure safety relief valve

2. Replace o-ring and ensure that

the steel ball is present and

clean

6-2

Page 20

6700-0078-000 Rev1 06/2009

7/Service - Disassembly and Assembly

7.1 Service Tools and Equipment

CAUTION

Use of lubricants other than recommended may degrade plastic or rubber

components.

The following items should be on hand during any service procedure.

• Supply vacuum: 500 mm Hg/ ± 10 mmHg (67 kPa ±

1.3 kPa) & 50 LPM open air flow minimum

• Supply Vacuum Regulator with Gauge, 760 mm Hg

(101.3 kPa) Full Scale.

• Low Vacuum Calibration Gauge, 225 mm Hg (30

kPa) Full Scale* (Ohio Medical P/N 6700-0353-800)

• High Vacuum Calibration Gauge, 760 mm Hg (101.3

kPa) Full Scale*(Ohio Medical P/N 6700-0352-800)

• 50 LPM Flowmeter (Ohio Medical P/N 6700-0355-

800)

• Hexagonal Allen Wrench 3/32 inch

• Phillips Head Screwdriver, No. 2

• Flat Head Screwdriver, 1/4 inch

• Pliers

• Dow® 111 Grease (Ohio Medical P/N 6700-0074-

200)

• Loctite® 242 Removable Thread Locker (Ohio

Medical P/N 0220-5016-300)

• Tubing Clamp

• Bubble Leak Tester

• Tweezers (Filter Remover)

• Wooden Tooth Pick (O-ring Remover)

• Pipe Cleaner

(*) Accuracy: ±1% of full scale deflection

®Dow is a registered trademark of the Dow Chemical Corporation

7.2 Continuous Vacuum Regulators (All

Models)

7.2.1 Disassembly

WARNINGS If the Vacuum Regulator is repaired

or disassembled in any manner, the

Service Checkout Procedure must be

performed before using the equipment on a patient.

Clean and sterilize all suction equipment if contaminated before disassembly, to ensure service personnel

are not exposed to hazardous contamination.

When servicing a Low Vacuum

Regulator, perform the Vacuum Relief

Valve Adjustment and Low Vacuum

Limit Setting Procedure.

CAUTION

The gauge assembly must be handled

with utmost care to retain its precision. If

the lens is removed, do not rest the

gauge on its face.

7-1

Page 21

6700-0078-000 Rev1 06/2009

Service - Disassembly and Assembly/7

1. Cover Screw (4)

2. Cover Assembly

3. Low Vacuum Limiting Screws

(2) (Not Shown) (On old versions of the

Low Models Only)

1. Mode Selector Switch

2. Switch Plate

3. Screw

4. O-ring, Vacuum Relief Valve

(Low Models Only)

5. Vacuum Relief Valve & O-ring

(Low Models Only)

6. Gauge Assembly (includes gauge, o-rings, and lens)

7. Lens

8. O-ring (2), Gauge

9. Regulator Module

10. Positive Pressure Safety Relief Valve

11. Filter (Internal)

12. Base

13. O-ring, Stem

14. O-ring, Regulator Module

1. Remove the four cover screws from the back of the regulator.

2. Carefully pull the cover assembly off the back body.

3. To remove the gauge assembly, grasp the assembly and

pull straight out. The snap-fit lens can also be removed

(if applicable) for replacement.

4. To remove the regulator module from the cover assembly , rotate the suction control knob counterclockwise until

the regulator module is free.

5. Using tweezers, remove the filter. Replace with a new filter.

6. Grasp the positive pressure safety relief valve, and pull it

from the back body.

7. Remove the mounting screw from the switch plate

assembly and remove the switch plate and mode switch.

8. Low models ONLY: Grasp the vacuum relief valve and

pull it from the back body.

Pull down plastic tab with

right index finger while

holding gauge

Snap Fit Lens Removal

7-2

1

2

1

12

11

1

14

13

9

3

4

8

5

6

7

3

2

Page 22

6700-0078-000 Rev1 06/2009

7/Service - Disassembly and Assembly

7.2.2 Assembly

CAUTION To prevent stripping the plastic threads,

place the screw in the hole and turn

counterclockwise until it drops into the

original thread. Tighten screw.

1. Place the positive pressure safety relief valve in position and push onto the back body.

2. Low models ONLY: Lubricate the vacuum relief valve

O-ring and install it in the valve housing.

3. Lubricate the switch gasket surface with a thin coating of Dow 111 Grease. Place the mode switch on

the base with the arrow at 12 o’clock. Place the

switch plate onto the switch so that the OFF/O is

under the arrow. Install and tighten the mounting

screw. Test the mode switch at all positions.

4. Place the internal filter into the proper cavity and

push until it hits the bottom of the base.

5. Place the regulator module into the cover with the

screw thread facing the knob. Align the protruding

ears at 3 and 9 o’clock and rotate the suction control

knob clockwise until the threads engage.

6. Install the snap-fit lens by placing one of the retaining tabs over the edge of the gauge face, and then

pressing lightly until the other tab snaps onto the

gauge face. Rotate the lens to confirm proper installation.

7. Install the gauge assembly by lubricating the gauge

o-rings with a thin coating of Dow 111 Grease and

pushing the gauge into the base mount. Ensure that

the gauge is properly aligned.

8. Place the cover assembly onto the base and push

together until the base and back of the cover are

flush.

9. Install the 4 cover screws.

7.3Suction Level Limit Setting-Low Models

ONLY

WARNING

This Low Vacuum Limit Setting

Procedure must be followed when

repairing Low Vacuum Regulators.

Failure to do this may result in suction exceeding the prescribed level.

The design of the low continuous vacuum regulator has

been changed to eliminate the low vacuum limiting set

screws located inside the cover behind the suction control knob. The vacuum relief valve has also been

changed to limit the vacuum to the same level as the set

screws did. This new vacuum relief valve has four vent

holes; the old valve had two. If a new cover is used, a

new vacuum relief valve must be used.

Versions with limiting screws have two means of limiting

the suction level:

1. Low vacuum limiting screws in the cover; these can

be set at 140 mmHg/19 kPa (± 10 mmHg/1.0 kPa).

2. Vacuum relief valve; this can be set at 165 mmHg ±

15 mmHg (22 kPa ± 2 kPa).

These vacuum limit settings may be reduced to

accommodate user requirements. If the vacuum limit

settings are reduced, the vacuum relief valve must

be set 25 mmHg ± 15 mmHg (3 kPa ± 2 kPa) higher

than the vacuum limiting screws.

Versions without the limiting screws use only the relief

valve to limit the suction level. The relief valve can be set

at 140 mmHg ± 5 mmHg (18.7 kPa ± 0.7 kPa).

7-3

Page 23

6700-0078-000 Rev1 06/2009

Service - Disassembly and Assembly/7

7.3.1 Low Vacuum Limiting Screws

CAUTION

When adjusting the vacuum limiting

screws, be sure to adjust them to an equal height.

CAUTION

Remove the “Increase” label careful-

ly. Press firmly in place when replacing.

1. Remove the “Increase” label and place it aside. Be

careful not to damage the face or glued back of the

label.

2. Adjust the two vacuum limiting screws located

behind the suction control knob until they are the

same height in the case. Use a 3/32” hexagonal allen

wrench.

3. Connect the vacuum supply to the adapter port and

occlude the fitting port.

4. Be certain that the screws remain at an equal height

by adjusting both low vacuum limiting screws the

same amount and in the same direction. Adjust the

screws to supply a maximum vacuum of 150 mm Hg

(20 kPa) and not less than 130 mm Hg (17 kPa).

7.3.2 Vacuum Relief Valve Adjustment

1. Remove the cover.

2. Connect the supply vacuum to the adapter port.

3. Turn the mode selector switch to I/ON.

4. Occlude the fitting port.

5. Slowly pull the regulator module away from the base.

Note the suction level at which the relief valve opens.

The relief valve should open at 165 mmHg ± 15

mmHg (22 kPa ± 2 kPa) on units with limiting

setscrews and140 mmHg ± 5 mmHg (18.7 kPa ± 0.7

kPa) for units without limiting setscrews.

6. If adjustment is required, grip the vacuum relief valve

firmly with pliers and rotate the screw about 1/8 turn

with a screwdriver. Repeat the previous step and

check the suction level at which the valve opens.

Note: Clockwise rotation will increase the suction

level at which the relief valve opens.

Counterclockwise rotation will decrease it.

WARNING

Excess Loctite® may seal the steel

ball to the seat. This will disable the

vacuum relief valve and may allow

suction to exceed the preset limit.

CAUTION

When Loctite is used on the vacuum

relief safety valve, ensure that it only

contacts the metal parts. Loctite causes

many plastic parts to deteriorate.

7. Lock the adjusting screw with a drop of removable

thread locker such as Loctite 242. Repeat step 5 to verify the vacuum relief valve setting.

® Loctite is a registered trademark of the Loctite Corporation.

Cover and Knob

Assembly

Allen

Wrench

Set Screws

Increase Label

Setting the Vacuum Limiting Screws

Vacuum Relief Valve

Valve

Body

Steel

Ball

O-Ring

Screw

w/Magnet

Loctite

242

7-4

Page 24

6700-0078-000 Rev1 06/2009

7.4 Regulator Module

WARNING

If repairing or replacing a regulator

module on a Low Vacuum Regulator,

you must perform the Suction Level

Limit Setting-Low Models ONLY

Procedure. Failure to do this may

result in suction exceeding the prescribed level.

CAUTION

Do not lubricate any internal components of the regulator module.

The cap screws can strip the regulator

module housing threads if they are

screwed in too tight.

7.4.1 Disassembly

1. Remove the cap screws (2) and remove the cap.

2. Remove the o-rings (2).

3. Observe the position of the diaphragm convolution to

aid in assembly.

4. Withdraw the diaphragm/stem assembly from the

housing.

5. Remove the spring.

6. Grasp the stem with your fingers and unscrew the

stem screw.

7. Remove the retainer, diaphragm and piston from the

stem.

7/Service - Disassembly and Assembly

1. O-ring, Stem

2. O-ring

3. Housing

4. Stem

5. Spring

6. Piston

7. Diaphragm

8. Retainer

9. Stem Screw

10. Cap

11. Cap Screw

1

11

11

10

9

8

7

6

5

4

3

2

Regulator Module Parts and Descriptions

7-5

Page 25

6700-0078-000 Rev1 06/2009

Service - Disassembly and Assembly/7

7.4.2 Assembly

1. Return the diaphragm to its original position (convoluted), with the molded number facing the retainer.

2. Assemble the diaphragm onto the retainer by lining

up their center holes as shown in the diagram.

3. Insert the piston into the diaphragm and ensure that

the retainer mates with the recess in the piston.

4. Insert the stem through the piston.

5. Holding the retainer/diaphragm/piston/stem as an

assembly with your fingers, insert the stem screw

and tighten.

6. Place the spring in the housing.

7. Insert the retainer/diaphragm/piston/stem assembly

through the spring and into the cavity in the housing.

Fit the diaphragm bead into the groove in the housing.

8. Install the cap and the two cap screws.

9. Apply a small amount of Dow® 111 Grease to the orings only.

10. Install o-rings onto the stem and housing.

Diaphragm Assembly

Stem

Retainer

Set Screw

Diaphragm

Piston

7-6

Page 26

6700-0078-000 Rev1 06/2009

8/Service Checkout Procedure

WARNING

If the Vacuum Regulator is rep aired or

disassembled in any manner, the

Service Checkout Procedure must be

performed before using the equipment on a patient.

Important: This entire Service Checkout Procedure

must be performed in numerical order.

8.1 Set-up

1. Verify that there is 500 mmHg ± 10 mmHg (67 kPa ±

1.3 kPa) vacuum on the supply gauge.

2. The supply open flow must be 50 LPM minimum.

3. Connect the supply vacuum to the adapter port.

8.2 Flow Test

1. Connect the regulator's fitting port to the flowmeter

with tubing.

2. Rotate the suction control knob fully clockwise

(increase).

3. Turn the mode selector switch to I (On) and verify

that the flow rate exceeds 30 LPM.

4. Turn the mode selector switch to MAX (if available)

and verify that the flow rate exceeds 30 LPM.

5. Turn the mode selector switch to O (Off).

6. Disconnect the flowmeter.

Mode

Selector

Switch

Supply Vacuum gauge

0-760 mmHg (0-101.3 kPa)

Supply Vacuum Reg. set to

500 mmHg +

10 mmHg

(64 kPa +

1.3 kPa)

Supply Vacuum

500 mmHg (67 kPa)

Minimum and

Open Flow of

50 LPM Minimum

Occluded

Low Vacuum

Calibration Gauge

225 mmHg/30 kPa

High Vacuum

Calibration Gauge

760 mmHg/101.3 kPa

Flowmeter

50 LPM

Service Checkout Tests

8-1

60

W

O

40

L

20

E

D

M

100

80

120

mmHg

140

H

I

G

H

160

180

200

F

U

C

L

A

L

V

Page 27

6700-0078-000 Rev1 06/2009

Service Check Out Procedure/8

8.3 Gauge Test

Note: All Ohio Medical gauges are supplied with an accuracy of ±5% of full scale deflection throughout their

range. The table below is provided for reference.

Gauge Range Tolerance

Standard 0-200 mmHg (0-26 kPa) ±10 mmHg (1.3 kPa)

Vacuum

Low 0-160 mmHg (0-20 kPa) ±8 mmHg (1.1 kPa)

Vacuum

High 0-760 mmHg (0-100 kPa) ±38 mmHg (5 kPa)

Vacuum

Note: All gauge needles should come to rest within the

zero range bracket or return to the stop pin when no suction is being supplied. Gauges which do not comply may

be out of calibration.

When checking gauge accuracy , be sure that the calibration gauge has an accuracy of 1% of full scale deflection

or better.

8.3.1 High Vacuum Gauges ONLY

1. Connect the regulator's fitting port to the high calibration gauge with tubing.

2. Turn the mode selector switch to I (On).

3. Assure that the gauge is in agreement with the high

vacuum calibration gauge within the ±38 mmHg (5

kPa) tolerance. Recommended test points are 100,

300, and 500mm Hg.

8.3.2 Standard and Low Vacuum Gauges ONLY

1. Connect the regulator's fitting port to the low calibration gauge with tubing.

2. Turn the mode selector switch to I (On).

3. Assure that the gauge is in agreement with the low

vacuum calibration gauge within the ±10 mmHg (1.3

kPa) or the ±8 mmHg (1.1 kPa) tolerance for standard and low gauges respectively. Recommended

test points are 40, 80, and 140 mmHg.

4. For the Standard Gauge ONLY: Rotate the suction

control knob fully clockwise (increase) and verify its

reading is in the FULL VAC range.

8.4 Regulation Test

1. Disconnect the calibration gauge and occlude the fitting port.

2. If using a High Vacuum Regulator, set its gauge to

300 mmHg (40 kPa). If using a Low or Standard

Vacuum Regulator, set its gauge to 100 mmHg/14

kPa.

3. Open and close the fitting port several times.

4. With the fitting port occluded, the gauge should

return to the setting listed in step 2 within a tolerance

of:

±38 mmHg (5 kPa) for high vacuum gauge

or

±10 mmHg (1.3 kPa) for the standard

vacuum gauges

or

±8mmHg (1.1 kPa) for the low vacuum gauge.

8.5 Low Vacuum Regulators ONLY

1. Occlude the fitting port.

2. Rotate the suction control knob fully clockwise

(increase).

3. Verify that the suction delivered does not exceed 150

mm Hg (20 kPa) or the maximum suction requested

by the clinician.

Note: For setting the Suction level limit, refer to

Suction Level Limit Setting-Low Models ONLY.

8.6 Bleed Test

1. Occlude the fitting port and set the vacuum level to

100 mm Hg (14 kPa).

2. Turn the selector switch to O (Off) and observe the

gauge needle. It must return to the zero range bracket or stop pin within 10 seconds.

8-2

Page 28

6700-0078-000 Rev1 06/2009

8/Service Checkout Procedure

8.7 Leak Test - Supply Side

1. Connect the supply vacuum tubing to port “A” of the Bubble Leak Tester.

2. Connect port “B” of the Bubble Leak Tester to the regulator adapter port.

3. Turn the mode selector switch to O (Off). Allow the fitting port to be open to air.

4. Wait 20 seconds. No More than 6 bubbles should appear in the next ten seconds.

Important: Prior to venting port "A" of the Bubble Leak Tester to atmosphere (i.e. turning the supply regulator off),

ensure the tubing from port "B" has been disconnected from the adapter port of the vacuum regulator.

8.8 Leak Test - Patient Side

1. Connect the supply vacuum tubing to the regulator adapter port.

2. Connect the regulator fitting port to port “A” of the Bubble Leak Tester with tubing. Allow port “B” of the Bubble

Leak Tester to be open to air.

3. Rotate the suction control knob a minimum of one full turn clockwise (increase). No bubbles should appear in the

next ten seconds.

4. Rotate the suction control knob fully

counterclockwise (decrease).

5. Turn the mode selector switch to I (On).

No bubbles should appear in the next ten

seconds.

Supply Vacuum Gauge

0-760 mmHg (0-101.3 kPa)

Bubble Leak

Tester

1/4” I.D.

Clear Tubing

Sealed

Port B

Port A

1.0 in.

Fitting port

Adapter Port

Vacuum

Regulator

Supply

Vacuum

Supply Regulator

500 mmHg (67 kPa)

Water

Bubble Leak Test - Supply Side

Mode

Selector

Switch

1.0 in.

Bubble Leak

Tester

Water

1/4” I.D.

Clear

Tubing

Port B

Port A

Sealed

Suction

Control

Knob

Vacuum

Regulator

Bubble Leak Test -Patient Side

8-3

E

D

M

100

80

120

mmHg

60

140

W

O

40

L

20

H

I

G

H

160

180

200

F

U

C

L

A

L

V

Page 29

6700-0078-000 Rev1 06/2009

Maintenance/9

WARNING

The Pre-Use Checkout Procedure

must be performed before using this

equipment on each patient. If the regulator fails any part of the Pre-Use

Checkout Procedure, it must be

removed from service and repaired

by qualified service personnel.

WARNING

Clean and sterilize all suction equipment if contaminated before disassembly, to ensure service personnel

are not exposed to hazardous contamination.

Continuous Vacuum Regulators should be kept in

use or used on a rotating basis.

Unused equipment may tend to deteriorate.

Maintenance of the vacuum piping system is as important as maintenance of the suction equipment. The use

of Collection Bottles with reliable shut-off valves,

Overflow Safety Trap assemblies and disposable suction

filters will protect the regulator and piping system. The

flow rate at the wall outlet should be checked on a yearly basis and suitable cleaning of the outlets should be

performed. The flow rate measurement should meet

local standards.

Routine maintenance and inspection are important to the

performance of suction equipment. The following is a

recommended list for care of suction equipment after

each patient use.

1. Perform a thorough cleaning by washing all bottles,

tubing, metal connectors, etc, and removing all

residue.

2. Wipe all exterior surfaces with a solution of water

and mild detergent.

3. Perform a careful visual inspection.

4. Check that the High Flow Disposable Suction Filter is

clean and in good condition.

5. Check that all tubing is in good condition and connected securely to the correct ports.

6. Check the floats in the Overflow Safety Trap and

Collection Bottle for correct operation.

7. Perform the Pre-Use Checkout Procedure.

9.2 Recommended Maintenance Schedule

In addition to the Pre-Use Checkout Procedure, the following periodic maintenance should be performed.

9

.2.1 Maintenance Schedule

Item Minimum Frequency Comments

Service Checkout Every 12 months If the regulator does not pass the

Procedure Service Checkout Procedure,

refer to the Troubleshooting section of

this manual. Repair as necessary.

Elastometric As Required Cleaning and replacement interval

Components,O-rings, will depend greatly on hours of usage and

switch gasket, environmental conditions. Replace and

reg. module diaphragm, repair as necessary.

positive pressure safety valve) and Internal Filter

9-1

Page 30

6700-0078-000 Rev1 06/2009

9/Maintenance

9.3 Repair Policy

WARNING

Clean and sterilize all suction equipment before shipment or service to

ensure transportation personnel

and/or service personnel are not

exposed to any hazardous contamination.

CAUTIONS Do not steam autoclave or liquid sterilize

the Continuous Vacuum Regulator.

Severe impairment to the operation of

the regulator will result. The only acceptable method of sterilization is with gas

(ethylene oxide).

Only competent individuals trained in the

repair of this equipment should attempt

to service it.

Do not use malfunctioning equipment. Make all necessary repairs. Have the equipment repaired by qualified

service personnel or by Ohio Medical. Parts listed in the

service manual for this product may be repaired or

replaced by a competent, trained person who has experience in repairing devices of this nature. After repair, perform the Service Checkout Procedure to ensure that it is

functioning properly, and complies with the published

specifications.

9.4 Technical Assistance

If technical assistance is required, contact Ohio Medical

technical support or field operations listed on the back

cover.

9.5 Return Instructions

1. Call 866-549-6446 for a returned goods authorization.

2. Clean and sterilize the Vacuum Regulator.

3. Package the Vacuum Regulator securely for protection; preferably in the original container.

4. Include a letter describing in detail any difficulties

experienced with the Vacuum Regulator. Include the

person, title, and telephone number to contact for

functional questions.

5. Ohio Medical now offers a ten year warranty on vacuum regulators sold on or after July 1, 2005. If the

vacuum regulator was purchased on or after July 1,

2005 and is less than ten years old or if the vacuum

regulator is covered under the previous warranty and

is less than five years old, include the warranty information that came with the device and a copy of the

invoice.

6. Include a purchase order to cover repair of a regulator not under warranty.

7. Ship the Vacuum Regulator prepaid. Write your

return address and billing address information on the

package or letter that comes with the package.

For all Repairs Contact your nearest Ohio Medical office

or authorized Ohio Medical Distributor.

9-2

Page 31

6700-0078-000 Rev1 06/2009

Ordering Information/10

Description Part Number

1. Cover Screw (4) . . . . . . . . . . . . . . .6700-0152-400

2. Cover Assembly

Low* . . . . . . . . . . . . . . . . . . . . . . . .6700-0629-850

Std/High . . . . . . . . . . . . . . . . . . . . .6700-0628-850

3. Low Vacuum Limiting Screw (2)

(Not Shown) (Low Models Only) . .6700-0058-400

* If current unit does not have limit screws inside the

cover behind the control knob and the relief valve has 4

vent holes, the Std/High part can be purchased.

Description . . . . . . . . . . . . . . . . . . . . . . . .Part Number

1. Switch . . . . . . . . . . . . . . . . . . . . . . .6700-0078-500

2. Switch Plate

3 Mode . . . . . . . . . . . . . . . . . . . . . .6700-0193-500

2 Mode/Low . . . . . . . . . . . . . . . . . .6700-0194-500

3. Screw . . . . . . . . . . . . . . . . . . . . . . .6700-0152-400

4. O-ring, Vacuum Relief Valve

(Low Models Only) . . . . . . . . . . . . .6700-0135-500

5. Vacuum Relief Valve

& O-ring (Low Models Only) . . . . . .6700-0660-850

6. Gauge Assembly (Includes gauge, o-rings and lens)

North American Standard,

0-200 mmHg . . . . . . . . . . . . . . . . . .6700-0050-206

North American Low, 0-160 mmHg 6700-0050-207

North American High, 0-760 mmHg6700-0050-208

International Low . . . . . . . . . . . . . .6700-0050-209

International High . . . . . . . . . . . . . .6700-0050-210

International Standard . . . . . . . . . . .6700-0050-211

7. Lens . . . . . . . . . . . . . . . . . . . . . . . .6700-0087-500

8. O-ring (2), Gauge . . . . . . . . . . . . . .6700-0130-500

10.1 Illustrated Parts

9. Regulator Module

Standard/High Models . . . . . . . . . .6700-1225-800

Low * . . . . . . . . . . . . . . . . . . . . . . . .6700-0428-800

10. Positive Pressure Safety Relief

Valve . . . . . . . . . . . . . . . . . . . . . . . .6700-0115-800

11. Filter (Internal) . . . . . . . . . . . . . . . .0206-5159-300

12. Base

North American Standard & High

(2 & 3 Mode) . . . . . . . . . . . . . . . . . .6700-0018-203

North American Low . . . . . . . . . . . .6700-0029-203

International Low . . . . . . . . . . . . . .6700-0029-200

International Standard & High . . . .6700-0018-200

13. O-ring, Stem . . . . . . . . . . . . . . . . . .0210-0527-300

14. O-ring, Regulator Module . . . . . . . .6700-0136-500

* If current unit does not have limit screws inside the

cover behind the control knob and the relief valve has 4

vent holes, the Std/High part can be purchased.

1

10

14

13

12

11

1

2

3

4

8

5

9

6

7

3

2

10-1

Page 32

6700-0078-000 Rev1 06/2009

10.2 Service Kits

Standard and High Models . . . . . . . . . .6700-0043-200

Includes the following parts:

O-ring (2), Gauge

Filter (Internal)

Positive Pressure Safety Relief Valve

Regulator Module Replacement Kit

Low Models . . . . . . . . . . . . . . . . . . . . . .6700-0044-200

Includes the following parts:

O-ring (2), Gauge

Filter (Internal)

Positive Pressure Safety Relief Valve

Regulator Module Replacement Kit

O-ring, Vacuum Relief Valve

Increase Label (Universal)

Regulator Module

Replacement Kit . . . . . . . . . . . . . . . . . .6700-0030-700

Includes the following parts:

O-ring, Stem These parts are available

O-ring only in kit form. If other

Diaphragm parts are needed for reStem Screw placement, the entire

Cap Screw (3) Module must be ordered

(6700-1225-800).

O-rings and Filters Kit . . . . . . . . . . . . . .0221-5871-870

Includes the internal filter and 6 O-rings

Continuous Regulator Module (6) . . . . .6700-0028-700

Low Cont. Regulator Module (6)* . . . . .6700-0190-700

Regulator Module Replacement

Parts Kit (6) . . . . . . . . . . . . . . . . . . . . . .6700-0031-700

The following kits for U.S. regulators only

Standard Vacuum Gauge (4) . . . . . . . .0205-8689-871

High Vacuum Gauge (4) . . . . . . . . . . . .6700-0097-201

Low Vacuum Gauge (4) . . . . . . . . . . . .6700-0098-201

Standard & High Backplate (4) . . . . . . .6700-0194-700

Low Backplate (4) . . . . . . . . . . . . . . . . .6700-0198-700

* If current unit does not have limit screws inside the cover behind the control

knob and the relief valve has 4 vent holes, the continuous regulator modules

can be purchased.

10/Ordering Information

10.3 Fittings and Adapters

Description . . . . . . . . . . . . . . . . . . . . . . . .Part Number

1. Diamond Adapter . . . . . . . . . . . . . .0221-2685-802

2. NCG Adapter (Round) . . . . . . . . . .0221-0204-802

NCG Adapter (Rectangle) . . . . . . . .0221-0205-800

3. Schrader Adapter . . . . . . . . . . . . . .0221-0690-731

4. DISS Union Nut & Gland . . . . . . . .6700-0094-700

5. DISS Hand-I-Twist Nut & Gland . . .0204-6717-800

6. OES Adapter . . . . . . . . . . . . . . . . . .0221-0152-300

7. Puritan Adapter . . . . . . . . . . . . . . . .0221-0106-300

8. Medstar Adapter . . . . . . . . . . . . . . .0221-0163-300

9. 90° Tubing Nipple . . . . . . . . . . . . . .6700-0095-700

10. 45° Locking Gland . . . . . . . . . . . . .6700-0143-700

11. 45° Threaded Locking Gland . . . . .6700-0141-700

12. Tubing Nipple . . . . . . . . . . . . . . . . .0204-9020-535

13. Locking Gland . . . . . . . . . . . . . . . . .6700-0144-700

14. Threaded Locking Gland . . . . . . . .6700-0142-700

15. DISS Male . . . . . . . . . . . . . . . . . . .0204-7989-535

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

10-2

Page 33

6700-0078-000 Rev1 06/2009

Ordering Information/10

10.4 International

10.4.1 Regulator Options

Instructions: Select the vacuum regulator and fittings to form an 11-digit part number. (For yellow cover, replace

5700 with 4700)

Example: 5700-1229-901 = Three Mode High Continuous Regulator w/Tubing Nipple

5700-12XX-900

w/o Inlet Fittings

5700-12XX-901

w/Tubing Nipple

5700-12XX-902

w/Tubing Nipple,

12" Tubing,

1/2 gal. Bottle,

Cap & Float

Assembly and Wall

Slide (Straight)

5700-12XX-904

w/Locking Gland

5700-12XX-905

w/Locking Gland and

Overflow Safety Trap

5700-12XX-906

w/Locking Gland,

Overflow Safety Trap,

12" Tubing, 1/2 gal. Bottle,

Cap & Float Assembly and

Wall Slide (Straight)

5700-12XX-911

w/Locking Gland,

Overflow Safety Trap,

12"Tubing, 1/2 gal.

Bottle, Cap & Float

Assembly and Wall

"V" Slide

(International)

5700-12XX-912

w/Tubing Nipple,

12" Tubing, 1/2 gal. Bottle,

Cap & Float Assembly and

Wall "V" Slide

(International)

0221-2685-802

Diamond

0204-6717-800

Hand-I-Twist

0221-0205-800

NCG (Rectangle)

0221-0204-802

NCG (Round)

0221-0106-300

Puritan

0221-0163-300

MedStar

0204-9020-535

Tubing Nipple

0221-0152-300

OES

0221-0690-731

Schrader

6700-0094-700

DISS Nut & Gland

6700-0095-700

90° Tubing Nipple

Regulators Inlet Fittings Probes

5700-12XX-9XX 5700-12XX-9XX

4700-12XX-9XX 4700-12XX-9XX

5700-1229-9XX

Three Mode

High Continuous

(Anti-clockwise)

5700-1233-9XX

Two Mode

Low Continuous

(Anti-clockwise)

5700-1230-9XX

Two Mode

High Continuous

(Anti-clockwise0

10-3

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

100

80

120

60

12

14

10

16

140

8

18

40

6

20

4

2

20

a

P

k

-

g

H

m

High Flow

m

-

Low Vacuum

Page 34

6700-0078-000 Rev1 06/2009

10/Ordering Information

10.4.2 Other Options (International)

Instructions: Select the desired configuration and write down the first four and the last three digits of the part num-

ber. Select the vacuum regulator desired (below) and insert the middle four digits in the "XXXX" section of the

selected 11-digit part number.

Example: 5711-1229-913 = Three Mode High Continuous Regulator with MPTS (Slide) Bracket and

Overflow Safety Trap

5700-1229-9XX

Three Mode

High Continuous

(Anti-clockwise)

5700-1233-9XX

Two Mode

Low Continuous

(Anti-clockwise)

5700-1230-9XX

Two Mode

High Continuous

(Anti-clockwise0

Regulator 12XX Options for Additional Accessories

Regulator with 30

o

Fitting, Overflow Safety

Trap

5711-XXXX-930

Regulator & MPTS

(Slide) Bracket,

Overflow Safety Trap

5711-XXXX-913

Regulator and

Dovetail Bracket,

Overflow Safety

Trap

5711-XXXX-935

10-4

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

120

16

140

18

20

Low Vacuum

100

14

High Flow

80

60

12

10

8

40

6

4

2

20

a

P

k

-

g

H

m

m

-

Page 35

6700-0078-000 Rev1 06/2009

Appendix

Installation procedure for Adapters/Probes

and Fittings.

All adapters/probes and fittings should be sealed and

installed properly to prevent leaks and to support the

equipment when mounted. Both vacuum regulator ports

are 1/8-27 NPTF tapered pipe threads. It is important to

note that adapters/probes and fittings seal on the thread

and may have threads exposed after they have been

tightened properly.

Prior to installing the adapter/probe or fitting, seal the

thread with Teflon® (PTFE) tape or one of the following

lubricants:

Dow® 111 (Ohio Medical P/N 6700-0074-200)

Ball Vac Kote (37951M) (Ohio Medical P/N 0220-0091-

300)

CAUTION

Do not use any Loctite products to seal

the threads (or products which contain

Methacrylate Ester as an active ingredient).

The torque range for installing adapters/probes and fittings is 4.0 ft-lb (5.4 N-m) minimum to 10.0 ft-lb (13.6 Nm) maximum.

Adapters/probes and fittings which are not keyed for

specific orientation, should be torqued to approximately

6.0 ft-lb (8.1 N-m).

Adapters/probes and fittings that are keyed to specific

orientation, must be torqued initially to 4.0 ft-lbs.

Additional torque is applied only until orientation is correct.

®Teflon is a registered trademark of the DuPoint Company.

A-1

Page 36

6700-0078-000 Rev1 06/2009

Ohio Medical Corporation

Authorized Representative

(OxygenCare Ltd.)

Corrig Road

Sandyford Industrial Est.

Dublin 8

Ireland

Phone +35 31 295 3421

North America

United States

Customer Service and Distribution Center

Technical Support

Sales and Service

Equipment Service Center

Ohio Medical Corporation

1111 Lakeside Drive

Gurnee, Il, 60031-4099 USA

Toll free: 866-549-6446

Phone: +1 847-855-0800

Fax: +1 847-855-6218

www.ohiomedical.com

Loading...

Loading...