Ohaus Corporation

29 Hanover Road

Florham Park, NJ

07932-0900

MECHANICAL BALANCES

FIELD SERVICE / PARTS

MANUAL

SERVICE MANUAL

Mechanical Balances

OHAUS® is the registered trademark of Ohaus Corporation, as are

the following trademarks: CENT-O-GRAM®, CHECK-O-GRAM®,

DEC-O-GRAM®, DIAL-O-GRAM®, PRIMER®, 5-0-5®, AND 10-10®.

Ohaus Corporation

29 Hanover Road

Florham Park, NJ

07932-0900

The information contained in this manual is believed to be accurate at the time of

publication, but Ohaus Corporation assumes no liability arising from the use or

misuse of this material. Reproduction of this material is strictly prohibited.

Material in this manual is subject to change.

© Copyright 1997 Ohaus Corporation, all rights reserved.

® Registered trademark of Ohaus Corporation.

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

1.1 Introduction.............................................................................................1-1

1.2 Service Facilities..................................................................................... 1 -1

1.3 Tools and Test Equipment Required ......................................................1-2

1.3.1 Standard Tools and Test Equipment List........................................1-2

1.4 Test Masses Required............................................................................1-2

1.5 Specifications..........................................................................................1-2

CHAPTER 2 CARE OF MECHANICAL BALANCES

2.1 Care of Balances ....................................................................................2-1

CHAPTER 3 SERVICING

3.1 Service of Series 700 Triple Beam Balance ...........................................3-1

3.2 Service of Models 310/311 Hanging Pan Balance..................................3-3

3.3 Service of Series 1200 School Balance.................................................3-3

3.4 Service of Series 1400 and 1500 Harvard Trip Balances.......................3-4

CHAPTER 4 PARTS LISTS

4.1 Parts Lists ...............................................................................................4-1

Page No.

LIST OF TABLES

TABLE NO. TITLE

1-1 Mass Values......................................................................................1-2

1-2 Models 310 and 311 Specifications...................................................1-2

1-3 Series 700 Triple Beam Specifications..............................................1-3

1-4 Series 1200 School Balance Specifications ......................................1-3

4-1 Model 700 Series Parts List ..............................................................4-2

4-2 Model 311 Cent-O-Gram Parts List...................................................4-3

4-3 Model 1200 School Balance Parts List..............................................4-4

4-4 Model 1400 and 1500 Series Harvard Trip Balance Parts List .........4-4

LIST OF ILLUSTRATIONS

FIGURE NO. TITLE

5-1 Typical Triple Beam Drawing ..................................................... 5-3/5-4

5-2 Models 310 and 311 Balance Drawing....................................... 5-5/5-6

5-3 Seies 1200 Balance Drawing ..................................................... 5-7/5-8

5-4 Series 1400 and 1500 Harvard Trip Balance Drawing ............. 5-9/5-10

i

ii

CHAPTER 1 INTRODUCTION

1.1 INTRODUCTION

This manual is not to be considered a service manual for service technicians. This

manual is designed to assist the end user for maintenance and making minor repairs.

This manual contains information needed to perform routine field maintenance and

service on the Mechanical Balances, Models: 310/311 with Hanging pan, Series 700 Triple Beam, Series 1400 and 1500 - Harvard Trip Balance and Series 1200 - School

Balance. The contents of this manual is contained in five chapters and are listed as

follows:

Chapter 1 Introduction - Contains information regarding service facilities, tools,

measuring masses, and specifications.

Chapter 2 Care of Mechanical Balances - Contains information on the care of

mechanical balances.

Chapter 3 Servicing - Contains typical problems and solutions for servicing.

Chapter 4 Parts Lists - Contains a partial parts list for each model or series and

identifies all field replaceable components.

Chapter 5 Drawings - Contains a drawing for each model or series and identifies all

field replaceable components. Each item on the drawings contain part numbers which

can be ordered.

Before servicing the balance, you should be familiar with the Instruction Manual which

is packed with every balance.

1.2 SERVICE FACILITIES

To service Mechanical Balances, the service area should meet the following requirements:

• Must be free of air currents or drafts from air conditioning/heating ducts, open

windows, people walking by, fans, etc.

• Area must be clean and air must not contain excessive dust particles.

• Work surface must be stable and level.

1-1

CHAPTER 1 INTRODUCTION

1.3 TOOLS AND TEST EQUIPMENT REQUIRED

In order to properly service Mechanical Balances, certain test items are required. These

items are listed as follows:

1.3.1 Standard Tools and Test Equipment List

1. Standard Tool Kit.

2. Mass sets up to 2610 grams are required. Ohaus makes various calibration

sets available. Please contact your nearest Ohaus dealer for further details.

1.4 TEST MASSES REQUIRED

The masses required to test the Mechanical Balances must meet or exceed the

requirements of ASTM Class 4 Tolerance. The mass values are listed in Table 1-1.

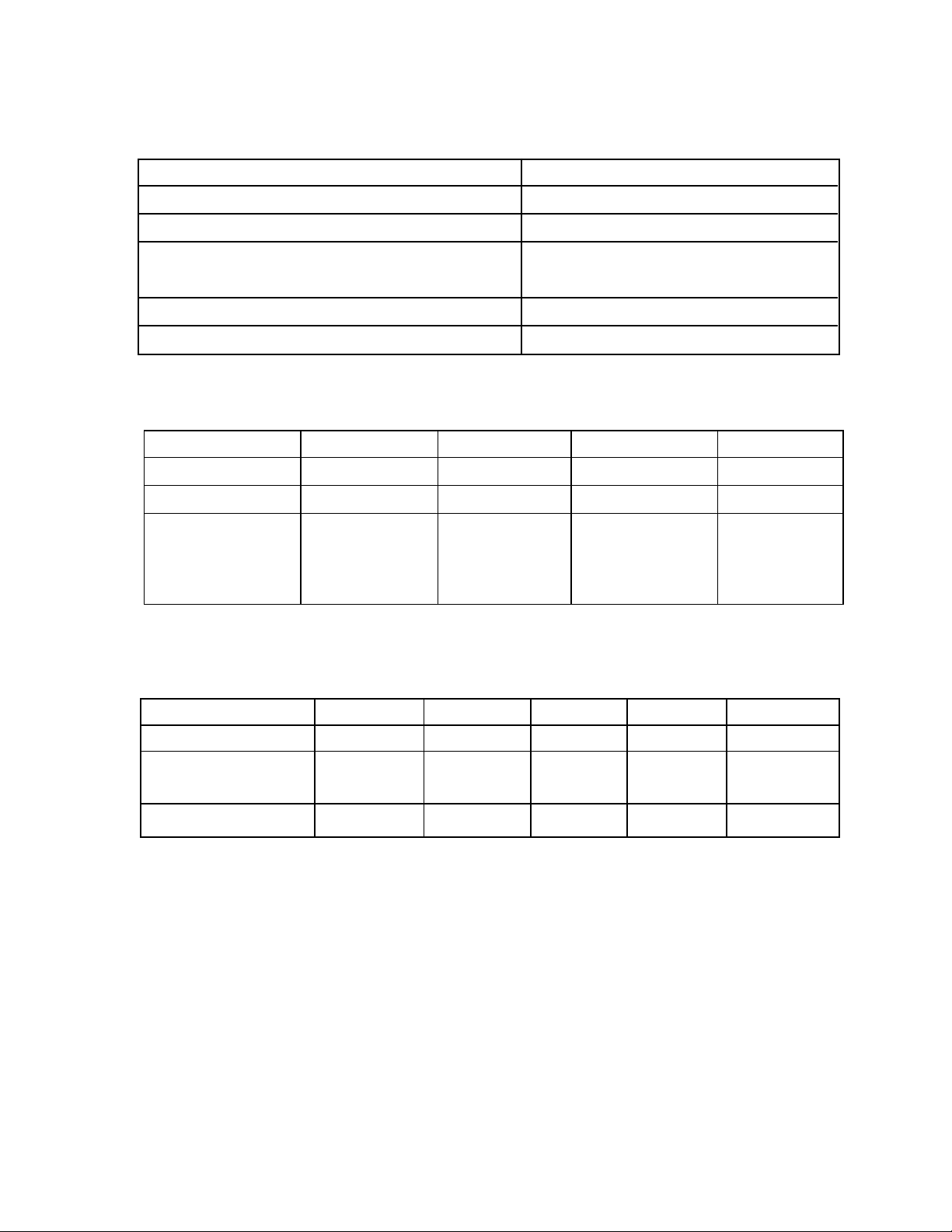

TABLE 1-1. MASS VALUES

MODEL CAPACITY CALIBRATION MASS PART NUMBER

310 310g 300g 51035-05

311 311g 300g 51035-05

700 Series 2610g 500g 51055-06

1200-00 2000g 1000g (2 required) 51016-06

1210-00 2000g 1000g (2 required) 51016-06

1400 Series 2000g 1000g (2 required) 51016-06

1500 Series 2000g 1000g (2 required) 51016-06

1.5 SPECIFICATIONS

Complete specifications for the Mechanical Balances are listed in Tables 1-2, 1-3, 1-4

and 1-5. When a balance has been serviced, it must meet the specifications listed in

the tables. Before servicing the balance, determine what specifications are not met.

TABLE 1-2. MODELS 310 AND 311 SPECIFICATIONS

Model 310 311

Capacity (g) 310 311

Readability (g) 0.01 0.01

1-2

CHAPTER 1 INTRODUCTION

1.5 SPECIFICATIONS (Cont.)

TABLE 1-3. SERIES 700 TRIPLE BEAM SPECIFICATIONS

Capacity (g) 610

Capacity (g) with accessory mass set 2610

Readability (g) 0.1

Calibrations:

Front beam 10g x 0.1g

Middle beam 500g x 100g

Rear beam 100g x 10g

TABLE 1-4. SERIES 1200 SCHOOL BALANCE SPECIFICATIONS

Model 1200-00 1200-50 1210-00 1210-50

Capacity (g) 2000 2000 2000 2000

Readability (g) 0.5* 0.5* 0.5 0.5

Calibrations:

Beam ------ ------ 10g x 0.5g 10g x 0.5g

Mass set 50g to 1g ------ 50g x to 10g ------

TABLE 1-5. SERIES 1400 AND 1500 HARVARD TRIP BALANCE SPECIFICATIONS

Model 1450-SD 1550-SD 1560-SD 1510-DO 1454-SD

Capacity (g) 2000 2000 2000 2000 2000

Weigh beam capacity 10g x 0.1g 10g x 0.1g 10g x 0.1g 10g x 0.1g 1oz x 0.01oz

x readability 200g x 10g 200g x 10g 200g x 10g 28.4 x 0.2g

Tare range ------- ------ 225g ------ ------

* Models 1200-00 and 1200-50 do not have a graduated beam, however, they are

sensitve to 0.5 gram.

1-3

CHAPTER 1 INTRODUCTION

1-4

CHAPTER 2 CARE OF MECHANICAL BALANCES

2.1 CARE OF BALANCES

Mechanical balances are precision instruments and as such, they should be handled,

treated and cleaned with care. This section briefly outlines some of the preventive

handling and storing methods to be applied to mechanical balances.

2.1.1. Keep them clean

• Pans - clean with soap and water, dry thoroughly.

• Beams, graduated strip - a commercially available spray cleaner.

• Knife edges - compressed air or an air syringe - no oils or lubricants.

• Magnets - avoid ferrous (magnetic) material contact - clean with adhesive

backed tape.

2.1.2. Always secure beam when handling

• Prevent side -to- side Beam movement - damages and dulls Knife Edges.

• Prevent excessive up-down beam movement - causes premature wear of Knife

Edges.

• Never carry Balance by the Beam. Hold beam tightly in place with one hand and

carry Balance by placing second hand under the balance base.

2.1.3 Never store balance with zero weight

• Constant oscillation dulls the Knife Edges.

• Causes a jolt when lifted.

2.1.4 Check calibration and linearity periodically

• Use known weights/calibrated masses.

2-1

CHAPTER 2 CARE OF MECHANICAL BALANCES

2-2

CHAPTER 3 SERVICING

3.1 SERVICE OF SERIES 700 TRIPLE BEAM

Refer to Figure 5-1 in Section 5 for identification of parts.

NOTE: Non-removable Knife Edges, you must replace the Beam

A. Non-Repeatability

Problem: Damper Vane touching the end of Trig Loop

Solution: Loosen the screw holding Trig Loop to Base and move it back.

Problem: Bent Damper Vane that is making contact with magnets in Trig Post

Assembly

Solution: Bend Vane with fingers or needle nose pliers (hold Beam down when

performing this operation) or remove the Trig Loop, remove the Vane and hammer

straight.

Problem: Dull Knives

Solution: To check Knives, hold Beam down. Does it return to zero? Hold Beam

up. Does it return to zero? If not, replace the Beam. This may also indicate chipped

Knife Edges.

B. Can Not Zero Balance

Problem: Missing Poise (This is the Weight that slides on the Beam.)

Solution: Replace new Poise and secure by forcing Check Pin up with a pair of

needle nose pliers. (The 100g Poise has the Check Pin, the 500g Poise does not.)

Problem: Shot Missing from under Pan.

Solution: Set Zero Adjustment at mid point of travel. Set all Poises at zero. Unscrew

the Balance Pan and place it upside down on the Balance. Add lead shot or pieces

of metal to bring Balance close to zero. Transfer shot to Balance Cup and

reassemble Balance Pan.

Problem: Chipped Knife Edge: (or dull worn Bearing [notches]). To check, pry off

Bearing Covers (these will have to be replaced by new ones). Remove Friction

Plates and lift out the Beam.

Solution: If Knife Edges are chipped or worn, replace the Beam. If Bearings are

worn, slide them up and replace with new Bearings. (NOTE: Balance that does not

have repeatability is also a symptom of worn bearings).

C. No Beam Movement

Problem: Twisted Beam or Vane rubbing.

Solution: Refer to Section A.

Problem: Foreign Material on Magnets.

Solution: Remove with adhesive backed tape or remove Trig Loop and clean

magnets.

3-1

CHAPTER 3 SERVICING

3.1 SERVICE OF SERIES 700 TRIPLE BEAM (Cont.)

C. No Beam Movement (Cont.)

Problem: Check Pin Missing

Solution: Replace. NOTE: There is a long rod under the Balance that is held in place

by 2 pins.

Problem: Broken Magnet

Solution: Remove Trig Loop and replace Magnet. NOTE: Magnets should attract

each other in force.

Problem: Rubber stoppers used in shipping at the end of the Beam and under the

Pan are still in place.

Solution: Remove both.

D. Beam Graduations need replacing.

Solution: Replace with new Lexan Graduated Strip. The old Graduated Strip will

peel off. When replacing, move front Poise completely to the left and line up new

Graduated Strip at zero.

E. Zero Adjust Knob Replacement

Hold down Leaf Spring with a small screw driver or ball point pen and screw in until

flare has passed over the Spring. This is the most common cause of not being able

to zero the balance. Check to see if the leaf spring is missing.

F. Replacing cracked or broken Balance Cup. NOTE: This is a frequent occurrence

when a balance is dropped and lands on the pan edge. Unscrew Balance Pan and

remove Counterweights and shot from Balance Cup. Remove screw holding Balance Cup to Parallel Loop Assembly and remove old Balance Cup. Reassemble,

adding or removing shot to bring Balance to zero.

3-2

CHAPTER 3 SERVICING

3.2 SERVICE OF MODELS 310/311 HANGING PAN BALANCE

Refer to Figure 5-2 in Section 5 for identification of parts.

A. Non-Repeatability

Problem: Bent Damper Vane

Solution: Straighten with fingers or needle nose pliers. (Note: Hold down Beam

when performing this operation.)

Problem: Foreign material on magnets

Solution: Remove with adhesive backed tape.

Problem: Dull Knife Edges

Solution: To check, set Balance at zero, hold down Beam and release. Hold Beam

up and release. If Balance does not return to zero, knife edge should be replaced.

These parts are replaceable in the field but it is not recommended. Special tools are

required to reassemble End Loop, and even though the Knife Edges can be

replaced in the field, the alignment technique is difficult without extensive training.

B. Can Not Zero Balance

Problem: Zero Adjust Knob missing or Leaf Spring missing.

Solution: Replace with new assembly. (Note: Hold down Leaf Spring until flare on

Knob has passed over the spring. To perform this operation, Beam should be

removed from the balance.)

Problem: Shot missing from Pan Support assembly

Solution: Remove hanging assembly and place it upside down on desk or bench.

Remove screws on Pan Support Assembly and all weights and shot. Re-hang Pan

and with Zero Knob set at mid point. Set all parts on the Pan (poise at Zero). Add

or take away shot until Balance returns to zero. Then re-assemble. (Note: hanging

Pan Balances are adjusted with Pans and Balance Serial Numbers matched. Mixing

up Pans will cause this problem. When replacing the removable Pan you will have

to go through this operation.)

Problem: Dial-O-Gram® balance Dial is out of calibration. Solution: This is a problem

that should be corrected by a trained technician.

3.3 SERVICE OF 1200 SERIES SCHOOL BALANCE

Refer to Figure 5-3 in Section 5 for identification of parts.

NOTE: Non-Removable Knife Edges, must replace Beam.

Problem: Beam does not move.

Solution: Check Beam Dampening Device. (Metal Loop that looks like a paper clip

coming out the left side of the Balance Base). Bend so it does not touch Beam when

not in use

3-3

CHAPTER 3 SERVICING

3.3 SERVICE OF SERIES 1200 SCHOOL BALANCE (Cont.)

.

Problem: Zero adjust does not move.

Solution: Turn the balance over. You will see a black horse shoe shaped piece with

an endless screw passing through. The horse shoe device must have parallel sides,

or the endless screw will jam. This is your zeroing device. Bend with needle nose

pliers to make sides parallel.

NOTE: Your balance was adjusted with the red and yellow removable pans that

came with your balance.

3.4 SERVICE OF SERIES 1400 AND 1500 HARVARD TRIP BALANCES

Refer to Figure 5-4 in Section 5 for identification of parts.

Note: Non-Removable Knife Edges, you must replace the Beam.

A. Non-Repeatability

Problem and Problem Confirmation Technique: Dull Knife Edges. To check set

Balance at zero. Hold down one Pan and release. Repeat with other Pan. If Balance

does not return to zero, Knife Edges are chipped or worn.

Solution: Return balance to Ohaus for service.

Do Not Mix Pans with other balances.

Problem: Bent Damper Vane.

Solution: Bend Damper Vane with fingers or needle nose pliers. (Note: The easy

way to observe this is to elevate the Balance with the Rod Support.)

Problem: Foreign material on magnets.

Solution: Remove with adhesive backed tape.

B. Can Not Zero Balance

Problem: Zero Adjust Knob missing.

Solution: Replace with proper Zero Adjust Assembly. (Note: hold Leaf Spring down

with a screw driver or ball point pen until flare passes over the Spring.

Problem: Shot missing from Pan Support Cup.

Solution: Unscrew Pan or Fork Assembly and add metal pieces or shot until

balance comes to zero. Note: Make sure all Poises (movable Weights on the Beam)

are at zero and tare weight is pushed all the way to the left.

C. Pans vs. Plates

A Pan is the removable sample Platform that is 6" diameter x 3/4" deep. Pans on

Harvard Trip Balances are matched for an individual Balance and when replacing,

you will get a matched set. Pans are NOT interchangeable between Balances. The

Pan sits in the Fork of the Balances.

A Plate is the flat sample holder and is not removable under normal use. It screws

directly into the Balance Cup.

3-4

CHAPTER 4 PARTS LISTS

4.1 PARTS LISTS

This section of the manual contains selected replacement parts which are identified in

Figures 5-1 through 5-4.

1. In all cases, when a part is replaced on any product, the product must be

thoroughly checked to insure accurate performance to factory specifications.

2. Part numbers in the replacement parts lists are only shown for parts which are

field serviceable.

3. When a part number is preceded by an asterisk (*), refer to the note relative to

that part located at the bottom of the page.

4. When more than one of each item is used in the manufacture of a product, the

quantity will be listed in parenthesis following the description.

5. Some descriptions are followed by the fastener part number and quantity

required. Fasteners must be ordered separately.

6. Prices and specifications are subject to change without notice.

7. See last page in this section for a Glossary of Terms.

Approximate restoration fee: Triple Beam (750 Series) $50 - $60

Triple Beam (800 Series) $75

310/311 Hanging Pan $55 - $60

Harvard Trip $70

NOTE:

If further technical information is needed, in the United States call Ohaus Aftermarket

toll-free 1-800-526-0659 between 8.00 a.m. and 4.00 p.m. EST. An Ohaus factory

service technician will be available to provide assistance. Outside the U.S.A., please

contact:

Ohaus Corporation

29 Hanover Road

Florham Park, NJ 07932, USA

Tel: (201) 377-9000,

Fax: (201) 593-0359

4-1

CHAPTER 4 PARTS LISTS

TABLE 4-1. MODEL 700 SERIES PARTS LIST

PART NO. DESCRIPTION

1008-23 Agate Bearing (4)

1023-10 Balance Cup [L1107-63 Screw]

1034-00 Friction Plate (3)

1035-03 Bearing Cover (4)

1039-02 Pan (Model 710)

1093-00 Check Pin (2)

1097-00 Balancing Slug (3) (Model 750S)

1247-00 Friction Plate with Tab

3045-00 Stainless Steel Scale Plate (Model 750)

3051-00 Check Rod Assembly

3125-10 Graduated Beam Insert, 10g x .1g

3126-10 Graduated Beam Insert, 500g x 100g

3127-10 Graduated Beam Insert, 100g x 10g

3128-00 0-10 gram Poise

3134-02 0-500 gram Poise

3135-10 0-100 gram Poise (pin .125" from edge)

3135-11 0-100 gram Poise (pin .196" from edge)

3225-00 Compensator Spring

3254-00 Damper Vane, [D2202-14 Screws (2)]

3359-00 Compensator Knob

9704-00 Tare Beam Assembly

4-2

TABLE 4-2. MODEL 311 CENT-O-GRAM PARTS LIST

PART NO. DESCRIPTION

1008-23 Agate Bearing (4)

1034-00 Friction Plate (2)

1035-03 Bearing cover (2)

1097-00 Balancing Slug (3)

3551-01 Dial Assembly

4511-00 1g Poise Assembly

4512-10 200 g Graduated Beam Insert

4513-10 100 g Graduated Beam Insert

CHAPTER 4 PARTS LISTS

4514-10 10 g Graduated Beam Insert

4515-10 1 g Graduated Beam Insert

4516-00 Damper Vane [D-2202-14 (2)]

4519-00 Balance Compensator Spring (D-2202-14)

4529-10 Threaded Rod

4534-00 Balance Compensator

4535-00 10 g Poise Assembly

4536-00 100 g Poise Assembly

4537-03 200 g Poise Assembly

4561-00 Wrench

4600-00 Pan Without Serial Number

6396-00 *Magnet (sold in pairs only)

9702-00 Pan Support Assembly

NOTE: Magnet 6396-00 must be magnetized. Pricing is per pair.

4-3

CHAPTER 4 PARTS LISTS

TABLE 4-3. MODEL 1200 SCHOOL BALANCE PARTS LIST

PART NO. DESCRIPTION

2743-00 Red Pan

2743-01 Yellow Pan

TABLE 4-4. MODEL 1400/1500 SERIES HARVARD TRIP BALANCE PARTS LIST

PART NO. DESCRIPTION

1008-23 Agate Bearing (6)

1023-10 Balance Cup (2) (L-1107-63 Screw)

1034-00 Friction Plate (4)

1035-03 Bearing Cover (5)

1071-01 Stainless Steel Pan Set

1097-00 Balance Slug (4) (Pan Model)

1240-00 10 gram Poise, Single Beam

1247-00 Friction Plate with Tab (2)

1316-10 200 gram Graduated Insert

1318-00 10 gram Graduated Insert

1320-00 10 gram Poise (Double Beam)

1322-00 Damper Vane

1325-00* Magnet (sold in pairs only) (2 pairs required)

3045-00 Scale Plate (2)

3225-00** Compensator Spring

3359-00 Compensator Knob

4-4

CHAPTER 4 PARTS LISTS

GLOSSARY OF TERMS

Agate Bearing: The V shaped Bearing that supports the Knife Edge.

Balance Cup: The Plastic Cup that attaches to the Beam with a bolt and

receives the Balance Plate, Cross or Fork.

Bearing Cover: The Stainless Steel cover that holds the Friction Plate in

place. It must be pried off to check Knife Edges and must

be replaced with new product when removed.

Compensator Assembly: Zero Adjust Knob.

Damper Vane: The Aluminum metal part that is attached to the Beam

and moves between the Magnets to slow the Beam

movement.

How does it work? The Aluminum Vane is nonferrous

and is not attracted to the Permanent Magnet, it is

however an electrical conductor. When it moves through

a magnetic field, it sets up a magnetic field opposing the

magnetic field of the Permanent Magnets. This slows

the Beam movement. The faster the Beam moves, the

stronger the magnetic field. The speed of the Vane is

proportional to the strength of the magnetic field pro-

duced.

Fork: The support mechanism that holds the Scoop.

Cross: The support mechanism that holds the Balance Pan.

Friction Plate: This is the black hardened metal piece that keeps the

Knife Edge in place.

Pan: The removable part of the balance upon which the

sample is placed (raised edge).

Plate: The non-removable part of the balance upon which the

sample is placed (flat).

Poise: The Mass or weight that moves along the Beam.

NOTE: On a two Pan Equal Arm Balance, the sample

is always placed on the left Pan or plate.

4-5

CHAPTER 4 PARTS LISTS

4-6

CHAPTER 5 DRAWINGS

5.1 DRAWINGS

This section of the manual contains drawings which indicate the field replaceable parts.

NOTE:

In all cases where a part is replaced, the

balance must be thoroughly checked after the

replacement is made. The balance MUST

meet the parameters of all applicable specifications in this manual.

If further technical information is needed, in the United States call Ohaus Aftermarket tollfree 1-800-526-0659 between 8.00 a.m. and 4.00 p.m. EST. An Ohaus factory service

technician will be available to provide assistance. Outside the U.S.A., please contact:

Ohaus Corporation

29 Hanover Road

Florham Park, NJ 07932, USA

Tel: (201) 377-9000,

Fax: (201) 593-0359

5-1

CHAPTER 5 DRAWINGS

5-2

CHAPTER 5 DRAWINGS

Figure 5-1. Typical Triple Beam Drawing. 5-3/5-4

CHAPTER 5 DRAWINGS

Figure 5-2. Models 310 and 311 Balance Drawing. 5-5/5-6

CHAPTER 5 DRAWINGS

Figure 5-3. Series 1200 Balance Drawing. 5-7/5-8

CHAPTER 5 DRAWINGS

Figure 5-4. Harvard Trip Balance Drawing. 5-9/5-10

MECHANICAL BALANCES P/N 79815-01

Loading...

Loading...