Page 1

MODEL

OHAUS CORPORATION

D500M

PORT ABLE BEAM SCALE

ASSEMBL Y MANUAL AND

OPERATING INSTRUCTIONS

Page 2

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

2

Page 3

OHAUS CORPORATION

INDEX

I. DESCRIPTION........................................................................................................................................................................04

II. SPECIFICATIONS.................................................................................................................................................................. 04

III. ASSEMBLY/INSTALLATION................................................................................................................................................ 06

IV . SHIFT....................................................................................................................................................................................... 08

V. ZERO ADJUSTMENT............................................................................................................................................................ 09

VI. OPERATING INSTRUCTIONS............................................................................................................................................ 09

CAUTION

PLACE WEDGES

UNDER WHEELS

BEFORE USING

SCALE

OHAUS CORPORATION RESERVES THE RIGHT TO MAKE REFINEMENTS OR

CHANGES WITHOUT NOTICE

3

Page 4

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

I. DESCRIPTION

The OHAUS D500M is as compact industrial scale designed to meet a variety of weighing needs where simplicity and low cost

are a must.

The D500M features an easy to read flat beam with a shadow-proof poise providing quick reading under all lighting conditions.

A positive beam lock secures the indicator when the scale is not in use.

This scale utilizes a rugged fabricated steel design and is equipped with phenolic wheels for easy portability. A stainless steel

platform is available to tailor the scale to a specific application.

II. SPECIFICATIONS

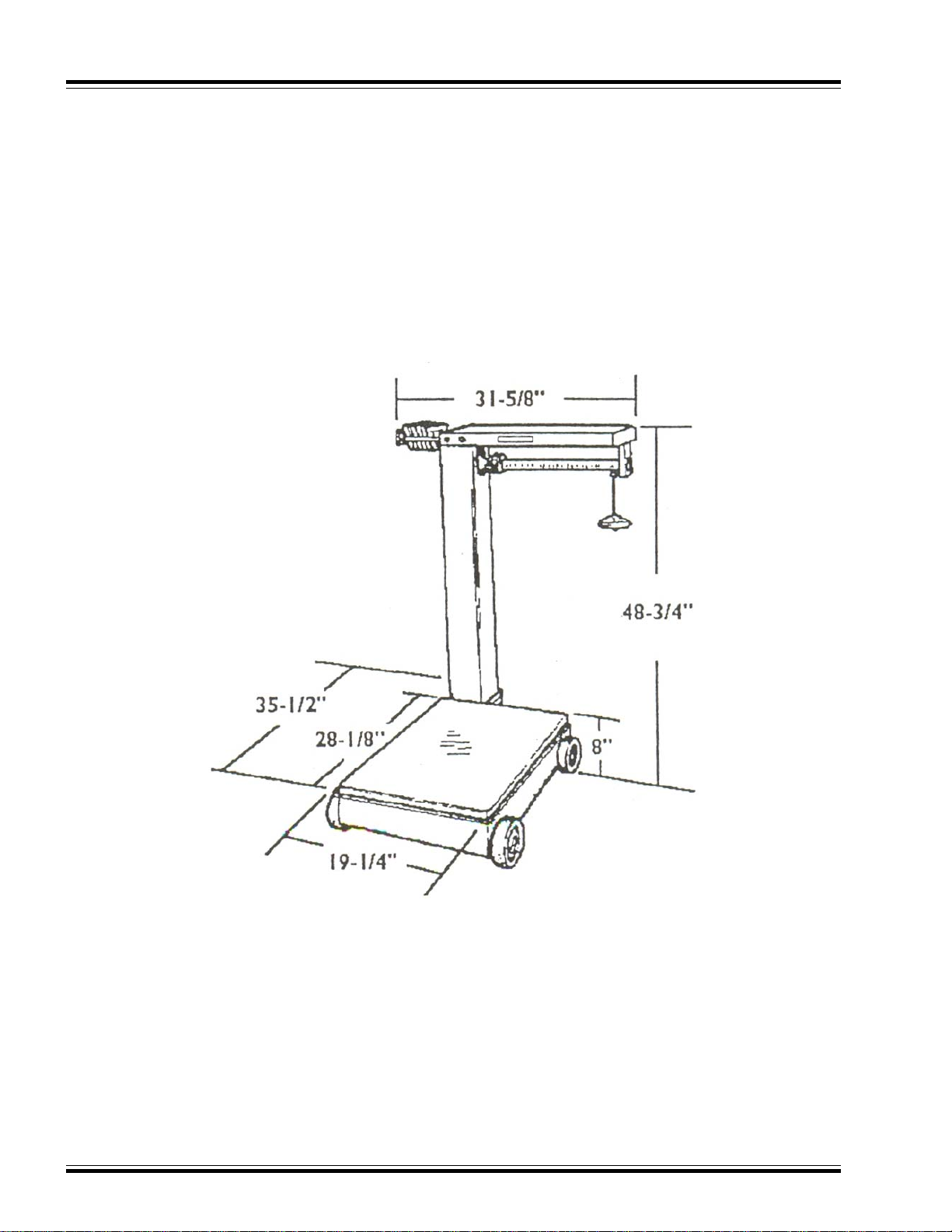

Figure 1

Available Counterpoise Weights Total

Beams (Included) Capacity

100 lb x 8 oz 2 of 100 lb

1 of 200lb 1000 lb

1 of 500lb

Or

50 kg x 200g 1 of 50 kg

2 of 100 kg 500 kg

1 of 200 kg

Combination beam: avoirdupois (front) and metric (back); includes both sets of counterpoise weights as listed above.

4

Page 5

OHAUS CORPORATION

A - Scale Platform

B - Spider Assembly

C - Beam Assembly

D - Column

E - Beam Shelf

F - Scale Base

G - Load Box Assembly

H - Level Bubble

I - Screw, 1/2-13 x 3 1/4

J - Flat Washer

K - Wheel

L - Hook’s Nose

M - Nut, 3/8-16

N - Lockwasher, 3/8

O - Screw # 10-32 x 3/8

P - Nut, 1/2-13

Figure 2

Q -Counterpoiser´s

R - Lever Assy - Long

S - Rod, Steelyard

T - Screw 1/4 - 20 x 1 1/4"

U - Nut, 1/4 - 20

V - Long Set the Hook

X - Loop Assy - Center

Y - Lever Assy - Short

Z - Short Hook

A1 - Washer

A2 - Screw

5

Page 6

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

III. ASSEMBLY / INSTALLATION

(NOTE: Refer to the exploded view diagram, Figure 2, for assembly assistance).

A. Each D500M carton contains five individually packed items. These items are:

1. One scale base.

2. One fog white column, consisting of one foursided column piece, and one steelyard rod.

3. One charcoal black beam shelf.

4. One silver-colored gratuated beam assembly. It is packed inside of the white fog column (item2).

5. One box of loose parts containing (in order of assembly):

a. four wheels.

b. four 1/2" axle bolts, each with one 3/8" nut and two washers, for the wheels.

c. two lock washers and two 3/8" nuts, to tighten the column to the colum support plate.

d. one hook, to be hung on the steelyard rod.

e. four 1/4" hex head screws and four flat washers, to tighten the beam shelf to the column.

f. one triangular load box assembly.

g. one set of counterpoise weights as described in Section II of this manual (two sets of weights, on combination lb/kg

versions).

h. two screw # 10-32 x 3/8.

B. for easy assembly the following tools are recommended:

a. 3/4" socket and ratchet

b. 3/4" open end wrench

c. 7/8" open end wrench

d. 9/16" open end wrench

e. 9/16" deep socket and ratchet

f. 1/4" slotted screwdriver

g. 7/16" socket, box, or open end wrench

C. Following the steps below, assemble your D500M:

1. Remove the plastic wrapping from the scale base.

2. Remove the scale platform from the scale base and set it aside.

3. For reinstallation purppose, note the location of the level bubble (item H, figure 2) on the spider assembly. Also note

the position of the two bolts in the center front and center back of the spider assembly. Lift out the spider assembly

and place it off to the side

4. Remove any cardboard packing and bag of silica gel from inside the scale base.

5. Install each wheel in the following sequence:

a. Slide one flat washer onto the 1/2" axle bolt and slide the bolt through the black phenolic wheel.

b. Slide another flat washer onto the bolt.

c. Lifting the scale base the required distance (appoximately 2-1/2"), insert the bolt through the hole in the scale base

from the outside and screw the bolt through the nut that is welded to the inside of the scale base. Allow sufficient

clearance for the wheel to tum freely.

d. From the inside of the scale base, add the nut onto the bolt.

e. Repeat these steps for the remaining three wheels.

f. Tighten all bolts and nuts for the wheel at this time.

6. Remove the packing around fog white column. Remove also the steelyard rod and the beam assembly from the inside

of the column. Place the column piece onto the column support plate. Ohaus Label on the column must be facing

the scale platform. From underneath the column support plate, install a lock washer and 3/8" nut onto the column roads

and tighten.

Column Rod

Holes For Column Rods

Figure 3

Column

Support

Plate

Figure 4

Column Rod

Lock Washer

Nut 9/16"

6

Page 7

OHAUS CORPORATION

7. Remove the plastic bubble from the beam shelf and beam assembly. Place the beam shelf upside down on the scale

platform. NOTE: Place some type of protection (i.e. carboard) on the scale platform to protect the platform and the beam

shelf from getting scratched.

8. Turn the beam assembly upside down and insert the rounded tip of the beam through the trig opening end of the beam

shelf assembly. To attach the beam assembly to the beam shelf, align the two holes in the plate of the beam assembly

with the two holes in welded plate, install and tighten the two screws # 10-32 x 3/8" (See Figure 5).

Welded Plate

# 10-32 x 3/8" screw

# 10-32 x 3/8" screw

Zero Adjustment Screw

9. Place the hook onto the bottom end of the steelyard rod (refer to the exploded view diagram, Figure 2, for proper

positioning). Lift the assembled beam, turn it over, and attach the top of the steelyard rod through the stirrup on

the beam assembly.

10. Place the assembled beam with the steelyard rod over the column and tighten the column and the assembled beam

by inserting the hex head screws on both sides of the column. These screws should be finger-tightened only.

Beam Shelf

Beam

Assembly

Figure 5

11. From underneath the column support plate, connect the hook that is on the steelyard rod under the pivot at the end

of the main lever of the scale base. Raising the tip of the main lever and some slight twisting of the hook by hand may

be required to get the hook under the pivot.

12. Be sure that the beam shelf is correctly leveled, and tighten the hex head screws (installed in step 10) firmly so as not

to allow any movement. NOTE: BE ALSO SURE THAT THE ROUNDED BEAM TIP IS CENTERED IN THE TRIG

OPENING (FRONT TO BACK) BEFORE TIGHTENING.

13. On the scale base, be sure that the four gold-colored fulcrum assemblies on the lever system are properly hooked

in the slot on the base flange.

14. Reinstall the spider assembly that was removed in step 3. Tilt the front end of the spider assembly, closest to the

column, downward slightly, for ease of reinstallation. The L-shaped bracket located in the center-front on the spider

assembly must be under the base flange; the heads of the two hex head bolts located in the center-front and center

back of the spider must both be inside of the base flange. Once installed, be sure that the four bearings are

properly seated on the four pivots of the main lever system.

15. Reinstall the scale platform removed in step 2.

16. Hook the load box assembly onto the stirrup located at the rounded end of the beam assembly, just inside of the trig

opening.

17. Adjust the scale to zero, if necessary. See Section V of this manual.

18. Place the counterpoise weights in the rack.

7

Page 8

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

IV. SHIFT (as needed)

A. TEST

Place a half capacity test load in the center of each quarter of the platform, or use a quarter capacity test load over each

load pivot successively.

If a correction is not needed, proceed to the operating instructions. In a mechanical base, shift refers to the pivot distances

of the levers. If, on a lever, the distances are equal, then a lever is said to have no shift error. Also, two levers which have

the same ratio will have no shift error.

B. ADJUST

The lever illustration of the D500M designates the pivots as follows:

F - Fulcrum Pivot

L - Load Pivot

P - Power Pivot

C - Center Connection

8

Page 9

OHAUS CORPORATION

The rule is to lengthen the distance between the fulcrum and the load pivots to increase the indication. Conversely, shorten

the distance between the fulcrum and the load pivots to decrease the indication. Use hone part number 085061020 (fine) and

part number 085062020 (coarse) to adjust the pivots.

TO LENGTHEN

THE DISTANCE

Note the direction of honing. Always hone away from the load edge of the pivot.

1. Side to Side

To correct a shift error side on a lever, note the indication at each location, and hone the load pivot as needed to correct

the side to side error on either lever. Hone only the load pivots to correct an error on either lever for a side to side correction.

2. Front to Back

When the indications on each load point of each lever are equal side to side and the indications of the levers are different

front to back, then hone the power pivot of the short lever until the two levers are equal front to back. Do not hone the

power pivot of the long lever. Increase the pivot distance from the power pivot to the fulcrum pivot on the short lever

if the short lever has a higher indication than the log lever.

When the Shift error is corrected, recalibrate the scale and retest the shift. Continue calibration and shift test/adjustment

until no shift error is found after the scale is calibrated.

TO SHORTEN

THE DISTANCE

V. ZERO ADJUSTMENT (as needed)

Check the zero balance by positioning the beam poise at "0" on the beam. Turn the locking lever to free the beam. The

beam should float without touching the top bottom of the trig opening. If it touched the top, turn the zero adjustment screw

(Figure 4) counter-clockwise with a screwdriver. Turn the screw clockwise until it is touching the bottom.

VI. OPERATING INSTRUCTIONS

A. SCALE OPERATION

The OHAUS D500M beam utilizes a balancing beam principle to indicate weight. With the scale loaded, slide the

beam poise toward the trig loop (away from the column). Adjust the beam poise until the tip of the beam is in a balance

state within the trig loop. The position of the beam poise indication (red pointer) on the beam will indicate the amount

of weight on the scale platform.

NOTE: When operating the scale, use wedges at the two wheels to prevent the scale from moving.

9

Page 10

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

B. INCREASING SCALE CAPACITY

The beam on the D500M provides weight indication up to 100 lb (50 kilograms) and is graduated by 8 ounces (200 grams).

The beam will counter balance a maximum load of 100 lb ( or 50 kilograms). To increase the capacity of the scale, simply

place one or more of the additional counterpoise weights on the load box assembly. (For example, the avoirdupois

D500M includes counterpoise weights, which are (2) 100 lb, (1) 200 lb, and (1) 500 lb). The additional counterpoise

weights are stored in a rack attached to the column cap. Each weight is "notched" to fit the load box assembly.

Counterpoise weights may be used separately or in combination. When using one more of the additional counterpoise

weightsto determine weight on the platform, adjust the beam poise until a balance state is achieved. The weight on the

platform can be determined by adding the sum of the additional counterpoise weights on the load box assembly to the

amount indicated on the beam.

Example: both additional 100 lb counterpoise weights are secured to the load box assembly. The beam poise is indicating

"45 lb", and beam is balance in the trig loop; weight on the scale platform totals 245 lb.

C. FILLING OPERATIONS

When filling containers on the scale, adjust the beam poise to the desired target weight. Add additional counterpoise

weights to the load box assembly if necessary.

A set screw is provided on the bottom of the beam poise to secure to the beam. To inhibit the beam poise from traveling

on the beam (and changing the target weight), It is advisable to tighten the set screw. Fill container until the beam exhibits

a balance condition indicating that the target weight has been achieved.

D. TRIG LOCKING MECHANISM

When moving the scale, it is recommended that the beam be locked in place to prevent damage. A locking mechanism

is provided on the trig loop to inhibit vertical travel of the beam whenever the base is moved. The trig loop locking device

must be disengaged when the scale is in use.

10

Page 11

OHAUS CORPORATION

11

Page 12

MODEL D500M PORTABLE BEAM SCALE ASSEMBLY MANUAL AND OPERATING INSTRUCTIONS

For information in

U.S and Canada, contact:

OHAUS Corporation

19A Chapin Road, P.O. Box 2033

Pine Brook, NJ 07058-2033, USA

Phone: +1-973-377-9000

Fax: +1-973-944-7177

www.ohaus.com

For information in other countries, contact the manufaturer:

TOLEDO DO BRASIL

INDÚSTRIA DE BALANÇAS LTDA.

R. Manoel Cremonesi, 1

Tel. 55 (11) 4356-9000

CEP 09851-330 - Jardim Belita - São Bernardo do Campo - SP - Brasil

site: www.toledobrasil.com.br

e-mail: exp@toledobrasil.com.br

P/N 80252764 © OHAUS Corporation 2008, all rights reserved

*80252764*

Printed in Brazil

3474278

RE: 00-10-08

Loading...

Loading...