Page 1

Model CD-11 Indicator

Instruction Manual

Indicador Modelo CD-11

Manual de instrucciones

Indicateur modèle CD-11

Manuel d’instruction

*

Page 2

Page 3

3

Ohaus Corporation, 19A Chapin Road, P.O. Box 2033 Pine Brook, New Jersey, 07058, USA

Declaration of Conformity We, Ohaus Corporation, declare under our sole responsibility that the balance models listed below marked with

“CE” - are in conformity with the directives and standards mentioned.

Declaración de Conformidad

indicados a continuación - con el distintivo ,CE’ - están conformes con las directivas y normas citadas.

Déclaration de conformité Nous, Ohaus Corporation, déclarons sous notre seule responsabilité, que les types de balance ci-dessous cité

- munis de la mention «CE» - sont conformes aux directives et aux normes mentionnées ci-après.

Model/Modelo/Modèle CD-11

EC Marking: EC Directive Applicable Standards

Marcado EC Directive EC Normas aplicables

Marquage CE Directive CE Normes applicable

Nosotros, Ohaus Corporation, declaramos bajo responsabilidad exclusiva que los modelos de balanzas

73/23/EEC EN60950-1:2001

Low Voltage

Baja tensión

Basse tension

89/336/EEC EN61326-1: 1997 + A1:98 + A2:01 +A3:03

Electromagnetic compatibility

Compatibilidad electromagnética

Compatibilité électromagnétique

For non-automatic weighing instruments used in an Article 1, 2.(a) application, additional metrological marking according to Annex

IV of Council directive 90/384/EEC must be attached to the instrument

Para instrumentos de pesaje no automático usados en una aplicación descrita en el Artículo 1, 2.(a), se debe colocar sobre el

instrumento una marcación metrológica adicional de acuerdo con el Anexo IV de la Directriz del Consejo 90/384/EEC.

Pour les instruments de pesage non-automatiques utilisés dans une application Article 1, 2.(a), un repérage métrologique

additionnel conforme à l’Annexe IV de la Directive 90/384/EEC du Conseil doit être présent sur l’instrument.

90/384/EEC EN45501:1992

year

Non Automatic Weighing Instruments

Para balanzas no automátäcas

010

Balances à fonctionnement non automatique

1) 2)

M

1) Applies only to certified non-automatic weighing instruments

Aplicable solamente a instrumentos de pesaje aprobados de funcionamiento no automático

S’applique uniquement aux instruments de pesage à fonctionnement non automatique approuvés

2) Valid only for CW-11 terminals in connection with approved load cells

Valable seulement pour les indicateurs CW-11 connectés à des cellules de pesée approuvées.

Válido solamente para terminales CW-11 en conexión con células de carga aprobadas

Date: May, 5, 2006

Ted Xia

President

Ohaus Corporation

Pine Brook, NJ USA

Urs Muller

General Manager

Ohaus Europe

Greifensee, Switzerland

Page 4

Important notice for verified weighing instruments

Weighing Instruments verified at the place of manufacture bear one of the preceding mark on the packing label and

the green ‘M’ (metrology) sticker on the descriptive plate. They may be put into service immediately.

Weighing Instruments to be verified in two stages have no green ‘M’ (metrology) on the descriptive plate and bear one

of the preceding identification mark on the packing label. The second stage of the initial verification must be carried

out by the approved service organization of the authorized representative within the EC or by the national weight &

measures (W+M) authorities.

The first stage of the initial verification has been carried out at the manufacturers work. It comprises all tests according to the adopted

European standard EN 45501:1992, paragraph 8.2.2.

If national regulations limit the validity period of the verification, the user of the weighing instrument must strictly observe the re-verification

period and inform

the respective W+M authorities.

Notificación importante para instrumentos de pesaje verificados

Los instrumentos de pesaje verificados en el sitio de fabricación llevan una de las marcas precedentes en el rótulo del

empaque y la etiqueta de la ‘M’ verde (metrología) en la placa descriptiva. Estos instrumentos se pueden poner en

funcionamiento inmediatamente.

Los instrumentos de pesaje a ser verificados en dos etapas no tienen ninguna ‘M’ verde (metrología) en la placa

descriptiva, y presentan una de las marcas de identificación precedentes sobre el rótulo del empaque. La segunda

etapa de la verificación inicial debe ser llevada a cabo por la organización de servicio aprobada del representante

autorizado dentro de la CE o por las autoridades nacionales de pesos y medidas.

La primera etapa de la verificación inicial ha sido llevada a cabo en el sitio de fabricación. Ésta comprende todas las pruebas

estipuladas por el estándar europeo adoptado: EN 45501:1992, párrafo 8.2.2.

Si las normas nacionales limitan el periodo de validez de la verificación, el usuario del instrumento de pesaje debe seguir estrictamente

el periodo de re-verificación e informar a las correspondientes autoridades de pesos y medidas.

Avis important pour les instruments de pesage vérifiés

Les instruments de pesage vérifiés sur le site de fabrication portent l’une des marques précédentes sur l’étiquette de

l’emballage avec un autocollant M (pour Métrologie) en vert sur la plaque descriptive. Ces instruments peuvent être

immédiatement mis en service.

Les instruments de pesage à vérifier en deux étapes ne portent pas d’autocollant M (pour Métrologie) en vert sur la

plaque descriptive et portent l’une des marques d’identification précédentes sur l’étiquette de l’emballage. La deuxième

étape de la vérification initiale doit être exécutée par l’organisation de service homologuée du représentant agréé au

sein de la CE ou par les autorités nationales de poids et mesures.

La première étape de la vérification initiale a été exécutée sur le site du fabricant. Elle se compose des tests requis par la norme

européenne EN45501:1992, paragraphe 8.2.2.

Si des règlements nationaux limitent la durée de validité de la vérification, il incombe à l’utilisateur dudit instrument de pesage de

respecter strictement la période de re-vérification et d’informer les autorités de poids et mesures respectives.

Page 5

Disposal

In conformance with the European Directive 2002/96 EC on Waste Electrical and Electronic Equipment (WEEE) this

device may not be disposed of in domestic waste. This also applies to countries outside the EU, per their specific

requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for electrical and

electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from which you purchased this

device.

Should this device be passed on to other parties (for private or professional use), the content of this regulation

must also be related.

Thank you for your contribution to environmental protection.

Eliminación de residuos

De conformidad con las exigencias de la directiva europea 2002/96 CE sobre residuos de aparatos eléctricos y

electrónicos (RAEE), este equipo no puede eliminarse como basura doméstica. Esta prohibición es asimismo

válida para los países que no pertenecen a la UE cuyas normativas nacionales en vigor así lo reflejan.

Elimine este producto, según las disposiciones locales, mediante el sistema de recogida selectiva de aparatos

eléctricos y electrónicos.

Si tiene alguna pregunta al respecto, diríjase a las autoridades responsables o al distribuidor que le proporcionó el

equipo.

Si transfiere este equipo (por ejemplo, para la continuación de su uso con fines privados, comerciales o

industriales), deberá transferir con él esta disposición.

Muchas gracias por su contribución a la conservación medioambiental.

Elimination

En conformité avec les exigences de la directive européenne 2002/96 CE relative aux déchets d'équipements

électriques et électroniques (DEEE), cet appareil ne doit pas être éliminé avec les déchets ménagers. Logiquement,

ceci est aussi valable pour les pays en dehors de l'UE conformément aux règlementations nationales en vigueur.

Veuillez éliminer cet appareil conformément aux prescriptions locales dans un conteneur séparé pour appareils

électriques et électroniques.

Pour toute question, adressez-vous aux autorités compétentes ou au revendeur chez qui vous avez acheté cet

appareil.

En cas de remise de cet appareil (p. ex. pour une utilisation privée ou artisanale/industrielle), cette prescription doit

être transmise en substance.

Merci pour votre contribution à la protection de l'environnement.

Page 6

FCC Note

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada Note

This Class B digital apparatus complies with the Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

ISO 9001 Registration

In 1994, Ohaus Corporation, USA, was awarded a certificate of registration to ISO 9001 by Bureau Veritus Quality International (BVQI),

confirming that the Ohaus quality management system is compliant with the ISO 9001 standard’s requirements. On May 15, 2003,

Ohaus Corporation, USA, was re-registered to the ISO 9001:2000 standard.

Registro ISO 9001

En 1994, Bureau Veritus Quality International (BVQI) le otorgó a Ohaus Corporation, EE.UU., un certificado de registro ISO 9001 el cual

confirma que el sistema administrativo de calidad de Ohaus cumple con los requerimientos del estándar ISO 9001. En mayo 15 del

2003, Ohaus Corporation, EE.UU., fue registrada nuevamente al estándar ISO 9001:2000.

Enregistrement ISO 9001

En 1994, le Bureau Veritus Quality International (BVQI) a octroyé la certification d’enregistrement ISO 9001 à Ohaus Corporation, ÉtatsUnis d’Amérique, confirmant que le système de gestion de la qualité Ohaus était conforme aux conditions normalisées de l’ISO 9001. Le

15 mai 2003, Ohaus Corporation, États-Unis d’Amérique, a été ré-enregistrée à la norme ISO 9001:2000.

Page 7

CD-11 Indicator

EN-1

TABLE OF CONTENTS

OVERVIEW OF CONTROLS AND INDICATOR FUNCTIONS ................................................................................................. 3

1. GETTING TO KNOW YOUR INDICATOR ..................................................................................................................... 4

1.1 Introduction ....................................................................................................................................................... 4

1.2 Features......... ..................................................................................................................................................... 4

1.3 Safety precautions ................................................................................................................................................ 4

2. INSTALLATION ...................................................................................................................................................... 5

2.1 Unpacking and Checking ....................................................................................................................................... 5

2.2 Selecting the Location ........................................................................................................................................... 5

2.3 Connecting the Indicator to a Scale Base ................................................................................................................ 5

2.4 Connecting the RS232 Interface.............................................................................................................................. 7

2.5 Connecting Power ................................................................................................................................................. 7

2.5.1 AC Adapter ................................................................................................................................................. 7

2.5.2 Battery Installation ...................................................................................................................................... 7

2.5.3 Switching on the Indicator ........................................................................................................................... 8

2.6 Initial Setup ....................................................................................................................................................... 8

2.6.1 Control Functions ........................................................................................................................................ 8

2.6.2 Menu Structure ........................................................................................................................................... 9

2.6.3 Load Parameters....................................................................................................................................... 10

2.6.4 Setup Menu .............................................................................................................................................. 11

2.6.5 Readout Menu .......................................................................................................................................... 13

2.6.6 Print menu ............................................................................................................................................... 17

2.6.7 Lockout Menu ........................................................................................................................................... 19

3. CALIBRATION AND SEALING ................................................................................................................................. 21

3.1 Legal for Trade (LFT) Operation and LFT Sealing ................................................................................................... 25

4. OPERATION ..................................................................................................................................................... 26

4.1 Turning On Indicator ........................................................................................................................................... 26

4.2 Turning Off Indicator ........................................................................................................................................... 26

4.3 Zero Operation .................................................................................................................................................... 26

4.4 Tare Operation .................................................................................................................................................... 26

4.5 Gross/Net/Tare Recall Operation ........................................................................................................................... 27

Page 8

EN-2

CD-11 Indicator

TABLE OF CONTENTS (Cont.)

4.6 Clear Tare Operation ........................................................................................................................................... 27

4.7 Unit Switch Operation .......................................................................................................................................... 27

4.8 Parts Counting Operation ..................................................................................................................................... 28

4.9 Establishing the Average Piece Weight (APW) ....................................................................................................... 28

4.10 Returning to a Weighing Mode ........................................................................................................................... 29

4.11 Returning to a Preset APW ................................................................................................................................. 29

4.12 Display Hold Modes .......................................................................................................................................... 29

4.12.1 Manual Display Hold (dHMAn)................................................................................................................. 29

4.12.2 Semi-automatic Display Hold (dHSEM) ..................................................................................................... 30

4.12.3 Automatic Display Hold (dHAuto) ............................................................................................................. 31

4.13 RS232 Commands ............................................................................................................................................ 31

4.14 Printing Data .................................................................................................................................................... 32

5. CARE AND MAINTENANCE ................................................................................................................................... 33

5.1 Troubleshooting.................................................................................................................................................. 33

5.2 Error Codes List .................................................................................................................................................. 35

5.3 Service Information ............................................................................................................................................. 35

5.4 Replacement Parts .............................................................................................................................................. 35

5.5 Accessories ..................................................................................................................................................... 35

5.6 Technical Data ................................................................................................................................................... 35

Page 9

CD-11 Indicator

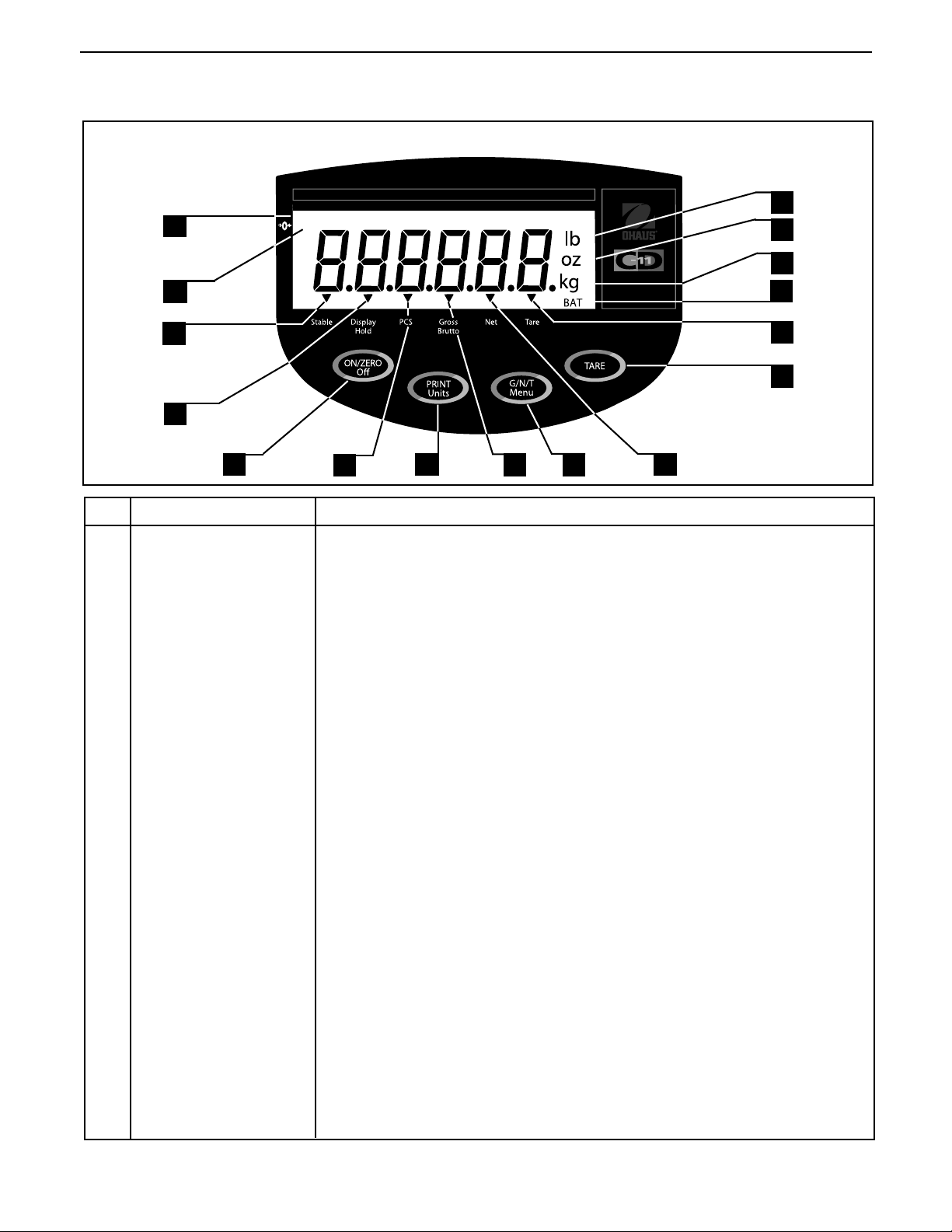

OVERVIEW OF CONTROLS AND INDICATOR FUNCTIONS

1

2 13

*

EN-3

16

15

14

3

12

11

4

5

No. Designation No. Designation

No. Designation

No. Designation No. Designation

1 Display LCD display, indicates weight, modes and setup information.

2 Center of Zero LCD indicator prompt, indicates center of zero when within +/- 0.25d.

3 Stable LCD indicator prompt, indicates that the measured value has become stable.

4 Display Hold LCD indicator prompt, indicates display hold is active.

Off

5 ON/ZERO/

6 Pcs LCD indicator prompt, indicates parts counting function is active.

7 PRINT/

button Turns Indicator on or off. Secondary use, provides zero function.

Units

button Short press, prints data which is displayed on the Indicator.

6

FunctionFunction

Function

FunctionFunction

Long press, changes unit of measure or mode.

When in menus, each press advances through the menus.

When in submenus or establishing Average Piece Weights, each press

toggles through settings.

7

8

9

10

8 Gross Brutto LCD indicator prompt, indicates gross weight.

Menu

9 G/N/T/

10 Net LCD indicator prompt indicates net weight.

11 TARE button When pressed, enters tare value into memory.

12 Tare LCD indicator prompt indicates tare weight.

13 BAT LCD indicator prompt, indicates low battery.

14 kg LCD indicator, when lit, indicates weight in kilograms.

g LCD indicator, when lit, indicates weight in grams.

15 oz LCD indicator, when lit, indicates weight in ounces.

16 lb LCD indicator, when lit, indicates weight in pounds.

button Recalls Gross/Net/Tare. Long press allows entry into menus.

When in menus, accepts the settings.

when in parts counting mode, long press sets up Average Piece Weight.

When establishing print interval, increments through the settings.

Page 10

EN-4

CD-11 Indicator

1. GETTING TO KNOW YOUR INDICATOR

1.1 Introduction

Thank you for deciding to purchase a CD-11 Indicator from Ohaus. The Ohaus CD-11 Indicator is a rugged,

reliable, electronic weight indicator designed for easy operation.

Behind your instrument stands OHAUS, a leading manufacturer of precision Indicators, Scales and Balances.

An Aftermarket Department with trained instrument technicians is dedicated to providing you with the fastest

service possible in the event your instrument requires servicing. OHAUS also has a Customer Service Department to answer any inquiries regarding applications and accessories.

To ensure you make full use of the possibilities offered by your CD-11 Indicator, please read the manual

completely before installation and operation.

1.2 Features

Major features include:

• 6 digits, 7-segments, 25 mm high digits; backlit LCD display

• 4 function membrane switch

• Supports up to four (4) 350 ohm analog load cells

• Up to 20,000d displayed resolution

• Flexible unit switching: lb/kg/oz/g

• Capacities from 5 to 20,000 lb/kg

• AC power adapter or 6 Alkaline "C" battery operation

• Power-saving Auto Shut-off timer

• Low battery warning

• Standard built-in RS-232 interface

• Parts Counting or Display Hold modes

• Available table, wall or tower mounting accessories

1.3 Safety Precautions

Model CD-11 Indicator

must not be operated in hazardous areas.must not be operated in hazardous areas.

must not be operated in hazardous areas.

must not be operated in hazardous areas.must not be operated in hazardous areas.

Before connecting the AC adapter, verify that the voltage printed on it corresponds to the local mains voltage.

If this is not the case, please contact your local Ohaus dealer.

Model CD-11 Indicator may only be used in a dry environment.

Page 11

CD-11 Indicator

EN-5

2. INSTALLATION

2.1 Unpacking and Checking

Open the package and remove the instrument and the accessories. Check the completeness of the delivery.

The following accessories are part of the standard equipment of your new Indicator.

Remove packing material from the instrument.

Check the instrument for transport damage. Immediately inform your Ohaus dealer if you have complaints or

parts are missing. Your Indicator package should contain:

• Indicator CD-11

• AC Adapter

• Warranty card

• Capacity label

• Screw driver (for terminal connections)

• Instruction Manual

• Sealing Kit

• RS232 connector

Store all parts of the packaging. This packaging guarantees the best possible protection for the transport of

your instrument.

2.2 Selecting the Location

The Indicator should be used in an environment which is free from corrosives, vibration, temperature or

humidity extremes. These factors will affect displayed weight readings. Scale bases used with the Indicator

should be located on a stable level surface and kept away from vibrating sources such as large machinery.

Maximum accuracy will be achieved when the area is clean and vibration free.

2.3 Connecting the Indicator to a Scale Base

Turn the Indicator over and using a Phillips screw driver, remove the four screws which secure the rear cover.

Two screws are under the battery cover.

Remove the rear cover.

Pass the load cell cable through the liquid tight connector on the left side of the housing.

Refer to the color code of the load cell cable and connect the wires to Terminal Strip J4. Tighten all screws

securely.

Page 12

EN-6

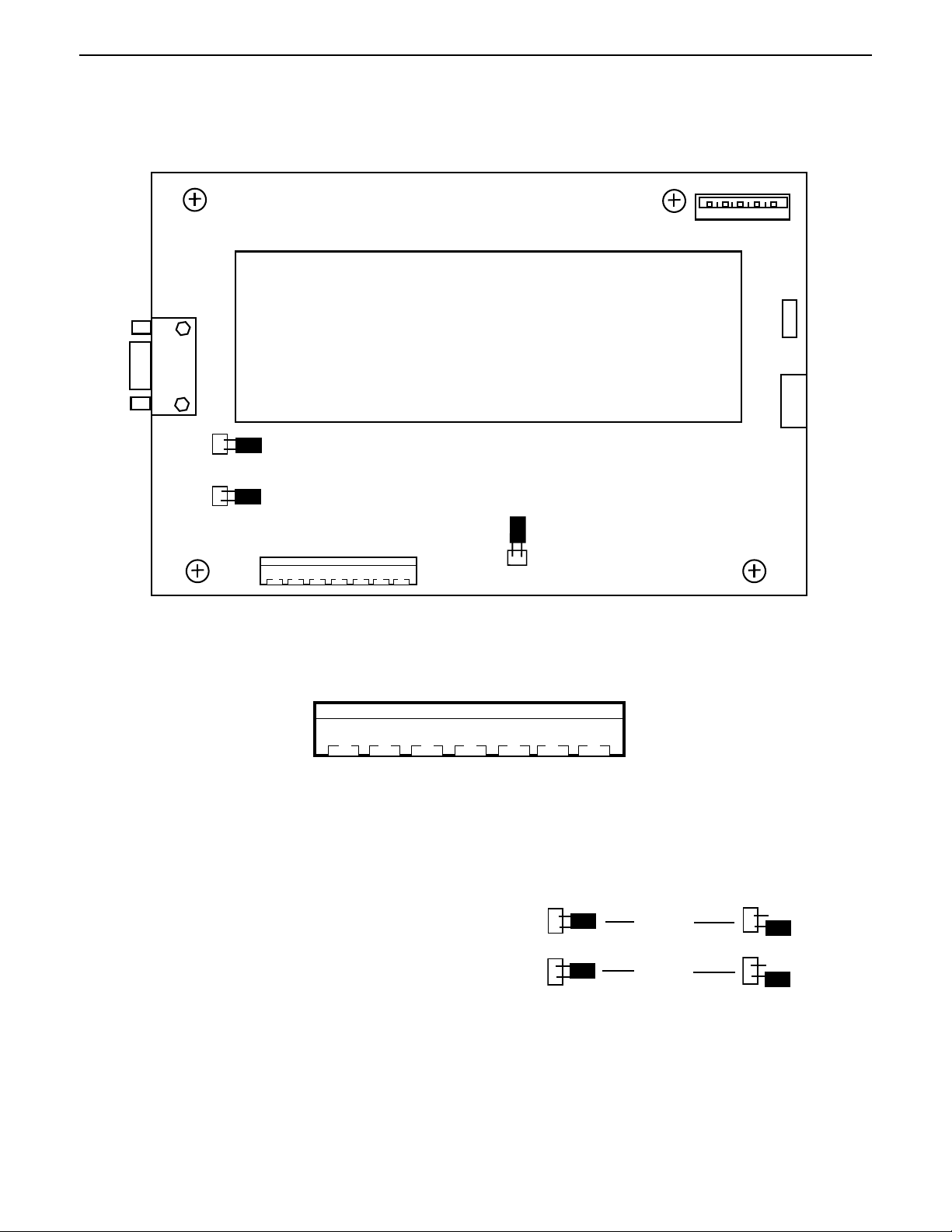

J

2.3 Connecting the Indicator to a Scale Base (Cont.)

CD-11 Indicator

1

5

J5

3

2

5

6

DISPLAY

J3

9

1

J6

1

4

J7

1

JUMP 1

JUMP 2

CAL

J4

12 3 4 5 67

+EXE +SEN +SIG CGND -SIG -SEN -EXE

Printed Circuit Board Connector Locations.

12 3 4 5 67

4

+EXE +SEN +SIG CGND -SIG -SEN -EXE

Connector J4 Terminations.

For load cells without sense capability (4-wire), Jump 1

and Jump 2 must be shorted as shown in the illustration.

For load cells with sense capability (6-wire), Jump 1

and Jump 2 must be open.

4-Wire

Jumper Connections.

JUMP 1

JUMP 2

6-Wire

Jumper Connections.

Page 13

CD-11 Indicator

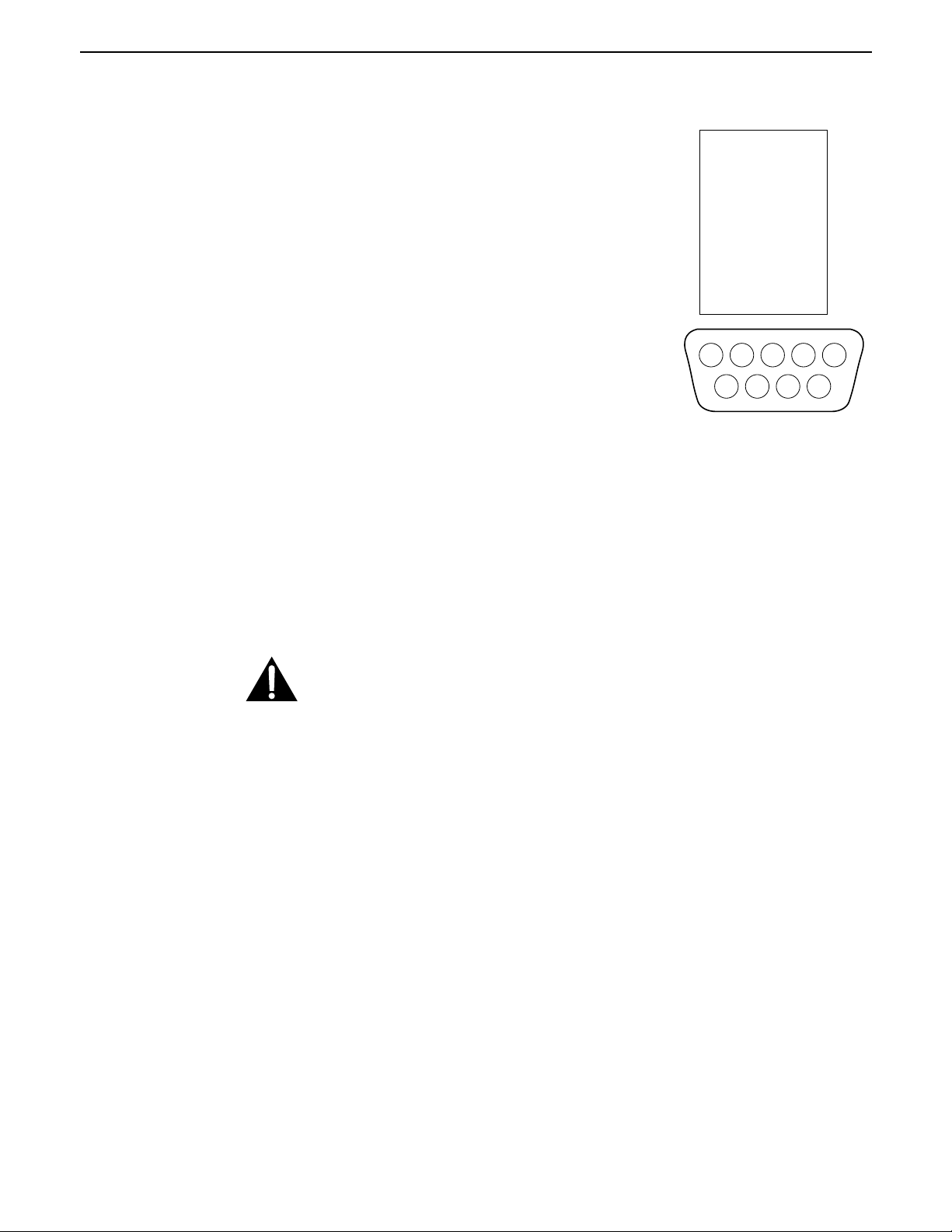

2.4 Connecting the RS232 Interface

CD-11 Indicators are equipped with a standard IBM

tional RS232 interface for communication with printers and computers. When

the Indicator is connected directly to a printer or a PC, displayed data can be

recorded at any time by simply pressing the Print/

Connecting the Indicator to a computer enables you to operate several functions of the Indicator from the computer, as well as receive data such as

displayed weight, weighing mode, stability status, etc.

TM

compatible, bi-direc-

Units

button.

EN-7

1 N/C

2 RXD

3 TXD

4 N/C

5 GND

6 N/C

7 N/C

8 N/C

9 N/C

Hardware

A 9-pin female “D” connector located on the left side of the indicator is provided for interfacing to other devices. Pin connections are shown in the adjacent illustration.

45

3

8

9

RS-232 Connector Pin Layout.

1

2

6

7

2.5 Connecting Power

The CD-11 Indicator may be operated using the AC Adapter supplied, or 6 Alkaline C-type batteries (not supplied).

2.5.1 AC Adapter

Connect the AC Adapter connector to the receptacle located at the right-hand side of the Indicator and plug the

adapter into a convenient outlet.

NOTICE:

The socket/outlet must be installed near

the equipment and shall be easily accessible.

2.5.2 Battery Installation

Open the battery cover on the bottom of the housing.

Insert 6 Alkaline C-type batteries into the two battery sleeves (3 in each sleeve) making sure the batteries are all

facing in the same direction.

Place the batteries into the two slots in the housing. Orient the batteries so that the positive (+) ends are against

the reeds and the negative (-) ends rest against the springs.

Page 14

EN-8

CD-11 Indicator

2.5.2 Battery Installation (Cont.)

NOTE: It is recommended that when the CD-11 is operated from batteries, the Auto-Off Timer feature be turned

on to extend battery life.

2.5.3 Switching On the Indicator

Once the Indicator and Scale Base are connected and installed, follow the setup procedure outlined below.

Power On/Off

With the Indicator connected to an appropriate power supply, press the ON/ZERO

performs a self-test, displays the software revision momentarily and then goes to a weighing mode.

At this point, the Indicator is on and ready for initial setup.

Off

button. The Indicator

Stabilization

Before initially using the Indicator, allow time for it to adjust to its new environment. Recommended warm up

period is five (5) minutes.

2.6 Initial Setup

The CD-11 Indicator is equipped with menus which permit certain functions to be locked out (not changed)

during operation. If locking out changes to the setup selections, access the CAL jumper located on the circuit

board following the setup procedure. Once all setup procedures are completed, reassemble the Indicator. For

first time setup, step through all menus and set the parameters as desired. As the last step, enter the CAL menu

and calibrate the system.

The Indicator has five menus; CAL (Calibration), SEtuP (Setup), rEAd (Read) , Print (Printing) and LOCSW

(Lockswitch) which are entered by pressing and holding the G/N/T/

releasing it. The display then switches to CAL.

To access the rest of the menus, the PRINT/

reached.

Units

button is repeatedly pressed until the desired menu is

Menu

button until MEnu is displayed, then

2.6.1 Control Functions

During setup, the following buttons are used.

Units

PRINT/

Change between menus horizontally or change sub-menu parameters.

Button

G/N/T/

Menu

Button

Press and hold to enter menu. Enters menu and steps through sub-menus vertically.

Tare Button

Change print interval settings.

Page 15

CD-11 Indicator

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

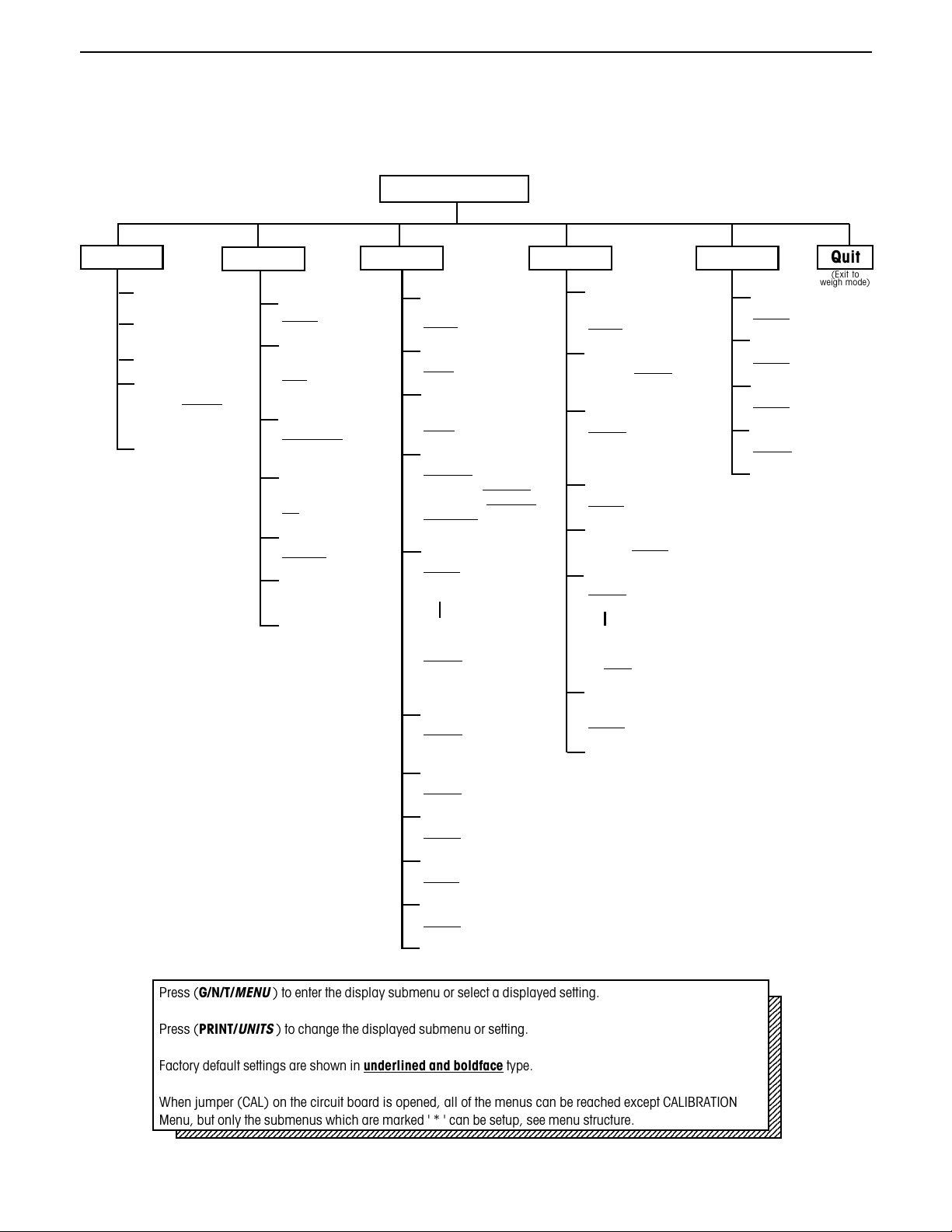

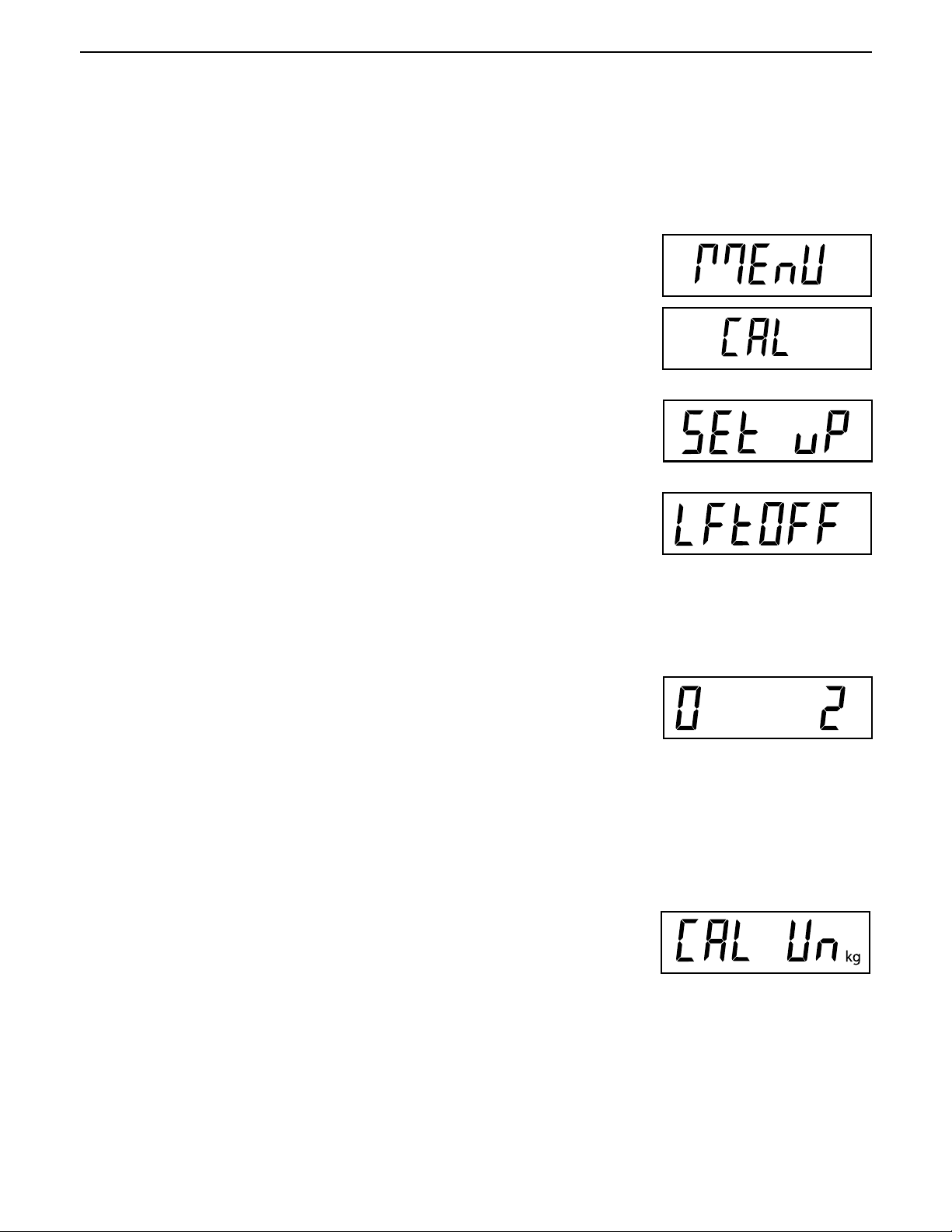

2.6.2 Menu Structure

The following table illustrates the menu structure in the CD-11 Indicator.

MAIN MENU

EN-9

CAL

CALIBRATION

SPAN Y

LIN Y

GEO (Value)

GEO 0...gEO 12...

GEO 31

Save Settings

SAVE

SEt uP rEAd Print LOCSW

Legal for Trade

LFtOn

,,

, LFtCan

,,

LFtOFF,

Zero (Range)

0 2 (2%),

0 18 (18%),

0 100 (100%)

Calibration Unit

CAL Un kg,

CAL Un lb

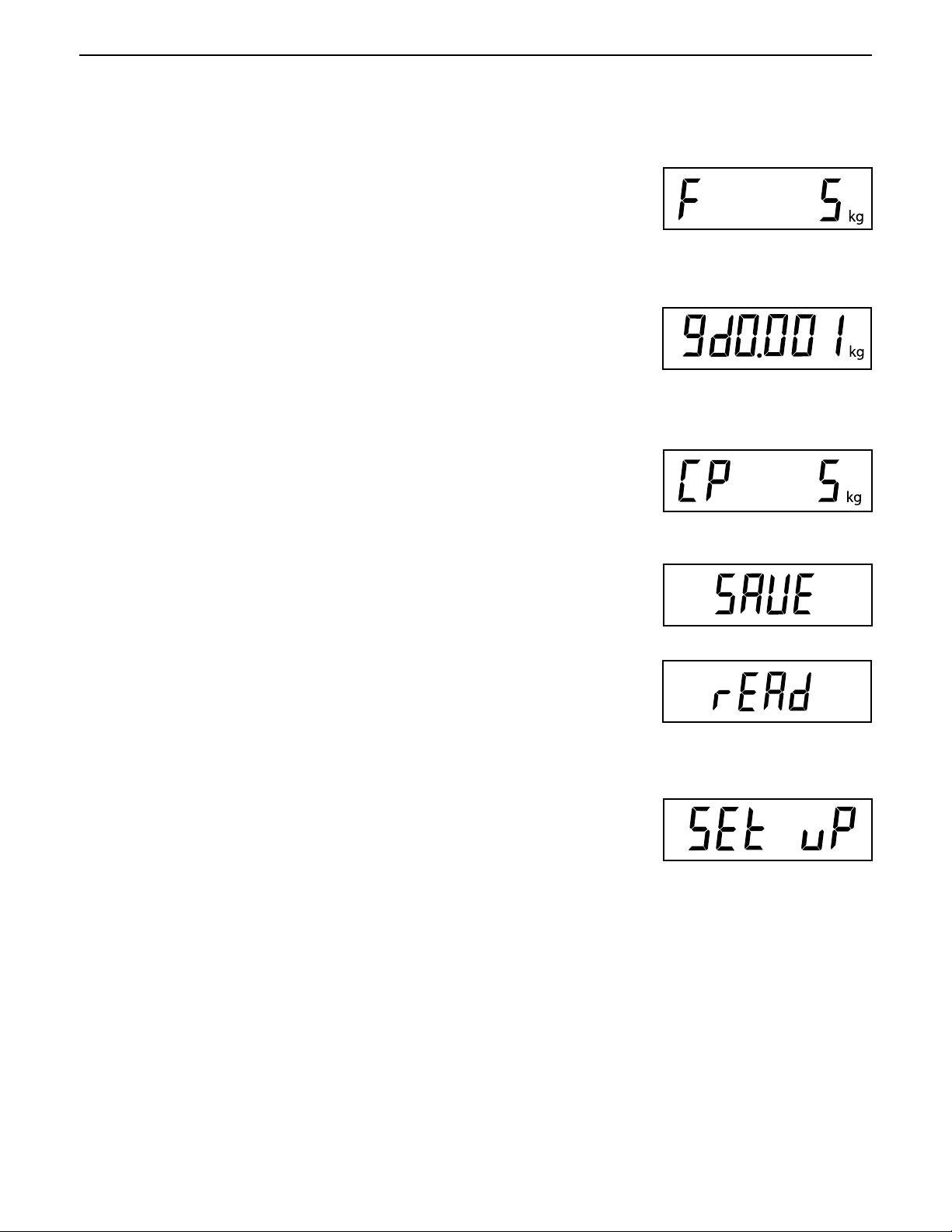

Full Scale

capacity

F 5, to....... F20000

Graduation Size

gd0.001, to ....gd 20

Calibration Point

CP 5, to....C20000

Save Settings

SAVE

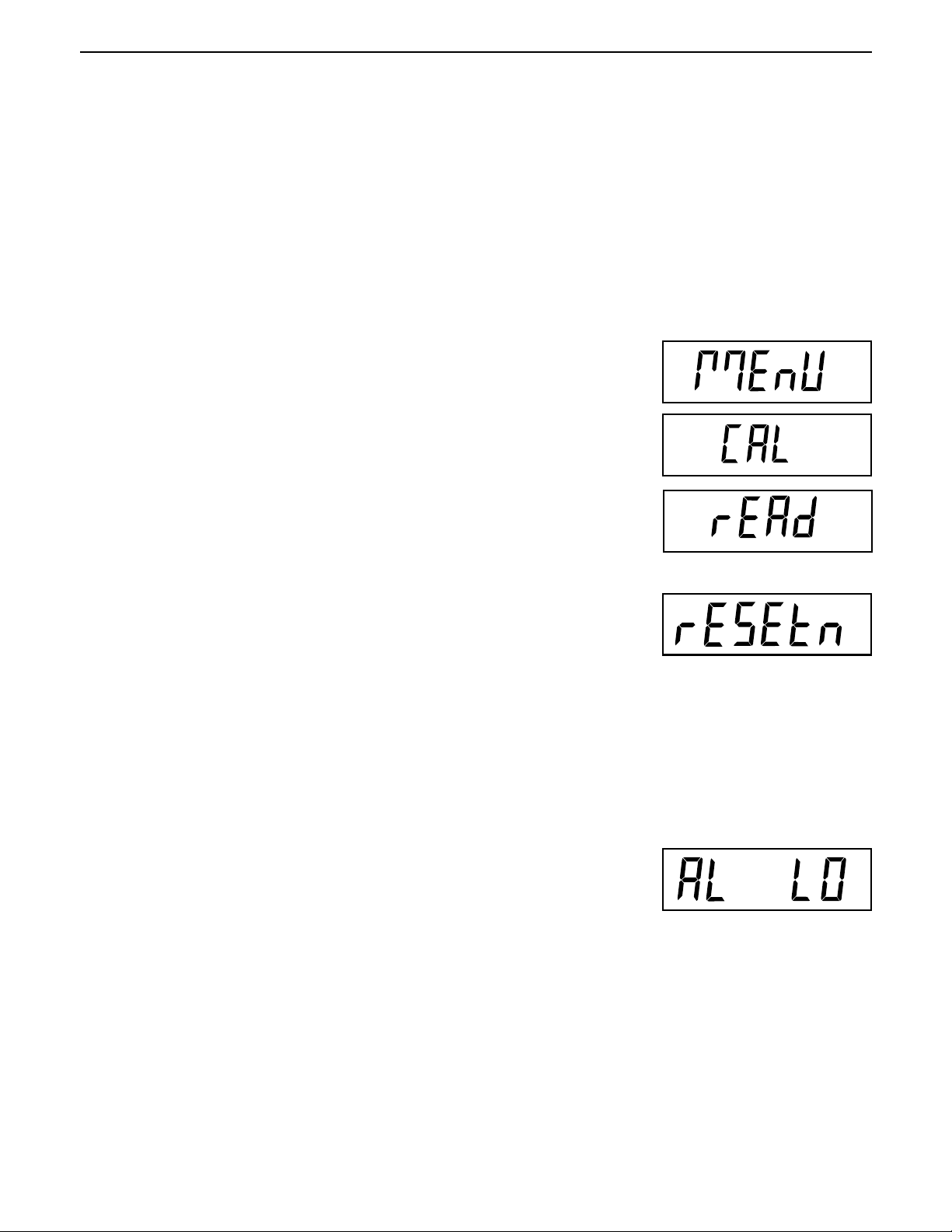

* Reset rEAd menu to

factory defaults

rESEtn (no), rESEtY (yes)

* Averaging Level

AL LO, AL HI

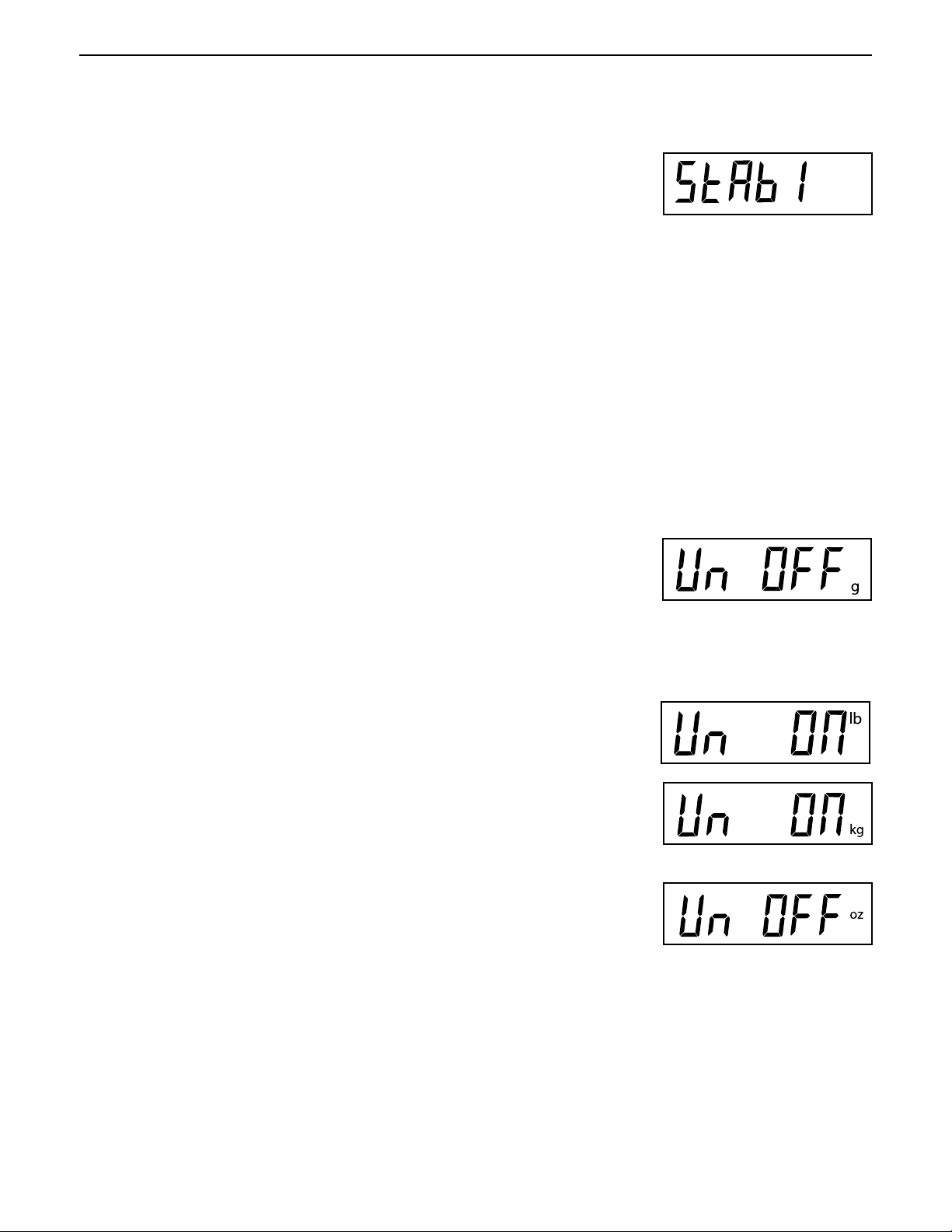

* Stability Level

StAb0.5 (0.5d),

StAb1 (1d), StAb3 (3d)

*Unit of Measure

Un OFF g, Un On g,

Un OFF lb, Un On lb,

Un OFF kg, Un On kg,

Un OFF oz, Un On oz,

Alternate Mode

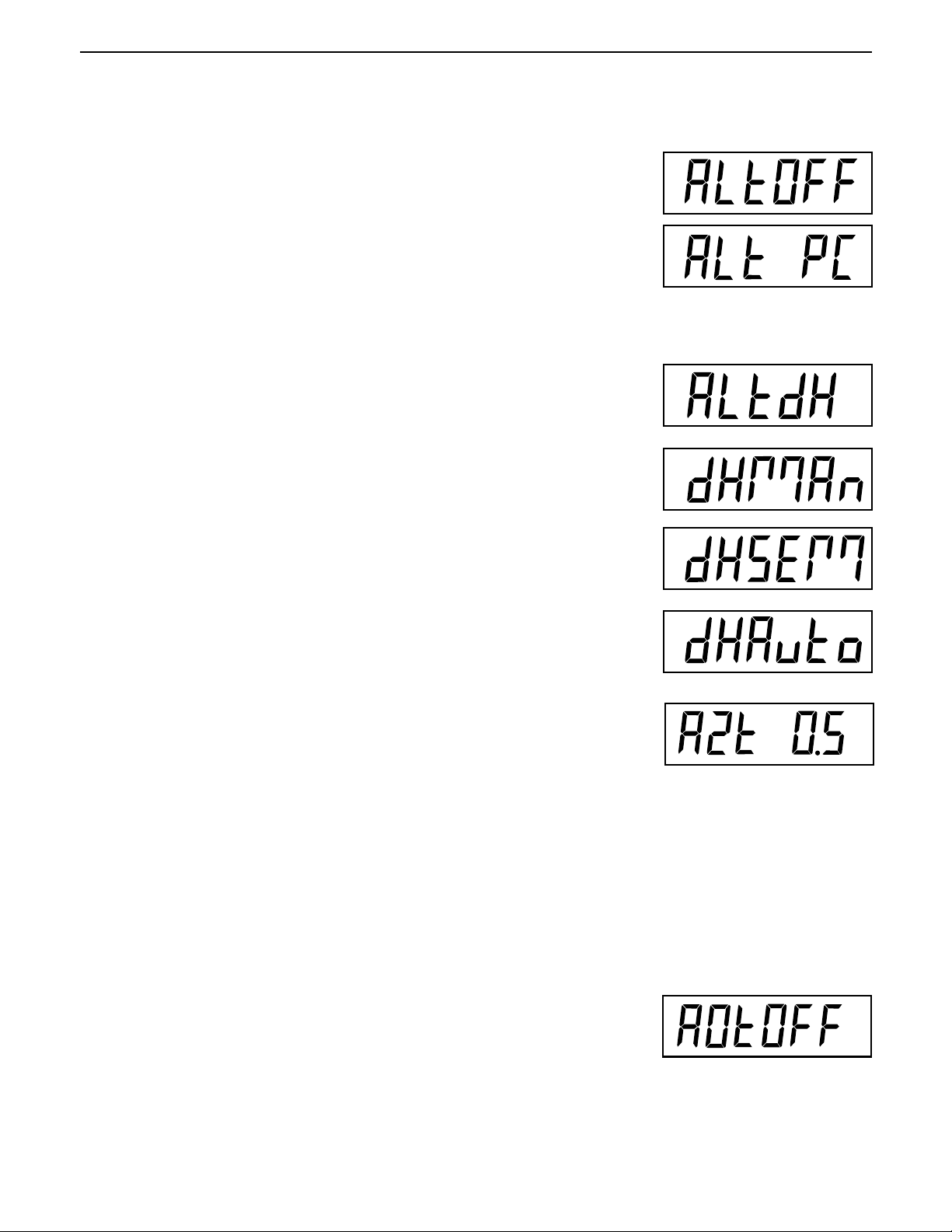

ALtOFF, (none)

ALtPC (Parts counting),

ALtdH (Display hold)

(If ALtdH is selected, set

display hold type)

dHMAn (manual),

dHSEM (semi-automatic),

dHAuto (Automatic)

*Auto Zero Tracking

AZt 0.5 (0.5d), AZt 1 (1d),

AZt 3 (3d)

*Auto Off Timer

AOtOFF, AOt On

* Reset Print menu to

Factory defaults

rESEtn (no), rESEtY (yes)

* Baud Rate

bd1200, bd2400, bd4800,

bd9600, bd19,200

*Parity

PAr nO (none),

PAr Odd (odd),

PAr E (even)

*Data Length

dAtA 7, dAtA 8

*Stop Bit

StOP 1, StOP 2

Auto Print mode

AP OFF, APCont, AP Int,

AP StbL

If AP Int is selected, set

Auto print interval

Int 0001 to 3600

Only print data when

stable

StbOFF, Stb On

* Save Settings

SAVE

Quit

(Exit to

weigh mode)

Lock SEtUP menu

LStOFF, LST On

* Lock rEAd menu

LrdOFF, Lrd On

* Lock Print menu

LPtOFF, LPtOn

Lock CAL menu

LCLOFF, LCL On

* Save Settings

SAVE

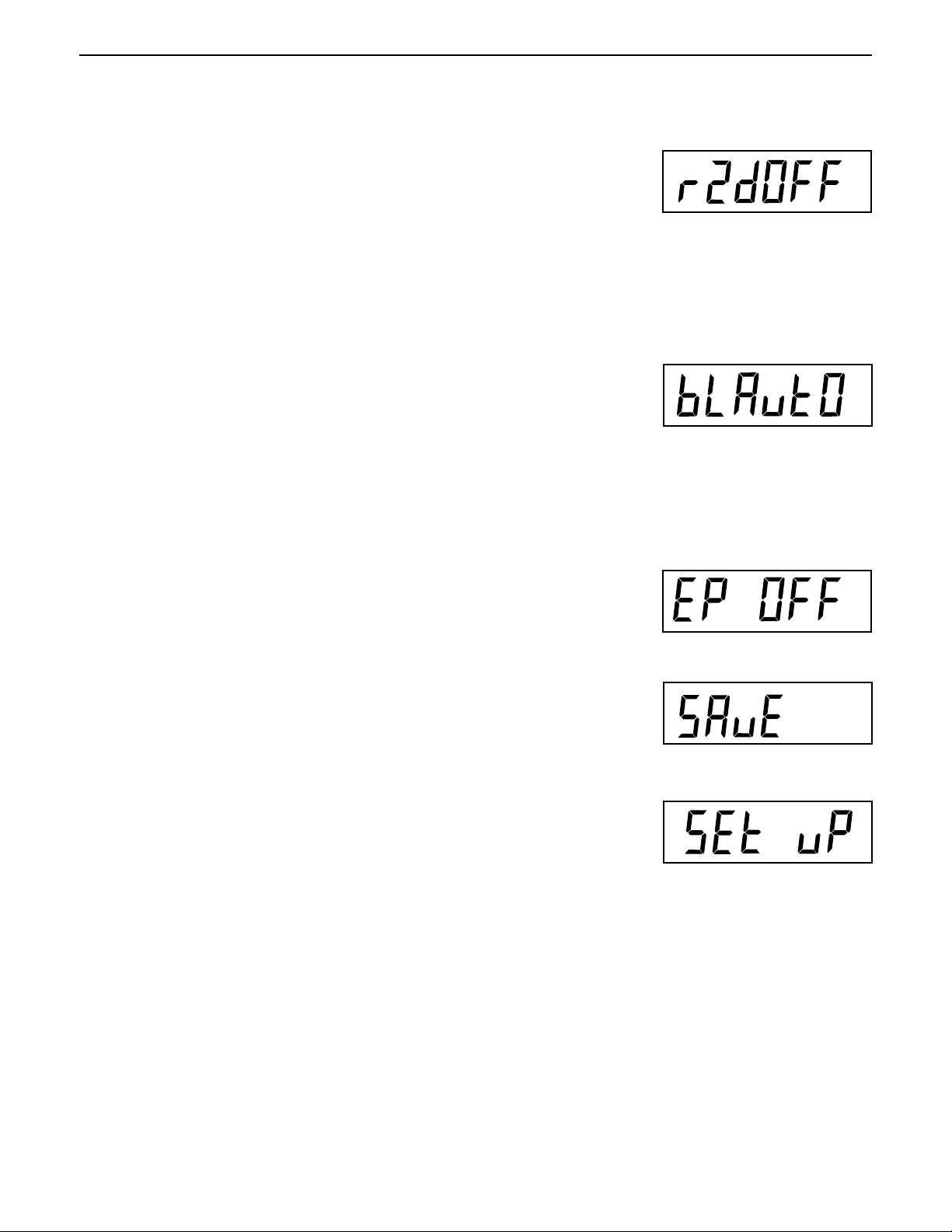

*Retain Zero Data

rZdOFF, rZd On

Backlight

bLAuto, bL On, bL OFF

EP (Service mode)

EP OFF or EP On

* Save Settings

SAVE

Press (G/N/T/

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Press (PRINT/

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Factory default settings are shown in underlined and boldface type.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

When jumper (CAL) on the circuit board is opened, all of the menus can be reached except CALIBRATION

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Menu, but only the submenus which are marked ' * ' can be setup, see menu structure.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

MENU

) to enter the display submenu or select a displayed setting.

UNITS

) to change the displayed submenu or setting.

Page 16

EN-10

CD-11 Indicator

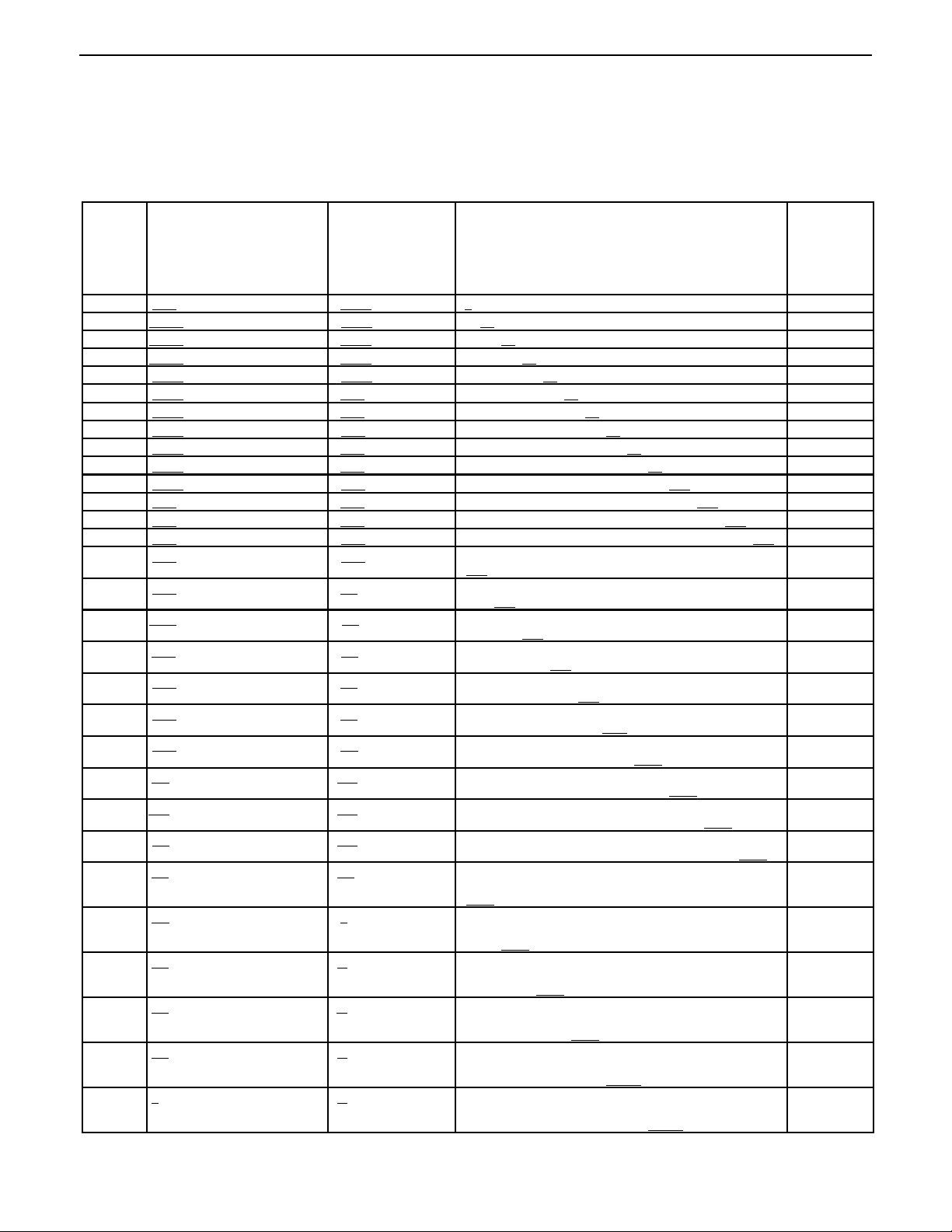

2.6.3 Load Cell Setup Parameters

Review the specifications of the scale base to be used with the Indicator. Make sure the settings you select in

the indicator are compatible with the scale base. The Capacity (full scale), readability (graduation size) and

calibration point (Span and Linearity) selections are shown in the setup table below.

Full Scale Graduation Size Graduation Size Span Calibration Point Linearity

Capacity with LFT OFF with LFT On and (CPxxxx) Calibration

(Fxxxxx) (gdxxxx) LFT CAn Points

( not user

selectable)

5 0.001, 0.002, 0.005 0.001, 0.002, 0.005 5 2 & 5

10 0.001, 0.002, 0.005, 0.01 0.002, 0.005, 0.01 5, 10 5 & 10

15 0.001, 0.002, 0.005, 0.01 0.005, 0.01 5, 10, 15 5 & 15

20 0.001, 0.002, 0.005, 0.01, 0.02 0.005, 0.01, 0.02 5, 10, 15, 20 10 & 20

25 0.002, 0.005, 0.01, 0.02 0.005, 0.01, 0.02 5, 10, 15, 20, 25 10 & 25

30 0.002, 0.005, 0.01, 0.02 0.01, 0.02 5, 10, 15, 20, 25, 30 15 & 30

40 0.002, 0.005, 0.01, 0.02 0.01, 0.02 5, 10, 15, 20, 25, 30, 40 20 & 40

50 0.005, 0.01, 0.02, 0.05 0.01, 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50 25 & 50

60 0.005, 0.01, 0.02, 0.05 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50, 60 30 & 60

75 0.005, 0.01, 0.02, 0.05 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50, 60, 75 30 & 75

100 0.005, 0.01, 0.02, 0.05, 0.1 0.02, 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100 50 & 100

120 0.01, 0.02, 0.05, 0.1 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120 60 & 120

150 0.01, 0.02, 0.05, 0.1 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150 75 & 150

200 0.01, 0.02, 0.05, 0.1, 0.2 0.05, 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200 100 & 200

250 0.02, 0.05, 0.1, 0.2 0.05, 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 120 & 250

300 0.02, 0.05, 0.1, 0.2 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 150 & 300

400 0.02, 0.05, 0.1, 0.2 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 200 & 400

500 0.05, 0.1, 0.2, 0.5 0.1, 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 250 & 500

600 0.05, 0.1, 0.2, 0.5 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 300 & 600

750 0.05, 0.1, 0.2, 0.5 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 300 & 750

1000 0.05, 0.1, 0.2, 0.5, 1 0.2, 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 500 & 1000

1200 0.1, 0.2, 0.5, 1 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 600 & 1200

1500 0.1, 0.2, 0.5, 1 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 750 & 1500

2000 0.1, 0.2, 0.5, 1, 2 0.5, 1, 2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 1000 & 2000

2500 0.2, 0.5, 1, 2 0.5, 1, 2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 1200 & 2500

3000 0.2, 0.5, 1, 2 1, 2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 1500 & 3000

5000 0.5, 1, 2, 5 1, 2, 5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 2500 & 5000

7500 0.5, 1, 2, 5 2, 5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 3000 & 7500

10000 0.5, 1, 2, 5, 10 2, 5, 10 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 5000 & 10000

20000 1, 2, 5, 10, 20 5, 10, 20 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 10000 & 20000

250

250, 300

250, 300, 400

250, 300, 400, 500

250, 300, 400, 500, 600

250, 300, 400, 500, 600, 750

250, 300, 400, 500, 600, 750, 1000

250, 300, 400, 500, 600, 750, 1000, 1200

250, 300, 400, 500, 600, 750, 1000, 1200, 1500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 7500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 7500, 10000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 7500, 10000, 20000

Page 17

CD-11 Indicator

2.6.4 Setup Menu

The CD-11 Indicator SEtuP Menu

parameters to match the Indicator. Do not attempt to calibrate the Indicator before initially setting up the

SEtuP Menu. All other menus should be entered and set up the first time the Indicator is used.

Procedure

must be entered the first time

the Indicator is used to set the scale base

EN-11

With the Indicator ON, press and hold the

displayed. When the G/N/T/

CAL jumper on the PC board is in place. When the CAL jumper is removed, the

Indicator will not permit calibration. This jumper should be in place initially.

Press the

Press the G/N/T/

are:

Press the PRINT/

Press G/N/T/

are:

2%: zero operating range is -2% to +2%.

18%: zero operating range is -2% to +18%,

100%: zero operating range is -2% to +100%.

PRINT/

Units

Menu

'ON' - LFT (Legal for Trade) is ON

'OFF' - LFT is OFF.

'CAn' - LFT is set for Canada

Units

Menu

button, 0 2 is displayed. This is the Zero setting. Selections

Menu

button is released, CAL is displayed if the

button, SEtuP is displayed.

button, LFtOFF is displayed. Legal for trade selections

button until desired LFT setting is reached.

G/N/T/

Menu

button until MEnU is

: :

NOTE

: If LFT is ON, only 2% and 18% are available.

: :

Press the PRINT/

Press the G/N/T/

unit setting. Selections are:

'lb' - calibration unit is lb

'kg' - calibration unit is kg.

Press the PRINT/

Units

button until desired zero setting is reached.

Menu

button, CAL Un kg is displayed. This is the calibration

Units

button until desired calibration unit setting is reached.

Page 18

EN-12

2.6.4 Setup Menu (Cont.)

Procedure

CD-11 Indicator

Press the G/N/T/

setting. xx= value last set. Available selections are are shown in the Setup

Table in section 2.6.3.

Press the PRINT/

Press the G/N/T/

size setting. Available selections are shown in the Setup Table in section

2.6.3.

Press the PRINT/

Press the G/N/T/

calibration point setting. The range is from 5kg/lb to 100% Full scale capacity.

Press the PRINT/

Press the G/N/T/

Menu

F xx is displayed

Units

button until desired capacity value is reached.

Menu

button, gd0.001 is displayed. This is the graduation

Units

button until desired graduation value is reached.

Menu

button, CP 5 kg is displayed. This is the full scale

Units

button until desired calibration value is reached.

Menu

button to end this block, SAVE is displayed.

..

. This is the full scale capacity

..

Press the G/N/T/

rEAD is displayed. The Indicator is now matched up with the scale base and

the Indicator parameters may now be set and calibrated.

Press the PRINT/

changes.

or

Menu

button to save the menu setup setting. The next menu

Units

button to return to the SEtuP menu without saving

Page 19

CD-11 Indicator

EN-13

2.6.5 Readout Menu

The Readout menu is used to adapt the Indicator to environmental conditions and set various features that

include: averaging level, stability level, measuring units, parts counting, display hold, auto zero tracking, timer,

retain zero data, backlight and a factory service mode. Review all of the settings available before proceeding.

Procedure

To select any of the items in the Readout menu, proceed as follows:

NOTE: If entering from the preceeding menu, disregard the first step.

With the Indicator ON, press and hold the

displayed. When the G/N/T/

press the

Press the G/N/T/

rEAd menu to factory defaults.

Press the PRINT/

PRINT/

rESEtn = no, does not reset settings.

rESEty= yes, will reset the entire readout menu to factory defaults as

follows:

AL Lo, StAb 1, UnOff g, Un On kg, Un On Lb, Un Off oz, Alt Off, AZt 0.5,

AOt Off, rZd Off, bLAuto and EP OFF (service mode).

Units

button until rEAd is displayed.

Menu

button, rESEtn is displayed. This allows resetting the

Units

button for selections N or Y.

Menu

button is released, CAL is displayed, then

G/N/T/

Menu

button until MEnU is

AVERAGING LEVEL

Press the G/N/T/

settings. Selections are:

'Lo' - Less processing, less stability and faster stabilization time.

'Hi' - More processing, greater stability and slower stabilization time.

Averaging level compensates for vibration or excessive air currents on the

scale base. During operation, the Indicator continually takes weight readings

from the load cell. Successive readings are then digitally processed to achieve

a stabilized display. Using this feature specifies how much processing is

needed.

Press the PRINT/

Menu

button, AL LO is displayed. This is the averaging level

(This is the default setting)

Units

button until desired averaging level setting is reached.

Page 20

EN-14

2.6.5 Readout Menu (Cont.)

STABILITY

Press the G/N/T/

Selections are:

0.5d Smallest range: stability indicator is ON only when displayed

weight is within .5 division.

1d Normal stability (this is the default setting). Fixed for LFT.

3d Higher stability, less sensitive.

The stability range specifies the weighing results and must be within a preset

tolerance limit for a certain time to turn the stability indicator ON. When a

displayed weight changes beyond the allowable range, the stability indicator

turns OFF, indicating an unstable condition.

Menu

button, StAb1 is displayed. This is the stability setting.

CD-11 Indicator

Press the PRINT/

Units

button until desired stability setting is reached.

UNITS SELECTION

Press the G/N/T/

setting.

NOTE: g unit is not available for full scale capacities 100kg and above.

Press the PRINT/

setting.

Press the G/N/T/

setting. This will be displayed when CAL UNIT kg was selected. When lb was

selected as calibration unit, kg will display.

Press the PRINT/

Press the G/N/T/

setting.

Menu

button, Un OFF g is displayed. This is the unit gram

Units

button for selections ON or OFF. OFF is the default

Menu

button, Un ON lb is displayed. This is the unit pound

Units

button for selections ON or OFF. ON is the default setting.

Menu

button, Un OFF oz is displayed. This is the unit ounce

Press the PRINT/

setting.

Units

button for selections ON or OFF. OFF is the default

Page 21

CD-11 Indicator

2.6.5 Readout Menu (Cont.)

ALTERNATE MODE - not available with LFT ON or CAN

Press the G/N/T/

setting.

Selections are: OFF Standard weighing (this is the default setting)

Press the PRINT/

Alternate Mode enables either simple parts counting or display hold functions.

When ALtdH (display hold) is selected, a choice of manual, semi-automatic

or automatic settings are available. The alternate mode can be turned off so

that neither mode is available. It is not possible to have both modes activated

at the same time. For a complete description of alternate modes, refer to

Section 4 Operation.

Menu

button, ALtOFF is displayed. This is the alternate mode

PC Parts Counting

DH Display Hold - Man (manual)

Semi (semi-automatic)

Auto (automatic)

Units

button until desired alternate mode setting is reached.

EN-15

AUTO ZERO

Press the G/N/T/

Threshold setting. Selections are:

0.5d Sets threshold to 0.5 divisions. (this is the default setting)

1d Sets threshold to 1 division.

3d Sets threshold to 3 divisions.

Auto Zero minimizes the effects of temperature changes and small disturbances on the zero reading. The Indicator maintains the zero display until the

threshold is exceeded.

Press the PRINT/

reached.

Menu

button, AZt 0.5 is displayed. This is the Auto Zero

Units

button until desired auto zero threshold setting is

AUTO OFF TIMER

Press the G/N/T/

setting. When set ON, the Indicator will shut off automatically after 5 minutes

has elapsed on the condition that no button is pressed and the scale base

platform is stable during that period.

Press the PRINT/

Menu

button, AOtOFF is displayed. This is the Auto Off Timer

Units

button for selections ON or OFF. OFF is the default setting.

Page 22

EN-16

2.6.5 Readout Menu (Cont.)

RETAIN ZERO DATA

Press the G/N/T/

Data setting. When set On, the Indicator stores the current zero point and

restores it on the power-up.

button, Un rZdOFF is displayed. This is the Retain Zero

Menu

CD-11 Indicator

Press the PRINT/

setting.

button for selections ON or OFF. OFF is the default

Units

LCD BACK LIGHT

Press the G/N/T/

setting. Selections are:

Auto Turns off the backlight in 5 seconds (this is the default setting)

ON Backlight is on continuously

OFF Backlight does not turn on

Press the PRINT/

MENU

button, bLAutO is displayed. This is the LCD backlight

Units

button until desired LCD backlight setting is reached.

EP

This is a service function and is not a user-operated feature. OFF is the default

setting.

Not available with LFT ON or CAN.

SAVE

Press the G/N/T/

MENU

button to end this block, SAVE is displayed.

MENU

Press the G/N/T/

menu Print is displayed.

Press the PRINT/

changes.

NOTE: If initial setup, go to the next paragraph. To exit from the SEtuP menu,

press the PRINT/

the G/N/T/

MENU

button to save the readout menu settings. The next

or

Units

button to go back to the SEtuP menu without saving

Units

button to skip to PRINT then to LOCKSW, then Quit. Press

button to go back to the weighing mode.

Page 23

CD-11 Indicator

EN-17

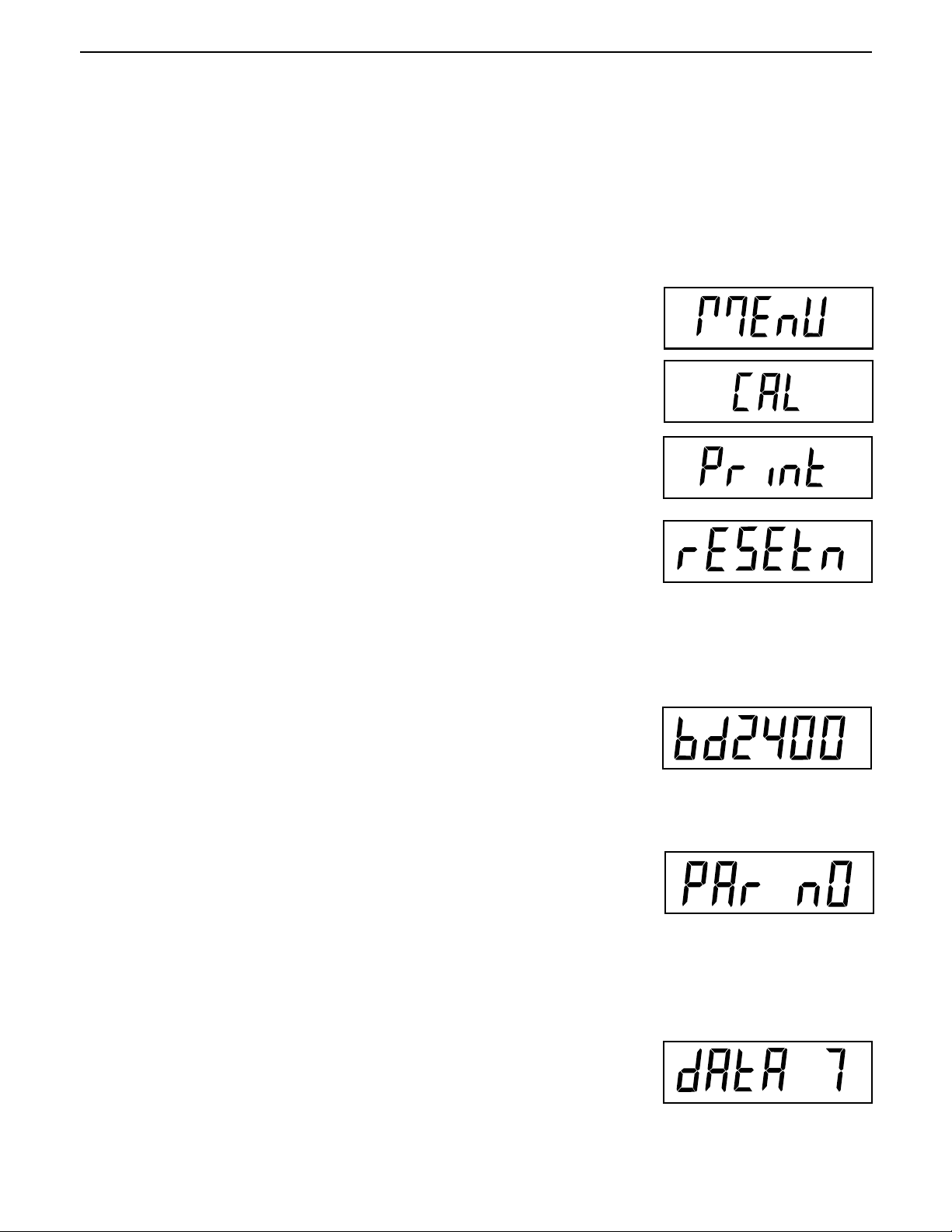

2.6.6 Print Menu

The Print menu provides data communication settings. It contains 9 submenus: Reset, Baud rate, Parity, Data

Length, Stop Bits, Auto Print, Interval, Stable and Save.

Procedure

To select any of the items in the Print menu, proceed as follows:

NOTE: If entering from the preceeding menu, disregard the first step.

With the Indicator ON, press and hold the

displayed. When the G/N/T/

press the

Press the G/N/T/

Print menu to factory defaults. rESETn = no, does not reset settings.

rESETy=yes, will reset the entire Print menu to factory defaults as follows:

Press the PRINT/

Press the G/N/T/

Selections are: 1200, 2400, 4800, 9600 and 19,200. 2400 is the default

setting.

PRINT/

Baud rate =2400, parity =none, data length=7, stop bit=2, Auto

Print=AP OFF, if interval is selected=.0001, Stable Print= StbOFF.

Units

button until Print is displayed.

Menu

button, rESEtn is displayed. This allows resetting the

Units

button for selections N or Y.

Menu

button, bd2400 displayed. This is the baud rate setting.

Menu

button is released, CAL is displayed, then

G/N/T/

Menu

button until MEnU is

Press the PRINT/

Press the G/N/T/

Selections are:

PAr nO=none (this is the default setting)

PAr Odd=odd

PAr E=even

Press the PRINT

Press the G/N/T/

setting.

Press the PRINT/

dAtA 7.

Units

button until the desired baud rate is reached.

Menu

button, PAr nO is displayed. This is the parity bit setting.

Units

button until desired parity bit setting is reached.

Menu

button, dAtA 7 is displayed. This is the data length

Units

button for selections dAtA 7 or dAtA 8. Default setting is

Page 24

EN-18

2.6.6 Print Menu (Cont.)

CD-11 Indicator

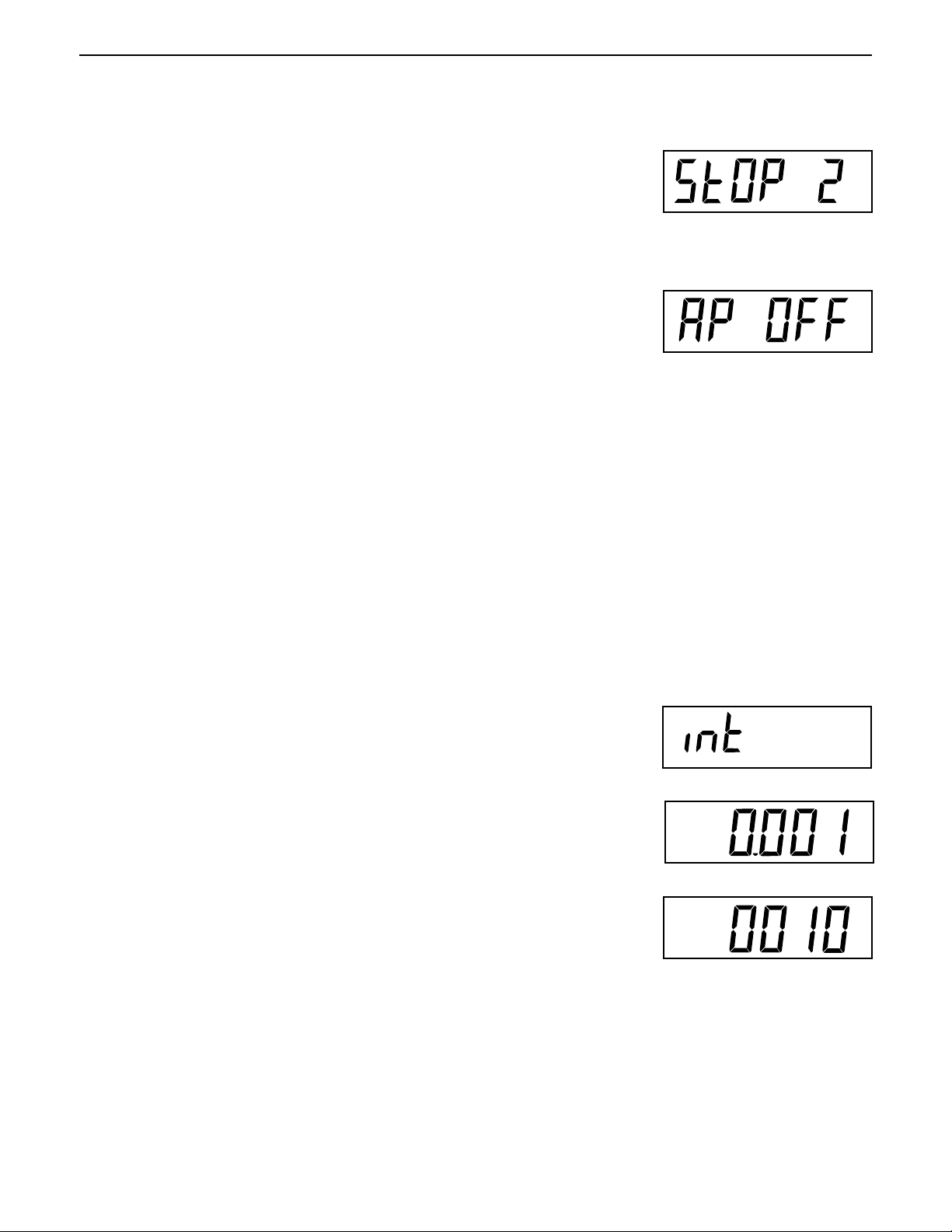

Press the G/N/T/

Press the PRINT/

StOP 2.

Menu

button, StOP 2 is displayed. This is the stop bit setting.

Units

button for selections StOP 1 or StOP 2. Default setting is

AUTO PRINT

Press the G/N/T/

This is the Auto print setting which enables data to a printer or PC to be printed

automatically. Selection are:

OFF (this is the default setting)

Cont Prints data continuously

Int Prints data on user selected intervals

Stbl Print first stable non-zero value after each change in weighing

value.

Press the PRINT/

Menu

button, AP OFF is displayed.

Units

button until desired auto print setting is reached.

INTERVAL PRINTING

When interval has been selected in the previous step, an interval from 1 to

3600 seconds can be set. If Interval was not selected, this submenu does not

appear.

Press the G/N/T/

display appears which allows the interval time in seconds to be set.

Pressing the PRINT/

the TARE button increments the active digit from 0 to 9.

Sample at right indicates 10 seconds.

NOTE: 0000 not valid.

Menu

button, int is displayed. After a few seconds, a second

Units

button advances the zero from left to right. Pressing

Page 25

CD-11 Indicator

2.6.6 Print Menu (Cont.)

STABLE

Press the G/N/T/

When set to Stb ON, allows only stable weight values to be printed. When set

Stb OFF, prints immediate value with stability indication. In LFT, fixed to Stb ON.

Menu

button, Stb OFF is displayed.

EN-19

Press the PRINT/

OFF.

Units

button for selections Stb ON or Stb OFF. Default setting is

SAVE

Press the G/N/T/

Press the G/N/T/

LOCSW is displayed.

Press the PRINT/

NOTE:If initial setup, go to the next paragraph. To exit from the SEtuP, press

the PRINT/

button to go back to the weighing mode.

Menu

Menu

Units

button to skip to LOCKSW, then Quit. Press the G/N/T/

button to end this block, SAVE is displayed.

button to save the Print menu settings. The next menu

or

Units

button to go back to the rEAd menu without saving.

Menu

2.6.7 Lockout Menu

The Lockout menu (LOCSW) allows the user to lock and unlock the settings in the CAL, SEtuP, rEAd, and Print

menus to prevent tampering or accidental changes. When used in conjunction with the Lock Switch (jumper)

on the printed circuit board, the CAL, SEtuP, rEAd and Print menus can be read only and not changed.

Procedure

To select any of the items in the LOCSW menu, proceed as follows:

NOTE: If entering from the preceeding menu, disregard the first step.

With the Indicator ON, press and hold the

displayed. When the G/N/T/

press the PRINT/

Units

Menu

button is released, CAL is displayed, then

button until LOCSW is displayed.

G/N/T/

Menu

button until MEnU is

Page 26

EN-20

*

2.6.7 Lockout Menu (Cont.)

CD-11 Indicator

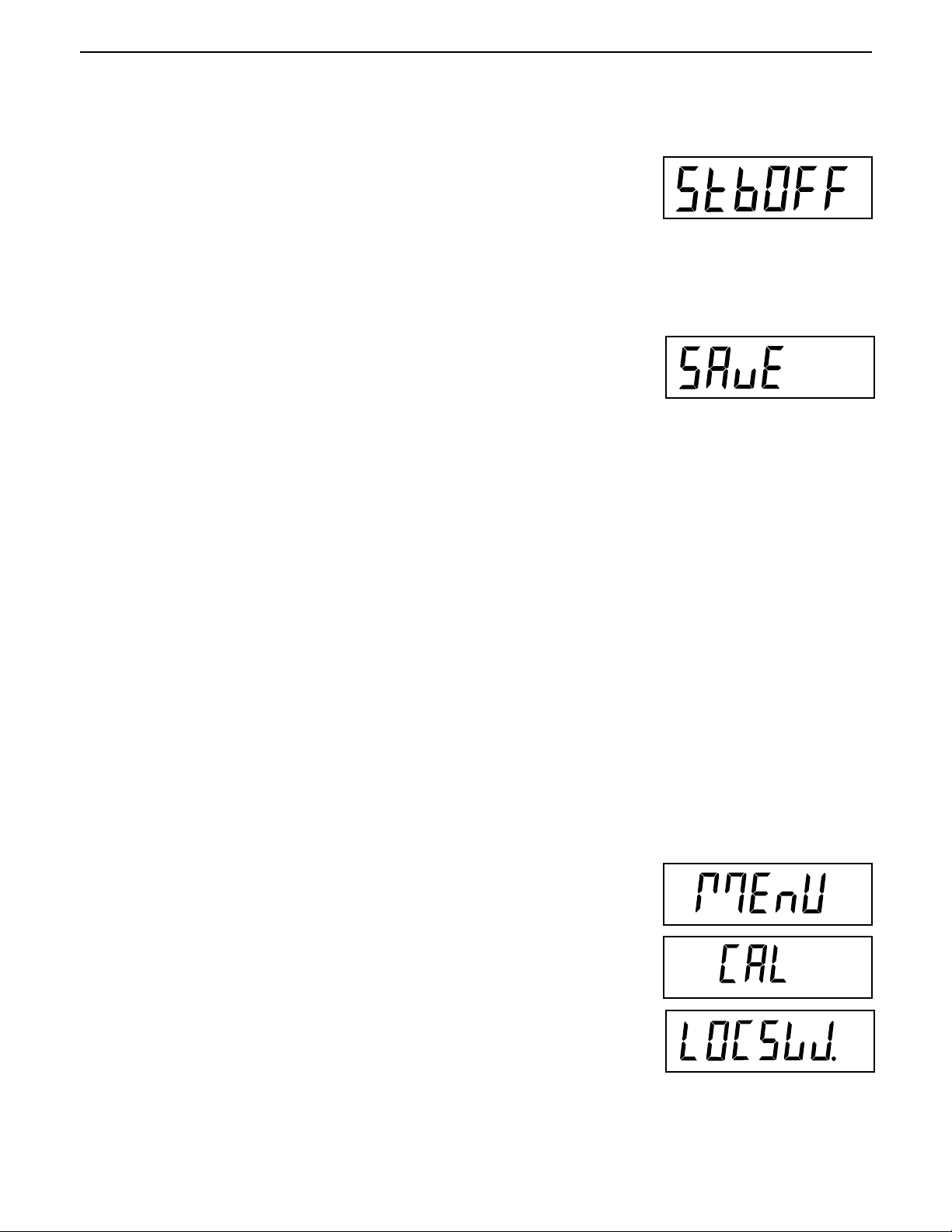

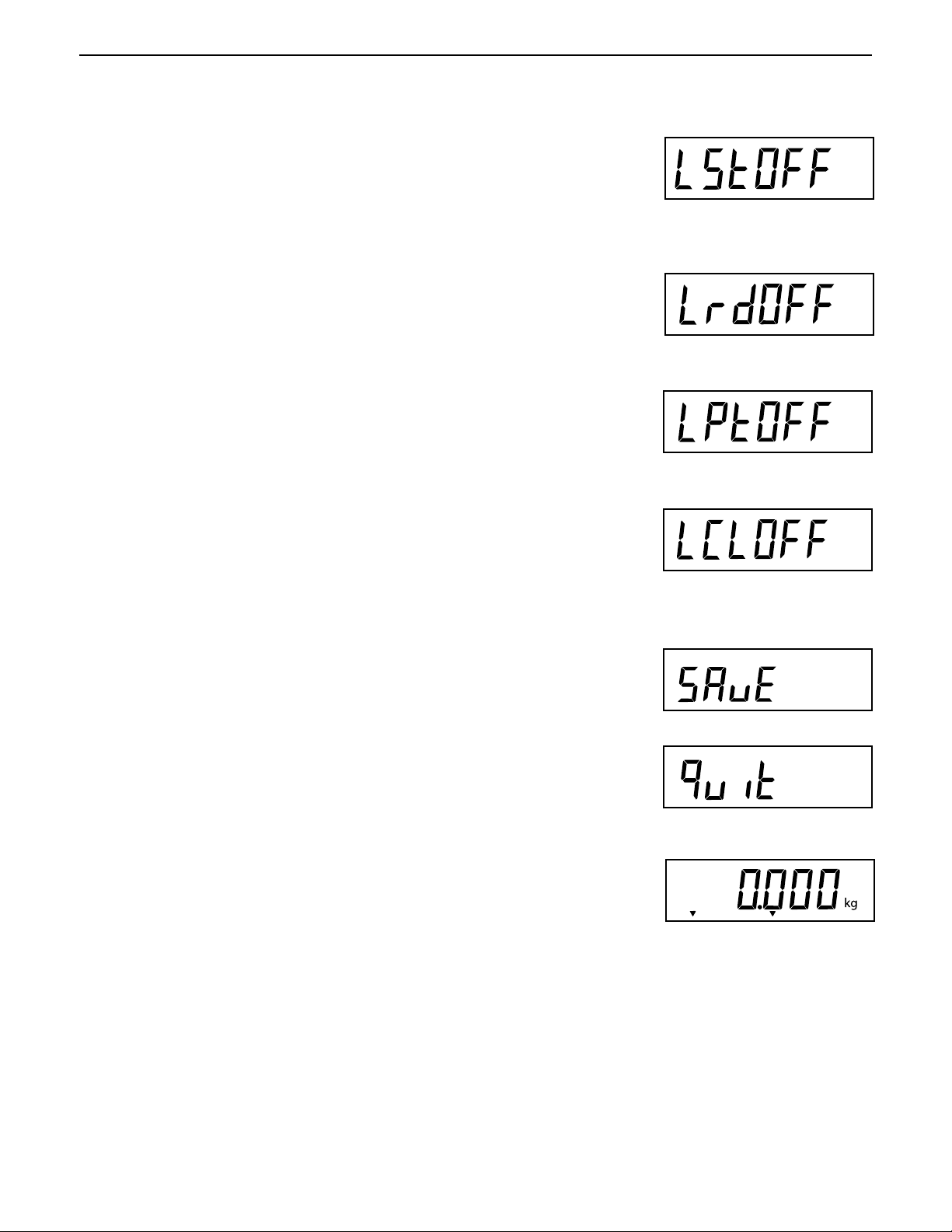

Press the G/N/T/

Menu

button, LStOFF is displayed. This permits locking the

SEtuP menu. LStOFF is unlocked, LSt On is read only (locked). This menu is

hidden if the CAL jumper is off.

Press the

Press the G/N/T/

PRINT/

Units

Menu

button for selections LSt ON or LStOFF.

button, LrdOFF displayed. This permits locking the rEAd

menu. LrdOFF is unlocked, Lrd On is read only (locked).

Press the PRINT/

Press the G/N/T/

Units

button for selections Lrd On or LrdOFF.

Menu

button, LPtOFF is displayed. This permits locking the

Print menu. LPtOFF is unlocked, LPtOn is read only (locked).

Press the PRINT/

Press the G/N/T/

Units

Menu

button for selections LPtOn or LPtOFF.

button, LCLOFF is displayed. This permits locking the

Calibration menu. LCLOFF is unlocked, LCL On is read only (locked). This

menu is hidden if the CAL jumper is off.

Press the PRINT/

Press the G/N/T/

Press the G/N/T/

Units

Menu

Menu

button for selections LCL On or LCLOFF.

button to end this block, SAVE is displayed.

button to save the lockout menu settings. The next

menu Quit is displayed.

or

Press the PRINT/

After saving the lockout menu settings, press the PRINT/

CAL or press the G/N/T/

Units

button to go back to the lockout menu without saving.

Units

button to go to

Menu

button to return to a weighing mode.

NOTE: At this point, the Indicator must be calibrated and the jumper removed

from the CAL connector in order to lock the menus. The top cover of the Indicator should be free to gain access to the CAL jumper.

>0<>0<

>0<

>0<>0<

Stable

Gross

Brutto

Page 27

CD-11 Indicator

EN-21

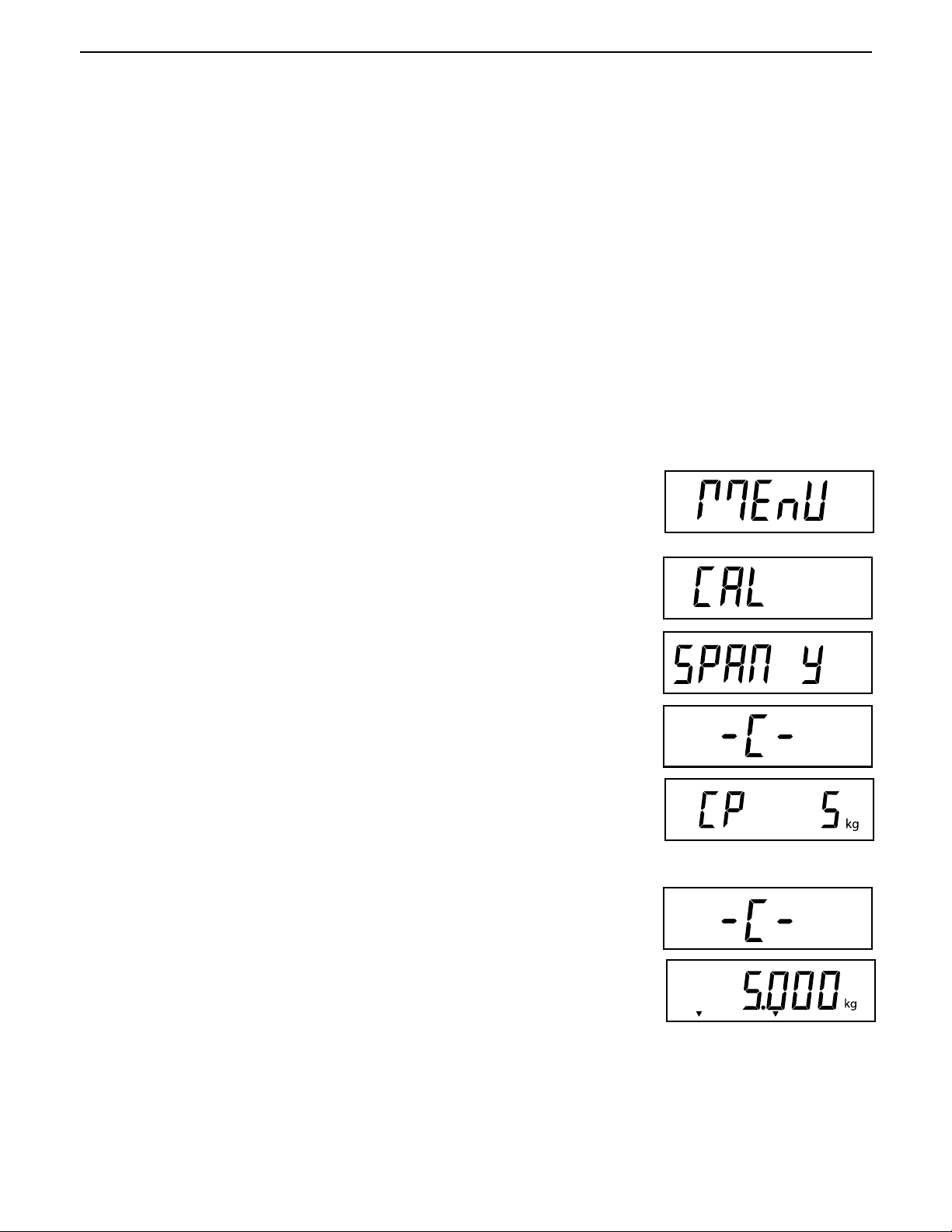

3. CALIBRATION AND SEALING

Model CD-11 Indicator requires span calibration before using. Span calibration ensures that the Indicator

reads correctly within specifications. For best results, calibrate at or near full capacity. Calibration unit can be

set to either kg or lb.

NOTE: When the Indicator is used in Legal for Trade or legally controlled applications, the calibration

menu is locked out and is not accessible.

tion.

Before beginning calibration, make sure masses are available. If you begin calibration and realize calibration

masses are not available, exit the menu. The Indicator will retain previously stored calibration data. Calibration should be performed as necessary to ensure accurate weighing. Masses required to perform the procedures should be in compliance with the requirements of the scale base being used with the Indicator.

You have a choice of either span or linearity calibration. Span calibration checks zero and full span calibration points. Linearity calibration checks zero, mid span and full span points.

Procedure

SPAN CALIBRATION

With the Indicator ON, press and hold the

displayed. When the

G/N/T/

Menu

button is released, CAL is displayed.

This is to prevent unauthorized personnel from changing calibra-

G/N/T/

Menu

button until MEnU is

Press the G/N/T/

Press the G/N/T/

during this period as it establishes a zero point. After a few seconds, the

requested weight value is displayed. The sample illustration indicates a 5kg

weight value (Cal Point CP was set for 5kg).

Place the indicated mass on the platform. Keep the platform stable during this

period.

Press the G/N/T/

reading and then displays the weight of the mass.

If the calibration was successful, the calibration weight is displayed and the

calibration data is saved automatically. If unsuccessful, refer to the troubleshooting section.

Remove calibration masses from the platform.

NOTE: If the Indicator is to be used for legal for trade or legally controlled applications, it must be calibrated and

the jumper removed from the CAL connector in order to lock the menus. The top cover of the Indicator should be

free to gain access to the CAL jumper. Refer to section 3.1 for sealing for legal for trade use.

Menu

button, SPAN Y is displayed.

Menu

button, -C- is displayed. The scale base

Menu

button, -C- is displayed while the Indicator stores the

MUST

be stable

Stable

Gross

Brutto

Page 28

EN-22

Procedure

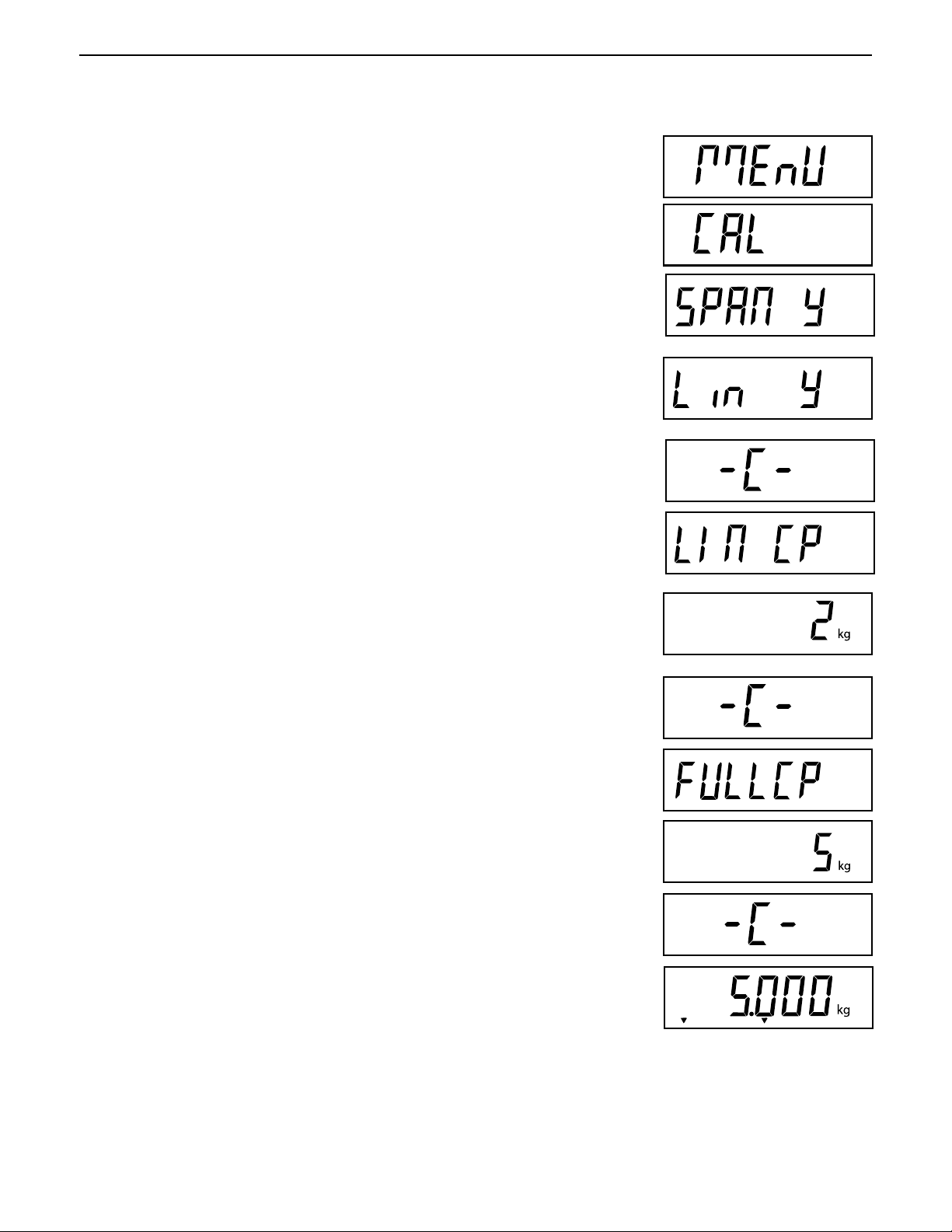

LINEARITY CALIBRATION

With the Indicator ON, press and hold the

displayed. When the

G/N/T/

Menu

button is released, CAL is displayed.

button G/N/T/

Menu

CD-11 Indicator

until MEnU is

Press the G/N/T/

Press the PRINT/

Press the G/N/T/

Menu

button, SPAN Y is displayed.

Units

button, Lin Y is displayed.

Menu

button, -C- is displayed. The scale base

MUST

be stable

during this period as it establishes a zero point. After a few seconds, the display flashes LIN CP twice and the requested weight value is displayed. The

sample illustration indicates a 2kg center point for a 5kg scale.

Place the indicated mass on the platform. Keep the platform stable during this

period.

Press the G/N/T/

button, -C- is displayed. The scale base

MUST

be stable

Menu

during this period as it establishes a center point. After a few seconds, the display flashes FULLCP twice and the requested weight value is displayed.

Menu

Place the indicated mass on the platform and press the G/N/T/

button -C-

is displayed.

If linearity calibration was successful, the calibration weight is displayed and

the calibration data is saved automatically. If unsuccessful, refer to the troubleshooting section.

Stable

Gross

Brutto

Remove calibration masses from platform.

NOTE: If the Indicator is to be used for legal for trade or legally controlled applications, it must be calibrated

and the jumper removed from the CAL connector in order to lock out the menus. The top cover of the Indicator

should be free to gain access to the CAL jumper. Refer to section 3.1 for sealing for legal for trade use.

Page 29

CD-11 Indicator

GEOGRAPHICAL FACTOR (For Europe Only)

EN-23

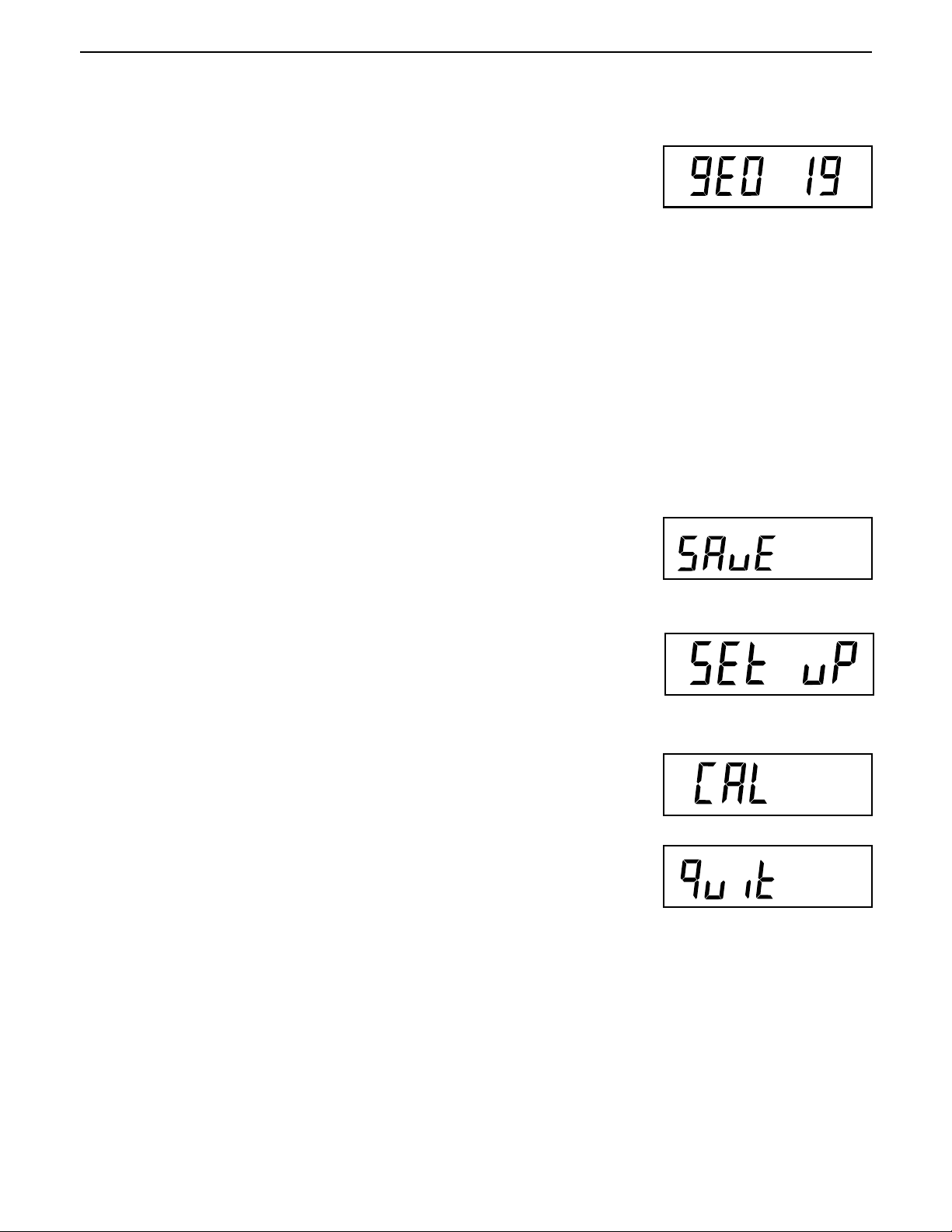

Press the G/N/T/

graphical adjustment value.

The geo factor includes settings from 0 to 31 and is used to compensate for

varying gravity at different geographical areas (complete geographical adjustment settings are listed in the following table).

Only an authorized manufacturer’s representative or certified verification

Changing the geographical setting alters the calibration values.

Press the Print/

reached. The factory default setting is gEO 19

SAVE

Press the G/N/T/

Menu

button, gEO 19 is displayed. This is the current geo-

NOTE:

personnel may make these changes.

Units

button until the desired geographical adjustment value is

Menu

button to end this block, SAVE is displayed.

Press the G/N/T/Menu button to save the geographical factor setting. The next

menu SEt uP is displayed.

or

Units

Press the Print/

changes to the geographical setting.

QUIT

To exit from the CAL menu, press the Print/

Then press the G/N/T/

button to go back to the CAL menu without saving

Units

button to advance to Quit.

Menu

button to go back to the weighing mode.

Page 30

EN-24

CD-11 Indicator

GEOGRAPHICAL FACTOR (cont.)

GEOGRAPHICAL ADJUSTMENT VALUES

Elevation above sea level in meters

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

Geographical latitude in 325 650 975 1300 1625 1950 2275 2 6 00 2925 3250 3575

the northern or southern Elevation above sea level in feet

hemisphere in degrees 0 106 0 2130 3200 4260 5330 6400 7460 8530 9600 10660

and minutes 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

0°0'-5°46’ 5 4 4 3 3 2 2 1 1 0 0

5°46'-9°52’ 5 5 4 4 3 3 2 2 1 1 0

9°52'-12°44’ 6 5 5 4 4 3 3 2 2 1 1

12°44'-15°6’ 6 6 5 5 4 4 3 3 2 2 1

15°6'-17°10’ 7 6 6 5 5 4 4 3 3 2 2

17°10'-19°2’ 7 7 6 6 5 5 4 4 3 3 2

19°2'-20°45’ 8 7 7 6 6 5 5 4 4 3 3

20°45'-22°22’ 8 8 7 7 6 6 5 5 4 4 3

22°22'-23°54’ 9 8 8 7 7 6 6 5 5 4 4

23°54'-25°21’ 9 9 8 8 7 7 6 6 5 5 4

25°21'-26°45’ 10 9 9 8 8 7 7 6 6 5 5

26°45'-28°6’ 10 10 9 9 8 8 7 7 6 6 5

28°6'-29°25’ 11 10 10 9 9 8 8 7 7 6 6

29°25'-30°41’ 11 11 10 10 9 9 8 8 7 7 6

30°41'-31°56’ 12 11 11 10 10 9 9 8 8 7 7

31°56'-33°9’ 12 12 11 11 10 10 9 9 8 8 7

33°9'-34°21’ 13 12 12 11 11 10 10 9 9 8 8

34°21' - 35° 31' 13 13 12 12 11 11 10 10 9 9 8

35°31' - 36° 41' 14 13 13 12 12 11 11 10 10 9 9

36°41' - 37° 50' 14 14 13 13 12 12 11 11 10 10 9

37°50' - 38° 58' 15 14 14 13 13 12 12 11 11 10 10

38°58' - 40° 5' 15 15 14 14 13 13 12 12 11 11 10

40° 5' - 41° 12' 16 15 15 14 14 13 13 12 12 11 11

41°12' - 42° 19' 16 16 15 15 14 14 13 13 12 12 11

42°19' - 43° 26' 17 16 16 15 15 14 14 13 13 12 12

43°26' - 44° 32' 17 17 16 16 15 15 14 14 13 13 12

44°32' - 45° 38' 18 17 17 16 16 15 15 14 14 13 13

45°38' - 46° 45' 18 18 17 17 16 16 15 15 14 14 13

46°45' - 47° 51' 19 18 18 17 17 16 16 15 15 14 14

47°51' - 48° 58' 19 19 18 18 17 17 16 16 15 15 14

48°58' - 50° 6' 20 19 19 18 18 17 17 16 16 15 15

50° 6' - 51° 13' 20 20 19 19 18 18 17 17 16 16 15

51°13' - 52° 22' 21 20 20 19 19 18 18 17 17 16 16

52°22' - 53° 31' 21 21 20 20 19 19 18 18 17 17 16

53°31' - 54° 41' 22 21 21 20 20 19 19 18 18 17 17

54°41' - 55° 52' 22 22 21 21 20 20 19 19 18 18 17

55°52' - 57° 4' 23 22 22 21 21 20 20 19 19 18 18

57° 4' - 58° 17' 23 23 22 22 21 21 20 20 19 19 18

58°17' - 59° 32' 24 23 23 22 22 21 21 20 20 19 19

59°32' - 60° 49' 24 24 23 23 22 22 21 21 20 20 19

60°49' - 62° 9' 25 24 24 23 23 22 22 21 21 20 20

62° 9' - 63° 30' 25 25 24 24 23 23 22 22 21 21 20

63°30' - 64° 55' 26 25 25 24 24 23 23 22 22 21 21

64°55' - 66° 24' 26 26 25 25 24 24 23 23 22 22 21

66°24' - 67° 57' 27 26 26 25 25 24 24 23 23 22 22

67°57' - 69° 35' 27 27 26 26 25 25 24 24 23 23 22

69°35' - 71° 21' 28 27 27 26 26 25 25 24 24 23 23

71°21' - 73° 16' 28 28 27 27 26 26 25 25 24 24 23

73°16' - 75° 24' 29 28 28 27 27 26 26 25 25 24 24

75°24' - 77° 52' 29 29 28 28 27 27 26 26 25 25 24

77°52' - 80° 56' 30 29 29 28 28 27 27 26 26 25 25

80°56' - 85° 45' 30 30 29 29 28 28 27 27 26 26 25

85°45' - 90° 00' 31 30 30 29 29 28 28 27 27 26 26

Page 31

CD-11 Indicator

EN-25

3.1 Legal for Trade (LFT) Operation and Sealing

Before this product can be used in legal-for-trade or legally controlled applications, it must be inspected in

accordance with local weights and measures or approval agency regulations. It is the responsibility of the

purchaser to ensure that all pertinent legal requirements are met. Please contact your local weights and measures office or authorized manufacturer's representative for further details.

Legal for Trade (LFT) operation is possible through a software controlled

LOCSW menu which can be set to lock out the CAL, SEtuP, rEAd, and Print

menus by setting the lock settings to ON. When the menus have been locked

and the Indicator has been calibrated, the Indicator can be used to operate in

a legal for trade application after sealing. The software settings work in

conjunction with a Lock Switch ( CAL jumper) located on the PC board. The

Indicator MUST

be calibrated prior to performing this procedure.

Procedure

Perform the procedure in section 2.6.7 and set all menu items ON. This

effectively locks all menus from being changed but can be viewed.

Remove the front cover from the Indicator to expose the PC board and tilt it

back. Be careful as the cover is connected to the PC board by a flexible

cable.

Refer to the illustrations on the right and note the position of the CAL jumper.

The first illustration shows the jumper in place. To lock out the menus,

remove the jumper and position it on one pin as shown in the second

illustration. This removes the jumper and stores it in the event it has to be repositioned.

1

J5

5

6

9

1

J3

JUMP 1

JUMP 2

J4

1234 567

+EXE +SEN +SIG CGND -SIG -SEN -EXE

DISPLAY

CAL

J6

J7

PC Board Connections.

J4

1234 567

+EXE +SEN +SIG CGND -SIG -SEN -EXE

CAL

CAL Jumper Shown in Stored or

ON Position.

5

3

2

1

4

1

Replace the four cover screws and one sealing screw.

Replace the batteries and battery cover.

After the Indicator has been tested and found to comply with local applicable

regulations by local approving personnel, it may be sealed as follows:

LEAD AND WIRE SEAL

Replace the pan head screw with the hex socket security screw and washer in

the plastic bag containing the accessories. See illustration at right. Place

wire seal through the hole as shown and compress lead seal in place.

PAPER SEAL

If an audit trail or paper seal will be used, install the pan head screw to the

case and place seal over the screw area. The sealing area is located on the

bottom of the case in a recessed area.

LEAD SEAL

HEX SOCKET HEAD SCREW

PAPER SEAL

PAPER SEAL

Sealing Methods

Page 32

EN-26

*

*

CD-11 Indicator

4. OPERATION

Before using the Indicator, make sure it has been properly set up and calibrated. Refer to Sections 2 and 3 and

the Overview of Controls and Indicator Functions to review settings.

4.1 Turning On Indicator

Press the ON ZERO/

Off

button until the LCD display

appears. The display momentarily displays segment

check, the software version of the Indicator and then goes

into a weighing mode. The weighing mode and decimal

point position may be different depending on the setup of

the Indicator.

4.2 Turning Off Indicator

To turn the Indicator off, press and hold the ON ZERO/

Stable Display

ON/ZERO

Off

Hold

2II

PCS Gross

button until OFF is displayed.

4.3 Zero Operation

Press the ON ZERO/

by indicating the selected measuring unit followed by a zeroed display.

NOTE: Stable cursor must be lit to accept zero operation.

Place item to be weighed on the scale platform. The display indicates a sample

of 5kg, gross weight.

Off

button to zero the Indicator. The display acknowledges

Net Tare

Brutto

PRINT

8QLWV

>0<>0<

>0<

>0<>0<

Stable Gross

G/N/T

0HQX

TARE

Brutto

Stable

Gross

Brutto

4.4 Tare Operation

When weighing material or objects that must be held in a container, taring

stores the container weight in the Indicator’s memory. To store the container

weight, proceed as follows:

Place the container on the scale. Sample shown is 2kg.

Press the TARE button. Scale is tared and shows Net weight.

Stable

NOTE: Stable cursor must be lit to accept tare operation.

If the tare weight is removed from the scale, the Net weight is displayed as a

negative value

Stable

Stable

Gross

Brutto

Net

Net

Page 33

CD-11 Indicator

*

4.5 Gross/Net/Tare Recall Operation

When a container has been placed on the platform and tared, it's weight is

stored in memory. Adding material to the container is shown as NET weight.

The gross weight is a combination of the tared weight and the material. The

G/N/T/

Repeatedly press the G/N/T/

readings. The sample illustrations indicate a tare weight of 2kg simulating a

container, a net weight of 3kg which would be the material in the container

and a gross weight of 5kg which is the total weight of the container and

material. After a few seconds, the display will return to a NET weight.

Menu

button allows switching between GROSS, NET and TARE weights.

Menu

button to cycle through Gross, Tare and Net

Stable

Stable

Gross

Brutto

EN-27

Tare

4.6 Clear Tare Operation

To clear the tared weight stored in memory, proceed as follows:

With no load on the scale base, press the TARE button.

4.7 Unit Switch Operation

To switch measuring units, proceed as follows:

Press and hold PRINT/

ing unit. Depending on which units are enabled in the menu, you have a

choice of g, lb, kg or oz. The display sample indicates 3kg load changed to

lbs.

Units

button until display changes to selected measur-

>0<>0<

>0<

>0<>0<

Stable

Stable

Stable

Stable

Gross

Brutto

Gross

Brutto

Net

Net

Stable

Gross

Brutto

Page 34

EN-28

*

4.8 Parts Counting Operation

CD-11 Indicator

Parts counting is enabled only when selected in the rEAd menu (refer to

section 2.6.5). In the parts counting mode, the Indicator displays the quantity of parts placed on the platform. The Indicator determines the quantity

based on the average weight of a single part. All parts must be uniform in

weight for accurate measurements.

4.9 Establishing the Average Piece Weight (APW)

Press and hold the PRINT/

Press and hold the

G/N/T/

about 1 second, then SEt 5 is displayed.

Units

button until the PCS cursor is displayed.

Menu

until SEtPCS is displayed. This is displayed for

>0<>0<

>0<

>0<>0<

Stable

Stable

PCS

PCS

PCS

PCS

Gross

Brutto

Gross

Brutto

Gross

Brutto

Select an alternate sample size by pressing and holding the PRINT/

Units

button. Choices are 5, 10, 20, and 50. Place count samples on platform.

Press the G/N/T/

Menu

button to accept current sample. The new APW is

established. Place parts on platform or in a container to count. If a container

is used, be sure to tare the empty container first.

Additional samples may be added to the platform as long as the same sample

weight intially entered is used with the samples being weighed.

Stable

Stable

Stable

Stable

PCS

PCS

PCS

PCS

Gross

Brutto

Gross

Brutto

Gross

Brutto

Gross

Brutto

Page 35

CD-11 Indicator

*

*

4.10 Returning to a Weighing Mode

EN-29

Press the PRINT/

Units

button until the display indicates the desired measuring

unit either kg, lb, g or oz.

4.11 Returning to a Preset APW

If the APW has been calculated previously, the Indicator stores the value in

memory. Proceed as follows to use a previously set APW:

Press and hold the PRINT/

Place samples on the platform. The display indicates the number of pieces

based on the previously entered data. Sample shown at right indicates 100

pieces.

WHEN POWER IS TURNED OFF, APW

WILL ALWAYS RETURN TO THE PREVIOUSLY STORED APW.

button until PCS cursor is displayed.

Units

CAUTION

>0<>0<

>0<

>0<>0<

>0<>0<

>0<

>0<>0<

Stable

Stable

Stable

PCS

PCS

Gross

Brutto

Gross

Brutto

Gross

Brutto

4.12 Display Hold Modes

The Display Hold mode is enabled by entering the Alternate mode sub-menu in

the rEAd menu. The Alternate mode selections are: ALtOFF, ALt PC, ALt dH.

To enable the Display Hold mode, select ALt dH.

When ALt dH (display hold) is selected, the following choices are available:

dHMAn (manual display hold), dHSEM (semi-automatic display hold), and

dHAuto (automatic display hold). dHMan is the default setting. These choices

are displayed only if ALt dH is selected.

The Display Hold mode allows the maximum stable weight value to be held on

the display and sent to a peripheral device prior to being cleared.

The Display Hold types operate as described below:

4.12.1Manual Display Hold (dHMAn)

To activate the Manual Display Hold mode, press and hold the PRINT/

button until the LCD cursor lights above the Display Hold text on the panel.

The cursor will blink to indicate that the scale is ready. Display shown at right

indicates an empty platform.

Units

>0<>0<

>0<

>0<>0<

*

Stable

Display

Hold

Gross

Brutto

Page 36

EN-30

*

4.12.1 Manual Display Hold (dHMAn) (Cont.)