Ohaus 30253005, 30253015, 30253017, 30253012, 30253013 User Manual

...

Scout

TM

Series Balances - STX

Instruction Manual

TM

Balanzas Scout

Series - STX

Manual de instrucciones

TM

Balances Scout

Séries - STX

Mode d’emploi

TM

Scout

Waagen - Serien - STX

Bedienungsanleitung

TM

Bilance Serie Scout

- STX

Manuale d’Istruzioni

STX EN-0

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................... 1

1.1 Description ................................................................................................................................................... 1

1.2 Definition of Signal Warnings and Symbols ................................................................................................. 1

1.3 Safety Precautions ....................................................................................................................................... 1

1.4 Features ......................................................................................................................................................... 2

2. INSTALLATION ................................................................................................. 4

2.1 Installing Components ................................................................................................................................. 2

2.1.1 Releasing the Transportation Lock .......................................................................................................... 2

2.1.2 Installing the Weighing Pan ..................................................................................................................... 2

2.1.3 Security Slot ............................................................................................................................................. 2

2.2 Selecting the Location .................................................................................................................................. 3

2.3 Leveling the Balance ..................................................................................................................................... 3

2.4 Connecting Power ........................................................................................................................................ 3

2.5 Calibration .................................................................................................................................................... 4

3. OPERATION...................................................................................................... 5

3.1 Controls ........................................................................................................................................................ 5

3.2 Overview of Display, Home Screen ............................................................................................................. 5

3.3 Principal Functions and Main Menu ............................................................................................................ 6

4. APPLICATIONS ................................................................................................ 8

4.1 Weighing ...................................................................................................................................................... 7

4.1.1 Item Settings ............................................................................................................................................ 7

4.1.2 Sample Name .......................................................................................................................................... 8

4.1.3 Print / Save to USB .................................................................................................................................. 8

4.1.4 Menu……………………………………… .................................................................................................. 8

4.2 Parts Counting ............................................................................................................................................. 8

4.2.1 Item Settings ............................................................................................................................................ 9

4.2.2 APW/Samples .......................................................................................................................................... 9

4.3 Percent Weighing ....................................................................................................................................... 10

4.3.1 Item Settings .......................................................................................................................................... 11

4.3.2 Recalculate Reference Weight .............................................................................................................. 11

4.4 Dynamic/Animal Weighing ......................................................................................................................... 12

4.4.1 Item Settings .......................................................................................................................................... 13

4.5 Density Determination ................................................................................................................................ 14

4.5.1 Measuring the Density of a Solid Using Water (default) ........................................................................... 14

4.5.2 Measuring the Density of a Solid Using an Auxiliary Liquid ..................................................................... 16

4.5.3 Measuring the Density of a liquid using a Calibrated Sinker (not supplied) .............................................. 16

4.5.4 Measuring the Density of Porous Material Using Oil ................................................................................ 18

4.6 Check Weighing ......................................................................................................................................... 19

4.6.1 Item Settings .......................................................................................................................................... 20

4.6.2 Limits…………………………………………. ........................................................................................... 20

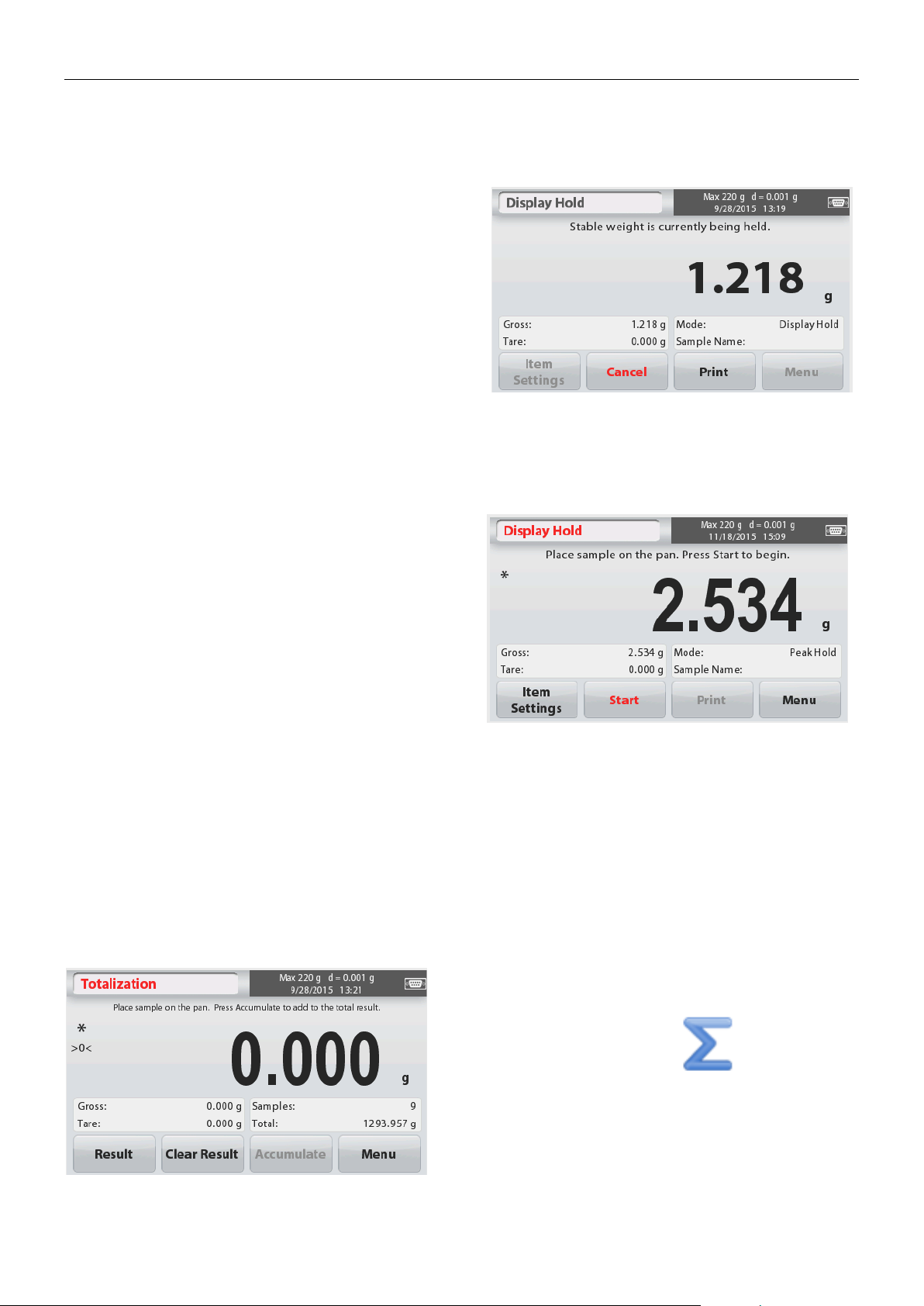

4.7 Display Hold ............................................................................................................................................... 21

4.7.2 Display Hold Mode .................................................................................................................................... 22

4.7.3 Peak hold mode ........................................................................................................................................ 22

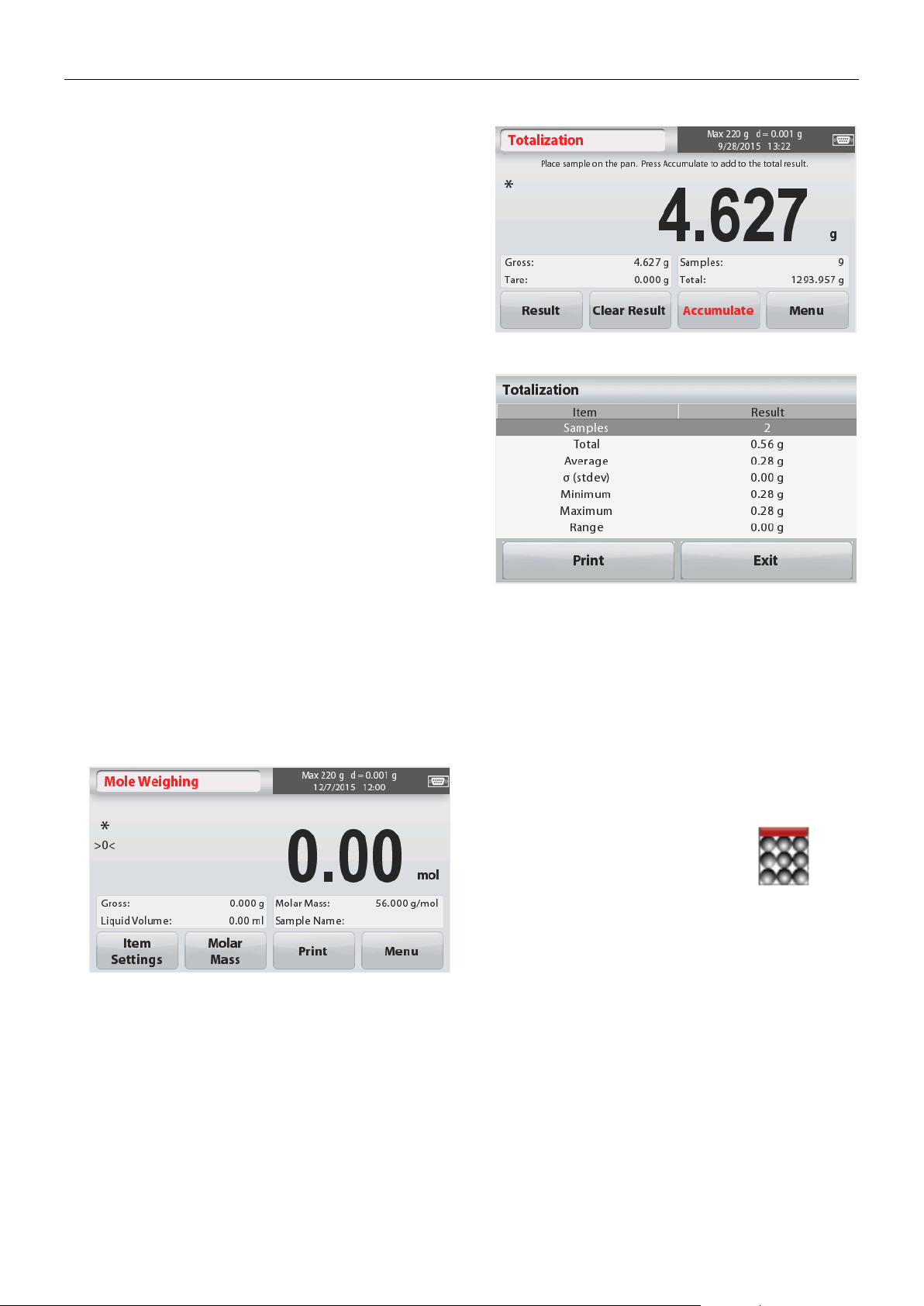

4.8 Totalization ................................................................................................................................................... 22

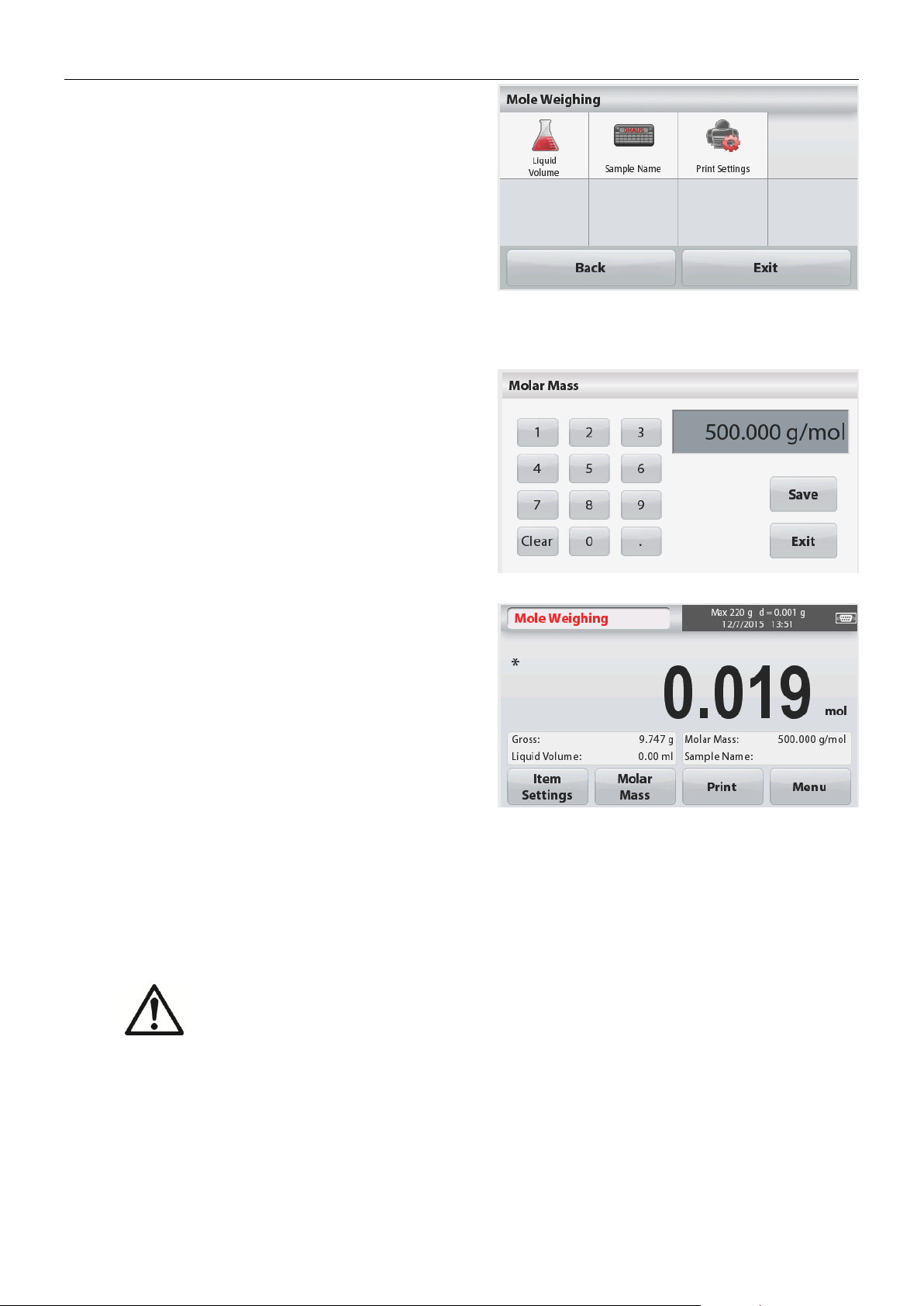

4.9 Mole Weighing ............................................................................................................................................. 23

4.9.1 Item Settings ............................................................................................................................................. 23

4.9.2 Enter Molar Mass ...................................................................................................................................... 24

4.9.3 Calculate Molarity ..................................................................................................................................... 24

4.10 Additional Features .................................................................................................................................... 24

4.10.1 Weigh Below ........................................................................................................................................... 24

4.10.2 Connecting the Interface ......................................................................................................................... 24

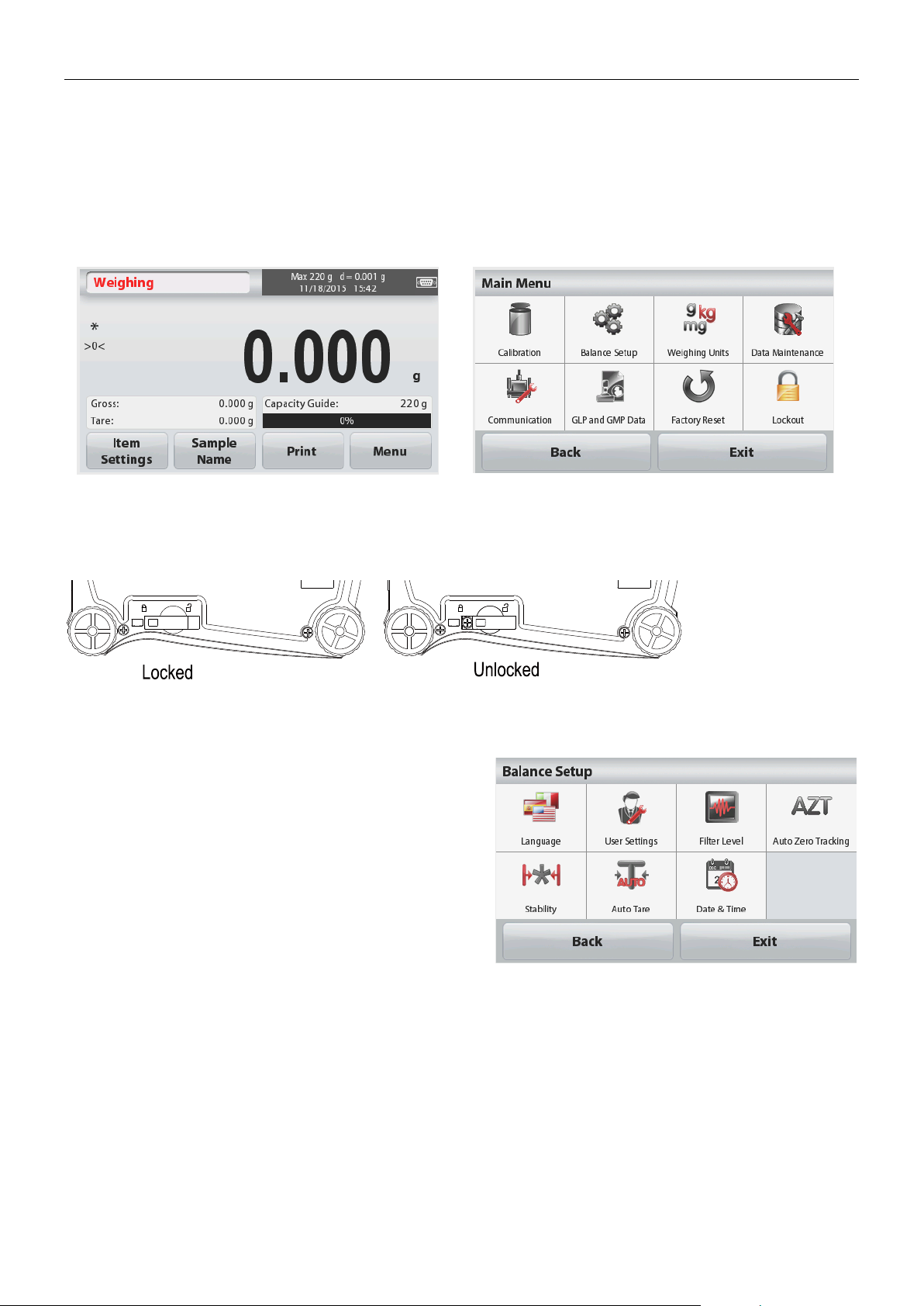

5. MENU SETTINGS ........................................................................................... 26

5.1 Menu Navigation ........................................................................................................................................ 26

5.1.1 Changing Settings .................................................................................................................................. 26

5.2 Main Menu ................................................................................................................................................. 26

5.2.1 Calibration .................................................................................................................................................. 27

5.2.1.1 Span Calibration ..................................................................................................................................... 27

5.2.1.2 Linearity Calibration ................................................................................................................................ 27

5.2.2 Balance Setup ............................................................................................................................................ 28

STX EN-1

5.2.3 Weighing Units ........................................................................................................................................... 30

5.2.4 Data Maintenance ...................................................................................................................................... 31

5.2.5 Communication .......................................................................................................................................... 31

5.2.6 GLP and GMP Data ................................................................................................................................... 36

5.2.7 Factory Reset ............................................................................................................................................. 37

5.2.8 Lockout ....................................................................................................................................................... 37

6. MAINTENANCE .............................................................................................. 39

6.1 Calibration ................................................................................................................................................... 38

6.2 Cleaning ...................................................................................................................................................... 38

6.3 Troubleshooting .......................................................................................................................................... 38

6.4 Service Information ..................................................................................................................................... 38

7. TECHNICAL DATA ......................................................................................... 40

7.1 Specifications .............................................................................................................................................. 39

7.2 Drawings and Dimensions .......................................................................................................................... 41

8. SOFTWARE UPDATES .................................................................................. 42

9. COMPLIANCE ................................................................................................. 43

STX EN-1

General Hazard

Electric Shock Hazard

Caution: Read all safety warnings before installing, making connections, or servicing

this equipment. Failure to comply with these warnings could result in personal injury

and/or property damage. Retain all instructions for future reference.

1. INTRODUCTION

1.1 Description

The Scout STX balance is a high quality weighing instrument that will provide you with years of

service if properly cared for. Models are available with ranges from 120g to 8200g.

1.2 Definition of Signal Warnings and Symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and

warnings. Ignoring the safety notes may lead to personal injury, damage to the instrument,

malfunctions and false results.

Signal Words

WARNING For a hazardous situation with medium risk, possibly resulting in injuries or

death if not avoided.

CAUTION For a hazardous situation with low risk, resulting in damage to the device or

the property or in loss of data, or injuries if not avoided.

Attention For important information about the product.

Note For useful information about the product.

Warning Symbols

1.3 Safety Precautions

Verify that the input voltage range printed on the data label and the plug type matches

the local AC power to be used.

Make sure that the power cord does not pose a potential obstacle or tripping hazard.

Use the balance only in dry locations.

Do not drop loads on the pan.

Use only approved accessories and peripherals.

Operate the equipment only under ambient conditions specified in these instructions.

Disconnect the equipment from the power supply when cleaning.

Do not operate the equipment in hazardous or unstable environments.

Service should only be performed by authorized personnel.

Do not position the balance such that it is difficult to reach the power connection.

EN-2 STX

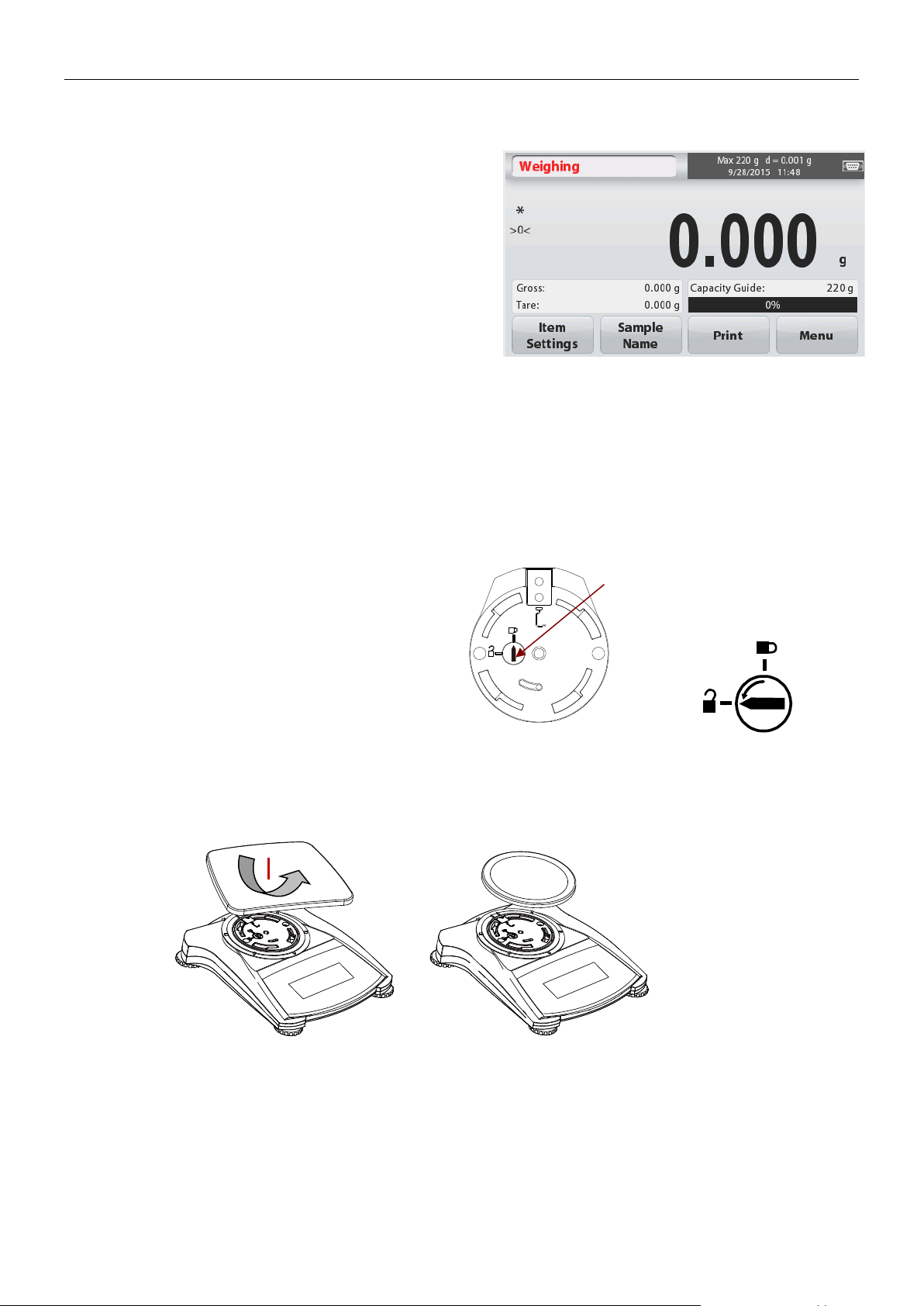

Touch Controls: Quick, graphical access to all

control functions, applications and features.

Release the red transportation lock on the

sub-platform of the balance by turning the

pointer 90 counter-clockwise.

Unlocked

Position

Locked

Position

Sub-platform

Transportation

1.4 Features

2. INSTALLATION

2.1 Installing Components

Refer to the illustrations and instructions below to identify and assemble your Scout balance

with its components. All components must be assembled before using the balance.

2.1.1 Releasing the Transportation Lock

2.1.2 Installing the Weighing Pan

Balances with a rectangular platform are placed into the sub-platform and rotated counterclockwise until it locks. Round platforms are placed straight down on sub-platform.

2.1.3 Security Slot

A security slot is provided at the rear of the balance allowing the balance to be secured by an

optional cable and lock accessory.

STX EN-3

2.3 Leveling the Balance

The Scout has an illuminated level indicator as a reminder that

the balance should be leveled for accurate weighing. There is a

level bubble in a small round window on the front of the

balance. To level the balance, adjust the feet at each corner

until the bubble is centered in the circle.

Be sure the balance is level each time its location is changed.

See the Level Assist screen in the User Settings Menu.

AC Adapter Input Jack

Battery Compartment Cover

Interface Connection

Security Switch

Weigh Below Hole

Security slot (Anti-theft lock slot)

2.2 Selecting the Location

For best performance, the Scout balance should be used in a clean, stable environment. Do not

use the balance in environments with excessive drafts, with rapid temperature changes, near

magnetic fields or near equipment that generates magnetic fields, or vibrations.

2.4 Connecting Power

AC Adapter Installation

AC power is used to power the balance when battery power is not needed. First, connect the

AC Adapter (supplied) to the AC Adapter Input jack at the rear of the balance then connect the

AC plug to an electrical outlet.

Battery Installation

Install the four “AA” batteries with polarity as shown in the battery compartment.

Note:

After power on, it is recommended to let the balance warm up for at least 5 minutes before

using it.

EN-4 STX

2.5 Calibration

When the Balance is first installed, and when it is moved to another location, it must be

calibrated to ensure accurate weighing results. If preferred, the balance can be manually

calibrated with external masses. Have the appropriate calibration masses available before

beginning calibration. Refer to the Calibration and Specification Sections for masses and

calibration procedure.

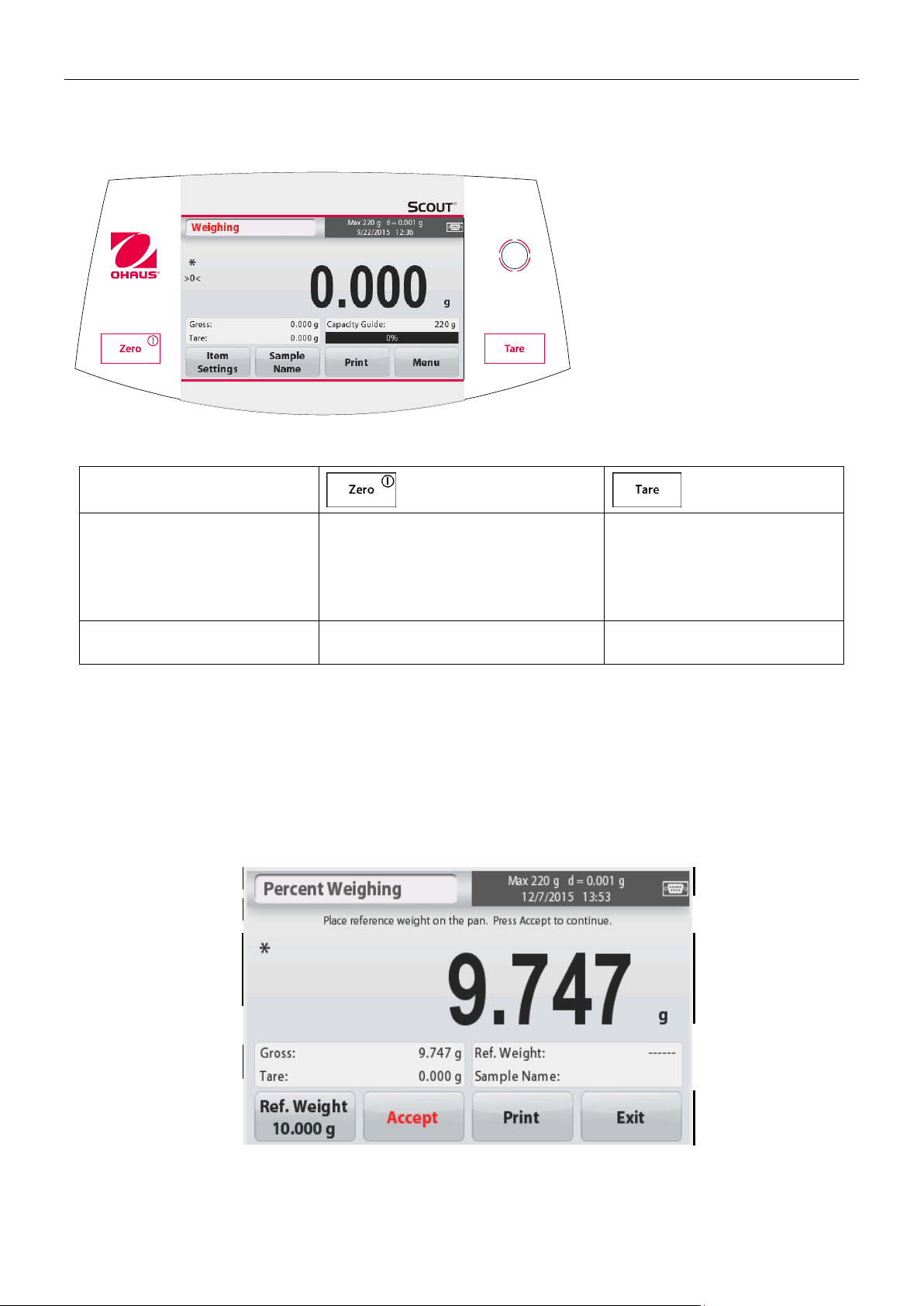

STX EN-5

Button

Primary Function

(Short Press1)

On

Turns the balance on

Zero

If balance is On, sets Zero

Tare

Enter/clear a tare value.

Secondary Function

(Long Press2)

Off

Turns the balance Off.

Application

Instructional Messages

Stability (*), Net (NET),

Gross (G) and/or center

of zero (>0<) indicators

Reference Fields

Application Buttons:

Functions vary by

application

Result Field: Information

varies by application

Touch g to change unit

Capacity and readability

3. OPERATION

3.1 Controls

Button Functions

Table 3-1.

Notes: 1 Short Press: Press less than 1 second.

2

Long Press: Press and hold for more than 2 seconds.

3.2 Overview of Display, Home Screen

This equipment utilizes a touch-sensitive display. Touch areas and Buttons to control the

equipment’s functions.

Main Application Screen:

EN-6 STX

Touch Menu to open the menu list.

Calibration:

Touch to view calibration options.

Balance Setup:

Touch to view balance settings.

Weighing Units:

Touch to view weighing units.

Data Maintenance:

Touch to view data maintenance options.

Communication:

Touch to view COM Device Settings and

Print Settings.

Factory Reset:

Touch to do a Factory reset.

GLP and GMP Data:

Insert user data for traceability.

Lockout:

Touch to access the Lockout

menu list.

Secondary

result line and

unit-of-measure

indicator

Instructional Message

line

Stability indicator,

NET, G, and/or

>0< (center of 0).

Capacity Bar:

Color indicates capacity

used. Meaning varies by

application.

Primary

result line and

unit-of-measure

indicator

Results lines –

meaning varies by

application.

Touch control

function Icons

to…

…access more functions

…Call up the menu or specific functions…

Tare and application

buttons – functions vary

by application

Touch control

function Icons

to…

…access more functions

…Call up the menu or specific functions…

3.3 Principal Functions and Main Menu

Weighing: Press Zero to set the display to zero. Place an item on the pan. Display indicates

gross weight.

Taring: With no load on the pan, press Tare to set the display to zero. Place an empty

container on the pan and press Tare. Add material to the container and its net weight

is displayed. Remove container and container’s weight appears as a negative

number. Press Tare to clear.

MENU & SCREEN NAVIGATION

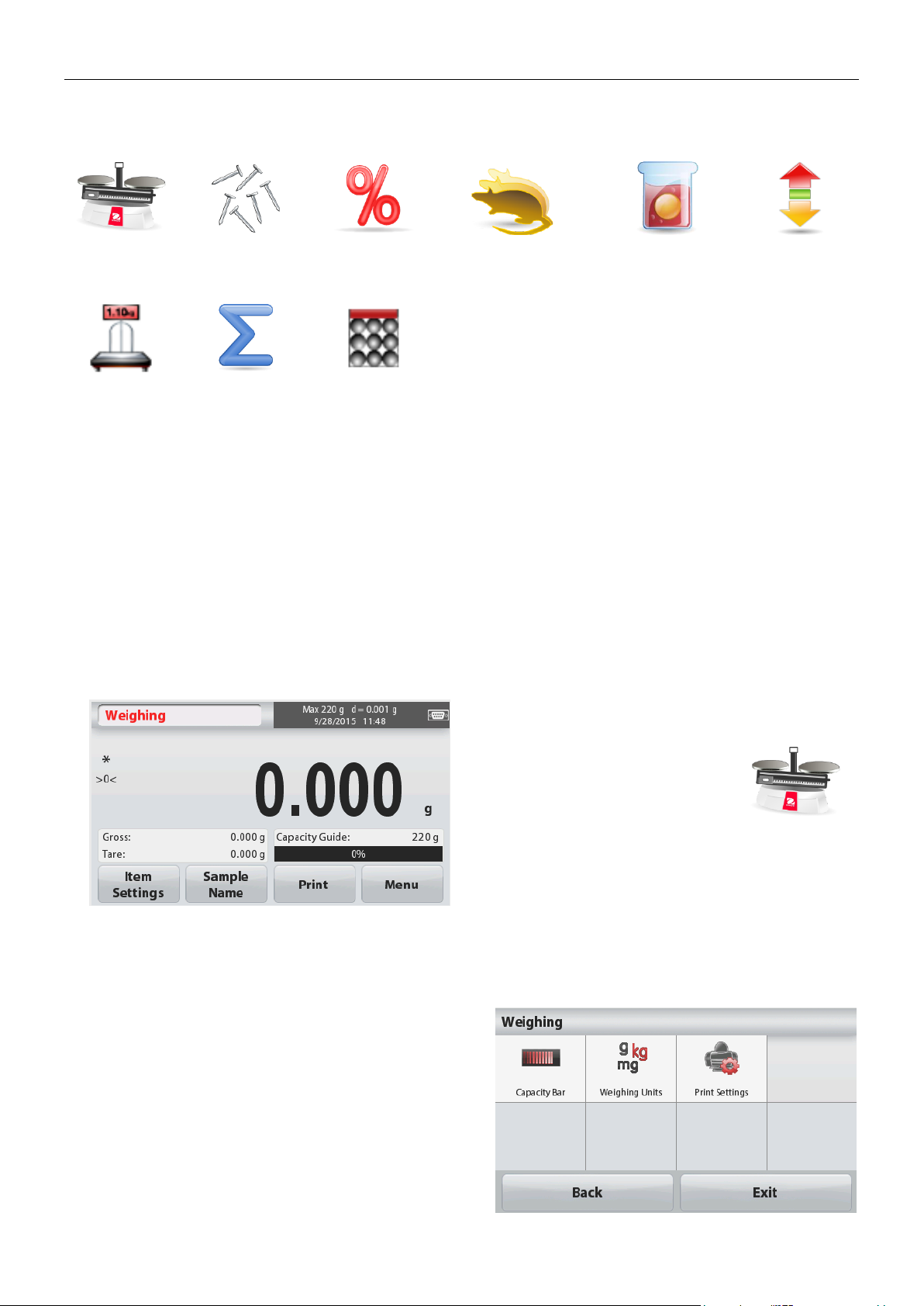

4. APPLICATIONS

The balance can be configured to operate in various Application modes.

Touch the top left button in the Application area to choose the mode:

STX EN-7

Weighing

Parts

Counting

Percent

Weighing

Dynamic

(Animal)

Weighing

Density

Determination

Check

Weighing

Display

Hold

Totalization

Mole

Main Display Line

Reference Fields

Application Buttons

Application

Icon

To view or adjust the current settings

Touch the

Item Settings

button. The Settings

screen appears.

Capacity Bar:

Set to On to display the

capacity guide on the weighing main screen.

Weighing Units:

Select the displayed unit.

Print Settings:

To view or adjust the print

settings.

The Scout Balance incorporates the following Applications.

Note: Before using any application, be sure the balance has been leveled and calibrated.

4.1 Weighing

Use this application to determine the weight of items in the selected unit of measure.

Weighing

1. In the upper left portion of the home screen, select Weighing (this application is the

default).

2. Press Tare or Zero if necessary to begin.

3. Place objects on the pan to display the weight. When stable, the * appears.

The resulting value is displayed in the main Weighing Line in the active unit of measure.

The WEIGHING Home screen:

4.1.1 Item Settings

EN-8 STX

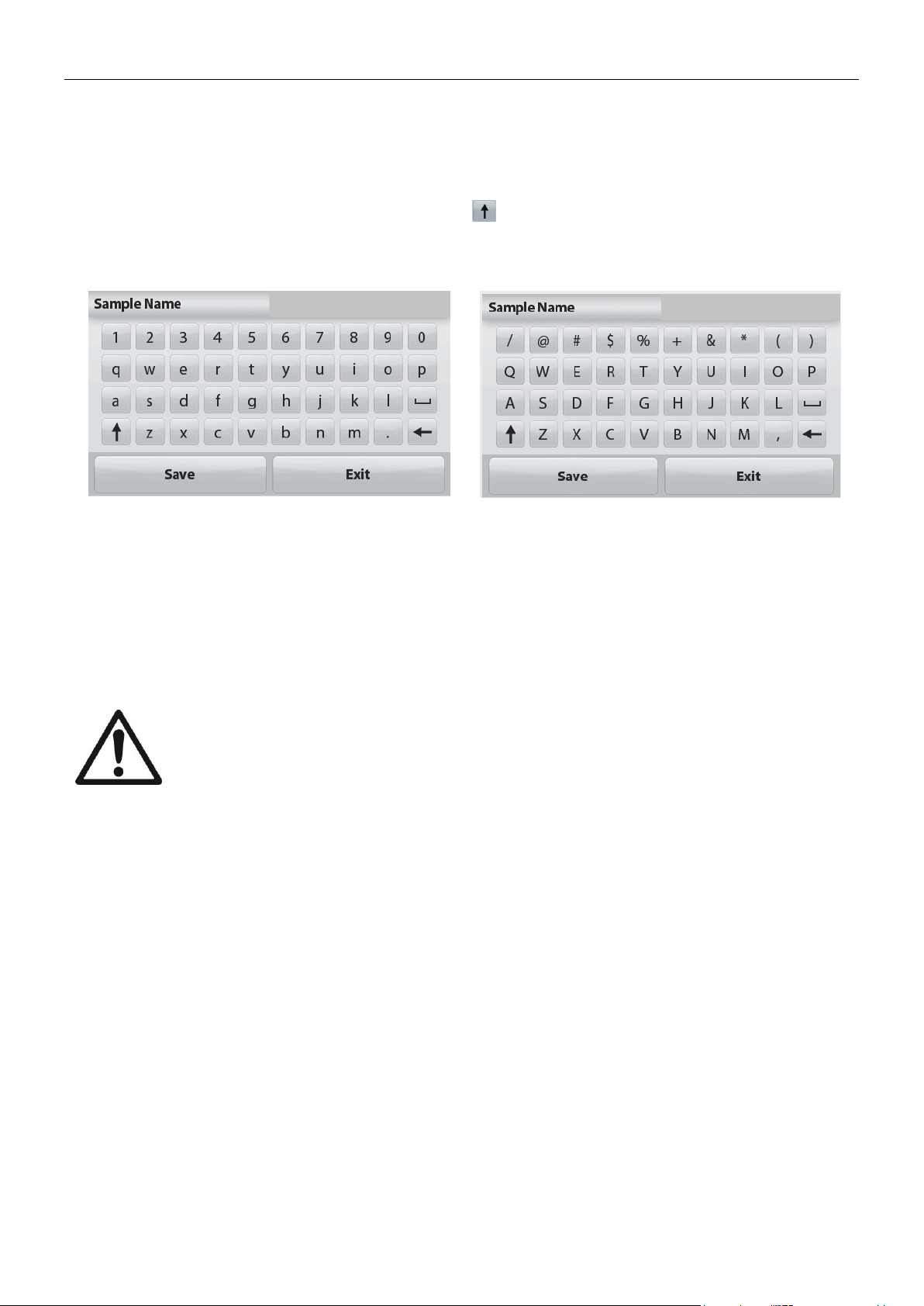

Enter a sample name with the alphanumerical keypad and then press Save to store the name

and return to weighing mode main screen. Press to alternate between Lower and Upper

case characters.

Lower Case:

Upper Case:

Print the information based on the settings in Print Settings menu.

Note: This button will be disabled if the optional interface kit (buy separately) is not installed.

When the USB Host interface kit is installed, “Save to USB” will be shown.

Save to USB

Insert the USB flash drive into the USB slot. Next, press the Save to USB button to save the

data to the USB flash drive. Once saved, the button will momentarily change color to orange.

CAUTION:

Depending on the USB drive used, all data might not be transferred from the

balance or the display might freeze. If this happens, unplug the USB flash drive

and try another USB flash drive.

Ohaus takes no responsibility if data on USB flash drive is erased or if the USB

flash drive breaks while it is connected to the balance.

To minimize the risk of problems arising, Ohaus suggests using a high quality

USB flash drive.

For more information, please refer to USB Host instruction manual.

To view the Main Menu options.

4.1.2 Sample Name

4.1.3 Print / Save to USB

4.1.4 Menu

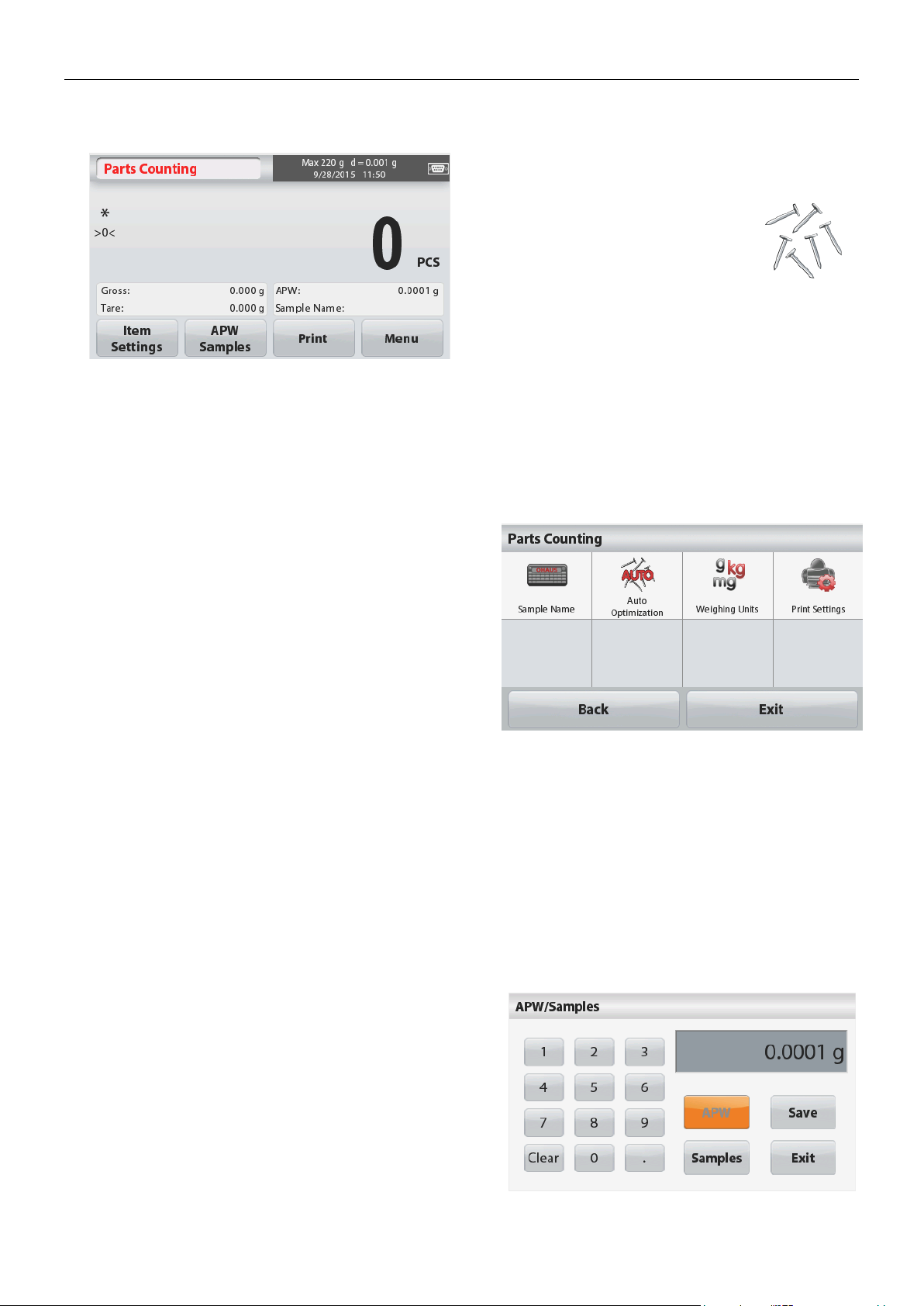

4.2 Parts Counting

Use this application to count samples of uniform weight.

1. In the upper left portion of the home screen, select Parts Counting.

2. Press Tare or Zero if necessary to begin.

3. Establish an Average Piece Weight (APW), the default (or last) APW is displayed.

4. Place objects on the pan to display the number of pieces on Main Display Line.

STX EN-9

Main Display Line

Reference Fields

Application Buttons

Application

Icon

4.2.1 Item Settings

To view or adjust the current settings, touch the Item Settings button:

Touch the

Item Settings

button. The Settings

screen appears.

Sample Name: Enter a sample name

with the alphanumerical keypad and then

press Save to store the name and return

to Item Settings screen as shown to the

right.

Auto Optimization:

It re-calculates the

piece weight automatically to improve

counting accuracy as parts are added.

By default Auto Optimization is

Off

.

Weighing Units:

Select the displayed

unit.

Print Settings:

To view or adjust the print

settings.

4.2.2 APW/Samples

Enter to set APW and Sample size in pieces by

the numerical keypad.

Establish an Average Piece Weight (APW)

Each time a new type of part is counted, the

nominal weight of one piece (Average Piece

Weight or APW) must be established using a

small quantity of pieces. This APW is stored until

replaced by another APW.

There are two methods to establish the APW

value: APW and Samples.

The PARTS COUNTING Standard Home screen:

EN-10 STX

APW:

Set a known Average Piece Weight (APW)

To adjust the APW value directly, touch the

APW

button

.

A numeric input window appears.

Key in the desired APW Weight, then press

Save.

The display returns to the application home

screen with the new APW value in the reference

field.

Samples:

Set a new Average Piece Weight (APW) –

Derived

To establish a new APW, touch the Samples

button.

A numeric input window appears.

Key in the desired Sample Size (1 to 10000

pieces), then press

Save

.

The display returns to the application home

screen. Follow the screen instructions to

establish a new APW.

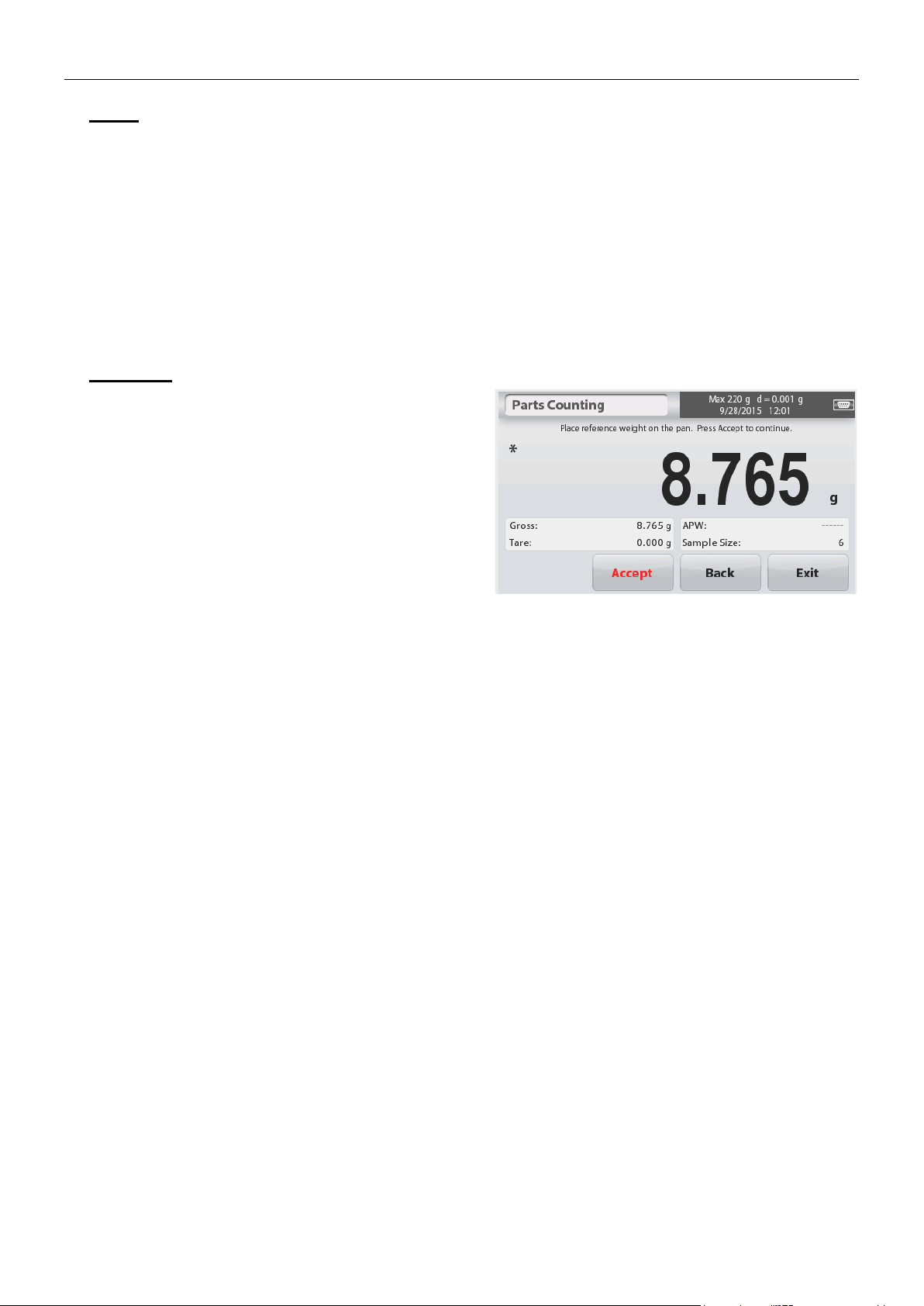

Place the reference weight on the pan and

press Accept to continue. The sample size

displayed will be used. The new APW value is

shown in the reference field.

The Main screen returns with the new APW

value calculated.

4.3 Percent Weighing

Use Percent Weighing to measure the weight of a sample displayed as a percentage of a preestablished Reference Weight.

The default (or last) Reference Weight is displayed.

1. In the upper left portion of the home screen, select Percent Weighing.

2. Place an object on the pan. The difference between the sample and the Reference Weight

is displayed as both a weight and a percentage.

STX EN-11

The PERCENT WEIGHING Home screen:

Main Display Line

Reference Fields Application Icon

Application Buttons

Touch the

Item Settings

button. The Settings

screen appears.

Sample Name:

Enter a sample name with

the alphanumerical keypad and then press

Save to store the name.

Weighing Units:

Select the displayed unit.

Print Settings:

To view or adjust the print

settings.

To establish a new reference weight value,

touch the Recalculate Ref. Weight button.

Follow the screen instructions to establish a

new reference weight.

Alternatively, press the Ref. Weight button

from the Percent Weighing Recalculate Ref.

Wgt screen to establish a new reference

weight manually through a numerical keypad.

Key in the desired Reference Weight, then

press Save.

The display returns to the Percent Weighing

home screen.

4.3.1 Item Settings

To view or adjust the current settings

4.3.2 Recalculate Reference Weight

EN-12 STX

Main Display Line

Reference Fields

Application Buttons Application Icon

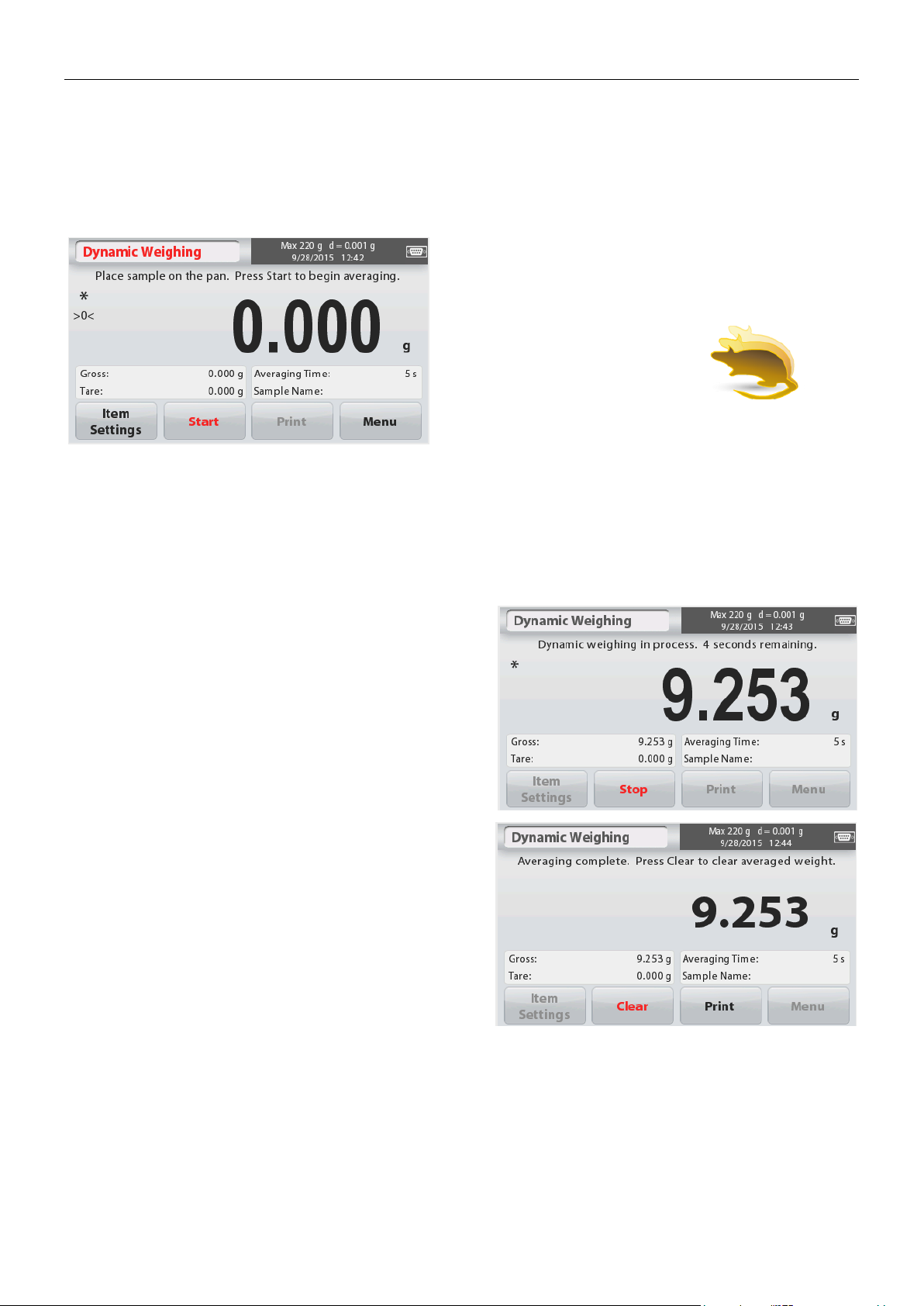

Dynamic Weighing – Manual (default)

1. In the upper left portion of the home screen, select Dynamic Weighing.

2. Press Tare or Zero if necessary to begin.

3. Place objects on the pan. Press the

Start

button.

4. The balance begins a countdown (averaging

process).

During the countdown, the information line

displays the time remaining.

If necessary, press

Stop

to quit and return to

the Home screen.

5. When the countdown ends, the result is

displayed and held.

Press Clear to clear the held weight and

return to the Initial screen.

Note:

Clear the pan before beginning a new

Dynamic Weighing cycle.

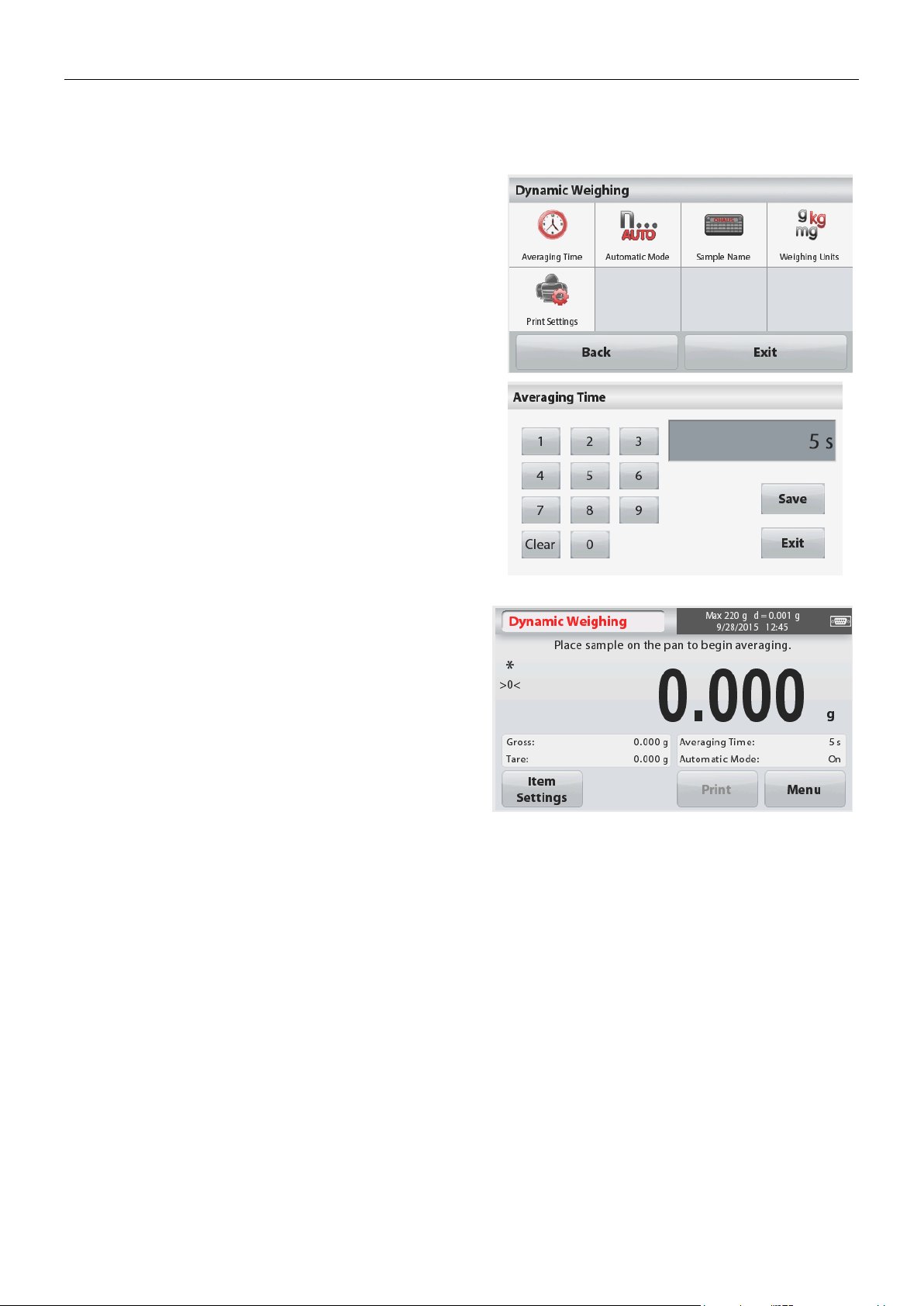

4.4 Dynamic/Animal Weighing

Use this application to weigh an unstable load, such as a moving animal. Two different

start/reset modes can be selected: Manual (start and stop via key press) and Automatic (start

and stop automatically).

The DYNAMIC WEIGHING Home screen:

STX EN-13

Touch the

Item Settings

button. The Settings

screen appears.

Averaging Time:

The Averaging Time can be

set from 1 to 99 seconds.

The default value is 5 seconds.

Automatic Mode:

The cycle begins when an object (animal) is

placed on the pan, and the held value is

automatically reset when the object is removed

from the pan (10-second delay).

Sample Name:

Enter a sample name with the

alphanumerical keypad and then press Save to

store the name.

Weighing Units:

Select the displayed unit.

Print Settings:

To view or adjust the print

settings.

4.4.1 Item Settings

To view or adjust the current settings:

EN-14 STX

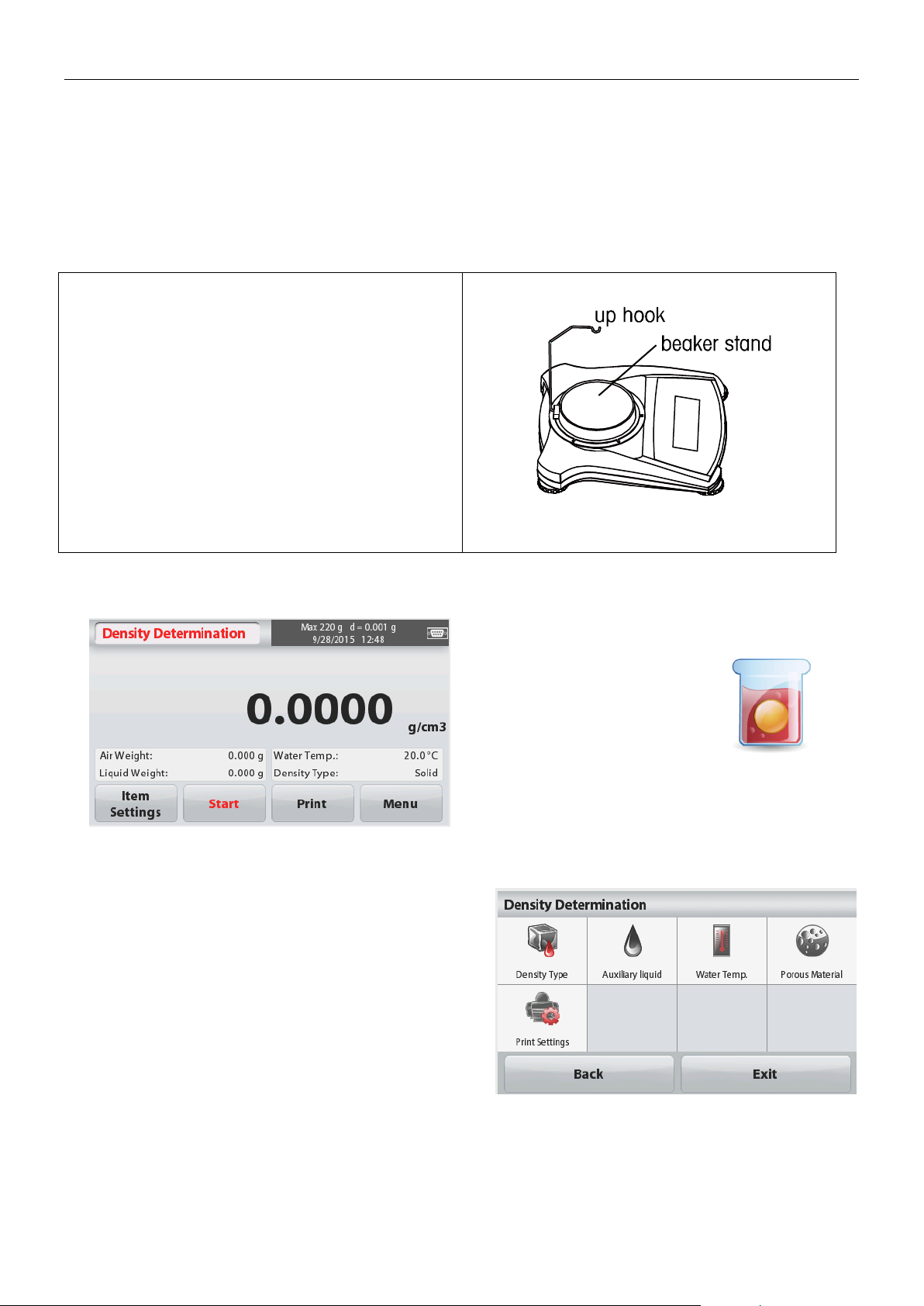

Prepare the balance as shown right

1. Turn off the balance.

2. Remove the balance platform.

3. Insert they up hook and install the beaker

stand (beaker is not supplied).

4. Power on the balance

5. In the upper left portion of the home

screen select Density Determination.

6. Follow below instructions to determine the

object’s density.

Main Display Line

Reference Fields Application Icon

Application Buttons

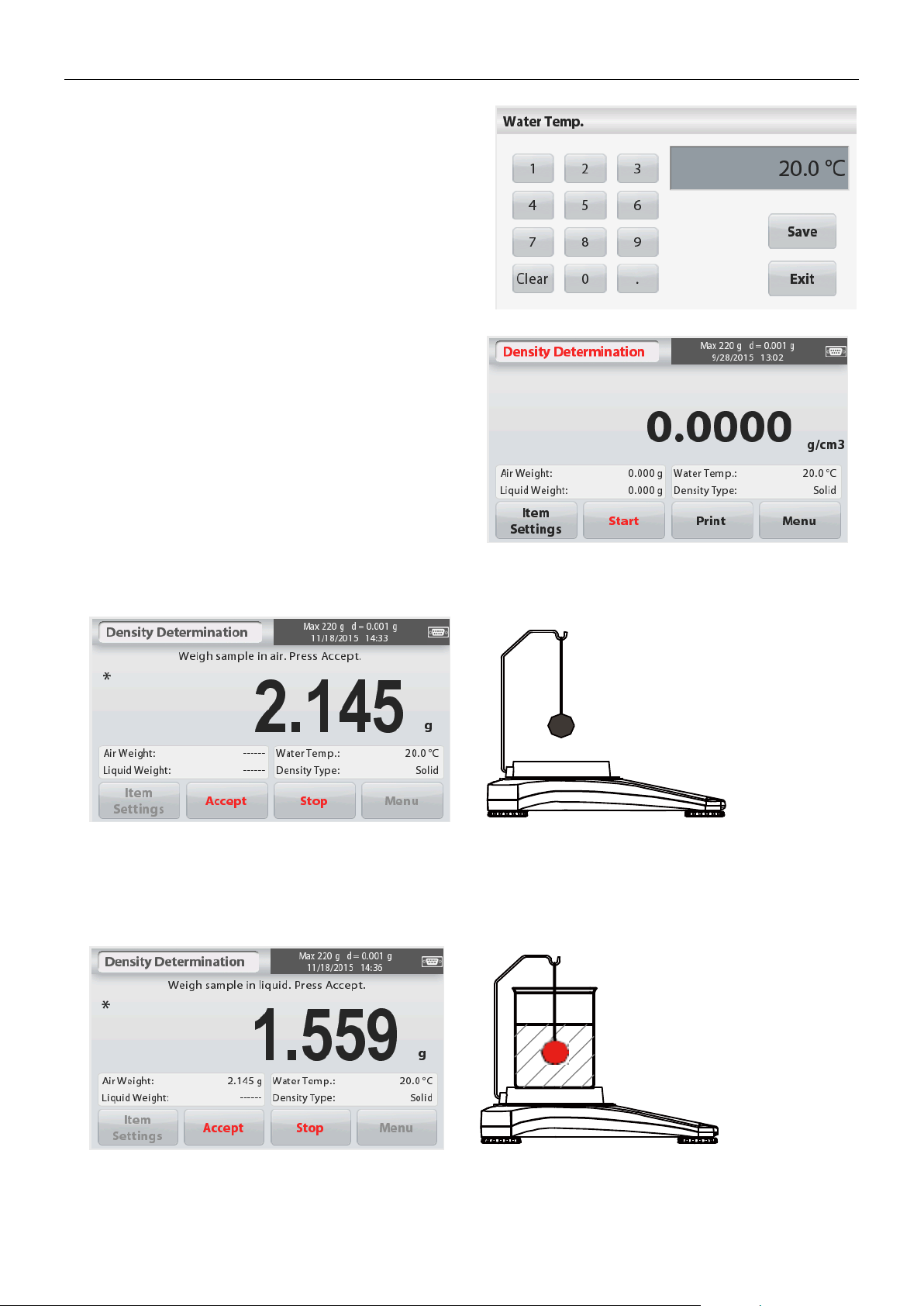

Press the Item Settings button to open the

Density Determination Settings screen.

Confirm the following Setups are selected:

Density Type: Solid

Auxiliary Liquid: Water

Porous Material: Off

To adjust the water temperature value,

touch the Water Temp button.

A numeric input window appears.

Enter the actual water temperature, then press

Save.

4.5 Density Determination

The Scout can be used to determine an object’s density including solid and liquid.

A density determination kit (not included, buy separately) is designed to be used with Ohaus

Scout STX. However, you may use whatever lab apparatus that suits the requirements for

density measurements. The weigh below hook is recommended to use if the solids weight is

more than 200g.

The DENSITY DETERMINATION Home screen:

4.5.1 Measuring the Density of a Solid Using Water (default)

STX EN-15

The balance calculates water density based on

the water temperature value entered (internal

lookup table). Measure the actual water

temperature using a precision thermometer.

Press

Back

to return to the Density

Determination home screen.

To begin the Density Determination process,

press

Start

.

Step 1 of 2 – Weigh the Sample in Air.

Press Start. Follow screen instructions, and then press Accept to store the dry sample weight

(“in air”).

Step 2 of 2 – Weigh the Sample Submerged in the Liquid.

Follow the screen instructions, then press Accept to store the sample weight (submerged in

liquid).

EN-16 STX

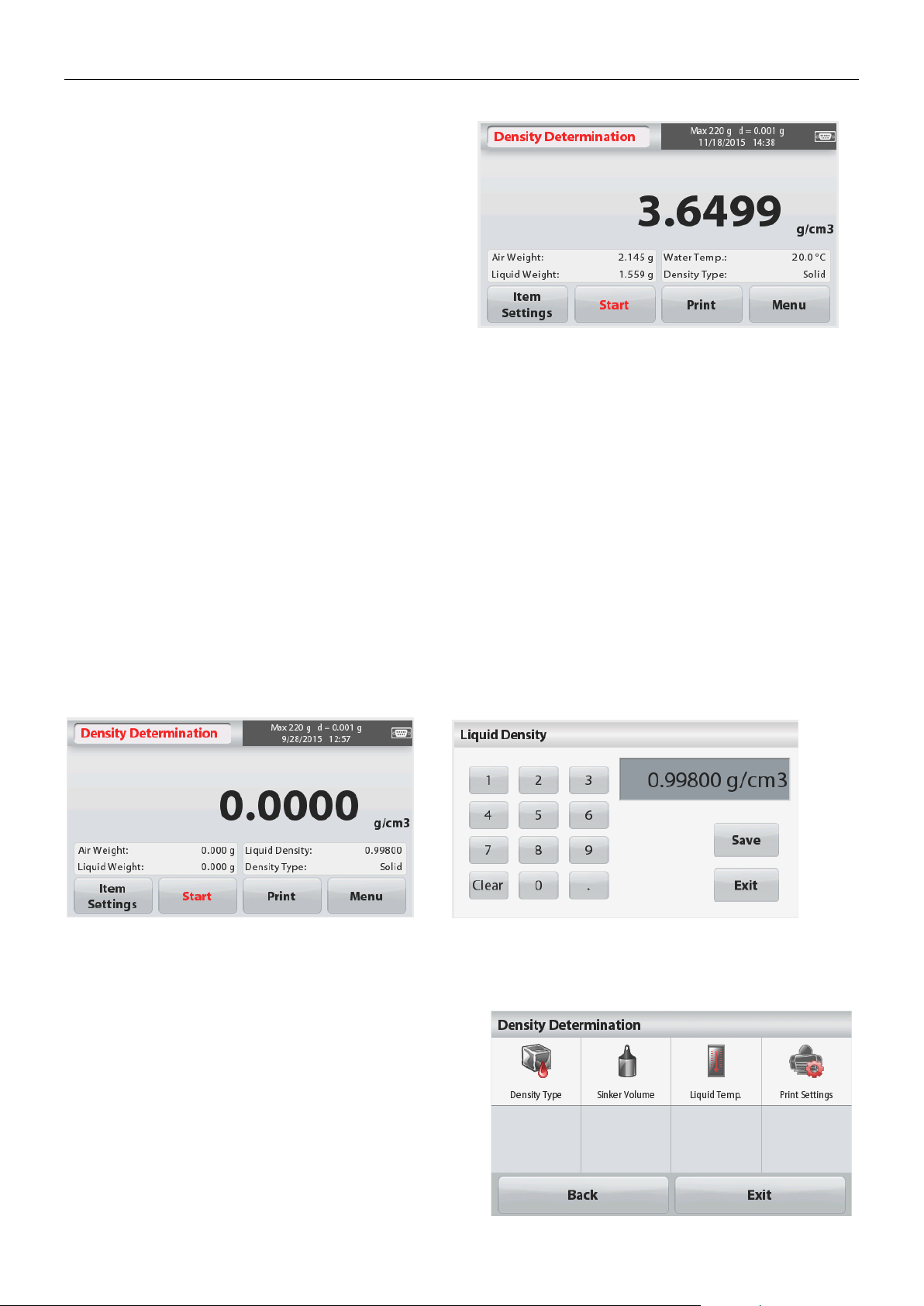

Once the necessary weights have been

determined, the density of the sample is

displayed in

g/cm

3

(along with the weight

in air, weight in water) on the Application

screen.

Density Type: Liquid

Note: when the Density Type is set to Liquid, the

Liquid type and Porous material selections are

disabled.

Press

The balance can also be used to measure the Density of a Buoyant Material Using Water.

Follow the same procedure as Solid Material above, except in Density Determination step 2,

push the sample down (requires special tool, not supplied) into the liquid until it is fully

submerged.

to reset all the weight values and restart the process.

Start

4.5.2 Measuring the Density of a Solid Using an Auxiliary Liquid

To enable this feature, enter the Item Settings screen and select the following:

Density Type: Solid

Auxiliary Liquid: Other

Porous Material: Off

Confirm the default values displayed (Liquid Density, etc) are correct.

Begin the Density determination process by pressing Start and following the screen

instructions.

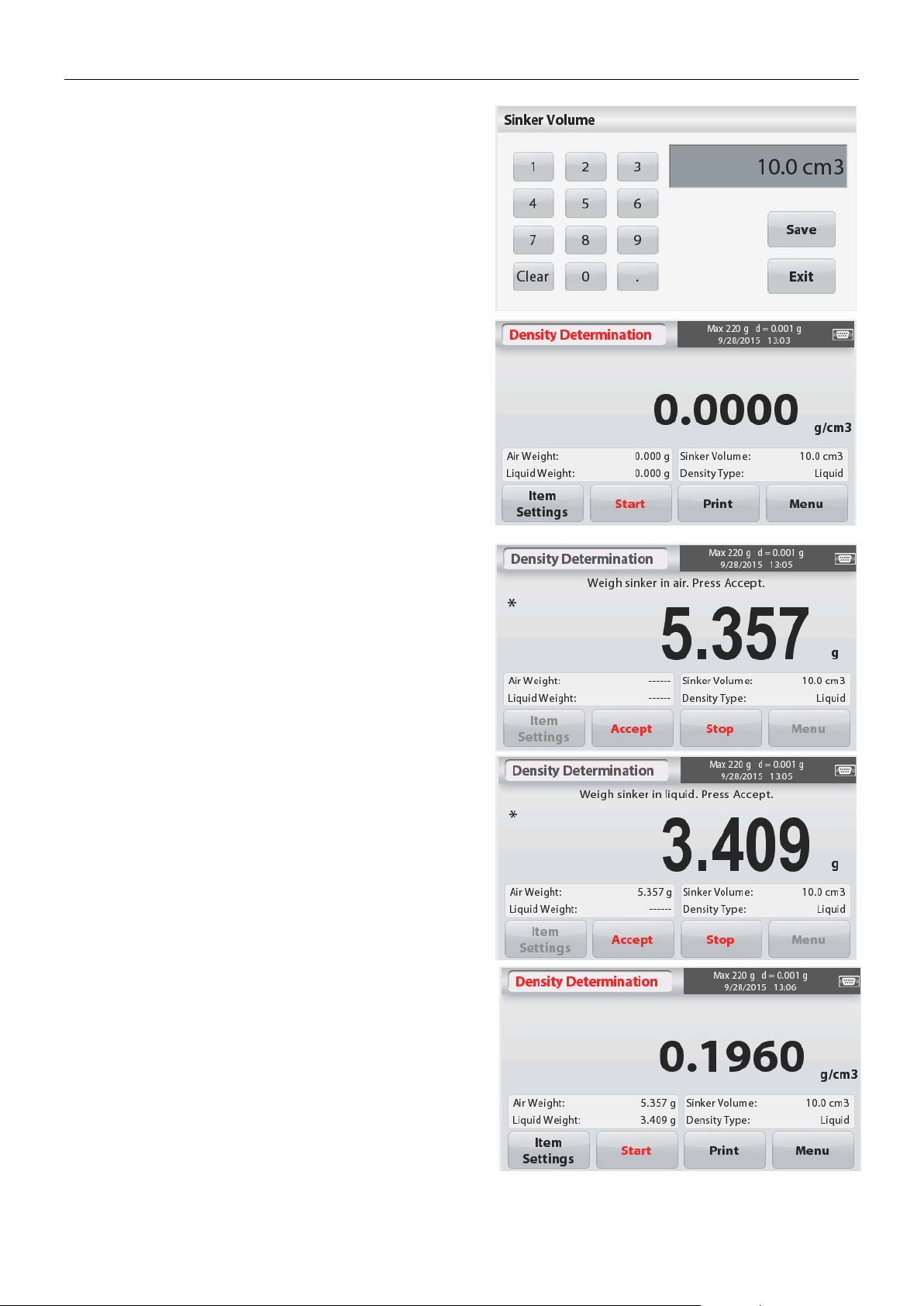

4.5.3 Measuring the Density of a liquid using a Calibrated Sinker (not

supplied)

Enable this feature, enter the Density Item Settings screen and select the following;

STX EN-17

Confirm that the default value displayed (sinker

volume) is correct. To edit the default values,

touch

Sinker Volume

.

A numeric input window is displayed.

Key in the desired value, then press Save.

The display returns to the previous screen.

Edit the Liquid temperature if required.

To return to the Density Determination home

screen, touch Back.

Press

Start

to start the process.

Step 1 of 2 – Weigh the Sinker in Air.

Follow the screen instructions, then press

Accept

to store the sinker weight (“in air”).

Step 2 of 2 – Weigh the Sinker Submerged

in the Test Liquid.

Follow the screen instructions, then press

Accept

to store the sinker weight (submerged

in liquid).

Once the necessary weights have been

determined, the density of the Liquid sample is

displayed in g/cm3(along with the weight in air,

weight in water) on the Application screen.

Press

Start

to reset all the weight values and

restart the process.

EN-18 STX

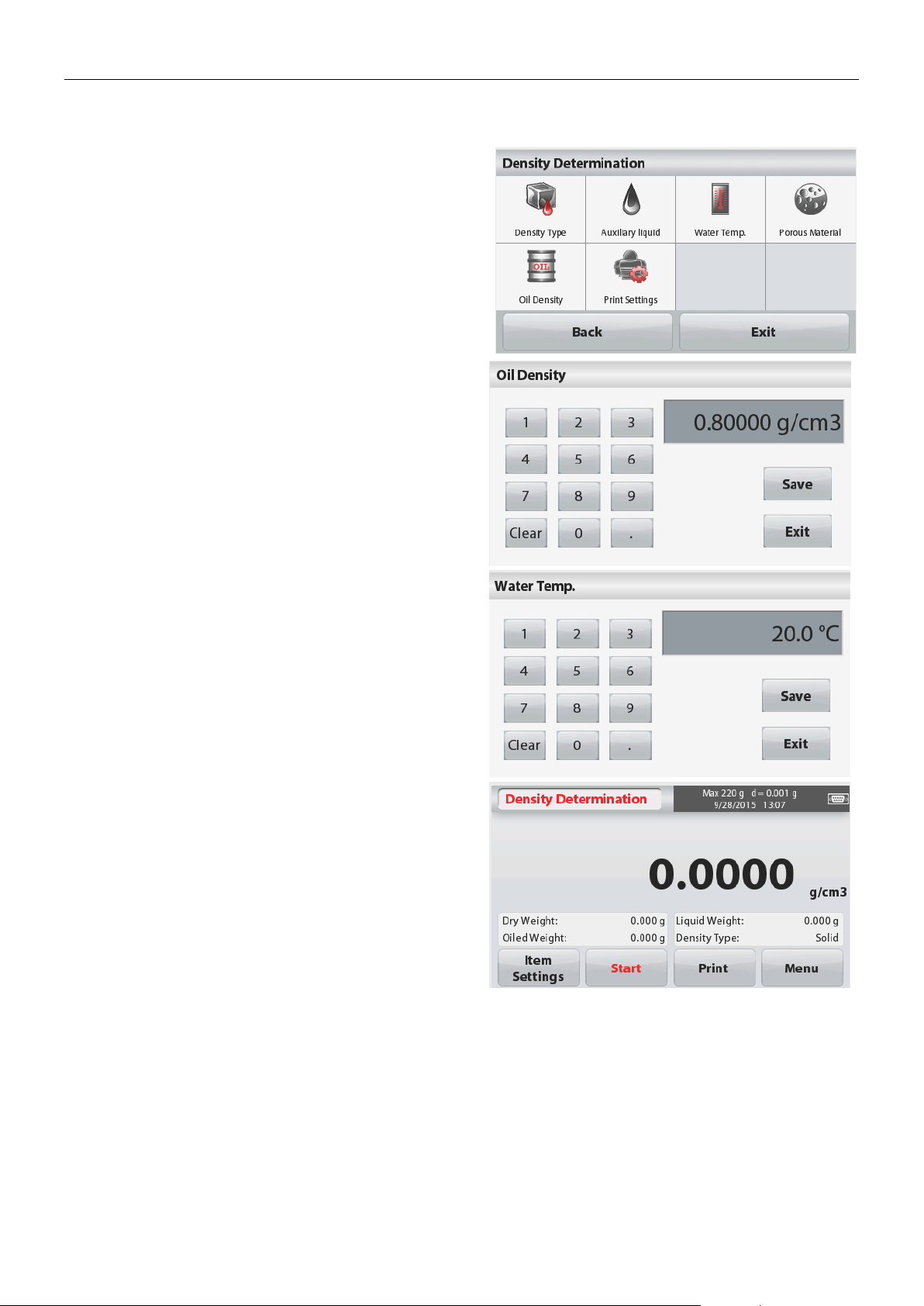

To enable this feature, enter the Item Settings

screen, and select the following:

Density Type: Solid

Auxiliary Liquid: Water

Porous Material: On

To adjust the Water Temperature or Oil

Density values, touch the Water Temp or Oil

Density button.

The balance calculates water density based

on the water temperature value entered (lookup table).

Measure the actual water temperature using a

precision thermometer.

Numeric input windows appear.

Key in the desired value, then press Save.

To return to the Density Determination home

screen, touch Exit.

Press Start to begin density determination.

Step 1 of 3 – Weigh the Un-Oiled Sample in

Air.

Follow the screen instructions then press

Accept

to store the dry sample weight (in air).

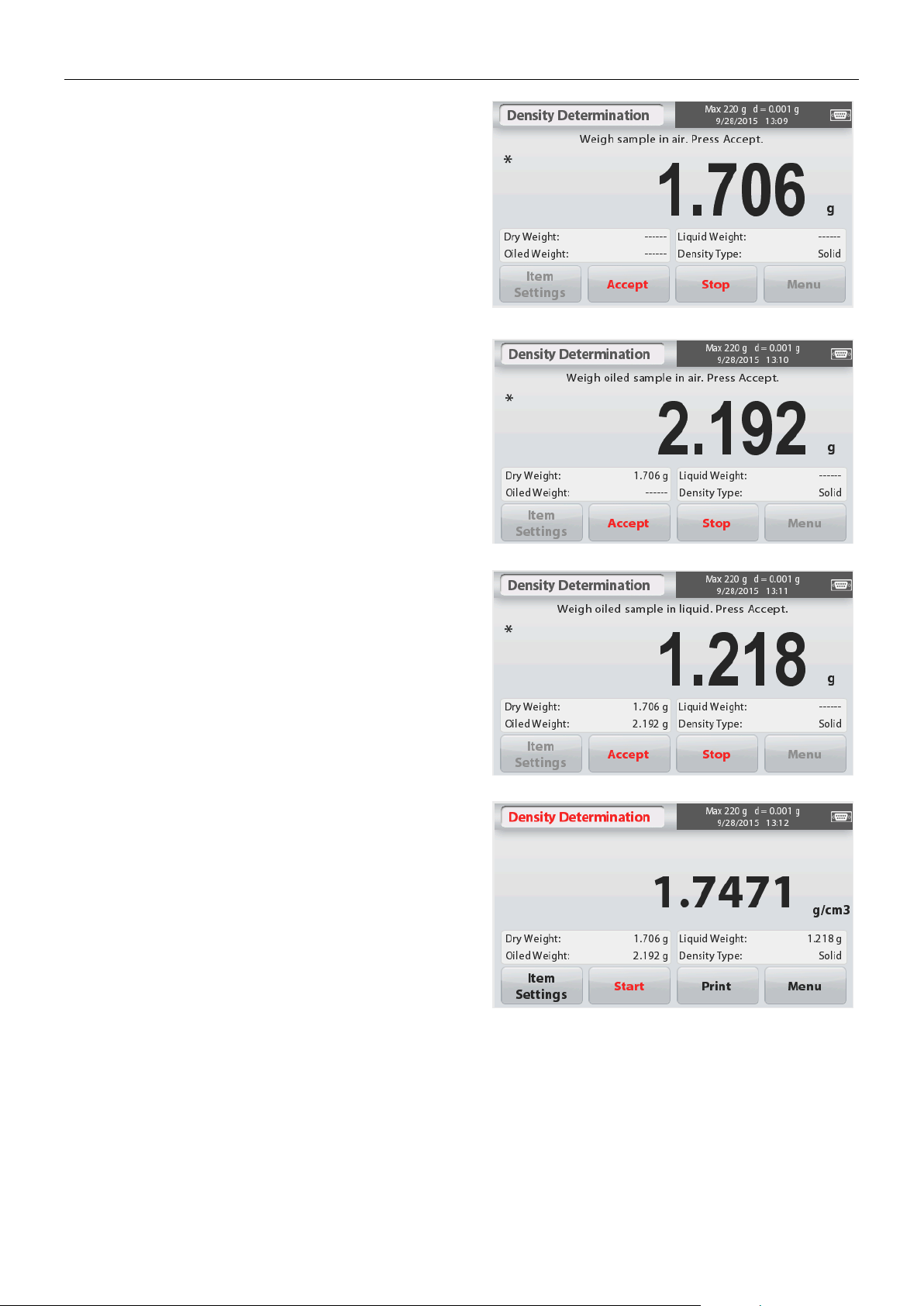

4.5.4 Measuring the Density of Porous Material Using Oil

STX EN-19

Step 2 of 3 – Weigh the Oiled Sample in Air.

Follow the screen instructions then press

Accept

to store the sample weight (oiled).

Step 3 of 3 – Weigh the Oiled Sample

Submerged in Liquid.

Follow the screen instructions then press

Accept

to store the oiled sample weight (submerged

in liquid).

Once the necessary weights have been

determined, the density of the sample is

displayed in g/cm3 (along with the weight in

air, un-oiled and oiled, and weight in water) on

the Application screen

The value stays on the display until Start is

touched.

Press

Start

to reset all the weight values and

restart the process.

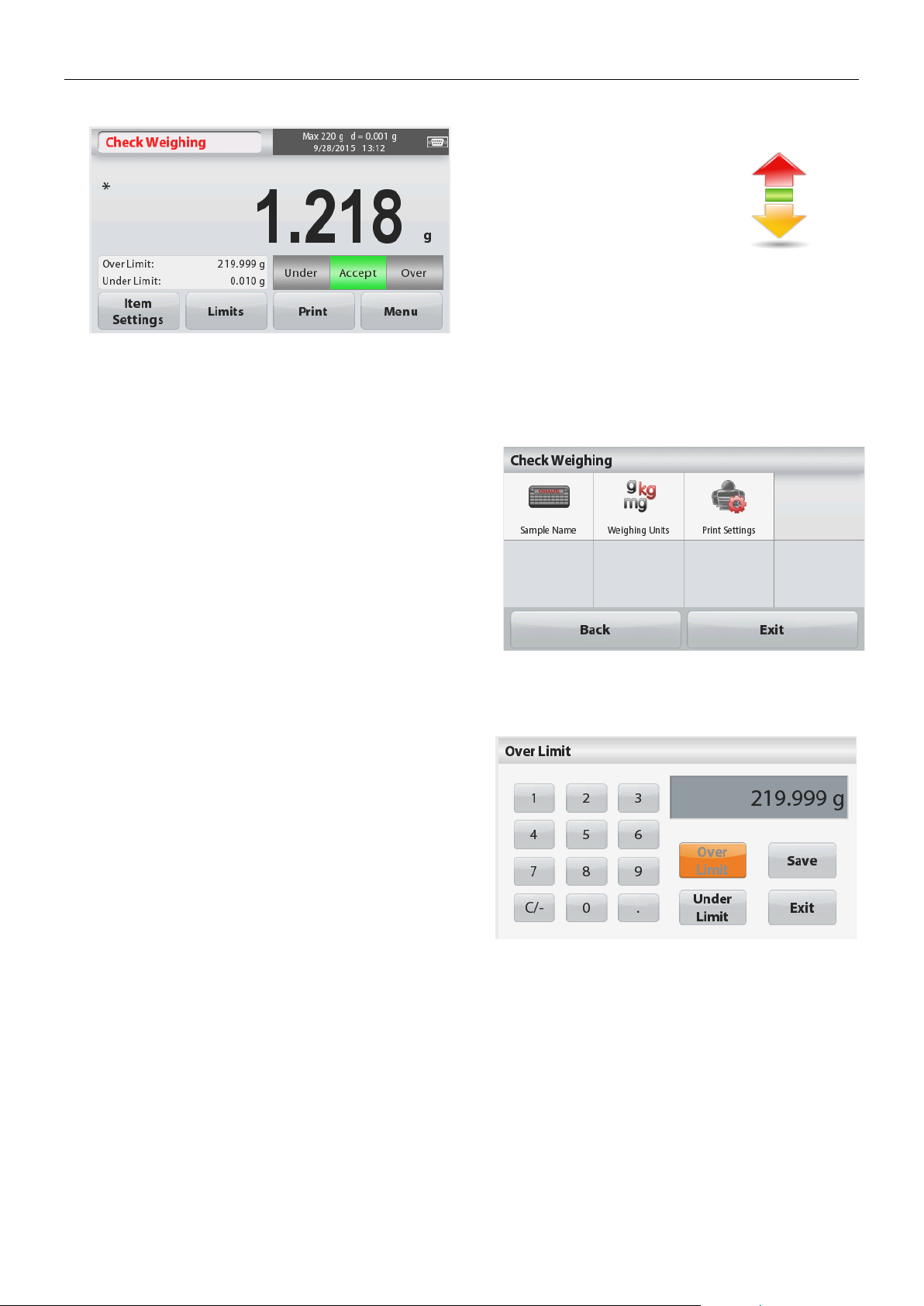

4.6 Check Weighing

Check Weighing is used to compare the weight of a sample against target limits.

1. In the upper left portion of the home screen, select Check Weighing.

2. The default (or last) Check weigh limits are displayed.

3. Place objects on the pan.

4. The Under/Accept/Over status is shown in the progress bar area while the actual weight of

the item is shown on the main Display Line.

EN-20 STX

Main Display Line

Reference Fields Application Icon

Application Buttons

Touch the Item Settings button. The Settings

screen appears.

Sample Name: Enter a sample name.

Weighing Units: Select the displayed unit.

Print Settings: To view or adjust the print

settings

Touch the

Limits

button. The limits settings

screen appears.

The check limit values are displayed in the

settings screen.

To set the Over Limit value, touch the Over

Limit button and then enter the desired limit

weight.

To set the Under Limit value, touch the

Under

Limit

button and then enter the desired limit

weight.

When finished, press

Exit

to return to

application home screen.

The CHECK WEIGHING Home screen:

4.6.1 Item Settings

To view or adjust the current settings

4.6.2 Limits

To view or adjust the current settings

Positive Check

Positive check is used to determine when the material added to the balance is within the target

range. In this case the UNDER and OVER limits must be positive values. (The OVER limit must

be greater than the UNDER limit.)

Add material to the balance until it is within the ACCEPT range.

STX EN-21

Main Display Line

Reference Fields Application Icon

Application Buttons

Touch the Item Settings button. The Settings

screen appears.

Mode: Select the mode to either Peak Hold or

Display Hold (default).

Sample Name: Enter a sample name.

Weighing Units: Select the displayed unit.

Print Settings: To view or adjust the print

settings

Negative Check

Negative check is used to determine when the material removed from the balance is within the

target range. In this case the UNDER and OVER limits are both negative values.

(The UNDER limit must be greater than the OVER limit.)

Place the item to be weighed on the balance and press TARE.

Remove a portion of the item until it is within the ACCEPT range.

Zero Check

Zero check is used when comparing subsequent samples to an initial reference sample. In this

case, the UNDER limit must be a negative value and the OVER limit must be a positive value.

Place the reference item on the balance and press TARE. Remove the reference sample and

place the item to be compared on the balance to determine if it is within the ACCEPT range.

4.7 Display Hold

The Display hold application allows the user to capture and store the highest stable weight in a

series of weight measurements.

In the upper left portion of the home screen, select Display hold.

The DISPLAY HOLD Home screen:

4.7.1 Item Settings

To view or adjust the current settings:

EN-22 STX

1. Place item on the pan and press

Hold

.

The capture process starts.

2. The Main Display Line now shows the first

stable weight.

3. Press Clear to remove the hold and return

to Display Hold Home screen.

1. Select Peak Hold Mode in Item settings

(see section 4.7.1).

2. Place item on the pan and press

Start

.

The capture process starts.

3. Continue to weigh items. The highest

stable weight will be held.

4. Press

Stop

to remove the hold and return

to normal operation screen.

1. Touch the upper left portion of the home screen.

Application menu appears. Touch the More icon to

enter next page then select Totalization if it is

present.

2. Place items on the pan to begin.

Main Display Line

Reference Fields Application Icon

Application Buttons

4.7.2 Display Hold Mode

This mode allows the user to hold a stable weight reading.

Follow the screen instructions to begin.

4.7.3 Peak hold mode

This mode allows the user to hold the highest stable weight reading.

Follow the screen instructions to begin.

4.8 Totalization

Totalization measures the cumulative weight of a sequence of items. The cumulative total may

exceed the capacity of the Balance. The maximum number of samples (n) is 99.

The TOTALIZATION Home screen:

STX EN-23

The sample weight is shown on the Main Display

Line.

3. Press Accumulate to add the weight of the

item to the total.

When stable, the new total is shown on the

secondary Display Line.

4. Remove the item from the weighing pan, then

add the next item and continue as above.

5. Press

Result

to view the accumulation results

and if needed print them out or save to a USB

flash drive.

6. When finished, press the

Clear Result

button.

A confirmation window will appear.

Press

Yes

to reset the total weight to zero.

Press No to return to the main screen.

Main Display Line

Reference Fields Application Icon

Application Buttons

4.9.1 Item Settings

To view or adjust the current settings:

Touch the Item Settings button. The Settings

screen appears.

Liquid Volume: Set the Solution volume of

the Liquid if molarity info is required.

Sample Name: Enter a sample name.

4.9 Mole Weighing

Use this application to measure the amount of a sample.

1. In the upper left portion of the home screen, select Mole (if it does not appear, press the

More icon).

2. Press Molar Mass to set the Molar mass of the substance.

3. Place the substance on the pan to begin.

The Mole Weighing Home screen:

EN-24 STX

Weighing Units: Select the displayed unit for

gross and tare.

Print Settings:

To view or adjust the print

settings

4.9.2 Enter Molar Mass

Press

Molar Mass

, and use the numeric

keypad to enter the required Molar Mass value

of the substance, and then press

Save

.

4.9.3 Calculate Molarity

The Molarity is only calculated when the Liquid

Volume is set up. If Liquid Volume is set, the

Molarity value can be seen at the bottom right

window block.

4.10 Additional Features

4.10.1 Weigh Below

The Scout Balance is equipped with a weigh below hook for weighing below the balance.

The weigh below hook is located at the reverse side of the battery cover as shown below.

To use this feature, remove the red protective cover underneath for the weigh below opening.

Attention:

Support (if present), and turn the transportation lock to “locked” position to

prevent damage.

Before turning the balance over, remove the Pan and Pan

STX EN-25

Use an optional interface connectivity kit to

connect the balance either to a computer, printer

or OHAUS auxiliary display.

Below Interface kit accessories are available:

RS232, USB Host, USB Device, Ethernet,

Bluetooth®*.

Interface connection on the rear of the

balance:

* Interface kits may vary according to local regulations

Interface connection

AC Adapter Jack

Security Slot

Weigh Below Hook

Weigh Below Hook installed

Weigh below opening

The balance can be supported using lab jacks or any other convenient method. Ensure the

balance is level and secure and that the transportation lock has been released. Power on the

Balance, then use a string or wire to attach items to be weighed.

4.10.2 Connecting the Interface

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG,

Inc. and any use of such marks by OHAUS is under license.

EN-26 STX

Enter the Menu

From any Application screen, Touch Menu.

The Main Menu List appears on the display.

Select the Sub-Menu

Locate to the desired item of the Main Menu

List and touch it. The Sub-Menu appears.

Select the Menu Item

Continue until the desired setting is chosen in

the Menu list. Touch the setting to change it.

The changed setting will be displayed as

highlighted yellow for about 1 second to

confirm the changed value.

5. MENU SETTINGS

5.1 Menu Navigation

All menu navigation is performed by touching the display. To enter the Menu, touch Menu

from any Application Home screen. The Main menu appears, with buttons for Back and Exit.

Continue touching the appropriate list item to navigate to the Menu items or touch a button to

change location.

When the Security Switch is in locked position, the Calibration and Lockout menus will be

hidden.

Security switch:

5.1.1 Changing Settings

To change a menu setting, navigate to that setting using the following steps:

Exit the Menu and Return to the Current Application

After the setting is confirmed, touch Back or Exit to return to the Application.

Loading...

Loading...