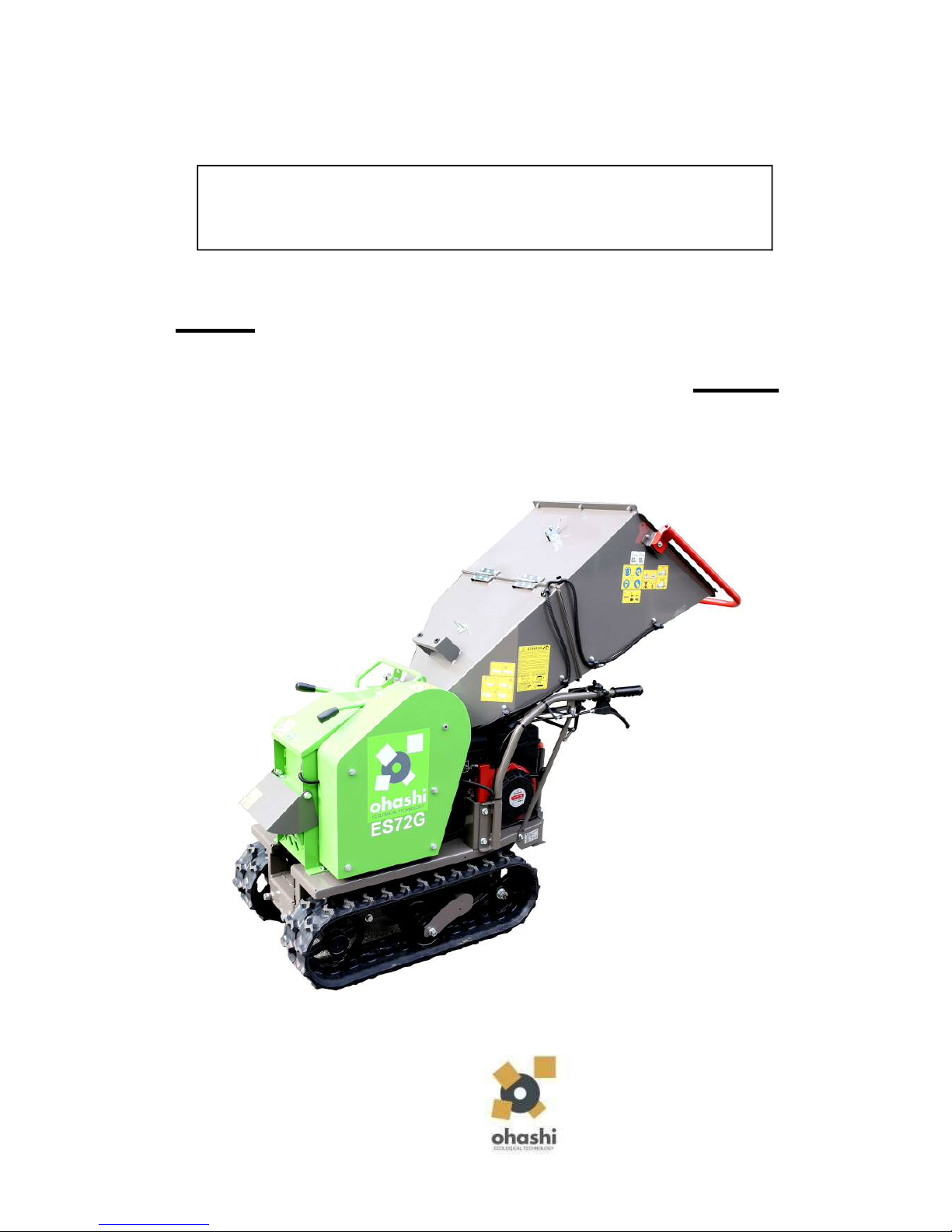

OHASHI ES72G Operation Manual

ORIGINAL INSTRUCTIONS

WOOD CHIPPER

ES72G

OHASHI INC.

401 Sakimura, Chiyoda, Kanzaki

Saga 842-0065, Japan

EUROPE TEL : +44 20 3286 2252

JAPAN TEL : +81 952 44 3135

WEB : www.ohashi-inc.com

E-mail : global@ohashi-inc.com

is separately provided by the engine manufacturer.

safety instructions, controls, servicing and maintenance of the

OPERATION MANUAL

Before attempting to operate this machine, read and fully understand

the contents of this Operation Manual. Make yourself familiar with

machine. Operators must also read through the engine manual which

INTRODUCTION

To operate this machine most comfortably and effectively, it is essential for you to perform daily checks

and regular inspection, servicing and maintenance jobs. This can be likened to your medical check-up.

To keep the machine in optimum condition at all times and prevent accident and injury, carry out daily

checks and servicing on a routine basis.

Take care of detecting even a small problem in the early stage before it becomes a big problem. If you have

some problem with the machine, do not put the machine into operation. Please feel free to contact and

consult the dealer from whom you purchased the machine to solve the problem.

When notifying the dealer, please report MODEL NUMBER and SERIAL NUMBER of the machine,

For the purpose of product improvement, specifications including spare parts may change without prior notice.

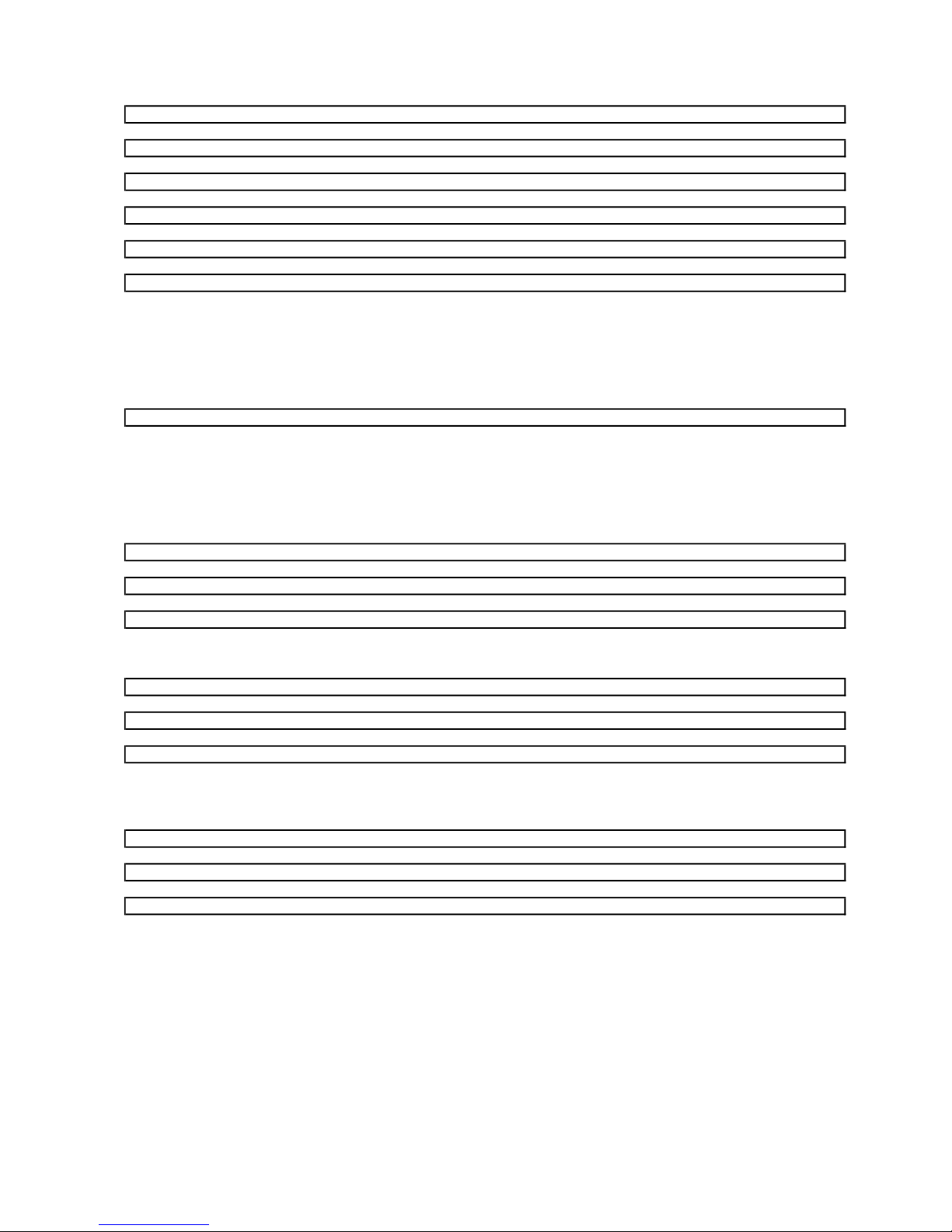

CONTENTS

SAFETY INSTRUCTIONS

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・

1

DECALS

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・ ・・・・ ・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・

2

USE OF THIS MACHINE AND SPECIFICATIONS

・・・・・・・ ・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・

11

NAME OF THE COMPONENT PARTS

・・・・ ・・・・・・・・・・・ ・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・

12

PRE-OPERATING CHECKLISTS

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・

13

HOW TO OPERATE MACHINE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・ ・・・・・・・ ・・・・

15

STARTING THE ENGINE

・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・

15

DISPATCH UNIT ANGLE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・

19

HOW TO DRIVE THE MACHINE

・・・・ ・・・・・・・・・・・ ・・

16

ROTOR CLUTCH

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・

19

HOW TO STOP THE MACHINE

・・・・ ・・・・・・・・・・・ ・・

16

FEED ROLLER OPERATION

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・

20

ADJUSTING THE THROTTLE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・

17

FEED ROLLER SAFETY BAR

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・ ・・・・ ・

20

TURNING THE MACHINE

・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・

17

FEED ROLLER CLOGGING PREVENTION

・・・・ ・・・・・・

21

LOADING, UNLOADING & SLOPES

・・・・ ・・・・・・・・・・・ ・・・・・

18

FEED ROLLER CLOGGING RELEASE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・

22

REGULAR MAINTENANCE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・

23

KNIFE BASICS

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・

23

PARKING BRAKE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・

28

REMOVE & AFFIX KNIVES

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・

24

ROTOR CLUTCH

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・・・・

29

KNIFE ADJUSTMENT

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・

25

FEED ROLLER CHAIN

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・

30

RE-FUELING

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・・・・・・・・・・・ ・・・・ ・・・・・・・ ・・・

26

RUBBER CRAWLER

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・

31

TRANSPORT CLUTCH ADJUSTMENT

・・・・ ・・・・・・・・・・・ ・・・・・・・・ ・・・・・・

27

ENGINE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・ ・・・・ ・・・・・

32

TURNING CONTROL LEVER ADJUSTMENT

・・・・・・・・・・・ ・・・・・・・・・・・・・・・・ ・・

27

LUBRICATION CHART

・・・・・・・ ・・・・ ・・・ ・・・・ ・・・・・・・・・・・ ・・・・・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・

35

TIGHTENING NUTS & BOLTS

・・・・・・・ ・・・・ ・・・ ・・・・ ・・・・・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・

36

SERVICING AFTER OPERATION/LONG TERM STORAGE

・・・・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・

37

SERVICING AFTER OPERATION

・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・・

37

ACCESSORY TOOL LIST

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・

38

LONG TERM STORAGE

・・・・・・・ ・・・・ ・・・ ・・・・ ・・・

38

LIST OF THE CONSUMABLE PARTS

・・・・ ・・・・・・・・・・・ ・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・

39

TROUBLESHOOTING

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・

40

MAINTENANCE SCHEDULE

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・

42

NOISE TEST

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・

43

ELECTRONIC WIRING DIAGRAM

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・ ・

45

MACHINE DIMENSIONS

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・・

44

CE DECLARATION OF CONFORMITY

・・・・・・ ・・・・ ・・・・・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・ ・・・ ・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・

46

WARRANTY STATEMENT

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・・・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・ ・・・・・・

47

JUST IN CASE OF EMERGENCY

・・・・ ・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・ ・・・・・・・ ・・・・・・・ ・・・・・・・・・・・ ・・・・

48

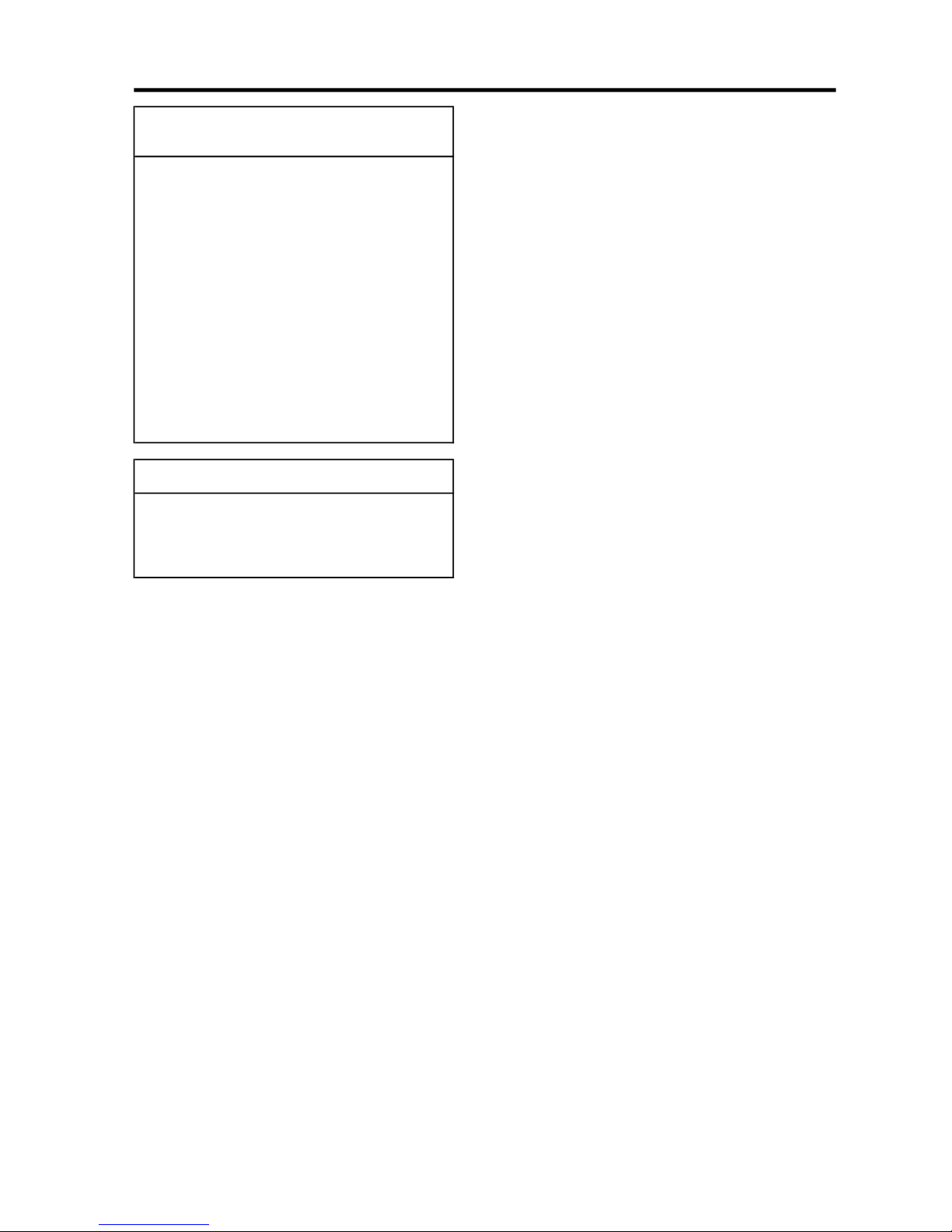

SAFETY INSTRUCTIONS

7. Never operate the machine alone. This

machine must be operated by two or more

operators.

1. This operation manual must be retained within

easy access of operators. Operators must be 8. Never attempt to touch the muffler and

careful not to lose or damage the operation

surroundings during operation because it

manual. becomes very hot.

2. If the operation manual is missing or illegible

due to damage, obtain new one from our 9. Don't directly touch the feed roller or

dealers and retain it within easy access. its attaching portions.

3. If the machine discussed in this operation

manual is rented, be sure to provide the manual 10. Do not insert your fingers into the shooter

with the machine. Let the renter read and or low dispatch unit. Your hands might be

understand the manual. Give new operators caught in the rotor and this could cause

proper instructions and training before they serious injury.

start operating the machine.

4. If the machine is transferred to other people, 11. Gasoline is extremely flammable.

make sure that this operation manual is Extreme caution must be taken when handling

provided with the machine. the fuel.

(1) Use only fresh, clean gasoline.

(2) Use an approved fuel container for the fuel

tank. Fuel container's outlet must fit the

fuel tank's inlet. Check to see if these

1. Operators of this machine must read and ports fit. If not, use a suitable fuel pump.

understand the contents of this operation (3) Do not remove the fuel tank cap or add fuel

manual before attempting to operate it.

while the engine is running or hot.

2. If safety decals are torn and illegible, obtain (4) Do not fill the fuel tank indoors.

new ones from our dealers and replace them. (5) Wipe off any spilled fuel.

(6) Do not use gasoline as a cleaning fluid.

1. Read through this operation manual and make (7) Never smoke while handling gasoline.

yourself familiar with the operation, servicing and

(8) Do not handle fuel near a naked flame or

maintenance of this machine before use. uncovered electric light.

(9) Keep the fuel container away from open

2. Never operate the machines without repairing or flames and equipment that may spark.

replacing the deformed or defective parts.

12. Wait until the machine has cooled before

3. Never alter or modify this machine. storing indoors and remove key.

4. The machine cannot be towed on crawlers on 13. When performing maintenance with two or

a public road. Extended towing on crawlers more people stay aware of each others

will damage machine. location by talking to avoid accidents.

5. If towing very short distances on crawlers 14. Remove chips or other material in and around

at no more than allowable top speed of the crawlers as this could cause

gear in use, always tow using a vehicle transmission troubles.

with enough driving and braking force. Be

very careful on slopes. 15. Never perform chipping operations inside

a building.

6. When a machine is loaded/unloaded on/from

truck or trailer for transport, stop the truck on

a level surface, engage the truck's parking

brake, and position it securely with

wheel stoppers. Extreme caution must

be taken not to topple the machine from

the ramps or truck. (refer "

Loading, Unloading &

Slopes

")

CAUTION

CAUTION

-1-

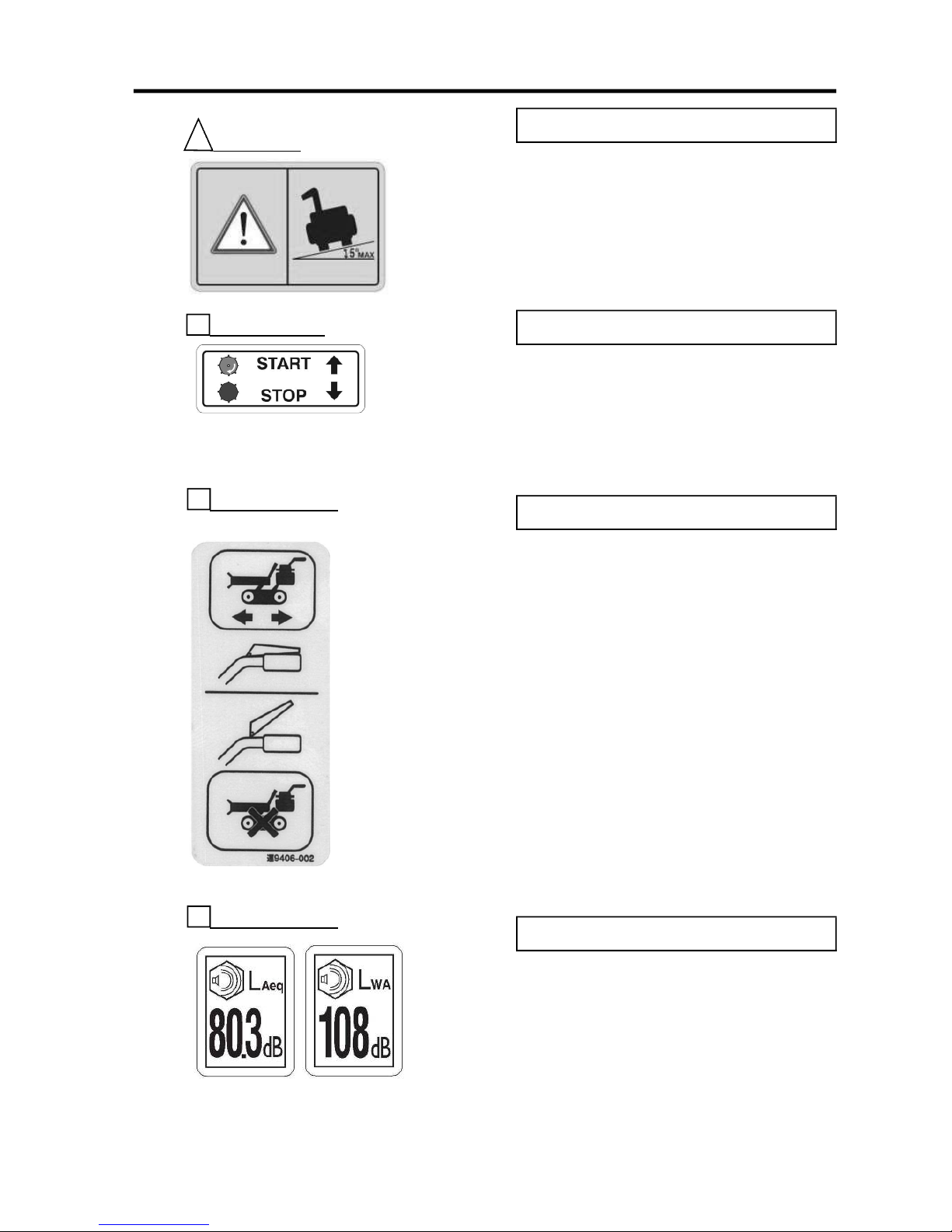

DECALS

Before attempting to operate the machine, read these decals and fully understand the instructions

and meaning. If any decal is worn, damaged, illegible or missing, obtain new one from our dealers.

Safety decals must be placed to their proper location as indicated below.

For locations of other decals, see the following photographs and illustrations and affix them

to their respective places. Keep all decals always legible.

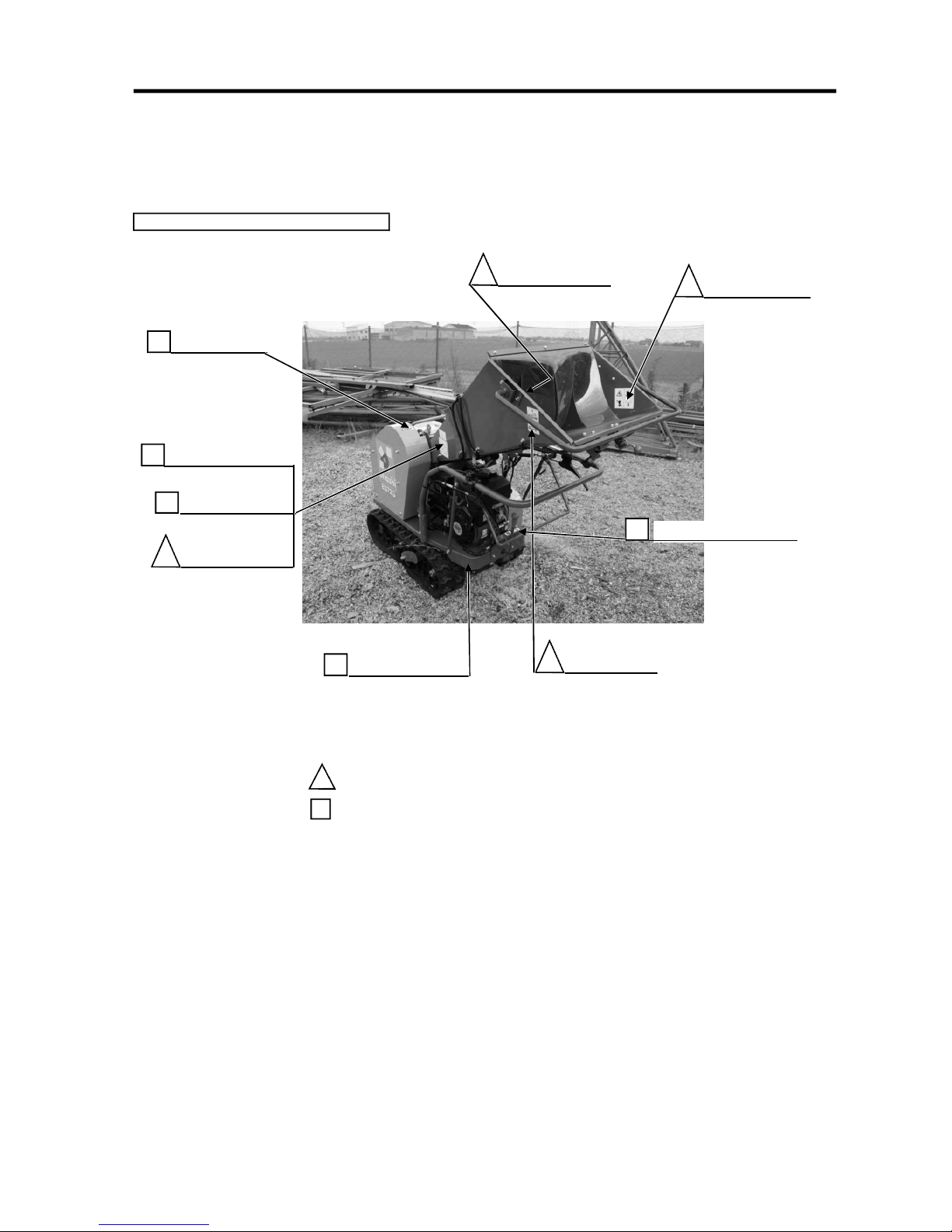

Location of SAFETY decals

SAFETY BAR

1

SAFE AREA

OF OPERATION

5

4

CRAWLER

FEED ROLLER

20

I

NSTRUCTION

DECAL

SAFETY

DECAL

IDENTIFICATION

PLATE

2

BEFORE

STARTING ENGINE

3

6

OIL

24

SHIFT LEVER

CUTTING & CHIP

PROJECTILE

23

-2-

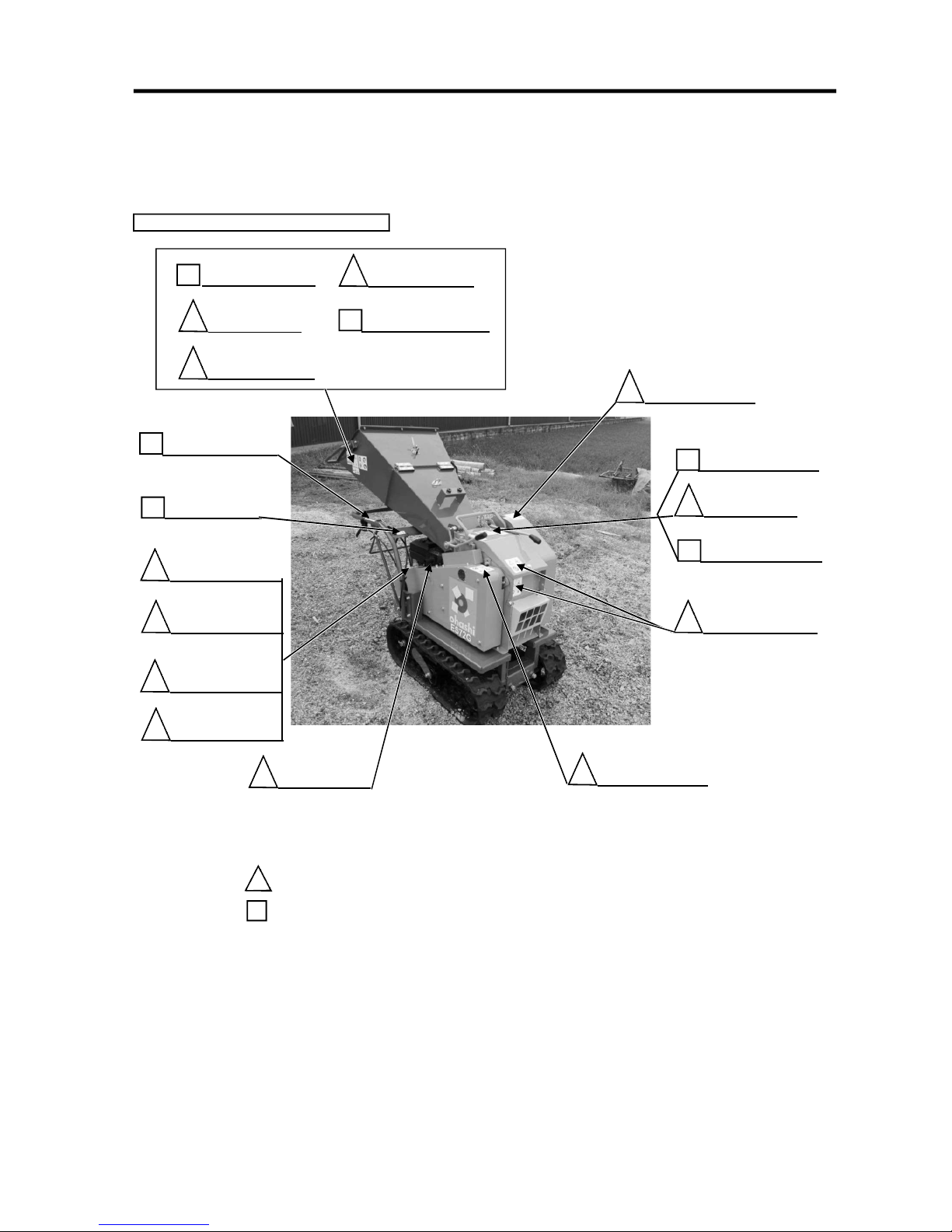

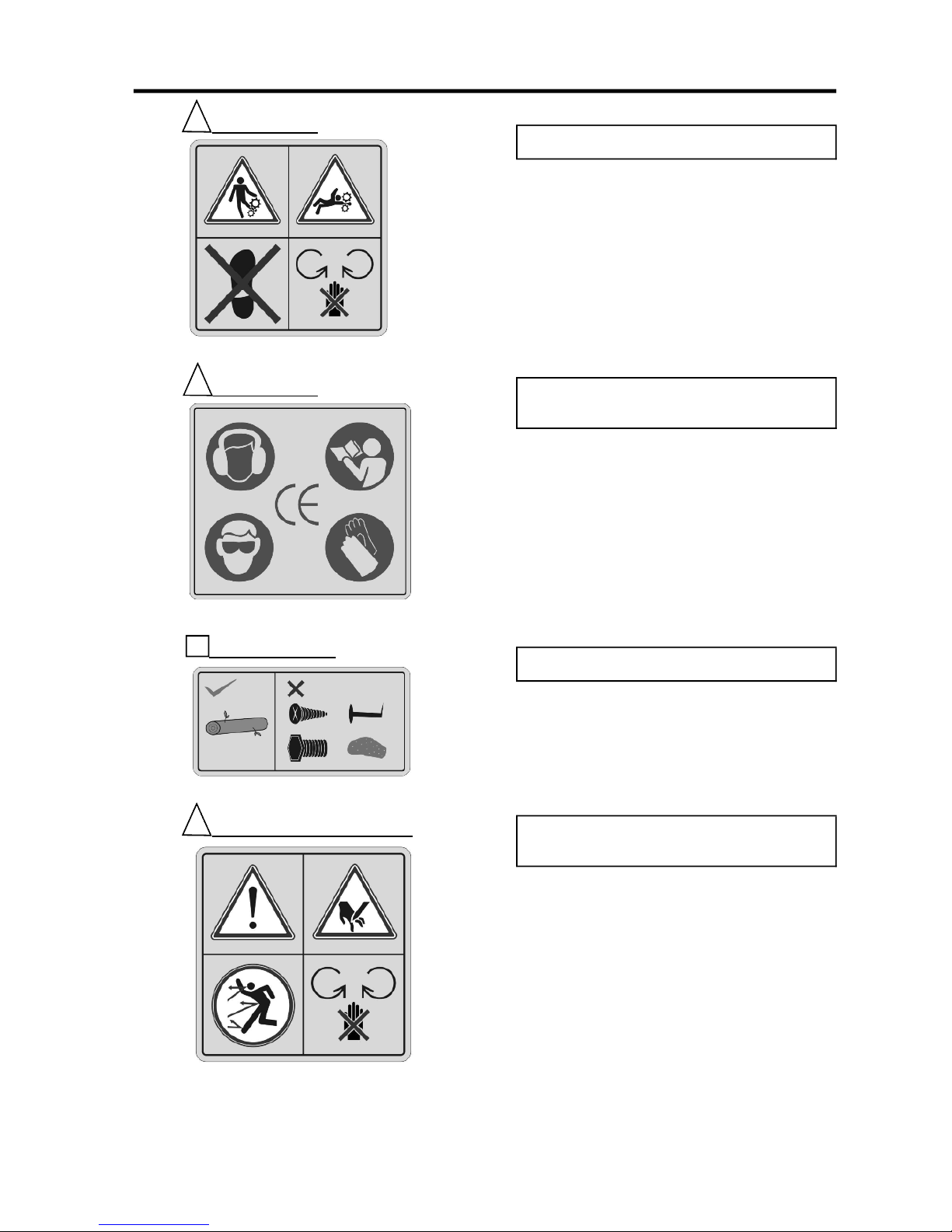

DECALS

Before attempting to operate the machine, read these decals and fully understand the instructions

and meaning. If any decal is worn, damaged, illegible or missing, obtain new one from our dealers.

Safety decals must be placed to their proper location as indicated below.

For locations of other decals, see the following photographs and illustrations and affix them

to their respective places. Keep all decals always legible.

Location of SAFETY decals

I

NSTRUCTION

DECAL

SAFETY

DECAL

FEED BOX

9

CUTTING PARTS

11

MUFFLER

12

18

BRAKE HANDLE

SAFETY BAR

1

FEED ROLLER

20

SAFETY WEAR

21

22

FEED MATERIALS

19

SOUND LABELS

MOVING PARTS

7

FEED ROLLER

RELEASE LEVER

8

ROTOR

CLUTCH LEVER

10

MOVING PARTS

7

CRUSHING

RISK

13

LOADING &

UNLOADING

14

SLOPE

STABILITY 1

15

SLOPE

STABILITY 2

16

17

FEED SWITCH

-3-

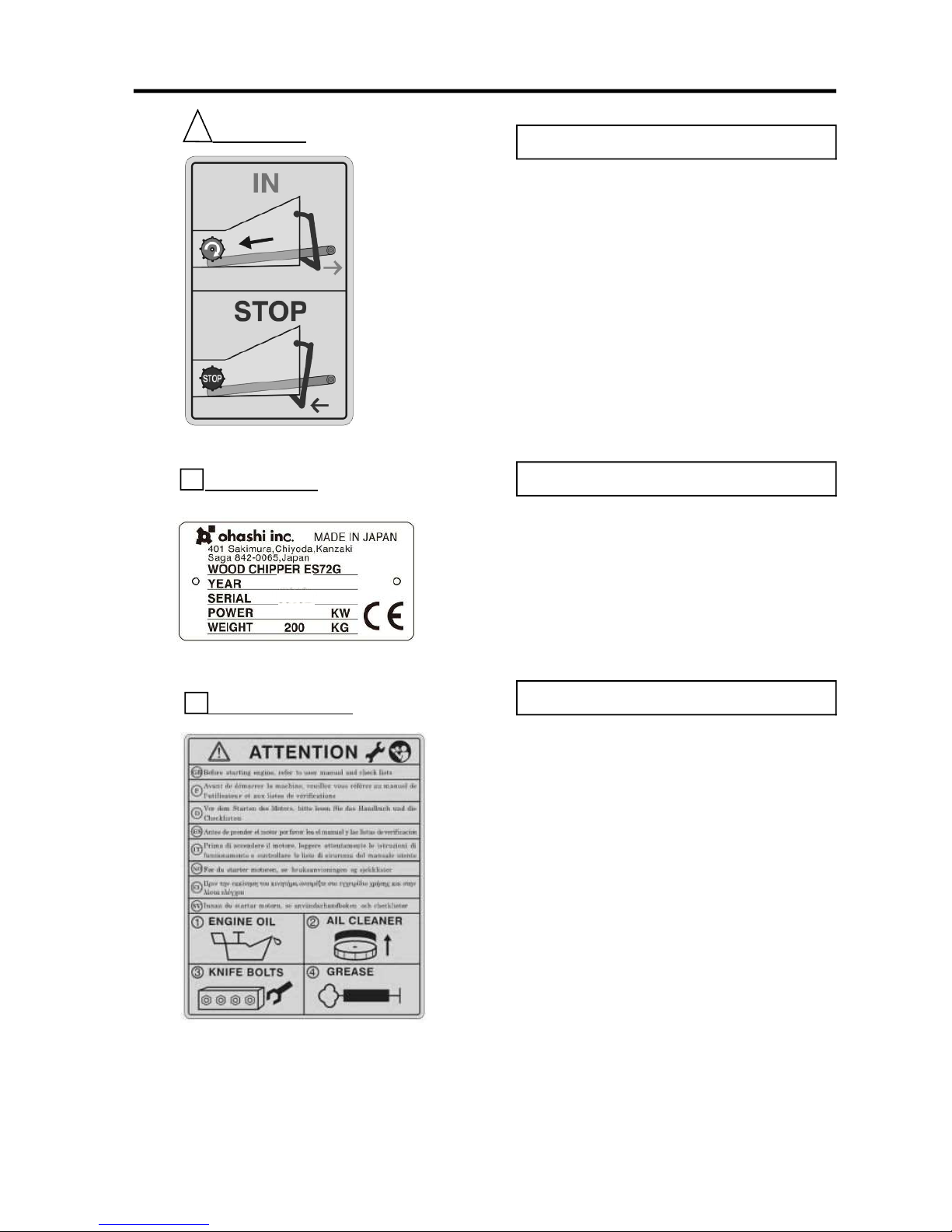

DECALS

The safety bar operates to stop the feed roller in

the case of an emergency.

Pull the safety bar out to activate the feed roller

so that feed material is pulled into the machine.

Push the safety bar in to de-activate the feed roller

so that the feed roller no longer move.

The details of Ohashi inc., the CE mark and

the specific details of the machine purchased.

Before starting the engine perform the following

to maintain the machine in good condition.

As well as reading the user manual and

checklists before starting the engine users

must especially take care of the following

4 points to maintain the machine in good

condition and prevent damage to the machine.

SAFETY BAR

1

IDENTIFICATION

PLATE

2

BEFORE

STARTING ENGINE

3

5.1

-4-

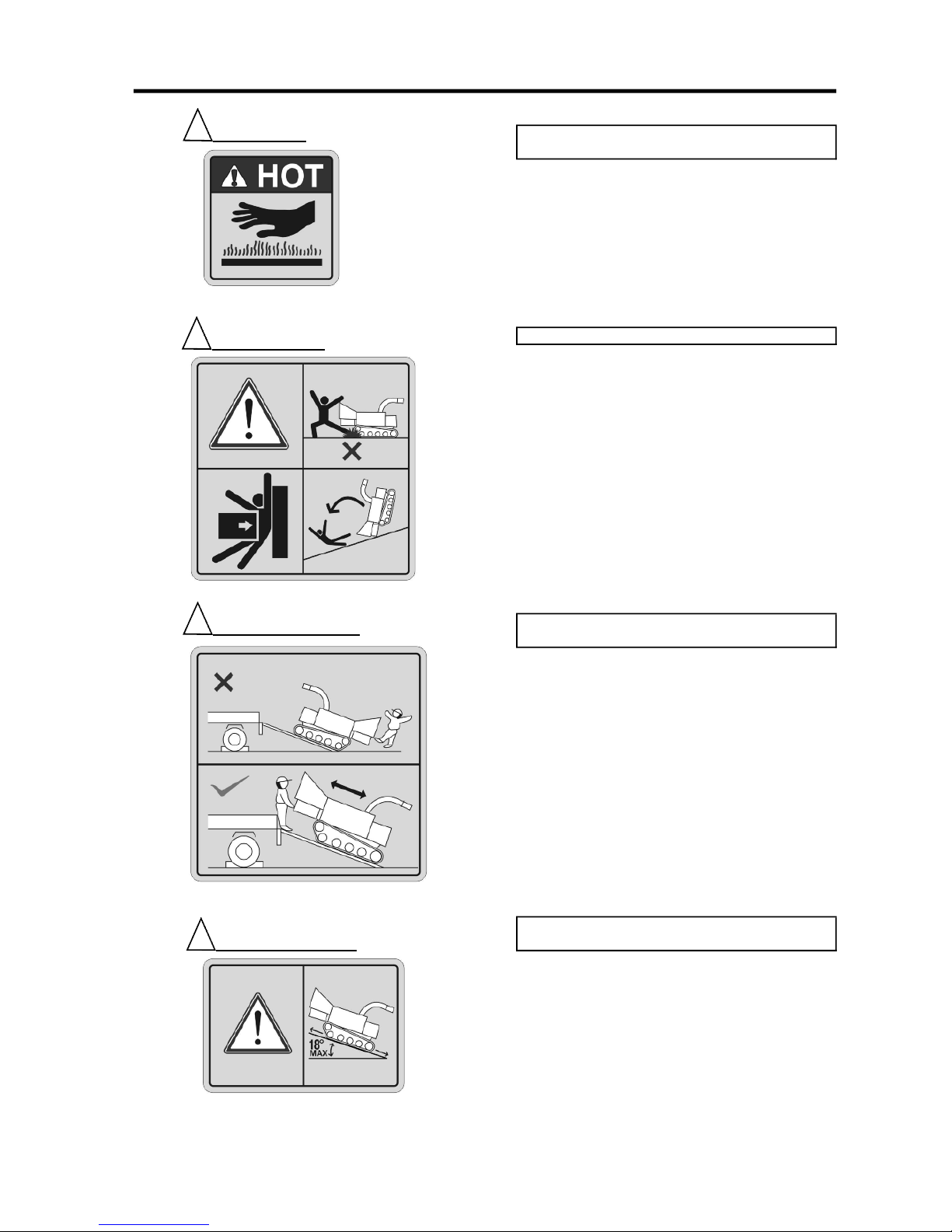

DECALS

The crawlers and the area between the crawler

wheels should be kept clean and free of

materials.

Be sure to clear the crawlers from any materials

as this may damage the transmission.

The area around the machine should be checked

thoroughly before operating the machine.

Check around the machine before use. Check

for things you may not see from the operators

control area.

Be careful not to damage the crawlers or the

transmission by driving into holes or over

obstacles.

Oil lubrication points.

Refer to "

Lubrication Chart

" in this

user manual for further instructions.

Moving parts of the engine and machine are

dangerous and may cause injury.

Engine belts and other moving parts of the engine

and machine can cause injury if touched during

motion.

Do not attempt to remove covers while the

machine is running or moving parts are moving.

4

CRAWLER

SAFE AREA

OF OPERATION

5

6

OIL

MOVING PARTS

7

-5-

DECALS

The feed roller can be rotated manually if it

becomes clogged.

Refer to "

Feed Roller Clogging Release

" section

in this user manual for further instructions.

The feed box when in motion can be dangerous

and cause injury.

The feed roller when activated can move up and

down creating movement of the feed box. This

movement can cause injury so therefore do not

approach or put your hands or body near the

feed box when the machine is operating.

The rotor clutch lever activates the rotor.

Pull the rotor clutch lever from OFF to ON slowly.

Ensure the throttle is at full.

Pause between OFF and ON so that the rotor

clutch engages.

Moving parts here will cut flesh and cause

serious injury if touched by a persons hands

or other body parts.

Do not remove safety covers while the engine is

on or moving parts have not yet stopped.

FEED ROLLER RELEASE

8

FEED BOX

9

ROTOR CLUTCH LEVER

10

CUTTING PARTS

11

-6-

DECALS

The muffler is hot during and after operation. Do

not touch or a burn injury may occur.

Even after use the muffler may remain hot.

Wait until the machine cools down before making

any contact with the muffler.

Be careful to avoid being crushed by the machine.

Be careful not to have your feet or other body parts

crushed under the moving crawlers.

Be careful not to be crushed while driving the

machine between the machine and another object.

Be careful not to drive the machine at a dangerous

speed on a slope or on a slope which is too steep

or the machine may tip and crush you.

Load and unload the machine in the correct

manner or injury may occur.

When loading or unloading the machine onto a

truck, trailer, van or higher platform using ramps

do not stand on the downward side of the machine.

Always stand upward from the machine in the

higher position so that if the machine rolls or

tumbles you are in a safe position.

Only drive the machine up/down a slope of

18° or less.

When unloading or loading or when driving the

machine anywhere do not drive the machine on

a slope of more than 18° in a straight up or down

direction on the slope.

MUFFLER

12

CRUSHING RISK

13

LOADING & UNLOADING

14

SLOPE STABILITY 1

15

-7-

DECALS

Only drive the machine across a slope of 5°

or less.

When unloading or loading or when driving the

machine anywhere do not drive the machine on

a slope of more than 5° in a horizontal across

direction along the slope.

The feed switch controls the movement of the

feed roller.

Move the switch to START to activate the feed

roller to pull materials into the rotor.

Move the switch to the STOP area to stop the

feed roller movement.

The brake handle activates the transmission

and initiates the movement of the machine.

To initiate the movement of the machine hold down

the brake handle.

To stop the movement of the machine let go of

the brake handle and let it rise to the up

position.

Sound labels display the sound levels which

users are likely to be exposed to.

Users must use ear protection equipment

when operating this machine and must insist

other people close to the machine also wear

ear protectors.

18

BRAKE HANDLE

SLOPE

STABILITY 2

16

17

FEED SWITCH

19

SOUND LABELS

-8-

DECALS

If caught in the feed roller serious injury will

occur.

Do not place your hands, feet or any other body

part near the feed rollers.

Do not attempt to climb into or on the lower edge

of the hopper or you may be caught in the feed

roller.

Read the user manual, and wear helmet, ear

protectors, eye protectors, gloves and non-snag

clothing before using the machine.

The machine is only designed to chip organic

material like wood.

Do not place sand, dirt, metal, stones, plastic,

rope, clothing, cardboard, books, newspapers

rubber, glass or any other non-wood material

into the hopper to be chipped or damage will

occur to the machine.

Moving parts may cut flesh and cause serious

injury. Feed material occasionally projected out

of the hopper can cause injury.

Do no place hands or body parts near the area

where moving parts may cut flesh and cause

injury. Do not remove covers while the machine

is on or moving parts have not stopped.

Do not stand in front of the hopper while the

machine is processing feed material. Stand to

the side to avoid being struck by feed material

that occasionally projects out of the hopper.

SAFETY WEAR

21

FEED ROLLER

20

22

FEED MATERIALS

CUTTING & CHIP PROJECTILE

23

-9-

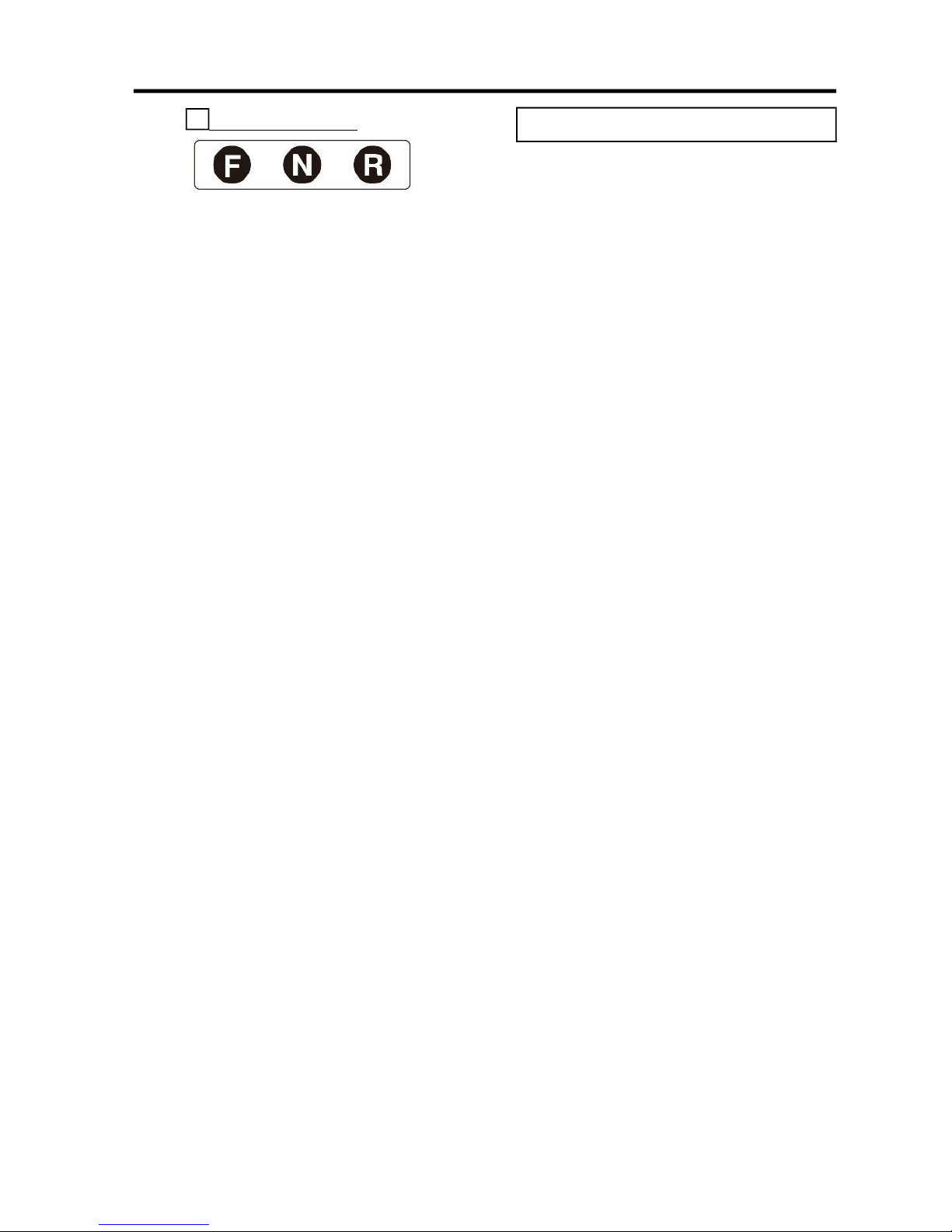

DECALS

The shift lever allows the machine to move

forward or in reverse.

To initiate the movement of the machine, move

the shift lever to FORWARD or REVERSE and

hold down the brake handle.

24

SHIFT LEVER

-10-

USE OF THIS MACHINE AND SPECIFICATIONS

This operating machine is designed to chip / shred wood and other similar organic materials.

Make sure before chipping that no materials such as soil, sand, stones, metals, bottles etc.

are contained in the woods.

Do not use the machine in any other way than its intended use.

Description Wood chipper / shredder

Model No. ES72G

Overall LengthxWidthxHeight (mm) In use - 1690x660x1370 In transport - 1280x660x1455

Weight (kg) 200

Drive Belt clutch, V-belt

Max. diameter of wood treated (mm) 70

Cutting 2 chipper knives and a counter knife

Infeed dimensions (mm) 180x90

Feeding system

Electromagnetic clutch with automatic no stress system

Discharge system

Forced by air

Height of duct (mm) 540

Discharge angle

Adjustable

Transport system Rubber crawler

Forward : 1.9 Km/h

Reverse : 1.9 Km/h

EX21D Subaru Gasoline Engine

Max. output 7 HP / 5.1 kW

Fuel tank capacity (

) Approx. 3.2, Unleaded gasoline

Note: As product improvement takes place, specifications may change without prior notice.

For engine and battery, refer to respective manufacturer handling manuals.

USE OF THIS MACHINE

SPECIFICATIONS

Transport speed

Engine Model

-11-

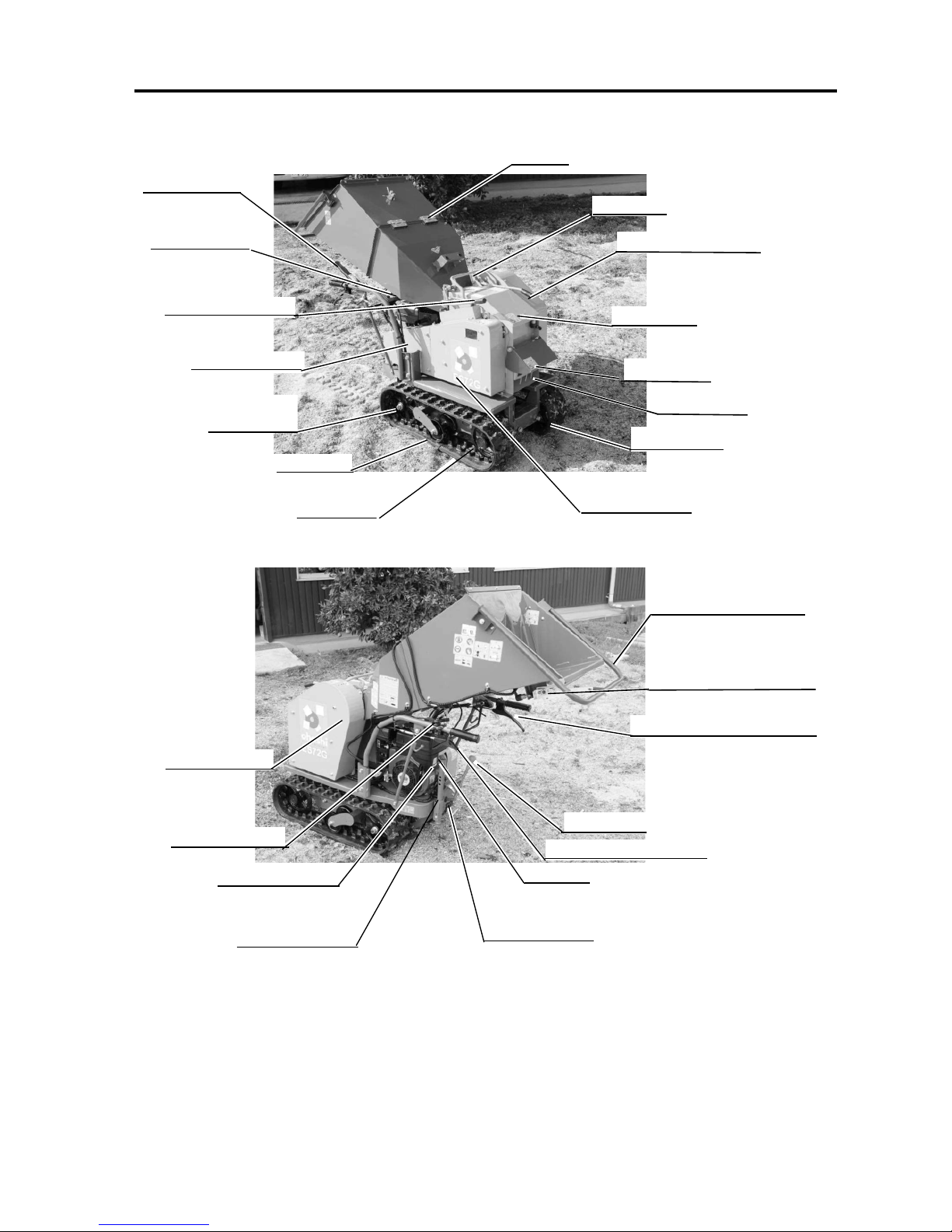

NAME OF THE COMPONENT PARTS

See the machine with your own eyes and identify each component.

Right Turning Control Lever

Rotor Clutch Lever

Hopper

Rotor Cover

Left Side Cover

Shift Lever

Transmission

Throttle Lever

Idle Wheel

Sprocket &

Wheel

Right Side Cover

Right Side Cover

Engine

Left Turning Control Lever

Crawler Tracks

Feed Roller Release

Track Roller

Recoil Start Cord

Feed Box

S

afety Bar Release Lever

Feed Roller Safety Bar

Feed

S

witch

D

ispatch Unit

Safety Guard

Brake Handle

Balance Stand

-12-

PRE-OPERATING SAFETY CHECKLIST

To prevent injuries and fire hazards, comply strictly with the following instructions.

BEFORE STARTING ENGINE AND ACTIVATING TRACK CRAWLERS

1. All safety and operating sections of User Manual

MUST

have been read, understood and applied where

applicable.

2.

CHECK

all machine safety covers, guards and housing are closed and fitted securely with securing

devices, bolts, locks etc and if engine is running

DO NOT REMOVE

. Do not lose covers' nuts and bolts.

3. Walk at least once around machine to

ENSURE

there are no obstacles, people or small children

near machine and Track Crawlers and maintain your visibility of surrounding areas at all times.

4.

ENSURE

Rotor Clutch Lever is in OFF position, Shift Lever in N Position, Feed Switch in STOP

position and that Brake Handle is in the up position.

5.

ENSURE

machine is in a well ventilated, open area. Exhaust fumes are very dangerous when breathed.

6.

ENSURE

machine is located on a flat, stable area.

7.

CHECK

for fluid leaks. If found

CONSULT

User Manual or dealer to locate the source and apply a remedy.

8.

WEAR

appropriate clothing, helmet, protectors for eyes, ears and gloves for hands. Clothing

MUST

fit

operator tightly. Loose clothing

MUST

be avoided as it may get caught and pull operator into

machine, causing serious injury or death.

9.

NEVER

smoke while operating machine or when handling fuel for refueling or transport.

NEVER

refuel

or handle fuel near open flames or uncovered electric lighting.

BEFORE OPERATING THE CHIPPING FUNCTIONS (Feed Roller and Rotor)

1.

TEST

Feed Roller Safety Bar is working properly in Emergency Stop Position and Forward Feed Roller

Position. If it is not working contact your dealer to repair the bar and / or it's sensor immediately.

2. This machine is designed to chip / shred wood and similar organic material.

ENSURE

soil, sand, stones,

metals, rope, glass, wires and other such non-organic man-made materials are

NOT

contained in

material to be inserted for chipping / shredding.

3.

DO NOT

operate machine's chipping / shredding functions on slopes and / or inside a building.

4.

ENSURE

that no person is located close enough to Dispatch Unit to be struck by wood chips

and that Dispatch Unit is securely fixed in position so as not to move during operation.

5.

ENSURE

before chipping and switching the Rotor Clutch Lever ON, that the engine is at full throttle.

6.

SET

the Balance Stand so that the machine is stable.

BASICS

1.

NEVER

have safety covers off or refuel with engine on, parts still moving or machine still hot.

2.

PERFORM

inspections or tests of machine in an open, flat area free of obstacles and hazards.

3.

REPLACE

all covers, guards and housing parts after any inspection is performed.

4. If you feel any strange noise / vibration in machine,

STOP

the engine and

AFTER

moving parts have

stopped consult your User Manual, inspect machine and if necessary contact your dealer.

5. Before leaving machine unattended,

CONFIRM

that engine is off, and all moving parts stop,

and the Rotor Clutch Lever and Feed Switch are in the OFF/STOP position and the Brake Handle is up.

6.

INSPECT

and clean machine parts after use.

7.

NEVER

drive up / down a slope slanting more than 18 ° or drive sideways on a slope slanting more

than 5° and always stand up slope from the machine when driving.

8.

DO NOT

operate in insufficient lighting or in a situation where visibility is poor.

9.

DO NOT

operate machine if tired, sick or under the influence of drugs or alcohol.

10.

DO NOT

allow a child and / or untrained person to operate machine.

11. Where materials become caught in Feed Roller

DO NOT

remove directly with hands.

USE

a

wooden broom or other such long wooden object to remove stuck material.

12.

STAND

to the side of Hopper during operation to avoid being hit by infeed materials returning irregularly.

13.

DO NOT

place hands near the Feed Box while the Feed Roller is in operation.

-13-

PRE-OPERATING MACHINE CHECKLIST

To keep machine in top working condition, comply strictly with the following instructions.

1.

CLEAN

air cleaner

2.

CHECK

engine oil level, cleanliness and for any spillage (SE grade or above)

※

1

3.

CHECK

for cracks and / or wear on the chipper knives

4.

CHECK

for cracks and / or wear on the counter knife

5.

CHECK

for cracks and / or wear on the shredder knives and that the knives axle is secure

※

2

6.

RETIGHTEN

the bolts of chipper knives and counter knife

7.

GREASE

Lubrication Points as per the User Manual Lubrication Chart using a lithium grease

8.

LUBRICATE

machine parts as per the User Manual Lubrication Chart and ensure machine

has sufficient transmission oil, and gasoline

※

3

9.

CLEAN

engine and track crawlers.

10.

CHECK

for incorrect tension, cracks and / or wear of belts and chains

11.

LUBRICATE

with Shell Spirax S3 T 15W-40 oil, WD-40 or its equivalent all wire and lever

supporting points and any friction and sliding sections

12.

RECORD

the hours indicated on the Hour Metre.

13.

CHECK

that the tension of the wires engaging the parking brake, side clutch, transport clutch

and rotor clutch is appropriate and effective.

Notes:

※

1 Engine oil must be replaced in first 25 hours and then every 50 hours.

※

2 Shredder knives are optional

※

3 Shell Spirax S3 T 15W-40; Gasoline unleaded

Refer to the User Manual List of Consumable Parts and the Regular Service and Maintenance

sections for parts details and instructions for regular service and maintenance.

-14-

Loading...

Loading...