Ogden RCR812 Owner's Manual

Owner’s Manual

For Hay Rakes after serial #01425

Read, Understand, and Follow the information and procedures in this

manual to safely operate and maintain the Hay Runner wheel rake.

Contents

1. INTRODUCTION ...........................2

1.1 Welcome. . . . . . . . . . . . . . . . . . . 2

1.2 Description and Intended Use . . . . . . . . 2

1.3 Safe Operation . . . . . . . . . . . . . . . 2

1.5 Intended Usage . . . . . . . . . . . . . . . 3

1.6 Operator Orientation. . . . . . . . . . . . . 3

1.7 Product Improvements . . . . . . . . . . . 3

1.9 Serial Number Location . . . . . . . . . . . 4

2. SAFETY..................................5

2.1 General . . . . . . . . . . . . . . . . . . . 5

2.2 Safety Alert Symbol . . . . . . . . . . . . . 5

2.3 Safety Icons Nomenclature . . . . . . . . . 6

2.4 General Safety Instruction . . . . . . . . . . 7

2.5 Operation Safety. . . . . . . . . . . . . . . 8

2.6 Transporting Safety . . . . . . . . . . . . . 8

2.7 Storage Safety. . . . . . . . . . . . . . . . 8

2.8 Maintenance Safety . . . . . . . . . . . . . 8

2.9 Training . . . . . . . . . . . . . . . . . . . 8

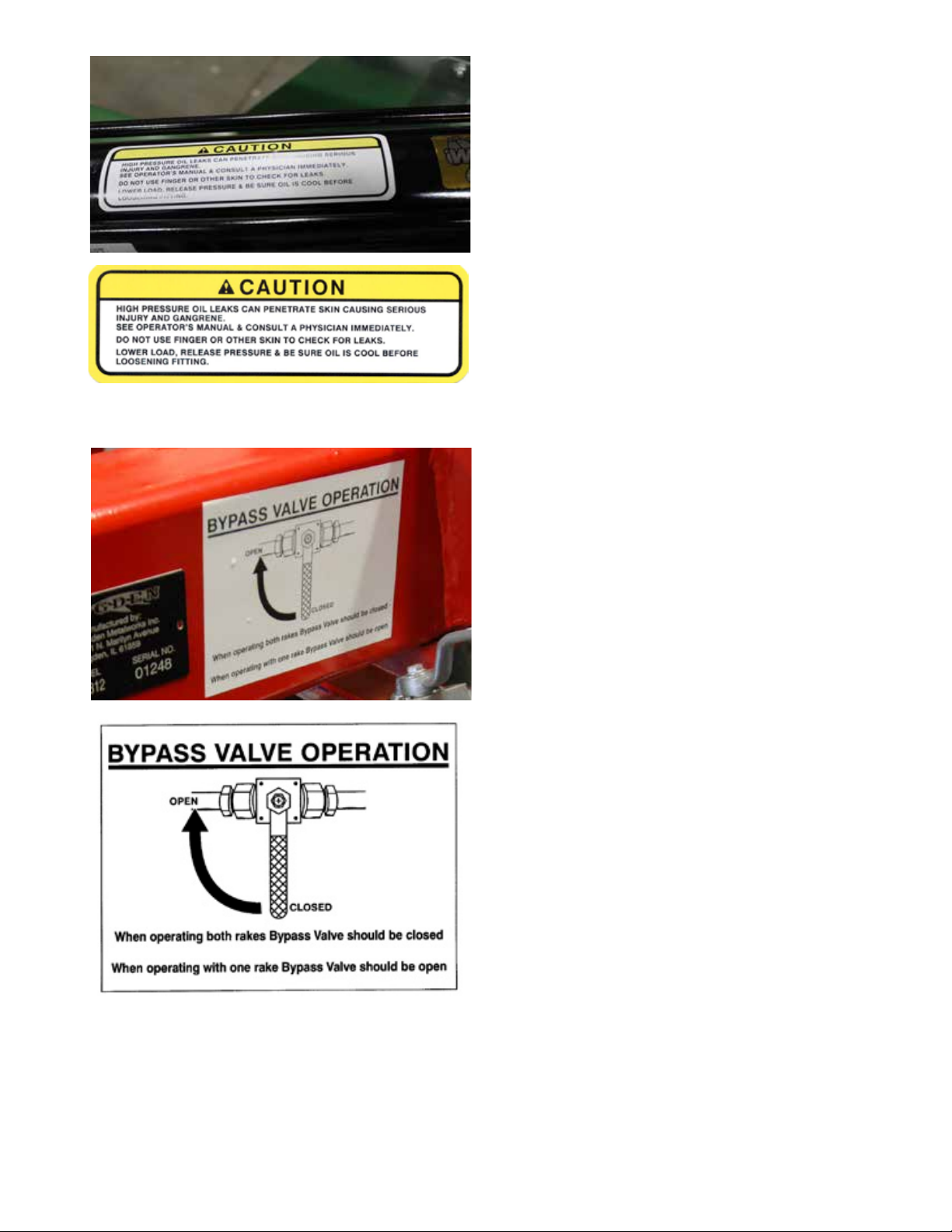

3. SAFETY SIGNS AND LABELS ..............10

3.1 General Information . . . . . . . . . . . . . 10

3.2 Decals . . . . . . . . . . . . . . . . . . . . 10

3.3 How to Install Replacement Safety Signs . . 10

3.4 Safety Sign Locations . . . . . . . . . . . . 11

7.2 Transporting Procedure . . . . . . . . . . . 28

8. STORAGE ...............................29

8.1 Placing In Storage . . . . . . . . . . . . . .29

9. MAINTENANCE ..........................30

9.1 General Maintenance Safety . . . . . . . . 30

9.2 Work Area . . . . . . . . . . . . . . . . . . 30

9.3 Parts Replacement . . . . . . . . . . . . . 30

9.4 Hydraulic System Safety . . . . . . . . . . 31

9.5 Welding Repairs . . . . . . . . . . . . . . .31

9.6 Wheel Bearings . . . . . . . . . . . . . . . 31

9.7 Replacing Tines . . . . . . . . . . . . . . . 32

9.8 Inspection . . . . . . . . . . . . . . . . . . 33

9.9 Replacing Rake Wheel Tension Spring . . . 34

10. TROUBLESHOOTING .....................36

11. REPLACEMENT PARTS....................37

11.1 Ordering Parts . . . . . . . . . . . . . . . 37

12. WARRANTY .............................46

4. ASSEMBLY ..............................14

4.1 Assembly Area. . . . . . . . . . . . . . . .14

4.2 Quick Reference Guide . . . . . . . . . . . 14

4.3 Tongue Extension . . . . . . . . . . . . . . 14

4.4 Attach the Tongue Assembly . . . . . . . . 15

4.5 Rake Arm Transport Locks . . . . . . . . . 16

4.6 Attach Optional Single or Double

Wheel Extension . . . . . . . . . . . . . . .16

4.7 Hay Rake Wheels . . . . . . . . . . . . . . 17

4.8 Adjust Height of Hitch . . . . . . . . . . . . 17

4.9 Grease the Pivot Pins . . . . . . . . . . . .17

4.10 Optional Center Wheel Kit . . . . . . . . . 18

5. INITIAL SET UP...........................20

5.1 Setting Up the Wheel Rake . . . . . . . . . 20

5.2 Attaching to Tractor . . . . . . . . . . . . .20

5.3 Purge Air from Hydraulic Lines and

Cylinders . . . . . . . . . . . . . . . . . . .20

5.4 Level the Rake . . . . . . . . . . . . . . . 21

5.5 Wing Extension Adjustment . . . . . . . . . 21

5.6 Rake Angle Adjustment

(rear center rake wheels) . . . . . . . . . . 22

5.7 Rake Angle Adjustment

(front center rake wheels) . . . . . . . . . . 22

5.8 Adjust Rake Wheel Ground Pressure . . . . 23

6. WHEEL RAKE OPERATION.................24

6.1 User Safety . . . . . . . . . . . . . . . . . 24

6.2 Hydraulic Requirements . . . . . . . . . . .24

6.3 Using the Wheel Rake. . . . . . . . . . . .25

6.4 Detaching From Tractor . . . . . . . . . . .27

7. TRANSPORTING .........................28

7.1 Transporting Safety (Road) . . . . . . . . . 28

Hay Runner™ Hay Rake 1 Ogden Metalworks, Inc. — 217-582-2552

1. Introduction

WARNING

1.1 Welcome

RCR812 Hay Runner™ Family of Wheel Rakes

Congratulations on your choice of an Ogden

Metalworks, Inc. RCR812 family of wheel rakes.

The Hay Runner wheel rake has been engineered

and built for ease of operation and long service life.

Many features incorporated into this wheel rake are

the result of suggestions made by customers like

you. Read this manual carefully to learn how to

operate the wheel rake safely and how to set it to

provide maximum efficiency.

By following the operating instructions, in

conjunction with a good maintenance program, your

Ogden Metalworks wheel rake will provide many

years of trouble-free service.

1.3 Safe Operation

Safe, efcient, and trouble-free operation of your

wheel rake requires that you, and anyone else

who will be using or maintaining the unit, read and

understand the information contained within this

manual and other related OEM equipment manuals.

Store this manual in the Manual Canister on the

tongue for future reference.

1.2 Description and Intended Use

This wheel rake is designed to invert cut hay or

other forage crops to allow wet hay on the bottom of

the swath to be exposed to sun and wind, to merge

swaths together, and to narrow the swath into a

windrow of the required width for harvester or baler

pick-up. Our family of rakes has eight, ten, or twelve

wheels with an optional set of front-mounted kicker

wheels to turn the center of the windrow.

To prevent personal injury or even death, be

sure you read, understand, and follow all of the

instructions in this manual and other related

OEM equipment manuals! The wheel rake, if not

used and maintained properly, can be dangerous

to users unfamiliar with its operation. Do not

allow operating, maintaining, adjusting, or

cleaning of this wheel rake until the user has

developed a thorough understanding of the

safety precautions and functions of the unit.

This wheel rake is designed for the specic

purpose of raking hay and other forage crops.

DO NOT modify or use this wheel rake for any

application other than that for which it was

designed.

Wheel rakes maintained or operated improperly

or by untrained personnel can be dangerous;

exposing the user and bystanders to severe

injury or even death.

Ogden Metalworks, Inc. — 217-582-2552 2 Hay Runner™ Hay Rake

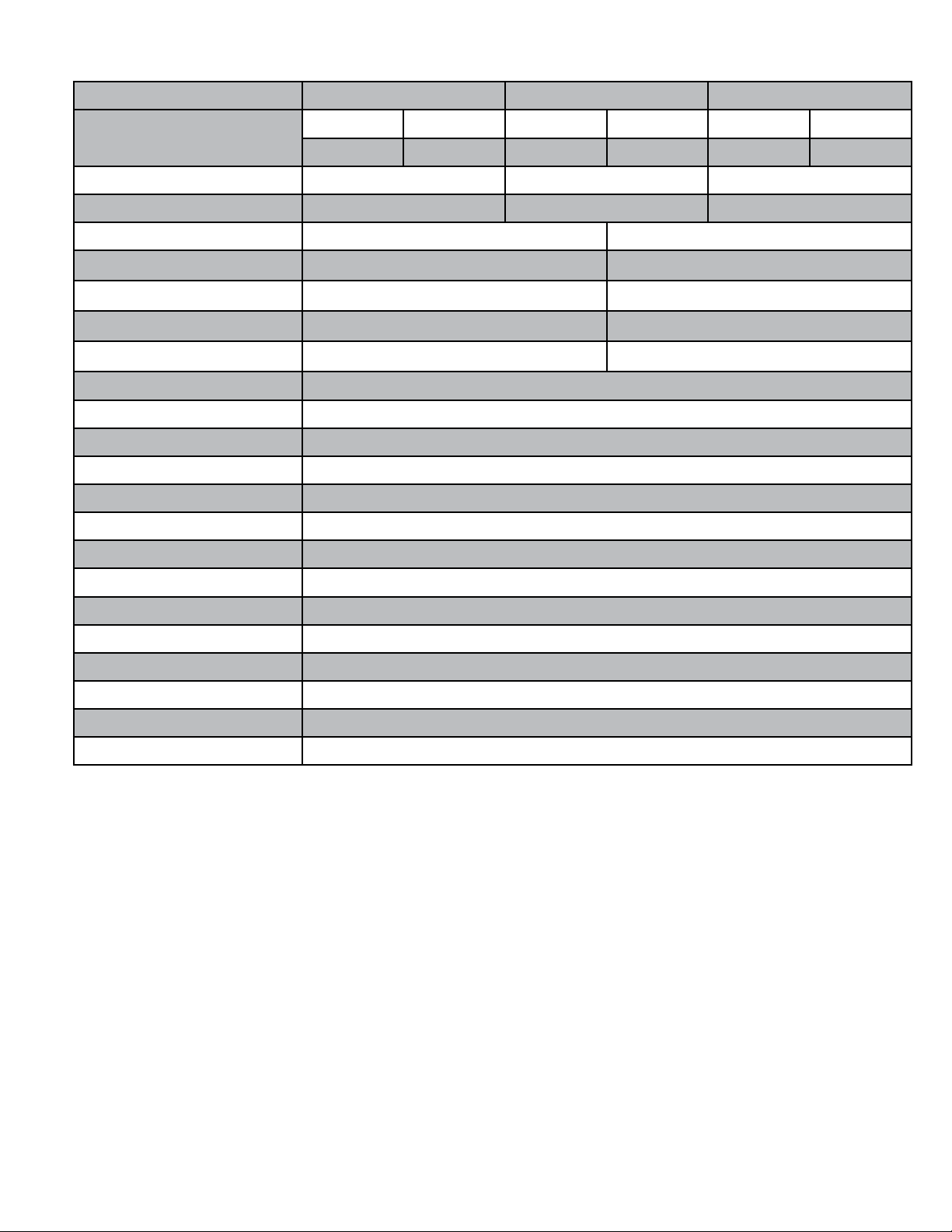

1.4 Specifications

DESCRIPTION RCR 8 RCR 10 RCR 12

Raking Width*

Number of Wheels 8 10 12

Weight in Pounds 1960 2135 2300

Transport Width** 8’ 10’ 6”

Transport Length** 17’ 21’

Transport Height** 9’ 11’

Windrow Width** 3’ 6’

Wheel Hubs & Bearings Greasable Tapered Roller Bearings

Wheel Diameter 55” & 60”

Tine Diameter 7 mm & 7.5 mm

Number Of Tines Per Wheel 40

Rake Wheel Suspension Independent Arm For Each Wheel – Teon Bushings

Ground Pressure Adjustment At Pivot

Hydraulic Cylinders Patented Adjustable Torsion Spring On Each Wheel

Minimum Maximum Minimum Maximum Minimum Maximum

17’ 22’ 6” 19’ 22’ 6” 21’ 26’ 6”

Minimum Maximum

Hydraulic Pressure 3” x 12” Double Acting

Requirement Minimum 1900 PSI

Hydraulic Remote Ports Required One Set

Tires 205/75-15”

Hydraulic Center Wheel Kit Optional

Walking Tandem Axles Optional

Wind Guards Optional

* Will vary depending on crop conditions ** Dimensions vary per model

1.7 Product Improvements

1.5 Intended Usage

Do not use this wheel rake for any other purpose than

its intended use of raking hay and other forage crops.

If the wheel rake is used or altered in any way

from the original design, the manufacturer does

not accept any liability for injury or warranty.

Because Ogden Metalworks maintains an ongoing

program of product improvement, we reserve the

right to make improvements in design or changes

in specifications without incurring any obligation to

install them on units previously sold.

1.8 Disposal of Equipment at End of Useful

Life

1.6 Operator Orientation

The directions left, right, front, and rear, as

mentioned throughout this manual, are as seen from

the tractor operator’s seat and facing in the direction

of travel.

The Ogden Metalworks family of wheel rakes have

been designed for the specific purpose of raking hay

and other forage crops. When this unit is no longer

capable of doing its designed purpose, it should be

dismantled and scrapped. Do not use any materials

or components from this unit for any other purpose.

Hay Runner™ Hay Rake 3 Ogden Metalworks, Inc. — 217-582-2552

1.9 Serial Number Location

1.10 Owner/Operator Manual Storage

The hay rake’s serial number is located on the

center tube of the main frame near the rear of the

unit. Please use this number when requesting

service, seeking information, or ordering parts.

Record the serial number in the space provided for

easy reference when contacting Ogden Metalworks

with questions.

Store the Operator manual and other operating

materials in the document storage tube located on

the tongue.

1.11 Unanswered Questions

If you have any questions not answered in this

manual, require additional copies, or the manual is

damaged, please contact your dealer or:

Serial Number _____________________________

Model Number ____________________________

Purchase Date ____________________________

Dealer ___________________________________

Address _________________________________

_________________________________

Phone Number ____________________________

Ogden Metalworks

PO Box 128

301 N. Marilyn Ave.

Ogden, IL 61859

PH: (217) 582-2552

Fax: (217) 582-2746

www.ogdenmetalworks.com

email: ogdenmetalworks@ogdenmetalworks.com

Ogden Metalworks, Inc. — 217-582-2552 4 Hay Runner™ Hay Rake

2. Safety

DANGER

WARNING

CAUTION

NOTICE

SAFETY

2.1 General

Most work-related accidents are caused by failure

to observe basic safety rules or precautions. An

accident can often be avoided by recognizing

potentially hazardous situations before an accident

occurs. As you operate and maintain the wheel rake

you must be alert to potential hazards. You should

also have the necessary training, skills, and tools to

perform any assembly procedure.

Improper operation or maintenance of this unit could

cause a dangerous situation that results in injury or

death.

Do not use this unit until you read and understand

the information contained in this manual. Do not use

the wheel rake for anything other than its intended

purpose.

Do not use the wheel rake until you

read and understand the information

contained in this manual.

Safety precautions and warnings are provided

in this manual and on the unit. If these hazard

warnings are not followed, bodily injury or death

could occur to you or other persons.

2.2 Safety Alert Symbol

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible injury

or death.

This manual contains DANGERS, WARNINGS,

CAUTIONS, IMPORTANT NOTICES, and NOTES

which must be followed to prevent the possibility

of improper service, damage to the equipment,

personal injury, or death. The following keywords

call the readers attention to potential hazards.

Hazards are identified by the “Safety Alert Symbol”

and followed by a signal word such as “DANGER”,

“WARNING”, or “CAUTION”.

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations.

Ogden Metalworks cannot anticipate every

possible circumstance that might involve

a potential hazard. The warnings in this

manual and on the product are, therefore,

not all‑inclusive. If a method of operation not

specically recommended by us is used, you

must satisfy yourself that it is safe for you and

others. You should also ensure that the unit

will not be damaged or be made unsafe by the

methods that you choose.

The information, specifications, and illustrations in

this manual are based on the information that was

available at the time this material was written and

can change at any time.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

Indicates that equipment or property damage can

result if instructions are not followed.

INSTRUCTIONS

Safety instructions (or equivalent) signs

indicate specic safety-related instructions or

procedures.

Note: Contains additional information important to a

procedure.

Hay Runner™ Hay Rake 5 Ogden Metalworks, Inc. — 217-582-2552

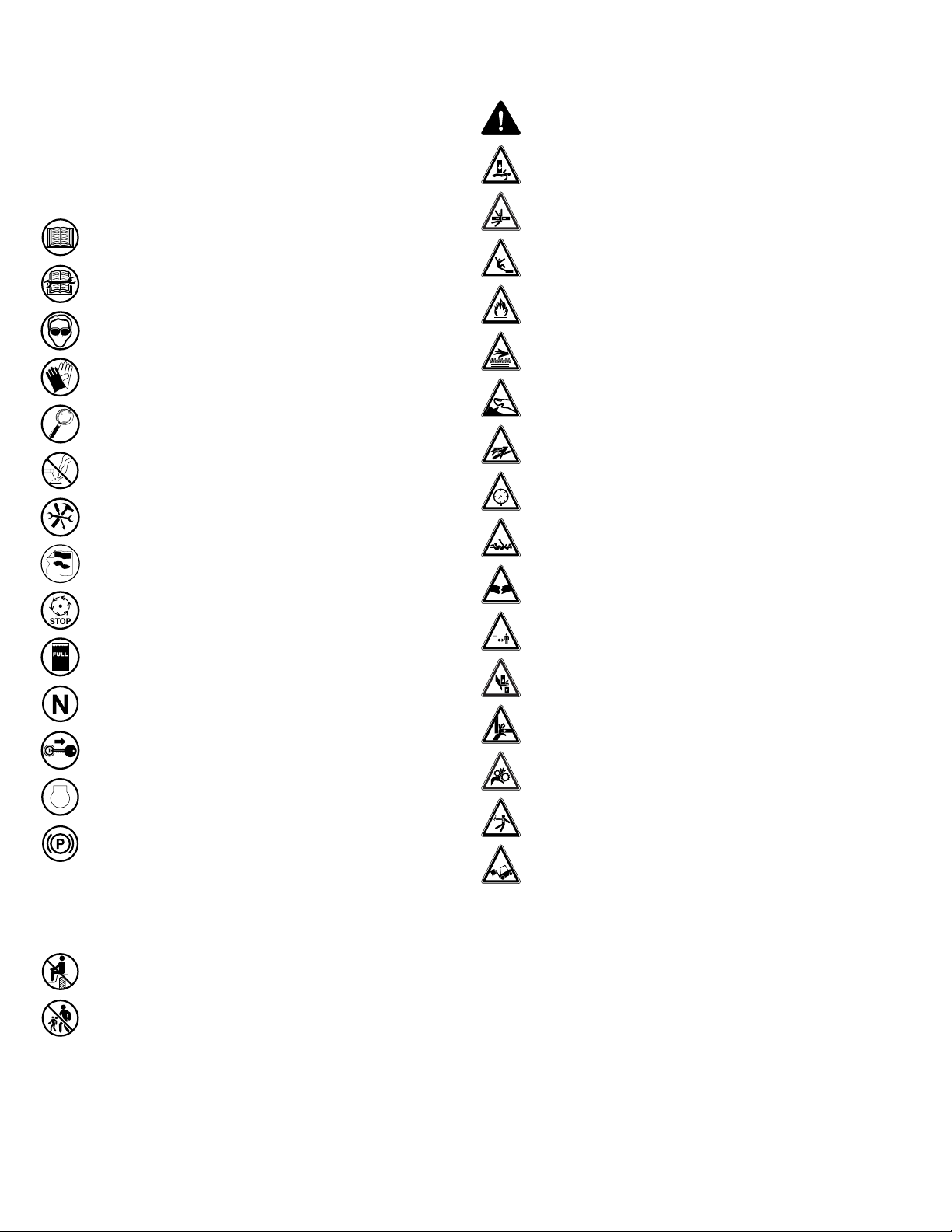

2.3 Safety Icons Nomenclature

STOP

0

This manual and the equipment have numerous

safety symbols. These safety symbols indicate

important information about personal injury hazards.

2.3.3 Hazard Avoidance

Safety alert symbol

2.3.1 Personal Protection/Important

Information

Read the manual

Maintenance procedure

Eye protection

Hand protection

Inspect equipment

Do not weld

Use proper tools

AR

N

I

NG

Warning decal alert

Stop machine engine

Check/Maintain Fluid Levels

Place in neutral

Remove key

Stop engine

Set parking brake

Crushing hazard

Crushing hazard

Falling hazard

Fire hazard

Hot surface

Sharp object hazard

High pressure fluid hazard

Zero pressure

Entanglement hazard

Defective or broken part

Maintain safe distance

Pinch point hazard

Pinch point hazard

Pinch point hazard

Electrocution hazard

Tip over hazard

2.3.2 Prohibited Actions

No riders

No children

Ogden Metalworks, Inc. — 217-582-2552 6 Hay Runner™ Hay Rake

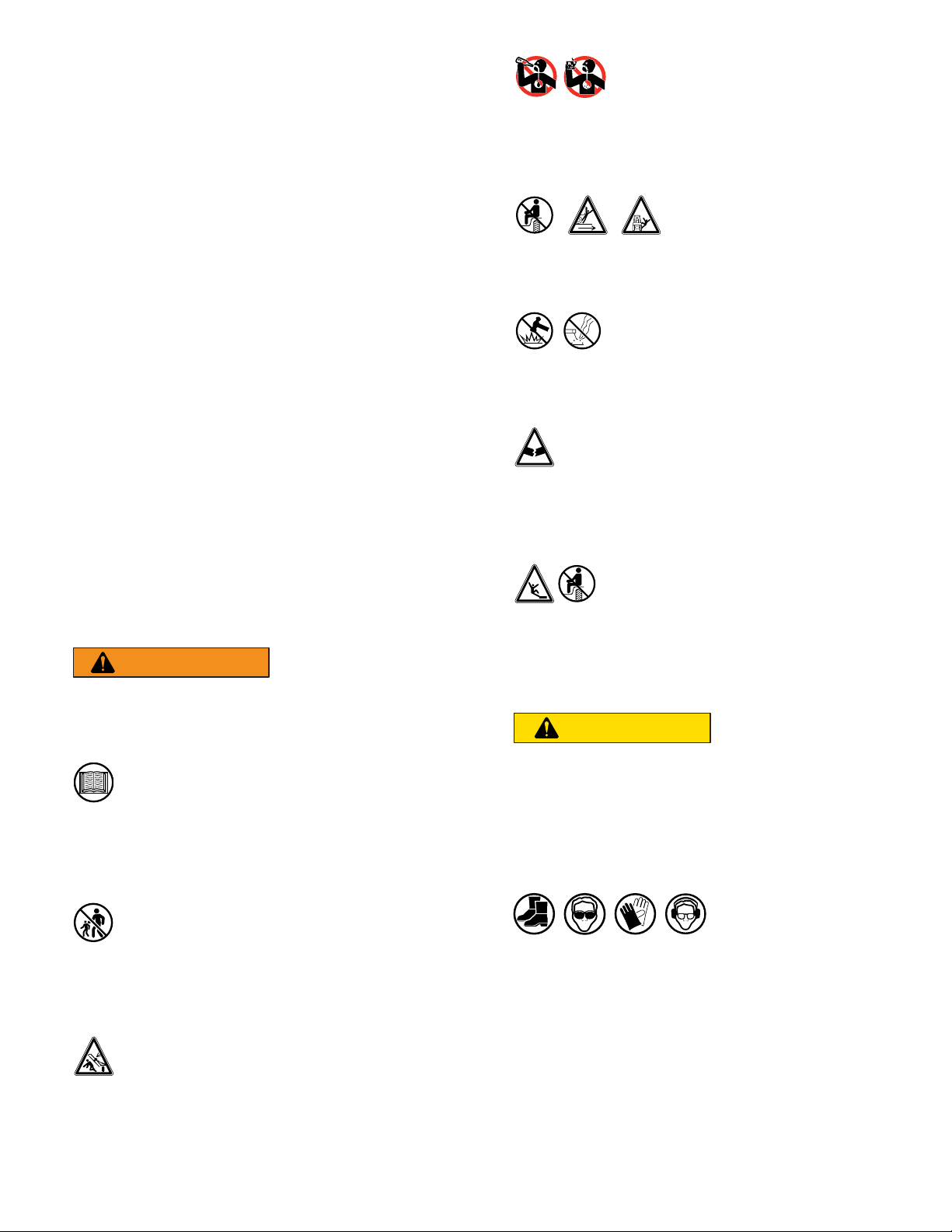

2.4 General Safety Instruction

WARNING

CAUTION

The owner/operator is responsible for the SAFE

use and maintenance of the wheel rake. Make sure

anyone who is operating, maintaining, or working

around the wheel rake is familiar with the operating

and maintenance procedures and related SAFETY

information contained in this manual. This manual

will take you step-by-step through your working

day and alerts you to all good safety practices that

should be used while using the wheel rake.

In addition to the design features of the wheel

rake, including safety signs, accident prevention is

dependent upon the awareness, concern, prudence,

and proper training of the people involved in the

operation, maintenance, and storage of the wheel

rake.

Impaired User Hazard

Do not attempt to assemble,

operate, or maintain this wheel rake

under the inuence of drugs or alcohol. Consult

your doctor before using this wheel rake while

taking prescription medications.

Fall or Crush Hazard

Do not allow anyone to ride

on the tractor or the wheel

rake. Falling or crushing hazards could result in

severe injuries or death.

No Unauthorized Modifications

Do not modify the wheel rake or its

safety devices. Do not weld on the

unit. Unauthorized modications may affect the

unit’s function, or create safety hazards.

These general safety instructions apply to the overall

use and maintenance of the wheel rake.

In addition to this safety section, also refer to

safety messages and instructions in each of the

appropriate sections of this manual.

More specific instructions on safety are found in the

operation, transporting, maintenance, and storage

sections of this manual. Refer to these sections

before performing any of these tasks.

Failure to comply with

the following safety

instructions could result in serious injury and

possibly even death if they are not understood

and followed.

Provide User with Literature

The wheel rake’s owner must provide

operator instructions to anyone using the

wheel rake before use, and at least annually

thereafter. Refer to “2.10 OSHA Training

Requirements” on page 8.

Stay Clear

Clear the area of people, especially small

children, before using the wheel rake.

Under no circumstances should young children

be allowed to work with or around the wheel

rake.

Crush Hazard

Hydraulic or mechanical failure can allow a

wing to drop suddenly without warning.

Do not allow anyone to walk under or stand near

a raised rake arm.

Damaged Parts Hazard

Do not use the wheel rake if any parts

are damaged. If the wheel rake is

believed to have a defect which could cause it

to work improperly, immediately stop using it

and remedy the problem before continuing.

Fall Hazard

Do not use the unit as a work

platform. Do not stand on top of the

unit at any time. Do not ride on the unit or allow

others to ride on it.

The following safety

instructions are

provided to help prevent potential injury. Not

following these instructions may lead to injury.

Personal Protection Equipment

When using this wheel rake, wear appropriate

personal protective equipment. This list may

include, but is not limited to:

• Protective shoes with slip resistant soles

• Protective eyewear

• Protective clothing and gloves

• Hearing protection

Hay Runner™ Hay Rake 7 Ogden Metalworks, Inc. — 217-582-2552

Hearing Loss

INSTRUCTIONS

Prolonged Exposure To Loud Noise May

Cause Permanent Hearing Loss!

Working environments with noise‑producing

equipment can cause partial to permanent

hearing loss. We recommend using hearing

protection any time noise levels exceed 80

decibels (dB). Noise levels over 85 dB, on a

long‑term basis, can cause severe hearing loss.

Noise levels over 90 dB over a period of time can

cause permanent and even total hearing loss.

Hearing loss from loud noise is cumulative over

a lifetime without hope of natural recovery.

2.6 Transporting Safety

Refer to “2.6 Transporting Safety” on page 8 for

safety recommendations related to transporting the

wheel rake. All applicable safety recommendations

in other sections should also be followed.

2.7 Storage Safety

Refer to “2.7 Storage Safety” on page 8 for

safety recommendations related to storing the wheel

rake. All applicable safety recommendations in

other sections should also be followed.

Crush Hazard

The tractor should be equipped with

a Roll Over Protective Structure

(ROPS) and a seat belt. A crushing hazard may

occur if the driver is ejected from the seat while

the tractor is in motion. Fasten the seat belt

whenever the tractor is moving.

SAFETY

The following safety

instructions are provided to

help prevent injury or limit equipment damage.

Safety Signs

AR

N

I

NG

Replace any missing or hard‑to‑read safety

signs or instructional labels. Use care

when washing or cleaning the wheel rake.

Replacement safety sign locations and part

numbers are provided in this manual and are

available from an authorized dealer parts

department or the factory.

First Aid Kit

Have a rst aid kit available for use should

the need arise and know how to use it.

2.8 Maintenance Safety

Refer to “9. Maintenance” on page 30 for safety

recommendations related to maintaining the wheel

rake. All applicable safety recommendations in

other sections should also be followed.

2.9 Training

Anyone who will be using and/or maintaining the

wheel rake must read, clearly understand, and

follow ALL safety, operation, and maintenance

information presented in this manual, other related

OEM manuals, and the safety signs

If you do not understand any information in

this manual, see your dealer or contact Ogden

Metalworks before proceeding.

Do not use or allow anyone else to use this wheel

rake until all information has been reviewed.

Annually review this manual before the season startup.

Make periodic reviews of SAFETY and OPERATION

of the wheel rake a standard practice. An untrained

operator is not qualified to use this wheel rake.

Fire Extinguisher

Have a re extinguisher available for use

should the need arise and know how to

use it.

2.10 OSHA Training Requirements

The following training requirements have been taken

from Title 29, Code of Federal Regulations Part

1928.57 (a) (6). www.osha.gov.

2.5 Operation Safety

Refer to “6.1 User Safety” on page 24 for safety

recommendations related to using the wheel rake.

All applicable safety recommendations in other

sections should also be followed.

Operator instructions. At the time of initial

assignment and at least annually thereafter, the

employer shall instruct every employee who

operates an agricultural tractor and implements

in the safe operating practices and servicing of

equipment with which they are or will be involved,

and of any other methods dictated by the work

environment.

Ogden Metalworks, Inc. — 217-582-2552 8 Hay Runner™ Hay Rake

2.11 Federal Laws and Regulations

IMPORTANT FEDERAL LAWS AND REGULATIONS

CONCERNING EMPLOYERS, EMPLOYEES AND OPERATORS

This section is intended to explain in broad terms the concept and effect of the following federal laws and

regulations. It is not intended as a legal interpretation of the laws and should not be considered as such.

U.S. PUBLIC LAW 91‑596 (The Williams‑Steiger Occupational Safety and Health Act of 1970) OSHA

This Act Seeks:

“ ... to assure so far as possible every working man and woman in the nation safe and healthful working conditions and to preserve

our human resources ... “

DUTIES

Sec. 5(a) Each Employer ‑

(1) shall furnish to each of its employees employment and a place of employment which are free

from recognized hazards that are causing or are likely to cause death or serious physical harm to

its employees.

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards

and all rules, regulations, and orders issued pursuant to this Act which are

applicable to his or her own actions and conduct.

OSHA Regulations

Current OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the

employer shall instruct every employee in the safe operation and servicing of all equipment with which the

employee is, or will be involved.” These will include (but are not limited to) instructions to:

Keep all guards in place when the machine is in operation;

Permit no riders on equipment;

Stop engine, disconnect the power source, and wait for all machine movement to stop before

servicing, adjusting, cleaning, or unclogging the equipment, except where the machine must be

running to be properly serviced or maintained, in which case the employer shall instruct employees

as to all steps and procedures which are necessary to safely service or maintain equipment.

Make sure no one is within 300 feet of machinery before starting the engine, engaging power,

or operating the machine.

EMPLOYEE TRACTOR OPERATING INSTRUCTIONS:

1. Securely fasten your seat belt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going, especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by tractor manufacturers.

9. When tractor is stopped, set brakes securely and use park lock if available.

Child Labor Under 16 Years Old

Some regulations specify that no one under the age of 16 may operate power machinery. It is your

responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor,

Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102).

Hay Runner™ Hay Rake 9 Ogden Metalworks, Inc. — 217-582-2552

3. SAFETY SIGNS AND LABELS

INSTRUCTIONS

WARNING

3.1 General Information

The types of safety signs (hazard labels) and

instructional labels, along with their locations on the

equipment, are shown in the following illustrations.

Good safety practices require that you familiarize

yourself with the various safety signs, the type

of warning, and the area or particular operation

related to that area that requires your SAFETY

AWARENESS.

THINK

SAFETY!

Pay close attention to the safety signs and

instructional labels attached to the tractor and the

wheel rake. Duplicate safety signs, which are

attached to the wheel rake, can also be found in this

section. If the wheel rake is missing a label or one

is unreadable, replace the label before using the

wheel rake.

AR

N

I

NG

1. Keep safety signs or instructional labels clean

and legible at all times. Use a clean, damp

cloth to clean safety decals.

2. Replace any missing or hard‑to‑read safety

signs or instructional labels.

3. Use care when washing or cleaning the

equipment not to remove or damage the

labels. When using a pressure washer to

clean the wheel rake, avoid spraying too close

to decals; high‑pressure water can enter

through very small scratches or under edges

of decals causing them to peel or come off.

Think SAFETY!

Work SAFELY!

SAFETY

Safety Signs and

Instructional Labels

3.2 Decals

AR

N

I

NG

To prevent

serious

injury or death from not following posted safety

instructions, make sure all decals are attached

to the unit and are legible at all times.

Safety decals provide a vital role in helping to

reduce injuries and/or possibly even death. To

ensure the greatest level of safety, all decals must

be in place and legible at all times. Remember, it is

the user’s responsibility to maintain these decals.

All decals must be in place and legible or all

warranties are void.

3.3 How to Install Replacement Safety

Signs

1. Clean and dry the installation area.

Note: Do not install the signs if the temperature is

below 50°F.

2. Determine the exact position before you remove

the backing paper.

3. Remove the backing paper.

4. Align the sign over the specified area and

carefully press the sign to the part/frame.

Note: Small air pockets can be pierced with a pin

and smoothed out using the piece of backing

paper.

4. Locations for the labels and replacement part

numbers are shown in this section.

5. Replacement parts must have replacement

labels attached during installation and/or

before the wheel rake is used.

6. Labels are available from your authorized

dealer or from Ogden Metalworks at no

charge.

Ogden Metalworks, Inc. — 217-582-2552 10 Hay Runner™ Hay Rake

3.4 Safety Sign Locations

Item Part

Number

1 HR169 Decal, Warning Operating 1

2 HR170 Decal, Overhead Hazard 2

3 0-70 Decal, Caution Stay Clear 5

4 HR171 Decal, Warning Pinch Point 2

5 0-82 Decal, Hydraulic Caution 1

6 0-71 Decal, Red Reector 2

7 B489A Decal, Yellow Reector 2

Description Qty.

Hay Runner™ Hay Rake 11 Ogden Metalworks, Inc. — 217-582-2552

3.4.1 Wheel Rake Safety Signs

1.

3.

4.

2.

Ogden Metalworks, Inc. — 217-582-2552 12 Hay Runner™ Hay Rake

5.

6.

Hay Runner™ Hay Rake 13 Ogden Metalworks, Inc. — 217-582-2552

4. Assembly

4.1 Assembly Area

1. The assembly area should be a clean, at, solid

surface.

2. It will be necessary to use a lifting mechanism

such as a forklift or overhead lifting device.

3. Sturdy supports or blocking may also be needed.

Note: When reading the assembly instructions, the

directions (LEFT and RIGHT) are always

referred to from standing behind the piece of

equipment (BACK) looking forward toward

the tractor (FRONT).

4.2 Quick Reference Guide

1. With the rake on the ground and the rake arms in

the raised and locked position, support the front

of rake right behind the shipping support stand.

7. Lower the rake arms and, if necessary, attach

the single or double rake wheel extension. For

detailed information refer to “4.6 Attach Optional

Single or Double Wheel Extension” on page

16.

a. The unit is already set up for an eight wheel

configuration.

b. For a ten wheel configuration, attach the

single rake wheel extension.

c. For a twelve wheel extension, attach the

double rake wheel extension.

8. Install the optional center wheel kit. For detailed

information refer to “4.7 Hay Rake Wheels” on

page 17.

9. Adjust the height of the hitch. For detailed

information refer to “4.8 Adjust Height of Hitch” on

page 17.

10. Grease the pivot pins. For detailed information

refer to “4.9 Grease the Pivot Pins” on page

17

2. Remove the shipping support stand.

3. If a center wheel kit is not being installed, the

tongue extension can be removed. Typically

the tongue extension would only be removed to

shorten the overall length of the unit which is not

commonly done. For detailed information refer to

“4.3 Tongue Extension” on page 14.

4. Attach the tongue assembly. For detailed

information refer to”4.4 Attach the Tongue

Assembly” on page 15.

5. Connect hydraulic supply and return hoses.

11. Install any other optional accessories, such as

the center wheel kit. For detailed information

refer to “4.10 Optional Center Wheel Kit” on

page 18.

4.3 Tongue Extension

The tongue extension comes standard with every

rake; however, it can be removed to shorten the

length of the tongue.

6. Release the transport lock on both rake arms.

For detailed information refer to “4.5 Rake Arm

Transport Locks” on page 16.

Ogden Metalworks, Inc. — 217-582-2552 14 Hay Runner™ Hay Rake

Loading...

Loading...