Ogden ETR-9004 Instruction Manual

INSTRUCTION

MANUAL

MANUAL #27

1/8 DIN Solid State Temperature

Indicator Model ETR-9004

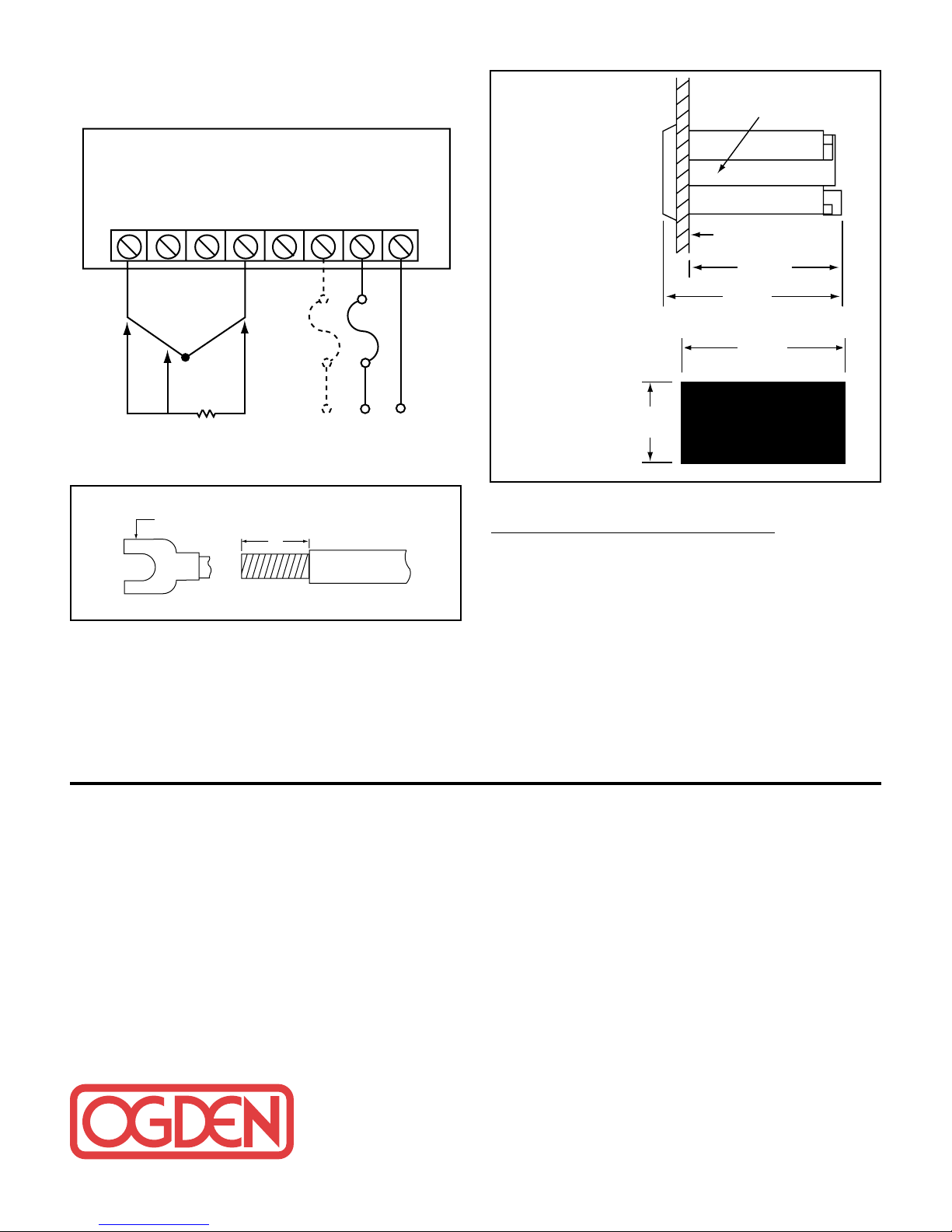

All temperature indicators in this series are made to fit

into panel cut-outs which measure 113⁄16” x 35⁄8” (46mm x

92mm). Aminimum of 3

1

⁄2” (89mm) in depth is required

for electrical clearances of rear terminal connections.

The following specifications are common to all models:

INPUT

Thermocouple (T/C) Type K, J. Specified on

Control Label.

RTD PT 100 ohm, 2 or 3-wire

(

= .00385) DIN

(

= .00392) JIS

Cold Junction

Compensation Automatic

Input Break Built-in, upscale on open

sensor.

Input Impedance 1M ohm.

Common Mode

Rejection (CMR) CMRR 120dB, Min.

Normal Mode

Rejection (NMR) NMRR 60dB, Min. (60Hz)

POWER

Rating 120/240VAC field

selectable, 50/60Hz.

12-24VDC models

available on special order.

Accuracy 0.2% of SPAN.

Consumption Less than 3VA.

ENVIRONMENTAL & PHYSICAL

Operating Temperature 10° to 125°F (-12 to 52°C).

Humidity 5 to 90% RH (non-

condensing).

Insulation 20M ohm Min., (5000VDC).

Breakdown 2000VAC, 50/60Hz,

1 minute.

Vibration 10 - 55Hz, Amplitude

1.0mm.

Shock 660 ft./S

2

(20g.)

Weight 11 oz. (312 grams)

DIMENSIONS H – 17⁄8” (48mm)

W – 33⁄4” (96mm)

D – 31⁄4” (83mm)

Depth behind panel – 3”

(76mm)

DIN Case Plastic, with screw

terminals on rear,

adjustable brackets for

panel mounting.

MOUNTING

When mounting the instrument, it is important the

instrument remains within the ambient temperature

range of 10 to 125°F. Mounting it in any position is

permissible. After inserting the instrument into the

panel, secure it with the mounting bracket provided with

each unit.

• Both solderless terminals or “stripped” leads

can be used for power leads. Only “stripped” leads

should be used for thermocouple connections to

prevent compensation and resistance errors.

• Take care not to over-tighten the terminal screws.

• Unused control terminals should not be used as

jumper points as they may be internally connected,

causing damage to the unit. This indicator is not

to be used in hazardous locations as defined in

Article 500 of the National Electric Code.

Telephone: (847) 593-8050 • FAX: (847) 593-8062

© Ogden Manufacturing Co. 1996 PRINTED IN U.S.A. 2/96

MARCA REGISTRADA

OGDEN and ETR are Registered Trademarks of Ogden Manufacturing Co.

Specifications subject to change without notice

TROUBLE SHOOTING

Experience has proven that many control problems are

not caused by a defective instrument. See list below

for some of the common causes of failures:

Line wires are improperly connected.

No voltage between line terminals.

Incorrect voltage between line terminals.

Connection to terminals are open, missing or loose.

Thermocouple or RTD is open at tip.

Thermocouple or RTD lead is broken.

Shorted thermocouple or RTD leads.

Short across terminals.

Burned out line fuses.

Defective line switches.

Defective circuit breakers.

If these points have been checked and the indicator still

does not function, it is suggested that the instrument be

returned to the factory for inspection.

Do not attempt to make repairs. It usually creates

costly damage. Also, it is advisable to use adequate

packing materials to prevent damage in shipment.

Return To:

OGDEN MANUFACTURING CO.

ATTN: Repair Department

719 W. Algonquin Road

Arlington Heights, IL 60005

Temperature Ranges of Ogden Indicators:

ETR-9004-01 0-1200°F Type “J” Thermocouple

ETR-9004-02 0-600°C Type “J” Thermocouple

ETR-9004-03 0-2500°F Type “K” Thermocouple

ETR-9004-04 0-1200°C Type “K” Thermocouple

ETR-9004-05 0-700°F PT-100 RTD DIN

ETR-9004-06 0-450°C PT-100 RTD DIN

CALIBRATION INSTRUCTIONS

W

ARNING–HIGH VOLTAGE PRESENT!

The indicator should be allowed to warm-up for 1/2 hour

before accurately checking calibration.

Remove the front faceplate by twisting a flat screwdriver in the slot under the front-center area of the faceplate.

Calibration is accomplished by using the two potentiometers located on the right-hand side of the bottom

PC board. The potentiometer to the right is the zero

adjustment. The potentiometer to the left is the span

adjustment. The two potentiometers have a slight effect

on each other, so calibrate low-scale and high-scale at

least three times.

Mounting

Dimensions

WIRING

All wiring should conform to local and national codes.

Rear Terminal Connections

Panel

Cutout

Mounting Bracket

12

45678

3

+ –

RED

FUSE

3A

T/C

B

B

RTD

SPADE TONGUE

CONNECTOR FOR

NO. 6 STUD

A

3/8"

Lead Termination

240V 0V120V

POWER INPUT

Panel

3"

(76mm)

3-1/4"

(83mm)

3-5/8"

(92mm)

1-13/16"

(46mm)

Loading...

Loading...