Ogden ETR-3 Instruction Manual

MANUAL NO. 33

ETR-3 FM SUB-PANEL MOUNT

HI-LIMIT CONTROL

INSTRUCTION

MANUAL

The ETR-3 Series is designed for industrial and commercial applications which require high temperature

protection. These controls feature a latching, manually

resettable relay output which de-energizes whenever

the sensed temperature exceeds the set point temperature. It can also be configured as an on-off temperature

control.

SPECIFICATIONS

Power Input:

120VAC ±15%, 50/60Hz, 3VA max.

standard (240VAC and other AC/DC voltages

optional).

Control Output: SPDT Relay rated 3.8 (1.5) Amps

Res. and 1.5 (.8) Amps Pilot Duty 120 (240)VAC.

100,000 cycles. Optional DC output to drive SSR.

Control Mode: Latching with Manual Reset or power off.

Reset Function: Integral reset switch standard;

terminals available for optional remote reset switch.

Set Point Adjustment: Local SP dial adjustment.

Compensation (TC only): Automatic cold junction

compensation.

Control Stability: Typically less than ±5µV/°F ambient

and 0.1% of SPAN/% rated line voltage.

Set Point Accuracy: ±3% of FS maximum at 78°F

(25°C) and rated line voltage.

Sensor Break Protection:

Contacts 4 and 5 open for thermocouple or RTD

break.

Ambient Operating Temperature:

32 - 140°F (0 - 60°C).

MECHANICAL

Enclosure Material: Noryl, Black color.

Field Terminations: Screw Terminals with wire

clamping plates and touch safe shield.

Mounting: 35mm DIN rail or surface mounting.

AGENCY APPROVALS: UL 873 and CUL per CSA

C22.2 No.24 File #E179225; FM 3545.

Switc

t

DIMENSIONS:

MOUNTING

The ETR-3 can be surface mounted or mounted on a DIN

rail. The ETR-3 must be located inside a suitable control

enclosure. It can be mounted to any suitable flat surface

using two #8 screws (not supplied). To install simply

position the top set of rear clips over the top of the DIN

rail. Then swing the bottom of the controller toward the

rail applying pressure until the lower clips snap on to the

bottom of the DIN rail. To remove apply pressure to the

top of the controller’s base and move the bottom of the

controller toward you. Then lift the top pf the controller

off the upper DIN rail.

3-5/16"

(84mm)

3/8"

(9.5mm)

Limit Controller

234

1

N.C.

L2

N.O.

Relay

Output

L1

AC

+ –

DC

Power

Input

2-1/2"

(63.5mm)

200

150

°F

RESET

56789

+ –

COM

TC or

RTD

Sensor

350

300

Optional N.O.

Remote Reset

2-9/16"

(65mm)

3"

(76.2mm)

Integral Rese

Button

h

Set point

adjust

2-1/2"

(63.5mm)

Panel mounting foot

with clearance holes

for #8 screw

(2 places)

35mm

DIN rail

mounting clips

WIRING

Carefully follow the terminal diagram pictured on the controller’s housing and shown above. The power and load

wiring should be 18 AWG or larger size. Be sure to observe

that the ratings for voltage and current are not exceeded. All

local and national electrical codes must be followed. Use only

the sensor type as indicated on the control and maintain correct polarity. THE RED THERMOCOUPLE LEAD ALWAYS

CONNECTS TO THE NEGATIVE (–) TERMINAL.

To reduce electrical noise, the thermocouple wire must be isolated from any power or heater wiring. Shielded thermocouple wire may be necessary in high noise environments or

when lead lengths exceed 10 feet. Thermocouples are tip

sensitive and must be in good mechanical contact with the

load.

OPERATION

The set point temperature is adjustable by turning the integral

dial. If the set point is exceeded, contacts 4 and 5 will open.

It will remain in this state until the temperature drops below

the set point and

the controller is manually reset. Manual

reset can be accomplished by one of the following means: a)

Press the “reset button”. b) Amomentary switch closure

between terminals 8 and 9. c) Interrupt power to the control.

CAUTION

This controller must be mounted in an enclosure suitable for

protection against normally expected operation environments

and to minimize unauthorized tampering with the limit settings. This control is not to be used in hazardous locations as

defined in Articles 500 and 505 of the National Electric Code.

MAINTENANCE

No specific maintenance is required. However, it is recommended that all wiring be checked periodically for loose connections and damaged wires. Disconnect power to the panel

before any maintenance is performed. Check wires and

tighten connections.

TROUBLE SHOOTING

RISK OF ELECTRIC SHOCK -

Dangerous and potentially

fatal voltages are present when working on this equipment.

Before installation or beginning any troubleshooting procedures, the electric power to this equipment must be disconnected and locked out as described by OSHA Standards.

Units suspected of being faulty must be removed and

returned to Ogden for inspection and/or repair. They contain

no user serviceable components.

Experience has proven that many control problems are not

caused by a defective instrument.

Some of the common causes of failure are broken sensors,

open fuses and poor wire connections.

If these points have been checked and the control still does

not function, it is suggested that the instrument be returned

for inspection.

Use adequate packing materials to prevent damage in

shipment.

Return Control To:

OGDEN MANUFACTURING CO.

ATTN: Repair Department

64 West Seegers Road, Arlington Heights, IL 60005

(847) 593-8050 • Fax: (847) 593-8062

www.ogdenmfg.com

©Ogden Manufacturing Co. 2001 PRINTED IN U.S.A. 02/2001

OGDEN and ETR are Registered

Trademarks of

Ogden Manufacturing Co.

MARCA REGISTRADA

Specifications subject to change without notice.

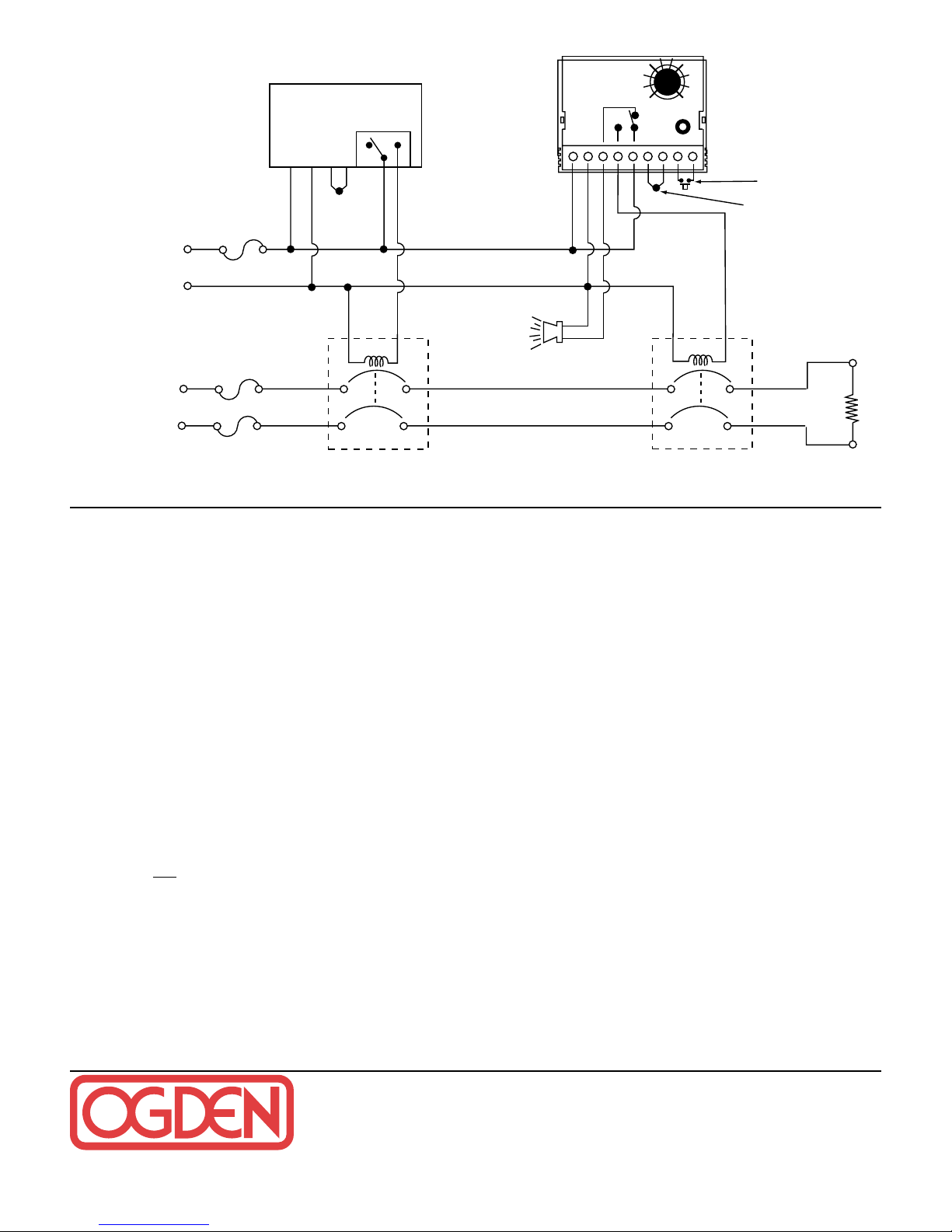

TYPICAL WIRING DIAGRAM

Control

Fuse

H

5A

120V

Control

Power

N

Primary

Temperature

Control

120VAC

T/C

or

RTD

NC

C

Coil

NO

Optional Alarm

or Warning

Lamp

ETR-3

Limit

234

1

200

150

NC

NO

C

+

56789

350

300

°F

–

Optional N.O.

Remote Reset

Switch

T/C or RTD

Coil

Heater Power

1 or 3 Phase

Heater

Fuses

Primary

Control

Contactor

Heater(s)

ETR-3

Limit

Contactor

Loading...

Loading...