INSTRUCTIONS

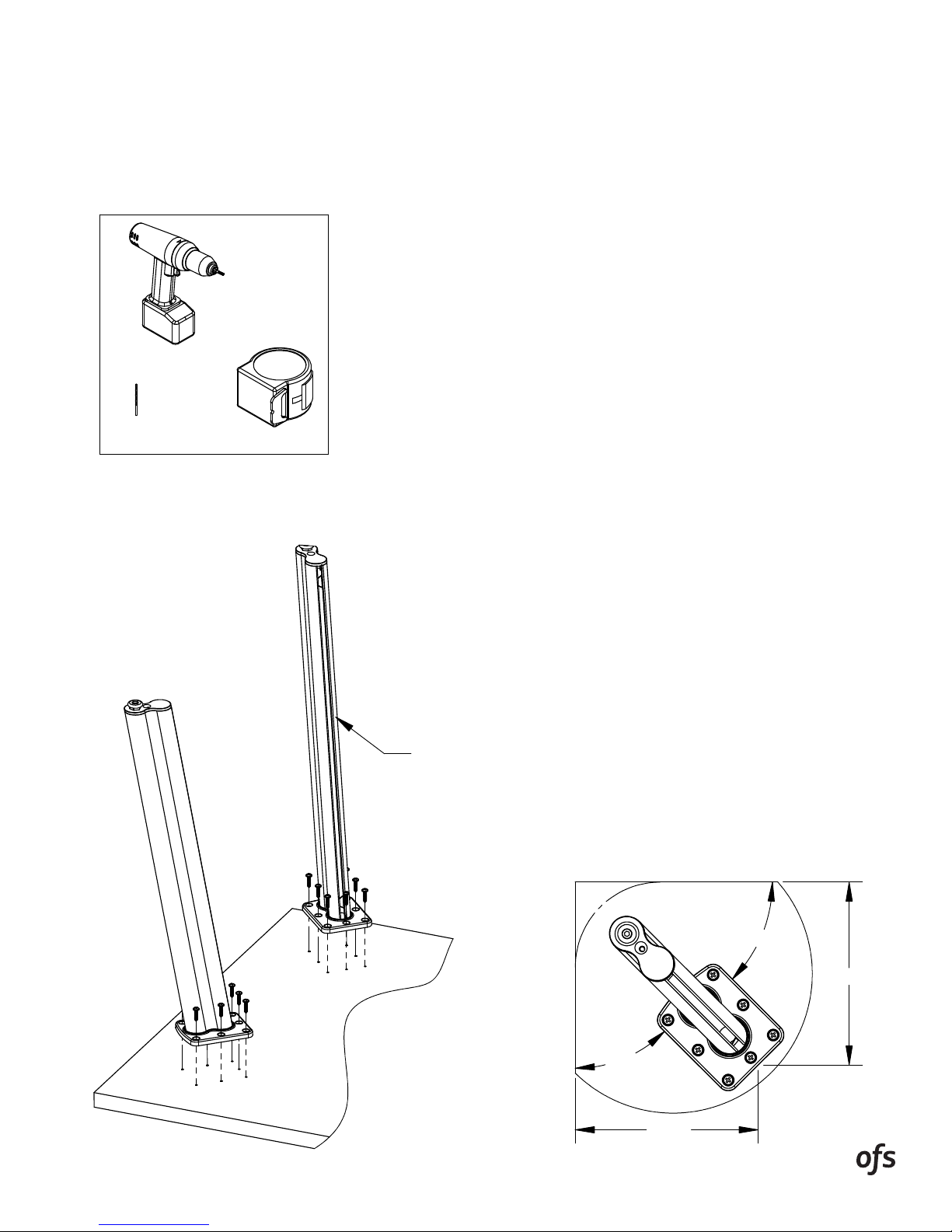

STEP 1: CHECK BOTTOM SIDE OF TOP FOR PRE BORED MOUNTING HOLES (IF

DONE MOVE TO STEP 4)

STEP 2: IF TOP ORDERED DOES NOT HAVE PREBORED MOUNTING HOLES,

PLACE TOP UPSIDE DOWN ON A PROTECTIVE SURFACE AND LOCATE

DUOFOIL LEGS AT A 45 ANGLE TO EDGE OF TOP WITH WIRE CAVITY

FACING TORWARD KNEESPACE AT A DISTANCE OF 8 5/8" FROM EDGE

OF TOP TO THE CENTER OF THE MOUNTING PLATES BACK EDGE

(SEE ILLUSTRATION BELOW)AND MARK LOCATION OF EACH HOLE USING

MOUNT PLATE HOLES AS LOCATION GUIDE.

DUOFOIL LEGS

Rev:

Dwg:

APTOS

INSTRUCTIONS

1/8" DRILL BIT

TAPE MEASURE

DRILL

UPTO 1" TO LEVEL THE TOP AS NEEDED.

STEP 1: CHECK BOTTOM SIDE OF TOP FOR PRE BORED MOUNTING HOLES (IF

DONE MOVE TO STEP 4)

STEP 2: IF TOP ORDERED DOES NOT HAVE PREBORED MOUNTING HOLES,

PLACE TOP UPSIDE DOWN ON A PROTECTIVE SURFACE AND LOCATE

DUOFOIL LEGS AT A 45 ANGLE TO EDGE OF TOP WITH WIRE CAVITY

FACING TORWARD KNEESPACE AT A DISTANCE OF 8 5/8" FROM EDGE

OF TOP TO THE CENTER OF THE MOUNTING PLATES BACK EDGE

(SEE ILLUSTRATION BELOW)AND MARK LOCATION OF EACH HOLE USING

MOUNT PLATE HOLES AS LOCATION GUIDE.

STEP 3: AFTER MARKING MOUNTING PLATE HOLE LOCATIONS REMOVE DUOFOIL

LEGS AND PREBORE 1/8" X 13/16" DEEP HOLES AT PREVIOUSLY MARKED

LOCATIONS.

STEP 4: ATTACH DUOFOIL LEGS TO BOTTOM SIDE OF TOP (WIRE CAVITY FACING

KNEESPACE) WITH HK-98, ALIGNING HOLES IN MOUNT PLATE WITH

PRE-BORED HOLES IN TOP.

STEP 5: LEVELER IN BOTTOM OF DUOFOIL LEGS CAN BE ADJUSTED OUT

DUOFOIL LEGS

Rev:

Dwg:

DUOFOIL LEGS

INSTALLATION INSTRUCTIONS

1/8" DRILL BIT

/" DRILL BIT

DRILL

DRILL

TAPE MEASURE

TAPE MEASURE

TAPE MEASURE

PA RT # 17 1125 8

INSTRUCTION SHEET # 2555INS

1. Check bottom side of top for pre-bored mounting holes. (If done, move to

Step 4.)

2. If top ordered does not have pre-bored mounting holes, place top upside

down on a protective surface and locate duofoil standoffs at a 45° angle to

edge of top with wire cavity facing toward kneespace at distance of 8 /"

from edge of top to the center of the mounting plates back edge (see

illustration below) and mark location of each hole using mount plate holes

as location guide.

3. After marking mounting plate hole locations, remove duofoil legs and prebore /" diameter x /" deep holes at previously marked locations.

4. Attach duofoil legs to bottom side of top (wire cavity facing kneespace) with

HK-71, aligning holes in mount plate with pre-bored holes in top.

5. Leveler in bottom of duofoil legs can be adjusted out, up to 1", to level the

top as needed.

WIRE CAVITY

WIRE CAVITY

STEPS 2 & 3: TO LOCATE LEGS IN

STEP 2 & 3: TO LOCATE LEGS IN

NON PREBORED TOP

45°

NON PRE-BORED TOP

45°

8.625

8.625

45°

45°

8.625

8.625

INSTRUCTIONS

STEP 1: CHECK BOTTOM SIDE OF TOP FOR PRE BORED MOUNTING HOLES (IF

DONE MOVE TO STEP 4)

STEP 2: IF TOP ORDERED DOES NOT HAVE PREBORED MOUNTING HOLES,

PLACE TOP UPSIDE DOWN ON A PROTECTIVE SURFACE AND LOCATE

DUOFOIL LEGS AT A 45 ANGLE TO EDGE OF TOP WITH WIRE CAVITY

FACING TORWARD KNEESPACE AT A DISTANCE OF 8 5/8" FROM EDGE

OF TOP TO THE CENTER OF THE MOUNTING PLATES BACK EDGE

(SEE ILLUSTRATION BELOW)AND MARK LOCATION OF EACH HOLE USING

MOUNT PLATE HOLES AS LOCATION GUIDE.

DUOFOIL LEGS

Rev:

Dwg:

APTOS

INSTRUCTIONS

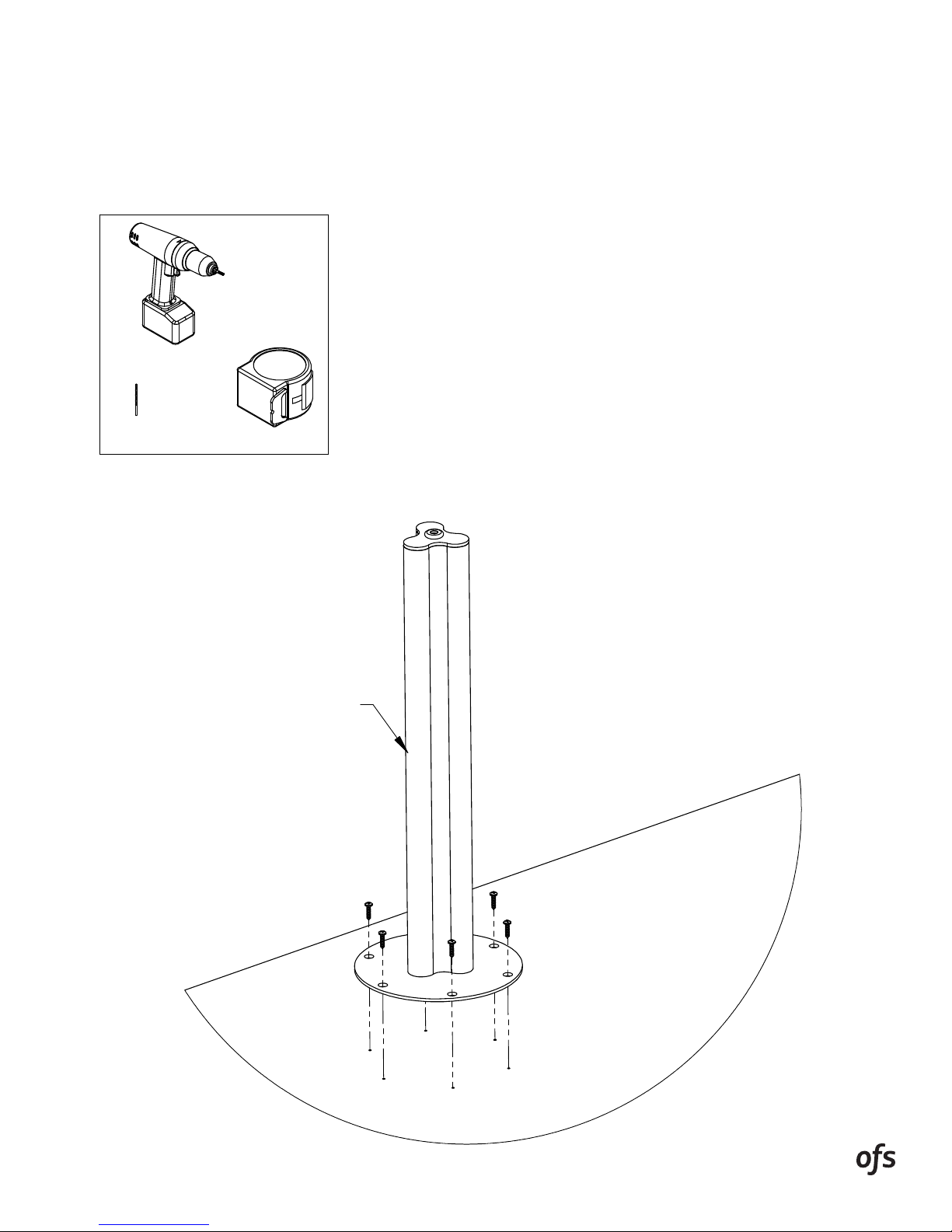

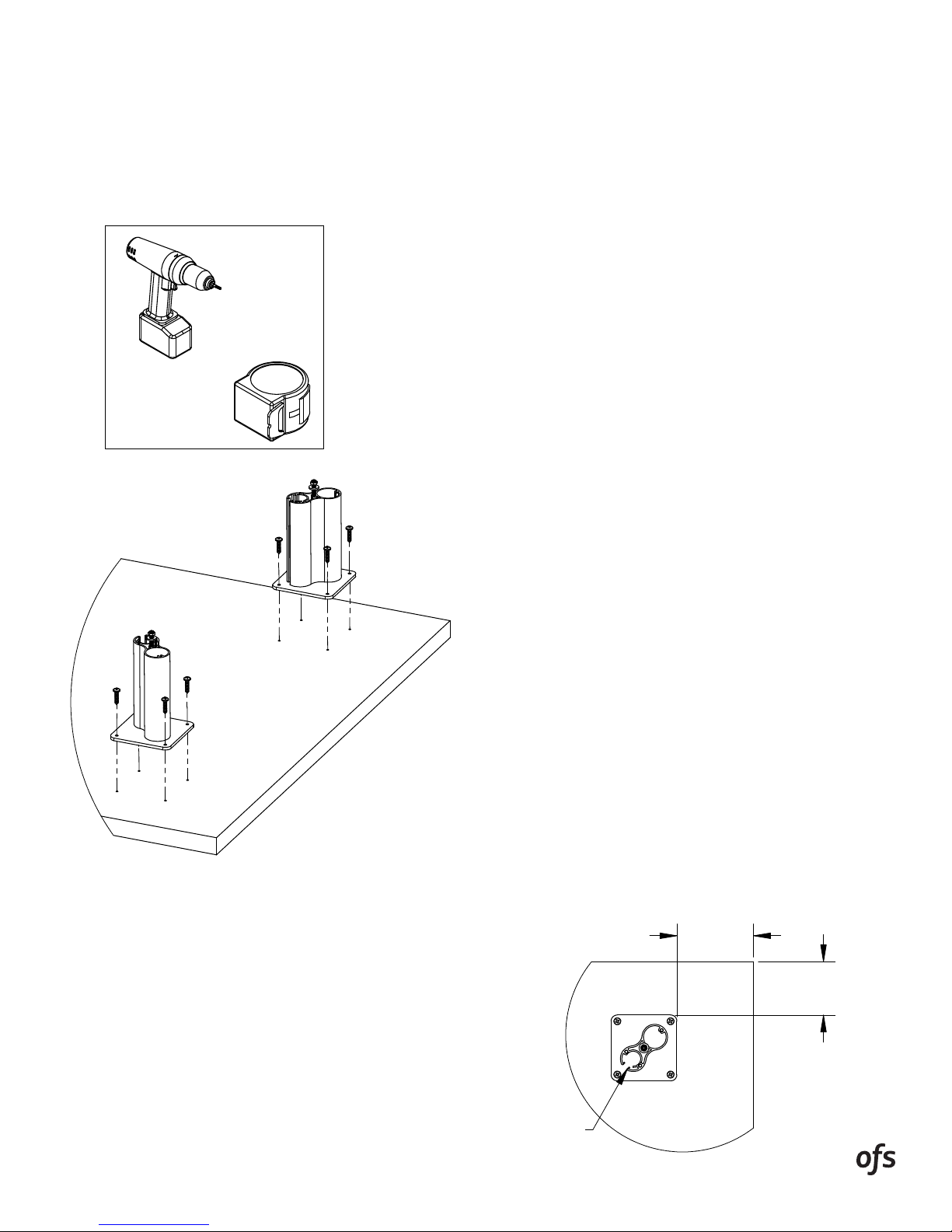

TRIFOIL COLUMN

STEP 1: CHECK BOTTOM SIDE OF TOP FOR PRE BORED MOUNTING HOLES (IF

DONE MOVE TO STEP 5)

STEP 2: IF TOP ORDERED DOES NOT HAVE PREBORED MOUNTING HOLES,

PLACE TOP UPSIDE DOWN ON A PROTECTIVE SURFACE AND LOCATE

TRIFOIL COLUMN IN DESIRED LOCATION CENTERED IN TOP DEPTH AND

NO MORE THAN 18" FROM END OF TOP TO CENTER OF COLUMN AND

MARK LOCATION USING MOUNT PLATE HOLES AS LOCATION GUIDE.

STEP 3: AFTER MARKING MOUNTING PLATE HOLE LOCATIONS REMOVE TRIFOIL

COLUMN AND PREBORE 1/8" X 13/16" DEEP HOLES AT PREVIOUSLY

MARKED LOCATIONS.

STEP 4: ATTACH TRIFOIL COLUMN TO BOTTOM SIDE OF TOP WITH HK-98,

ALIGNING HOLES IN MOUNT PLATE WITH PRE-BORED HOLES IN TOP.

STEP 5: LEVELER IN BOTTOM OF TRIFOIL COLUMN CAN BE ADJUSTED OUT

UPTO 1" TO LEVEL THE TOP AS NEEDED.

Dwg:

Rev:

2554INS

DRILL

TAPE MEASURE

1/8" DRILL BIT

TRIFOIL COLUMN

INSTALLATION INSTRUCTIONS

PA RT # 17 1125 7

INSTRUCTION SHEET # 2554INS

1/8" DRILL BIT

/" DRILL BIT

DRILL

DRILL

TAPE MEASURE

TAPE MEASURE

TAPE MEASURE

1. Check bottom side of top for pre-bored mounting holes. (If done, move to

Step 4.)

2. If top ordered does not have pre-bored mounting holes, place top upside

down on a protective surface and locate trifoil column in desired location

centered in top depth and no more than 18" from end of top to center of

column and mark location using mounting plate holes as location guide.

3. After marking mounting plate hole locations, remove trifoil column and

pre-bore /" diameter x /" deep holes at previously marked locations.

4. Attach trifoil column to bottom side of top with HK-98, aligning holes in

mount plate with pre-bored holes in top.

5. Leveler in bottom of trifoil column can be adjusted out, up to 1", to level the

top as needed.

TRIFOIL COLUMN ASSEMBLY

TRIFOIL COLUMN ASSEMBLY

HK-98

HK98

BOTTOM OF TOP

BOTTOM OF TOP

INSTRUCTIONS

* With top upside down on a protective surface

Dwg:

Rev:

2567INS - PAGE 1

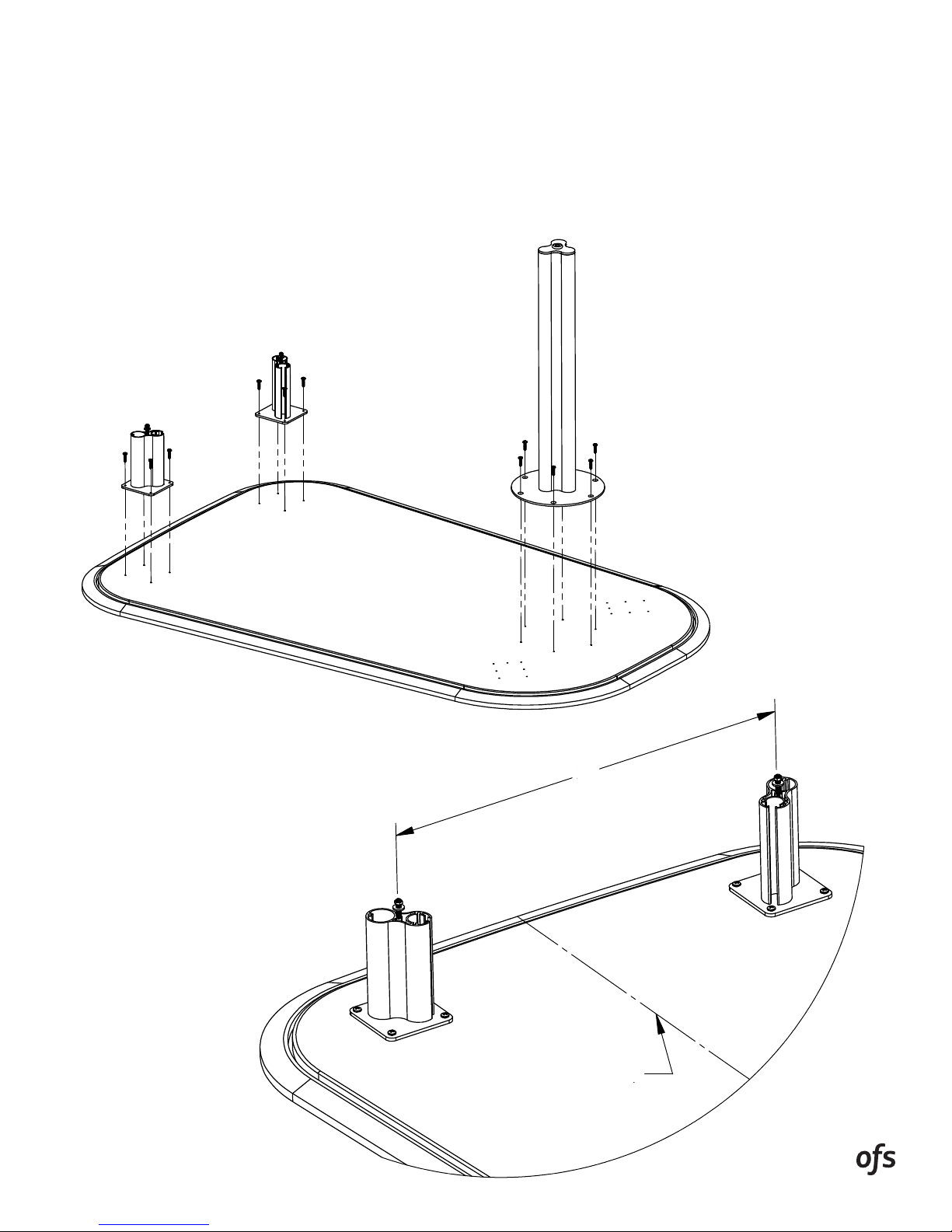

ELEVATED RUNOFF TOP INSTALLATION

APTOS

INSTRUCTION SHEET # 2567INS

PART # 1699910

ELEVATED RUNOFF TOP

INSTALLATION INSTRUCTIONS

1. With top upside down on a protective surface install both

install both Duofoil standoffs and the runoff support

Duofoil standoffs and the runoff support (Trifoil column,

(Trifoil column, Duofoil legs, Runoff end panel)using

Duofoil legs, Runoff end panel) using the instructions &

the instructions & hardware supplied with each item.

hardware supplied with each item.

* Aligning the holes in the mounting plates with the

2. Aligning the holes in the mounting plates with the pre-bored

pre-bored holes in the top. Position the wire cavity so

holes in the top. Position the wire cavity so that it faces the

that it faces the knee space of the top.

knee space of the top.

* The Duofoil pieces will be rotated at a 45

angle

3. The Duofoil pieces will be rotated at a 45 angle.

4. Measure the center to center distance of the

* Measure the center to center distance

mounting studs on the Duofoil standoffs.

of the mounting studs on the Duofoil standoffs.

5. This measurement will be used to bore the

* This measurement will be used to bore the

mounting holes in the top of the low height

mounting holes in the top of the low height

cabinet in the next step.

cabinet in the next step.

XX

XX

CENTER LINE OF TOP

Center line of top

INSTRUCTIONS

Dwg:

Rev:

2567INS - PAGE 2

* Determine application (open plan or private office), open plan is located 3.5" off front edge

of cabinet, private office is located 9" off the back edge of the cabinet.

* Locate desired placement side to side on the low height cabinet and mark the center line location of

the elevated runoff top.

* Divide the C-C measurement peviously taken from the standoffs on the elevated runoff top &

divide it by 2.

* Measure this distance both ways from the top center line along with the front to back dimension

(3.5" or 9") depending on the application to find center points of the standoffs.

INSTRUCTIONS

XX/2

XX/2

XX

(C-C of standoff

mounting studs)

Dwg:

Rev:

2567INS - PAGE 2

* Verify that the marked locations of the standoff mounting holes are not located over a

divider panel or end panel. If they are shift location of top to clear obstructions.

* Tape off area to be drilled to help protect the finished surface. Center punch the 2 locating

holes to be bored.

* Bore the 2 mounting holes for the standoffs using a 3/8" drill bit thru the top of the low height

cabinet.

* Remove tape and carefully install the elevated runoff top being careful not to scratch the finished

top surface of the low height cabinet when placing the studs into the bored holes.

* Once the elevated runoff top is placed secure it with the washer and nut supplied with the standoffs.

* Level top with the adjustable leveler in the runoff end support.

* Determine application (open plan or private office), open plan is located 3.5" off front edge

of cabinet, private office is located 9" off the back edge of the cabinet.

* Locate desired placement side to side on the low height cabinet and mark the center line location of

the elevated runoff top.

* Divide the C-C measurement peviously taken from the standoffs on the elevated runoff top &

divide it by 2.

* Measure this distance both ways from the top center line along with the front to back dimension

(3.5" or 9") depending on the application to find center points of the standoffs.

Locate center line of eleveated runoff top

9

Private Office

3.5

Open Plan

APTOS

PART # 1699910

INSTRUCTION SHEET # 2567INS

ELEVATED RUNOFF TOP

INSTALLATION INSTRUCTIONS

6. Determine application (open plan or private office), open plan is located 3.5” off front edge of cabinet, private office is located

9” off the back edge of the cabinet.

7. Locate desired placement side to side on the low height cabinet and mark the center line location of the elevated runoff top.

8. Divide the C-C measurement peviously taken from the standoffs on the elevated runoff top & divide it by 2.

9. Measure this distance both ways from the top center line along with the front to back dimension (3.5” or 9”) depending on the

application to find center points of the standoffs.

XX

(C-C of standoff

(CC OF STANDOFF

MOUNTING STUDS)

mounting studs)

XX

XX/2

XX/2

XX/2

XX/2

PRIVATE OFFICE

Private Office

9"

9

3.5

3.5"

OPEN PLAN

Open Plan

10. Verify that the marked locations of the standoff mounting holes are not located over a divider panel or end panel.

If they are shift location of top to clear obstructions.

11. Tape off area to be drilled to help protect the finished surface. Center punch the 2 locating holes to be bored.

12. Bore the 2 mounting holes for the standoffs using a 3/8” drill bit thru the top of the low height cabinet.

13. Remove tape and carefully install the elevated runoff top being careful not to scratch the finished top surface of

the low height cabinet when placing the studs into the bored holes.

14. Once the elevated runoff top is placed secure it with the washer and nut supplied with the standoffs.

15. Level top with the adjustable leveler in the runoff end support.

LOCATE CENTER LINE OF ELEVATED RUNOFF TOP

Locate center line of eleveated runoff top

INSTRUCTIONS

DUOFOIL STANDOFFS

NOTE: TOPS REQUIRE TWO STANDOFFS AT EACH ELEVATED END

ELEVATED RUN OFF TOPS:

STEP 1: ON A PROTECTIVE SURFACE, PLACE TOP UPSIDE DOWN.

Dwg:

Rev:

2556INS

APTOS

INSTRUCTIONS

TAPE MEASURE

DRILL

DUOFOIL STANDOFFS

NOTE: TOPS REQUIRE TWO STANDOFFS AT EACH ELEVATED END

ELEVATED RUN OFF TOPS:

STEP 1: ON A PROTECTIVE SURFACE, PLACE TOP UPSIDE DOWN.

STEP 2: POSITION THE STANDOFF AT A 45 ANGLE TO THE EDGE

OF THE TOP WITH THE WIRE CAVITY SLOT FACING TOWARD

THE KNEESPACE, ALIGN HOLES IN THE MOUNT PLATE WITH

THE PRE BORED HOLES IN THE TOP & ATTACH USING HK-31.

STEP 3: REPEAT STEPS 1-2 FOR REMAINING STAND OFFS.

Dwg:

Rev:

2556INS

Dwg:

Rev:

2556INS

DUOFOIL STANDOFFS

INSTALLATION INSTRUCTIONS

PA RT # 17 11259

INSTRUCTION SHEET # 2556INS

Note: TOPS REQUIRE TWO STANDOFFS AT EACH ELEVATED END

DRILL

DRILL

BOTTOM

BOTTOM

SIDE

SIDE

TAPE MEASURE

TAPE MEASURE

ELEVATED RUN OFF TOPS:

1. On a protective surface, place top upside down.

2. Position the standoff at a 450 angle to the edge of the top with

the wire cavity slot facing toward the kneespace, align holes

in the mount plate with the pre bored holes in t he top and

attach using HK-31.

3. Repeat the above two steps for remaining standoffs.

MODULAR TOPS:

1. On a protective surface, place top upside down.

2. Position the standoffs at a 450 angle to the edge of the top

with the wire cavity slot facing toward the kneespace. See

diagram to the right for locations.

(Note: The edge of the mounting plate will be parralel with

the edge of top)

3. With the standoff in the correct position attach using HK-31

(No pre boring needed).

4. Repeat the above three steps for remaining standoffs.

MOUNTING LOCATIONS FOR MODULAR TOPS

BEING USED IN AN ELEVATED APPLICATION

WIRE CAVITY

MOUNTING LOCATIONS FOR MODULAR TOPS

BEING USED IN AN ELEVATED APPLICATION

4.875

END OF

TOP

1" FOR 18"D TOPS

1" FOR 18"D TOPS

2" FOR 24"D TOPS

2" FOR 24"D TOPS

4.875

INSTRUCTIONS

1. WITH TOP UPSIDE DOWN ON A PROTECTIVE SURFACE

PLACE END PANEL ASSEMBLY ON TOP AS SHOWN

(CENTERED SIDE TO SIDE), INSET 1/8" FROM OUTER END OF TOP

& ATTACH WITH HK-98.

Rev:

Dwg:

2549INS

APTOS

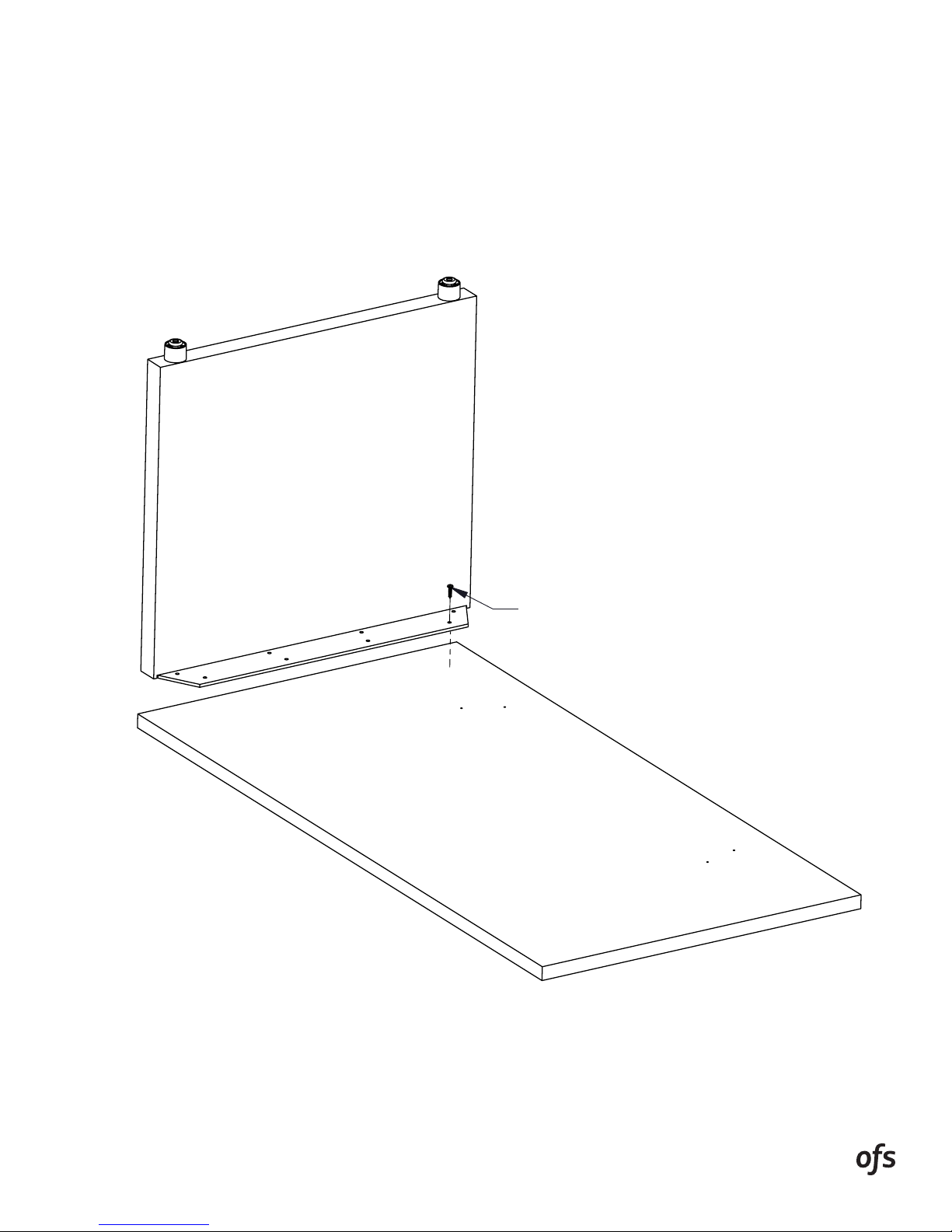

END PANEL

ASSEMBLY INSTRUCTIONS

PA RT # 169 76 63

INSTRUCTION SHEET # 2549INS

HK-98

HK-98

(8) #12 x 1" Screws

(8) #12 X 1" SCREWS

BOTTOM OF TOP

BOTTOM

OF TOP

1. With top upside down on a protective surface, place end

panel assembly on top as shown (centered side-to-side).

2. Inset /" from outer end of top and attach with HK-98.

APTOS

HEIGHT ADJUSTABLE CREDENZA

INSTALLATION INSTRUCTIONS

WARNING: UNIT WILL NOT STAND ON IT’S OWN ONCE ASSEMBLED.

MUST BE CONNECTED TO A PED OR END PANEL AT BOTH ENDS (18”D minimum).

PA RT # 17 1125 6

INSTRUCTION SHEET # 2553INS

1. Place top upside down on a protective surface.

2. Install the control box with HK-92 and control switch with

2 screws from HK-83 aligning with pre-bored holes. (Switch can

be mounted on left or right side of top.)

3. Position base upside down on top and align holes in mount plates

with pre-bored holes in top. (Stabilize the base through the next

steps until secured to the top.)

4. Connect each lift column to the control box using one control

cable, then insert into control box and plug into a power source.

STEP 6: HK71

DETAIL A

SCALE 1:4

RECESSED FINGER GRIP

ON BOTTOM PANEL

5. Press the down arrow button on the control switch to syncronize

the lift columns. Press the up arrow on the control switch to raise

the base approx 10" allowing access to the mounting plates.

6. Attach the base to the top using HK-71 through the mounting

plates aligning with the pre-bored holes in the top.

7. Use the remaining screws from HK-83 along with the cord clips &

one wraps to clean up & secure wires underneath the top

as desired.

LOWER FRONT PANEL REMOVABLE

(PULL AWAY FROM CABINET)

A

STEP 2

HK83

STEP 2

HK92

APTOS

INSTRUCTIONS

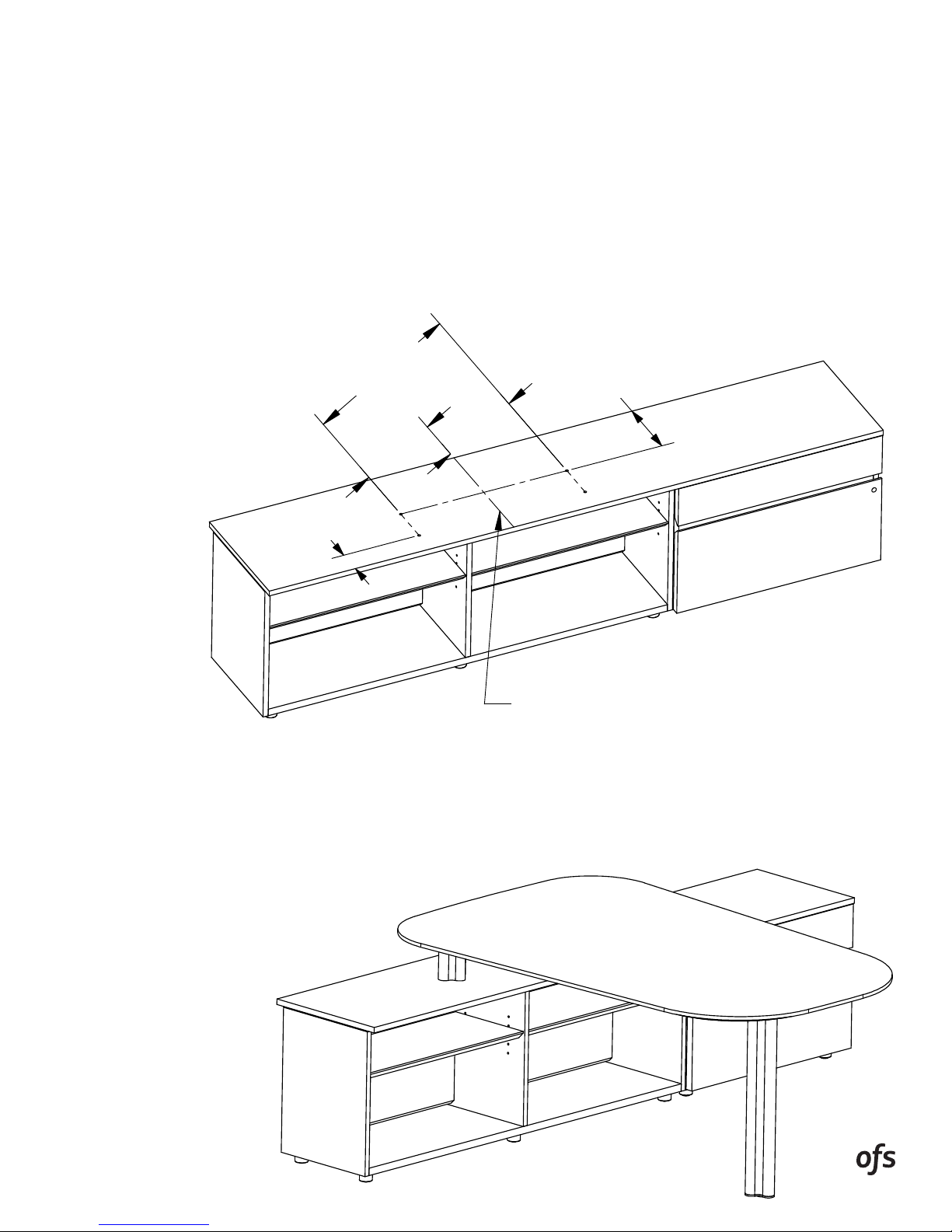

ATTACHING HEIGHT ADJUSTABLE CREDENZA TO ADJOINING CABINET

* Remove lower face panel of height adjustable credenza (pulling away from cabinet) using machined finger grips

wood screws in pre-bored holes. Repeat for cabinet on opposite side of height adjustable credenza.

on bottom side of cabinet.

* Pre-bore minimum of four .125" holes in both end panels of height adjustable credenza from inside of cabinet.

* Align height adjustable credenza cabinet with adjoining cabinet and level. Once level and aligned insert 4 #8 x 1.25"

2553INS - Page 2 Rev: _Dwg:

INSTRUCTION SHEET # 2553INS

HEIGHT ADJUSTABLE CREDENZA ATTACHING TO ADJOINING CABINET

INSTALLATION INSTRUCTIONS

WARNING: HEIGHT ADJUSTABLE CREDENZA WILL NOT STAND ON IT’S OWN.

STABALIZE CABINET AT ALL TIMES UNTIL SECURED TO ADJOINING CABINETS.

Note: MUST HAVE A CABINET OR END PANEL MINIMUM 18”D ATTACHED ON EACH SIDE FOR STABILITY.

1. Remove lower face panel of height adjustable credenza (pulling away from

cabinet) using machined finger grips on bottom side of cabinet.

2. Pre-bore minimum of four .125" diameter holes in both end panels of height

adjustable credenza from inside of cabinet.

3. Align height adjustable credenza cabinet with adjoining cabinet and level. Once

level and aligned, insert 4 #8x1.25" wood screws in pre-bored holes. Repeat for

cabinet on opposite side of height adjustable credenza.

PA RT # 17 1125 6

PREBORE FOR ATTACHMENT

pre-bore for attachment

REPEAT ON OPPOSITE SIDE,

repeat on opposite side,

LOCATIONS ARE APPROXIMATE.

locations are approximate.

MACHINED FINGER GRIPS

Machined finger grips

FOR PANEL REMOVAL.

for panel removal

INSTRUCTIONS

Rev:

Dwg:

APTOS

HEIGHT ADJUSTABLE PENINSULA DESK

INSTALLATION INSTRUCTIONS

PA RT # 17 1125 5

INSTRUCTION SHEET # 2552INS

DRILL

DRILL

4MM ALLEN WRENCH

4MM ALLEN WRENCH

HEIGHT ADJUSTABLE PENINSULA DESK

STEP 1: LOCATE WALL CABINET IN DESIRED LOCATION & LEVEL. REMOVE SCREWS

FROM ADJUSTABLE SHELF CLIPS FOR ACCESS TO FLIP DOWN BACK PANEL IN

OPEN STORAGE AREA. (THE LOWER FRONT OF THE LIFT COLUMN CAVITY IS

REMOVABLE BY PULLING PANEL AWAY FROM THE CABINET)

FINGER GRIP FOR

FINGER GRIP FOR

REMOVABLE PANEL

REMOVABLE PANEL

NOTE: 2 PERSON INSTALL

NOTE: 2 PERSON INSTALL

1. Locate wall cabinet in desired location and level. Remove

screws from adjustable shelf clips for access to flip down

back panel in open storage area. (The lower front of the lift

column cavity is removable by pulling panel away from the

cabinet.)

REMOVABLE PANEL ASSEMBLED

FACING KNEESPACE

REMOVABLE PANEL

REMOVABLE PANEL

STEP 2: REMOVE MOUNT PLATE ON RUNOFF BASE

2. Remove mount plate on runoff base and rotate 90°

AND ROTATE 90

from shipping position to assembly position as shown

TO ASSEMBLY POSITION AS SHOWN AND RE ATTACH.

and re-attach.

FROM SHIPPING POSITION

INSTRUCTIONS

2552INS - Page 2 Rev:

Part # - 2 Pages

APTOS

HEIGHT ADJUSTABLE PENINSULA DESK

INSTALLATION INSTRUCTIONS

PA RT # 17 1125 5

INSTRUCTION SHEET # 2552INS

STEP 2C

STEP 5

3. With worksurface upside down on a protective surface,

STEP2: A. WITH WORK SURFACE UPSIDE DOWN ON A PROTECTIVE SURFACE

INSTALL THE CONTROL BOX WITH HK-92

B. ATTACH THE CONTROL SWITCH WITH HK-83 (USE REMAINING SCREWS

IN KIT TO SECURE WIRES AT THE END OF THE ASSEMBLY PROCESS)

C. LOCATE RUNOFF BASE ASSEMBLY OVER PRE-BORED HOLE LOCATIONS

IN TOP AND ATTACH USING HK-71(ONLY 4 HOLES WILL BE ACCESIBLE

DURING THIS STEP).

STEP 2B

STEP 4

STEP 3

install the control box with HK-92.

4. Attach the control switch with HK-83. (Use remaining screws

in kit to secure wires at the end of the assembly process.)

5. Locate runoff base assembly over pre-bored hole locations

in top and attach using HK-71. (Only 4 holes will be accesible

during this step.)

STEP 2A

STEP 3: A. FLIPOVER PREVIOUSLY ASSEMBLED TOP & RUNOFF BASE AND PLACE ON WALL CABINET MOUNTING

6. Flip over previously assembled top and runoff base and

PLATE AS SHOWN BELOW. (WILL NOT BE FASTENED UNTIL STEP 3 D).

place on wall cabinet mounting plate as shown below. (Will

B. CONNECT RUNOFF BASE LIFT COLUMN WITH THE LONG CONTROL CABLE TO THE CONTROL BOX

not be fastened until Step 9.)

AND THE WALL CABINET LIFT COLUMN TO THE CONTROL BOX WITH SHORT CONTROL CABLE.

7. Connect the runoff base and wall cabinet lift columns to the

THEN CONNECT THE CONTROL SWITCH TO THE CONTROL BOX. NEXT CONNECT THE MAINS (POWER)

CABLE TO THE CONTROL BOX AND PLUG INTO A POWER SOURCE.

control box using the supplied motor cables. Then connect

C. SYNCRONIZE THE LIFT COLUMNS BY PRESSING THE DOWN ARROW BUTTON ON THE CONTROL SWITCH UNTIL

the control switch to the control box. Next, connect the

THEY BOTTOM OUT. ONCE RESET PRESS THE UP ARROW BUTTON TO RAISE THE WORKSURFACE APPROX

Mains (power) cable to the control box and plug into a

10" TO ACCESS THE LIFT COLUMN MOUNTING PLATES.

power source.

D. ONCE THE WORSURFACE IS RAISED FINISH INSTALLING THE REMAINING SCREWS FROM HK-71

8. Syncronize the lift columns by pressing the DOWN arrow

ALIGNING THE HOLES IN THE MOUNT PLATES WITH PRE-BORED HOLESIN THE TOP.

button on the control switch until they bottom out. Once

E. USE REMAINING SCREWS FROM HK-83 ALONG WITH WIRE CLIPS & ONE WRAPS TO CLEAN UP

reset, press the UP arrow button to raise the worksurface

WIRES UNDERNEATH THE TOP AS DESIRED.

approx. 10" to access the lift column mounting plates.

F. USE THE DOWN ARROW BUTTON ON THE CONTROL SWITCH TO LOWER THE TOP BACK TO THE

9. Once the worksurface is raised, finish installing the

remaining screws from HK-71, aligning the holes in the

mount plates with pre-bored holes in the top.

10. Use remaing screws from HK-83, along with wire clips and

one wraps to clean up wires underneath the top as desired.

11. Use the DOWN arrow button on the control switch to lower

the top back to the lowest position and level the runoff base

as needed to level the worksurface.

LOWEST POSITION AND LEVEL THE RUNOFF BASE AS NEEDED TO LEVEL THE WORKSURFACE.

INSTRUCTIONS

WORK SURFACE INSTALLATION

LOW HEIGHT CABINET

Cabinets can be built either upright or upside-down.

Remove drawers and adjustable shelves from pedestals.

Lower fold-down backs in open pedestals.

Cabinets can be pilot bored and screwed together using

•

WORK SURFACE

HEIGHT CABINET

Rev:

Dwg:

2561INS

LOW HEIGHT CABINET

Rev:

Dwg:

2561INS

LOW HEIGHT CABINET

LOW HEIGHT CABINET

1.25 1.25

Rev:

Dwg:

2561INS

1.25 1.25

Rev:

Dwg:

2561INS

LOW HEIGHT CABINET

1.25 1.25

Rev:

Dwg:

2561INS

APTOS

INSTRUCTIONS

WORK SURFACE INSTALLATION

LOW HEIGHT CABINET

WORK SURFACE

HEIGHT CABINET

LOW HEIGHT CABINET

Pre-drilled holes

Pre-drilled holes

1.25 1.25

BACK PANEL INSTALLATION

Cabinets can be built either upright or upside-down.

•

Remove drawers and adjustable shelves from pedestals.

•

Lower fold-down backs in open pedestals.

•

Cabinets can be pilot bored and screwed together using

•

#8 x 1 1/4" pan head screws. (Note that this will deface

the outside of these cabinets).

Place work surface on cabinets with 1.25" overhang to front

•

and back of SIDE PANEL.

Attach work surface by screwing #8 x 1 1/4" pan head screws (HK-15)

•

through pre-drilled holes in case spacers or top panels.

WORK SURFACE

HEIGHT CABINET

Rev:

Dwg:

2561INS

MODULAR PEDESTALS

ASSEMBLY INSTRUCTIONS

PA RT # 169 7 86 3

INSTRUCTION SHEET # 2561INS

Worksurface Installation

1. Cabinets can be built either upright or upside down.

2. Remove drawers and adjustable shelves from pedestals.

3. Lower fold-down backs in open pedestals.

4. Cabinets can be pilot bored and screwed together using #8 x 1/" pan head screws.

(Note that this will deface the outside of these cabinets).

5. Place worksurface on cabinets with 1.25" overhang to front and back of SIDE PANEL.

6. Attach worksurface by screwing #8 x 1/" pan head screws (HK-15) through pre-drilled

holes in case spacers or top panels.

WORKSURFACE HEIGHT CABINET

Pre-drilled holes

Pre-drilled holes

(Reference #6)

LOW HEIGHT MODULAR CABINET

(Reference #5)

Pre-drilled holes

(Reference #6)

•

•

•

Back Panel Installation

1. Place back panel against cabinets so vein lined edge is against end panels. (Figure A)

2. Use a pry bar to lift back panel until it contacts the worksurface and is flush to the

bottom of the end panels.

3. When back panel is in place, secure by screwing #8 x 1/" pan head screws (HK-15)

through pre-drilled holes in case spacers.

WORKSURFACE HEIGHT CABINET

Pre-drilled holes

Pre-drilled holes

(Reference #3)

LOW HEIGHT MODULAR CABINET

Pre-drilled holes

(Reference #3)

Figure

fig. A

A

VEIN

Vein

LINE

Line

INSTRUCTIONS

CENTER PUNCH LOCATING

Rev:

Dwg:

2548INS

APTOS

SURFACE MOUNT PRIVACY SCREENS

ASSEMBLY INSTRUCTIONS

PA RT # 17 1125 3

INSTRUCTION SHEET # 2548IN S

TEMPLATE

TEMPLATE

TAPE OFF AREA

TAPE OFF AREA

TO BE DRILLED

TO BE DRILLED

30

30

VERIFY BEFORE DRILLING

VERIFY BEFORE DRILLING

NOTE: If unit was pre-bored at the factory, move to Step 4.

1. Determine “Y” dimension (center of privacy panel) and tape off area to be

drilled to protect finished surface.

2. Locate template in desired location using centerlines of template and

center punch the 2 locating holes on template.

3. Remove template and verify 30" center to center between locating hole

marks and drill 2 holes /" diameter to a depth of /" at previously

marked locations, remove tape after drilling.

4. Install (HK-118) mounting pins into /” diameter holes and secure with

supplied #10 x 1" screw (2 per pin) long edge of plate parallel to length

of privacy screen.

5. Position privacy screen onto mounting pins aligning holes in bottom of

privacy screen and slide down to worksurface.

STEP 2:

STEP 2:

CENTER PUNCH LOCATION

HOLES ON TEMPLATE

HOLES ON TEMPLATE

“Y”

"Y"

CASEGOODS

WALLMOUNT STORAGE & TACKBOARD

INSTALLATION INSTRUCTIONS

PA RT # 169 819 9

INSTRUCTION SHEET # 2566INS

68 1/4

35

TACKBOARD WITH

NO WALL UNIT

3

38.75

TACKBOARD UNDER

WALL UNIT

17.5

WORKSURFACE HEIGHT LOW HEIGHT

1. After cabinets are assembled and leveled in desired location, use a

carpenter’s level to draw a line where the top of the wallmount storage

or tackboard will be.

2. The line will be either 38.75" above a worksurface height cabinet or 46"

above a low height cabinet.

3. Draw a second line 3 inches lower than the first line for the wall unit or

upper tackboard wall bracket.

TACKBOARD UNDER

WALL UNIT

TACKBOARD WITH

NO WALL UNIT

46

40

3

4. If mounting a tackboard under a wall unit, draw an additional line 17.5"

below the first line.

5. Draw last line for lower tackboard wall brackets 35" lower than first line

for worksurface height cabinets or at 40" for low height cabinets.

6. Position the wall brackets (DETAIL B) so the bottom edges are on lines

and are also positioned so they will line up with the brackets that are

mounted onto the back of the panels. (A small level is included and can

be snapped onto the wall bracket, to aid with installation (BRACKET B).

Mark the hole locations.

7. Drill holes into the wall where marked and fasten the wall brackets.

Hardware is provided, but may not be appropriate for your wall type. A

professional contractor should determine the best attaching hardware

for each specific application.

8. Remove the small level from the wall brackets once they are attached to

the wall.

9. Hang tackboards onto the wall brackets first. Then hang wall units.

Wall Bracket

Wall Mounted

Portion of

Brackets

Small level snaps

Pencil Line

Cabinet

Mounted

Portion of

Brackets

in place here

INSTRUCTIONS

WORK SURFACE STORAGE INSTALLATION

Rev:

Dwg:

2562INS

INSTRUCTIONS

ALIGN FLUSH

TO BACK EDGE

WORK SURFACE STORAGE INSTALLATION

Rev:

Dwg:

2562INS

APTOS

WORKSURFACE STORAGE

INSTALLATION INSTRUCTIONS

TWOSIDED TAPE

TWO-SIDED TAPE

PA R T # 169 9 5 41

INSTRUCTION SHEET # 2562INS

ALIGN FLUSH

ALIGN FLUSH

TO BACK EDGE

TO BACK EDGE

1. Peel off one side of backer on two-sided tape.

2. Apply two-sided tape to bottom of cabinet.

3. Peel off second backer.

4. Position cabinet where desired, with back edge flush to the edge of the

top, and set in place.

FLUSH TO BOTTOM

EDGE OF TOP

Stack-EM-Pak

5. Position Stak-EM-Paks (HK-7) so they are parallel and inset from the

edge of the back panel by at least /". The rounded edge of the Stak-EMPak should also be flush to the bottom edge of the top.

6. Mark hole locations and pre-drill /" diameter x /" deep pilot holes.

7. Secure Stak-EM-Paks with #8 x /" pan head screws. (HK-7)

APTOS

INSTRUCTIONS

Dwg:

Rev:2583INS

Part # 1763420

EDGE MOUNT PRIVACY PANELS

INSTALLATION INSTRUCTIONS

PART # 1763420

INSTRUCTION SHEET # 2583INS

1. Aligning the holes in the brackets with the pre-bored holes in the panel

attach (3) mounting brackets to the privacy panel using (2) #8 x 1.5" pan

head wood screws in each bracket.

1. Aligning the holes in the brackets with the pre-bored

holes in the panel attach (3) mounting brackets to

the privacy panel using (2) #8 x 1.5" pan head wood

screws in each bracket.

Aptos - Edge Mount Privacy Panels

2. Leaving a 1.5" wire management gap between the

2. Leaving a 1.5" wire management gap between the

worksurface edge and the face of the privacy panel,

worksurface edge and the face of the privacy panel,

locate the privacy panel centered in the kneespace

locate the privacy panel centered in the kneespace

of the desk with the top of the mounting brackets flush

of the desk with the top of the mounting brackets

to the underside of the work surface and attach the

flush to the underside of the worksurface and attach

brackets to the work surface using (4) #8 x 1" pan head

the brackets to the worksurface using (4) #8 x 1" pan

wood screws in each bracket.

head wood screws in each bracket.

APTOS

INSTRUCTIONS

LOCATE CROSS RAIL & MEASURE FINISHED TOP

OF ASSEMBLY TO DETERMINE KNEE SPACE SIZE

XX

2564INS - PAGE 1

Rev: _Dwg:

STEP 1: UNPACK AND VERIFY ALL CABINETS, CROSS RAILS, & TOPS.

STEP 2: DETERMINE FOOT PRINT SIZE.

A.WIDTH (X) IS FIGURED BY ADDING ALL HEIGHT ADJUSTABLE CABINET DEPTHS

AND KNEE SPACES (ADD 8" FOR 6"D BASES.

B. DEPTH (Y) IS DETERMINED BY ADDING ALL WIDTHS OF ADD ON STORAGE

CABINETS IN THE LONGEST RUN.

OUTSIDE OF BASE 2".

INSTRUCTIONS

2564INS - PAGE 1

STEP 1: UNPACK AND VERIFY ALL CABINETS, CROSS RAILS, & TOPS.

STEP 2: DETERMINE FOOT PRINT SIZE.

A.WIDTH (X) IS FIGURED BY ADDING ALL HEIGHT ADJUSTABLE CABINET DEPTHS

OPEN PLAN

INSTALLATION INSTRUCTIONS

XX

LOCATE CROSS RAIL & MEASURE FINISHED TOP

LOCATE CROSS RAIL AND MEASURE FINISHED TOP

OF ASSEMBLY TO DETERMINE KNEE SPACE SIZE

OF ASSEMBLY TO DETERMINE KNEE SPACE SIZE

INSTRUCTION SHEET # 2564INS

X

XX

XX

1. Unpack and verify all cabinets, cross rails and tops.

2. Determine foot print size.

A. Width (X) is figured by adding all height adjustable cabinet depths and

knee spaces (Add 8" for 6"D bases).

B. Depth (Y) is determined by adding all widths of add on storage cabinets

in the longest run.

STEP 3: USING THE FOOT PRINT SIZE LOCATE THE CENTER OF THE UNIT TO START ASSEMBLY.

3. Using the foot print size, locate the center of the unit to start assembly.

XXX

YY

YYY

YY

YY

NOTE: IF A 6"D END BASE IS CHOSEN, ADD 8"

WHEN CALCULATING OVERALL FOOTPRINT WIDTH,

THE WORKSURFACE WILL OVERHANG OUTSIDE OF

BASE 2".

NOTE: IF A 6"D END BASE IS CHOSEN, ADD 8"

WHEN CALCULATING OVERALL FOOTPRINT

WIDTH, THE WORKSURFACE WILL OVERHANG

APTOS

INSTRUCTIONS

Rev: _2564INS - PAGE 2Dwg:

BASES. CONNECT THE IN-FEED AND HAVE WIRED INTO FLOOR CORE.

STEP 9: IF APPLICABLE - TO INSTALL PRIVACY PANELS REFERENCE INSTRUCTION SHEET 2548INS (COMES WITH PRIVACY PANELS)

STEP 4: AFTER DETERMINING THE CENTER OF THE UNIT IN THE SPACE AVAILABLE PLACE THE HEIGHT ADJUSTABLE BASES TO MATCH THE CONFIGURATION

OF THE SPEC DWG FOR THE SET UP. INSERTING THE CROSS RAILS INTO WIRE MANAGEMENT CUT OUTS ON THE SIDE OF THE HEIGHT ADJUSTABLE

BASES. SECURINGTHEM AT A LATER TIME. (6"D BASES WILL NOT STAND ALONE UNTIL ATTACHED TO THE CROSS RAIL)

STEP 5: ROTATE THE WORKSURFACE MOUNTING PLATES FROM THE SHIPPING POSITION TO OVERHANGING THE KNEE SPACE AS SHOWN BELOW.

STEP 6: BEGIN LEVELING 2 OF THE BASES USING A LEVEL TO SPAN THE MOUNTING PLATES FRONT TO BACK AND ACROSS THE KNEESPACE TO THE NEXT

BASE SIDE TO SIDE. UP TO 1" OF ADJUSTMENT IS AVAILABLE BY TURNING THE LEVELER FOOT OUT. ONCE THE BASES ARE LEVEL THE CROSS RAIL

CAN BE ATTACHED. MARK THE CENTER OF THE TOP OF THE HEIGHT ADJUSTABLE BASES AND EACH END OF THE CROSS RAIL TOP FOR ALIGNMENT.

REMOVE THE LOWER PANEL OF THE BASES( PULL TOWARDS KNEE SPACE) FOR ACCESS AND ATTACH CROSS RAIL USING A HK-15. PLACE A

SQUARE ALONG THE EDGES OF THE CROSS RAIL TOP AND BASE TOP TO ENSURE SQUARENESS BEFORE SECURING.

STEP 7: REPEAT UNTIL ALL BASES ARE LEVEL AND CROSSRAILS ARE INSTALLED SQUARE.

STEP 8: CONNECT THE POWER JUMPER FROM ONE CROSS RAIL TO THE NEXT THROUGH THE WIRE MANAGEMENT CUT OUT IN THE HEIGHT ADJUSTABLE

NOTE: IT IS IMPORTANT THAT THE HEIGHT ADJUSTABLE BASES AND CROSS RAILS ARE INSTALLED LEVEL AND SQUARE

TO AID IN THE REST OF THE ASSEMBLY PROCESS.

OPEN PLAN

INSTALLATION INSTRUCTIONS

INSTRUCTION SHEET # 2564INS

4. After determining the center of the unit in the space available,

place the height adjustable bases to match the configuration

of the spec drawing for the set up. Inserting the cross rails

into wire management cut outs on the side of the height

adjustable bases. Securing them at a later time. (6”D bases

will not stand alone until attached to the cross rail.)

5. Rotate the worksurface mountaing plates from the shipping

position to overhanging the knee space as shown below.

6. Begin leveling 2 of the bases using a level to span the

mounting plates front to back and across the kneespace to

the next base side to side. Up to 1” of adjustment is available

by turning the leveler foot out. Once the bases are level the

cross rail can be attached. Mark the center of the top of the

STEP 5 - ROTATE MOUNT PLATES

STEP 5 - ROTATE MOUNT PLATES

height adjustble bases and each end of the cross rail top for

alignment. Remove the lower panel of the bases (pull towards

kneespace) for access and attach cross rail using a HK-15.

Place a square along the edges of the cross rail top and base

top to ensure squareness before securing.

7. Repeat until all bases are level and cross rails are installed

square.

8. Connect the power jumper from one cross rail to the next

through the wire management cut out in the height adjustable

bases. Connect the in-feed and have wired into floor core.

9. If applicable - to install privacy panels reference instruction

sheet 2548INS (Comes with Privacy Panels).

STEP 6 - LEVEL ACROSS MOUNTING

STEP 6 - LEVEL ACROSS MOUNTING PLATES

PLATES ON EACH BASE

ON EACH BASE

STEP 9 - PRIVACY SCREENS

STEP 9 - PRIVACY SCREENS

STEP 4 - LOCATE & SET CABINETS IN PLACE

STEP 4 - LOCATE AND SET CABINETS IN

WITH CROSS RAILS

PLACE WITH CROSS RAILS

APTOS

INSTRUCTIONS

_2564INS - PAGE 3 Rev:Dwg:

STEP 10: LOCATE AND PLACE SHARED STORAGE CABINETS. ALIGN AND LEVEL WITH PREVIOUSLY INSTALLED HEIGHT ADJUSTABLE BASES.

STEP 11: TEMPORARILY CONNECT CONTROL BOX TO THE LIFT COLUMNS WITH THE CONTROL CABLES, CONNECT CONTROL SWITCH TO THE

CONTROL BOX & CONNECT THE MAINS (POWER) CABLE TO THE CONTROL BOX AND THEN PLUG INTO A POWER SOURCE.

STEP 12: PRESS THE DOWN ARROW BUTTON ON THE CONTROL SWITCH TO SYNCRONIZE THE LIFT COLUMNS. PRESS THE UP ARROW BUTTON ON

ON THE CONTROL SWITCH TO RAISE THE LIFT COLUMNS, ALLOWING ACCESS FROM THE BOTTOM TO ATTACH THE WORK SURFACES.

STEP 13: PLACE A WORKSURFACE ON TWO LIFT COLUMNS SPANNING ACROSS A KNEE SPACE. WITH ONE PERSON SUPPORTING THE TOP AND

A SECOND PERSON SECURING THE WORK SURFACE FROM UNDERNEATH USING A HK-71 ALIGNING THE HOLES IN THE MOUNT PLATES

WITH THE PRE-BORED LOCATING HOLES IN THE BOTTOM OF THE SUB TOP. REPEAT FOR REMAINING TOPS.

STEP 14: MOUNT THE CONTROL BOX WITH HK-73 ALIGNING WITH THE 2 LOCATING HOLES IN THE BOTTOM OF THE WORK SURFACE AND THE

CONTROL SWITCH USING HK-83 USING THE PRE-BORED LOCATING HOLES ON THE LEFT OR RIGHT SIDE OF THE USER EDGE OF THE

WORKSURFACE.

STEP 15: USE THE REMAINING SCREWS FROM HK-83 ALONG WITH THE CORD CLIPS & ONE WRAP TO CLEAN UP AND SECURE WIRES UNDERNEATH

THE WORK SURFACE AS DESIRED.

OPEN PLAN

INSTALLATION INSTRUCTIONS

INSTRUCTION SHEET # 2564INS

10. Locate and place shared storage cabinets. Align and level with

previously installed height adjustable bases.

11. Temporarily connect control box to the lift columns with the

control cables, connect control switch to the control box and

connect the mains (power) cable to the control box and then

plug into a power source.

12. Press the down arrow button on the control switch to

syncronize the lift columns. Press the up arrow button on the

control switch to raise the lift columns, allowing access from

the bottom to attach the worksurfaces.

HK-71 aligning the holes in the mount plates with the prebored locating holes in the bottom of the sub top. Repeat for

remaining tops.

14. Mount the control box with HK-73 aligning with the 2 locating

holes in the bottom of the worksurface and the control switch

using HK-83 using the pre-bored locating holes on the left or

right side of the user edge of the worksurface.

15. Use the remaining screws from the HK-83 along with the cord

clips and one wrap to clean up and secure wires underneath

the worksurface as desired.

13. Place a worksurface on two lift columns spanning across a

knee space. With one person supporting the top and a second

person securing the worksurface from underneath using a

STEP 13 - INSTALLING THE WORKSURFACES

STEP 13 - INSTALLING THE WORKSURFACES

STEP 10 - INSTALL STORAGE CABINETS

STEP 10 - INSTALL STORAGE CABINETS

Loading...

Loading...