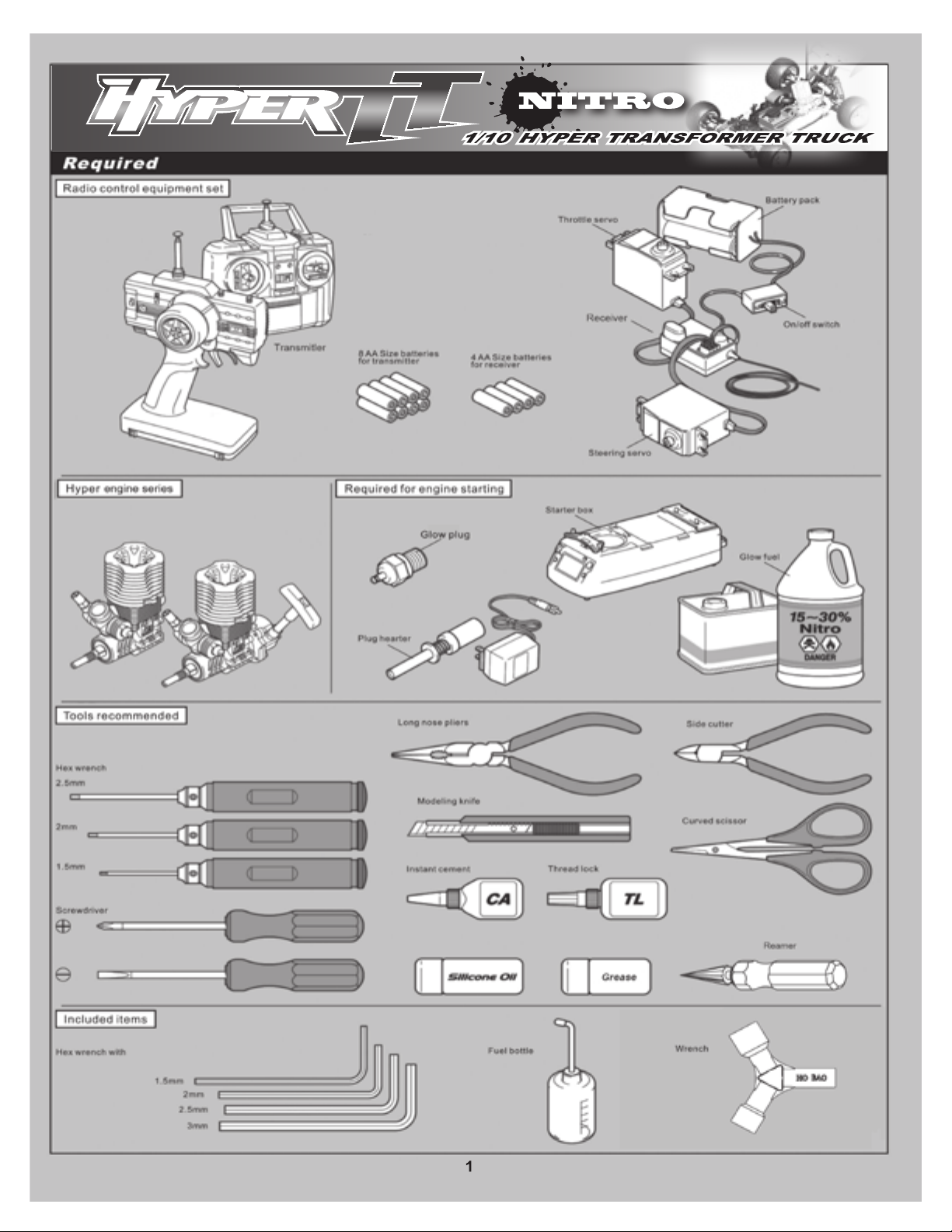

Page 1

Page 2

Page 3

Page 4

Page 5

LED Edition

2.4G DSSS Technology

3-Channel 2.4G Radio Control System

INSTRUCTION MANUAL

• Before using, read this manual carefully

AUX Channel

Steering Trim

Steering Wheel

TRIM LED

Power Switch

Charging Jack

Bind Switch

Throttle Trim

St. Dual Rate

Throttle Trigger

Battery Box

CAUTION

• To use your Radio with your models correctly and safely, read this manual carefully and keep it in a

safe place for future reference.

Warning:

1. This product is only equipped for radio controlled cars;

2. The usage of this product should be approved by local law or regulations;

3. We will not be responsible for the damages caused by unauthorized modification, adjustment

or replacement of parts on this product;

4. The manual may be change without prior notice. Please contact us if you have any corrections

or clarifications that should be made in the manual;

• Before turning on the transmitter, make sure the transmitter batteries are fresh. The voltage of the

transmitter batteries is never lower than 9.6V, and please check and confirm that the servos are

all well and properly connected.

• Keep the radio system away from moist, high temperature and strong vibrations. Do not clean radio

with any solvent.

• Make sure antenna does not touch anything when power switch is turned on. Do not leave this radio

in reach of small children.

• Please use this product according to your local laws and regulations, we are not responsible for any

incidents or damages.

Page 6

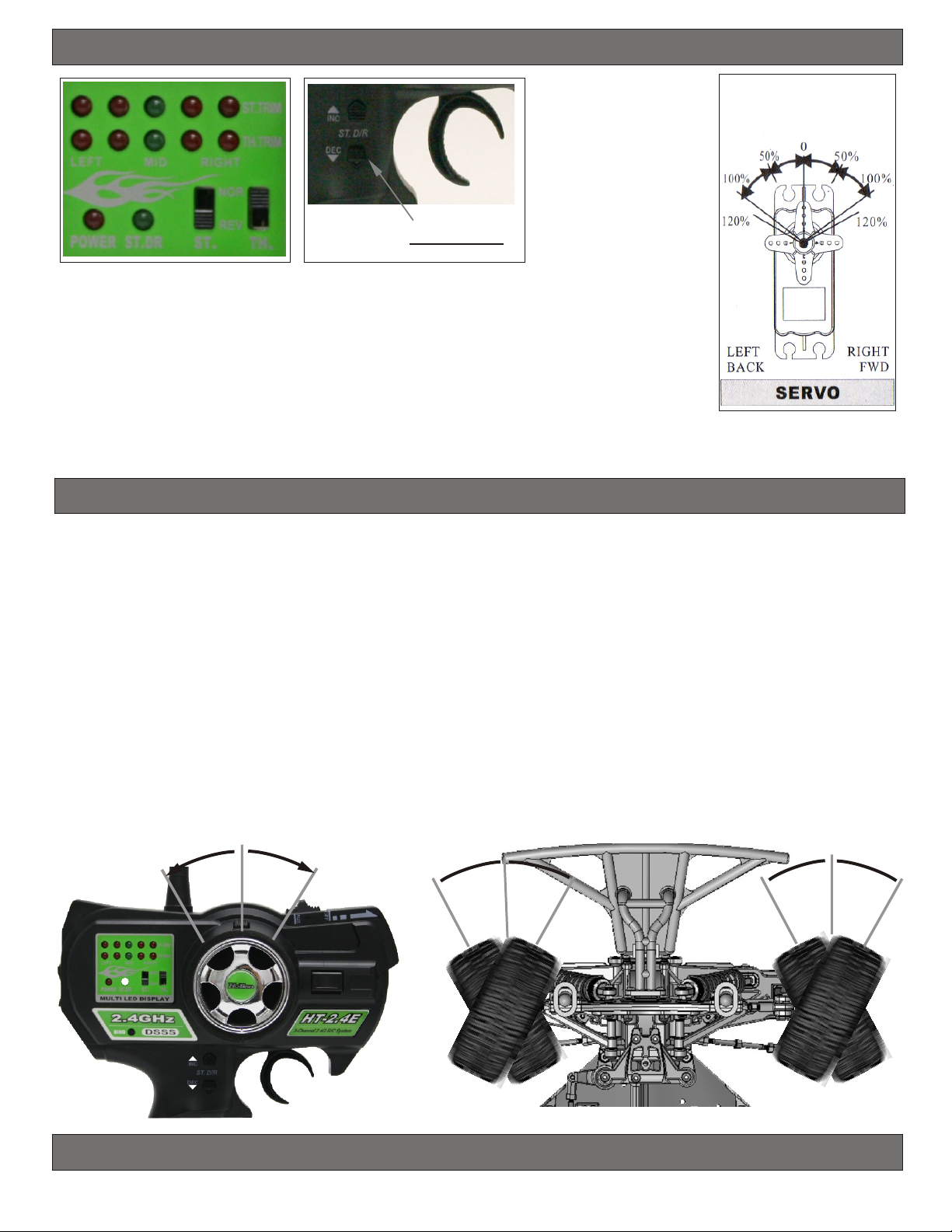

Steering Dual Rates Setup

LEFT

POWER

MID

ST.DR

RIGHT

ST.

ST.TRIM

TH.TRIM

NOR

REV

TH.

INC

ST.DR

DEC

ST.D/R SW

•DEFINITION:

Steering Dual Rate (ST. DR): Is the adjustment that allows the dual rate value (maximum

servo travel) to be increased (INC) or decreased(DEC) with in a range of 0% to 100%

of the steering servo. This functions very useful in a race conditions as it allows you to

tailor the steering radius and sensitivity for the current track conditions.

•ADJUSTMENT:

1.Press and hold the “INC” (Increase) button until the LED on the “ST.DR” turn solid

indicating the maximum turning radius or value of 100%.

2.Press and hold the “DEC” (Decrease) button until the LED on the ‘ST.DR” goes dim or out

to reach the minimum turning radius or value 0%.

CHECKING YOUR DUAL RATE

•To Check Your Dual Rate: First turn your radio “ON” then turn “ON” your

vehicle. Check your steering on your radio by turning left and right several

times. Now turn your steering wheel all the way to the left or right whichever

you choose and hold it their while pushing the “DEC” (decrease) button on

the “ST-DR” and hold it down, you should see that the wheel on your vehicle

decrease in radius and that the LED on “ST-DR” will start blinking and slowly

dim. Now to increase the dual rate turn the wheel left or right all the way and

hold it while pushing the “INC” button this will increase the radius of the wheel

and the LED on ST-DR will start blinking slowly and turning solid indicating

that the “Dual Rate” is at 100% . When running your vehicle try to run the

“Dual Rate” at maximum radius (100%). Then if you have too much steering

then decease as needed.

POWER ST.DR

00

1 %

INC

DEC

ST.D/R

0%

10

0%

0

%

1

00%

1

%00

0

0

1

0%

%

1

0

0

%

Page 7

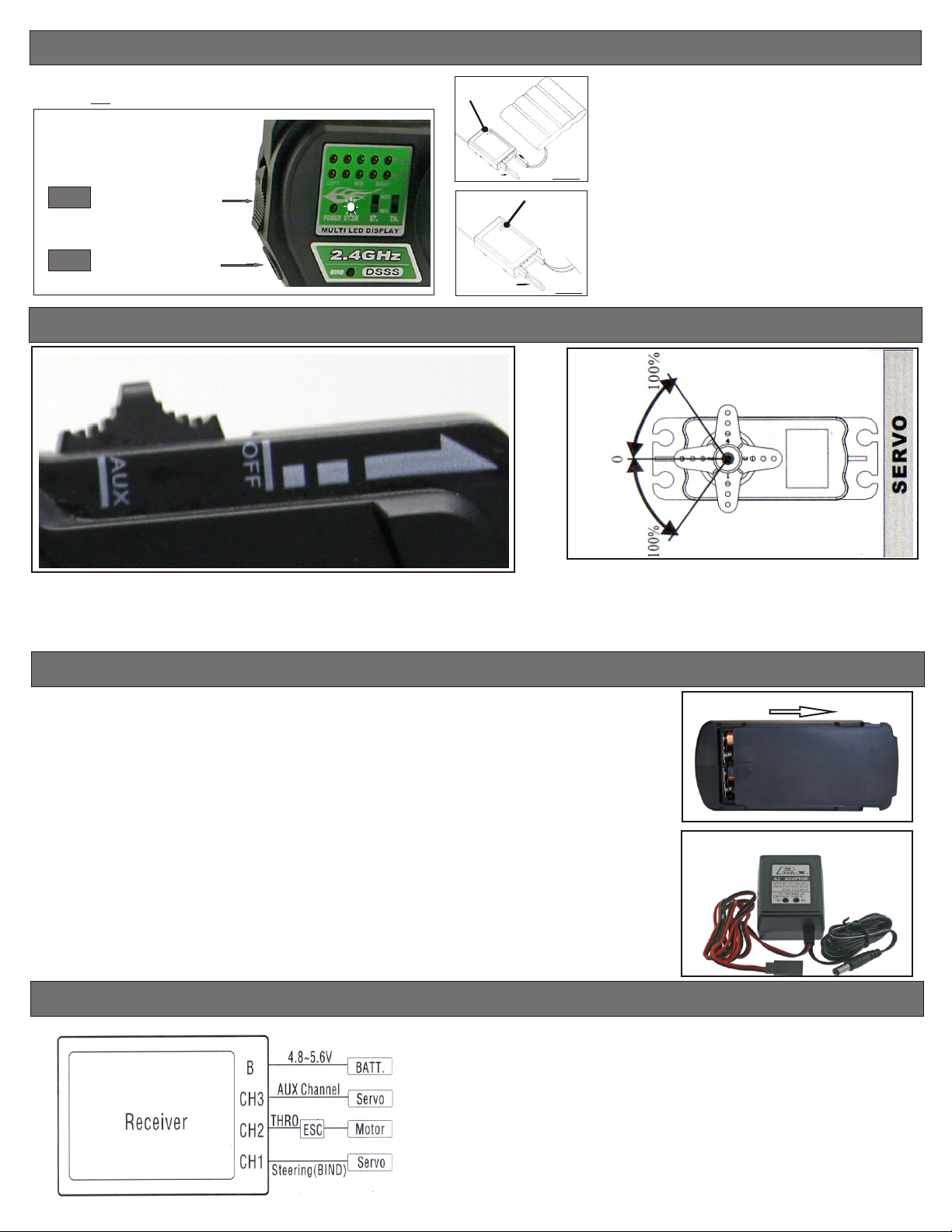

2.4Ghz Binding

•Press and hold the bind button on the front of the transmitter while

turning ON the power switch button until the (ST.DR) LED Flashes.

STEP 2

Power Switch (turn on)

STEP 1

Bind (Press and hold)

AUX Channel Function (CH3)

Flashing LED

Binding cable

Binding cable

Plug In

Solid LED

2. With the system hooked up as shown, insert the binding cable in

the charging plug receptacle. Turn on the power of the receiver

(4.8 - 5.6V), and now the LED should be flashing indicating

that the receiver is ready to bind.

Receiver

3. The LED should go solid, indicating the system

has connected. Now turn off the receiver and

remove the binding cable.

Receiver

•This switch control the transmitter’s third channel. A servo plugged in this Channel 3 will move to full travel in one direction when

the switch is in the “AUX” position, then move the switch to the “OFF” position the servo will move in the opposite position . This

channel can be use to turn on all sort of things in your vehicle. For example, lights, on board camera etc..... l

Handling Procedure For Batteries

Handling Procedure For Batteries

•Battery Replacement

1) Remove the battery cover from the transmitter by sliding it in the direction of the arrow.

2) Remove the used batteries.

3) Load the new 8 AA size alkaline, or Nickel Metal Hydride (NimH) rechargeable batteries,

and pay very close attention to the polarity marking on the batteries.

4) Slide the battery cover back onto the case.

5) If you use rechargeable batteries OFNA make this charger 10210 it will charge your Transmitter

9.6v at 100mA and Receiver battery 4.8v-6v at 100mA at the same time.

•Caution

Always make sure you reinsert the batteries are in the correct polarity order. If the batteries are loaded

incorrectly, the transmitter may not work or can be damaged.

When the transmitter is not used for a long period of time remember to remove the batteries. If the batteries

do happen to leak, clean the batteries case and contacts thoroughly and make sure the contacts are free of

corrosion.

•Battery Disposal

Some countries and state require special handling of used batteries, please contact the agencies responsible

for recycling hazardous wastes in your local area.

•Battery low voltage alarm indicator. LED Power light will flash.

Receiver Connection Diagram

Specification Data

•Transmitter

NOTICE THE DIRECTION OF BATTERY COVER

10210 - DUAL CHARGER, 4.8V-6V/9.6V TRANSMITTER AND RECEIVER

(Not included)

•Receiver

Channels: 3

Frequency: 2.4Ghz

Power DC: 9.6V - 12V

Measurement: 280 x 190 x 85mm

(Packing Meas.)

Net Weight: 510g

Channels: 3

Frequency: 2.4Ghz

Power DC: 4.8 - 5.6V

Net Weight: 13.5g

Page 8

B4218 ESC Instruction and Specification

WARNING ELECTRIC MOTOR AND ESC ARE EXTREMELY HOT AFTER

RUNNING, CAN CAUSE SERIOUS INJURY, HANDLE WITH CARE

•Special Features:

1. Exclusive feature for this model. Auto set to neutral position on the throttle. No programming

or adjustment is required. Just one second after powering on the system, the speed control

will beep indicating that is has auto set to the neutral position ( while the speed control is

setting the neutral position do not touch the throttle trigger, leave it at neutral ).

Fig.1

Fig.2

Fig.3

FORWARD

2. Thermal Protection Function of The ESC B4218. If the speed control over heats, the Thermal

Protection function will be activated. Once the “TP” is activated, the throttle will rapidly turn

on and off and acceleration becomes erratic. Stop driving immediately, do not drive the car

until the Speed Controller cools down.

3. LED indication, two colors Green/Red

4. Large sturdy aluminum heatsink for maximum heat dispersing.

NEUTRAL

BRAKE

AND

REVERSE

CAUTION

•THIS ESC DO NOT HAVE “LVC” (Low Voltage Cutoff): What this means is this ESC or

speed control do not have the circuitry to detect the low voltage of the Lipo or

Lithium Polymer battery to prevent the battery from discharging too low during

use, which would make the pack unusable and unstable. The cutoff is usually

around 6.25 volts or 3.0 volts per cell. Once a Lipo discharges below 3.0 volts per

cell, there is a chance that the battery will catch on fire. Use Lipo batteries at your

own discretion OFNA is not responsible for misused and damage to personal

property and injuries.

TH.TRIM

•Specification:

1. Input Voltage: 6~8.4V 6-7cell NiMh or NiCd

2. Power IC 150A at (77F), 100A at (212F)

3. Supported motor >12T - 27T Mabuchi Motor

4. Factory default Spec: Output Continuous/Peak Current 70A/120A(10sec)

5. Over temperature protection at 200F.

6. BEC Voltage 5V at 1Amp

7. FET internal: forward/reverse...........0.0025/0.005 ohm

8. Size:36 x 35 x 30.5mm

9. Weight......53.7g/1.89oz

FIG. 4

BATTERY

BLUE NEG

ORG. POS.

SWITCH

RECEIVER WIRE

Page 9

FIG. 5

•Throttle Neutral and ESC setting:

1. Switch on the transmitter.

2. Set the throttle trim to the middle or the green LED on your Transmitter “TH”

3. Switch on the power of the ESC

4. The ESC will sound 3 beeps (DO RE MI) confirmation, indicating the ESC

is ready & the throttle is at neutral position.

•Operating Instructions:

1. Connect the ESC wires to the motor. (Blue is neg and Orange is Positive See Fig. 5)

2. Plug the receiver wire into the throttle or #2 channel on the receiver

3. Ventilation - Mount the ESC in a location that has good ventilation & isolate it from vibration

and shock. Ventilation is extremely important for cooling the ESC & Motor.

4. Plug in your battery, before turning on the ESC, make sure your transmitter is on & the throttle

trigger is at the neutral position. (See Fig 2)

5. Turn on your ESC, the LED light on the ESC will flash red then goes to solid green and a tone

will sound indicating that the ESC is set and ready to go.

FOR ADDITIONAL HELP YOU CAN CALL OFNA TECH SUPPORT AT (949)586-2910 OR

GO TO WWW.OFNA.COM/GUIDE.HTML FOR HOW TO VIDEO

Page 10

Warranty Period

OFNA warranties that the Products purchased (the “Products”) will be free from defects in materials and workmanship at the

date of purchase by the Purchaser.

Limited Warranty

(1) This warranty is limited to the original Purchaser (”Purchaser”) and is not transferable. REPAIR OR REPLACEMENT AS

PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty covers

only those Products purchased from and authorized OFNA dealer. Third party transactions are not covered by this

warranty. Proof of purchase is required for warranty claims. Further, OFNA reserves the right to change or modify this

warranty without notice and disclaims all other warranties, express or implied.

(2) Limitations - OFNA MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NON INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE

PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY

MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(3) Purchaser Remedy - OFNA sole obligation hereunder shall be that OFNA will, at its option, (1) repair or (2) replace, any

Product determined by OFNA to be defective. In the event of a defect, these are the Purchaser’s exclusive remedies.

OFNA reserves the right to inspect any and all equipment involved in a warranty claim. Repair or replacement decisions

are at the sole discretion of OFNA. This warranty does not cover cosmetic damage or damage due to acts of God,

accident, misuse, abuse, negligence, commercial use, or modification of or to any part of the Product. This warranty does

not cover damage due to improper installation, operation, maintenance, or attempted repair by anyone other than OFNA.

Return of any goods by Purchaser must be approved by OFNA before shipment.

Damage Limits

OFNA SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM

IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. Further, in an event shall the liability of

OFNA exceed the individual price of the Product on which liability is asserted. As OFNA has no control over use, setup, final

assembly, modification or misuse, no liability shall be assumed nor accepted for any resulting damage or injury. By the act

of use, setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this Product, you are advised

to return this Product immediately in new and unused condition to the place of purchase.

Safety Precautions

This is a sophisticated hobby Product and not a toy, It must be operated with caution and common sense and requires some

basic mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury of damage to

the Product or other property. This Product is not intended for use by children without direct adult supervision. The Product

manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and

warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or injury.

FOR ADDITIONAL HELP YOU CAN CALL OFNA TECH SUPPORT AT (949)586-2910 OR

GO TO WWW.OFNA.COM/GUIDE.HTML FOR HOW TO VIDEO

Page 11

TO: OFNA TECHNICAL SUPPORT

7 VANDERBILT, IRVINE, CA 92618

TODAY’S DATE: month________day______

1. Print out form.

2. Fill out the form completely.

3. Make a copy of purchase receipt. All replacements/repairs will not be processed,

unless accompanied by proof that item(s) was purchased.

4. Call OFNA technical support at (949)586-2910 for assistance.

1. Your name

____________________________

2. Your address:

____________________________

6. Name of kit / part (on tag or end of box)

_____________________________

7. Kit/part number (on tag or end of box)

_____________________________

8. Purchased from (store name)

____________________________

3. Your Phone Number

(_____)______________________

_____________________________

a. Store phone: (_____) _________

b. _____Item was a gift?

4. Your e-mail address:

____________________________

9. If a part is missing form the kit, circle

the appropriate answers:

5. Summary of your problem (check lines):

a______part(s) is missing from my kit

b______part(s) seems to be defective

c______other problem

a. Yes / No: Is kit box damaged?

b. Yes / No: Factory Seal sticker was secure.

c. Yes / No: I am the original owner.

d. Yes / No: I have contacted the dealer first.

10. Describe your issue fully and include any part numbers:

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

Failure to fill out this form completely will cause a delay in processing!

11. Affix proof of purchase on second page. All replacement / repairs will not be processed

unless accompanied by proof that item(s) was purchased.

A. If you lost the store receipt, ask the store if they will give you a new one.

B. We do not accepted the following as a substitute: Hand written receipts, ebay transaction numbers/forms or

credit card statements.

Can’t find Proof of Purchase?

12. Send in form with your defective product, as instructed to do by the Ofna

technician,(Name)_________________ you spoke to. Ph:(949)586-2910 Fax: (949)583-9272

Page 12

OFNA DESCRIPTIONS RETAIL OFNA DESCRIPTIONS RETAIL

53012

BEARING,FRONT 7x19x6mm 6.95

53358

CONNECTING ROD HYPER 18 27.95

53024

HEX AXLE, PULL START, HYPER 10.95

53359

SCREWS SET HYPER 18 9.95

53058

BARREL STOP SCREW, HYPER 4.95

53360

PISTON, SLEEVE, ROD COMBO H18 109.95

53060

MAIN NEEDLE AND SEAL, HYPER 5.95

53361

BACK COVER & O-RING HYPER 18 13.95

53309

CLIPS, G, 5PCS 1.95

53362

O-RING COMPLETE SET HYPER 18 7.95

53312

CAP SCREW 3x16mm (4PCS) 1.95

53363

BALL BEARING,12x21x5mm H18 23.95

53315

REAR COVER PULLSTART & O-RING 13.95

53364

CRANKSHAFT HYPER 10 39.95

53316

CAP SCREW 3x10mm (4PCS) 1.95

53365

CRANKCASE W/FR&RR BEARING H18 75.95

53318

SILICONE MANIFOLD SEAL 3.95

53366

MAIN NEEDLE HOUSING SET H18 14.95

53321

THROTTLE RUBBER COVER 3.45

53367

TURBO FAN & ONE WAY HYPER 18 29.95

53324

SUPPLY FUEL NOZZLE & O-RING 5.95

53368

CARB. RESTRICTOR HYPER 18 5.95

53351

HEAD, HYPER 18 ENGINE 34.95

53369

CARBURETOR COMPLETE HYPER 18 69.95

53352

HEAD BUTTON HYPER 18 2.95

53370

CARB LOCKING PIN HYPER 18 9.95

53353

HEAD CAP SCREWS 3x12mm H18 2.95

53371

THROTTLE BALL STUD HYPER 18 6.95

53354

HEAD BUTTON STANDARD HYPER 18 22.95

53372

LOW END NEEDLE HYPER 18 7.95

53355

HEAD BUTTON TURBO HYPER 18 24.95

53373

CARB BODY AND THROTTLE H18 34.95

53356

PISTON & SLEEVE HYPER 18 82.95

53374

CAP SCREWS 2.6x7mm FOR PS H18 2.95

53357

WRIST PIN & G CLIPS HYPER 18 5.95

53375

PULLSTART COMPLETE HYPER 18 39.95

53121 HYPER 18 SG W/PULLSTART

53360

53309

53353

53352

53356

53354

53358

53351

53357

53355

53366

53324

53058

53373

53060

53368

53372

53321

53371

53369

53370

53012

53365

53361

53363

53364

53367

53315

53324

53362

53316

53375

53374

OFNA

7 VANDERBILT

IRVINE, CA 92618

PHONE: (949) 586-2910

WWW.OFNA.COM

WWW.RCDEAL.COM

Page 13

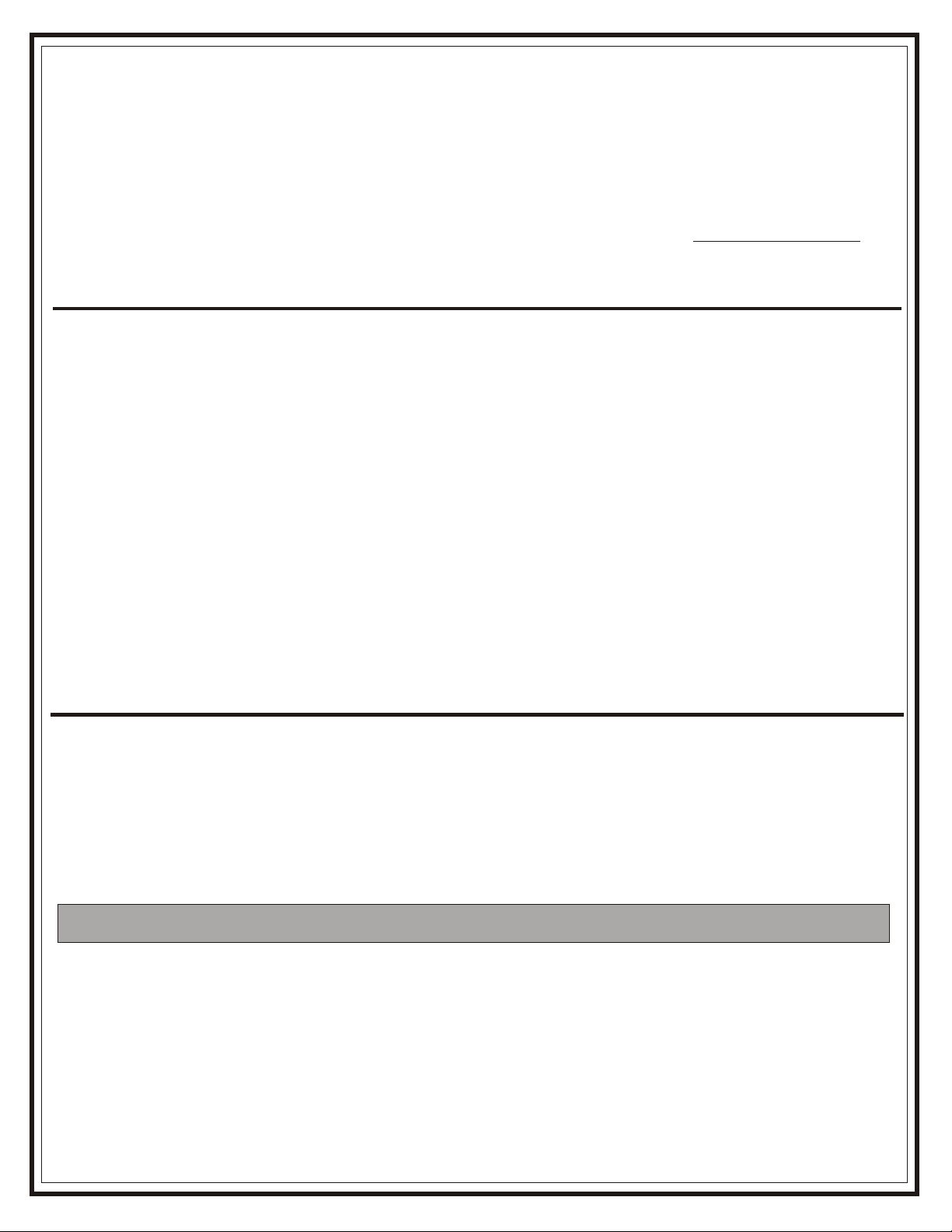

HYPER 18 ENGINE

PART # 53121

Thank you for purchasing a OFNA engine. We appreciate your choice and know you will enjoy running it. Please

note that the OFNA information in engine box is subject to change without notice.

NEW ENGINE BREAK-IN

Your OFNA engine is extremely tight when the piston is at the top of the stroke and turning the crankshaft by hand.

This is normal for a new ABC type engine. The piston and sleeve are matched for fit and the top of the sleeve is

tapered for a tight fit. As you run your engine, this tightness Should diminish. There is no cause for alarm, because

as the engine warms up, the brass sleeve will expand faster than the aluminum piston and the engine will turn free.

As with any new engine, there are many high spots and tight fits in the matching process. High spots create hot

spots that must be broke-in. Therefore, the break-in process is very important to provide good service by the

engine. So, you must run the engine rich (COOL) for the first two tanks of fuel. We recommend using 20% O’Donnell

0R BYRON’S 2000 as break-in fuel. Other break-in type fuels or added oil is NOT needed. DO NOT OVER REV. THE

THE ENGINE WHEN FIRST STARTING, this could break the rod, piston and over heat the sleeve. Let the engine run at

low RPM for one tank to break-in connecting rod bearing before starting full break-in.

Break-in the engine in the car, by running the engine at a rich setting. Factory high end or master needle is 4 turn

Out from all the way close. Run the car from a slow to fast speed with short bursts of speed. You need to build

Little heat in the engine, but not too hot. In a rich setting, the engine will run cool. In the leaner setting the engine run

Hot running hot is NOT good yet. Do not heat up the engine too much at this time. After about two (2) tank,

turn the Master Needle Valve, clock wise, 1/8 of a turn leaner or clockwise. Keeping the fuel tank full, continue the

process until you slowly turn the Master Needle Valve, 1/8 of turn each time, to a leaner point and in which the

engine runs at high RPM and power and the master needle should be at 3-3.5 turn out from close, but still keeping

The MAX TEMP UNDER 250 DEGREES F.

If you go over 250 degrees it is too lean of a setting and will over heat the engine and damage the piston.

Normal operating temperature is around 220 to 250 Deg.

Engine an shorten the life of the motor.

Temperatures of 260 Deg. and above will damage

NEEDLE SETTINGS After break-in:

Master Needle Valve - (High End) Set at 3 to 31/2 turns from closed. Adjust this needle for

maximum RPM and power without being too lean or too hot. Make sure you start at bottom of needle seat!!

Mid Range needle - The brass needle on the side of the carb. DO NOT TOUCH.

Side Carb. Needle (Low Speed) - This needle is in the center side of the carburetor where the blue boot is, provide

Throttle response. It is not the idle adjustment. Set NEEDLE flush with the ball end. Turning in is Lean and Out is Rich.

Do not adjust

Barrel Stop Screws - Used for adjusting Idle: Set for 1/16th inch gap to start new engines. You can open more for

faster idle.

This needle until the Master Needle is set for power and top speed. This will only effect throttle response.

OFNA/PICCO GLOW PLUG IS RECOMMENDED

51010 - B4 STANDARD HOT

51011 - B5 STANDARD MEDIUM

51012 - B6 STANDARD COLD

51013 - T4 TURBO HOT

51014 - T5 TURBO MED

51015 - T6 TURBO COLD

OFNA RACING , 7 VANDERBILT, IRVINE, CA. 92618 • TEL:(949)586-2910

Page 14

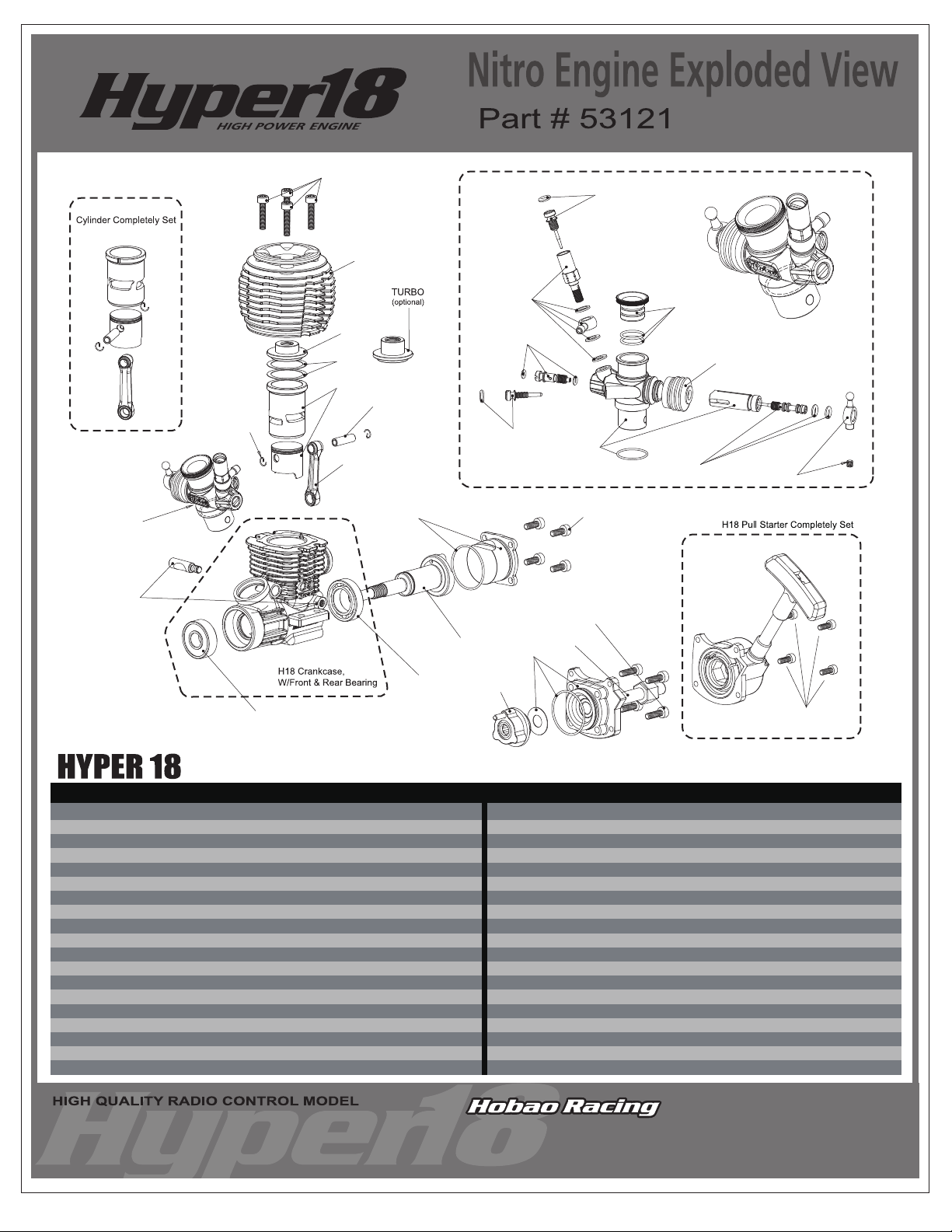

11066

21003

21006

11066

21003

21003

94046

21003

21004

21003

21004

21003

21004

11066

21001

1000wt Silicone

11066

21003

21003

21003

94046

21003

21004

5000wt Silicone

21038

11066

21003

21004

21003

11066

21037 Steel for Nitro

21317 Delrin for Electric

Page 15

94034

21005

21002

11065

94002

21015

21014

21002

21005

11065

21007

21007

21014 x 4

21016

22012

21015

36870

36870

21012

Page 16

11066

21017

18075

94043

21028

11066

18075

21017

21017

21009

21029

21029

21029

21123

94004

21009

21028

94043

21029

21029

21123

94004

Page 17

21008

94005

94005

21008

21018 x 4

21018

94005

21018

21030

21018

Page 18

94033

94034

94049

21028

21018

21019

21029

21029

21033

94041

21078

21033

21033

21011

21078

21033

21028

3.2mm

94041

21034

21078

21033

21033

21078

Page 19

94033

21033

21033

21033

21033

21013

21036

94002

21036

21023

21023

Page 20

94002

94004

94003

21019

21017

18075

36870

94041

21059

11066

21026

11066

21027

21058

21025

18075

21017

21059

Page 21

21123

94004

21029

21123

21028

21029

21021

21029

21029

94043

94043

21028

21024

21021

19031

94038

94003

21030

19031

21020

Page 22

94004

94041

21035

21022

94005

21035

21022

Page 23

21018

21018

94005

21018

21018

94033

94034

94021

94020

21018

21031

21031

21031

21031

Page 24

94002

21031

94033

21032

90020

94005

21032

21058

21032

Page 25

94020

21244

21019

21241

94019

21039 x 2

19052

21077

19052

21077

21040

21039

Page 26

21041

21041

21242

94002

21042

94033

21041

94019

21242

21039

21042

21242

21041

21041

21242

94038

10097

28061

28061

10097

21054

21054

Page 27

10010

10101

94056

10010

10101

10410

10410

18077

94017

21055

10410

10410

21055

94018

21054

Page 28

94019

21243

21044

10067

10181

10067

10181

Page 29

94034

94026

19082

10177

Page 30

94033

21050

94041

94002

21050

94022

21050

21050

21049

21050

21050

21049

94002

21049

21049

21047

21049

21049

10282

Page 31

94001

21046

21046

21046

21046

21046

28061

28081

Page 32

94017

21053

21053

21052

29056

21052

Page 33

21036

21035

21036

21035

21228

21228

21228

21228

90020

21228

21228

21062

21062

21067

21064

22012

21067

21067

21065

21228

21228

90020

22012

21067

Page 34

21063

21067

21064 Cap/Shock Body Front

21065 Cap/Shock Body Rear

21066

21067

21068

19018

21068

Page 35

19031

94005

94038

94005

21245

21246

Page 36

10993

10993

10993

10993

21071

21071

Page 37

21248 Clear

21249 Blue

21250 White

22086

Page 38

FOLLOW STEPS A TO H FOR ELECTRIC VERSION TO INSTALL CENTER DIFF AND MOTOR MOUNT.

A

21242

94017

21241

94019

21301

94017

21039

21242

21308

94056

94019

21315

B

21308

21254

94034

Doublesided Tape

94056

Page 39

C

94005

94005

21302

D

21307

Battery not included

21304

Page 40

94019

E

21304

94019

94017

94002

F

21049

94002

94017

21303

94017

Page 41

29076

G

29076

29076

H

21035

21036

Page 42

Page 43

Factory setup

Page 44

Page 45

Page 46

Page 47

21001 21011 21021

21031

21041

29056

21002

21003

21004

21005

21006

21012

21013

21014

21015

21016

21022

21023

21024

21025

21026

21032

21033

21034

21035

21036

21042

21241

21044

21243

21046

21052

21053

21054

21055

22084

21007

21008

21002

21002

21017

21018

21019

21020

21027

21028

21029

21030

21037

21038

21039

21040

21047

10181

21050

22071

21058

21049

21059

Page 48

21242

21070

22012

10101

21253

21281

21244

21062

21063

21064

21065

21071

21249

22086

21246

21245

21228

22075

28061

10097

11065

18075

18077

28081

10282

10993

21248

11064

28087

21251

21252

21066

21067

21068

21069

19082

21077

21078

21079

11066

22087

10010

29073

19018

19031

10177

Page 49

OFNA DESCRIPTIONS RETAIL OFNA DESCRIPTIONS RETAIL

10010

CLUTCH SHOES, BLACK, 3 SHOES 13.95

21054

ENGINE MOUNT HYPER MINI 19.95

10097

CLUTCH NUT SG HYPER 5.95

21055

CLUTCHBELL 14T STOCK HYPER M. 24.95

10101

SPRINGS,CLUTCH,GOLD 1.1M 3PCS 4.95

21058

BRACE, CHASSIS FR/RR H. MINI 6.95

10177

FUEL LINE 2FT. GRAY/BLACK 1.95

21059

HINGE PIN REAR 3x35mm H. 10SC 2.95

10181

JOINT, EXHAUST TUBES, 2PC 6.95

21062

SHOCK SHAFTS FR/RR HYPER MINI 10.95

10282

SWITCH COVER, SILICONE BLACK 3.95

21063

SHOCK BLADDER HYPER 10SC 6.95

10985

NYLOK FLANGE NUT,4mm BLUE 10P 8.95

21064

SHOCK BODY FRONT HYPER MINI 22.95

11064

BEARING 5x8, 4PCS. 11.95

21065

SHOCK BODY REAR HYPER MINI 22.95

11065

BEARING 5x11, 6PCS. SC 10 17.95

21066

SHOCK COLLAR THREADED H.10SC 12.95

11066

BEARING 10x15, 4PCS.SC 10 15.95

21067

SHOCK PLASTIC PARTS HYPER 10SC 7.95

18075

BEARING, 6x13mm. 4PCS.SC 10 15.95

21068

SHOCK SPRINGS SET FR/RR H.MINI 12.95

18077

BEARING, 5x10mm, 4PCS. 15.95

21069

SHOCK, FRONT SET HYPER MINI 39.95

19018

BOOT,SHOCK SHAFT,SILICONE 4PCS 8.95

21070

SHOCK, REAR SET HYPER MINI 45.95

19031

BALL,STEEL,SHOCKS 4PCS. 7.95

21077

BRAKE PADS 7.95

19082

MOUNT, PIPE WIRE 5.95

21078

BUSHING, 5x8mm HYPER 10SC 2.95

21001

GEAR, CROWN HYPER 10SC 24.95

21079

SCREW SET HYPER 10SC 19.95

21002

GEAR, PINION HYPER 10SC 12.95

21123

SUSPENSION PLATE F/R SC 6.95

21003

GEAR, DIFF HYPER 10SC 12.95

21141

SCREW SET HYPER 10SC 14.95

21004

DIFF CASE W/GASKET HYPER 10SC 6.95

21159

SERVO GRAPHITE PLATE H10SC 9.95

21005

DRIVE CUP CENTER HYPER 10SC 11.95

21162

CNC 7075 HINGE PIN PL FR/RR SC 8.95

21006

DRIVE CUP F/R DIFF HYPER 10SC 12.95

21163

CNC 7075 HINGE PIN HOLDER FR 8.95

21007

GEARBOX CASE HYPER 10SC 8.95

21164

CNC 7075 REAR HING PIN HOLDER 8.95

21008

SHOCK MOUNT FR HYPER MINI 6.95

21241

CENTER ALUM. DIFF PLATE TT 9.95

21009

FRONT HINGE PIN HOLDER FR 10SC 5.95

21242

DRIVE SHAFT CENTER ALUM. TT 12.95

21011

ARM, UPPER FRONT HYPER 10SC 6.95

21243

FUEL TANK FOR TT 12.95

21012

ARM, LOWER FRONT HYPER 10SC 9.95

21244

CHASSIS NITRO TT 48.95

21013

TOP PLATE FRONT HYPER MINI 5.95

21245

TIRES MOUNTED FOR TT 4PCS 39.95

21014

STEERING KNUCKLES FRONT H.10SC 10.95

21246

WHEELS WHITE FOR TT 4PCS 14.95

21015

PILLOW BALL HYPER 10SC 16.95

21247

TIRES FOR TT 4PCS 0

21016

CVA, FRONT HYPER 10SC 34.95

21248

BODY CLEAR FOR TT 28.95

21017

HEX HUB HYPER 10SC 6.95

21281

SHOCK PISTON OPTIONAL HYPER SC 7.95

21018

ANTI ROLL BAR SET HYPER 10SC 9.95

21308

SCREW SET HYPER 10SC 7.95

21019

BUMPER SET F/R HYPER MINI 9.95

22012

FLANGE BALL SET 12.95

21020

SHOCK TOWER REAR HYPER MINI 7.95

22017

ALU. COLLAR, 8PCS 5.95

21021

HINGE PIN HOLDER REAR H.10SC 5.95

22028

SHOCK REPAIR SET SC10 8.95

21022

ARM, UPPER REAR HYPER 10SC 6.95

22071

MANIFOLD 13.95

21023

TURNBUCKLE, STEERING H. 10SC 10.95

22075

MUFFLER PIPE 39.95

21024

ARM, LOWER REAR HYPER 10SC 10.95

22084

SPRING FOR MANIFOLD 2.95

21025

UP-RIGHT REAR HYPER 10SC 7.95

22086

SNAP PIN 3.95

21026

AXLES REAR HYPER 10SC 12.95

22087

ALUM. WASHER 3mm 7.95

21027

DOGBONES REAR HYPER 10SC 12.95

28061

FLYWHEEL HYPER 8 & HYPER 10SC 18.95

21028

HINGE PIN SET HYPER 10SC 11.95

28087

BRAKE PADS SPECIAL COMPOUND H8 16.95

21029

HINGE PIN BUSHING HYPER 10SC 4.95

29073

WASHER, M3.1x6, 6PCS M6.5x8 6P 3.95

21030

BODY POST FRONT HYPER MINI 6.95

21031

WING MOUNT HYPER MINI 11.95

21033

SERVO SAVER SET HYPER 10SC 19.95

21251

CNC FRONT CHASSIS BRACE FOR TT N/A

21034

SERVO SAVER ARM HYPER 10SC 6.95

21252

CNC REAR CHASSIS BRACE FOR TT N/A

21035

TURNBUCKLE REAR UPPER ARM 10SC 10.95

21253

TURNBUCKLE,HEX REAR UPPER ARM 9.95

21036

TURNBUCKLE ENDS HYPER 10SC 5.95 21254 CHASSIS ELECTRIC TT 48.95

21037

SPUR GEAR STEEL HYPER 10SC 24.95

21159

SERVO GRAPHITE PLATE H10SC 9.95

21038

CENTER DIFF OUTPUT HYPER 10SC 14.95

21301

CNC ALUM MOTOR MOUNT H. 10SC 34.95

21039

CENTER DIFF MOUNT HYPER 10SC 10.95

21302

CENTER DIFF UPPER PLATE H.10SC 7.95

21040

BRAKE DISC HYPER MINI 7.95

21303

ALUM RADIO TRAY HYPER 10SC 7.95

21041

BRAKE CAM SET HYPER MINI 12.95

21304

BATTERY BOX HYPER 10SC 14.95

21042

CENTER TOP DIFF PLATE H. MINI 5.95

21307

VELCRO BATTERY STRAP H.10SC 7.95

21044

FUEL TANK POST & LID PLR H.M. 3.95

21311

PINION GEAR 15T-3MM 12.95

21046

RECEIVER BOX HYPER MINI 12.95

21312

PINION GEAR 16T-3MM 12.95

21047

RADIO TRAY ALUM. HYPER MINI 10.95

21313

HEAT SINK, CNC HYPER 10sc HV 19.95

21050

THROTTLE LINKAGE SET H.M. 10.95

21314

PINION GEAR 12T-3M 12.95

21051

AIR FILTER TUBE HYPER MINI 6.95

21315

PINION GEAR 13T-3MM 12.95

21052

AIR FILTER SET HYPER MINI 8.95

21316

PINION GEAR 11T-3MM 12.95

21053

AIR FILTER FOAM REFILL H.M. 10.95

21317

SPUR GEAR DELRIN HYPER 10sc 18.95

HYPER TT PARTS LISTS

HYPER 10TT ELECTRIC/OPTIONS PARTS

Loading...

Loading...