Page 1

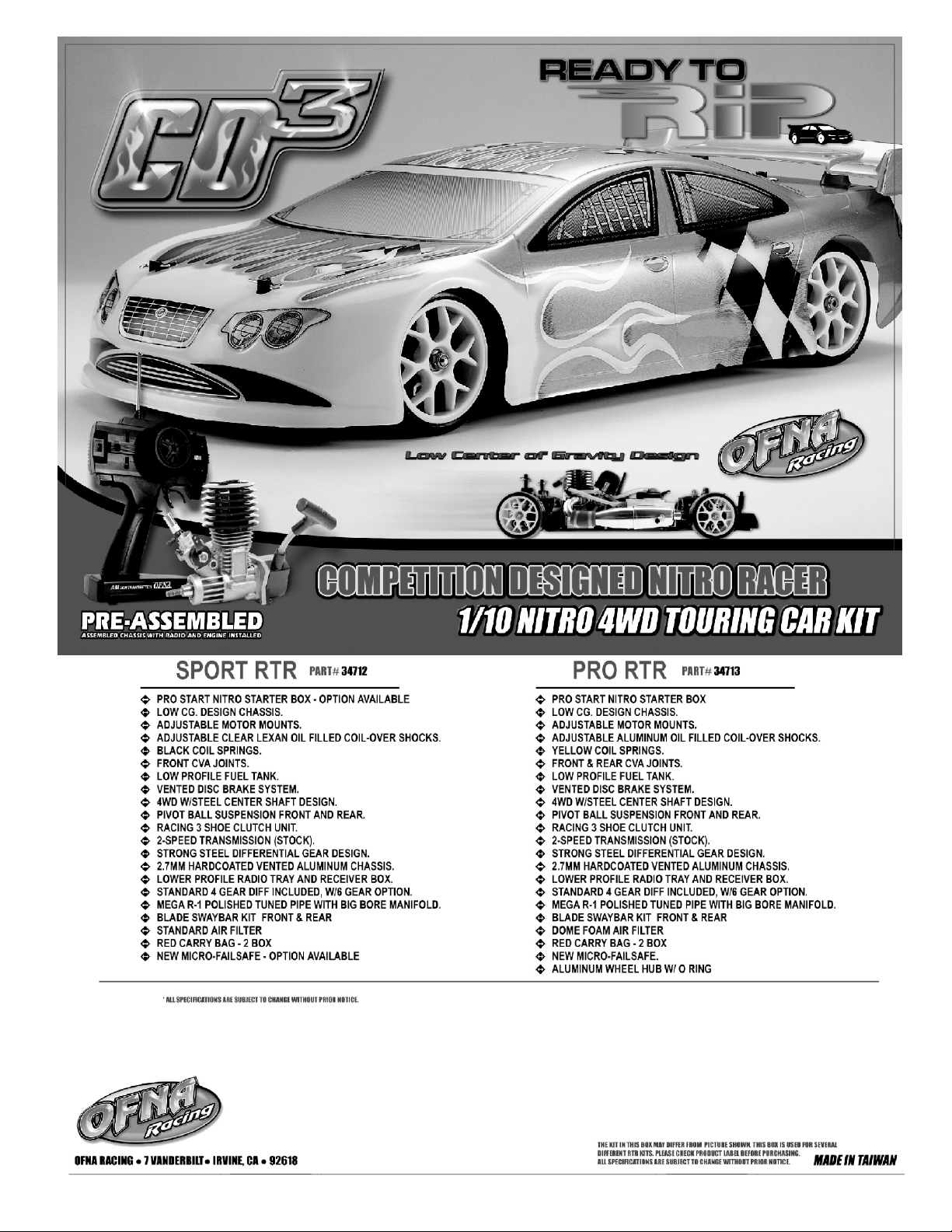

CD-3 SPORT RTR and PRO RTR

ASSEMBLY INSTRUCTIONS

Page 2

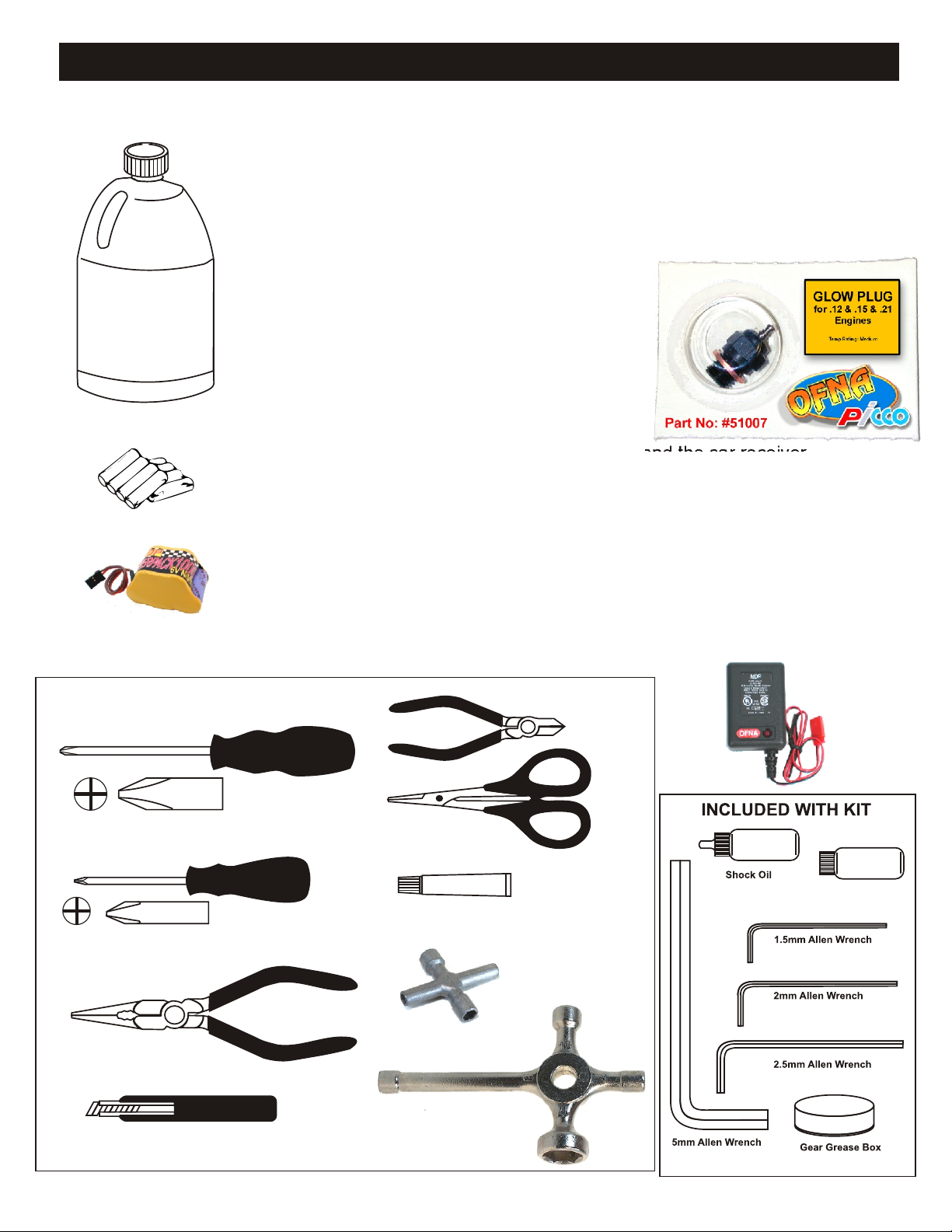

REQUIRED FOR OPERATION

THINGS NEEDED

Glow Fuel

20%

AA Batteries ( 12 pcs )

You will need to buy a few items to start the engine and run the car.

• Use 20% nitro CAR fuel. Do not use airplane or helli fuels, they will

over heat engine.

• Buy SHORT glow plugs, OFNA/PICCO Plu (#51007 or 51008) are

long therefore use two copper washers. Use plugs without idle bar.

Always use two copper washers with Picco glow plugs.

In your box you will find..

• #10163 - 250cc Fuel Bottle

• #10219 - Red “D” size glow heater

These parts change depending on stock!

You need to get batteries for the radio transmitter and the car receiver

packs.

• Radio TX needs (8) eight AA batteries.

• Car needs (4) four AA Ni-cad batteries, Alkaline type batteries will

work, but braking will be reduced. The best is to use a 5 cell hump

pack for increased voltage..

Recommended Option:

#10212 NiHm Hump Pack,

see charger 10214.

TOOLS NOT INCLUDED IN KIT,

BUT NEEDED TO MAINTAIN YOUR CAR.

Phillips Type Screw Drivers ( L )

Phillips Type Screw Drivers ( S )

Needle Nose Pliers

You may want to upgrade the car battery pack to a Ni-Cad or NiHm 5

cell type(600AE). This will give more run time. OFNA #10212

Cutter

Curved Scissors

Instant Cement

Cross Wrench

#17109 $3.95

10214

Over-nite

Charger

Diff Oil Silicone

Knife

Glow Plug & 17MM Cross Wrench

#10801 $6.95

Page 3

MUST READ THIS BEFORE RUNNING

Running a nitro kit is fun and easy, but to make this a safe rusting.

and good experience you must observe a few rules. This

kit is extremely fast, easily over 40MPH, and can seriously

injure someone if you are not careful.

Where to run car?

• Any running area you choose must be dry. Do not run

car near any water or wet dirt.

• Do not run on public streets. It is very easy to have the

car run over or damaged by hitting the curb.

• Do not operate car in tight confined places. The car is

very fast and will easily hit something.

• Do not run near people or animals.

and will too easily hit someone.

• Due noise, you will want to consider the surrounding

area when operating the car.

• Do not operate the car at night. You will not be able to

drive it without hitting something.

• Do not operate the car indoors. Engine exhaust is not

healthy.

Glow Fuel

• Glow fuel is poisonous!

• Glow fuel is flammable!

• Do not leave in fuel bottle with lid off at any time. label for additional precautions.

• Do not use any fuel other than glow fuel in this engine.

First Time Starting the Engine

Caution! When starting engine make sure the following is

observed. • Always turn off the car BEFORE turning off radio.

• Set engine Master needle to 3 turns (rich setting)

• Do not do this alone, get an experienced friend to help at • DAMAGE DUE CAR RUN AWAY IS NOT A WARRANTY

first. ISSUE.

• Fill fuel tank, try not to spill fuel. Do not spill fuel on

receiver

• Hold car off the ground, so it will not runaway when first

starts

• Turn on Radio and check the linkage before starting

engine.

• Turn on car receiver battery switch.

• Always have an air filter on the carburetor to keep dirt

out.

Engine Break-in

• See Engine Page.

The car is very fast

• Clean oil and dirt from chassis with a degreaser.

Precautions

• This kit is not a toy. Always run car with a second

person as a spotter and pitman.

• Hot Parts - The pipe, manifold, engine and head are very

hot and will cause burns.

• Rotating Parts - Keep hands away from the drive train,

wheels, and engine when engine is running.

• Radio - Check batteries life before running the car. If

radio does not have full control of the car with steering

and/or throttle/brake do not run until corrected. Failure to

correct this will result in possible injury and damage to the

car or property.

• Glow fuel - Do leave the glow fuel unattended with the lid

off. Fuel contains Methanol and Nitro Methane and is

flammable and poisonous.

Store fuel in cool ventilated location. Refer the glow fuel

• Car Fuel tank - Never store fuel in car tank, it will ruin the

engine if left in tank.

IF YOU DO NOT BREAK-IN ENGINE

CORRECTLY, MAINLY AT LOW RPM,

YOU WILL BREAK THE CONNECTING

ROD!

FAILURE TO NOT READ AND

FOLLOW BREAK-IN ENGINE

Emergency Stopping Engine When Running

• Remove air filter and cover carb. intake.

• Squeeze fuel line and hold until engine stops.

• With a rag, cover exhaust outlet.

Storing Car After Running

• Remove fuel from tank and fuel lines

• Turn off radio in car

• Put a few drops of after run in engine to keep it from

INSTRUCTIONS WILL VOID

WARRANTY!

CHECK RADIO SETTING AND

LINKAGE BEFORE STARTING

Page 4

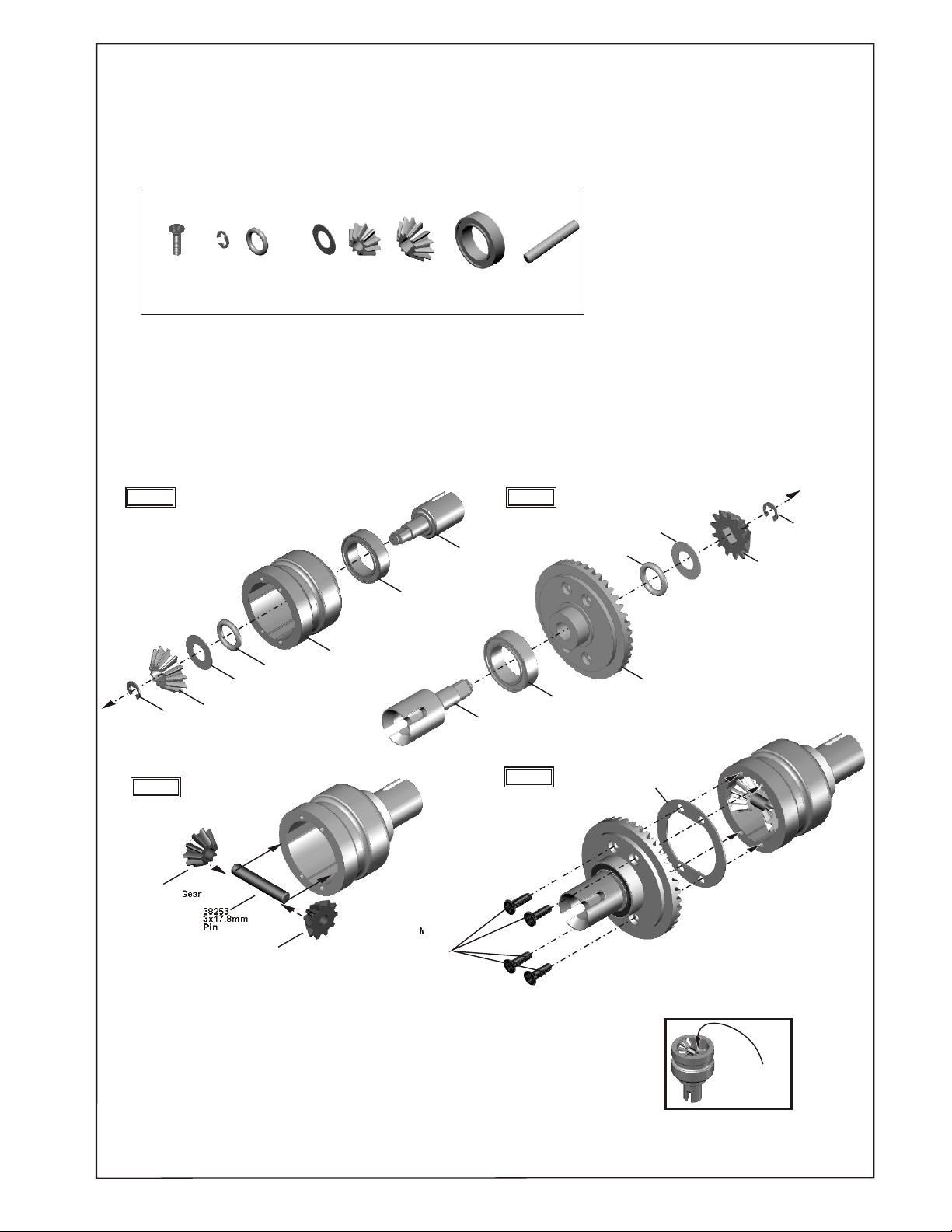

ASSEMBLY OF THE DIFFERENTIAL

(Build two differentials for front and rear.)

90020

94052

M2x7mm

Flat Head

Screw

2.5mm

E-Ring

38278

5x8x1.5mm

O-Ring

38632

5x10mm

Washer

38256

Diff.Gear

(small)

Diff.Gear

(Large))

37771

37450

10x15x4mm

Bearing

38253

3x17.8mm

Pin

Step 1

90020

E-Ring

2.5mm

Step 3

38256

10T Diff.Gear

(small)

37771

13T

Diff.Gear

38253

3x17.8mm

Pin

38632

Washer

5x10mm

38256

38278

5x8x1.5mm

O-Ring

10T Diff.Gear

(small)

38252

Diff.Case

37450

10x15x4mm

Ball Bearing

94052

M2x7mm

Flat Head

Screw

38255

Cap Joint

38255

Cap Joint

Step 2

Step 4

37450

10x15x4mm

Ball Bearing

38278

5x8x1.5mm

O-Ring

38287

Diff.Gasket

38632

5x10mm

Washer

38257

Large

Bevel Gear

90020

2.5mm

E-Ring

37771

13T

Diff.Gear(Large)

Put the grease

into the diff.

case before

assembly.

Page 5

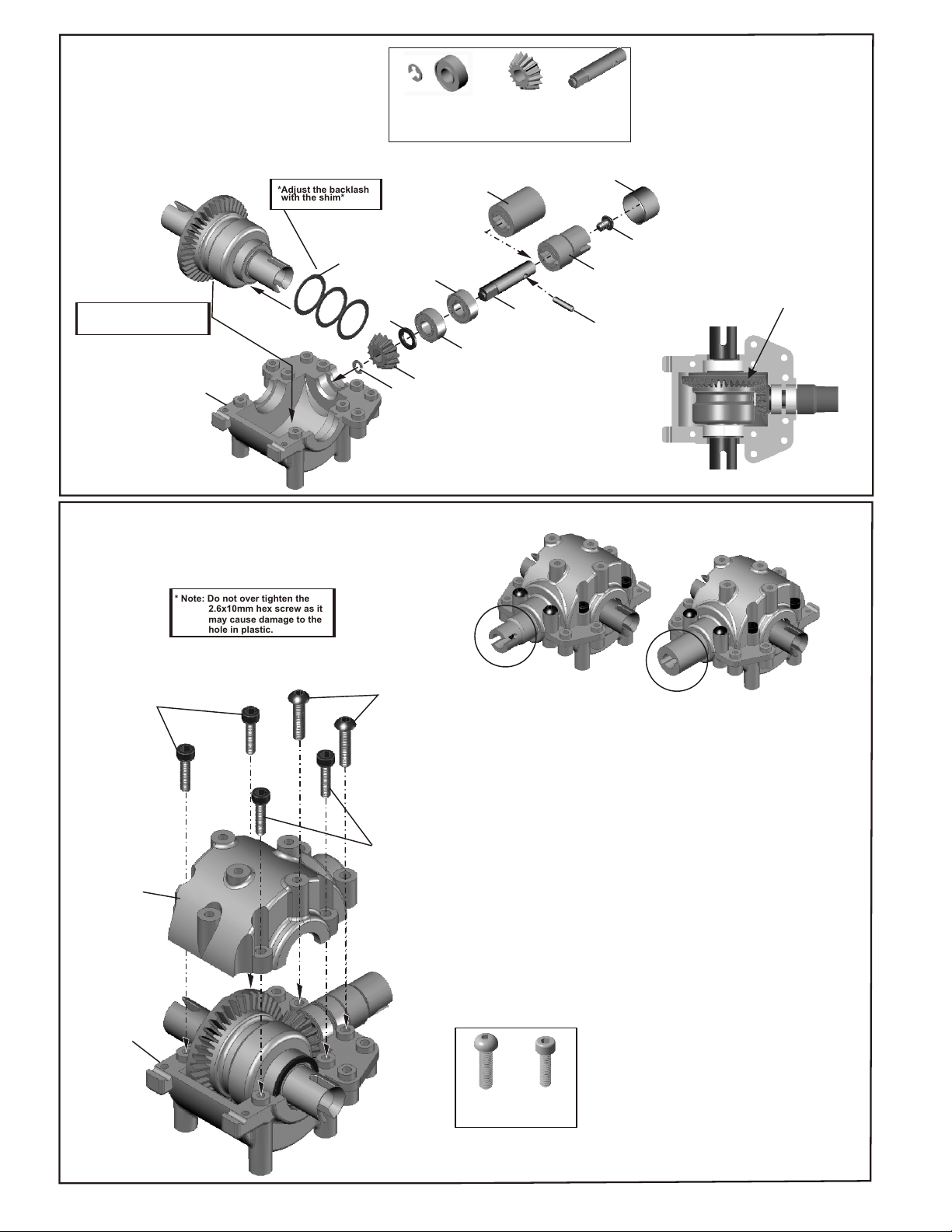

ASSEMBLY OF THE GEAR BOX

(Build two gear box for front and rear.)

*Adjust the backlash

with the shim*

38254

12x15x0.25mm

Shim

Note: Follow the instruction

to put the correct shim

in the right place.

38251

Gear case

90020

2.5mm

E-Ring

38633

5x8x0.8mm

Washer

2.5mm

E-Ring

90020

37430

5x11x4mm

Ball Bearing

38519

Bevel Gear

Cap Joint (R)

37430

5x11x4mm

Ball Bearing

37340

5x11x4mm

38258

16T Bevel Gear

(small)

Ball Bearing

38258

16T Bevel Gear

(small)

38526

Bevel Gear

Shaft (small)

* For the good gear mesh,

put the 5x8x0.8 washer

between L-06 and E-43.

Bevel Gear

Shaft (small)

38530

Steel Ring

(For Front Plastic

Cap Joint)

38526

38519

Bevel Gear

Cap Joint (F)

37400

2x8.8mm

Pin

To test the effectiveness of the gear

differential, hold the gear tightly with one

hand and turn one cap joint.

Does the other cap joint move in the

opposite direction and smoothly?

¡¯CHECKI NG YOUR DI FFE RENT I AL

ASSEMBLY

If gear differential does not move smoothly,

assemble the gear diff. once again.

94001

M3x4mm

Screw

* Put the gear in the

right position.

ASSEMBLY OF THE FRONT GEAR BOX

(Builds a gear box for the front.)

* Note: Do not over tighten the

2.6x10mm hex screw as it

may cause damage to the

hole in plastic.

94050

2.6x10mm

Hex Screw

38251

Gear Case

94004

M3X12mm

Screw

2.6x10mm

Hex Screw

For Front

For Rear

38251

Gear Case

94004

M3X12mm

Screw

94050

2.6x10mm

Hex Screw

* The picture shown is the gear box after

assembly.

* It is normal for the gears to make a noise.

After brake-in, the noise will be reduced.

Page 6

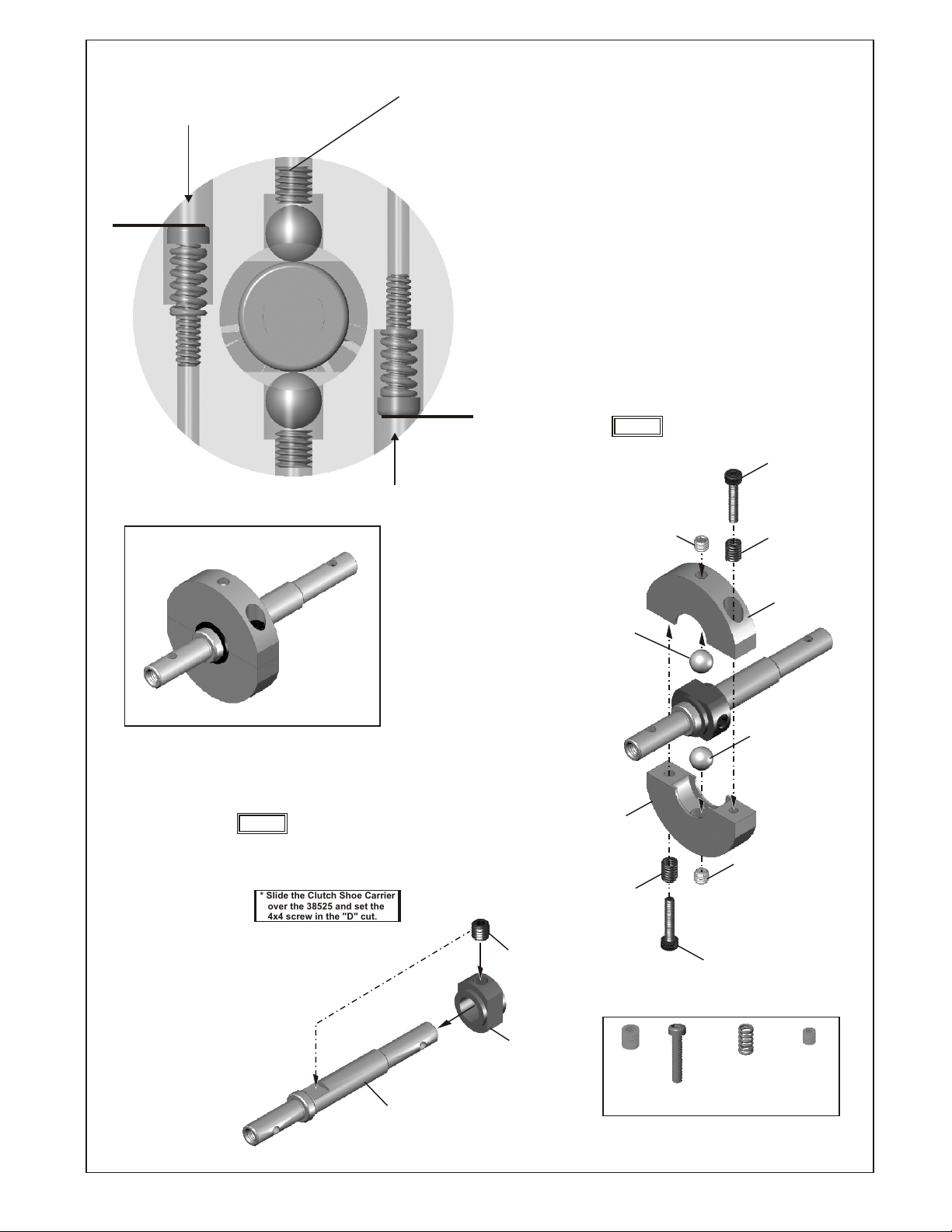

ASSEMBLY OF 2-SPEED CLUTCH TRIGGER DISC

SET BALL TO REST ON CAM, NOT PUSHING. IF

SCREW AS SHOWN,

LEVEL WITH HOLE EDGE

TOO TIGHT, THE BALL WILL PUSH ON CAM

SPREADING SHOE DISC AND WILL NOT FIT

INTO ALUM. CLUTCH BELL #38296

CARE MUST BE TAKEN TO BUILD

THIS ASSEMBLY CORRECTLY,

OTHERWISE 2-SPEED WILL NOT

ADJUST AND MAY NOT WORK AT ALL.

IN FACT, IF 2-SPEED DOES NOT

SHIFT, CHECK OUT THIS ASSEMBLY!.

Step 2

35325

M2x10mm

Hex Screw

SCREW AS SHOWN,

LEVEL WITH HOLE EDGE

ASSEMBLY OF THE TWO SPEED CLUTCH SHOES

Step 1

* Slide the Clutch Shoe Carrier

over the 38525 and set the

4x4 screw in the "D" cut.

94034

4x4mm

Set Screw

38315

Steel Ball

38312

2 Speed

Clutch Shoe

38313

Spring

94033

3x3mm

Set Screw

35325

M2x10mm

Hex Screw

38315

Steell Ball

94033

3x3mm

Set Screw

38313

Spring

38312

2 Speed

Clutch Shoe

38525

2 Speed Main Shaft

(Cd3 only)

38316

Clutch Shoe

Carrier

94034

Set Screw

4x4mm

M2x10mm

Hex Screw

38313

Spring

94033

3x3mm

Set Screw

Page 7

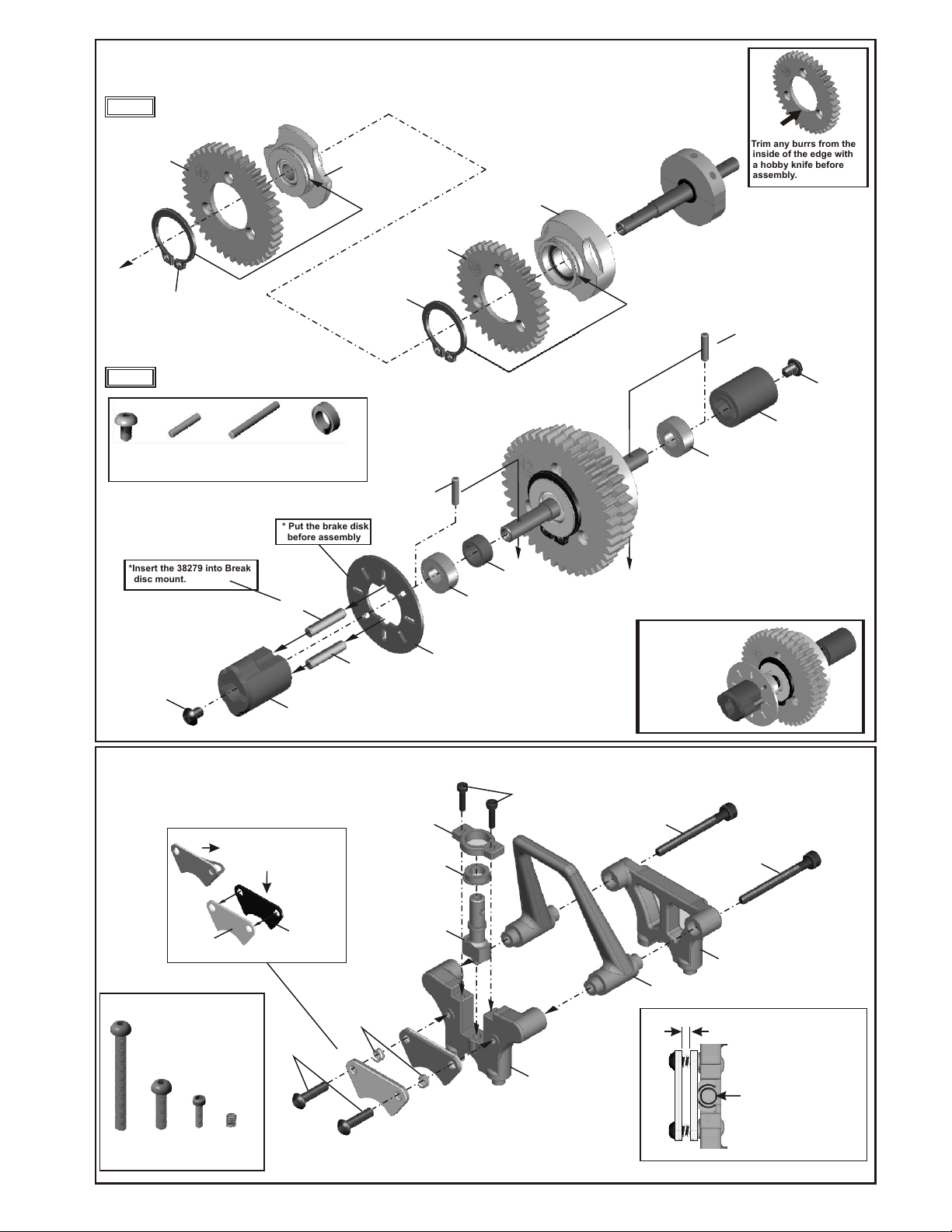

ASSEMBLY OF THE TWO SPEED GEAR

Step 1

38301

Spur Gear

38297

Retaining Ring

Step 2

94001

M3x4mm

screw

37400

2x8.8mm

Pin

*Insert the 38279 into Break

disc mount.

38279

3x13.8mm

Pin

38295

1 st Gear Carrier

(One-Way)

37430

5x11x4mm

Ball Bearing

* Put the brake disk

before assembly

38279

3x13.8mm

Pin

38300

38T

Spur Gear

38297

Retaining Ring

37400

2x8.8mm

Pin

38296

2nd Gear

Clutch Bell

(Ball Bearing)

38519

6x18.5x4mm

Plastic Washer

37430

5x11x4mm

Ball Bearing

* Trim any burrs from the

inside of the edge with

a hobby knife before

assembly.

37400

2x8.8mm

Pin

37430

5x11x4mm

Ball Bearing

38519

Bevel Gear

Cap Joint(R)

94001

M3x4mm

screw

40042

94001

M3x4mm

Screw

38519

Brake Disc

Mount

38279

3x13.8mm

Pin

ASSEMBLY OF THE BRAKE AND DIFF. MOUNT

38519

Bushing Support

M3x30mm

Screw

94000

M3x12mm

Screw

94004

Remove the double-side

tape before assembly.

38271

Brake Pad

Brake

Spring

40040

M2x8mm

Hex Screw

94047

38272

Brake Pad

Linings

94004

M3x12mm

Screw

40040

Blake Pad

Spring

38519

Plastic Bushing

38273

Brake Cam

Brake Disk

94047

M2x8mm

Hex Screw

38520

Brake Mount

(Upper)(Front)

94000

M3x30mm

Screw

38520

Roll Bar

94000

M3x30mm

Screw

38520

Brake Mount

(Upper)(Rear)

1.5mm

* Leave the 1.5mm space

between brake pads.

Please notice!

* Position the brake cam

in the direction as shown.

Page 8

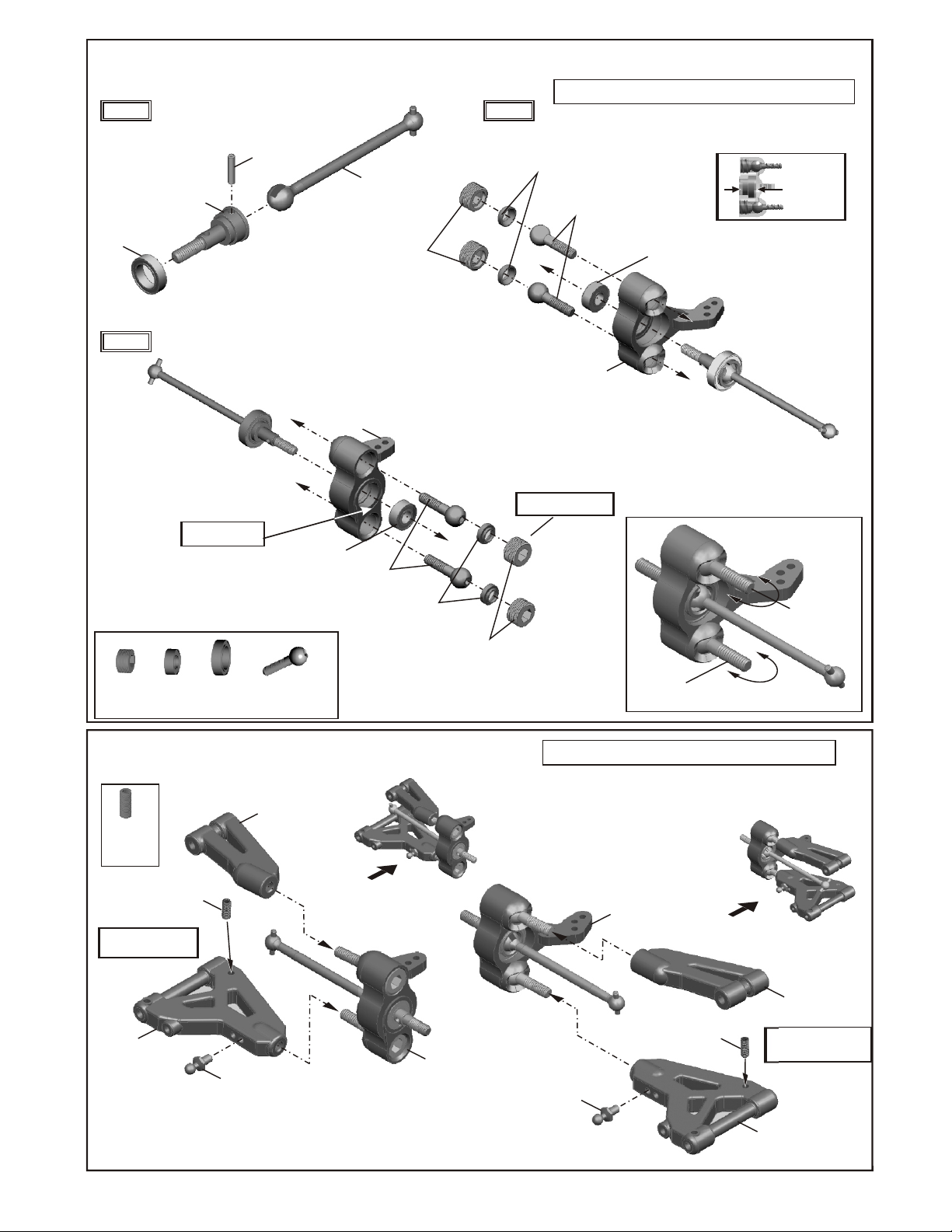

ASSEMBLY OF THE FRONT KNUCKLE ARMS AND CVD SHAFT

Step 1

37450

10x15x4mm

Ball Bearing

Step 3

39150

10mm Alum.

Set Screw

38406

CVD Shaft

*"L" make are for

left-side.

37430

5x11x4mm

Ball Bearing

37450

10x15x4mm

Ball Bearing

38524

2x9.8mm

Pin

39140

8mm

Steering Ball

38265

Front Knuckle

Arm (Left)

37430

5x11x4mm

Ball Bearing

38523

CVA Dog Bone

39150

10mm Alum.

Set Screw

39140

8mm

Steering Ball

39141

8mm

Steering Ball

Washer

Step 2

39150

10mm Alum.

Set Screw

39141

8mm

Steering Ball

Washer

*Notice the direction

of the hex screw.

Assembly of the right and left-side are the same.

Push 2 ball

bearings into

knuckle arm

39140

8mm

Steering Ball

38265

Front Knuckle

Arm (Right)

37430

5x11x4mm

Ball Bearing

Make steering

ball move

smooth.

as shown.

Make steering

ball move

smooth.

ASSEMBLY OF THE FRONT SUSPENSION ARMS

38399

Front Upper

94035

3x8 mm

Set Screw

3 x 8mm set screw is

used to adjust the

ride height.

38399

Front Lower

Arm

94035

3x8 mm

Set Screw

Arm

37360

4mm

Ball&Socket

FRONT KNUCKLE

ARM ASSEMBLY.

LEFT SIDE

Assembly of the right and left-side are the same.

RIGHT SIDE

FRONT KNUCKLE

ARM ASSEMBLY.

38399

Front Upper Arm

37360

4mm

Ball&Socket

94035

3x8 mm

Set Screw

A 3 x 8mm set screw

is used to adjust the

ride height.

38399

Front Lower Arm

Page 9

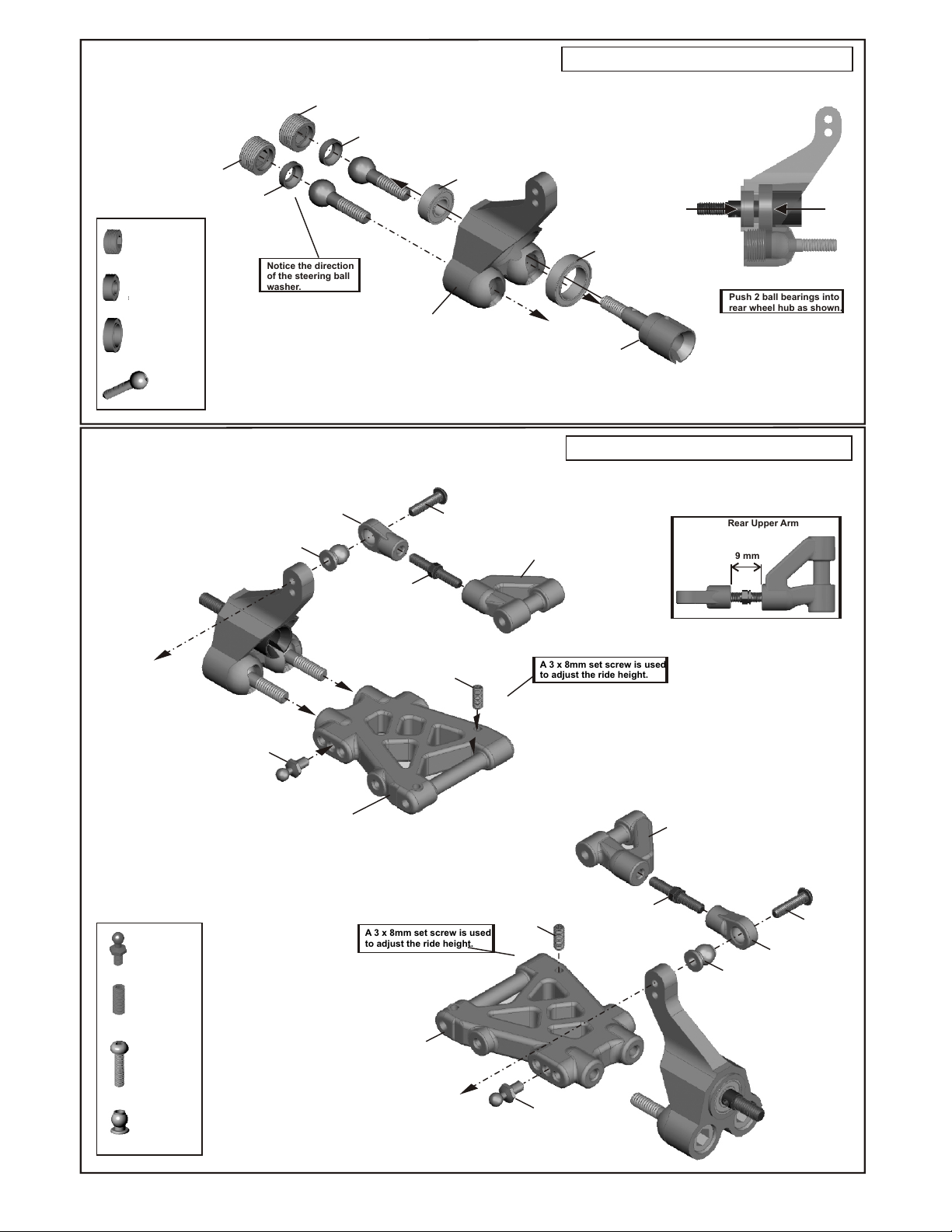

ASSEMBLY OF THE REAR WHEEL HUB

39150

10mm Alum.

Set Screw

39141

8mm

Steering Ball

Washer

39150

39150

10mm Alum.

Set Screw

37430

5x11x4mm

Ball Bearing

37450

10x15x4mm

Ball Bearing

39140

8mm

Steering Ball

10mm Alum.

Set Screw

39141

8mm

Steering Ball

Washer

Notice the direction

of the steering ball

washer.

37430

5x11x4mm

Ball Bearing

38266

Rear Wheel

Hub

Assembly of the right and left-side are the same.

37450

10x15x4mm

Ball Bearing

38267

Rear Wheel

Axle Shaft

Push

Push 2 ball bearings into

rear wheel hub as shown.

Push

ASSEMBLY OF THE REAR SUSPENSION ARMS

38399

Upper Arm

Plastic Rod End

(Left- Hand Side)

37360

Ball & Socket

94035

3x8 mm

Set Screw

94005

M3x16 mm

Screw

37370

6 mm

Ball & Socket

37370

6 mm

Ball & Socket

37360

Ball & Socket

38399

3x20mm

Turnbuckle

38399

Rear Lower Arm

A 3 x 8mm set screw is used

to adjust the ride height.

38399

Rear Lower Arm

3x8 mm

Set Screw

94005

M3x16 mm

Screw

94035

(Right- Hand Side)

Assembly of the right and left-side are the same.

38399

Rear Upper Arm

A 3 x 8mm set screw is used

to adjust the ride height.

94035

3x8 mm

Set Screw

37360

Ball & Socket

38398

3x20mm

Turnbuckle

Rear Upper Arm

38399

Rear Upper Arm

37370

6 mm

Ball & Socket

9 mm

94005

M3x16 mm

Screw

38399

Upper Arm

Plastic Rod End

Page 10

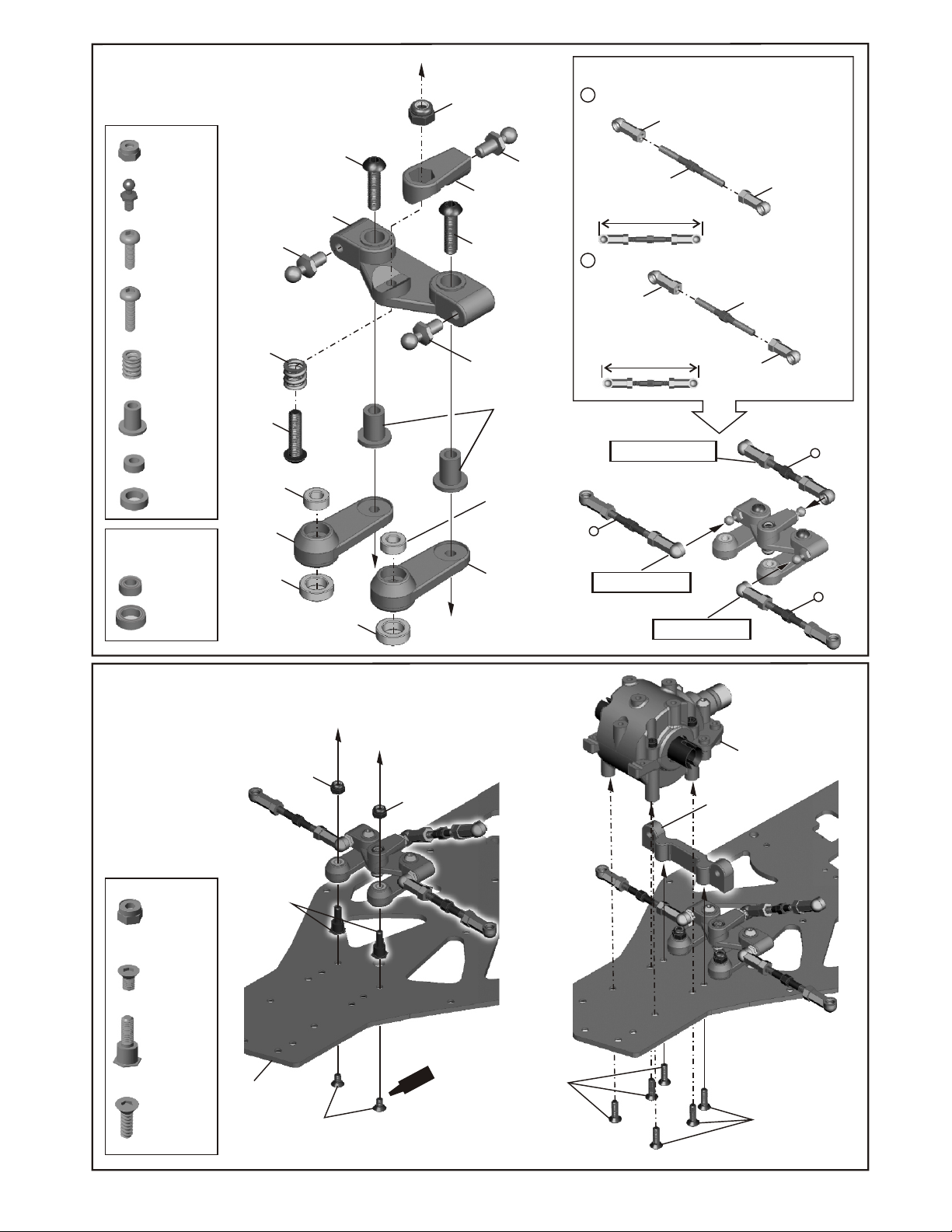

ASSEMBLY OF THE SEVRO SAVER

94041

M3

Nylon Nut

37360

4mm

Ball & Socket

94003

M3x10mm

Screw

94004

M3x12mm

Screw

38288

Servo Saver

Spring

36742

Servo Saver

Bushing

38276

3x6 mm

Brass Bushing

38277

5x8 mm

Brass Bushing

Option:

38644 Ballbearing Set

(For servo Saver )

3x6x2.5m

Ballbearing x2

35958

5x8x2.5mm

Ballbearing x2

37360

4mm

Ball & Socket

38288

Servo Saver

Spring

94004

M3x12mm

Screw

38644

3x6x2.5mm

Brass Bushing

38289

Servo Saver

35958

5x8x2.5 mm

Brass Bushing

94004

M3x12mm

Screw

38289

Servo Saver

35958

5x8x2.5 mm

Brass

Bushing

94041

M3

Nylon Nut

38289

Servo Saver

94004

M3x12mm

Screw

37360

4mm

Ball & Socket

37360

4mm

Ball & Socket

36742

Servo Saver

Bushing

38644

3x6x2.5mm

Brass Bushing

38289

Servo Saver

*Use the long ball end for both steering rod and steering servo rod.

Steering Rod

A

Steering Servo Rod

B

A

Put steering rod into

4mm ball & socket.

37650

4mm

Ball End (Long)

38281

3x40mm

Turnbuckle

Approx 57 mm

37650

4mm

Ball End (Long)

Approx 54 mm

Snap steering rod into

4mm ball & socket.

Put steering rod into

4mm ball & socket.

37650

4mm

Ball End (Long)

Made two steering rod for left and

right hand side.

38281

3x36mm

Turnbuckle

37650

4mm

Ball End

(Long)

B

A

ASSEMBLY OF THE SEVRO SAVER

AND STEERING RODS

94041

M3

Nylon Nut

94041

M3

Nylon Nut

94018

M3x5mm

Flat Head

Hex Screw

38275

Servo saver

Screw

94019

M3x10mm

Flat Head

HexScrew

38275

Servo saver

Screw

38528

Cd3 Stock

Chassis

94018

M3x5mm

Flat Head

Hex Screw

94041

M3

Nylon Nut

t

c

S rew

emen

C

94019

M3x10mm

Flat Head

HexScrew

Front Gear

Box Assembly.

38263

Arm Holder for 0

(Lower/Rear)

94019

M3x10mm

Flat Head

HexScrew

Page 11

ASSEMBLY OF THE FRONT ARM HOLDER

ONTO CHASSIS

38263

Lower Arm Holder for 0 and 1.5 and

2.5 degree.

Assembly of the right and left-side are the same.

Use the 0 degree for

front arm holder.

For assembly stabilizer:

* Use a 3mm drill to

hone out the front

lower arm holder.

M3x3mm

M3x10mm

Flat Head

Hex Screw

4mm

Ball & Socket

3x55mm

Lower Arm Shaft

94033

94019

37360

38419

38263

Arm Holder

(Front/Lower)

ASSEMBLY OF THE FRONT STABILIZER

94019

M3x10mm

Flat Head

HexScrew

M3x3mm

Insert the drive shaft

before assembly.

38419

3X55mm

Lower Arm Shaft

37360

4mm

Ball & Socket

*Put steering rod into

..

4mm ball & socket

M3x16mm

Screw

2.5mm

E-Ring

M3x3mm

Set Screw

94005

Assembly of front stabilizer

94005

90020

94033

2.5mm

E-Ring

M3x16mm

Screw

90020

38418

Stabilizer

Mount

M3x3mm

Set Screw

94033

38420

Stabilizer

2.5mm

E-Ring

90020

94033

M3x3mm

Set Screw

M3x16mm

Screw

94005

Stabilizer

Mount

38418

Stabilizer

Balance

Adjuster

*Keep stabilizer ball in the center.

*Turn stabilizer balance adjuster to

adjust the stabilizer to the same angle.

Center

Page 12

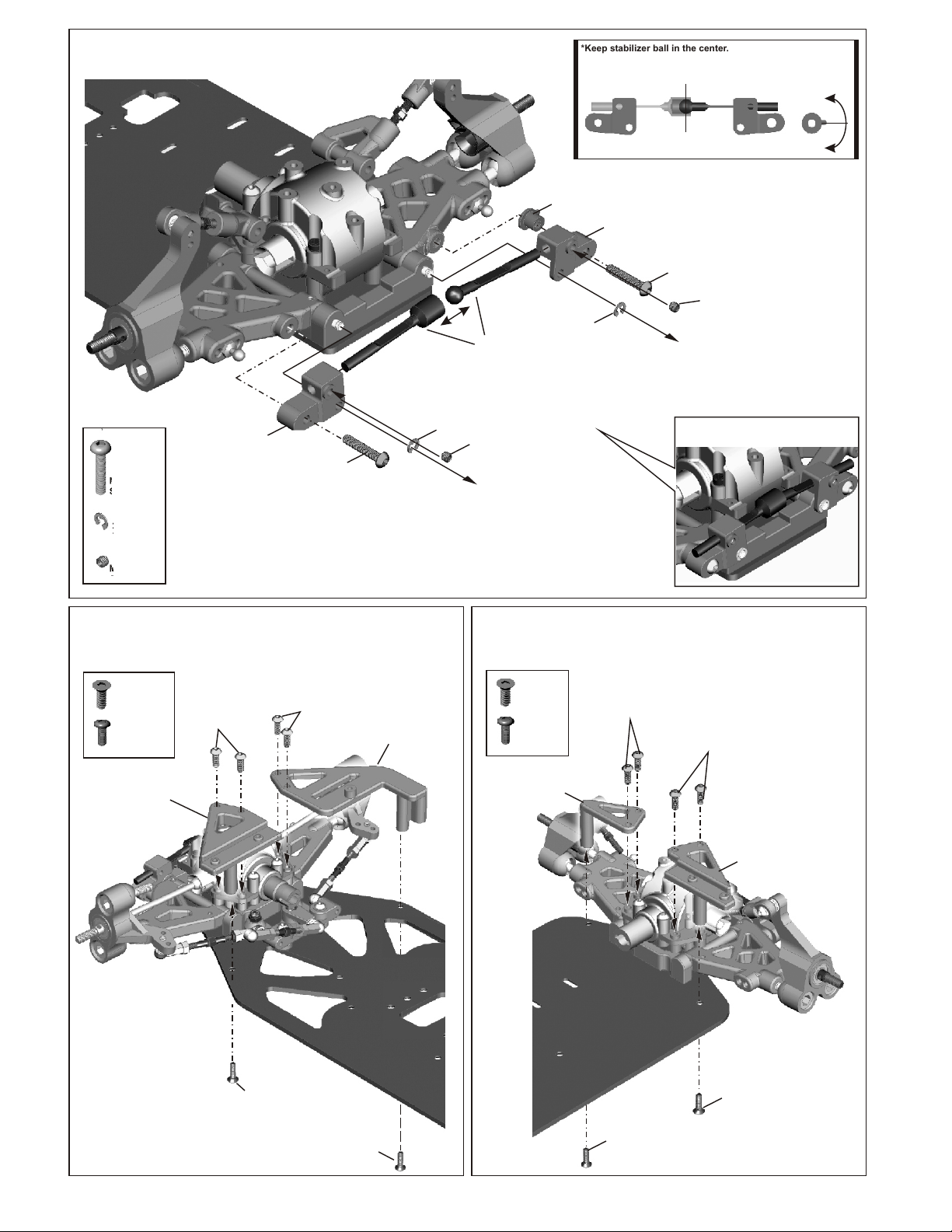

ASSEMBLY OF THE REAR STABILZER

38418

94005

M3X16mm

Screw

Stabilizer

Mount

94005

M3x16mm

Screw

90020

2.5mm

E-Ring

38420

stabilizer

94033

M3x3mm

Set screw

*Keep stabilizer ball in the center.

*Turn stabilizer balance adjuster to

adjust the stabilizer to the same angle.

38418

Stabilizer

Balance

Adjuster

90020

2.5mm

E-Ring

38418

Stabilizer

Mount

Center

94005

M3x16mm

Screw

94033

M3x3mm

Set screw

Assembly of rear stabilizer

2.5mm

E-Ring

94003

M3X3mm

Set Screw

ASSEMBLY OF THE FRONT STIFFENER

ONTO CHASSIS

94019

M3x10mm

Flat Head

Hex Screw

94032

M3x8mm

Screw

38518

Front Stiffener (Left)

94032

M3x8mm

Screw

94032

M3x8mm

Screw

38518

Front Stiffener (Right)

ASSEMBLY OF THE REAR STIFFENER

ONTO CHASSIS

94019

M3x10mm

Flat Head

Hex Screw

94002

M3x8mm

Screw

38518

Rear Stiffener (Right)

94002

M3x8mm

Screw

94002

M3x8mm

Screw

38518

Rear Stiffener (Left)

94019

M3x10mm

Flat Head

HexScrew

94019

M3x10mm

Flat Head

HexScrew

94019

M3x10mm

Flat Head

HexScrew

94019

M3x10mm

Flat Head

HexScrew

Page 13

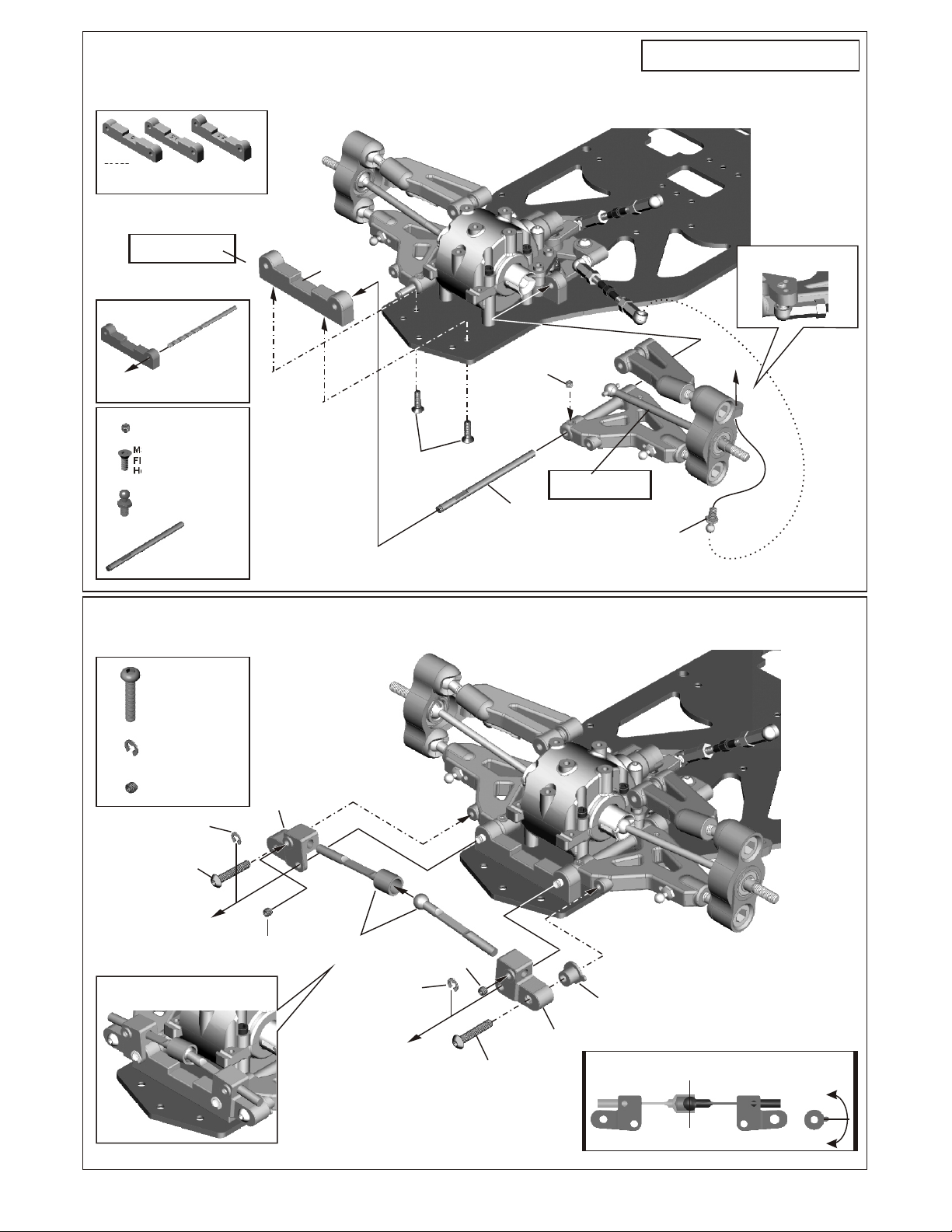

ASSEMBLY OF THE REAR GEAR BOX

AND ARM HOLDER ONTO CHASSIS

38263

Arm holder

M3x10mm

Flat Head

HexScrew

(Rear/Front)

Use the 0 degree for

rear arm holder.

94019

M3x10mm

Flat Head

HexScrew

94019

M3x10mm

Flat Head

HexScrew

Rear Gear Box

Assembly

94019

M3x10mm

Flat Head

HexScrew

ASSEMBLY OF THE REAR BLOCK ONTO CHASSIS

94033

M3x3mm

Set Screw

M3x10mm

Flat Head

HexScrew

38419

3x55mm

Lower Arm Shaft

94019

38263

Lower Arm Holder for 0 and 1.5 and

2.5 degree.

Use the 0 degree for

rear arm holder.

38263

Arm Holder

(Rear / Rear)

Assembly of the right and left-side are the same.

94033

M3x3mm

Set Screw

94019

M3x10mm

Flat Head

Hex Screw

38419

3x55mm

Lower Arm Shaft

Page 14

ASSEMBLY OF THE TWO SPEED ONTO CHASSIS

The mark on the center

drive shaft is used for the front.

M3x30mm

Flat Head

Hex Screw

M3x25mm

Flat Head

Hex Screw

38527

Center Drive Shaft

(Long/Front)

M3x25mm

Flat Head

Hex Screw

Brake Mount

Assembly (Upper)

2-Speed Assembly

38520

Brake Mount

(Lower)

*Insert the center drive shaft

before assembly the two speed

onto chassis.

38527

Center Drive Shaft

(Short/Rear)

M3x10mm

Flat Head

Hex Screw

ASSEMBLY OF THE STEERING SERVO

94002

M3X8mm

Screw

94003

M3X10mm

Screw

M3X8mm

Washer

M3X10mm

Screw

Align the servo horn in 90 degree.

Degree

90

M3X8mm

Washer

Screw

37360

4mm

Ball & Socket

38520

Servo Post Washer

10768

Steering

Servo Horn

M3x10mm

Flat Head

Hex Screw

38520

Servo Post

M3X8mm

Screw

Steering Servo

M3X8mm

Washer

M3x25mm

Flat Head

Hex Screw

M3X8mm

Screw

38520

Servo Post

38520

Servo Post Washer

M3x30mm

Flat Head

Hex Screw

Steering Servo After Assembly.

Note:

Use M3x30mm flat head screw

only in this position.

38517

Radio Tray

Use the screw

from your servo.

M3X10mm

Screw

Page 15

ASSEMBLY OF THE FRONT SHOCK STAY ONTO FRONT

GEAR BOX

90020

94004

M3x12mm

Screw

94002

M3x8mm

Screw

90020

2.5mm

E-Ring

2.5mm

E-Ring

38261

Front Upper

Arm Shaft

94004

M3x12mm

Screw

Assembly of the right and left-side are the same.

94002

M3x8mm

Screw

39141

Insert the front caster angle adjuster into front upper arm.

39141

Caster Angle

Adjuster(1.5mm)

1.5mm

1mm

Caster Angle

Adjuster

(1.0mm)

ASSEMBLY OF THE REAR SHOCK STAY ONTO REAR

GEAR BOX

38268

Rear Drive

Shaft

94002 94004

M3x8mm

Screw

M3x12mm

Screw

90020

2.5mm

E-Ring

Assembly of the right and left-side are the same.

90020

2.5mm

E-Ring

38261

Front Upper

Arm Shaft

90020

2.5mm

E-Ring

94004

M3x12mm

Screw

94002

M3x8mm

Screw

38268

Rear Drive

Shaft

* Insert the rear driver shaft

before assembly the upper arm.

90020

2.5mm

E-Ring

90020

2.5mm

E-Ring

Page 16

ASSEMBLY OF THE LEXAN SHOCK ABSORBERS

(USED ON SPORT RTR MODELS)

37070

37650

4mm

Ball End

3mm O-Ring

2mm E-Ring

37070

3mm O-Ring

2mm E-Ring

38325

Shock Shaft

37070

3mm O-Ring

37100

Front Cap

2mm E-Ring

37100

Piston

39030

Clear Lexan

Shock Body

FILLING THE SHOCKS WITH OIL

OilOil

Shock Oil

Use the No.2 for two

hole piston from

shock plastic tree.

ASSEMBLY THE SHOCK SPRING

38330

Shock Cap

(Gray)

37100

Ball end

37080

Pressure Top

Spring collar

38326

Shock Spring

37100

Spring

tension adjust

Pull down piston

37967

P3

O-Ring

(2 pcs)

and pour oil into

shock cylinder.

Remove air bubbles

by slowly moving

piston up and down

several times.

2mm

E-Ring

38325

Shock Shaft

*Insert the o-ring

into the groove

of the adjust nut.

37100

Piston

Use the No.2 for two hole

piston from shock plastic

tree.

37966

P12 O-Ring

Use the short ball end .

ASSEMBLY OF THE ALUMINUM CNC SHOCK ABSORBERS

(USED ON PRO RTR MODELS)

37967

Washer

(Block)

37965

Alum Shock Body

Step 1

The C-Ring must fit

into the groove.

37967

C-Ring

Step 2

Use a little shock oil to

lubricate o-rings before

screwing on adjusting nut.

37100

Spring Holder

ASSEMBLY THE SHOCK SPRING

Use the short shock

ball end.

38330 GRAY

Shock Cap

(Gray)

37100

Ball End

( Short)

37080

Pressure Top

37650

4mm

Ball End

* Use the short ball end .

38331-GRAY

Adjust Nut(Gray)

FILLING THE SHOCKS WITH OIL

OilOil

Pull down piston

and pour oil into

shock cylinder.

Shock Oil

Remove air bubbles

by slowly moving

piston up and down

several times.

38326

Shock Spring

37100

Spring Holder

Page 17

ASSEMBLY OF THE FUEL TANK ONTO CHASSIS

94002

M3X8mm

Screw

Fuel Nipple

M3X8mm

Screw

94003

M3x10mm

Flat Head

Screw

94002

Fuel Nipple

94002

M3X8mm

Screw

38518

Fuel Tank Post

38521

Cd3 Fuel Tank

Step 1

94005

M3X16mm

Screw

94005

M3X16mm

Screw

M3x8mm

Washer

38520

Servo Post Washer

2mm

38520

Servo Post Washer

2mm

94005

M3X16mm

Screw

M3x8mm

Washer

THROTTLE

SERVO

38520

Servo Post Washer

2mm

38520

Servo Post Washer

2mm

94019

M3x10mm

Flat Head

Screw

Step 2

*Use the screw provided

from your servo.

Put the receiver and

battery into box.

Screw

Receiver

30560

Antenna pipe

37410

Body Clip

38518

Battery Cover

Battery

38520

Servo Post

38520

Servo Post

10280

Switch Cover

Switch

Page 18

ASSEMBLY OF THE RADIO TRAY ONTO CHASSIS

94002

M3x8mm

Screw

94019

M3x10mm

Flat Head

Screw

94002

M3x8mm

Screw

M3x10mm

Flat Head

Screw

94019

M3x10mm

Flat Head

Screw

94019

M3x10mm

Flat Head

Screw

94002

M3x8mm

Screw

37410

Body Pin

Front Bumper

Post Tube

94004

M3x12mm

Screw

38291

39320

Body Holder

39320

Body Post

(Front)

38291

Front Bumper

Top Plate)

38291

Front Bumper

Post Tube

Insert body

pins into body

holder to the

desired

height.

39320

Body Holder

37410

Body Post

(Front)

37410

Body Pin

M3x12mm

Screw

38291

Front Bumper

Post Tube

38291

Front Bumper

94019

M3x10mm

Flat Head

Screw

94019

M3x10mm

Flat Head

Hex Screw

94019

M3x10mm

Flat Head

Hex Screw

Page 19

ASSEMBLY OF THE FRONT POST

94021

M3x16mm

Flat Head

Screw

38294

94002

M3x8mm

Screw

94004

M3x12mm

Screw

Foam Bumper

94002

M3x8mm

Screw

94020

M3x12mm

Screw

ASSEMBLY OF THE FRONT SHOCK INTO

SHOCK TOWER

94004

M3x12

Screw

38329

6mm Alum.

Ball & socket

(Gray)(Short)

94021

M3x16mm

Flat Head

Screw

94020

M3x12mm

Screw

ASSEMBLY OF THE REAR SHOCK INTO

SHOCK TOWER

94004

M3x12

Screw

38282

6mm Alum.

Ball & socket

(Long)

Snap ball end

into 37360 as

shown.

37360

4mm

Ball & socket

37360

4mm

Ball & socket

Snap ball end

into 37360 as

shown.

Page 20

ASSEMBLY OF THE ENGINE AND 2-SPEED CLUTCH BELL

38307

18T-1st

Clutch Gear

38309

22T-2nd

Clutch Gear

35958

5x8x2.5mm

Ball Bearing

3X6 mm

Washer

34110

5x10x4mm

Ball Bearing

35951

Clutch Bell

M3x5mm

CAP Screw

ASSEMBLY OF THE ENGINE ONTO ENGINE MOUNT ASSEMBLY OF THE MANIFOLD

30702

M3x12mm

Cap Screw

30702

M3x12mm

Cap Screw

90019

M3x20mm

Cap Screw

38162

Manifold Gasket

90019

M3x20mm

Cap Screw

Note:

Put the nylon nut

into the groove of the

engine mount.

94041

M3

Nylon Nut

38150

Engine Mount

38150

Engine Mount

94041

M3

Nylon Nut

38529

Manifold

(side exhaust)

Page 21

ASSEMBLY OF THE REAR BODY POST

37968

M3x12mm

Screw

M3x12mm

Screw

Body Holder

ASSEMBLY OF THE ENGINE

37968

Body Holder

37968

Body Post

(Rear)

37968

Body Post

(Rear)

37410

Body Pin

Insert body pins into

body holder to the

desired height.

94041

M3

Nylon Nut

3X6 mm

Washer

35958

5x8x2.5mm

Ball Bearing

34110

5x10x4mm

Ball Bearing

30702

M3x5mm

Cap Screw

30702

M3x12mm

Cap Screw

59020

Pilot Shaft

10330

7mm

Tapered Cone

10330

7mm

Tapered Cone

10098SG

Clutch Nut

SG Crank Shaft

When installing an engines with a SG crank shaft, you must

use the 10098 clutch nut and 7mm tapered cone.

Put the clutch spring into

the groove of the clutch

shoes before assembly.

38284

3 Shoe Flywheel

10100

Clutch Spring

10010

Clutch Shoes

10100

Clutch Spring

* Fit the flywheel using

a pair of the plier and cross wrench.

* Place the clutch shoes

with the clutch springs

over the 3 pins of the flywheel.

Using a phillips screw driver

or needle nose pliers and bend

the small end of the clutch

spring behind the pilot shaft

59020 or 10098 than press

down.

Bend

10010

Clutch Spring

10100

Clutch Spring

59020

Pilot Shaft

Page 22

ASSEMBLY OF THROTTLE HORN INTO SERVO AND BRAKE LEVER

Screw

THROTTLE

SEVRO

Use the screw provided

from your servo.

* Align the throttle servo horn in 90 degree.

* Attach the throttle ball end onto

the throttle ball on the carburetor

ASSEMBLY OF THE EXHAUST SYSTEM

Nylon Strap

(Middle)

38438

Silicone Tube

38514

Tuned Pipe

Nylon Strap

5x4mm

Set Screw

Insert the filter into air filter

holder.

Apply filter oil to the sponge

before use.

38401

Air Filter Holder

38531

Muffler Stay

3x8mm

Washer

94003

M3x10mm

Screw

Page 23

ASSEMBLY OF THE ENGINE ONTO CHASSIS

94003

M3x10mm

Screw

Note book Paper.

* Use the note book paper to set gear

backlash between Spur Gear and Clutch

Bell Gear. If the space is not correct, the

spur gear will be damaged.

Spur Gear

M3x10mm

Screw

ASSEMBLY OF THE BRAKE LINKAGE

( For slide carburetor. )

Step 1

36130

Throttle

Slider

10292

Throttle

Ball End

10724

2mm

Rod

10300

Throttle Spring

M3x10mm

Screw

94033

3x3mm

Set Screw

10300

Alum.

Stopper

94003

Step 3

90 Degree

* Loose or tighten 3x10mm cap screw

to align spur gear and clutch bell gear

to 90 degree.

M2x8mm

Screw

Clutch Bell

Step 2

94033

3x3mm

Set Screw

10300

Alum.

Stopper

Throttle Spring

bushing

10724

Brake Rod

10768

Servo Horn

10769

Insert for Servo Saver

Page 24

ASSEMBLY OF THE FUEL TUBE AND PRESSURE TUBE

Connect to muffler

pressure nipple.

10179

Fuel Tube

Connect to carbureter.

Connect to fuel nipple.

ASSEMBLY OF THE TIRES AND WHEELS

87630

Slick Tires

Super Glue

Connect to fuel tank

pressure nipple.

ASSEMBLY OF THE WHEELS ONTO FRONT

KNUCKLE ARM AND REAR HUB

Assembly of the right and left-side are the same.

(FRONT ASSEMBLY)

38328

2x 7.8mm

pin

87658

Inner Sponge

87610

Mesh Wheel

Insert the inner Sponge before

assembly.

Apply instant cement.

M5X9mm

Washer

(REAR ASSEMBLY)

37390

2x 10.8 mm pin

37590

Plastic Drive Nut

37390

2x10.8 mm pin

38328

Alum. Drive Nut

38328

2x 7.8mm

pin

38328

Alum. Drive Nut

The drive nut

will be use in

different kit.

10986

4mm Nylon Nut

The drive nut

will be use in

different kit.

Insert wheel into tire.

37590

Plastic Drive Nut

10986

4mm Nylon Nut

Page 25

SETTING THROTTLE LINKAGE

* ADJUSTING THROTTLE LINKAGE BEFORE START THE ENGINE

1. Turn on your transmitter at first and then the car's electronics (Set the transmitter trim-level in center).

Adjust the alum. stopper A to made the carburetor in idle position. Adjust the alum. stopper B to

leave 2mm space between alum. stopper and brake level.

2. Pull the full throttle trigger. The carburetor should be almost full open.

3. Apply the brake with your transmitter trigger, your carburetor should in idle position. The spring

between the alum. stopper and ball end should be compressed.

FOR SLIDER CARBURETOR

IN IDLE POSITION

* Carburetor at idle

position.

Brake Level

2mm space

B

FOR ROTARY CARBURETOR

IN IDLE POSITION

* Carburetor at idle

position.

IN BRAKE POSITION

* Carburetor at idle

position.

* The spring should be

compressed.

A

IN BRAKE POSITION

* Carburetor at idle

position.

* The spring should be

compressed.

* Carburetor at full

throttle position.

* Carburetor at full

throttle position.

IN FULL THROTTLE POSITION

IN FULL THROTTLE POSITION

Brake Level

2mm space

B

Notes:

1) Always check and change radio batteries when low. Running your car with low batteries

will greatly shorten the radio range. Loss of radio control will damage your car and is not

covered under warranty.

2) Check linkage operation for steering and throttle before starting your car. The directional

servo switches on radio may be in the wrong position and must be checked and set for

proper operation.

3) Battery problems are the biggest cause of car damage, always check radio operation when

running. If you feel the radio is not working correctly, shut down engine immediately and

check it out!

Page 26

APPENDIX PAGES

Page 27

INSTRUCTIONS

#38322 STANDARD SPEED TRANSMISSION

ADJUSTING THE SHIFT POINT

* Adjust the engine before adjusting the clutch shift timing.

Adjust the engine as per engine instruction manual.

M2x10

Hex Screw

Clockwise

(Tighten)

Counter-clockwise

(Loosen)

M2x10mm

3x3mm

Set Screw

* Use a 1.5mm allen wrench to

set the clutch shoe.

* Adjust the 3x3 set screw witch is used

to the distance between the clutch

adjust

shoe and clutch bell.

* Adjust the M2 x 10mm hex screw will be

change the shift timing of the clutch

shoe.

Hex Screw

1.5mm

Allen Wrench

SHIFT UP TIMING ADJUSTMENT

1. Once the engine adjustments have been completed, proceed to the

adjustment of the clutch shoe shift timing.

(Using a 1.5mm allen wrench to adjust the clutch shoe on either side.)

Note:

Clockwise--------Shift timing will become slower.

Counter-clockwise---Shift timing will become quicker.

2. Adjust the clutch shift timing for your track conditions.

As you tighten (Clockwise) the 2x10mm screw , the shift timing will

become slower.

As you loosen (Counter-clockwise ) the 2x10mm screw, the shift timing

will become quicker.

3. Set the shift timing to the track conditions while the car is running.

Here

NOT Here, at ball set screw!

STANDARD GEARING

2 SPEED GEAR RATIO COMBINATIONS

IMPORTANT:

The sum of the spur gear and clutch gear for1st gear must be equal.

Also, he sum of the spur gear and clutch gear for 2nd gear . be equal

44T/40T

43T/39T

42T/38T

41T/37T

¤j¾¦

1st gear 45+13=58

2nd gear 41+17=58

(4 tooth difference - OFNA standard)

16T/20T

16T/21T

Must be equal

CLUTCH GEAR

17T/21T 18T/22T 19T/23T

CLUTCH GEAR

(5 tooth difference)

17T/22T 18T/23T 19T/24T

Example:

( STANDARD)

SPUR GEAR

(MODIFY)

SPUR GEAR

2 SPEED OPTION PARTS

SPUR GEAR:

Number

38298 37T Spur Gear, Gray 1st

38299 41T Spur Gear, Gray 2nd

Short Track

Torque

38300 38T Spur Gear, Gray 1st

38301 42T Spur Gear, Gray 2nd

38302 39T Spur Gear, Gray 1st

38303 43T Spur Gear, Gray 2nd

38304 40T Spur Gear, Gray 1st

Long Track

Top Speed

38305 44T Spur Gear, Gray 2nd

CLUTCH GEAR:

Number

Short Track

Torque

35944 16T-1st Clutch Gear

38306 17T-1st Clutch Gear

38307 18T-1st Clutch Gear

38308 19T-1st Clutch Gear

Description

Description

44T/39T

43T/38T

42T/37T

* Also 2 tooth and 5 tooth differences are possible, but not shown..

35945 20T-2nd Clutch Gear

Long Track

Top Speed

35946 21T-2nd Clutch Gear

38309 22T-2nd Clutch Gear

38310 23T-2nd Clutch Gear

38311 24t-2nd Clutch Gear

Page 28

INSTRUCTIONS

#38640 0.8 GEARING 2-SPEED TRANSMISSION

ADJUSTING THE SHIFT POINT

* Adjust the engine before adjusting the clutch shift timing.

Adjust the engine as per engine instruction manual.

M2x10

Hex Screw

Clockwise

(Tighten)

Counter-clockwise

(Loosen)

M2x10mm

3x3mm

Set Screw

* Use a 1.5mm allen wrench to

set the clutch shoe.

* Adjust the 3x3 set screw witch is used

to the distance between the clutch

adjust

shoe and clutch bell.

* Adjust the M2 x 10mm hex screw will be

change the shift timing of the clutch

shoe.

Hex Screw

1.5mm

Allen Wrench

SHIFT UP TIMING ADJUSTMENT

1. Once the engine adjustments have been completed, proceed to the

adjustment of the clutch shoe shift timing.

(Using a 1.5mm allen wrench to adjust the clutch shoe on either side.)

Note:

Clockwise--------Shift timing will become slower.

Counter-clockwise---Shift timing will become quicker.

2. Adjust the clutch shift timing for your track conditions.

As you tighten (Clockwise) the 2x10mm screw , the shift timing will

become slower.

As you loosen (Counter-clockwise ) the 2x10mm screw, the shift timing

will become quicker.

3. Set the shift timing to the track conditions while the car is running.

Here

NOT Here, at ball set screw!

0.8 GEARING SET

2 SPEED GEAR RATIO COMBINATIONS

IMPORTANT:

The sum of the spur gear and clutch gear for1st gear must be equal.

Also, he sum of the spur gear and clutch gear for 2nd gear . be equal

Example:

( STANDARD)

SPUR GEAR

56T/50T

55T/49T

54T/48T

1st gear 55+20=75

2nd gear 49+26=75

(6 tooth difference - OFNA standard)

19T/25T

Must be equal

CLUTCH GEAR

20T/26T 21T/27T 22T/28T

Short Track

Torque

Long Track

Top Speed

23T/29T

2 SPEED OPTION PARTS

0.8 SPUR GEARS:

Number

38670 54T Spur Gear, 0.8 1st

38673 48T Spur Gear, 0.8 2nd

38671 55T Spur Gear, 0.8 1st

38674 49T Spur Gear, 0.8 2nd

38675 50T Spur Gear, 0.8 2nd

38672 56T Spur Gear, 0.8 1st

#38620 POWER CLUTCH GEARS:

Number

38655 19T-1st Clutch Gear

38656 20T-1st Clutch Gear

38657 21T-1st Clutch Gear

38658 22T-1st Clutch Gear

38659 23T-1st Clutch Gear

38660 25T-2nd Clutch Gear

38661 26T-2nd Clutch Gear

38662 27T-2nd Clutch Gear

38663 28T-2nd Clutch Gear

38664 29T-2nd Clutch Gear

Description

Description

Page 29

Page 30

Page 31

Page 32

Page 33

OFNA MICRO FAIL SAFE UNIT - #91002 (MICRO)

The OFNA Fail Safe unit is used to protect your RC car from loss of control due to:

• Weak radio signal

• Low radio batteries

• Radio interference of any kind

• Another radio on the same channel

• Low receiver car battery

• Fits most if not all U.S. RC radio’s

The Fuzzy logic CPU operates on 3.8 to 6.0 volts DC from your receiver battery pack.

Warning - If receiver battery is dead or removed or car battery switch is off, the fail safe

unit will not function nor provide any RC control protection.

Installation:

1) Connect the unit between your receiver and throttle servo. But, before applying power

check wiring color code to ensure correct polarity.

2) Locate unit in battery box or holder. It is best to keep dirt or water away from unit.

Also, secure unit so it is not loose and allowed to wiggle freely on leads.

3) To setup the unit, turn on the radio transmitter and car receiver. You should see the

throttle and steering servo’s operate normally. Also, the fail safe “red” light will be flashing quickly. If solid red, you may have radio problem or not turned ON.

4) With radio transmitter on, push throttle trigger to full brake and hold, not full throttle.

Then, with a pin, push the Set Position button on the fail safe unit. You should feel a one

click and a flashing red light indication. For a few seconds, the red led will flash quickly

then pause, this pause indicates the fail safe is set to your brake trigger position.

The unit is now set. To check, turn off radio transmitter. Note the throttle servo will immediately move to the brake position set, in this case FULL. Also, a red light will be on.

Solid Red means dangerous operation; Slow flashing red means possible problem or low

receiver battery. With either indication (Slow or Solid red), stop operation until interference or battery recharge is done.

IF YOU HAVE ANY QUESTIONS OR PROBLEMS, CALL TECHNICAL SUPPORT.

RED STATUS

Fast Flashing: Okay

Solid: Stop, Dangerous

Slow Flashing: Low Car Battery

Fast Flashing & Pause: Set

Push To

Set

& Hold

Page 34

CD-3 RTR SPORT and RTR PRO PRICE LISTCD-3 RTR SPORT and RTR PRO PRICE LIST

CD3 RTR SPORT AND PRO RTR MODELS

10010 SHOES, 3 SHOE TYPE, BLACK, 3 PCS. 12.95

10079 ALUM. PRESSURE NIPPLE, RIGHT ANGLE, 3 COLOR CHOICES 4.95

10098 CLUTCH NUT , SG 4.95

10100 SPRINGS, 3 SHOE TYPE CLUTCH, MED., GOLD 3+1 PCS. 4.95

10101 SPRINGS, 3 SHOE TYPE CLUTCH, PRO GRAY, 3 PCS. 4.95

10102 SPRINGS, 3 SHOE TYPE CLUTCH, BLACK, 3 PCS. 4.95

10121 SPRING, MANIFOLD, SMALL DIA. 5.95

10178 FUEL LINE TUBING, HARD WALL, SILICONE, 100cm YELLOW 1.95

10179 FUEL LINE TUBING, HARD WALL, SILICONE, 100cm BLUE 1.95

10270 CLIPS, FUEL TUBING 3.95

10273 SERVO BARS, BLUE WITH SCREWS 3.95

10280 SWITCH COVER, SILICONE , 1 PC 3.95

10300 ALUMINUM STOPPERS W/ SPRING 4.95

10330 SLIT METAL CORN 2.95

10375 BLUE FLANGE 4mm NYLOK NUTS, 10 PCS. 8.95

10376 PURPLE FLANGE 4mm NYLOK NUTS, 10 PCS. 8.95

10765 SERVO HORN, HD W/ CNC TOP, BLUE (AIR, SANWA, FU, HITEC, JR) 8.95

10766 SERVO HORN, HD W/ CNC TOP, RED (AIR, SANWA, FU, HITEC, JR) 8.95

10767 SERVO HORN, HD W/ CNC TOP, PURPLE (AIR, SANWA, FU, HITEC, JR) 8.95

10768 SERVO HORN, HD W/ CNC TOP, YELLOW (AIR, SANWA, FU, HITEC, JR) 8.95

10769 INSERTS SERVO SAVER, ALL RADIO'S (AIR, SANWA, FU, HITEC, JR) 0.95

30171 LEVERS, BRAKE 2 PCS. 1.95

30411 6mm BALLS, 6 PCS. 4.95

34110 BALL BEARINGS, 5x10mm 2 PCS. 7.95

35300 PILOT SHAFT, POWER CLUTCH 8.95

35303 ADJUSTING NUT, POWER CLUTCH 5.95

35304 CUP, SPRING, POWER CLUTCH 4.95

35309 SPRING, POWER CLUTCH 3.95

35951 CLUTCH BELL BASE, 5x8 /5x10mm BEARINGS 19.95

35958 BALL BEARING, 5x8mm, 1 PC. 4.50

36130 THROTTLE LINKAGE, 3 PCS. 3.95

36742 BUSHING, SERVO SAVER, COLLAR, 2 PCS. 1.95

37080 SEALS, TOP CAP, SHOCK 4 PCS. 1.95

37100 PLASTIC PARTS, SHOCKS 4.95

37210 TURNBUCKLE, 3x15mm 2 PCS. 2.95

37360 4mm BALL AND SOCKET, 10 PCS. 4.95

37370 6mm BALL AND SOCKET, 6 PCS. 3.95

37390 DRIVE PIN, 2x10.8mm, 3 PCS. 1.95

37400 DRIVE PIN, 2x8.8mm, 3 PCS. 1.95

37410 PINS, BODY, 10 PCS. 3.95

37430 BALL BEARING, 5x11mm, 8 PCS. 15.95

37450 BALL BEARING, 10x15mm, 4 PCS. 15.95

37590 DRIVE NUTS, 5mm BLACK PLASTIC, 4 PCS. 2.95

37650 4mm PLASTIC BALL END SOCKET, 10 PCS. 6.95

37751 MISC. E-CLIPS AND SET SCREW 9.95

37771 BEVEL GEAR, 13T, GEAR DIFF 3.95

37965 BODIES, SHOCK, THREADED, HARD COATED PAIR 19.95

37966 O-RING, P-12 COLLAR RING, SHOCK 4 PCS. 1.95

37967 REPAIR KIT, SHOCKS (THREADED BODY TYPE) 5.95

37968 BODY MOUNT KIT, UNIVERSAL, OFNA/HPI/YOK 8.95

38150 ENGINE MOUNTS, ADJUSTABLE 11.95

38162 GASKET, SIDE EXHUAST MANIFOLD 1.95

38180 LINKAGE, THROTTLE KIT 3.95

38251 CASE, MAIN GEAR CASE 5.95

38252 CASE, DIFF 4 & 6 GEAR 3.95

38253 PIN, 3x17.8mm, 3 PCS. 1.95

38254 WASHER, 12x15x.02mm, 6 PCS. 1.95

38255 CAP JOINT, DIFF 2 PCS. 9.95

38256 GEAR, 10T, DIFF 2 PCS. 3.95

38257 GEAR, 40T BEVEL 5.95

38258 GEAR, 16T PINION 3.95

38259 PIN, CROSS, DIFF 1.95

38260 CAP JOINT, BEVEL GEAR 9.95

38261 SHAFT, FRONT ARM, UPPER, 2 PCS. 3.95

38262 SHAFT, 3x50mm , ARMS, LOWER, 2 PCS. 3.95

38263 HOLDER, ARMS, 0, 1.5, 2.5 DEGEE SET 5.95

38265 FRONT KNUCKLE, 2 PCS. 5.95

38266 REAR UP-RIGHT HUB, 2 PCS. 5.95

38267 AXLES, REAR WHEEL, DOG BONE, 2 PCS. 8.95

38268 REAR DOG BONE, 2 PCS. 8.95

38269 CVA, FRONT PAIR 35.95

38270 TOWER, SHOCK, FRONT OR REAR 5.95

38271 BRAKE PLATES, 2 PCS. 3.95

Page 35

38272 PADS, BRAKE, 2 PCS. 2.95

38273 CAM, BRAKE 5.95

38274 LEVER, BRAKE 2.95

38275 SCREW, SERVO SAVER, 2 PCS. 2.95

38276 SCREW, 3x6mm BRAKE 2.95

38277 BUSHING, 5x8mm, 2 PCS. 3.95

38278 O-RING, 5x1.5mm, 4 PCS. 1.95

38279 PINS, 3x14.8mm, 2 PCS. 1.95

38280 TURNBUCKLES, 3x36mm, 2 PCS. 5.95

38281 TURNBUCKLES, 3x40mm, 2 PCS. 5.95

38282 MOUNT, ALUM. BALL, SHOCK, GRAY 2 PCS. 5.95

38283 CLUTCH UNIT, 3 SHOE & THREAD TYPE, BLACK, 3 PCS. 29.95

38284 FLYWHEEL, 3 SHOE, THREAD SHAFT 11.95

38285 FLYWHEEL, 3 SHOE, SG SHAFT 11.95

38286 MANIFOLD, .12 SIDE EXHAUST, LD3/CD3 15.95

38287 GASKET, DIFF CASE, 3 PCS. 2.95

38288 SPRING, SERVO SAVER 2.95

38289 SERVO SAVER & BRAKE MISC PARTS 6.95

38291 FRONT BUMPER 7.95

38292 RECEIVER BOX AND LID 5.95

38294 FOAM BUMPER, BLACK 6.95

38295 1ST GEAR HOLDER AND ONE-WAY BEARING 21.95

38296 2ND GEAR HOLDER AND 6x12mm BEARING 18.95

38297 RING, 16mm GEAR RETAINER, 2 PCS. 1.95

38298 GEAR, SPUR, 37T, 1ST GRAY 9.95

38299 GEAR, SPUR, 41T, 2ND GRAY 9.95

38300 GEAR, SPUR, 38T, 1ST GRAY 9.95

38301 GEAR, SPUR, 42T, 2ND GRAY 9.95

38302 GEAR, SPUR, 39T, 1ST GRAY 9.95

38303 GEAR, SPUR, 43T, 2ND GRAY 9.95

38304 GEAR, SPUR, 40T, 1ST GRAY 9.95

38305 GEAR, SPUR, 44T, 2ND GRAY 9.95

38306 GEAR, SCREW-ON, 17T, 1ST 9.95

38307 GEAR, SCREW-ON, 18T, 1ST 9.95

38308 GEAR, SCREW-ON, 19T, 1ST 9.95

38309 GEAR, SCREW-ON, 22T, 2ND 9.95

38310 GEAR, SCREW-ON, 23T, 2ND 9.95

38311 GEAR, SCREW-ON, 24T, 2ND 9.95

38312 SHOES, CLUTCH, 2-SPEED, BLACK 11.95

38312 CLUTCH SHOE 11.95

38313 CONE, TAPERED, FLYWHEELS 2.95

38314 SPRING, CLUTCH, 2-SPEED, HARD 1.95

38315 BALL, 4mm, 2-SPEED 1.95

38316 HOLDER, SHOE, 2-SPEED 3.95

38321 MISC SCREW BAG, HEX TYPE, LD3/CD3 RTR 17.95

38322 2-SPEED TRANSMISSION, STANDARD 112.95

38324 SHOCK, LEXAN, PAIR 23.95

38325 SHAFT, SHOCK, 28.5mm, PAIR 5.95

38326 SPRING, SHOCKS, BLACK 4 PCS. 7.95

38328 DRIVE HEX, ALUM. W/O-RING, GRAY 11.95

38329 POST, ALUM. MOUNT, SHOCKS, GRAY 9.95

38330 CAP, RING SHOCK, GRAY PAIR 9.95

38331 COLLER RING, SHOCKS, GRAY 2 PCS. 5.95

38332 SHOCK, ALUM. THREADED BODY, LD3/CD3 PAIR 31.95

38335 NIPPLE, PRESSURE, FUEL TANK 2 PCS. 3.95

38336 DECAL, TEAM OFNA LOGO 3.95

38338 DECAL, BODY M330 TRIM AND RTR WINDOWS 5.95

38339 BODY, CLEAR M330 200mm 24.95

38340 BODY, PRE-CUT M330 200mm FIRE AND RED 49.95

38341 BODY, PRE-CUT M330 200mm FIRE AND BLUE 49.95

38342 BODY, PRE-CUT M330 200mm FIRE AND PURPLE 49.95

38343 BODY, PRE-CUT M330 200mm FLAG AND RED 49.95

38344 BODY, PRE-CUT M330 200mm FLAG AND WHITE 49.95

38345 BODY, PRE-CUT M330 200mm FLAG AND SILVER 49.95

38346 BODY, PRE-CUT M330 200mm FLAG AND PURPLE 49.95

38350 BODY, M330 200mm FIRE AND RED (BODY NOT CUTOUT) 49.95

38351 BODY, M330 200mm FIRE AND BLUE (BODY NOT CUTOUT) 49.95

38352 BODY, M330 200mm FIRE AND PURPLE (BODY NOT CUTOUT) 49.95

38353 BODY, M330 200mm FLAG AND RED (BODY NOT CUTOUT) 49.95

38354 BODY, M330 200mm FLAG AND WHITE (BODY NOT CUTOUT) 49.95

38355 BODY, M330 200mm FLAG AND SILVER (BODY NOT CUTOUT) 49.95

38356 BODY, M330 200mm FLAG AND PURPLE (BODY NOT CUTOUT) 49.95

38398 AIR FILTER, N.R. CARBURETOR, FOAM DOME, BLACK 3.95

38399 ARMS, RPO UPPER & LOWER FRONT AND REAR 15.95

38400 AIR FILTER, N.R. CARBURETOR, FOAM DOME, BLACK 9.95

38401 AIR FILTER, PICCO CARBURETOR, FOAM DOME, BLACK 9.95

38402 GEAR, DIFF 12T (LARGE) 4 OR 6 DIFF ONLY 2 PCS. 3.95

38403 DIFF, 6 GEAR KIT, 12T & CROSS PINS 9.95

38404 PINS, DIFF CROSS PINS 1.95

38405 CVA, FRONT OR REAR, LD3/CD3 PAIR (Captured Pin) 35.95

Page 36

38406 AXLES, CVA DOG BONE PAIR (Captured Pin) 17.95

38407 DOG BONE, CVA PAIR 17.95

38408 MISC., LD3/CD3 CVA HARDWARE 5.95

38409 BEARING, THRUST, 4x9mm 15.95

38412 GEAR, STEEL BEVEL 40T, ONE-WAY ONLY 15.95

38413 CAP JOINTS, ONE-WAY 9.95

38414 GEAR, STEEL BEVEL AND OPINION, FOR DIFF CASE 23.95

38415 GEAR, STEEL BEVEL, SMALL 16T 7.95

38416 GEAR, STEEL BEVEL, LARGE 40T 15.95

38417 SWAYBAR, BLADE TYPE, FRONT AND REAR KIT 21.95

38418 BAR MOUNT, PLASTIC 1.95

38419 SHAFT, LONG, BLADE SWAYBAR KIT 7.95

38420 BAR, BLADE, SWAYBAR 2 PCS. 7.95

38422 ALUM. CNC CAP JOINT, CENTER/FRONT 13.95

38423 POWER CLUTCH, 30mm FLYWHEEL KIT 111.95

38424 ALUM. CNC FLYWHEEL, POWER CLUTCH, 30mm 19.95

38425 CLUTCH BELL, SCREW-ON, POWER CLUTCH 19.95

38426 SHOE, CLUTCH, BLACK 11.95

38427 SHOE, SLIDING, WHITE 11.95

38428 SPRING, POWER CLUTCH 3.95

38429 PILOT SHAFT, POWER CLUTCH 6.95

38430 COLLET, TAPER, POWER CLUTCH FLYWHEEL 3.95

38431 SPRING PLATE, POWER CLUTCH 3.95

38432 SPRING ADJUSTING NUT, POWER CLUTCH 5.95

38433 PLATE, CLUTCH SHOE, POWER CLUTCH 5.95

38434 SCREW, ADJUST, POWER CLUTCH 3.95

38435 ENGINE MOUNT, LOWER, NON-PULL START 31.95

38436 ALUM. CNC MOUNT, STEERING SERVO 11.95

38437 ALUM. CNC MOUNT, THROTTLE SERVO 11.95

38438 TUBE, SILICONE, PURPLE, LD3/CD3 MANIFOLD JOINT, SMALL 3.95

38439 BUMPER, TOP SUPPORT, GRAPHITE 21.95

38442 ALUM. CNC ARMS, UPPER AND SHOCK MOUNTS, 49.95

38443 ALUM. CNC ARM HOLDER, UPPER, 11.95

38444 TOWER, SHOCK, GRAPHITE 19.95

38445 HOLDER, ARM PIN, GRAPHITE 15.95

38446 ALUM. CNC HOLDER, FRONT AND REAR LOWER ARMS SET 23.95

38447 ALUM. CNC HOLDER, FRONT LOWER ARMS 11.95

38448 ALUM. CNC HOLDER, REAR LOWER ARMS 11.95

38449 PIVOT BALLS, STEEL, LOWER ARM HOLDERS 3.95

38451 ALUM. CNC DISC BRAKE HEAD, CENTER 9.95

38452 ALUM. CNC MOUNT, SWAYBAR 27.95

38453 ALUM. CNC SERVO SAVER UNIT 31.95

38454 ALUM. CNC SERVO SAVER TOP PLATE 7.95

38455 MOUNT, ALUM. CNC, SERVO SAVER LOWER 11.95

38456 ARM, ALUM. CNC, SERVO SAVER, NEW LONG TYPE 19.95

38457 PAD, BRAKE, BONDED CARBON&STEEL PAD 31.95

38458 ALUM. CNC GEAR 15T - GREEN, 1ST 9.95

38459 ALUM. CNC GEAR 16T - PINK, 1ST 9.95

38460 ALUM. CNC GEAR 17T - BLUE, 1ST 9.95

38461 ALUM. CNC GEAR 18T - GOLD, 1ST 9.95

38462 ALUM. CNC GEAR 19T - ORANGE, 1ST 9.95

38463 ALUM. CNC GEAR 19T - PURPLE, 2ND 9.95

38464 ALUM. CNC GEAR 20T - SILVER, 2ND 9.95

38465 ALUM. CNC GEAR 21T - LIGHT BLUE, 2ND 9.95

38466 ALUM. CNC GEAR 22T - GRAY, 2ND 9.95

38467 ALUM. CNC GEAR 23T - BLUE, 2ND 9.95

38468 ALUM. CNC GEAR 24T - RED, 2ND 9.95

38469 SPRING SET, FRONT/REAR, BLUE, YELLOW, & WHITE 13.95

38470 SPRING, SHOCKS, BLUE- SOFT 8.95

38471 SPRING, SHOCKS, YELLOW - MED. 7.95

38472 SPRING, SHOCKS, WHITE - HARD 7.95

38490 SNR RACING SPRING SET, LD3/CD3 6 PAIRS 23.95

38500 SNR CENTAX TOOL KIT 39.95

38501 SNR WRENCH PART, CENTAX TOOL KIT 27.95

38502 SNR JIG PARTS, CENTAX TOOL KIT 11.95

38505 SNR POCKET REAMER TOOL, HARD COATED 24.95

38506 SNR POCKET REAMER TOOL, BLACK 24.95

38507 SNR POCKET REAMER TOOL, POLISHED 24.95

38511 3x13.8 Pin for Shaft 5.95

38512 DECAL, CD3 LOGO 3.95

38513 1/10 Tire Inner Sponge 3.95

38514 1/10 Right Side Pipe 27.95

38515 1/10 Carry bag, 2 Case 59.95

38516 Brake Rod 3.95

38517 Radio Plate (plastic for CD3) 9.95

38518 Arm Stiffener & Battery Box for CD3 7.95

38519 Plastic Cap Joint for CD3 3.95

38520 Diff Housing for CD3 7.95

38521 Fuel Tank for CD3 11.95

38522 CVA Joint For Front / Rear 23.95

Page 37

38523 CVA Dog Bone 7.95

38524 2x9.8 Pin 1.95

38525 CD3 2-Speed Shaft 9.95

38526 CD3 Bevel Gear Shaft, small 1.95

38527 CD3 Center Drive Shaft, steel (F&R) 9.95

38528 3mm Chassis for CD3 23.95

38529 CD3 Manifold (side exhause) 15.95

38530 Quoit of Plastic Cap Joint for CD3 1.95

38531

38601 MISC PARTS, BALL.SHIM.SCREW 3.95

38602 ARM PIN, LD3/CD3 GRAPHITE PINS 3.95

38603 FLOATING BODT MOUNT. LD3/CD3 KIT 9.95

38620 POWER CLUTCH KIT, 4 SHOE, LD3/CD3/MTX3/NTC3 111.95

38621 FLYWHEEL, POWER CLUTCH, 4 SHOE 19.95

38622 SLIDE SHOES, POWER CLUTCH, 4 PCS. 11.95

38623 PLATE, POWER CLUTCH, 4 SHOE 3.95

38624 SHOE, POWER CLUTCH 19.95

38625 CLUTCH BELL, POWER CLUTCH 19.95

38626 STOPPER, THRUST BEARING 5.95

38627 BEARING, THRUST 5x10mm 14.95

38628 MOUNT, ENGINE (FOR LD3/CD3 W/38620 POWER CLUTCH) 12.95

38629 0.8 GEARING CLUTCH BELL GEAR, 21-1st (STD) 9.95

38630 0.8 GEARING CLUTCH BELL GEAR, 27-2nd (STD) 9.95

38631 CONE TAPPERED 3.95

38632 BEARING, 5x10x4mm 7.95

38640 0.8 GEARING LD3/CD3 2-SPEED TRANSMISSION KIT (LD3/CD3 ONLY) 99.95

38641 0.8 GEARING SPUR GEAR HOLDER 1st 21.95

38642 0.8 GEARING SPUR GEAR HOLDER 2nd 19.95

38647 CLUTCH SPRING 1.95

38648 BALL, STEEL 2PCS. 1.95

38649 CLUTCH SHOE CARRIER 3.95

38655 0.8 GEARING CLUTCH BELL GEAR, 19-1st 9.95

38656 0.8 GEARING CLUTCH BELL GEAR, 20-1st 9.95

38657 0.8 GEARING CLUTCH BELL GEAR, 21-1st (STD) 9.95

38658 0.8 GEARING CLUTCH BELL GEAR, 22-1st 9.95

38659 0.8 GEARING CLUTCH BELL GEAR, 23-1st 9.95

38660 0.8 GEARING CLUTCH BELL GEAR, 25-2nd 9.95

38661 0.8 GEARING CLUTCH BELL GEAR, 26-2nd 9.95

38662 0.8 GEARING CLUTCH BELL GEAR, 27-2nd (STD) 9.95

38663 0.8 GEARING CLUTCH BELL GEAR, 28-2nd 9.95

38664 0.8 GEARING CLUTCH BELL GEAR, 29-2nd 9.95

38670 0.8 GEARING SPUR GEAR, 54T-1st 6.95

38671 0.8 GEARING SPUR GEAR, 55T-1st (STD) 6.95

38672 0.8 GEARING SPUR GEAR, 56T-1st 6.95

38673 0.8 GEARING SPUR GEAR, 48T-2nd 6.95

38674 0.8 GEARING SPUR GEAR, 49T-2nd (STD) 6.95

38675 0.8 GEARING SPUR GEAR, 50T-2nd 6.95

39030 BODY, SHOCK, CLEAR LEXAN, PAIR 4.95

39053 FRONT ARM, LD3/CD3 3.95

39060 LOWER ARMS, FRONT & REAR & BODY MOUNT POSTS 11.95

39061 LOWER ARMS, FRONT & REAR 6.95

39063 HOLDER, BODY POST 3.95

39140 8mm BALL END, BLACK 4 PCS. 5.95

39141 WASHER INSERT, 8mm BALL 6.95

39150 10mm ALUM. SET SCREW, 4 PCS. 5.95

39320 BODY POSTS, OB4 & YOK & HPI 9.95

39331 LOWER, ARM, CNC NYLON, OB4 & LD3/CD3 49.95

39332 UPPER, ARM, CNC NYLON, OB4 & LD3/CD3 49.95

39473 AIR FILTER, FOAM DISC TYPE 5.95

39474 REFILL, FOAM DISC, AIR FILTER 1PC 1.95

40042 BRAKE DISCS, STEEL 4 PCS. 10.95

40044 SPRING, BRAKE SEPARATORS, 8 PCS. 5.95

59020 CLUTCH NUT, PILOT SHAFT, .12 & .15 OS TYPE 8.95

87610 WHEELS, "Y"SPOKE, 1.9" WHITE, 4 PAIRS(8 PACK) 7.95

87611 WHEELS, "Y"SPOKE, 1.9" BLACK, 4 PAIRS(8 PACK) 7.95

87612 WHEELS, "Y"SPOKE, 1.9" YEL, 4 PAIRS(8 PACK) 7.95

87613 WHEELS, LEXAN, "SPLIT"SPOKE, 1.9" WHITE, 4 PAIRS(8 PACK) 8.95

87614 WHEELS, LEXAN, "SPLIT"SPOKE, 1.9" BLACK, 4 PAIRS(8 PACK) 8.95

87615 WHEELS, LEXAN, "SPLIT"SPOKE, 1.9" YEL, 4 PAIRS(8 PACK) 8.95

87616 WHEELS, LEXAN, DISH, 1.9" CLEAR, 4 PAIRS(8 PACK) 8.95

87617 WHEELS, LEXAN, DISH, 1.9" WHITE, 4 PAIRS(8 PACK) 8.95

87618 WHEELS, LEXAN, DISH, 1.9" BLACK, 4 PAIRS(8 PACK) 8.95

87619 WHEELS, LEXAN, DISH, 1.9" YEL, 4 PAIRS(8 PACK) 8.95

87630 Slick Tire (normal), 26mm 9.95

87658 MOLDED FOAM TIRE INSERTS, BLUE PAIR 5.95

87659 MOLDED FOAM TIRE INSERTS, YELLOW PAIR 5.95

87660 TIRE, RADIAL STYLE, NITRO, PAIR 9.95

90012 METAL NIPPLE, RIGHT ANGLE, 2 PCS. 4.95

10986 NYLOK FLANGE NUT,4mmPURPLE 10P 8.95

Page 38

OWNER’S REGISTRATION CARD

OFNA Racing congratulates you on your purchase of our fine OFNA Product. With proper maintenance and handling this kit will provide many hours of enjoyment.

The registration card should be filled out and mailed to OFNA Racing within 10 days of purchase date.

In the event that the kit is incomplete or component parts are broken due to error in manufacturer, contact your

dealer from which you purchased the kit for replacement part or call OFNA at (949) 586-2910 for your nearest dealer

location. Other items such as radio and engine other covered by individual warranties.

IMPORTANT!

Please print or type, filling in the information listed below and mail immediately

MAIL TO:

OFNA RACING

7 VANDERBILT

IRVINE, CA. 92618

TEL: (949) 586-2910

Write in Your Model Name and Part Number

REGISTRATION CARD

RACER’S NAME TEL:( )

ADDRESS

CITY STATE ZIP

DEALER’S NAME TEL: ( )

ADDRESS

CITY STATE ZIP

OFNA RACING

7 VANDERBILT

IRVINE, CA. 92618

TEL: (949) 586-2910

Use this label

Loading...

Loading...