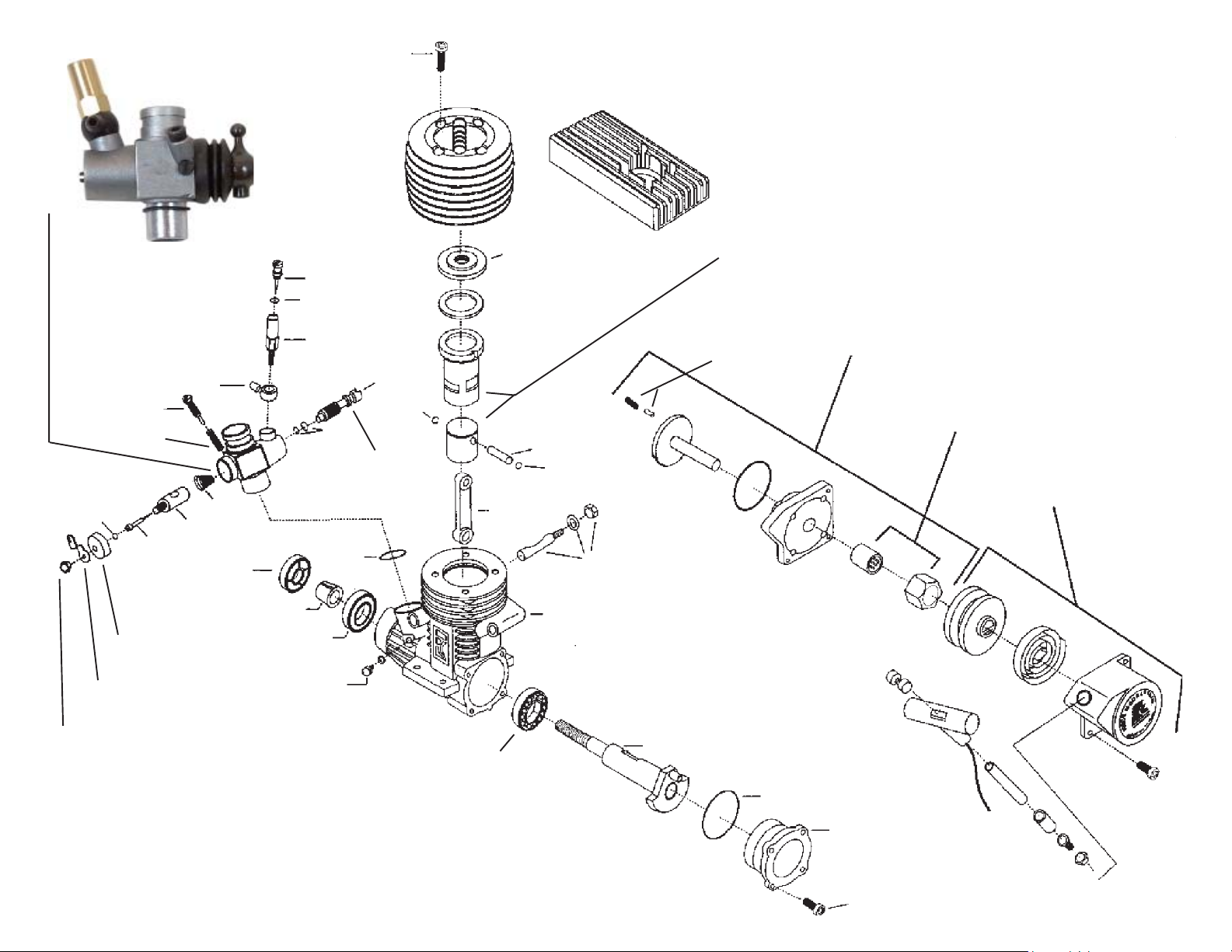

OFNA Racing 12 S,15 S User Manual

#57076

Slide Carburetor, complete

#57038

Screw set

NEW!

#57001

Head, tall (blue)

#57001A

Head, flat (black)

#57063

Head, tall (gray/black)

#57073

Head, tall (silver)

#57029

Main

#57016

Barrell Carburetor, complete

#57015

Body, carb.

#57024

Screw, stop

#57023

Spring, stop

#57038

Seals, low end

#57018

Throttle needle,

mid range

#57020

Boot, throttle

#57021

Lever, throttle

#57022

Nut, throttle

DO NOT SEND ENGINE FOR REPAIR UNLESS YOU DO THE FOLLOWING..

• ENGINE MUST BE ASSEMBLED, NOT IN PIECES.

• ENGINE CASE MUST BE CLEAN WITH NO OUTSIDE GREASE OR DIRT.

• ENGINE ACCESSORIES, i.e. FILTER, CLUTCH AND PIPE MUST BE REMOVED.

SEND TO:

OFNA RACING

22692 GRANITE WAY, STE. B

LAGUNA HILLS, CA. 92653

TEL: (949) 586-2910

#57027

Supply

nipple,

plastic

#57014

Barrel

#57019

Spring

#57014

Drvie hub

#10330

Brass corn

needle

#57035

Seal, main needle

#57028

Main seat

#57034

Seal set

$57033

Seal, carb.

#57030

Bearing, outside

#57013

Cap screw, plug

#57039

“G” clips

#57025

Low end needle

#57031

Bearing,

inside

#57002

Head button, .12

#57003

Head button,.15

#57064

Head button,.17

#57004

Head shim, .12

#57005

Head shim,.15

#57065

Head shim,.17

#57036

Pin, piston, .12

#57037

Pin, piston, .15/.17

#57039

#57008

Rod, stock

#57075

Rod,

special

“G” clips

#57009

Crankcase, .12 or .15

#57074

Crankcase, .12 pro

#57012

Carb. set pin

FORFOR

FOR

FORFOR

& .12S PR& .12S PR

& .12S PR

& .12S PR& .12S PR

#57001A

Head. flat

(black)

#57006

Piston/Sleeve, .12

#57007

Piston/sleeve,.15

#57062

Piston/sleeve,.17

#57070

Piston/sleeve,.12 pro

#57061

Spring and pin

(small dia.)

#57010

Crankshaft, .12 or .15 (large hole)

#57060

Crankshaft, .12 or .15 or .17 (small hole)

#57071

Crankshaft, pro (small hole)

CE .12SCE .12S

CE .12S

CE .12SCE .12S

#57039

Seal, rear cover

,,

.15S .15S

,

.15S

,,

.15S .15S

O ENGINE DRAO ENGINE DRA

O ENGINE DRA

O ENGINE DRAO ENGINE DRA

DO NOT SEND ENGINE FOR REPAIR UNLESS YOU DO THE

FOLLOWING..

• ENGINE MUST BE ASSEMBLED, NOT IN PIECES.

• ENGINE CASE MUST BE CLEAN WITH NO OUTSIDE

GREASE OR DIRT.

• ENGINE ACCESSORIES, i.e. FILTER, CLUTCH AND PIPE

MUST BE REMOVED.

#57040

Back plate assembly,

complete

#57011

Rear cover

#57038

Screw set

,,

.17S .17S

,

.17S

,,

.17S .17S

#57042

One-way

breaing unit

Can’t rebuild

WINGWING

WING

WINGWING

#57049

Pull start unit, complete

FORFOR

FOR

FORFOR

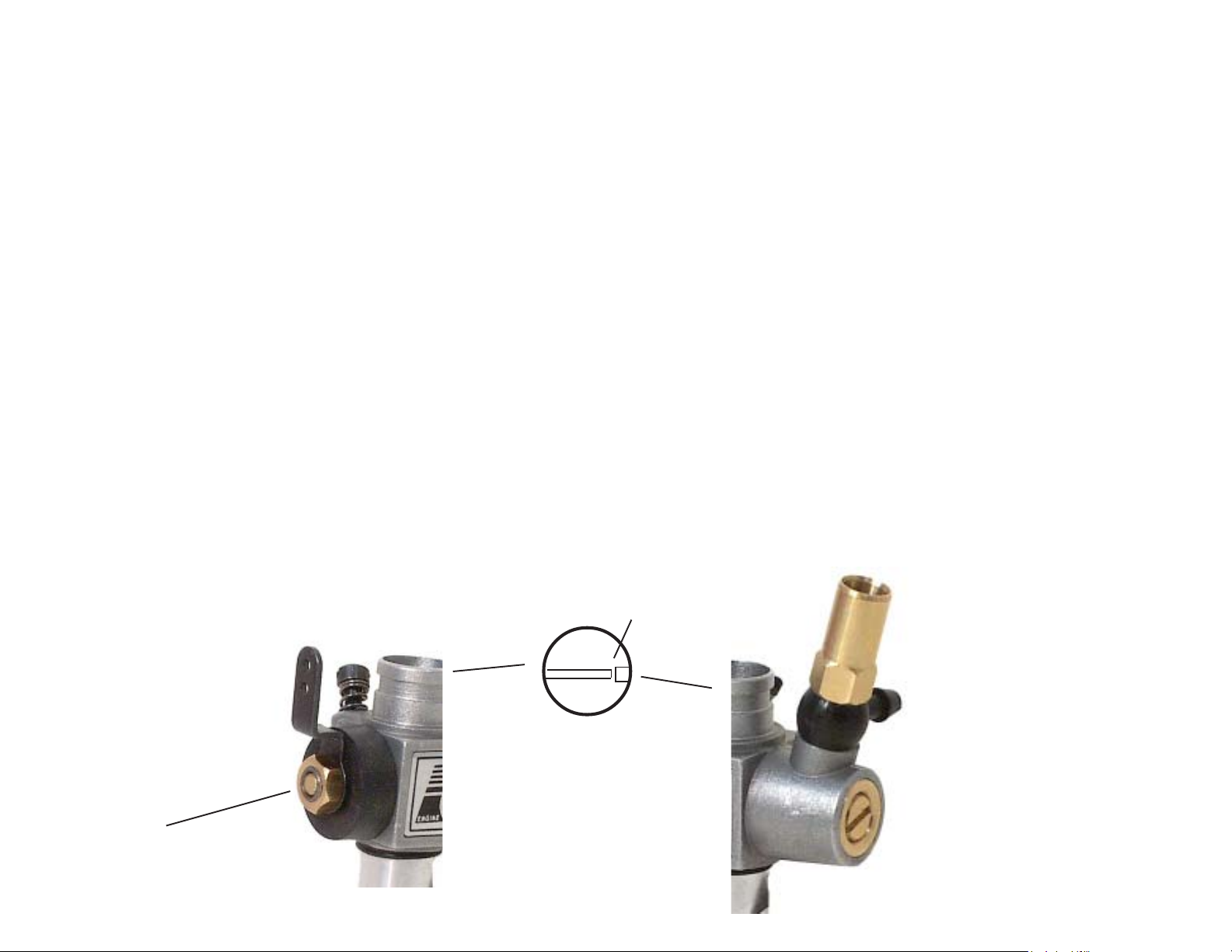

THE CARBURETOR IS FACTORY SET FOR THE LOW END NEEDLE, SO DO NOT ADJUST UNTIL BREAK-IN

IS COMPLETED. BUT YOU MUST ADJUST THE MASTER NEEDLE BEFORE STARTING.

ADJUSTMENTS

1) MASTER OR HIGH END NEEDLE - THIS ADJUSTS THE MAXIMUM SPEED OF THE CAR WHEN THE CARB IS FULLY OPEN. AFTER BREAK-IN IS COMPLETED, THE

NEEDLE SHOULD BE 1.5 TO 2.5 TURNS OUT. TURNING THE NEEDLE IN (CLOCKWISE) IS LEANING OUT FUEL MIXTURE AND INCREASES HEAT. SO, TURNING OUT

NEEDLE ( COUNTER CLOCKWISE) WILL RICHEN THE MIXTURE AND REDUCE HEAT. THE HEAT OF THE ENGINE SHOULD BE AROUND 250 DEGREES, LOWER IS

BETTER, BUT HOTTER IS BAD.

FOR BREAK-IN, TURN MASTER NEEDLE OUT 2 TO 3+ TURNS TO KEEP FUEL MIXTURE RICH AND KEEPING ENGINE RPM LOW. LET THE ENGINE FAST IDLE, CAR AND

WHEEL OFF THE GROUND, FOR AT LEAST ONE TANK OF FUEL. RUN THE CAR ON THE GROUND AT A SLOW/MEDIUM UP AND DOWN SPEED FOR ANOTHER FEW

TANKS. AFTER RUNNING THE ENGINE FOR A FEW TANKS OF FUEL, TURN NEEDLE SLOW IN (1/4 TO 1/2 TURNS) FOR EACH PROCEEDING TANK.

2) LOW END NEEDLE (JET) - THE LOW END NEEDLE CONTROLS THROTTLE RESPONSE. AFTER BREAK-IN, IF THE ENGINE THROTTLE RESPONDS WITH SLIGHT A

DELAY, TURN THE LOW END NEEDLE CLOCKWISE (1/8 TO 1/4) TO LEAN OUT MIXTURE. TRY TO USE SMALL 1/8 TURNS. FACTORY SETTING IS FLUSH, SEE FIGURE.

3) BARREL STOP / IDLE SCREW - THE SCREW MUST ALWAYS BE SET SO THE BARRELS DOES NOT FULLY CLOSE. LEAVE A SLIGHT GAP, THIS IS YOUR ENGINE IDLE.

A LARGER GAP WILL INCREASE IDLE, BUT ALSO, CHANGE LOW END SETTING. THEREFORE, YOU MUST WORK BACK AND FORTH WITH BOTH NEEDLE.

GLOW PLUG: ENGINE IS DESIGNED FOR A SHORT STYLE GLOW PLUG, SO USE O.S. 8 GLOW PLUGS. IF YOU WANT TO USE McCOY PLUGS, USE AN MC-59 WITH

TWO COPPER WASHERS TO PREVENT DAMAGE. IF THE MC-59 IS NOT RIGHT FOR YOUR AREA, MC-8 OR MC-9 CAN BE USED ALSO BUT WITH TWO COPPER WASHERS.

CE .12SCE .12S

CE .12S

CE .12SCE .12S

,,

.15S CARB .15S CARB

,

.15S CARB

,,

.15S CARB .15S CARB

URETURET

URET

URETURET

OR SETTINGOR SETTING

OR SETTING

OR SETTINGOR SETTING

FUEL: 20% FUEL IS RECOMMENDED, i.e. BYRONS; BLUE THUNDER, O’DONNEL. OTHER FUEL MAY CAUSE VARIOUS PROBLEMS SO BE CAREFUL WHEN BUYING

FUELS OTHER THAN MENTIONED..

NEW! EASY TUNE TWO NEEDLE CARB.

LOW END NEEDLE IS ON

OTHER SIDE OF CARB

BODY.

SMALL GAP

Carb. barrel picture, showing

low end needle setting in a

fully open position.

Factory setting

MASTER NEEDLE STARTING = 2.5 TURNS

BREAK-IN = 2.5 to 3.5 TURNS

WORKING = 1.5 to 2.5 TURNS

LOW END NEEDLE (JET)

PRESET = FLUSH

Loading...

Loading...