Page 1

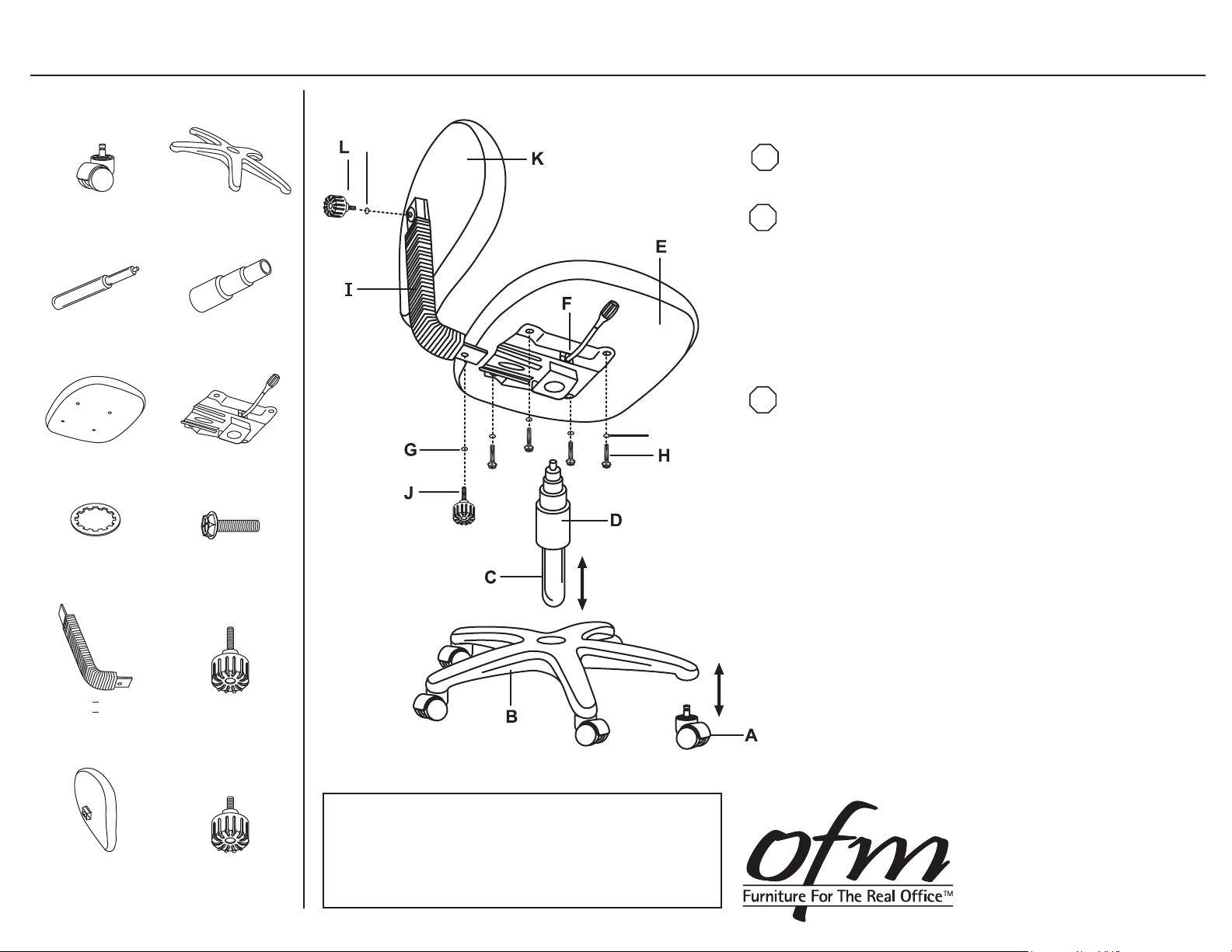

Models 105 / 105-AA / 105-DK / 105-AA-DK “Superchair” Task Chair & Stool

Parts Listing

A

Casters

5 pcs.

C

Gas Lift

1 pc.

E

Chair Seat

G

8 x 15mm Washers

6 pcs.

I

J-Bar

B

Base

D

Telescopic

Bellows

F

Seat Mechanism

H

M6 x 20mm Screw

4 pcs.

J

Back Depth

Adjustment

1 pc.

(Note longer stem)

G

WEIGHT CAPACITY: 250 lbs.

G

Assembly Instructions

Tools Needed: Phillips Head Screwdriver

STOP

Please read all instructions before assembly.

Step 1: Insert Casters (A) into Base (B).

If you are assembling a model with a DK Foot Ring please proceed to

STOP

subsequent pages for drafting kit assembly instructions.

Step 2: Insert Gas Lift (C) into Base (B).

Step 3: Cover Gas Lift (C) with 3 piece Telescopic Bellows (D).

Step 4: Place Chair Seat (E) on a level, non-abrasive surface and align

pre-drilled holes in Seat Mechanism (F), with holes in Chair Seat.

Step 5: Place four Washers (G) onto four M6 x 20mm Screws (H)

and insert through the holes in the Seat Mechanism (F),

and into the Chair Seat (E). Tighten with screwdriver.

If you are assembling a model with optional Adjustable Arms please

STOP

proceed to subsequent pages for armrest assembly instructions.

Step 6: Carefully place Chair Seat (E) with attached Seat Mechanism (F)

onto the Gas Lift (C), aligning the hole in the Seat Mechanism

with the Gas Lift. Press down on Chair Seat to secure onto Base.

Step 7: Slide J-Bar ( I ) (end with pre-drilled hole), under

Chair Seat (E) and into the slot on Seat Mechanism (F).

Step 8: Place Washer (G) on threaded end of Back Depth Adjustment (J),

and insert into slot on Seat Mechanism (F), and into pre-drilled

hole in J-Bar ( I ), hand tighten to hold in place.

Step 9: Slide receptacle, attached to Chair Back (K) over open

end of J-Bar ( I ).

Step 10: Place Washer (G) on threaded end of Back Height Adjustment (L),

and screw into Chair Back receptacle, tighten to hold in place.

Step 11: Carefully sit on chair to make sure the Gas Lift (C)

is properly inserted into the Base (B).

Step 12: Operate the Gas Lift Lever on the Seat Mechanism (F),

to be sure unit is working properly.

K

Chair Back

L

Back Height

Adjustment

1 pc.

Assembly Notes:

During assembly, hand tighten screws only. When all screws

are in place, you may then tighten all screws completely.

CAUTION:

1. Do not use this chair as a step ladder.

2. Check for loose screws and tighten them every 6 months.

12.12.13

161 Tradition Trail, Holly Springs, NC, 27540

800-520-7471 (voice) 919-362-4765 (fax)

919-303-6389 (voice) www.ofminc.com

support@ofminc.com

Page 2

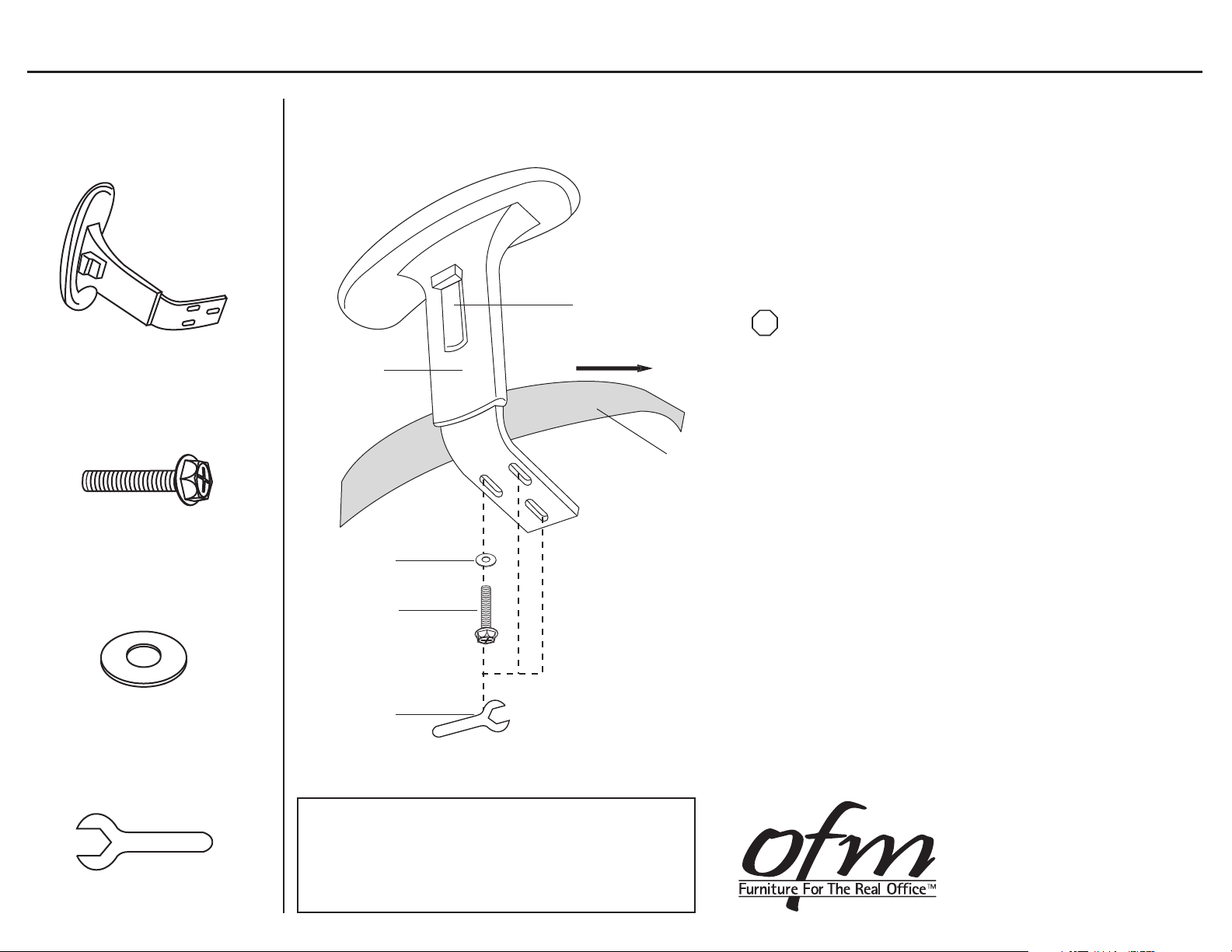

Model AA-1 Adjustable Arms

Parts Listing

A

AA-1 Adjustable Armrest

2 Units

B

M6x25mm Hex Screw

6 Units

C

Washer

6 Units

Height Adjustment

Button

Forward

A

Chair Seat

C

B

Assembly Instructions

Tools Needed: Phillips Head Screwdriver

STOP

Please read all instructions before assembly.

Step 1: Turn Chair Seat upside down and place on a

clean, non-abrasive surface.

Step 2: Align the pre-drilled holes in the Adjustable

Armrest (A) with the holes in the bottom of the

Chair Seat, making sure that the arms have the

height adjustment buttons facing out.

Step 3: Place three Washers (C) onto three M6x25mm

Hex Screws (B) and insert through the Armrest (C)

holes and into the Chair Seat.

Step 4: Tighten Screws (B) using supplied Wrench (D)

or screwdriver. It is recommended that to assure

screws are secure, a screwdriver is used to tighten.

To Adjust Arms:

Pull up on the Height Adjustment Button

and slide to desired height.

D

D

Wrench

1 Unit

Assembly Notes:

During assembly, hand tighten screws. Only when all screws

are in place, you may then tighten all screws completely.

CAUTION:

1. Do not use this chair as a step ladder.

2. Check for loose screws and tighten them every 6 months.

04.06.2010

161 Tradition Trail Holly Springs, NC, 27540

800-520-7471 (voice)

919- 303-6389 (voice)

support@ofminc.com

919-362-4765 (fax)

www.ofminc.com

Page 3

Model DK-2 Drafting Kit Assembly

Parts Listing

A

Circular Foot Rest

1 Unit

B

Tension Knob

1 Unit

C

9” Extension Tube

1 Unit

B

Gas Lift

C / D

Chair Seat

Assembly Instructions

STOP

Please read all instructions before assembly.

Prior to assembly, select only one Extension Tube

for desired Height

9” Extension Tube will change seat height from 24”-28”

12” Extension Tube will change seat height from 27-31”

Step 1: Slide the Circular Foot Rest (A) over the smaller

tapered end of your chosen Extension Tube (C / D).

Step 2: Screw in Tension Knob (B) and tighten to lock

Foot Rest (A).

Step 3: Place the tapered end of Extension Tube (C / D)

into your Chair Base.

Step 4: Insert bottom of Gas Lift Cylinder into the top

end of the Extension Tube (C / D).

Step 5: Place the Chair Seat onto the Gas Lift by

inserting top of Gas Lift into the hole in the

Seat Mechanism.

Step 6: Press down firmly to secure the chair.

Note: Save the left over extension tube for future use.

D

12” Extension Tube

1 Unit

A

Chair Base

161 Tradition Trail Holly Springs, NC, 27540

800-520-7471 (voice)

919- 303-6389 (voice)

support@ofminc.com

919-362-4765 (fax)

www.ofminc.com

Loading...

Loading...