OfiTE 173-00-C, 173-00-1-C Instruction Manual

Roller Oven With Programmable Timer and

Circulating Fan, 5 Roller

173-00-C (115 Volt)

173-00-1-C (230 Volt)

Instruction Manual

Updated 03/24/2015

Ver. 3.0

OFI Testing Equipment, Inc.

11302 Steeplecrest Dr. · Houston, Texas · 77065 · U.S.A.

Tele: 832.320.7300 · Fax: 713.880.9886 · www.ote.com

©

Copyright OFITE 2015

Table of

Introduction.....................................................................................2

Specications .................................................................................3

Contents

Components ...................................................................................4

Safety ............................................................................................... 6

Roller Ovens ...............................................................................6

Aging Cells .................................................................................. 6

Quick Start ......................................................................................7

Setup................................................................................................9

Operation.......................................................................................10

Timer .............................................................................................. 12

Maintenance .................................................................................. 15

Appendix .......................................................................................18

Temperature Units .....................................................................18

Warranty and Return Policy ........................................................19

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

1

Introduction

The OFITE Roller Oven (U.S. Patent No. 4,677,843) is an effective aid in de-

termining the effects of temperature and pressure on drilling uid as it circulates through the well bore. Aging the drilling uid in pressurized containers

effectively demonstrates the thermal effects on drilling uids in which a base

exchange reaction occurs and in determining the stability of mud additives

and emulsied uids such as oil muds. Aging is done under conditions that

vary from static to dynamic and from ambient to highly elevated temperatures.

Many mud constituents degrade slowly at high temperatures. Such degradation occurs while circulating, but it is more severe when the mud is left in the

lower part of the hole when making a trip. When running laboratory tests,

aging temperatures are often selected to be near the anticipated circulating or

bottom-hole temperatures and pressures, and aging cells are typically rolled

in an oven for at least 16 hours.

Routine laboratory analysis using roller ovens would include:

a. Simulate chemical reactions taking place in freshly prepared muds.

b. Determine the time it takes reactions to reach equilibrium under tem-

perature and pressure.

c. Determine the Viscosity of the uid prior to aging and after.

d. Determine ltration control properties prior to aging and after.

e. Determine the stability of drilling uid additives and drilling uids such

as oil muds.

f. Perform corrosion analysis.

The 4-roller oven can hold six 260-mL Aging Cells or three 500-mL Aging

Cells, while the 5-roller oven can hold twelve 260-mL Aging Cells or eight

500-mL Aging Cells. These are both ideal for laboratory use. OFITE rollers

are variable-speed controlled and constructed of stainless steel for longer life

and a cleaner environment inside the oven. Glass-impregnated Teon® roller

bearings extend the life of the rollers and allow for longer maintenance-free

service.

All models feature a digital temperature controller that can be read directly

from outside the oven. The temperature is controlled by an electronic solidstate thermostat and operates between 100°F and 450°F (38°C - 232.2°C).

The 4 and 5-roller ovens include a seven-day programmable timer as standard equipment. The timer may be preset to automatically start and stop the

heaters, allowing unattended operation. A circulating fan is included on all

models which greatly improves air circulation within the oven providing more

stable, consistent, and reliable uniform heating.

The Redundant Heat Control is available on select models and is a safety

feature for the heaters in the event one or more over-heat. Power to the

heaters will be shut down if the oven temperature exceeds a set maximum

temperature. The aging process due to the length of time required for completion of the test, is seldom monitored, so a heater failure may be serious.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

2

The OFITE Roller Ovens are designed to provide heating and rolling functionality simultaneously or independently. Therefore, they can be put to many

practical uses, for instance:

1. Heating Mode Only:

- Drying Oven

- Aging Oven

- Baking Oven

2. Rolling Mode Only:

- Ball Mill Roller

- To make homogenous mixtures of liquids

- To make homogenous mixtures of powders

- To agitate chemicals into solutions

- To de-aerate liquids

Specications

All OFITE Roller Ovens conform to the American Petroleum Institute’s (API)

Recommended Practice (RP) 13I. The oven is capable of maintaining a tem-

perature of 150° F ± 5° F (65° C ± 3° C) as specied in RP 13I.

- Temperature Range: 100 - 450°F (38 - 232.2°C)

- Digital Temperature Controller

- 25-RPM Motor

- Programmable Timer

- Material:

- Cabinet: 303 Stainless Steel

- Rollers: 304 Stainless Steel

- 350-Watt Heater, Qty: 2

- Capacity:

- 260 mL Aging Cells: 12

- 500 mL Aging Cells: 8

- 1000 mL Aging Cells: 4

- Size: 33.75" × 26.25" × 26" (85.7 × 66.7 × 66 cm)

- Weight: 172 lb. (78 kg)

- Crated Size: 38" × 33" × 34" (97 × 84 × 86 cm)

- Crated Weight: 290 lb. (131.5 kg)

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

3

Components

All Ovens:

#165-14-8 Type “J” Thermocouple, ⅛" × 6"

#165-14-10 Fuse, 1 Amp, Qty: 5

#165-45 Neon Lamp, Red

#165-45-1 Neon Lamp, Clear

#170-05 Thermostat, 50° - 500°F (10° - 260°C)

#172-01 Fuse, ½ Amp, for Temperature Controller, Box of 5

#172-02-2 Chain, 3 Feet

#172-02-4 Chain, 1 Foot

#172-03 Sprocket, ½" Bore, Qty: 9

#172-04 Connecting Link for Chain, Qty: 3

#172-08 Bearing for Roller Shafts, Qty: 8

#172-09 Fuse, 10 Amp, Box of 5

#172-11-1 Temperature Controller

#172-13 Fuse, Light Holder

#172-14 On/Off Toggle Switch

#172-15-1 Omron Programmable Timer

#172-23 Heater, 500 Watt, Qty: 2

#172-24 Solid State Relay, 240V-25A

#172-25 Fan Motor

#173-15 Knob, Oven Door, Black

#174-07-1 5" Fan Blade

#174-13 Motor

#174-14 Motor Controller

115-Volt Ovens (172-00-C):

#171-82 Power Cord, 8 Feet

#172-07 Fuse, 5 Amp, Box of 5

230-Volt Ovens (172-00-1-C):

#130-74 Transformer, 230/115 Volt, 50/60 Hz

#165-40-2 Power Cable, 6 Feet

#172-05 Fuse, 2 Amp, Box of 5

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

4

#173-00-SP Spare parts for #173-00-C, 5-Roller Oven with

Circulation Fan, 115 Volts

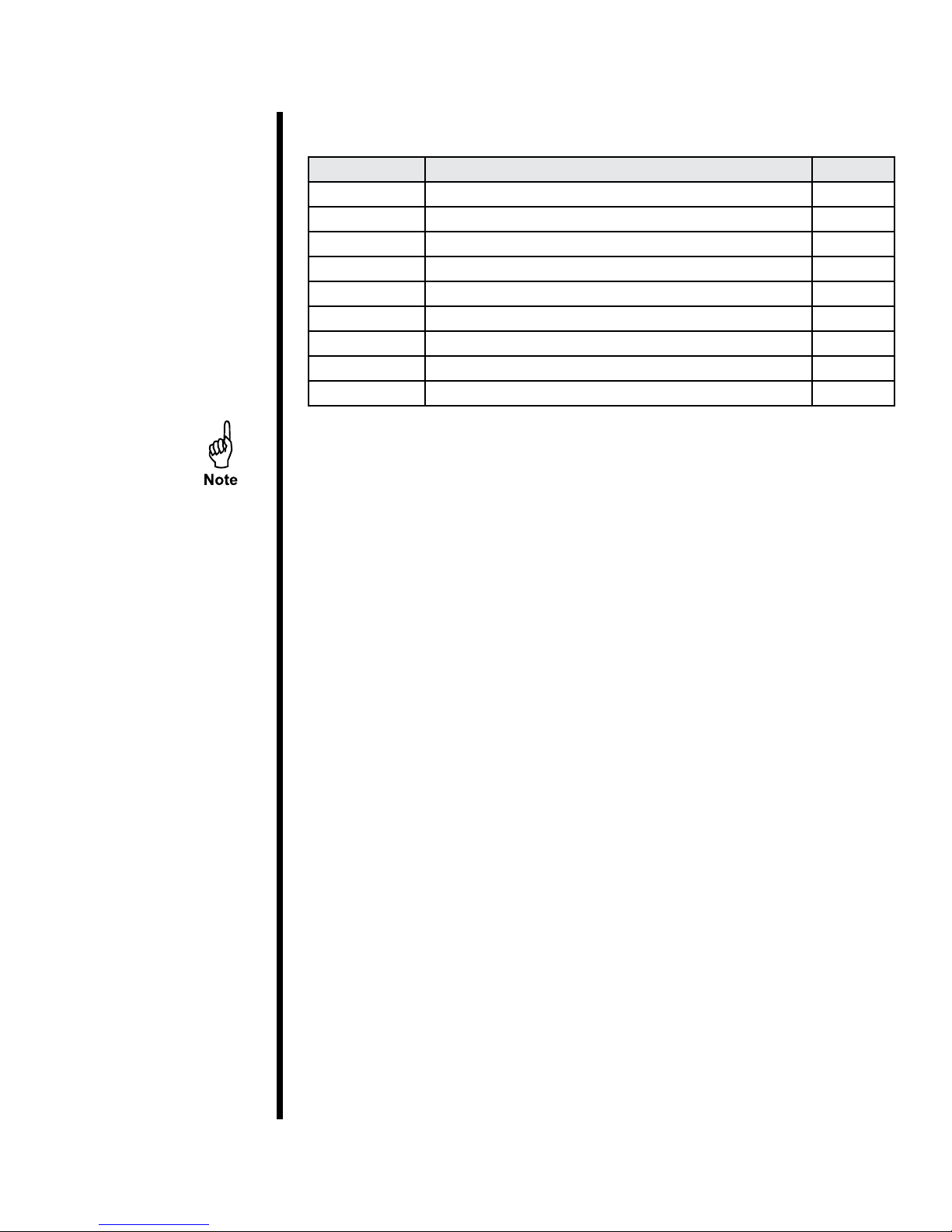

Part Number Description Quantity

#172-03 Sprocket 7

#172-04 Connecting Link for Chain 8

#172-05 Fuse, 2 Amp 5

#172-06 Half Link for Chain 8

#172-07 Fuse, 5-Amp 5

#172-08 Bearing, for Roller Shafts, Glass-Impregnated Teon

®

10

#172-09 Fuse, 10-Amp 5

#172-13 Fuse Light Holder 1

#172-23 Heater, 500-Watt 2

Spare parts listings are intended to be used as a reference for future purchases. Everyone’s consumable requirements will be different, and replacement quantities needed will depend upon the number of test performed on a

daily and/or weekly basis.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

5

Loading...

Loading...