OfiTE 170-182-1, 170-182 Instruction Manual

HTHP Filter Press for Cement Testing

with 175-mL, Double-Capped Test Cell and N2 Pressuring Manifold

Instruction Manual

11302 Steeplecrest Dr. · Houston, Texas · 77065 · U.S.A.

Tele: 832.320.7300 · Fax: 713.880.9886 · www.ote.com

#170-182: (115 V)

#170-182-1: (230 V)

Updated 6/20/2017

Ver. 3.0

OFI Testing Equipment, Inc.

©

Copyright OFITE 2015

Table of

Intro..................................................................................................2

Specications .................................................................................3

Contents

Components ...................................................................................4

Safety ............................................................................................... 8

Quick Start ....................................................................................12

Operation.......................................................................................15

Data ................................................................................................ 20

Cell Cap Assembly ....................................................................... 21

Maintenance .................................................................................. 22

Diagrams .......................................................................................24

Test Cell ....................................................................................25

Warranty and Return Policy ........................................................26

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

1

Intro

The OFI Testing Equipment (OFITE) High Temperature High Pressure

(HTHP) Filter Press is designed to evaluate the ltration characteristics of

drilling uids, cement slurries, fracturing uids, and completion uids under

elevated temperatures and pressures. Evaluating uids under HTHP conditions similar to the downhole environment is of paramount importance. Fluid

properties must be monitored while under high temperatures and pressures

as ltration behavior and wall cake building characteristics of permeable

formations change with changing environments. These characteristics are

affected by the shape, type, and quantities of solids present in the uid and

their physical and electro-chemical interactions, all of which are affected by

changing temperatures and pressures.

OFITE manufactures and provides HTHP ltration units in two basic sizes,

175 mL and 500 mL capacities. Both are used extensively throughout the

world and in all environments, but in general the 175 mL units are designed

for eld portability, while the larger 500 mL units are designed for laboratory

usage at higher temperatures and pressures. All OFITE Filtration devices fully

conform to American Petroleum Institute (API) specications.

A complete HTHP Filter Press consists of a controlled pressure source, usually Nitrogen pressurization or Carbon Dioxide bulbs for the 175 mL units.

Top and bottom pressure manifolds are provided to simulate the differential

pressures found in a down-hole environment, and to prevent evaporation

of the base uid if exceeding the boiling point of that uid. The test cells are

provided in a variety of assemblies, depending upon the type of uid tested,

the lter media, and the temperatures and pressures desired. The test cells

are encased inside a heating jacket, which is adjustable.

A variety of lter media are available, the most common being standard API

lter paper, cement screens, and ceramic lters. The ceramic lters may be

obtained to match the pore throat or permeability of the formation. Natural formation lters or cores may also be used of differing pore throat / permeability

sizes. Slotted disks of varying sizes are frequently used for lost circulation

materials studies.

Both the 175 mL and the 500 mL heating jackets are capable of reaching 400°F (204°C), but lower uid volumes due to uid expansion at higher

temperatures, limit the 175 mL units to a useful working temperature of 300°F

(149°C). Anyone running tests above 350°F (177°C) must substitute a complete set of o-rings after each and every test.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

2

Specications

Size: 7.5" × 11" × 23.5" (19.1 × 27.9 × 59.7 cm)

Weight: 27 lbs. (12.3 kg)

Shipping Size: 17" × 23.5" × 12.5" (43.2 × 59.7 × 31.8 cm)

Shipping Weight: 38 lbs. (17.2 kg)

Maximum Temperature

(Heating Jacket): 400°F (204°C)

Maximum Temperature (Cell): 500°F (260°C)

Maximum Pressure (Cell): 5,000 PSI

Maximum Pressure (Receiver): 750 PSI (5.1 MPa)

Pressure Source: Nitrogen (at least 1,500 PSI / 10,343 kPa) -

Not Included

Test Cell Capacity: 175 mL

Receiver Volume: 15 mL

Heater: 400 Watt

Power Requirement: 115 VAC, 5 Amps, 50/60 Hz

230 VAC, 3 Amps, 50/60 Hz

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

3

Components

#153-14 Graduated Cylinder, 50 mL × 1 mL

#154-10 Dual-Scale Thermometer with Dial, 5" Stem, 50° - 500°F (0° -

260°C)

#165-44-2 Anti Seize Compound, Silver, 7g Pouch

#170-00-1 Heating Jacket (115V) -OR#170-01-1 Heating Jacket (230V):

#130-10-52 Jam Nut; ⅜"-24; Stainless Steel; Qty: 2

#164-32 Male Connector for Power Cable (For 170-01-1 230V ONLY)

#170-05 Thermostat

#170-09 Insulation Board

#170-10 Thermostat Pilot Lot

#170-11 Heating Element; 115V; 200W; Qty: 2

#170-15 Base

#170-21 Stand Support Rod; Qty: 2

#170-25 Aluminum Well

#170-30 Stainless Steel Thermostat Cover

#170-44 ½" Rubber Foot; Qty: 4

#171-32 Midget Knob

#171-82 8' Power Cord with Male Plug 8; 16/3 SJ; Round (For 170-

00-1 115V ONLY)

#170-06-1 Back Pressure Receiver; 15-mL Stainless Steel Tube for N

#144-11 ⅛" 90 Street Ell

#144-15 Plate Brass Bushing; ¼" NPT Male to ⅛" NPT Female

#170-07 O-ring

#170-28 Receiver Body

#170-32 ⅛" × ⅛" NPT Male Needle Valve

#171-23-1 Safety Pin with Lanyard

#170-19 Filter Paper; 2½" (6.35 cm); Specially Hardened for Filter Presses

#170-35 6" Adjustable Wrench

#170-182-S Test Cell, Stainless Steel (For Cement Testing)

#120-910-028 O-ring for Rupture Disk, Viton 75D, Qty: 1

#130-81-040 Retaining Ring, Qty: 2

#165-44-2 Anti Seize Compound, Silver, 7g Pouch, Qty: 4

#170-13-3 O-ring for Cell, Viton 75D, Qty: 4

#170-16 Valve Stem, Qty: 2

#170-17 O-ring for Valve Stem, Viton 75D, Qty: 4

#170-18 Cement Screen, Qty: 2

#170-180-020-S Cell Body, 175 mL, Qty: 1

#171-190-023 Locking Ring, Qty: 2

#171-190-027 Rupture Disk, Qty: 1

#171-190-029 Cap Wrench, Qty: 1

#171-190-032-S Cell Cap, Outlet, Cement, Qty: 1

#171-190-033-S Cell Cap, Inlet, Cement, Qty: 1

#171-190-057 O-ring for Valve Stem, Viton 90D, Qty: 4

#171-190-058 O-ring for Rupture Disk, Viton 90D, Qty: 1

#171-190-060 O-ring for Cell, Viton 90D, Qty: 4

2

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

4

#171-24 1350 / 750 PSI (9,308 / 5,171 kPa) Nitrogen Manifold

#170-08 Regulator; Qty: 2

#170-20 Manifold Block

#170-32 ⅛" × ⅛" NPT Male Needle Valve

#171-22 Retainer Pin

#171-24-1 Chrome Nut; R.H.; Reg Inlet CGA-580

#171-24-2 Nipple with Filter

#171-24-3 ¼" Flare × ⅛" FNPT Female

#171-24-4 ¼" NPT Pipe Plug; 316 Stainless Steel

#171-24-5 ¼" NPT Street Tee; 316 Stainless Steel; Qty: 2

#171-25-1 Relief Valve set at 750 PSI (5171 kPa)

#171-25-2 Relief Valve set at 1350 PSI (9308 kPa)

#171-26 5000# Hose; " × 3'; Qty: 2

#171-28 Dual Manifold Body

#171-38 1,000 PSI Gauge; 2½"; ¼" NPT Bottom

#171-40 1,500 PSI Gauge; 2½"; ¼" NPT Bottom

#171-42 3,000 PSI Gauge; 2½"; ¼" NPT Bottom

#171-90-06 ¼" MNPT × ⅛" FNPT Reducing Bushing; 316 Stainless

Optional:

#170-13 O-ring for Test Cell, Buna, For tests below 300°F

#170-37 Nitrogen Cylinder; 21" × 7"; Right-hand Thread

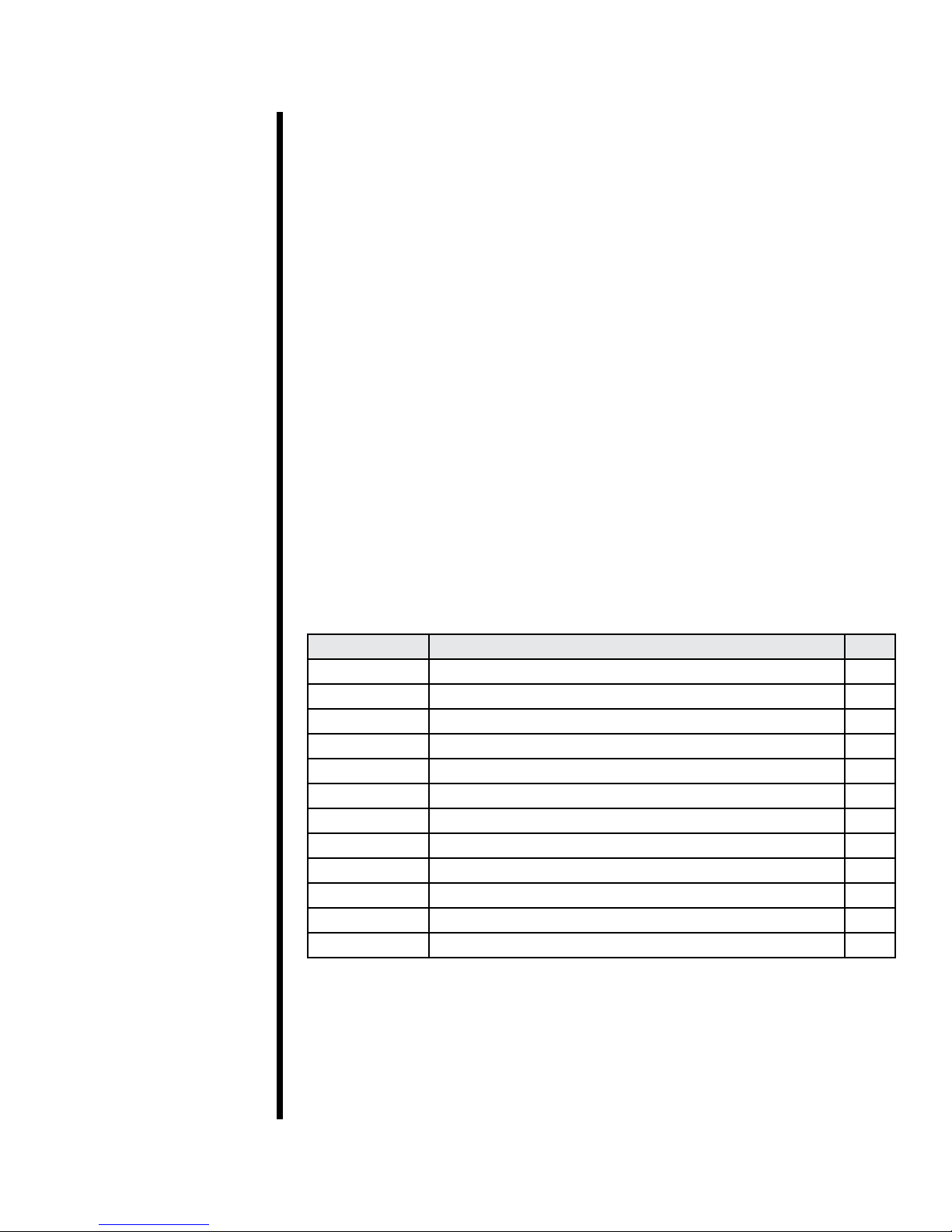

#170-182-SP Spare Parts Kit:

Part Number Description Qty.

#143-00-1 Diaphragm for Airco Regulator 1

#143-07 Repair Kit for Regulator (#143-00) 1

#153-14 Graduated Cylinder, 50 mL × 1 mL 2

#154-10 Dial Thermometer, 5" Stem, 50° - 500°F and 0 - 250°C 1

#170-07 O-ring for Back Pressure Receiver, Nitrile 3

#170-13-3 O-ring for Cell, Viton 75D 50

#170-16 Valve Stem 4

#170-17 Valve Stem O-ring 100

#170-18 Cement Screen 10

#171-190-057 O-ring for Valve Stem, Viton 90D 100

#171-190-060 O-ring for Test Cell, Viton

®

#171-23-1 Safety Pin with Lanyard 1

50

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

5

Optional Items for HTHP Filtration Testing:

The items listed below are not included in the HTHP Filter Press, but they are

items that will enable the technician to perform a more uniform and reproducible test while maintaining a high degree of safety. As optional items, the usage is not compulsory, but consideration should be given to these items when

running tests at elevated temperatures and pressures.

Interval Timer, 60 minute

(#155-20)

Cell Carrying Tool (#170-40)

Cell Cap Removal Tool

(#170-33)

(Set Screw Cell Assemblies Only)

HTHP Pressure Relief Tool

(#170-91)

(To release trapped pressure)

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

Safety Shield (#171-06)

6

Stand for HTHP Cell Assembly

(#171-190-028)

Thermocouple Assembly

(#171-45-1)

(Direct temperature measurement

Of the uid Inside the Cell)

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

7

Safety

Pressure and Temperature Considerations

Do not use or recongure this equipment in a manner not specied in this

manual.

Pressure

There are two reasons for operating at elevated pressures when performing a

ltration analysis.

1. To test uids at temperatures above the boiling point, the vessel must

be pressurized, which in turn elevates the vapor pressure (boiling

point) so that the uid remains liquid and does not turn to steam.

2. If testing for drilling applications, pressurization will more approximate

down-hole conditions, enabling the technician to match both bottom

hole temperatures and pressures.

HTHP Filter Presses are pressurized either with Carbon Dioxide or with

Nitrogen gas. The OFITE 175 mL HTHP Filter Press, 170-00 Series, is small

enough to be portable, so it is usually pressurized with small (65 mm length)

Carbon Dioxide (CO2) bulbs, which contain 10 cm3 of CO2 gas and weigh 8

grams. These bulbs are pressurized to approximately 1,000 PSI and they

contain plenty of carrier gas to run a complete 30 minute ltration test, if running the standard API 500 PSI differential test, which is usually 600 PSI on

the top manifold and 100 PSI on the bottom or back pressure.

For temperatures less than 200°F (93°C) a Back Pressure Receiver is not

required as the ltrate will not reach the boiling point. However when operating above the boiling point of water, a suitable Back Pressure Receiver is

required, otherwise the test uid will turn to steam and the test is invalidated.

The standard receiver tube supplied with the 175 mL HTHP Filter Press holds

15 mL of ltrate, so it is very important that the receiver outlet ball valve is

opened after approximately ten seconds of ltrate collection, as a uid with

poor ltration qualities can easily ll the 15 mL receiver tube almost instantaneously. If this happens the ltrate hopefully will all be ejected from the

safety bleeder valve, but if there is too much uid volume, the liquid may end

up inside the regulator rendering it useless which will require servicing by a

knowledgeable technician.

Temperature

Normally when one experiences a loss of pressure it is not due to a failure

of the metal alloy in the cell, but rather is a failure of the o-ring or elastomer,

which provides the seal. These o-ring may deform or melt under elevated

temperatures causing a pressurization failure of the cell, which is often sudden and catastrophic. For example, if the valve stem o-ring suddenly fails,

then steam at 400°F and under great pressure may shoot outward horizontally in one or several directions. A safety shield should always be used when

operating any HTHP Filter Press and especially when one is going to extreme

temperatures and pressures. Above 350°F (176°C) All o-rings must be replaced after each and every test.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

8

Loading...

Loading...