OfiTE 150-80, 150-80-1 Instruction Manual

Dynamic Linear Swell Meter

with Compactor

#150-80 - 115V

#150-80-1 - 230V

Software Version 3.09.0

Instruction Manual

Updated 6/28/2018

Ver. 6.0

OFI Testing Equipment, Inc.

11302 Steeplecrest Dr. · Houston, Texas · 77065 · U.S.A.

Tele: 832.320.7300 · Fax: 713.880.9886 · www.ote.com

©

Copyright OFITE 2015

Table of

Intro..................................................................................................2

Safety ............................................................................................... 2

Contents

Components ...................................................................................3

Installation.......................................................................................4

Software ..........................................................................................6

Zeroing the Channels ..................................................................8

Calibration ................................................................................... 9

Starting a Test ........................................................................... 10

Setup ......................................................................................... 12

Analog Input .............................................................................. 13

Operation.......................................................................................14

Sample Data .................................................................................. 15

Graph 1 .....................................................................................16

Graph 2 .....................................................................................17

Graph 3 .....................................................................................18

Graph 4 .....................................................................................19

Compactor ....................................................................................20

Assembly ..................................................................................20

Making Wafers ..........................................................................22

Disassembly .............................................................................. 23

Drawings .......................................................................................24

Cup Assembly ...........................................................................24

Head Assembly .........................................................................25

Main Assembly ..........................................................................26

Wafer Die ..................................................................................27

Warranty and Return Policy ........................................................28

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

1

Intro

The OFITE Dynamic Linear Swell Meter is a highly effective method of

examining the interaction between water based uids and mineral samples

containing reactive clays under simulated conditions while uid is in motion.

The observed swelling characteristics are utilized to anticipate and/or correct

the oftentimes unpredictable problems that are frequently encountered while

drilling in shale formations. It is a very useful tool when designing drilling

uids or when testing the behavior of existing muds because it shows the

changes in the clay/uid interaction for short periods of time (0 - 5 minutes) as

well as longer periods (>350 minutes). Bit balling, pipe drag, hole sloughing

and other “Gumbo” related shale problems may be predicted in advance,

enabling the operator to select the proper drilling uid and therefore achieve a

stable wellbore environment.

The OFITE multiple channel Dynamic Linear Swell Meter features multiple

measuring heads for simultaneously testing up to eight (8) cores or drilling

uids. A mineral (shale, core sample, cuttings, crude bentonite, etc.) wafer

is exposed to a drilling uid which is circulated around the wafer. A Linear

Variable Differential Transducer (LVDT) measures the expansion of the wafer

in the vertical direction (accuracy to 0.1%) and this information is then stored

as a function of time via the data acquisition system. A hydraulic compactor

unit prepares the mineral wafers for placement inside the transfer stand and

subsequent testing.

Safety

1. All electrical power cables should be three wire grounding cables and

should be plugged only into a grounded receptacle. The power switch on

the instrument should be in the OFF position when connecting the power

cable.

2. Always unplug the instrument from the electrical power source before

performing any disassembly or repair. With the cover off, it is possible to

touch exposed electrical terminals resulting in electrical shock if the power

cable is plugged in.

3. Ensure that all pressure has been released on the compactor before

removing core chambers. Both pressure gauges should read zero before

any work or maintenance is performed on the compactor.

4. Clean up any spilled hydraulic oil to prevent injury or re hazards.

5. The maximum temperature of the hot plate is 1,022°F (550°C), which

is well above the boiling point of water. Because the sample cup is

not pressurized, we recommend a maximum test temperature of

200°F (93.3°C). Testing above the boiling point could result in the uid

boiling out of the cup and splattering people and equipment. If this

happens, immediately decrease the temperature to a safe level.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

2

Components

Computer:

#130-75-71 Monitor

#500-300-015 Micro Computer

Swell Meter:

#130-76-03 Thermocouple

#150-80-101 Calibration Block, Multi Point

#150-80-03 Flat Screen; 1 " Diameter

#150-80-031 Teon Washer

#150-80-032 Transfer Stand

#150-80-033 Wafer Tube

#150-80-034 Bottom Plate

#150-80-035 Cup

#150-80-036 Cap for Wafer Tube

#150-80-064 LVDT

#150-80-094 Cable, LVDT to Swell Meter

#150-83 Stirring Hot Plate; 120 Volt Only

#150-84 Stirring Hot Plate; 230 Volt Only

#152-37 AC Power Cord; 3-Conductor

#153-53-1 Magnetic Stir Bar, 1"

#153-67 60 cc Disposable Syringe

Compactor (#150-82):

#150-80-072 Pump

#150-80-085 ½" Spacer

#150-80-086 ¾" Spacer

#150-80-087 Body for Wafer Mold

#150-80-088 Plunger for Wafer Mold

#150-80-089 Drop Tube for Wafer Mold

#150-85 Relief Valve; 2,900 PSI (20 MPa)

Optional:

#150-80-009 Brass Weight

#150-81-1 Swell Meter Control Assembly (115 V)

#150-81-2 Swell Meter Control Assembly (230 V)

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

3

Installation

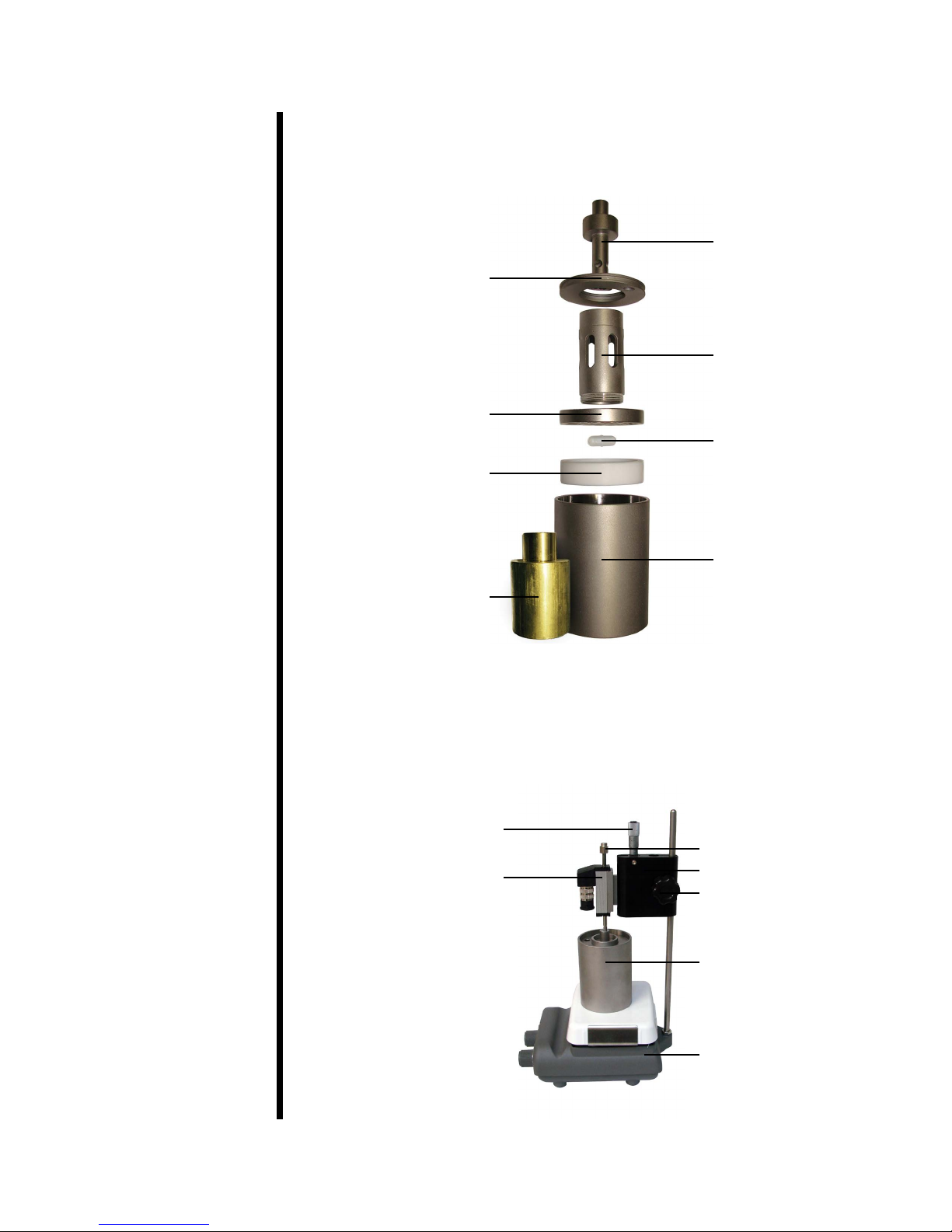

1. Assemble the Cup Assemblies as illustrated below and in the drawing

on page 24. The brass weight is an optional piece for simulating an

overburden pressure applied to the swelling core sample.

Transfer Stand

(#150-80-032)

Cap for Wafer Tube

(#150-80-036)

Wafer Tube

(#150-80-033)

Bottom (Main) Plate

(#150-80-034)

Teon Washer

(#150-80-031)

Brass Weight (Optional)

(#150-80-009)

Magnetic Stir Bar

(Comes w/Hot Plate)

(#153-53-1)

Cup

(#150-80-035)

2. Assemble the Main Assemblies as depicted below and in the drawing on

page 26. Adjust the height of the head assembly such that there is a

small gap (approximately 5 mm) between the bottom of the nut on the

spindle and the body of the LVDT without a wafer inserted into the cup

assembly.

Micrometer (#150-80-067)

Nut (#150-80-093)

LVDT (#150-80-064)

Head (#150-80-013)

Locking Nut (#150-80-001)

Cup Assembly (see above)

Stirring Hot Plate

(#150-83)

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

4

3. Connect the transducer cables to the LVDTs and then plug them into the

Swell Meter box.

4. Plug the magnetic stirrers into the electrical receptacles located on the

back of the unit.

These cables can be run under the Swell Meter box for a neater

appearance.

5. Insert the thermocouples into the cup assemblies and plug them into the

front of the Swell Meter box.

6. Ensure that the “POWER” switches (located on the back of the Swell

Meter) are in the “OFF” position and make the necessary electrical

connections in accordance to local codes. Ensure that the unit is

grounded.

7. Make sure the computer is securely mounted to the back of the monitor.

8. Connect all the necessary cables to the appropriate ports.

The computer connects to the Swell Meter via the supplied USB cable.

Make sure the Bluetooth receiver is plugged in so that the keyboard and

mouse can connect.

If the computer runs out of disk space, it will no longer be able to store

more test data. If this happens, move older test data to a network or ash

drive to free up additional space.

USB Cable (To Swell Meter)Bluetooth Receiver

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

5

Software

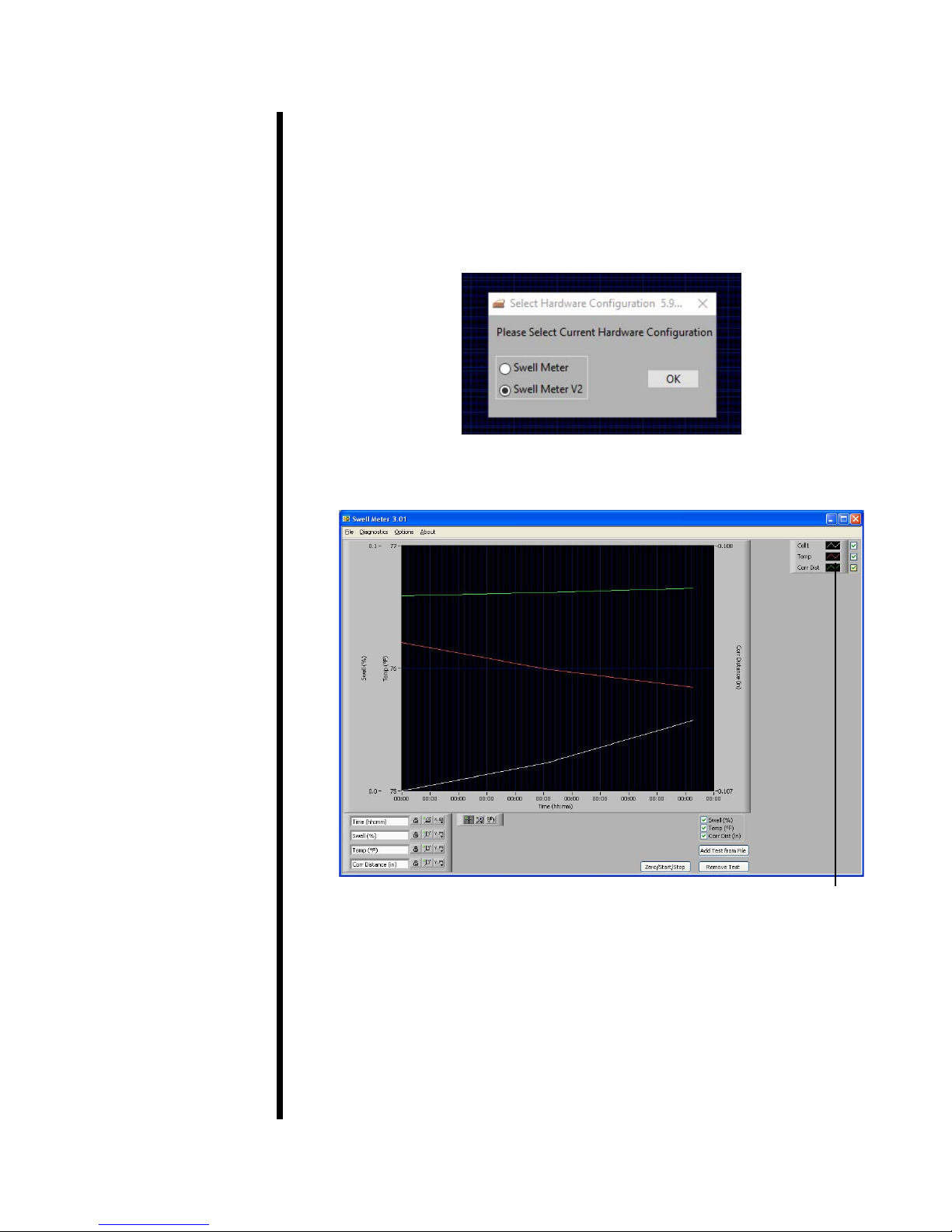

Turn the PC on and start the software by clicking the Swell Meter icon on the

desktop. The rst time you start the software, you will be asked to select a

hardware conguation. If your Swell Meter was manufactured before June

2018, choose “Swell Meter”. If it was manufactured in June 2018 or later,

choose “Swell Meter V2”. If you are not sure, look at the cable connecting

the computer to the Swell Meter. If it is a at, wide ribbon cable, select “Swell

Meter”. If it is a standard USB cable, select “Swell Meter V2”.

The Main Screen will appear:

The checkboxes at the bottom, right-hand corner of the graph control which

information (for all cells) is available to display on the graph. Once a test is

started, you can show or hide the swell percentage, temperature, or corrected

distance for all cells. For example, unchecking the “Temp” checkbox will

remove all temperature lines from the graph.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

Legend

6

The legend on the right-hand side of the screen controls which information

(for each individual cell) displays on the graph. Once a test is started, you can

show or hide the swell percentage, temperature, or corrected distance for a

give cell. For example, unchecking the “Temp” checkbox under “Cell1” will

remove only the temperature line for Cell1 from the graph. By right-clicking on

the checkboxes, you can view test details for the cell you clicked, export test

data, remove a test from the chart, or print a chart. If you choose “Print”, the

chart will print all the data point currently being displayed.

At times the graph may appear unexpectedly erratic, especially at the

beginning of a test. This is likely caused by the scale on the Y-axis being set

too low. To correct the issue, right-click on the Y-axis and deselect “AutoScale

Y”. Then click the top value on the Y-axis and change it to a higher number. It

may take some experimentation to get the right scale.

By default, the software is congured to run four cells at a time. If your Swell

Meter has been congured to run eight cells instead of just four, you will need

to change the “Number of Cells Available” option on the “Setup” screen to

8. This will enable to software to run all eight cells. Refer to page 12 for

instructions.

Export: There are two export procedures in the software. You can export

a test that is currently in process, or you can export a completed and

saved test. Both procedures create a le that can then be opened in

Microsoft Excel.

To export a test that is running, right-click the checkboxes on the legend

and select “Export” to save your test data to a le. This procedure exports

whatever data points are currently displayed on the graph.

To export a saved test, click “Export from File” on the “File” menu. Choose

the le corresponding to the test you want to export. Then choose a

destination for the exported le. This procedure will import the saved test

data and then export it into an Excel spreadsheet.

Zero/Start/Stop: Click this button to start or stop a test.

Add Test From File: Click this button to add data from a saved test to

the graph. This is useful for comparing the results of multiple tests on one

graph.

After adding a test to the graph, use the checkboxes below the graph and

on the legend to display the information you need to see.

Remove Test: Click this button to remove a test from the graph.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

7

Software

Zeroing the Channels

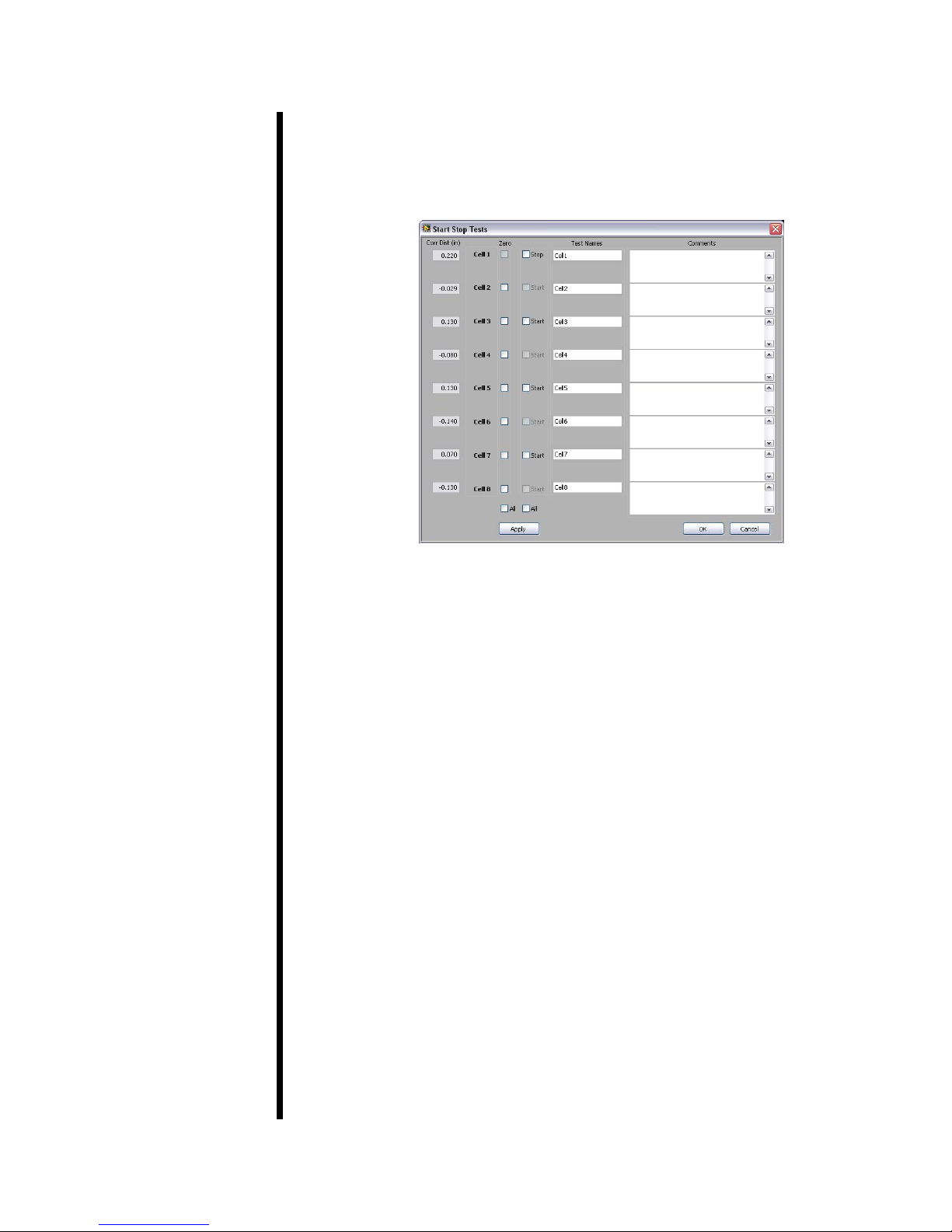

Each channel must be zeroed before every test. This gives the software a

starting point with which to calculate the percentage of swell during the test.

1. Click the “Zero/Start/Stop” button.

2. Repeat the following steps for each channel to be tested:

a. Enter a test name and any comments.

b. Place two screens into a fully-assembled cup. Place the cup on the

magnetic stirrer so that the LVDT spindle is resting on top of the

transfer stand. Check the box in the “Zero” column next to each cell to

be tested.

c. Click the “Apply” button to zero the channel. Make sure the “Corr Dist

(in)” eld reads 0.000.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com

8

Loading...

Loading...