INSTRUCTIONS

for installation and use

WND 040

WINE DISPENSER FOR

RESIDENTIAL AND PROFESSIONAL USE

How to use this manual

Thank you for choosing this innovative product.

These machines for pouring wine offer high quality and

characteristics of refrigeration based on the most advanced

technologies offered by the market.

This manual has been specially designed to guide you through the

functions and features of the Wineemotion dispenser.

Please read carefully

• Read all safety precautions in this manual

before using the dispenser to ensure a safe and proper use.

• The descriptions in this manual are based on default settings of dispensers.

• Images and screenshots used in this manual may differ from the actual product.

• The contents of this user manual may differ from the product or software from the manufacturer and are subject to modifications without

prior notice.

• The features and additional services may vary depending on

available dispenser or software.

• Wineemotion is not liable for performance issues or incompatibilities

caused by changing the settings of the machine or operating system

software, or when the machine is placed in environmental settings

that differ from recommendations contained in this manual.

Ofcine Gullo

2

The attempt to customize the system or alter either the electronics,

mechanical parts, or software could cause malfunction of the dispenser and the loss of warranty.

• You can check for software updates for the dispenser by visiting Wineemotion (www.wineemotion.com/upgrades).

• This dispenser supports services and applications that may require an

active data connection for its operation and updating.

• Keep this manual for future reference.

3

Ofcine Gullo

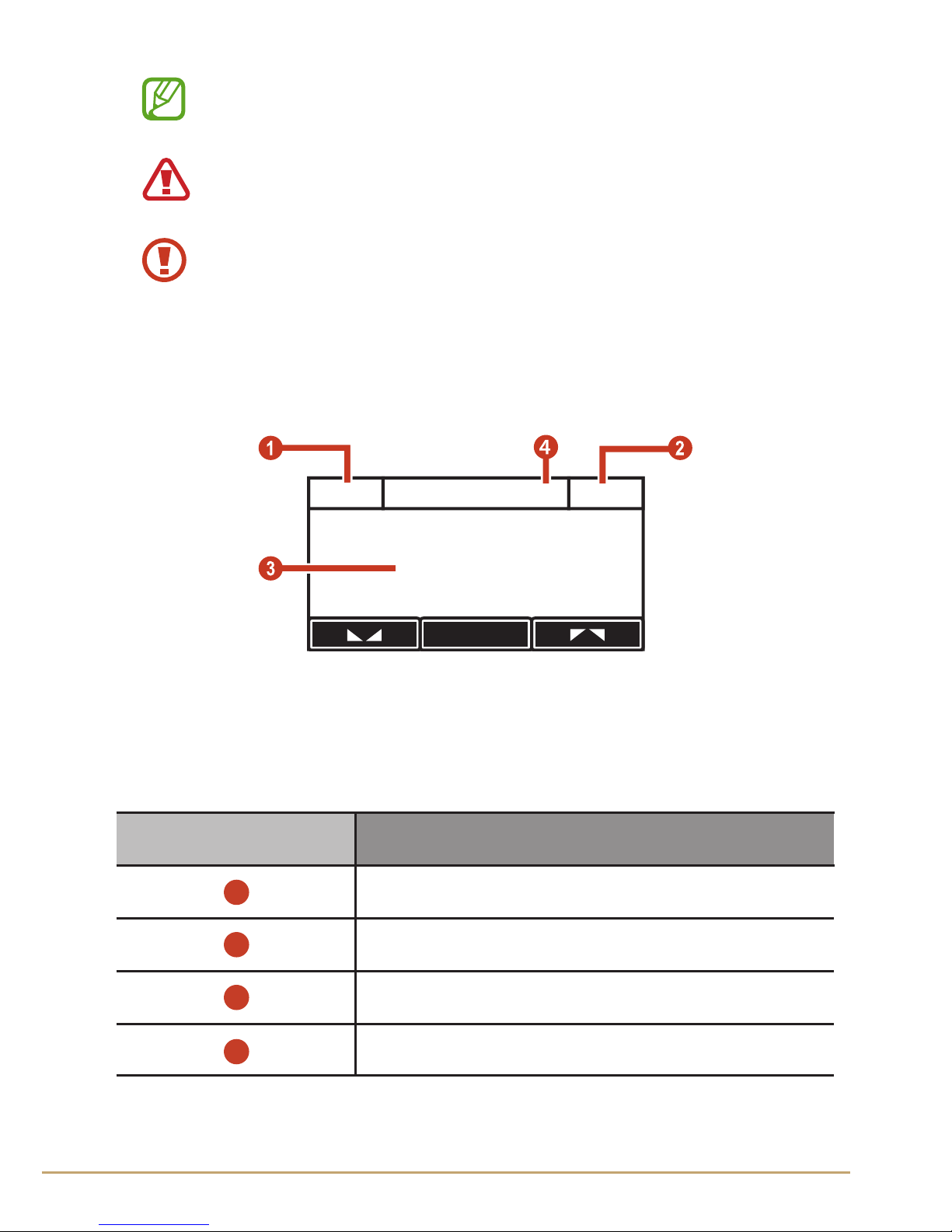

Information icons

To begin, please familiarize yourself with the icons used in this manual:

Warning - Situations that could cause problems in the proper

functioning of the system.

Caution - Situations that could cause damage to the device or

person.

Note - Notes, operational tips, or additional information.

Reference - Indicates where additional related information can

be found. For example, Chap. 1 (meaning "refer to

Chapter 1 ").

Followed by - Indicates in which order you must select the

options or menus to perform a step. For example:

In the Control Panel , select the Calibrating Menu

►

→

►

►

→

Ofcine Gullo

4

Manual of Use

1

Table of contents

1. Guidelines for reading the manual

2. Machine identication

2.1 Service request

2.2 Attached documents

. General description

4. Technical information

4.1 Dispenser overview

5. Technical data

5.1 Included Accessories

6. Safety information

6.1 General notes on safety

6.2 Environmental eects, safety warnings

7. Information on transport and storage

7.1 Packing and unpacking

7.2 Transport and storage

7.3 Transferring and Lifting

7.4 Checklist content "check integrity dispenser"

8. Installation

8.1 Installation position in cabinetry

8.2 Installation with encased positioning and multiple machines

8.3 Installation ush with front closure

8.4 Power supply

8.5 Pneumatic system

(for dispenser with external cylinders)

8.5.1 Pneumatic system (for dispensers with internal cylinders)

8.6 Climate controlled machines

5

Ofcine Gullo

2

8.7 Refrigeration system

8.8 Argon gas supply

8.9 Compressed air supply

8.10 Warning labels

8.11 Installation and replacement of cylinders

(mod. with internal cylinders)

8.11.1 Installation and replacement of cylinders

(mod. with external cylinders)

8.11.2 Connections

9. Operation

9.1 The front door

9.2 Suction tube

9.3 Piston components for bottle positioning

9.4 Correct positioning of the bottle

10. Dispensing

11. Display and visualization of the system

14.1 Error states of the system

12. Menu description

14.1 How to interact with the display

13. Operation from the main main

13.1 Calibrating

13.2 Display setting

13.3 Wine setting

13.4 Fridge setting

14. Maintenance and cleaning

14.1 Minimum qualication of personnel

14.2 Daily maintenance

14.3 Periodic maintenance

Ofcine Gullo

6

Manual of Use

3

14.4 Extraordinary maintenance

14.5 Special arrangements for troubleshooting

14.6 PPE required for maintenance personnel

14.7 Precautions for maintenance

15. Disposal of the machine

16. Declaration of compliance

17. Machine warranty

10. Certications held by SERIES 3 Dispensers

19. Authorized cleanind products

19.1 SaniPack MP 100

19.2 SaniKleen 512 WE

7

Ofcine Gullo

4

This manual is a guide for the use of the machine, please read it carefully

before unpacking the machine, as it contains important information

on safety at all stages of life of the machine, moving, unpacking,

installation, commissioning in service, operation, maintenance and

disposal of the machine.

If you are unsure about the correct interpretation of the

instructions, contact the manufacturer to obtain the necessary

clarications.

READ THE MANUAL BEFORE YOU UNPACK THE MACHINE.

KEEP THIS MANUAL WITH THE MACHINE.

1. Guidelines for reading the

manual

Ofcine Gullo

8

Manual of Use

5

2. Machine Identication

Each machine Wineemotion has an identication plate which shows

the company's data, the serial number of the machine, and the

electrical and pneumatic specications.

The plate should not be removed as it is useful to the service center

and Wineemotion to go back to the machine specications. The plate

is present in the certicate of conformity.

An example of the plate is shown below.

Designed by Wineemotion in Florence Assembled in Italy

CB

QR Code SN

Designed by Wineemotion in Florence Assembled in Italy

Series: SERIES2 Fuse:

2 x FX2,5A

Model:

Power Source Raiting

220 Vac 50 - 60Hz 0,6 A

1

12

2

13

11

3

5

6

4

14

15

7

8

9

10

16

17

220 Vac 50 - 60Hz 0,6 A

Fridge is climatic class N

power consuming 130W

2 x FX2,5A

2

9

Ofcine Gullo

6

9

10

Power source rating

Value fuse rating

►

Chap. 5

See manual for detailed information

QR code

11

12

Number Function

1

2

3

Manufacturer identification

Serial number

Manufacturer information

4

5

6

Reference mark initials for compliance with

national regulations

Model

Voltage, frequency and intensity

7

Product line

8

Model

Value fuse rating

►

Chap. 5

13

Warning: this machine is for indoor use only.

- This label reminds the user that the dispenser

is to be used only indoors and away from

atmospheric agents that may damage it.

Motor compressor thermally protected

system.

14

15

QR code

Serial number

16

17

Ofcine Gullo

10

Manual of Use

7

2.1 Service Request

If necessary, please contact the support team, or authorized

technicians.

If technical assistance is required, please always provide the

identication data on the label and details of any malfunctions that

have occurred. You can nd an up-to-date list of authorized service

centres on the www.wineemotion.com/assistance/ page.

2.2 Attached Documents

The following documentation is provided with this manual.

• EC Declaration of Compliance

• CB Declaration of Compliance

• Declaration of cETLus (U.S., Canada) compliance

•Warranty Statement

3. Overview

This wine dispenser is a machine designed for the preservation of the

wine from both an organoleptic and temperature perspective.

The presence of a controlled atmosphere of nitrogen or argon allows a

prolonged preservation to a maximum of 20 days.

The operating temperature of the machine is adjustable allowing you

to serve both white and red wines under optimum conditions.

Listening to our customers has helped Wineemotion develop a

product using materials and components that meet strict international

requirements in terms of safety and hygiene.

The image on the next page shows all the machine's features in detail.

Most of the aesthetic design details can be customized with dierent

types of materials and colours, thus giving customers the chance to

customise its look to match their needs.

For the current list of models and variants please visit www.

wineemotion.com

11

Ofcine Gullo

8

4.1 Dispenser overview

• The Wineemotion dispenser is designed and manufactured to pour

and enjoy high-quality wines by the glass.

The main feature of the dispensers is not to alter the taste of the wine,

followed by these main objectives:

1. Preserve the scent and avors

2. Prevent oxidation

3. Avoid waste

4. Control the temperature

• The dispenser is equipped with a cooling unit, ideal for the storage of

white and rosé wines.

• The dispenser has a control panel with push buttons, from where you

can choose the wine and the desired portion to be dispensed as well

as change the system settings.

• Images and descriptions in this manual refer to WINEEMOTION Dispenser Series 2.

• The Wineemotion dispenser can be used for small, medium or large

installation, for behind the bar or self service in restaurants, wine bars,

casinos etc.

• Please refer to the "Technical Data" section for more details on dimensions and technical specications of the dispenser as well as for the

precise installation notes and necessary prerequisites.

4. Technical Information

Ofcine Gullo

12

Manual of Use

9

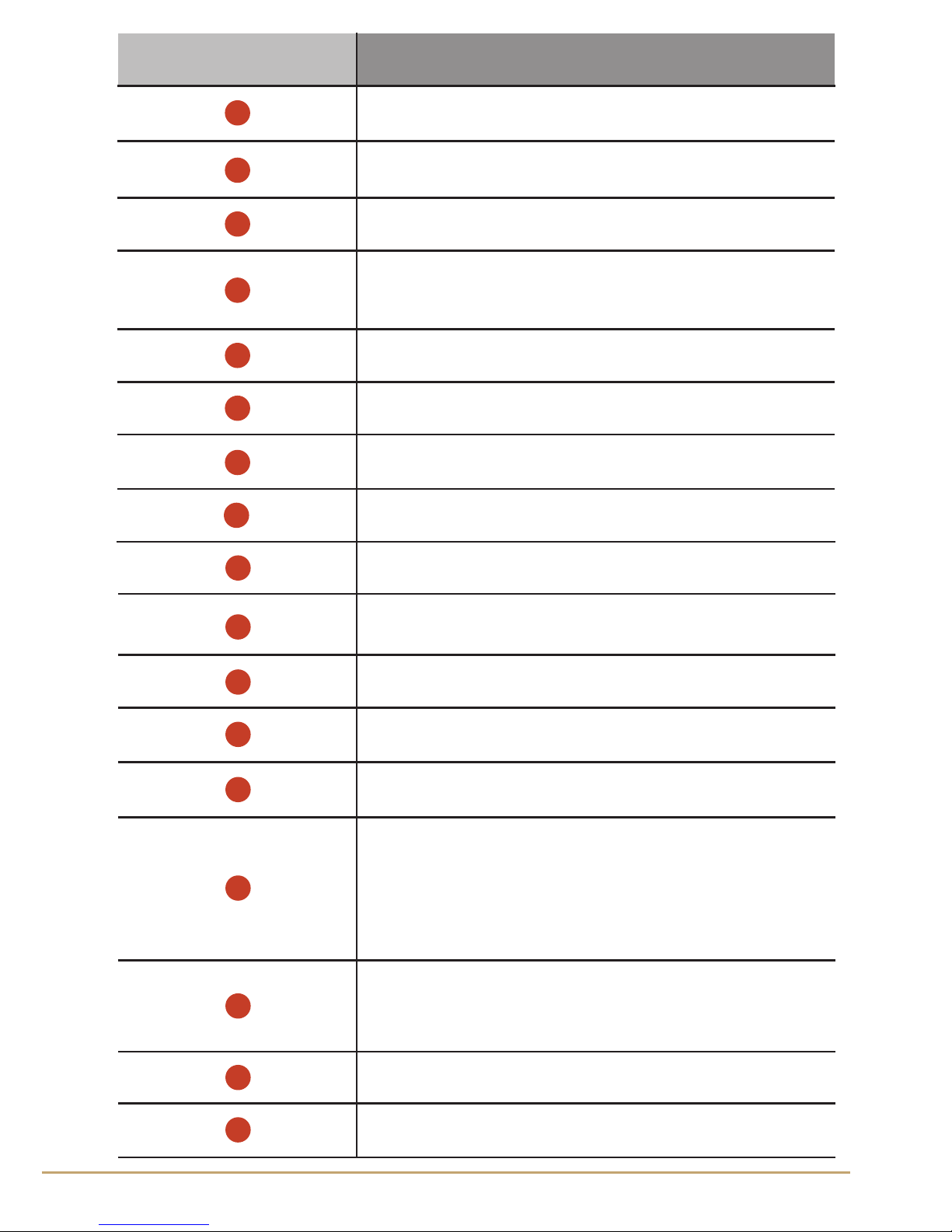

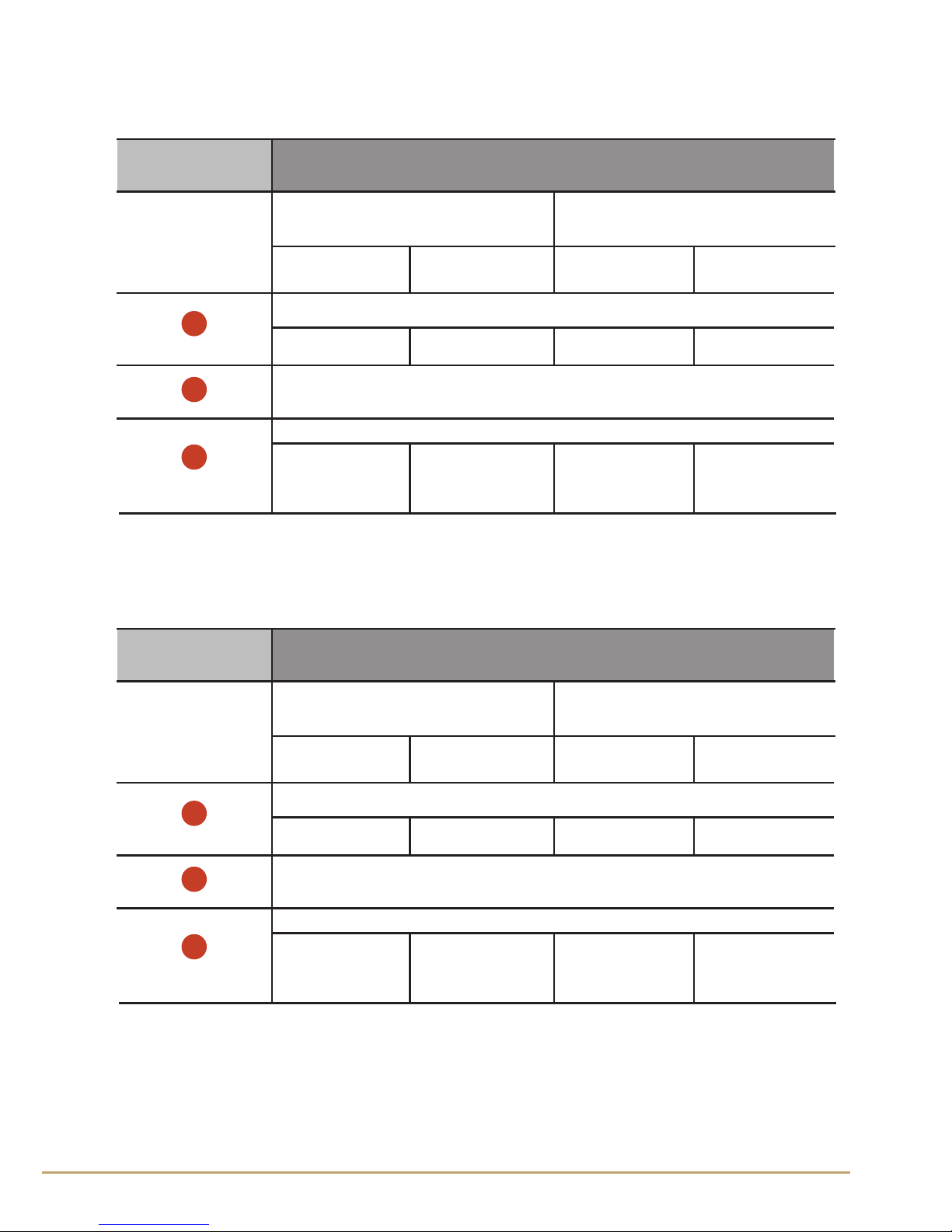

5. Technical data

A

P

L

4 BottlesModel with external cylinders

Height (H)

Length (L)

Depth (D)

566

550

320

Weight (Kg)

45

Dimensions (mm)

4 BottlesModel with internal cylinders

596

550

320

45

Dimensions (mm)

Height (H)

Length (L)

Depth (D)

Weight (Kg)

13

Ofcine Gullo

10

Nitrogen pressure with internal reg.

3-5 bar

Compressed air pressure 5 - 8 bar

Refrigerant used

R134A

Max cooling circuit pressure

10 bar

Nitrogen pressure with external reg.

max 200 mbar

Height

Maximum diameter

mm

mm

280÷355

100

4Model

Voltage (USA -Canada )

Frequency

Max power draw refrigerated

110V

50-60 Hz

130 W

4 BottlesDescription

Bottle specifications

Unit Description

Ambient temperature

Maximum relative humidity (Rhu)

Measurement

°C

Rhu

15÷27

70%

Installation environment specifications

Electrical Characteristics

Max power draw ambient temperature

50 W

Voltage EU

220V

Fuses for USA and Canada

F 4A

Fuses for Europe

F2.5A

Ofcine Gullo

14

Manual of Use

11

5.1 INCLUDED ACCESSORIES

The distributor is supplied with the following accessories:

→ copy of the installation manual paper or digital

→ warranty and compliance certificate

→ suction tubes

Any other accessories can be supplied in special versions.

15

Ofcine Gullo

12

6.1 General Safety Warnings

• The manufacturer, in the design and manufacture of regulators, is to

foresee and avoid risks to your health. The manufacturer realizes in full

compliance with the laws and materials at its disposal the know-how

in the design and implementation of the distributor. This information

warns users about possible risk behavior and how to avoid them. However, the precautionary information is essential and mandatory. The

safety also depends on the users.

Before turning on the dispenser for the rst time is strongly recommended to read this manual to fully understand the contents, especially the safety instructions.

• Taking some time to read and understand the contents of this manual will help you avoid hazardous conditions and abnormal behavior.

It would be too late to do what should have been done in case of an

accident.

• When lifting, follow the instructions for movement of the dispenser

on the packaging and in the manuals supplied.

• Pay attention to the symbols on the labels, shapes and colors refer to

important safety notices. Maintaing in good condition.

• Only persons who have read and understood the contents of the manual are allowed to use the dispenser.

• The dispenser must be installed in a dry environment provided sucient ow of 'fresh air according to the manufacturer's specications.

Environment Data

Ambient temperature Duty ° C 15 ÷ 27

Maximum relative humidity (Rhu) 70% Table 1: Technical data Dispensers

Description Unit Value

• The dispenser must be used according to the intended purpose only.

Improper use or misuse can lead to conditions of risk and economic

damage.

6. Safety information

Ofcine Gullo

16

Manual of Use

13

• When you use the dispenser, please make sure that there are no potential risks to health and safety, particularly for children and the disabled.

• Do not change any device / component inside the machine. Any service not described in this manual should be performed by qualied

personnel, in particular, authorized by the manufacturer.

Use only original spare parts.

• Keep the nozzle in perfect maintenance and perform maintenance as

described in this manual.

Good maintenance will keep the regulator working perfectly for a long

time and maintain high safety standards.

• Never wash the dispenser or direct jets of water to the parts inside or

outside of it, so as to prevent damage and / or damage to electronic

devices. Do not perform any maintenance if the regulator is powered

up or before removing the power cord. Make sure that it stays disconnected until the end of the service.

• The power cord should be carefully positioned to avoid interference with the person; to prevent general damage ensure that the cable

stays away from hot surfaces.

• Do not operate the machine in the event of a damaged power plug

or power cord.

• Never clean the dispenser with corrosive or abrasive materials, with

particular attention to the surfaces of the keyboard and the front glass,

which, being made of plastic materials, can scratch and need special

care to clean them. Refer to the appropriate chapter for specic machine cleaning techniques and products to use

• Never plug the power cord if the electrical characteristics of the dispenser does not match the voltage / frequency / power provided by

the manufacturer.

• Before you leave and, after leaving the distributor out of service for a

long time, always perform maintenance to ensure hygienic conditions.

• Do not install the regulator in critical environments at risk of explosion and re, next to heat sources or rooms with the risk of food contamination. The regulator should not be exposed to weather or corrosive

fumes.

17

Ofcine Gullo

14

6.2 Environmental eects, safety warnings

• Every organization has to apply specic procedures to estimate

the eects of its activities (Goods, services, etc.) may have on the

environment.

• The procedure to identify the signicant environmental eects, must

take into account the following elements:

Discharge

Drainage

Disposal

Mass pollution

Commodities and natural resources

Environmental eects, local issues

• All components of the package must be disposed of in accordance

with applicable laws.

• During installation the environment must be supplied with ducts for

hot air exhaust and to ensure fresh air for operation.

• During operation and maintenance, do not to dispose of degraded

products (oil, grease, etc.) into the environment, store the components

and dispose of in compliance with federal regulations.

• Keep the noise level to a minimum to reduce noise pollution.

• During the removal, store the components on the basis of the

chemical properties and dispose of in accordance with applicable law.

• In compliance with the law for WEEE (Waste Electrical Appliances

Electronics), the dispenser must be disposed separately from all

electrical and electronic components and specify the areas of

collection, or return the dispenser to the local distributor for credit

towards the rate of a new purchase.

• All components of the dispenser having dierent chemical

characteristics should be disposed of separatel.

Ofcine Gullo

18

Manual of Use

15

Illegal disposal of WEEE materials listed

in the law will be punished by local law

where the crime is committed.

19

Ofcine Gullo

16

7. Transport and storage

information

7.1 Packaging and unpacking

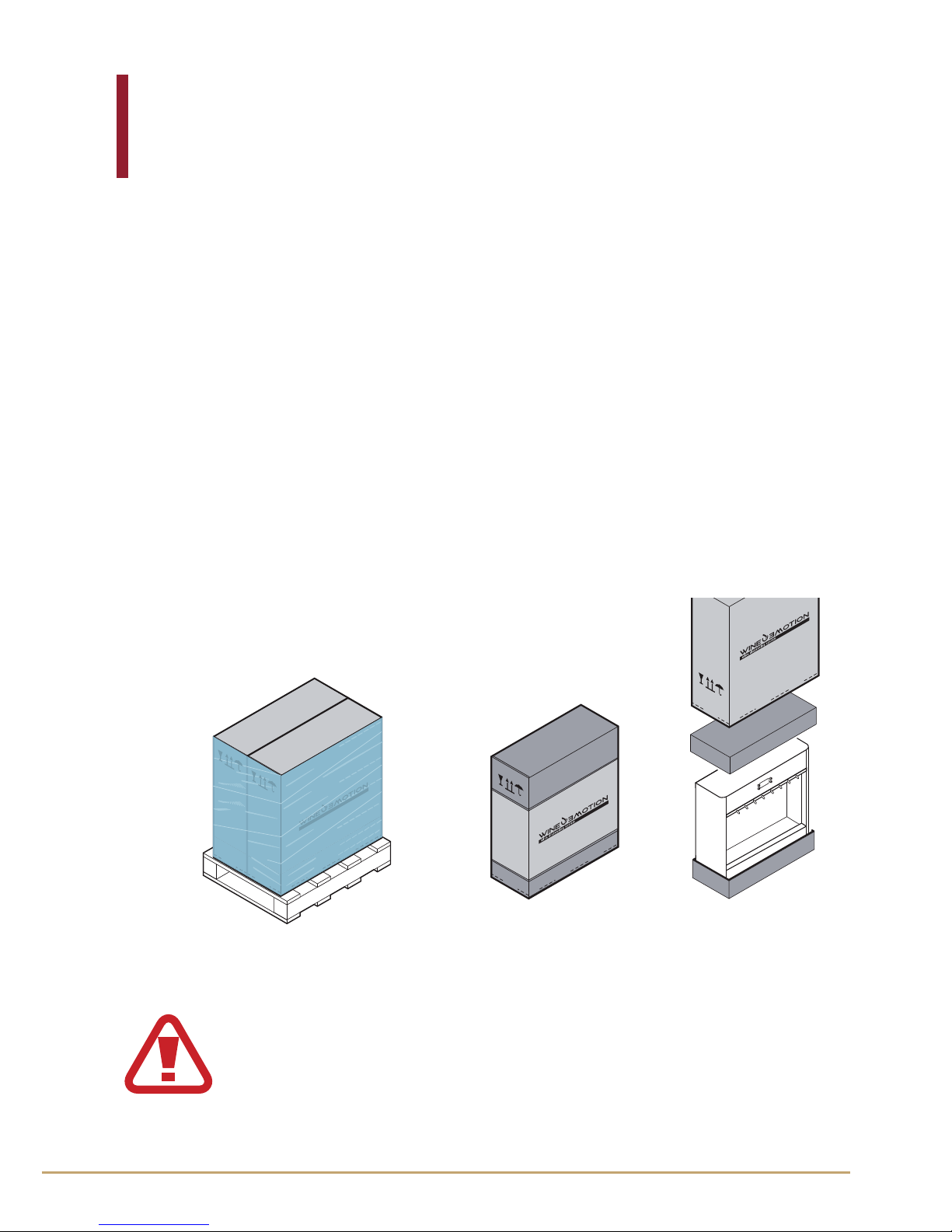

• The machine is packed in a cardboard box protected by an elastic

film. When unpacking, carefully extract the dispenser and check that

it is complete.

If any parts are damaged or missing, do not install the dispenser and

contact an authorized dealer to resolve the problem.

• Important: information about the safe transfer of the dispenser can

be found on the packaging.

The package must be disposed of according to applicable laws and

regulations.

Keep the box in case the machine needs to be transported to another

location in future.

CAUTION: DURING TRANSIT, DO NOT TILT THE

DISPENSER HORIZONTALLY. ENSURE IT IS KEPT UPRIGHT

AS SHOWN ON THE PACKAGING.

Ofcine Gullo

20

Manual of Use

17

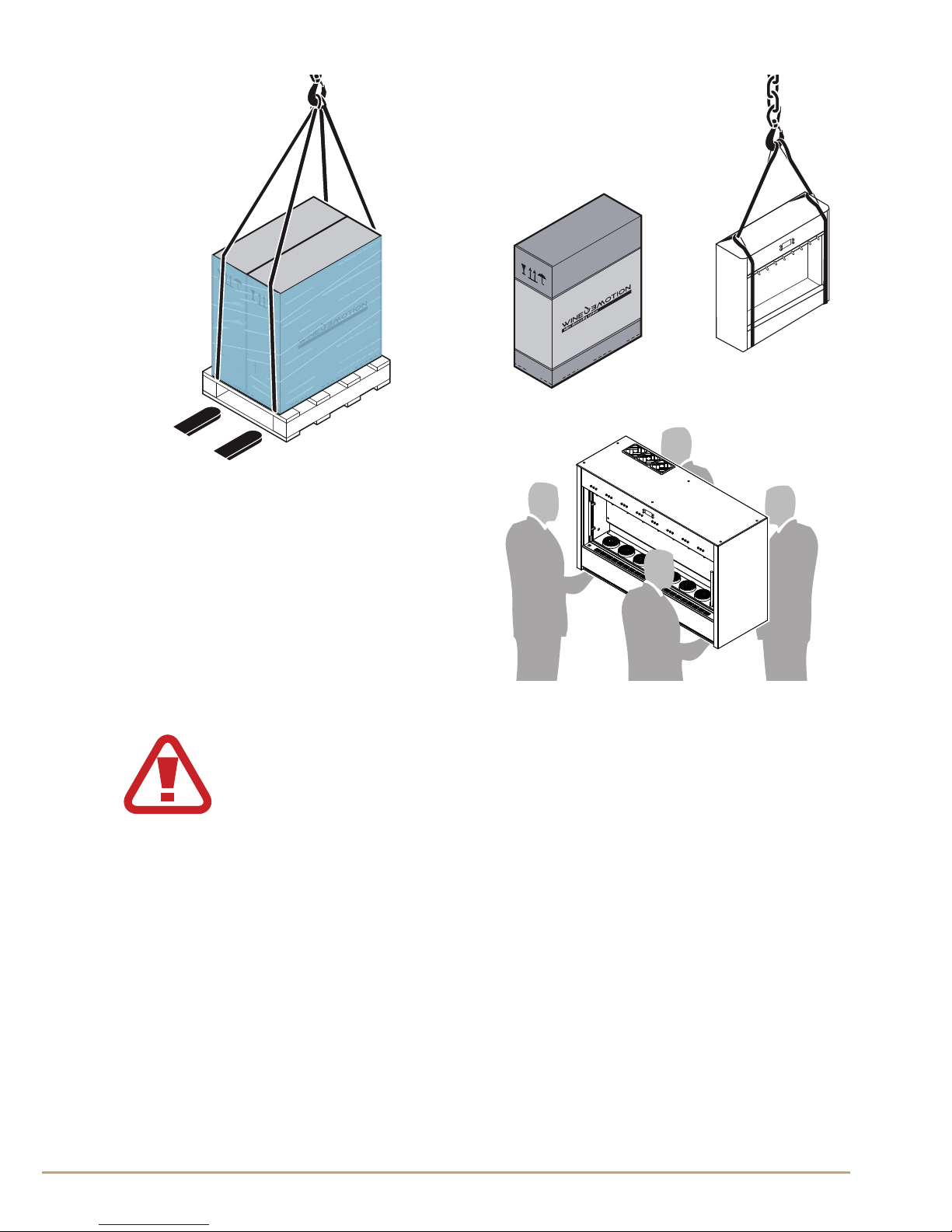

7.3 Moving and lifting

The dispenser may be moved, if placed on a platform, using forklifts,

(manual or automatic); or with straps, making sure these are secured

carefully to ensure even weight distribution prior to lifting.

7.2 Transport and storage

• The dispenser can be transported using dierent methods. The

following diagram shows the most common solutions.

• In order to protect the dispenser during transport, check the

packaging is as specied in

►

Chapter 7.1.

• If the dispenser is to be installed some time after its delivery, it will be

necessary to store it in a dry place with a temperature between 0° and

40°.

Transports methods

Handling methods

21

Ofcine Gullo

18

The illustrations demonstrate the movement and most suitable lifting methods.

7.4 "Dispenser integrity check" content checklist

•Each consignment includes a checklist with reporting documents and

descriptions.

• When you receive the checklist, refer to the "package contents" to

check the box numbers and ensure everything has been delivered.

If any components are damaged or missing, do not install the dispenser.

Contact an authorized dealer to resolve the problem.

It is recommended to lift the machine by mechanical

means, or with at least four persons, in compliance with

the current regulations on accident prevention

Ofcine Gullo

22

Manual of Use

19

50 20 20

150 150

900÷1000

A

450

B

50 20 20

400

450

B

8. Installation

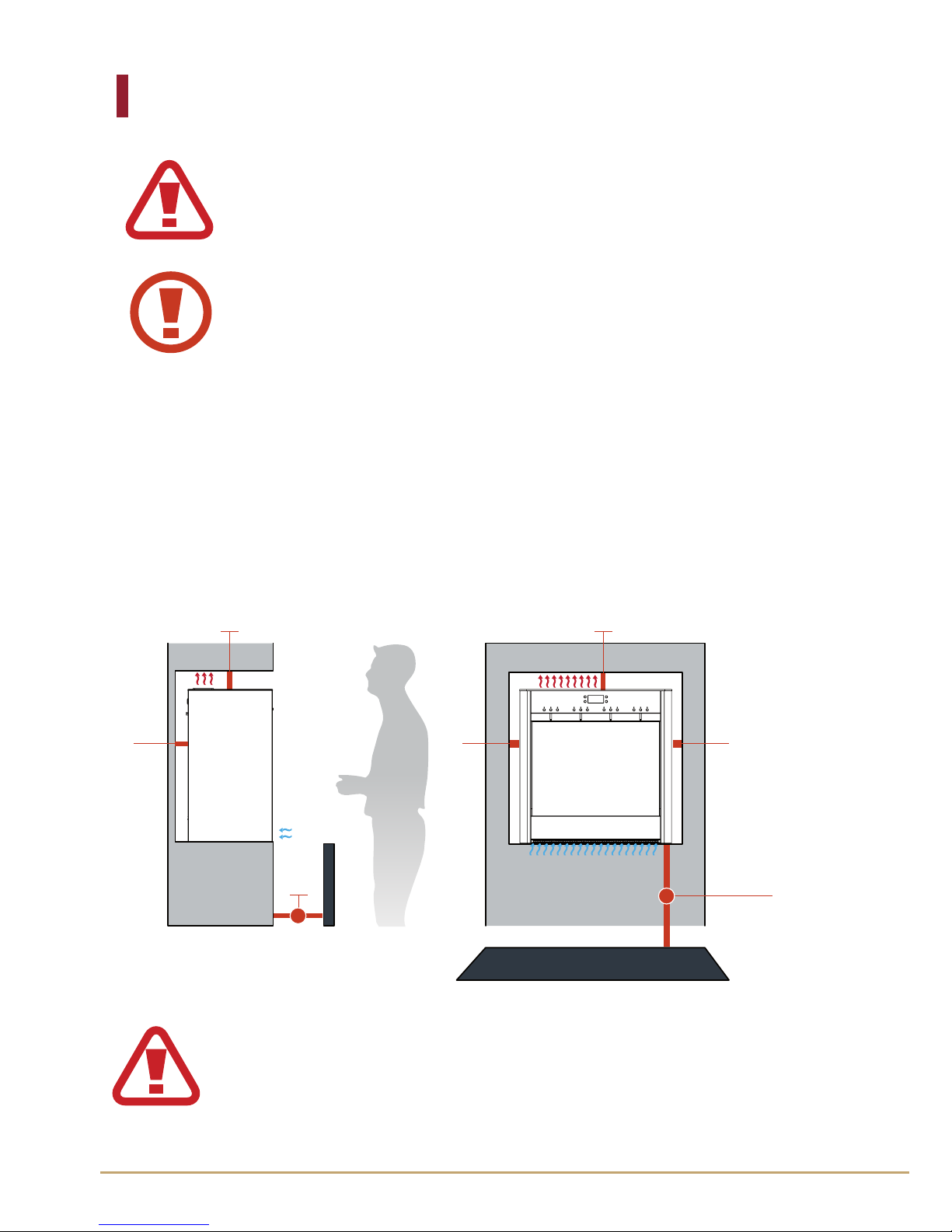

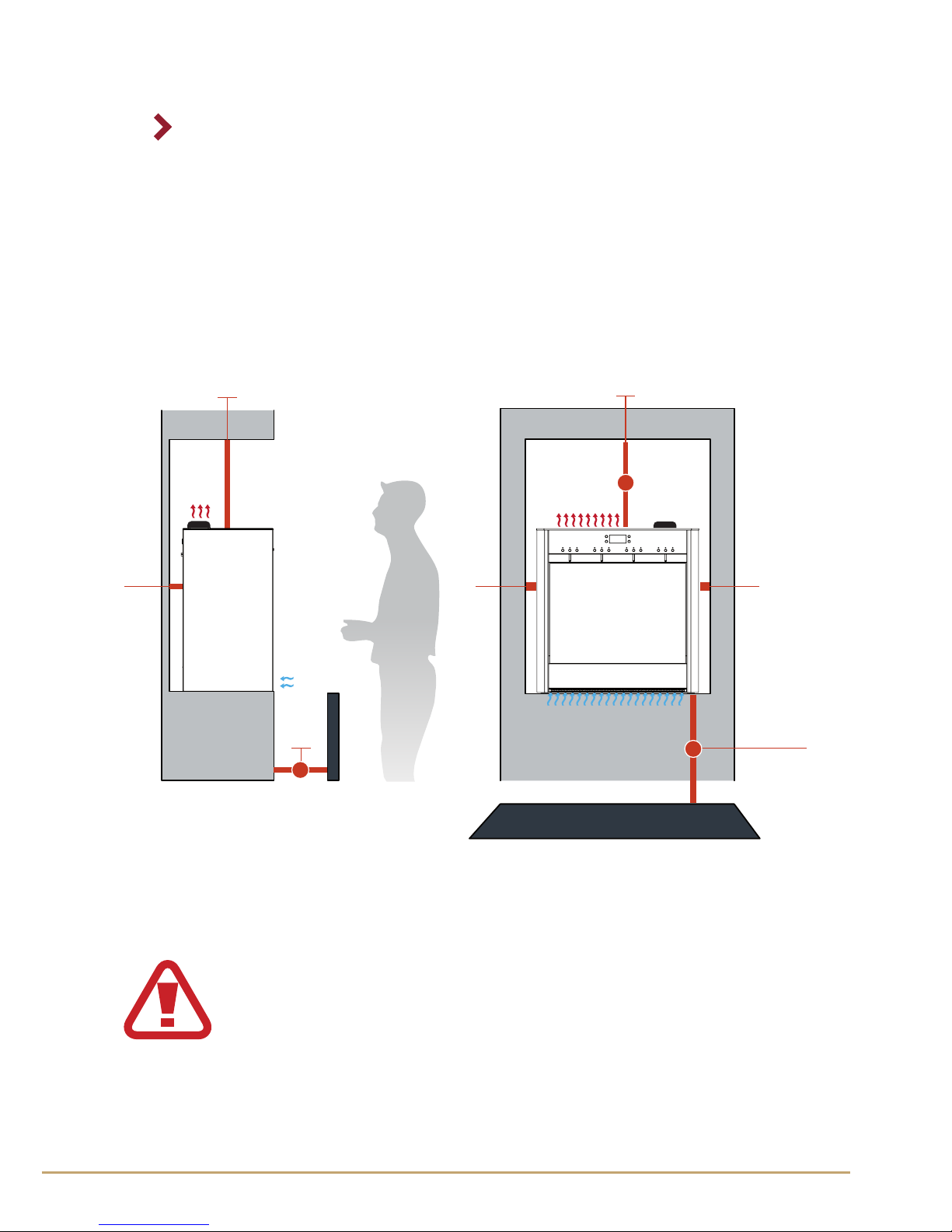

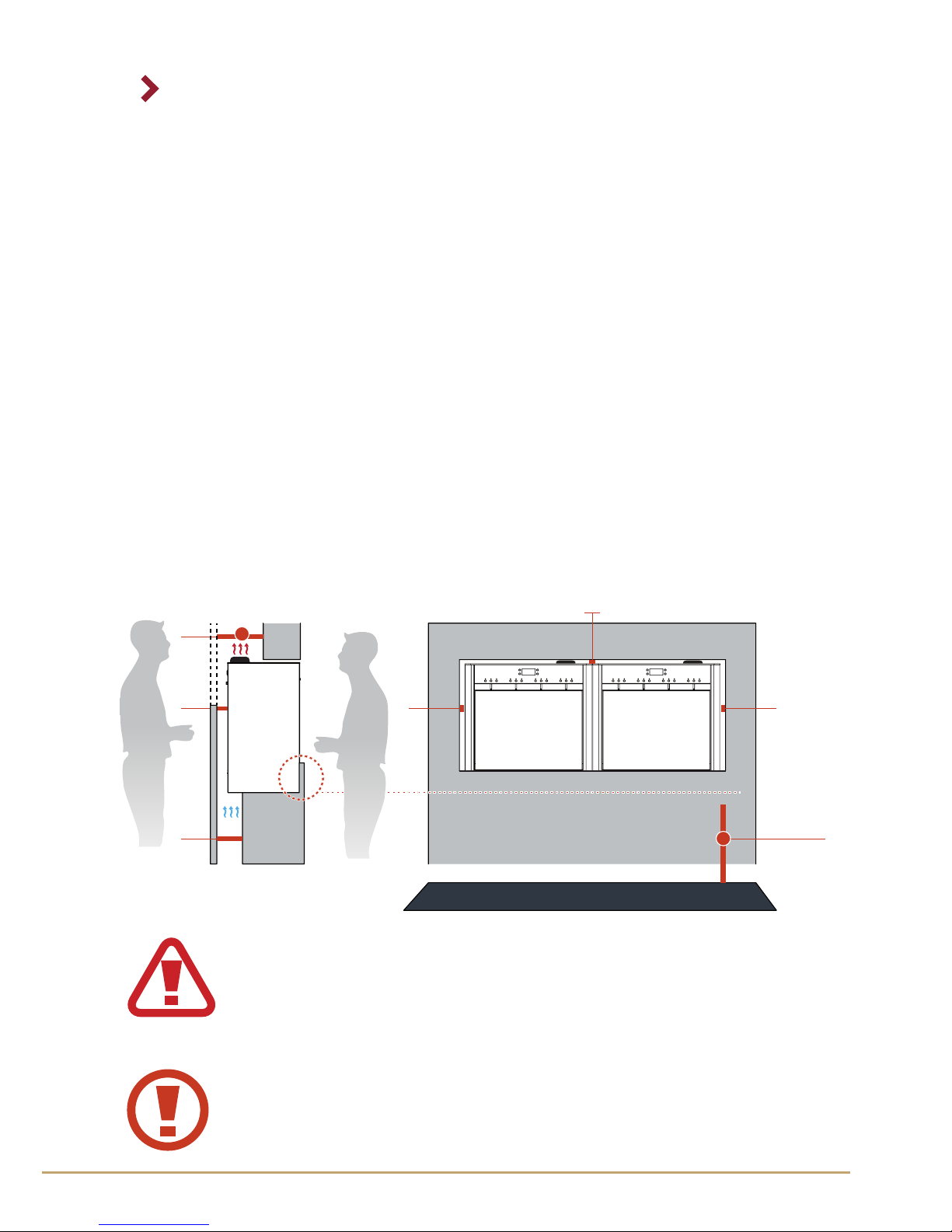

8.1 Recessed installations

The distance shown in the diagram is the recommended distance from

the oor, which must be 900 or 1000 mm. The distance B is the minimum

distance recommended for the exhaust: 450 mm. The spaces shown in

the diagram should not be covered up as they provide ventilation of

the machine.

WARNING: THE MACHINE MUST ALWAYS BE

HORIZONTAL POSITION

To not have danger or instability of the equipment you

need to successfully perform the procedures in this

manual.

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

23

Ofcine Gullo

20

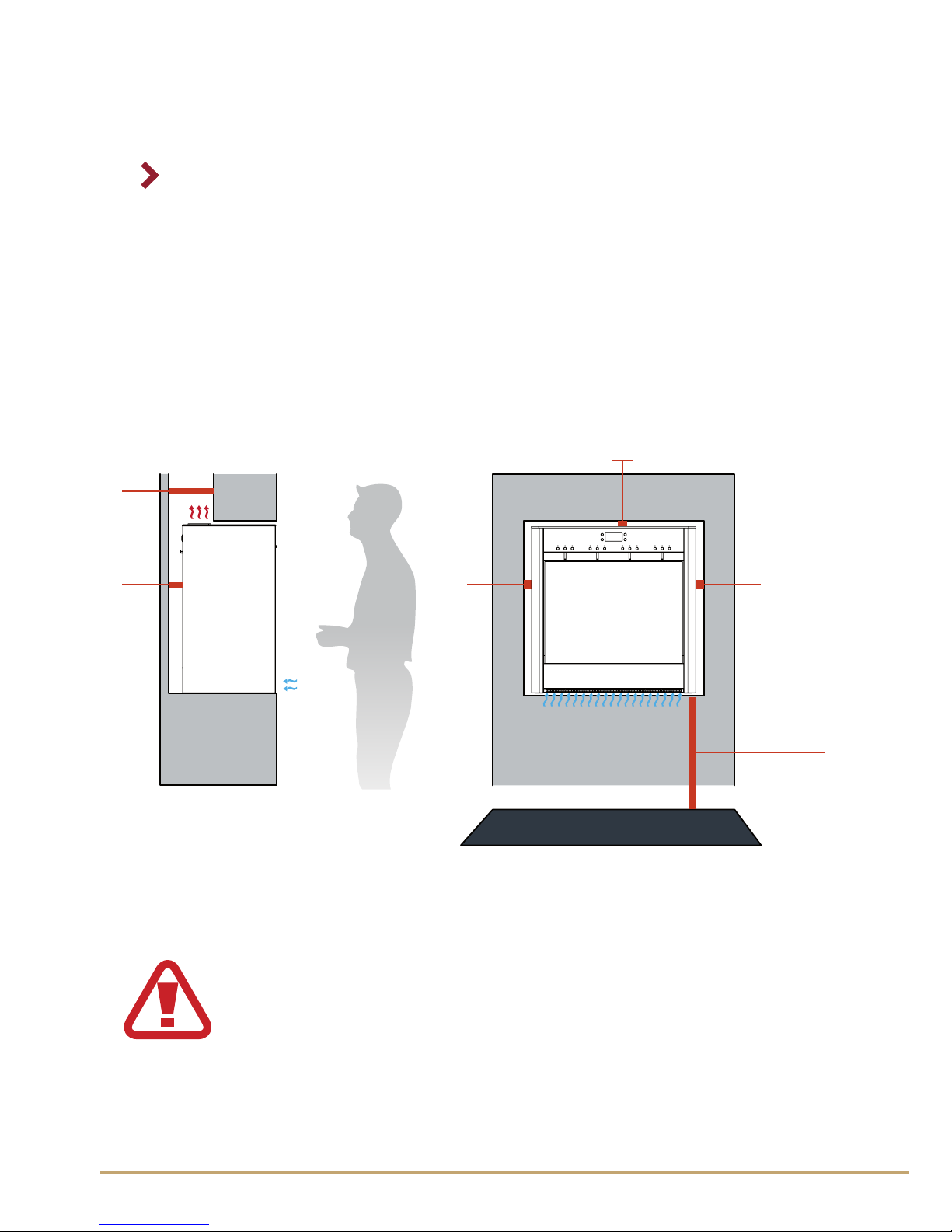

FOR DISPENSERS WITH INTERNAL CYLINDERS

The distance A shown in the gure is the recommended distance from

the oor that may be 900 to 1000 mm. The distance B is the minimum

distance for dispensing, 450mm, while the distance C is the minimum

recommended distance of 400mm for the correct insertion of the gas

into the dispenser. The spaces shown in the gure should not be closed

because they serve for ventilation of the machine.

50 20 20

400

400

900÷1000

A

450

B

C

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Ofcine Gullo

24

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Manual of Use

21

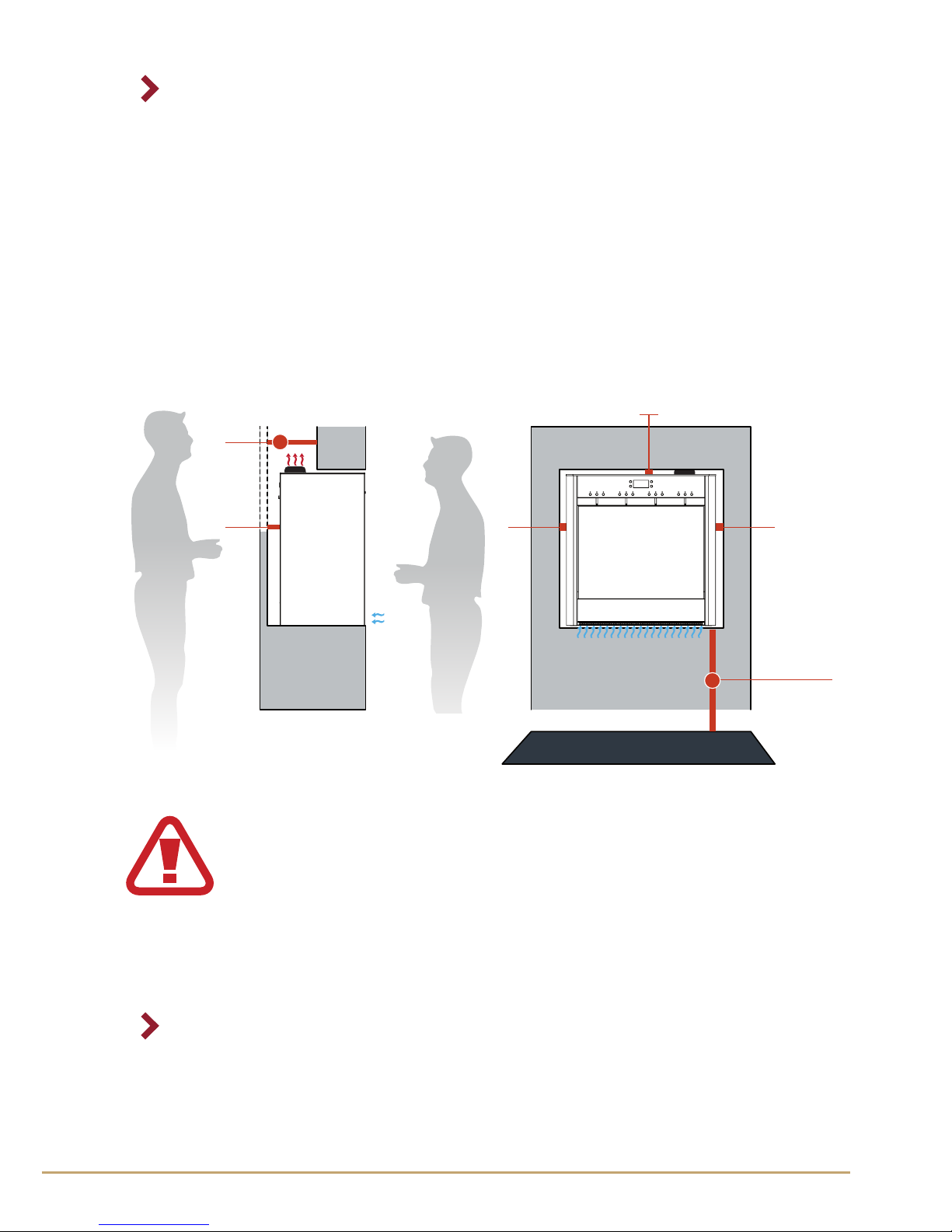

8.2 Installation with encased positioning and

multiple machines

FOR DISPENSERS WITH EXTERNAL CYLINDERS

When installing in a recessed structure please provide 163mm of

clearance on the back for the ventilation of the machine

This space must be open for the free passage of air.

The distance A shown in the gure is the recommended distance from

the oor that may be 900 to 1000 mm. The distance B is the minimum

distance for dispensing, 450mm.

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

200

50

50 20 20

400

B

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

25

Ofcine Gullo

22

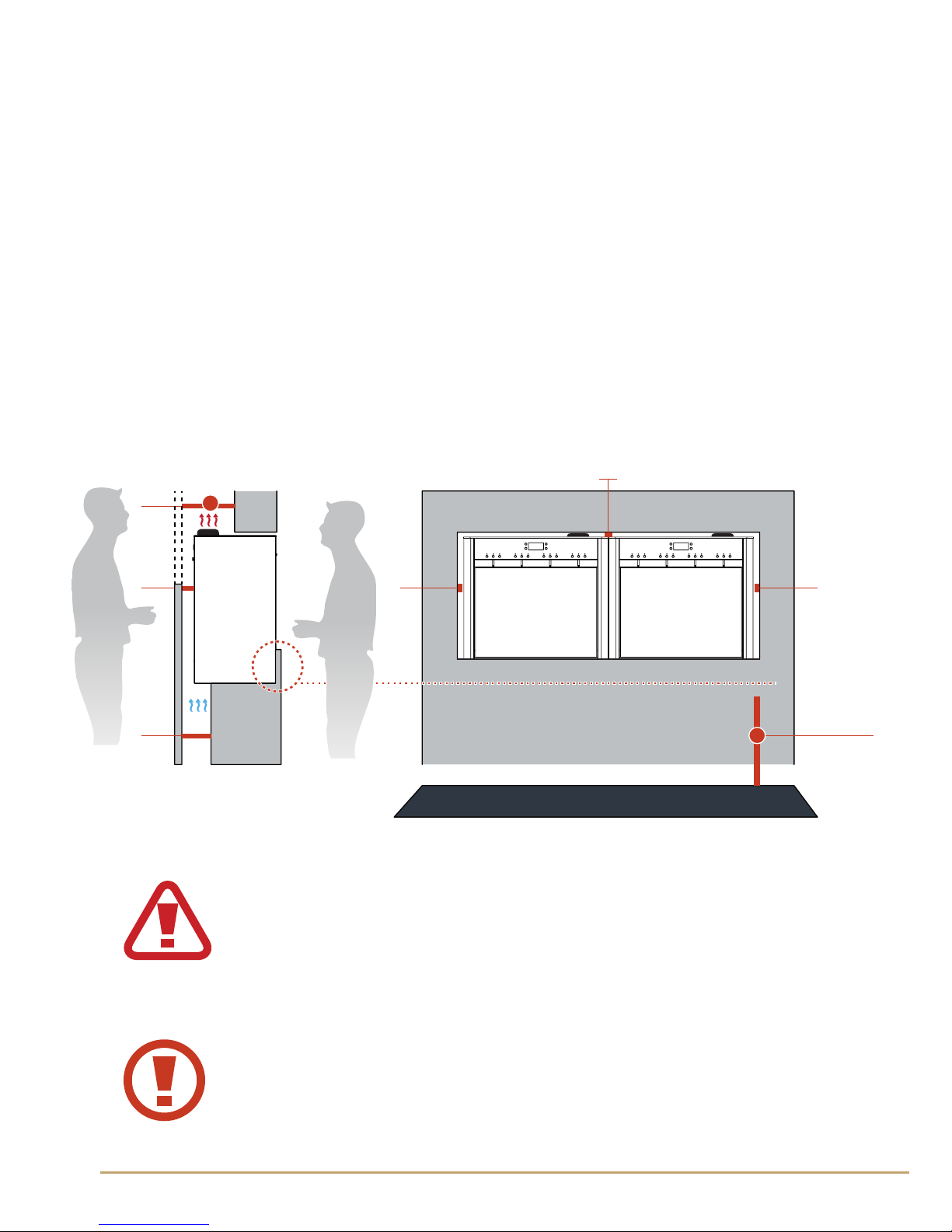

8.3 Installation ush with front closure

FOR DISPENSERS WITH EXTERNAL CYLINDERS

When you close the machine front you must create an opening on the

back, at the bottom, as the air is now drawn from the bottom instead

of the frontal zone.

FOR DISPENSERS WITH INTERNAL CYLINDERS

When installing in a recessed structure please provide 200mm of

clearance on the back for the ventilation of the machine and extraction

of the gas cylinder.

This space must be open for the free passage of air and must have

access to exchange the cylinder.

The distance A shown below is the recommended distance from the

oor that can be 900 or 1000mm. The distance B is the minimum

distance for the cylinder extraction which is 200mm.

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Ofcine Gullo

26

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Manual of Use

23

The opening of 136mm shown in the gure is the maximum that can

be done. The distance A shown in the gure is the recommended

distance from the oor that can be 900 to 1000mm. The distance B is

the minimum distance for dispensing which is 450mm.

The space C is for the front closure to be ush with the front panel and

must have a height of 146mm.

There being a radius of curvature on the front plate from a hygienic

point of view it is good to make the panel 2mm to 144mm or less,

otherwise you risk a deposit of dirt in 'space between the panel and

the radius of curvature space.

It is always best to ask for updates measurements and technical

specications from the Wineemotion oce as technical specications

and clearance requirements can change with model revisions.

20 20

900÷1000

200

136

50

20

B

A

CAUTION: DO NOT BLOCK THE FRONT BASE OPENING;

THIS LOCATION WAS DEVOTED FOR AIR INTAKE. IF YOU

BLOCK THE FRONT OPENING, YOU MUST PROMIDE AN

OPENING FOR REAR VENTILATION.

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

27

Ofcine Gullo

24

FOR DISPENSERS WITH INTERNAL CYLINDERS

When you close the machine front you must create an opening on the

back, at the bottom, as the air is now drawn from the bottom instead

of the frontal zone. The opening of 136mm shown in the gure is the

maximum that can be done. The distance A shown in the gure is the

recommended distance from the oor that can be 900 to 1000mm.

The distance B is the minimum distance recommended to facilitate air

ventilation and the extraction of the cylinder which is 200mm.

The space C is for the front closure to be ush with the front panel and

must have a height of 146mm.

There being a radius of curvature on the front plate from a hygienic

point of view it is good to make the panel 2mm to 144mm or less,

otherwise you risk a deposit of dirt in 'space between the panel and

the radius of curvature space.

It is always best to ask for updates measurements and technical

specications from the Wineemotion oce as technical specications.

and clearance requirements can change with model revisions

20 20

900÷1000

200

136

50

20

B

A

CAUTION: DO NOT BLOCK THE FRONT BASE OPENING; THIS LOCATION WAS

DEVOTED FOR AIR INTAKE. IF YOU BLOCK THE FRONT OPENING, YOU MUST

PROMIDE AN OPENING FOR REAR VENTILATION.

The air intake zone marked

50 20 20

20 20

150 150

900÷1000

900÷1000

163

50

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

must be clear for the

proper operation of the dispenser. After use, the dispenser

exhausts hot air from the top marked

20 20

900÷1000

900÷1000

20

A

450

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Ofcine Gullo

28

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

20 20

900÷1000

200

50

20

50 20 20

400

400

900÷1000

A

450

B

C

A

B

Manual of Use

25

P

L

Ingressi gas

Evaporazione condensa

Alimentazione

Scarico aria calda

(Superficie calda)

2x3ARUL

*

2

3

1

OR

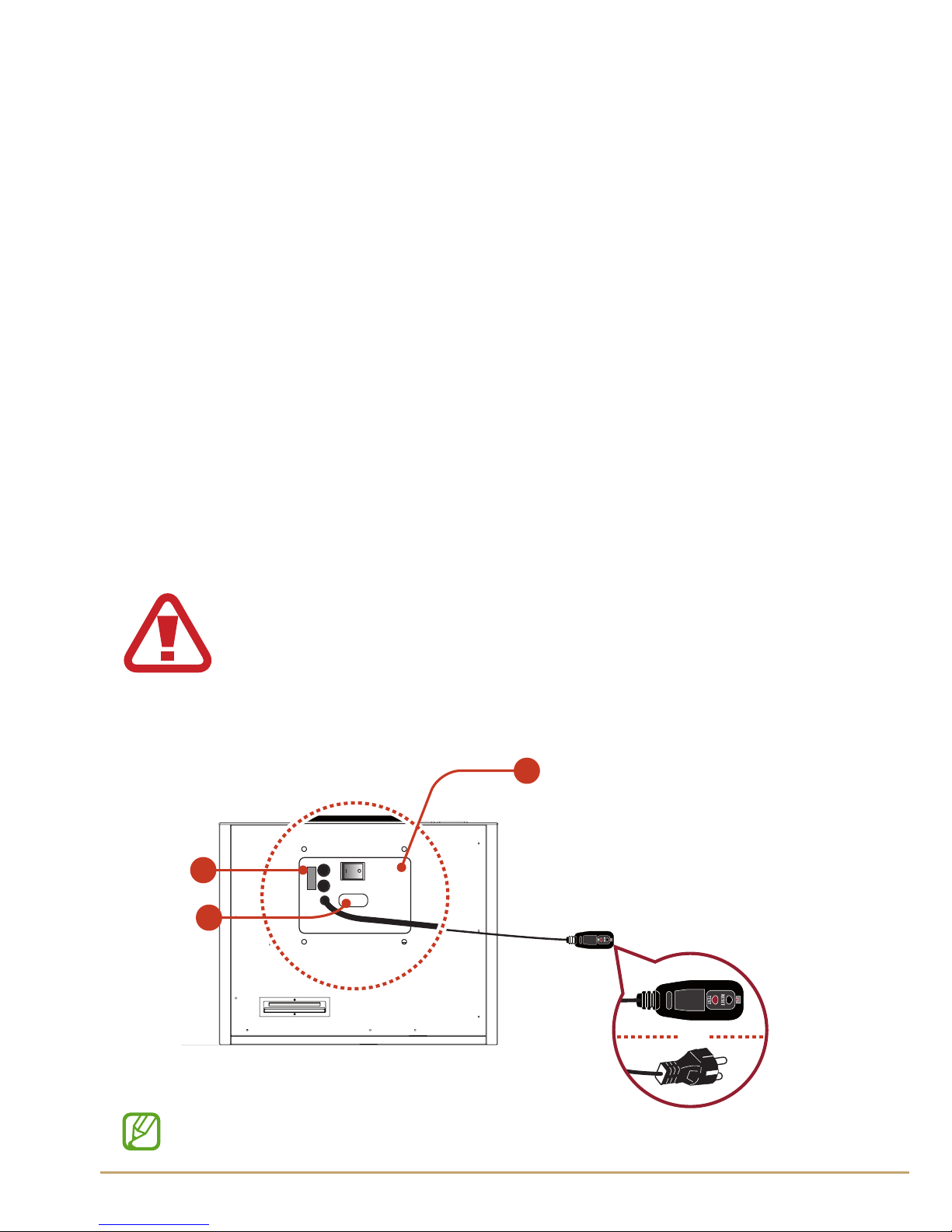

8.4 Power supply

The operating voltage of the machine is 110 Volt - 50Hz

►

chap. 5.

Before connecting the power cord to the machine make sure that the

voltage supplied meets the required specications.

Ensure that the main power line has a regular system of grounding and

all safety devices required by law.

The gure below shows the outlet where to insert the power cord and

the location of the power button.

The power button in the "O" position indicates that the machine is

turned o and the "I" indicates that the machine is on. Turn on the

machine by placing the button in position "I" only after connecting the

power cord. The fuses are located between the power button and the

power cord.

Always replace the fuse with another with the same

specifications as on the warning label; you need to

switch off and unplug the power cord, otherwise it is

impossible to replace the part.

* Socket with TEST only for USA and Canada.

29

Ofcine Gullo

26

Number Function

1

2

110V - 50 Hz

Programming port RS 232

3

USA e Canada:

F 2x3A fast

220V - 50 Hz

mod 4. Internal cylinder mod 4. external cylinder

110V - 50 Hz 220V - 50 Hz

Fuses

Electrical socket

EU: F 2X1.5A fast

USA e Canada:

F 2x3A fast

EU: F 2X1.5A fast

cod. S2041003011 cod. S2041003021 cod. S2041003010 cod. S2041003020

MODEL QUATTRO refrigerated

Number Function

1

2

110V - 50 Hz

Programming port RS 232

3

USA e Canada:

F 2x3A fast

220V - 50 Hz

mod 4. Internal cylinder mod 4. external cylinder

110V - 50 Hz 220V - 50 Hz

Fuses

Electrical socket

EU: F 2X1.5A fast

USA e Canada:

F 2x3A fast

EU: F 2X1.5A fast

cod. S2040003011 cod. S2040003021 cod. S2040003010 cod. S2040003020

MODEL QUATTRO ambient temperature

Ofcine Gullo

30

Manual of Use

27

31

Ofcine Gullo

28

1

2

8.5 Pneumatic system (for dispensers with external cylinders)

The pneumatic system provides two distinct and separate inlets:

1

Compressed air supply.

2

Nitrogen or argon gas supply.

Recall that the two pipes must be strictly separated to prevent there

being any danger of contamination of the preservation section of the

dispenser.

Set the operating pressure as indicated on the label.

Number Function

1

2

Service pressure, air (

►

chap.5)

Food-grade gas ( N2) or (Ar) (

►

chap. 5)

The dispenser leaves the factory provided with

2 extension tubes to facilitate installation in the

assembly phase.

To regulate the gasses to the recommended pressur

see chap. 5.

Ofcine Gullo

32

Manual of Use

29

8.5.1 Pneumatic system (for dispensers with internal cylinders)

Th e pneumatic system is supplied

with argon gas (E938) by means of

a cylinder provided by the factory,

inserted into the dispenser through

an opening on the topsuperiore.

Once the cartridge is inserted,

please don’t remove it for any

reasons until it is completely empty

and the display shows G EM (Gas

Empty).

If it would be necessary to remove

the cartridge in advance, please

contact the technical assistance

before proceeding with the

operation.

You can only use cylinder, issued by Wineemotion spa

because the connection and inlet are proprietary.

For installation and maintenance of the gas cylinders

see chap. 8.11.

33

Ofcine Gullo

30

8.8 Argon gas supply

The connections shown in the gure are feed points for the argon gas

supply in position

2

and compressed air in position 1.

The pressure of the food grade nitrogen or argon gas is used for the

operation of the dispensing and preservation system.

The compressed air supply is used to move the pistons to facilitate

inserting and positioning of the bottles.

Position

2

must be supplied with nitrogen or argon for food with a

degree of purity of at least 99.5%.

The supply of nitrogen or argon is facilitated through cylinders or by

the use of a nitrogen generator.

The nitrogen generator is used when you want to keep the costs of

supplying nitrogen down, especially when you have more than two

machines.

The cylinder of nitrogen or argon must have a pressure of between 150

and 200 bar, depending on the regulations of the country in which it

is used.

The cylinder must be placed in a safe, well-ventilated area and also

needs to be xed to a wall by means of chain or other fastening system.

For the use of the nitrogen generator please read your dedicated

manual from the generator manufacturer.

8.7 Refrigeration system

The R134 gas refrigeration system has a maximum working pressure

of 10 bar. The maintenance of the refrigeration system must only be

performed by a technician from an Authorized Service Center.

8.6 Climate controlled machines

This machine belongs to the N climate control class in accordance with

IEC 60335-5-24

Ofcine Gullo

34

Manual of Use

31

8.10 Warning labels

1

2

5

3

8.9 Compressed air supply

Compressed air is used to lower the pistons for the positioning and

insertion of bottles.

Compressed air is supplied to the machine by connecting the supply

line as shown in the gure above at position

2

.

For convenience compressed air may be replaced with nitrogen

pressurized at 4.5 bar.

Number Function

1

Serial of the machine, power supply voltage and the

rating of the fuses

►

chap.2

- This label indicates the model name of the machine

and species the power supply and the fuse ratings

contained in the power supply.

35

Ofcine Gullo

32

2

Caution hot surface (g.1)

- During the operation of the machine the

area indicated by the label may reach harmful

temperatures if it comes in contact with a person,

please do not touch this area for a minimum of 10

minutes after switching o the machine to allow

this surface to cool within acceptable temperature

ranges.

Attenzione temperatura elevata

Attention température élevée

Warning hot temperature

g. 1

Turn o the dispenser using the power switch to O (o) position,

unplug the power cord and turn o all electrical devices that can harm

people.

• Use all means necessary to inform the people in your surroundings

for their safety.

• If any parts are worn they should be replaced, please use only

original spare parts.

• Do not to change the characteristics of service and safety devices

and always use original spare parts.

Avoid using materials not authorized by the manufacturer.

8.11 Installation and replacement of argon

cylinders (models with internal cylinder)

3

Serial of the machine, power supply voltage and the

rating of the fuses

►

chap.2

Ofcine Gullo

36

Manual of Use

33

1. Make sure the machine is turned off.

2. Unscrew and remove the cap on top

of the dispenser which holds and protects

the cylinder from damage.

A

B

A

B

3. Attach the cap to the new cylinder

(A) and insert the cylinder into its seat. Screw

the cap counterclockwise (B) with the gas

cylinder and make sure the supply is properly

tightened and there are no leaks.

4. Tighten to close the cap on top of the

dispenser.

T he valve is reverse-threaded, rotate

counterclockwise to screw and

clockwise to unscrew.

The cylinder CANNOT BE RECHARGED!

Only cylinders issued by Wineemotion spa can be

used because the means of attachment is customized.

37

Ofcine Gullo

34

• Before carrying out any operation, make sure that the argon cylinder

is closed by the appropriate valve.

Turn off the dispenser using the power switch to O (off) position,

unplug the power cord and turn off all electrical devices that may

harm people.

• Use all means necessary to inform the people in your surroundings

for their safety.

• If any parts are worn they should be replaced, please use only

original spare parts.

• Do not to change the characteristics of service and safety devices

and always use original spare parts.

Avoid using materials not authorized by the manufacturer.

1. Replace the nitrogen cylinder when the high pressure gauge marks

10/5 bar. Below this threshold there is no guarantee for the correct

operation of the dispenser.

2. Make sure the machine is turned off.

3. Close the supply valves of the regulator (A)

A

8.11.1 Installation and replacement of argon

cylinders

(models with external cylinder)

Ofcine Gullo

38

Manual of Use

35

6. Remove the pressure regulator and replace the cylinder (D).

7. Replace the gasket to prevent any leaks.

4. Close the valve (C) of the cylinder (D).

5. Pull the valve ring (F) holding it in place so as to exhaust the residual

pressure in the regulator (D). ). Release when the pressure gauges (E1E2) show a value of 0 (zero).

A

D

C

A

D

C

E2

E1

F

I

39

Ofcine Gullo

36

N2

OR

2x3ARUL

8.11.2 Connections

1. Location of the supply lines of the gas (cylinders, generator, etc.).

2. Connect the gas lines to the gas supply and also to the pre-installed

inlets on the dispenser and pressurize the system according to the

instructions in

►

chap. 8.5.

3. Check the stability of the dispenser.

4. Connect the power supply cable to the dispenser.

Before connecting the cable to the power line socket, make sure

that the main switch is in the O (o) position and make sure the

voltage / frequency / power supplied match the values indicated on

identication label.

5. Check the working conditions of the dispenser and check that there

are no leaks (air, nitrogen / argon, etc.).

Ofcine Gullo

40

Manual of Use

37

9. Operation

PRESS

9.1 The front door

For the correct opening of the glass door, after unlocking the optional

keylock in the lower right corner, perform the following steps:

1. Press in on the glass door (g. 1).

2. Release and swing door to the desired opening (g. 2).

Avoid hygienic contamination and damage to the seals found around

the door.

9.2 Suction tube

The suction tube allows for the dispensing of wine through the tap.

The connection to the tap is extremely simple and is performed as

illustrated in g. 3, you can insert the tube as shown in step "A" in g. 3

and remove the tube as shown in step "B" in g. 3.

For proper use of the system and in accordance with hygiene rules, it

is suggested to ush the suction tube whenever you replace a bottle.

g. 1 g. 2

41

Ofcine Gullo

38

9.3 Piston components for bottle positioning

The positioning system for the wine bottle provides three main

components: the pad which serves to create a correct adhesion of the

bottle to the positioning system, the spacer which serves to compensate

for variations in height of the bottles and can be stacked together up

to a maximum of 4 and can be removed completely if necessary, and

nally the cylinder head that is xed to the pneumatic piston which is

appropriately controlled and moves up and down with a stroke of 50

mm. These parts together with the use of the spacer serve to ensure

that the neck of the bottle applies the correct pressure on the seal of

the dispenser to prevent leaks of gas (Nitrogen / Argon) and seal the

bottle for preservation.

This procedure must be performed by extracting the tube from the

machine and washing with common cleaning products designed for

food-handling equipment. Chap. Sanitation is commonly referenced

for performing normal cleaning cycles but does not cover the removal

of the suction tube, so please the recommendations in the sanitation

section together with those in this section.

g. 3

A B

Ofcine Gullo

42

Manual of Use

39

Number Function

1

2

3

bottle pad

spacer

piston head

43

Ofcine Gullo

40

9.4 Interaction and order of TAP

The order of the tap from one to four / eight and from right to left, ie

the rubunetto right is the No. 1 and one on the left is the N ° 4/8:

12345678

The keys instead go from left to right, one on the left is the N° 1 (lower

dose) and one on the right is the N° 3 (higher dose):

WP

O 17.2 C

1 2 3

Ofcine Gullo

44

Manual of Use

41

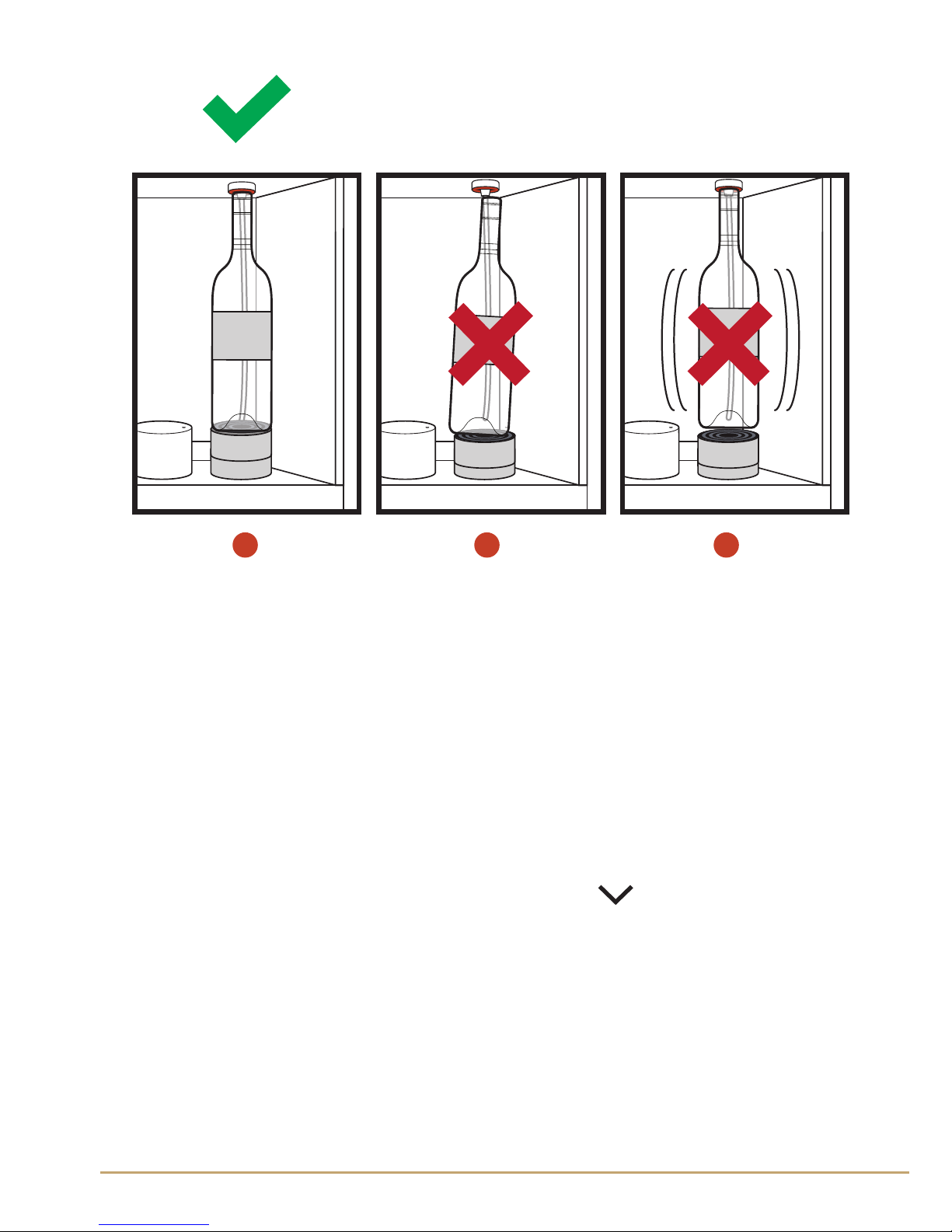

9.5 Correct positioning of the bottle

FOR DISPENSERS WITH AUTOMATIC PISTONS

For the insertion of a bottle into the machine it is suggested to perform

the following operations:

1. Make sure the machine is properly supplied either by nitrogen or

argon gas.

2. Insert suction tube

►

cHap. 9.2

WINEEMOTION

WINE

1.00$ 2.00$ 3.00$

3. Make sure the pad and the spacer of the piston are properly

positioned with consideration to the size of the bottle.

4. Press the P key in the upper left to activate the UP and DOWN

functions of the pistons (g. 1).

5. Once enabled, the LEDs of the rst 2 buttons of each tap will

illuminate indicating the following operation is possible (g. 2):

1

UP; the piston rises;

2

DOWN; the piston drops;

6. First press the function button "DOWN"

2

7. Position the bottle according to g.

A

8. Then press the function button "UP"

1

g. 1 g. 2

45

Ofcine Gullo

42

9. Verify that the bottle has sealed correctly with the gasket as

shown in g.

B

, , and note how the seal is insucient or partial in g.

C D

, which would require readjustment or addition of another spacer

and repeating the process from step "2" after removing the bottle.

10. To exit this functionality mode press the P button in the upper left

corner (g. 1).

FOR DISPENSERS WITH MANUAL PISTONS

For the insertion of a bottle into the machine it is suggested to perform

The following operations:

1. Make sure the machine is properly supplied either by nitrogen or

argon gas.

2. . Insert suction tube

►

cap. 9.2

3. Make sure the pad and the spacer of the piston are properly

positioned with consideration to the size of the bottle.

4. Position the bottle according to g.

A

5. Manually push the piston down to facilitate insertion of the bottle

into the space provided.

6. Gently release the piston and check that the neck of the bottle ts

snugly at the base of the tap seal.

A

Ofcine Gullo

46

Manual of Use

43

B C D

9.5.1 Inform the machine insertion of the bottle

in a certain position.

It serves to inform the machine that was iserita a bottle in a certain

position:

1. Press and hold the button for a few seconds at the bottom right

of the center display (Figure 1).

2. We will notice that the power of the TAP LED will begin to ash.

3. Select the nozzle where we inserted the bottle (Figure 2).

4. Once you have selected the location, the display will start a short

animation of the bottle (Figure 3).

5. Wait for the end of the animation.

47

Ofcine Gullo

44

WP

O 17.2 C

W G OK

C C 17.2 C

P

Waiting load wine

P

g. 3

g. 2

g. 1

Ofcine Gullo

48

Manual of Use

45

10. Dispensing

For a proper dispensing perform the following steps:

1. Turn on the dispenser by pressing the power button on the back.

2. At this point the machine is ready for use, simply press the button

on the desired dosage.

WP

O 17.2 C

2. Wait until the LED turns off before you remove the glass from below

the nozzle.

3. At the end of dispensing mode all LED will return to off.

49

Ofcine Gullo

46

Caution, try not to crash the glass on the regulator and

against the glass door of the bottle compartment.

Bring the glass gently to spout being careful not to damage

the glass or the door.

Warning!

The dispenser is not able to determine the level

of the wine in the bottle; in case the bottle is

removed for manual use and reinserted into

the dispenser, the preservation and correct

dispensing of the wine will be compromised.

ABSOLUTELY DO NOT REMOVE THE BOTTLE DURING USE

Ofcine Gullo

50

Manual of Use

47

11. Display and visualization

of the system

The dispenser is equipped with a special function that can display the

various states of the refrigerating that are inside the climate controlled

dispensers.

On the screen you can view the working status of the refrigerator.

The letter that appears at the top right of the display indicates status.

In addition to the display of the refrigerator, you can monitor the status of the rest of the system.

The display will show the letters that show the various activities being

done by the system in real time:

Number Function

1

Bottle empty or absent: G EM

Full bottle inserted:

G OK

Analyzing bottle:

G AN

LEFT

RIGHT

10°C

15°C

W G OK

C C 17.2 C

10°C

LEFT

5

When the display indicates Bottle empty or absent: G EM,

the machine will not dispense and will warn with the

message on the display: NO GAS

51

Ofcine Gullo

48

4

Indicates whether the glass door of the dispenser is open or closed.

O: Open

C: Close

The dispenser responds to the glass door

being open after approximately 90 seconds

from initiation, after which the machine performs a P cycle (see function n.

1

) until the

door is reinserted/closed.

2

W: (Working) The refrigeration compressor is

running and actively cooling.

S: (Stop) The cooling system is paused between cooling cycles after reaching temperature.

D: (Defrost) Normal defrost cycles.

P: (Pausa) A 3 minute pause experienced after

changing refrigeration settings or after a defrost cycle to allow the pressure in the system

to balance and prevent immediate restarting

of the compressor.

3

View the current temperature setpoint in the

dispenser in either F° or C°. To view the realtime live temperature of the dispenser, press

and hold the

button for a few seconds.

Indicates whether the gas valve is open or

closed.

5

Ofcine Gullo

52

Manual of Use

49

WP

O 17.2 C

E1 E2 E9 E11

g. 1

Number Type of Errore

1 fan 1 locked

2 fan 2 locked

fridge emergency stop over running status

E1

E2

E9

Gas bottle almost emptyE11

The error states are coded according to the following table:

Display number one on the machine will show error screens 1 at a time,

quickly and in sequence, after which the displays are sequenced at regular intervals between error and normal states, and the error screens

will disappear once the error is xed.

11.1 Error states of the system

In figure 1 we can see an example of the display when the dispenser is

in an error state and the corresponding error codes in the table below.

The first time the error is detected, the error screen will be displayed

on the dispenser for about 1 minute.

After inserting a card the system allows configuration work to be done

normally, and if the error is not resolved then it is displayed in 1-minute

intervals for about 10 seconds at a time so as to limite the visual impact

of maulfunction of the machine to the final customer.

53

Ofcine Gullo

50

12. Description of Menus

Main Menu

It is accessed by pressing "P" button in the top left, next to the display.

Index of menu functions in the display:

13. Main menu operations

13. 1. Calibrating

13. 2. Display Setting

• Disp Backlight

• Disp Contrast

• Disp bottle led

• Exit & Save

• Exit

13. 3. Wine Setting

• Glass volume 1

• Glass volume 2

• Glass volume 3

• Bottle Volume

• Exit & Save

• Select tap & Load

• exit

13.4. Fridge Setting

• Fridge C/F

• Fridge Defrost

• Fridge Evaporate

• Fridge Temp Left

• Fridge temp Right

• Fridge Power

• Reset Default

• Exit & Save

• Exit

Ofcine Gullo

54

Manual of Use

51

Come interagire con il display:

To enter the menu you must rst press the

key to activate the arrows and which

allow scrolling through the options. Use the

key to conrm a choice or enter a menu.

To scroll through the options in this menu

press these two side buttons

(•/•) together

simultaneously.

Use the

key in the lower left to enter a

function and use the and keys to select the desired paramenter.

To exit press the two side buttons

(•/•)

together simultaneously until EXIT is shown

and then press

key at the bottom left to

EXIT the menu and return to the previous

main menu.

0927 Calibrating 750

100 Mls

EXIT

0927 Calibrating 750

100 Mls

EXIT

OK

INSTALLATION

WINE

1.00$ 2.00$ 3.00$

0927 Calibrating 750

100 Mls

EXIT

By pressing the "P" on the upper left, you

enter the technical menu of the dispenser.

55

Ofcine Gullo

52

13.1 Calibrating

This function is used to calibrate the supply of the valves, allowing the

release of the perfect amount preset from the “Wine Setting”.

Calibrating Menu

LOAD

100Mls?

SAVE

EXIT

TASTE

NO

SI

(+ / -)

tap

da 1 a 8

13. Operation from the main menu

These features can be seen on the central display.

g. 1

or 1 to 4

Ofcine Gullo

56

Manual of Use

53

Operation

Press the "P" key on the top left and enter the Main Menu, then

press

, the key to activate the scrolling with the arrow keys and

select Calibrating

Once this function is selected, the center LED of each nozzle lights to

allow selecting which tap to work on (fig. 1).

Action Function

LOAD

It is used to load the liquid initially for

dispensing.

TASTE

It is used to dispense a calibration supply

which must be equal to 100ml. You must

use a graduated cylinder of measuring

cup accurately degraded in ml.

SAVE It is used to save the calibration parameters.

Exit Exit from the menu without saving.

To perform a Calibrating procedure use a bottle filled with

750 ml of water.

100Mls ?

If the supplied amount is equal to 100ml

confirm with the

key, If it is not, use

the and keys to enter the actual

amount dispensed as measured using your

desired measuring device and confirm by

pressing the

key .

Bevore performing the Calibrating make sure to insert the

bottle using the appropriate procedure

►

cap. 9.4

57

Ofcine Gullo

54

0927 Calibrating (2) 750

100 Mls ?

OK

-

+

Number Function

1

2

3

Once finished calibrating is important to SAVE, otherwise

the system will return to the previous parameters.

Dusing the LOAD and TASTE operations keep a measuring

cylinder under the nozzle because these transactions

involve the dispensing of fluid.

Base time for delivery of 100 Mls.

Residual volume left in the bottle.

The amount dispensed from the tap.

The TASTE operation must be repeated until the dispenser

supplies the exact quantity required (100 mls).

g. 2

4

Tap number currently being calibrated

Ofcine Gullo

58

Manual of Use

55

Operation

Press the "P" key on the top left and enter the Main Menu, press the

, key to activate the scrolling with the arrow keys and select Display

Setting.

Display Setting

Disp. Backlight

Disp. Contrast

Disp. Bottle Led

Exit & Save

Select tap

13.2 Display Setting

This function is used to set the functional parameters of the display

and lighting of the bottle compartment.

59

Ofcine Gullo

56

Option Function

Disp. Backlight

It is used to set the display backlighting

brightness.

Disp. Contrast

Used to set the contrast of the display.

Disp bottle led

Used to set the brightness of the bottle

lighting.

Exit & Save

Used to exit the menu and save the new

parameters.

Exit Exit the menu without saving

13.3 Wine Setting

This function is to set the portions of the inserted wine.

Wine Setting

Glass volume 2 Glass volume 3Glass volume 1

Select tap

tap

da 1 a 8

g. 1

Ofcine Gullo

60

Manual of Use

57

Wine Setting

Glass volume 2 Glass volume 3Glass volume 1

Select tap

tap

da 1 a 8

Bottle Volume

Exit & Save

1

Indicates the tap being modified.

Glass Volume 1

Used to set the volume of product

dispensed from button "1".

Glass Volume 2

Used to set the volume of product

dispensed from button “2”.

Glass Volume 3

Used to set the volume of product

dispensed from button “3”.

0927 tap 2 750

10 gr

EXIT

2

3

4

Operation

Press the "P" key on the top left and enter the Main Menu, press

the

, key to activate the scrolling with the arrow keys and select

Calibrating. Choose which tap to work with using the Select Tap &

Load function.

Option Function

61

Ofcine Gullo

58

Bottle Volume

Used to set the volume capacity of the

bottle (default 750 ml).

Exit & Save

Used to exit the menu and save the new

parameters.

Select Tap & Load

Used to select the dispensing tap on which

to perform the changes

Exit Exit the menu without saving

15.4 Fridge Setting

This function is used to set the parameters of the refrigeration system.

Operation

Press the "P" key on the top left and enter the Main Menu, press the

, key to activate the scrolling with the arrow keys and select Fridge

setting

The minimum portion is 10gr, below this threshold the

dispensiong option is set to o.

OPEN

When the option is set to OPEN, pressing

that button will dispense continuously

until the button is released

OFF

When the option is set to OFF, pressing

that button will not dispense any volume.

With the OPEN option, the portion is adjusted by the time

the button is depressed.

Ofcine Gullo

62

Manual of Use

59

Option Function

Fridge C/F

Used to set the temperature unit scale for

Celsius ( C° ) or Fahrenheit ( F° ).

Fridge Defrost

Used to set the defrost cycle frequency:

1 – light defrost ( 2 times per day)

2 – medium defrost ( 3 times per day)

3 – heavy defrost ( 5 times per day)

Fridge Evaporate

Used to set the evaporation time.

1 – low evaporation

2 – medium evaporation

3 – high evaporation

Fridge Temp. Left

(5/25 C°) Used to set the temperature of

the left compartment.

Fridge Temp. Right

Function not available

Reset Default

Used to reset the parameters to the default

state.

Exit & Save

Used to exit the menu and save the new

parameters

Exit

Exit the menu without saving

63

Ofcine Gullo

60

If the Fridge Temp. Left falls below the minimum

temperature that the machine can reach, the refrigeration

automatically turns off, displaying its status as OFF.

After making any changes remember to press Exit & Save

to send the new parameters to the refrigeration system.

After sending the new parameters, the compressor will

turn off and restart after 3 minutes. This is to allow for the

refrigerant to re-stabilize the pressure for a safe restarting

of the compressor.

Ofcine Gullo

64

Manual of Use

61

14. Maintenance and cleaning

14.1 Minimum qualication of personnel

Daily, periodic, extraordinary, and sanitatioin maintenance can be

performed by any unskilled operator.

Repairs must be performed by a qualied technician provided by an

authorized Wineemotion service center.

14.2 Daily maintenance

Clean the machine from the residues of wine with a soft sponge

and neutral detergents that do not aect either the stainless steel

or polycarbonate panels (front panel bottle display and front ditital

display).

Remove the grille as shown in the gure and remove the drip trays

underneath. Wash the trays and clean the interior cabinet of the

machine

Clean the wine suction tubes by immersing it in a container of water.

Thoroughly clean the dispensers to preserver the

quality of the wine.

65

Ofcine Gullo

62

14.3 Periodic manintenace

Clean the spouts and suction tubes of every bottle position for every

10 bottles consumed and no later than 20 days of operation, coinciding

with the wine bottle running out in that position. Perform the cleaning

with suitable detergents for food-grade equipment and wine, usually

citric acid.

It is a good idea to perform a cleaning before inserting a new bottle.

The cleaning is done in the following way:

→ a. Remove the bottle of wine and insert a bottle with 750ml capacity

containing a solution of water and 1 teaspoon or 20cc of cleaning

product provided by the supplier (

►

chap.19.1- SaniPack MP 100 in

packets o SaniKleen 512 i512 in containers of 500ml), with a ration of

20cc per 750ml of water.

→ b. Dispense the solution through the tap, waiting 10 to 15 seconds

between each pour and repeat until the solution is exhausted

→ c. Replace the bottle of cleaning solution with a 750ml bottle of

drinking water

→ d. Dispense the entire bottle of drinking water.

→ e. Replace the bottle of water with a bottle of wine and dispense

once to expel the last bit of water left in the suction tube.

Ofcine Gullo

66

Manual of Use

63

14.4 Extraordinary maintenance

Extraordinary cleaning should be done every 6 months for a perfectly

sanitized dispenser, using a disinfectant cleaner specic for enological

use and in the doses provided by the manufacturer. An optimal time

for such cleaning is during the changing of the bottles.

The procedure is as follows:

→ a. Replace the bottle of wine with a 750ml bottle containing a

solution of water and detergent to the extent provided by the supplier

(

►

chap.19.2- SaniKleen 512 ).

→ b. Dispense the solution through the tap, waiting 10 to 15 seconds

between each pour and repeat until the solution is exhausted.

→ c. Remove the bottle of wine and insert a bottle with 750ml capacity

containing a solution of water and 30cc of cleaning product provided

by the supplier (► chap.21.2- SaniKleen 512 ),with a ration of 30cc per

750ml of water.

→ d. Dispense the entire bottle of cleaning solution.

→ e. Replace the bottle of cleaning solution with a 750ml bottle of

drinking water

→ f. Dispense the entire bottle of drinking water.

→ g. Replace the bottle of water with a bottle of wine and dispense

once to expel the last bit of water left in the suction tube.

PERFORM AN INTENSE CLEANING BEFORE LEAVING

THE DISPENSER NOT OPERATING FOR A PERIOD OF

MORE THAN 3 DAYS.

PLEASE NOTE THAT THE USE OF SWEET OR

PARTICULARLY AGED WINES MAY CAUSE THE

FORMATION OF DEPOSITS IN VARIOUS DUCTS,

INTENSIFY THE CLEANING IN THIS CASE.

67

Ofcine Gullo

64

14.5 Troubleshooting notes

Problem Reason Solution

The machine does not turn on. The power button is off.

The power cord is not

connected.

Switch on the power button.

Connect the power cord.

Nitrogen is leaking. Gas cylinder connections are

loose.

Tighten connections.

The bottle is too short. Enter the shim between the

piston and metallic bottle

pusher cup.

The bottle is not correctly

inserted.

Check that the bottle

compresses correctly against

the seal pad of the dispenser.

Check the dispenser for leaks.

The wine dispensing is not

continuous

The gas cylinder is empty.

The pressure is low.

Replace the gas cylinder

Check the pressure.

The suction tube is not fitted

correctly

Insert the suction tube

correctly.

The suction tube filter is

blocked.

Remove the bottle and clean

the filter.

The machine is unable to reach

the correct temperature

There is insufficient air

circulation.

The fans are switched off.

The refrigeration system is not

working.

Check the machine has been

installed correctly, with the

required air circulation gaps.

Call technical support.

Call technical support.

Wine is dripping from the steel

tube of the dispenser

Wine sediments in the

dispenser.

Perform cleaning maintenance

with citric acid solution, as

described in the manual

Ofcine Gullo

68

Manual of Use

65

14.6 PPE required for maintenance personnel

All technicians performing repairs must wear protective equipment

for individuals, as dened under the Health & Safety At Work laws. In

particular, protective gloves and eye-wear are required.

14.7 Precautions for maintenance

These instructions are not intended for people including

children, with reduced physical or mental capacity, or

without the necessary experience and training, without

supervision or instruction by a person responsible for their

safety. Children must be supervised to ensure that they do not play

with the device.

69

Ofcine Gullo

66

When disposing of the machine, it is necessary to separate the plastic

and electrical components, which must be sent to separate waste sites

in accordance with local regulations.

Ordinary recycling can be used for the main metal body of the machine

as it is composed of steel, copper and aluminium.

Manufacturer:

WINEEMOTION S.P.A.

con sede legale in Strada di Sant'Appiano, 9/a

FOR

declares under sole responsibility that the product

DISPENSER AUTOMATIC FOR WINE model:

QUATTRO (WND040)

to which this declaration relates is in conformity with the

following standards:

15. Disposal of the machine

16. Declaration of compliance

Headquarters and factory

Via Della Torricella 29, Antella, Bagno a Ripoli

50012 Florence - Italy

Tel. +39 055 65 60 3324

+39 055 62 18 07

ofcinegullo.com | info@ofcinegullo.com

Ofcine Gullo

70

Manual of Use

67

-CEI EN 61000-3-2

“Electromagnetic Compatibility ” EMC. Part

3: limits. Section 2: limitations of voltage

fluctuations and flicker in low voltage supply

systems ( appliances with rated current <16A

per phase). File 4749 C

-CEI EN 61000-3-3 “Electro-Magnetic Compatibility” EMC

.Part3: limits. Section 3 limiting in voltage

fluctuation and of flickers in low voltage

feeding systems for appliances with nominal

current <16A . File 2650E

CEI EN 60335-1 modification A2, A13,

A14, A15, A16

“Household and similar electrical appliances

and similar”. General norm file n. 4196C

-CEI EN 50081-1 “Electro-Magnetic Compatibility” general

emissions standards Part 1:residential,

commercial and light industry environments.

File 3215 June 1997

-CEI EN 50082-1 “Electro-Magnetic Compatibility” general

immunity standards. Part 1: residential,

commercial and light industry environments.

File 4498 May 1998

Also declares that it conforms with the requisite Directives:

-Low Voltage Directive 2006/95 CE ( Directive: regulation concerning

the approach of State Members’ laws regarding the electric material

destined to be used within certain voltage limits)

- Electro-Magnetic Compatibility 2004/108 CE. (Directive regarding the

approach of State Members’ laws concerning about electro-magnetic

compatibility.

71

Ofcine Gullo

68

WE WARRANT that the Wineemotion Wine Serving Systems (the

Goods), models OTTO and QUATTRO, manufactured by Wineemotion

S.p:A. are sold and delivered to the Purchaser free from manufacturing

defects in materials and workmanship.

From the Installation Acceptance date Wineemotion (the Company)

undertakes that the Warranty shall cover free of charge to the Purchaser:

• the repair or replacement (at the Company’s sole discretion) of any

functionally inoperative PARTS that according to the Company’s

incontestable judgement, are deemed to be defective in workmanship

or materials because of a manufacturing defect detected within the

rst 24 months (excluding software);

• the diagnosis and elimination of any errors found in the SOFTWARE

programmes (provided that the errors are recurrent and documented)

by way of supply of new corrected versions of the software for the rst

6 months;

• the warranty shall include only the replacement of those defective

17. Garanzia della macchina

Also declares that it is formally conformed to all the Directives of the

MACHINES REGULATION CE 98/37as, following the comma 2 enclosed

1, the risk of the machine is to be considered MAINLY electric, therefore

is enough to full the above regulations 2006/95 CE// 2004/108 ce

Wineemotion S.p.A.

Strada di Sant'Appiano, 9/a

50021 Barberino Val D'Elsa

Firenze Italy

P.I. 06231920486

13_______________________

the last 2 digit of the year of production

Ofcine Gullo

72

Manual of Use

69

parts and shall not include LABOUR .

This is the Company’s entire liability in respect of such Warranty.

Wineemotion shall provide warranty services directly or through its

own authorised repair centres. Materials covered by warranty must

be sent to the Repair Centres free of charge for the manufacturer and

shall be sent back at the customer’s expense. Any parts replaced shall

remain the property of Wineemotion.

The Purchaser must save proof of the Installation Acceptance date as

detailed on the Installation Acceptance Certicate together with the

sales receipt or invoice stating the item numbers of the purchased

Goods. All claims for Goods under Warranty shall be forwarded to the

Company together with proof of the Installation Acceptance date and

a copy of this Statement of Warranty.

In the event that installation of the Goods is delayed by the Purchaser

for more than 1 month from the original date of delivery of the Goods

as requested by the Purchaser, then the Installation Acceptance date

shall be deemed to commence 1 month after the original date of

delivery of the Goods was requested. The Warranty only applies to the

original Purchaser of the Goods and is not transferable.

All Warranty service will be provided by the Company during normal

working hours.

Replaced parts become the property of the Company and repairs or

replacements do not extend the Warranty period. Any transportation

costs (including return shipment) associated with a Warranty claim will

be the responsibility of the Purchaser.

THE WARRANTY DOES NOT COVER any defect, failure or damage

arising from:

a) failure to follow normal operating procedures and instructions or

failure to ensure proper care, use and regular maintenance as outlined

in the documentation provided by the Company;

b) incorrect transportation, installation, removal or handling;

c) the eects of fair wear and tear, rusting or damage to varnish, enamel

or paintwork;

d) periodic general cleaning and any labour or part charges incurred as

a result of service in the nature of maintenance and support including

the replacement of consumable parts, house fuses or resetting of

73

Ofcine Gullo

70

circuit breakers;

e) incorrect storage or exposure to unusual or excessive environmental,

chemical, atmospheric, mechanical, electrical (including defective

house wiring or by operating the Goods on incorrect voltage or cycles

or uctuations or interruptions in the power supply) or thermal stress

during the course of installation or use;

f) any drawing, design or specication supplied by the Purchaser;

g) wilful or accidental damage, misuse, abuse or negligence;

h) any modication (whether by alteration, deletion, addition, repair or

otherwise) to the Goods by the Purchaser or any other unauthorised

persons unless the Purchaser has obtained the prior written consent

of the Company. If any such unauthorised modication is made, then,

without prejudice to the Company’s other rights and remedies, the

Warranty will be null and void;

i) the use of any spare parts that are not originals as supplied by the

Company;

j) if the original identication markings on the Goods have been

removed, defaced, or altered.

The Company will be under no liability under the above Warranty (or

any other warranty, condition or guarantee):

a) if the total price for the Goods has not been paid by the Purchaser

by the due date for payment;

b) for any indirect, incidental or consequential loss, damage, cost or

expense of any kind whatsoever, whether arising under an accident,

contracts tort (including negligence) or otherwise;

c) for compensation for any reasons whatsoever resulting from any

inoperative down time of the Goods including any loss of wine or

other beverage.

d) If the labels or marks are removed from the machines.

If a defect or failure of the Goods is found upon investigation not to be

the Company’s responsibility under this Warranty, the Company may

charge the Purchaser for all reasonable costs and expenses incurred by

the Company in the course of, or in consequence of, such investigation.

Without prejudice to the foregoing, the Company reserves the right to

charge for travelling time and incidental expenses incurred in respect

of attendance at your premises to investigate and rectify any problem

Ofcine Gullo

74

Manual of Use

71

18. Certications held by

SERIES 2 Dispensers

International:

CB

reported by you.

The Company’s obligations under the Warranty are contingent upon

the Company’s agents or servants being given full details of the defects

without delay and adequate time and access to the Goods during

normal working hours to rectify such defect. If the Company recties

the defect within a reasonable period of time then the Company will

have no other liability in any respect of, or arising from, such defect.

The above Warranty does not extend to parts, materials or equipment

not manufactured by Wineemotion S.p.A. in respect of which the

Purchaser will only be entitled to the benet of any such warranty

or guarantee as is given bythe supplier or service provider to the

Company.

WINEEMOTION S.p.A.

Amministratore Delegato

Riccardo Gosi

75

Ofcine Gullo

72

SaniPack MP 100 Solution sanitizing powder

Description

Water-soluble compound powder capable of generating a solution

of chlorine dioxide, formulated specically for the basic sanitization

of automated systems in dispensers of drinks intended for human

consumption. When used in accordance with the instructions, quickly

eliminates odours, biolms, microorganisms and fungi without

altering the avour of the drink. Although the product, in normal

concentrations, does not corrode metals, plastics, or rubber, it should

not be used for cleaning the exterior of the machine.

Appearance

Hermetically sealed silver sachet with easy opening.

Handling

Keep in the original container; open the bag immediately before

use; avoid exposure to heat; do not eat, drink or smoke during the

preparation of the solution.

Storage