Page 1

Minimini

Instruction manual

Before using the machine please carefully read the instructions

DOC. N. FM111000

REV. 01

ED. 10.2001

Page 2

INDEX

Chapter 1. Foreword

1.1. Introduction……………………………………………………………….. 1-1

1.2. Performances of packaging machine…………………………….. 1-1

1.3. Machine identification…………………………………………………. 1-1

1.4. Weight and dimensions of packed machine…………………… 1-3

1.5. Machine weight and dimensions…………………………………… 1-3

Chapter 2. Machine installation

2.1. Transport and positioning……………………………………………. 2-1

2.2. Environmental conditions…………………………………………….. 2-3

2.3. Electrical connections………………………………………………….. 2-5

Chapter 3. Machine adjustment and setting up

3.1. Adjustment………………………………………………………………… 3-1

3.2. Flap adjustment……………………….………………………………… 3-9

3.3. Film roll insertion………………………………………………………… 3-11

3.4. Installation of screened plate.……………………………………… 3-11

3.5. Roll holder adjustment………………………………………………… 3-13

3.6. Execution of 1^ film sealing………………………………………… 3-13

3.7. Fan exhauster connection and running….……………………… 3-15

3.8. Introducing the object to be wrapped…………………………… 3-17

3.9. Making up………………………………………………………………….. 3-17

Chapter 4. Limits and conditions in the use of machine

4.1. Max. packaging sizes…………………………………………………… 4-1

4.2. Items not to pack…………………….…………………………………. 4-1

Chapter 5. Film features

5.1. Films to be used…………………………………………………………. 5-1

5.2. Band A calculation………………………………………………………. 5-1

Chapter 6. Safety standards

6.1. Warnings……………………………………………………………………. 6-1

Chapter 7. Ordinary maintenance

7.1. Precautions for ordinary maintenance interventions………. 7-1

7.2. Sealing wire cleaning…………………………………………………… 7-1

7.3. Plastic film and other scrap removal……………………………… 7-1

7.4. Machine cleaning………………………………………………………… 7-3

7.5. Rubber and teflon replacement……………………………………. 7-3

7.6. Replacement of sealing wire.………………………………………. 7-5

7.7. Wiring diagram…………………………………………………………… 7-7

7.8. Spare parts………………………………………………………………… 7-9

7.9. Guide to find out animalies of functioning……………………… 7-11

7.10. Disassembling, demolition and elimination of residuals…… 7-17

Chapter 8. Guarantee

8.1. Certificate of guarantee………………………………………………. 8-1

8.2. Guarantee conditions………………………………………………….. 8-3

9.1. EC declaration of conformity………………………………………… 9-1

Page 3

Chapter 1. Foreword

1.1. Introduction

You have bought a machine with outstanding features and performance and we thank

you very much for your confidence in choosing it.

The MINIPACK System is unique in its own kind and has gained a worldwide success

with more than 50000 units operating in the field of packaging and wrapping. It is

handy, low-priced and protected by patents at home and abroad. The technological

concept underlining its design, as well as the components and materials used in the

manufacturing and testing process are the best assurance of proper operation and longlasting liability.

1.2. Performances of packaging machine

Thanks to its particular operating circuit, it can be used both as a sealing and shrinking

machine or as a plain sealing machine (sealing only).

In this case it is possible to pack the object in a soft bag without shrinkwrapping.

Technical grade or food grade films with thickness in the range of 15-50 micron can be

used. These products are manufactured and distributed by MINIPACK Torre S.p.A. The

film used in centerfolded execution can be micropunched or not when running through

the micropunches of machine itself. The machine can carry out up to 300 packages/hour.

1.3. Machine identification

In every communication with the Manufacturer, always

mention the model and the serial number specified on the

plate on the rear part of the machine.

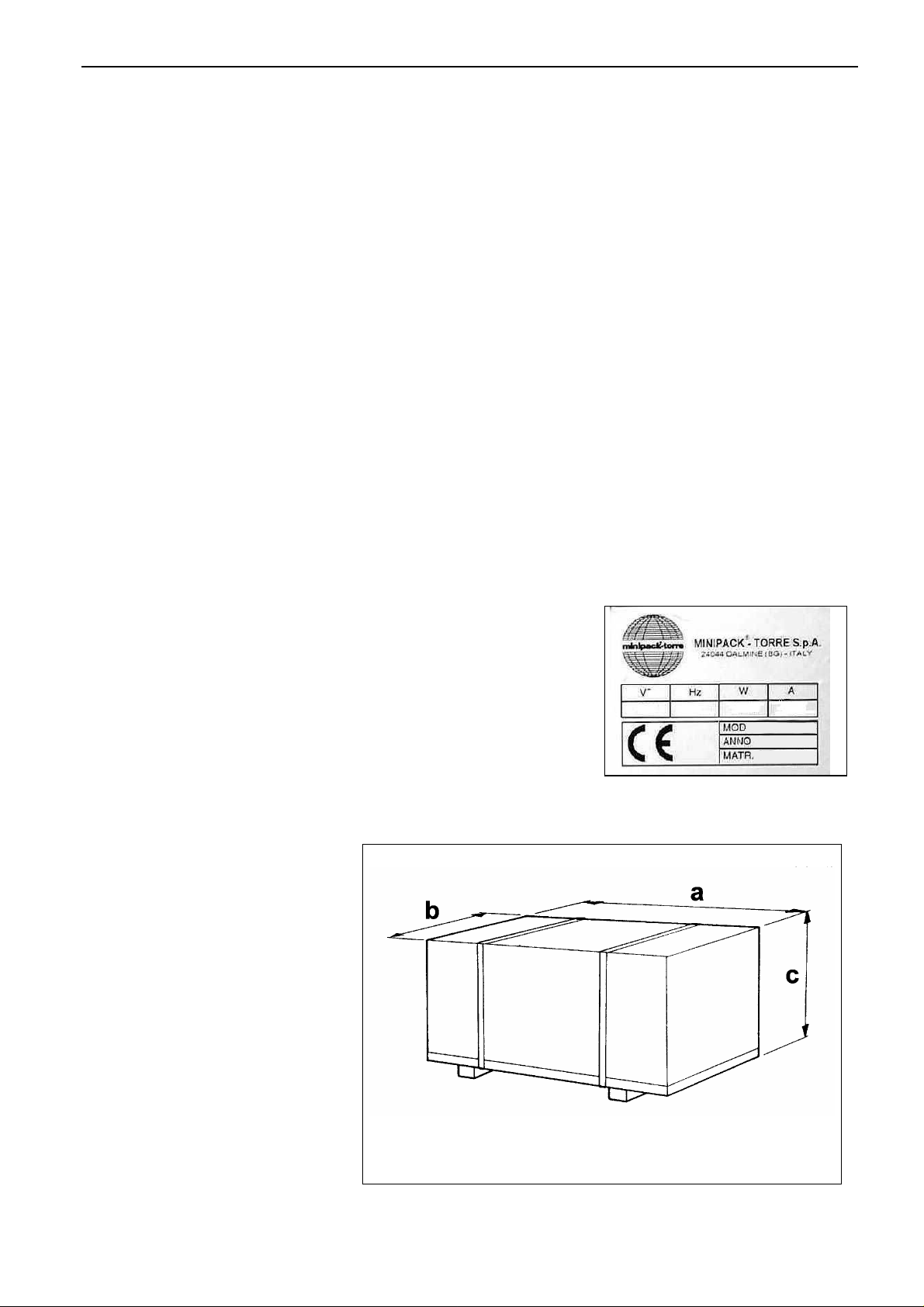

1.4. Weight and dimensions of packed machine

a = mm 900

b = mm 600

c = mm 500

Weight = Kg 33

Page 4

1.5. Machine weight and dimensions

a = mm 720

b = mm 530

c = mm 500

Weight = Kg 26

Chapter 2. Machine installation

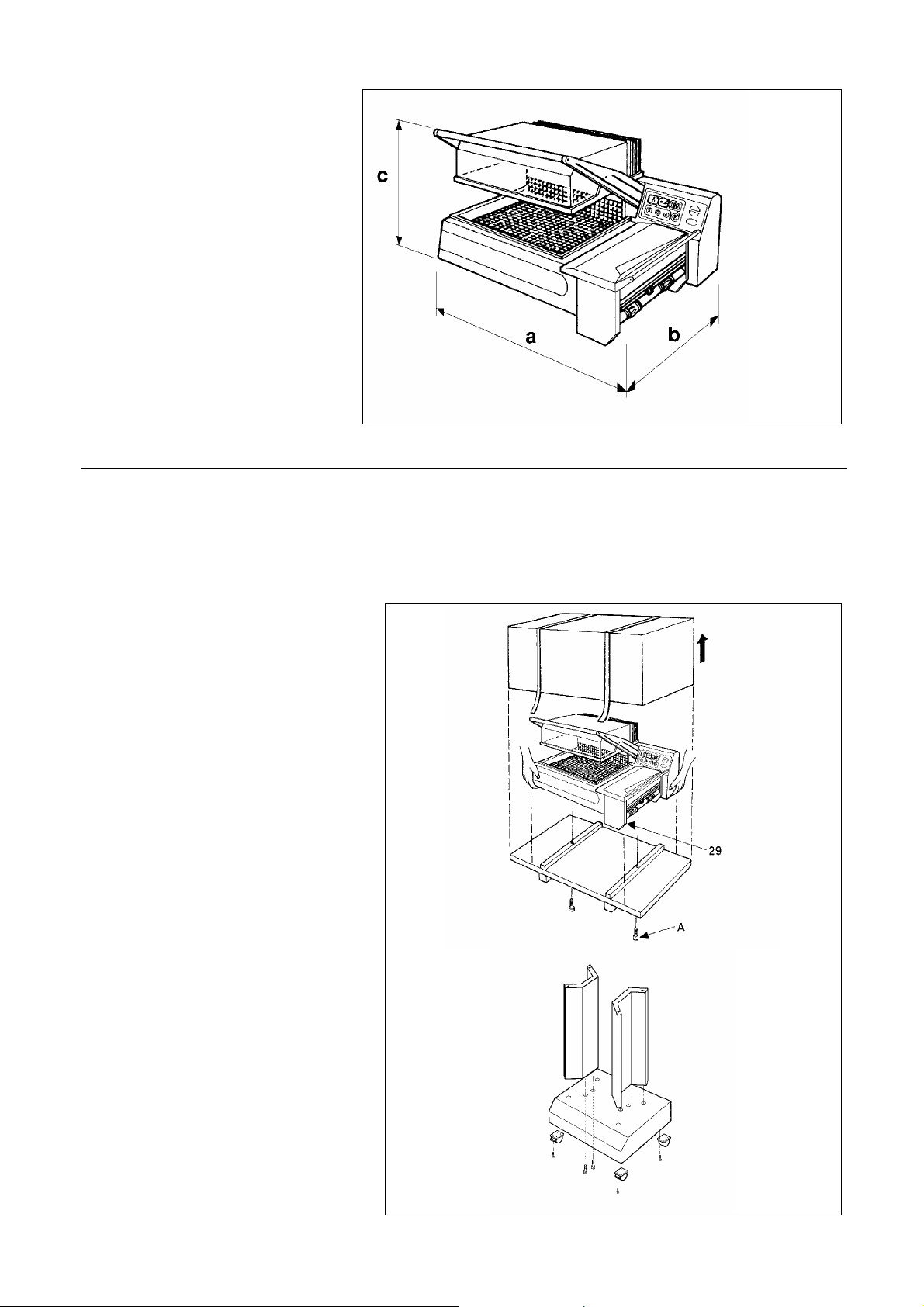

2.1. Transport and positioning

It is recommended to handle with great care during transport and

positioning!

• Cut the straps.

• Lift off the carton from above.

• Release the cover by cutting the

line holding it down.

• Unscrew the two locking screws

(A) from the bottom and

remove the machine from the

pallet.

• When lifting the machine,

always grip it by the ends (see

picture) and never by the roll

holder (29).

• Assemble the trolley (supplied

upon request).

Page 5

2.2. Environmental conditions

Working environmental conditions:

• Temperature from + 5°C to + 40°C

• Relative humidity from 30% to 90%,

without condensation

Machine safety factor = IP30

The aerial noise made by the

machine is lower than 70 dB

• Place the machine in a suitable area,

with no inflammable materials, gas or

explosives.

(If you have purchased the supporting

trolley, make sure the 4 feet fit correctly

in their seats when you rest the machine

on it).

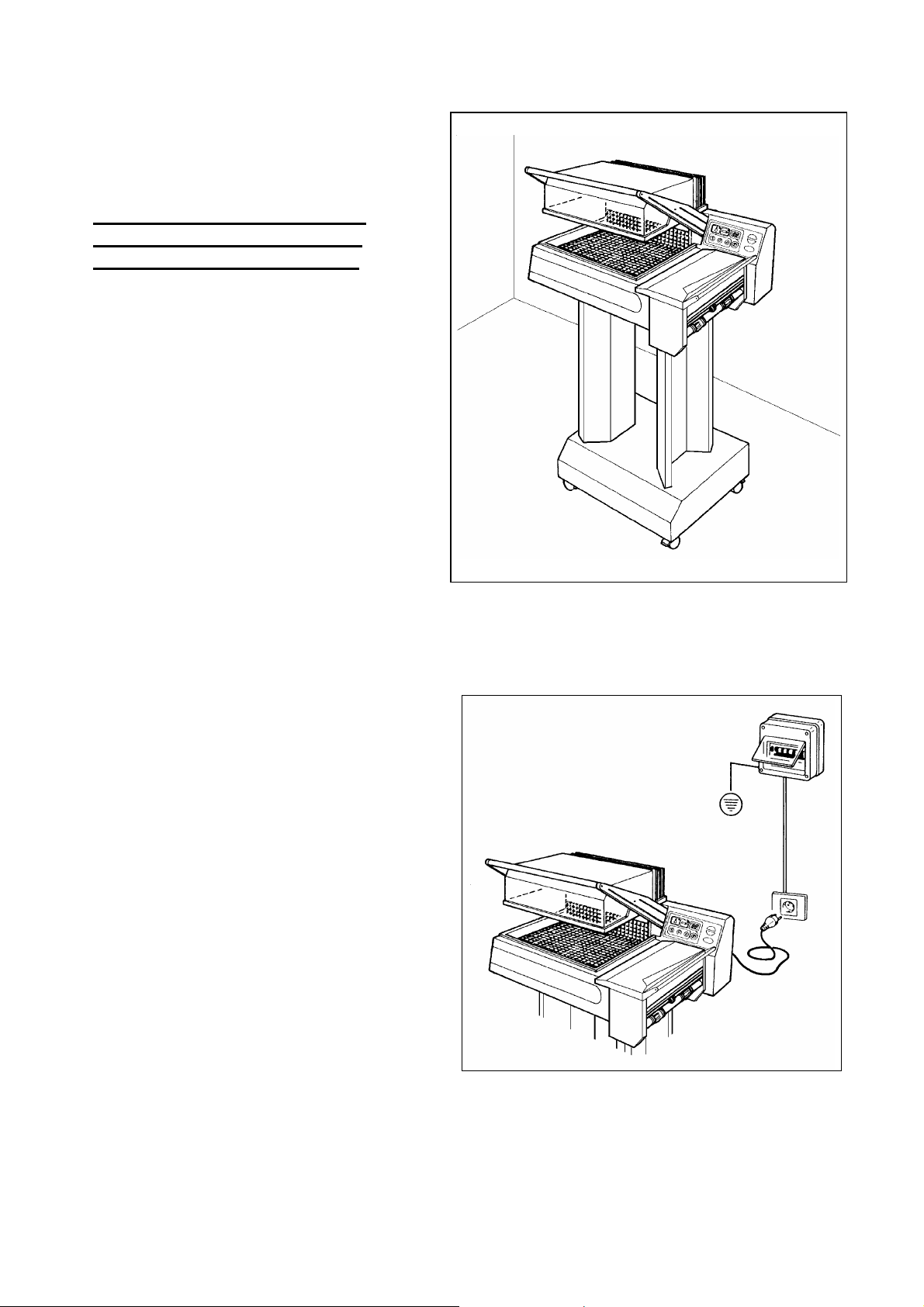

2.3. Electrical connections

OBSERVE HEALTH AND SAFETY REGULATIONS!

GROUNDING OF THE UNIT IS

MANDATORY!

Page 6

Before executing electrical connections,

make sure the mains voltage matches the

one on the plate on machine rear and that

the earthing contact complies with the

safety rules in force. In case of doubts

about the mains voltage, contact the local

public supply Company.

Chapter 3. Machine adjustment and setting up

3.1. Adjustment

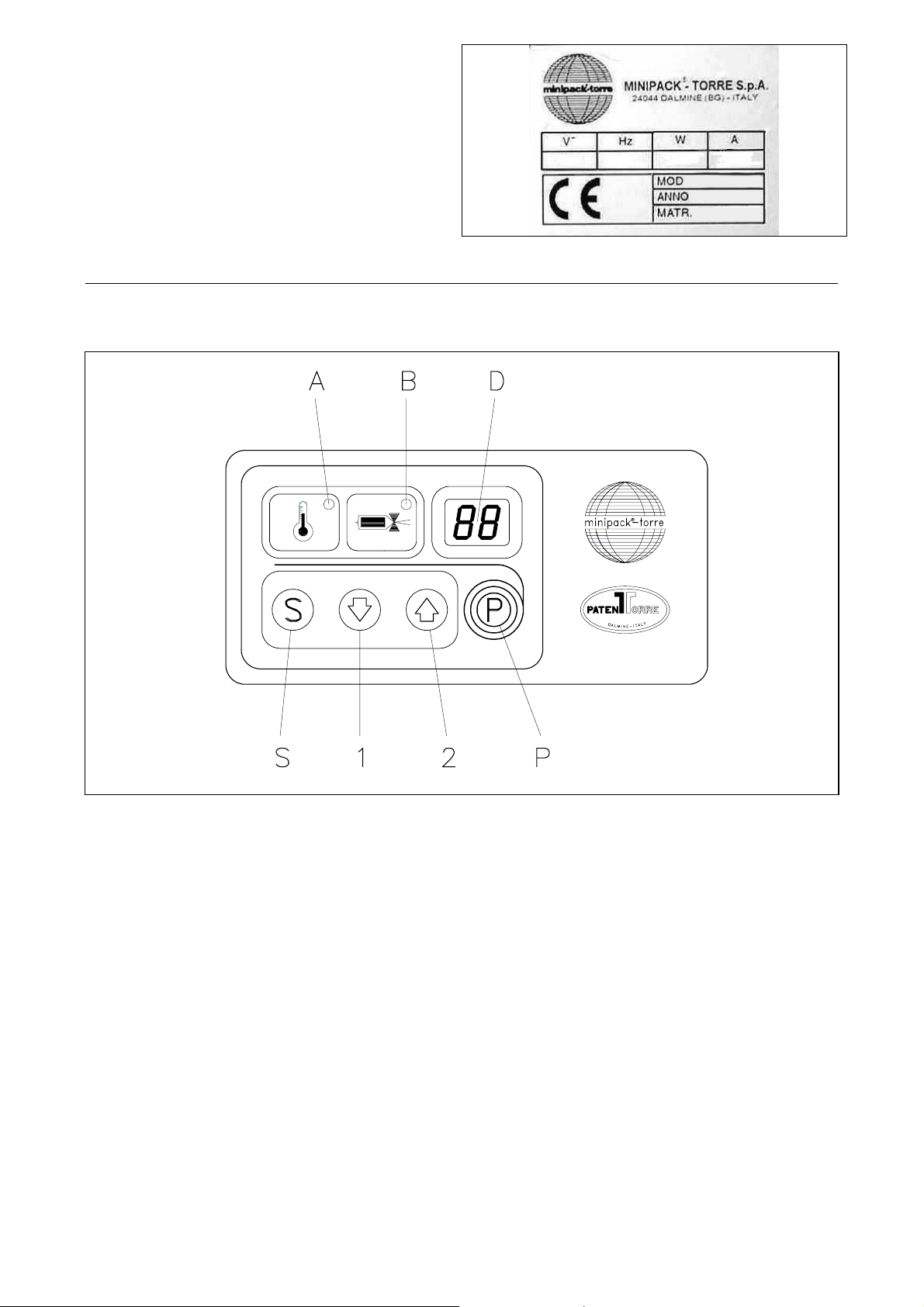

A Temperature warning light

B Sealing warning light

D Display

S Variables selection switch

P Program selection button

1 Adjusting button

2 Adjusting button

Page 7

3.1. Adjustment

ELECTRONIC BOARD FEATURES

The machine is equipped with 6 selectionable programs:

Program nr. Program features

P1

P2

P3

P4 - P5 - P6

Each program is composed by 3 variables which can be modified (in case it is not possible

to set one of them, such a variable will obviously not appear on the display) :

Variable Field Field features

1. Sealing

2. Fan delay after sealing

3. Temperature

PHASE NR.1 = SWITCHING THE MACHINE ON

Push the main switch (26) on the right hand side. The green LED incorporated in it will go

on.

Before using the machine, wait until the adjusting temperature is reached. This is

signalled by the warning light switching off (A). The heating chamber will get hot in about

10 min. The display (D) turns on and the number of the currently selected program will

appear.

PHASE NR.2 = PROGRAMS SELECTION

Push button (P) to select the number of the program.

PHASE NR.3 = VARIABLES PROGRAMING

Through button (S) it is possible to look through the variables of the selected program,

while through buttons (1) and (2) the memorized values can be modified. Once the value

has been set, push the S button and then release it; the LED of the next function will light

up. Set the value of the variables as previously described. To validate modifications,

presso button (S) until the number of the program appears on the display. The fan delay

time after sealing can be modified; there is not a LED indicating this variable which is

shown with an “r” on the left display, while the right one shows the time which has been

set. At the end of all variables to be adjusted, the display will show the code of the

program just chosen (for example P1).

N.B.: In case during programming the FC limit switch is being pressed, the unit quits the

scheduling, the selected program is executed and the display shows the number of the

program.

PHASE NR.4 = PERFORMANCE

Once all adjustments have been made, the machine is ready to start working.

Sealing only

Sealing + shrinking

Sealing + delayed shrinking to sealing end

Sealing + shrinking

0 ÷ 1,3

0 ÷ 9

0 ÷ 99

values expressed in seconds

values expressed in a tenth part of a seconds

corresponds to 120.....318°C (2°C each

point)-(medium value 75)

Page 8

In case of “ANOMALY” the display will show as follows:

E 1 Machine has been switched on when the hood was lowered. Lift the hood up.

E 2 Machine has been switched on when the (S) button was pressed. Release the

button. In case the error still persists, check the correct functioning of the button.

E 3 Working temperature hasn’t been reached in the set time (10 min.). Check the

correct positioning of the feeler. Check heater and fuses. Reset through (P)

button.

E 4 Temperature is higher than 380°C or feeler has been interrupted. Switch the

machine on to reset.

3.2. Flap adjustment

By adijusting screw (21) on the head of the

flap opening control rod, the size of the

opening can be set to obtain optimal outflow

of hot air.

3.3. Film roll insertion

Minimini machine

Insert film roll on the proper roller.

Position the roller on the film roll

support.

Run film through the micropunches

(28).

Move the film over the film drive

roller (19).

Run the film lower layer under the

packaging plate (18).

Run the film upper layer over the

packaging plate (18).

Page 9

Miniplus machine

Insert film roll on the proper roller.

Position the roller on the film roll

support.

Move the film over the film drive

roller (19).

Run film through the micropunches

(28).

Run the film lower layer under the

packaging plate (18).

Run the film upper layer over the

packaging plate (18).

3.4. Installation of screened plate

The screened plate (27) can be

placed according to the height of

the product to pack. To position it

follow this procedure:

1. Pull the screened plate in

direction of the arrows by

gripping it with both hands at

the openings located on the side

2. Remove it from the stops by

lifting it off at the bend

3. Position the plate on the stops at

the required height, proceeding

as described under (1)

N.B.: For a proper packaging the

screened plate must be positioned

so that film sealing is at the half

of the package height – See figure

2

3.5. Roll holder adjustment

The roll holder (29) must be

adjusted according to the width of

the item to be packed, leaving at

least 1cm between the item to be

packed and the sealing edge.

Page 10

3.6. Execution of 1^ film sealing

Place film as shown in the picture

to carry out the first seal.

Lower the handle of the cover

with your left hand and make a

pressure of 10-15 Kg. Machine will

automatically operate and the first

seal will be carried out on the side

of the film. With the right hand

detach the film from the sealing

blade. Film is now ready to carry

out wrapping.

3.7. Fan exhauster connection and running (where expected)

Install the fan exhauster (5) as

shown in the picture.

Insert the plug of the exhauster (6)

in the outlet (8) at the back of the

machine.

Press the button (7) at the back of

the exhauster.

Page 11

3.8. Introducing the object to be wrapped

Run the amount of film to contain

the product to be wrapped by

pulling it over the reticulated plate

with the left hand.

Slip the product into the bag

with your right hand (see

picture), and leave about 1 cm

between the product and the

inner sealing frame to allow air

passage for shrinkwrapping.

3.9. Making up

By pressing down the cover

handle with a pressure of about

15 kg, the hood will lean on the

teflon lining. Sealing is made on

the open sides of film (front +

right one). If You have chosen

the function “SEALING +

SHRINKWRAPPING” You will see

the film shrink onto the product.

Now slightly release the cover

handle to enable the film to

come away from the sealing area

on the inside. With the right

hand help to detach the film

from the sealing blades outwards

(see figure).

Page 12

Chapter 4. Limits and conditions in the use of machine

4.1. Max. packaging sizes

a = mm 350

b = mm 250

c = mm 100

Wieght = Kg 2

N.B.: max. dimensions shown on above scheme are referring to the max. dimension of

the single package.

Refer to chapter 5.2. to get max. dimension of package (b x c); the addition of (b + c) is

equal to film roll width 100 mm.

4.2. Items not to pack

The below listed products must absolutely not be wrapped to avoid damages to the

machine and seroius injuries to the operator in charge:

Wet and unstable products, liquids of any kind and density in

fragile containers, flammable and explosive materials,

pressurised gas cylinder of any kind, bulk and volatile powders,

bulk materials with grain size smaller than the holes of the

reticulated plate, any materials and products not listed but

which might harm operator and cause damages to the

Chapter 5. Film features

Machine can work with all

shrinkwrapping films with

thickness 15-25 micron

manufactured by ”MINIPACKTORRE S.p.A.”. The special

features of our films (which may

be manufactured with text and

drawings according to customer’s

needs) assure their outstanding

reliability, with regard both to

compliance with laws in force and

to an excellent machine

performance.

A = mm 350 MAX

D = mm 110 MAX

d = mm 40

machine.

Page 13

5.1. Films to be used

Band A = b + c + 100mm

Chapter 6. Safety standards

6.1. Warnings

Do not touch the sealing wire (23)

soon after sealing by reaching

beyond the safety guard.

Danger of burns due to

residual heat on the sealing

blade.

Do not keep on sealing in case the

sealing wire breaks (23).

Replace it at once.

Page 14

• Do not touch the chamber closing flap (22) during warm-up function. Danger of

burns.

• Do not touch the fan while moving or using the machine without the reticulated

plate (27).

• Make sure that the roll of film is properly lodged (30).

• In case the unit is installed on the special wheeled stand, make sure that the

rubber feet (35) are completely inside the housings of the wheeled stand.

• Make sure the heat chamber flap’s moving rod (21) moves freely.

ATTENTION !

• Every time you turn the machine off, it is recomended to leave the upper hood

open (as shown in the drawing).

Chapter 7. Ordinary maintenance

7.1. Precautions for ordinary maintenance interventions

BEFORE PROCEEDING TO MAINTENANCE, SWITCH THE MACHINE OFF AND

DISCONNECT IT BY OPERATING ON

THE MASTER SWITCH.

Page 15

7.2. Sealing wire cleaning

Using a dry cloth, wipe off the

residues clinging to the sealing

wire: do this at once after

sealing since they are

easier to remove when still

warm. Periodically lubricate the

sealing wire with the supplied

non-adhesive spray.

7.3. Plastic film and other scrap removal

Wait for the machine to cool down

completely before removing any

scraps stuck to the hot parts of the

machine (e.g. , on the flaps of the

heat chamber). If the lower cover

requires cleaning (where the fan is

installed), remove the reticulated

plate and take out any pieces that

may have fallen inside.

For a more careful cleaning of

the lower bell we recommend to

use a vacuum cleaner.

7.4. Machine cleaning

Use a cloth moistened with

water for machine cleaning.

For cleaning the hood inside and

outside we recommend to use a

normal detergent for glass

cleaning.

Do not use any detergents with

solvents which could damage

the hood and reduce the

transparency.

Page 16

7.5. Rubber and teflon replacement

When the Teflon-unings (24) are

worn out, replace them with

spare parts, paying attention that

the application is linear and even.

Before applying the Teflon selfadhesive strip clean the rubber

part (31) with a detergent.

If the rubber (31) is also

damaged, replace it as follows:

Remove the old rubber, clean

its housing, apply some drops

of glue in the housing, insert

the new rubber in a linear way,

clean the rubber with a

detergent, apply the selfadhesive Teflon-strip.

7.6. Replacement of sealing wire

Page 17

In order to change the sealing wire, proceed as follows:

• Push the pistons (32) all the way in using a screwdriver

• Block the tension spring by thrusting a pin (34) in the holes provided

• Using the setscrew wrench supplied, unscrew the 3 screws (33) which fasten the

wire at the centre and at the two ends so as to release the sealing wire (23)

• Replace the sealing wire (23) and tighten the locking screws (33)

• Remove the pins to enable tensioning the wire

• Make sure the sealing wire (23) is in the proper position and under the right

tension

7.7. Wiring diagram

LEGEND:

IG Main switch LST Cutting and sealing blade

IV Ventilator switch FC Hood limit switch

MV Ventilator motor TC Thermocouple

M Fan motor UCC Monitoring and control unit

R Heating resistance F1 Fuse (T 6,3A 250V X 230V/ T 10A 250V X 110V)

TR Transformer F2 Fuse (T 6,3A 250V X 230V/ T 10A 250V X 110V)

Page 18

7.8. Spare parts

CODE ITEM NAME

01 FE385611 Teflon-coated sealing wire

02 KR050001 Lower hood teflon kit

03 KR050012 Film roll support kit

04 KR050013 Micro-perfortator support kit

05 KR050004 Upper hood kit

06 KR050005 Spring + tie-rod kit

07 KR050007 Neoprene rubber kit

08 KR050008 Pistons + spring kit

09 KR050009 Microswitch kit

7.9. Guide to find out anomalies of functioning

PROBLEM CAUSE OF THE

PROBLEM

Temperature too high

for the film being

used

The machine

seals but film is

not

shrinkwrapping

The fan will not

Heating chamber flap

PROBLEM CAUSE OF THE

Heat sealing

occurs but is

not uniform

and

incomplete

The product to be

The film used has no

Failure to seal The sealing temperature

The sealing blade is

The electronic board is

Temperature too low Check the temperature set in the

rotate

isn’t opening

PROBLEM

Usuitable or poor quality

film

packed is too large, fully

close the reticulated

plate

pinholes and the air

cannot escape

is too low

unpowered

faulty

POSSIBLE REMEDIES

Insert the temperature value and adapt in

to the film being used

program. If this is already at maximum,

the reason is to be found in defects in the

electronic board or breaks in the internal

resistance. Contact the assistance service

This is a fault in the eletronic board or a

failure of the fan motor. Contact the

assistance service

Check the position of the adjusting screw

(see par. 3.2)

POSSIBLE REMEDIES

The type of film used must be of shrinkwrapping type. The lomgitudinal and

transverse shrink-wrapping indices must be

equal and between 40% and 50%

inclusive. It is recommended to use film

supplied by the manufacturer

The dimensions of the product must

always be less than those of the reticulated

plate

Move the film across the machine’s

pinholes

Increase the sealing temperature in the

program

Check the blade contacts and verify its

condition; if it is broken, replace it or

contact the assistance service

Contact the assistance service

Page 19

PROBLEM CAUSE OF THE

PROBLEM

The seal

splits during

shrink

wrapping

Sealing blade dirty or

Teflon strikers (24) worn Replace the Teflon

Insufficient pressure on

The film used has good

Should the machine still not operate correctly after the above checks have been made,

contact the assistance service giving an exact description of the fault encountered.

7.10. Disassembling, demolition and elimination of residuals

Proceed as follows:

1. disconnect machine from power mains

2. disassemble components

All wastes must be treared, eliminated or recycled according to their

classification and to the procedures in force established by the laws in force in

the country the equipment has been installed.

Sealing temperature too

high or not suitable for

the type of film used

damaged

the cap bandle

shrink wrapping

properties but poor

sealing ones

ATTENTION!

All operations about disassembling and demolition must be done by

qualified personnel with mechanical and electrical expertise required to

work in security conditions.

POSSIBLE REMEDIES

Adjust the sealing time in the program

Clean the sealing blade, check that it

properly rests on the Teflon stiker (24)

and replace if necessary

Slightly increase the pressure on the cap

handle during sealing

Replace the film. Use of films supplied by

the manufacturer is recommended

Page 20

Chapter 8. Guarantee

8.1. Certificate of guarantee

Model and Serial Number:

Equipment manufactured by minipack-torre is warranted to be free of defects in parts and

craftsmanship for a period of one (1) year from the date of installation, or 15 months from the

invoice, whichever occurs first, minipack-america's exclusive obligation under this warranty

is limited to repairing or, at its option, replacing any minipack-torre part that is determined by

minipack-america to be defective. The warranty is for the original purchaser of new equipment.

Component subsystems manufactured by minipack-torre carry the warranty as stated herein.

The warranty does not apply to subsystem component parts which are not manufactured by

minipack-torre. Subsystem component parts not manufactured by minipack-torre shall be

subject to any warranty of its manufacturer.

This warranty shall not apply to damage resulting from installation, modification, or repair by

anyone other than a minipack-america authorized distributor/dealer. Nor shall it apply to any

equipment which has been subject to accident, alterations, neglect, misuse or improper

maintenance.

In the event of highly corrosive or high moisture applications, special protective coatings or

stainless steel construction might be needed.

minipack-torre and minipack-america shall not be liable if minipack-torre equipment or

components are used with accessory equipment not manufactured by minipack-torre.

Representations and/or warranties, by whomever made (even if made by minipack-america

authorized distributors/dealers), which are inconsistent with the terms herein shall not

constitute a term of the mininpack-torre or minipack-america express warranty and shall not be

binding on minipack-torre or minipack-america.

THE LIMITED WARRANTY SET FORTH ABOVE IS THE SOLE AND ENTIRE

WARRANTY PERTAINING,TO THE PRODUCT AND IS IN LIEU OF AND EXCLUDES

ALL OTHER WARRANTIES OF ANY NATURE WHATSOEVER, WHETHER

EXPRESSED, IMPLIED OR ARISING BY OPERATION OF LAW, INCLUDING, BUT

NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY DOES NOT COVER OR

PROVIDE FOR THE REIMBURSEMENT OR PAYMENT OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY TYPE, MANNER OR DEGREE, AND ANY

LIABILITY BY MINIPACK-TORRE OR MINIPACK-AMERICA FOR SUCH

INCIDENTAL OR CONSEQUENTIAL DAMAGES IS HEREBY DISCLAIMED. Some

states do not allow this exclusion or limitation of warranties and/or damages, so the above

limitations and/or exclusions might not be applicable to you. This warranty gives you specific

legal rights, and you might also have other rights that vary from state to state.

Loading...

Loading...