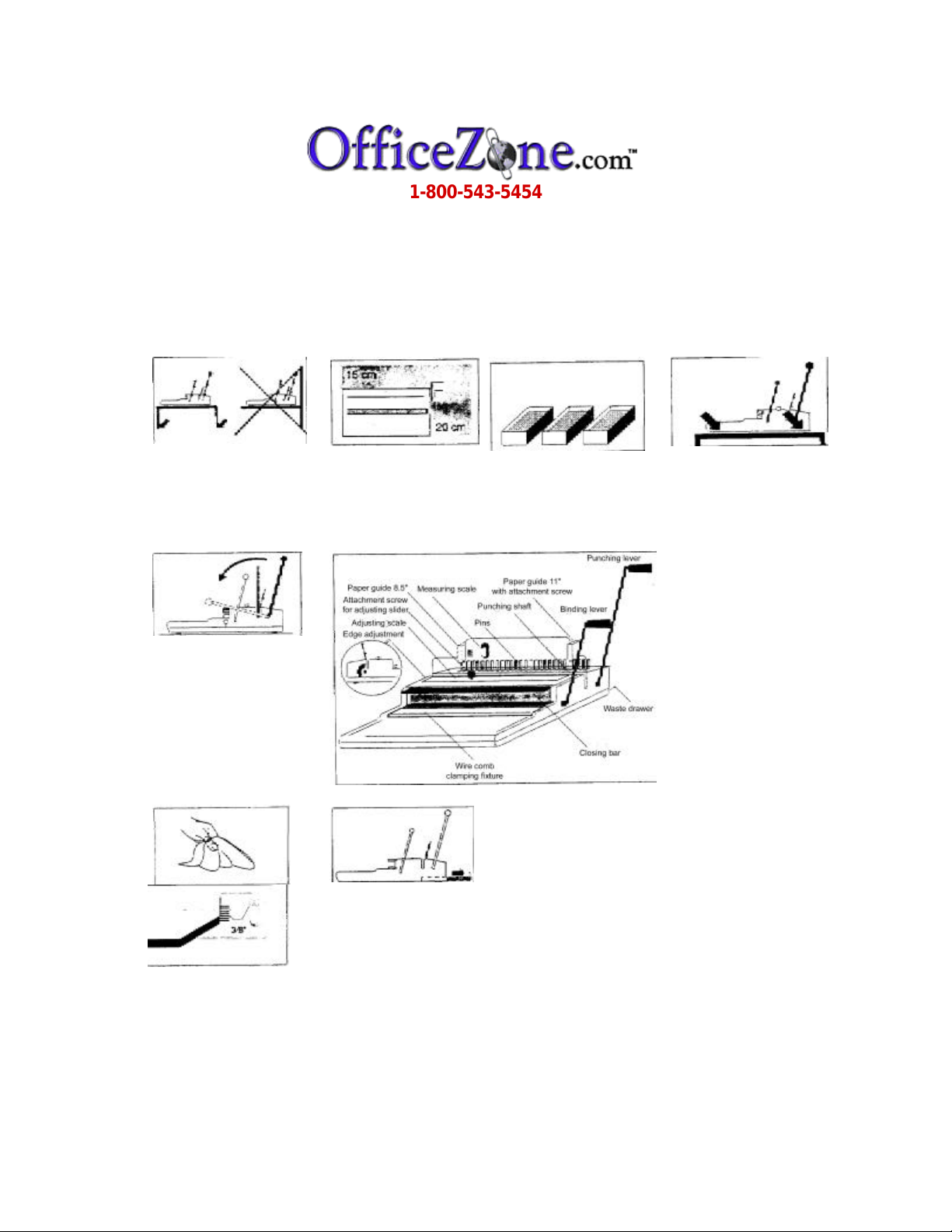

Officezone ECO-S Punch & Binding Machine 2:1 Pitch, ECO-S Punch & Binding Machine Operation Manual

Page 1

1

Set up

Office Zone

1-800-543-5454

1-800-543-5454

(801) 927-3026

Model ECO-S Punch and Binding Machine

2:1 Pitch

Operation

Maintenance

The machine

and the parts

1

Measure

Choose stable surface

Place machine on a stable

surface.

Shelves are not recommended.

Before first use:

Punch scrap paper to clean the

rust preventative from the

punch dies.

Place requirement.

Keep working space free:

Right 8” (20 cm)

Left 6” (15 cm)

Have binding elements near

work area.

Store binding elements in the

special boxes.

Size: 24 x 36 cm

9.5” x 14.2”

Protect sensitive furniture surface.

The machine stands on soft plastic feet.

Some surfaces may discolor after a

time.

Field of application:

Punch:

Paper:

Max 30 pages 20 # stock for

comfortable punching:

15-20 pages

Cardboard

Max thickness 1.5 mm

Plastic Foil

Max 2 pages for 0.3 mm thickness

Max. binding thickness 28 mm (1-1/8”)

Approx. 280 pages 20 # stock.

Determination of the diameter

Put the back on the edge against

the measuring scale.

Read the diameter of the binding

element (e.g. 3/8”)

Page 2

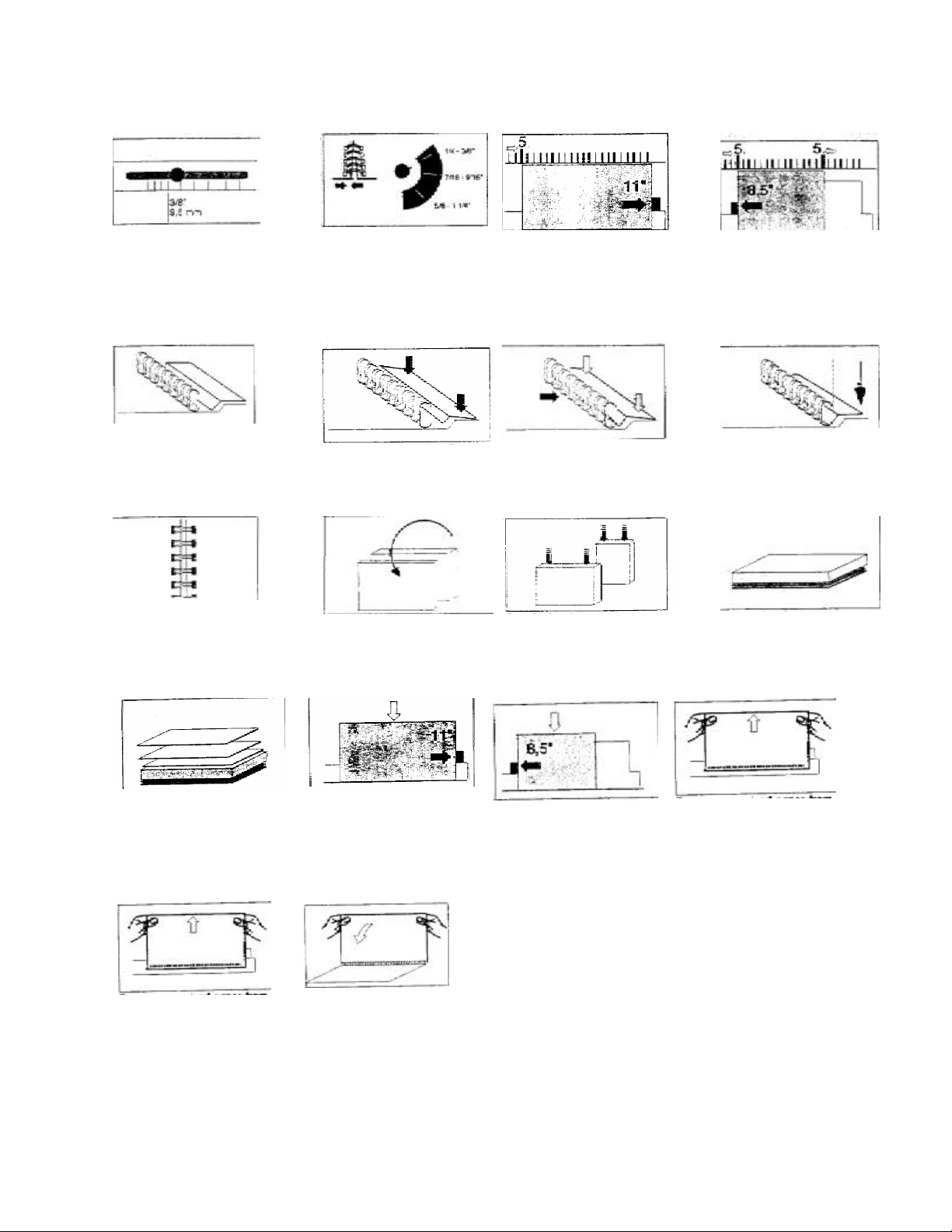

2

Adjust

3

Insert

4

Prepare

5

Punch

Scale for adjusting the diameter

Release attachment screw, determine

scale, adjust diameter, tighten

attachment screw

Lay binding element in front of the

clamping fixture

Small loops on top, facing rear.

The seam of the closed binding

element should be inside the book

Not outside the covers

Adjust distance edge to

according diameter turn knob

Turn knob index to the

according diameter (e.g. 3/8”)

bigger 0 – bigger edge.

Press down clamping fixture

Press back edge and front side

will open.

Set the book upright, binding

side to the top, place the back

cover in front

The front cover should be

behind the back cover.

Adjust format 11” Paper guide right

Pull pins

Screw down the right paper guide, pull

5 pins from left (21 loops).

Adjust format 8.5” Paper

guide left

Pull pins

Screw down the left paper

guide, pull 5 pins from left

and 5 pins from the right (16

loops).

Push binding element under the

clamping fixture.

Clamping fixture holds binding element

during insertion of the punched paper.

Jog the book Turn the book over, covers are

Release clamping fixture

possibly adjust binding

element vertically.

underneath

Take pages from the top

Adjust 8.5” format at the left

side.

For thicker books, repeat steps five and six until all pages are

Press punching level forward

until it stops, then return to

original position.

Hold the machine with the other

hand.

punched.

6

Insert

Punch max 30 pages 20# stock,

for comfortable punching: 15 –

20 pages

Punch plastics and thicker covers

separately.

Remove punched paper from the

punching slot.

Insert paper into punching slot,

slide the paper against the paper

guide

Adjust 11” format at the right

side, paper must stand evenly, if

not align it again

Insert paper onto the binding

element

Page 3

3

7

Adjust

8

Close

9

Ready

Press clamping fixture After the paper had been placed

Press binding lever forward until

it stops and back again

For bigger diameters use more

force.

on the binding element, remove

the paper with the element from

the clamping fixture.

Hold the paper that it does not

slide out of the binding element.

Proper bind Binding under closed:

Turn back cover over Ready

Put binding element under the

closing bar.

Adjust closing bar a little deeper

Release attachment screw and

move it slightly to the left. Fix

attachment screw. Press binding

lever again.

Binding element must stand

vertically at the back of the

closing bar

With opening of the binding

element to the book.

Binding over closed:

Adjust closing bar a litter higher

Release attachment screw and

move it slightly to the right. Fix

attachment screw. Close next

book.

Page 4

4

Page 5

5

Loading...

Loading...