Page 1

1

Office Zone

1-800-543-5454

1-800-543-5454

(801) 927-3026

Model 912

Cutsheet Signer

By Martin Yale

Installation, Operation and Maintenance Instructions

Model 912 Specifications

FUNCTIONAL

Paper Weight.…………………………..16 to 70 lb bond

Paper Width.. ………………………………2-3/4” to 14”

Paper Length………………………………..2-3/4” to 14”

Continuous Feed Load Capacity…………………..1 -3/8”

Speed………………………8,400 (3-1/2”) form per hour

Signature Spacing……………….2-1/2” W x 1-3/8 H area

Anywhere on the document

Optional……………………………….…Signature Plates

PHYSICAL

Color………………………………………………..Grey

Dimensions.………………..29” W x 12” H x 19 -1/2” D

(plus receiving tray)

Weight……………………………………66 lbs. (30 kg)

Shipping Weight…………………………73 lbs. (33 kg)

ELECTRICAL

Power……………………….110 / 120 VAC, 50 / 60 Hz

Optional…………………….220 / 240 VAC, 50 / 60 Hz

Fuse………………………..2A (1A for 220 / 240 VAC)

Introduction………………………………….

Features…………………………………..

Nomenclature…………………………….

The control panel………………………..

Installation……………………………….

Programming……………………………

Operation……………………………..

Troubleshooting………………………

Maintenance…………………………

Diagnostic Tests………………………..

Error Message Explanations…………….

Parts Diagram…………………………..

Parts List……………………………….

Wiring Diagram………………………..

SERIAL NUMBER ________________

Table of Contents

Introduction

Thank you for selecting the Martin Yale Model 912 Cutsheet Document Signer /

Imprinter. This programmable electronic signer was designed to provide a high level of

security, operational flexibility and easy programming. Each signer component has been

engineered to perform reliably and is 100% factory tested to ensure years of quality

service.

Page 2

2

We recommend that you familiarize yourself with the signer by carefully reading this

manual. Reading and thoroughly understanding this manual will help you avoid the most

common problems and eliminate operator -associated errors. Remember, signature plates

cannot be manufactured for every application they must be custom made. Therefore,

signature plates must be ordered separately. If you did not order signature plates when

you ordered your 912, do so now by calling your dealer.

Warning – Never connect power to the machine until you are ready to set up and

operate the 912. This machine contains moving parts. During setup, operation, and

maintenance keep hands, hair, loose clothing and jewelry away from all moving

parts. Serious bodily injury could result. Service, or disassembly of covers should

only be performed by qualified personnel with the power disconnected and locked

out.

Features

1. Security

a. Five-digit security codes at one or two levels guard against unauthorized usage.

b. Cover lock restricts access to signature plates until executive security codes in entered.

c. Executive control of batch quantity is optional for each run.

d. Lock key required to reprogram security codes and stored setups

e. Standard tri-colored ink roller (red, blue and purple).

2. Convenience

The Martin Yale Model 912 Cutsheet Signer is a table top office appliance that will sign

or imprint messages on checks and a wide variety of documents. Customized signature

plates are easily ordered and installed. Signature locations are entered by jogging the

document to reference line on the 912. No form measurements or calculations are

necessary. Signature locations and batch control are easily entered or selected from five

stored setups. Variable signature placements, electronically controlled, can be easily

adjusted during a run. Long life pre-inked roller is spring loaded for easy removal and

quick access to signature plates.

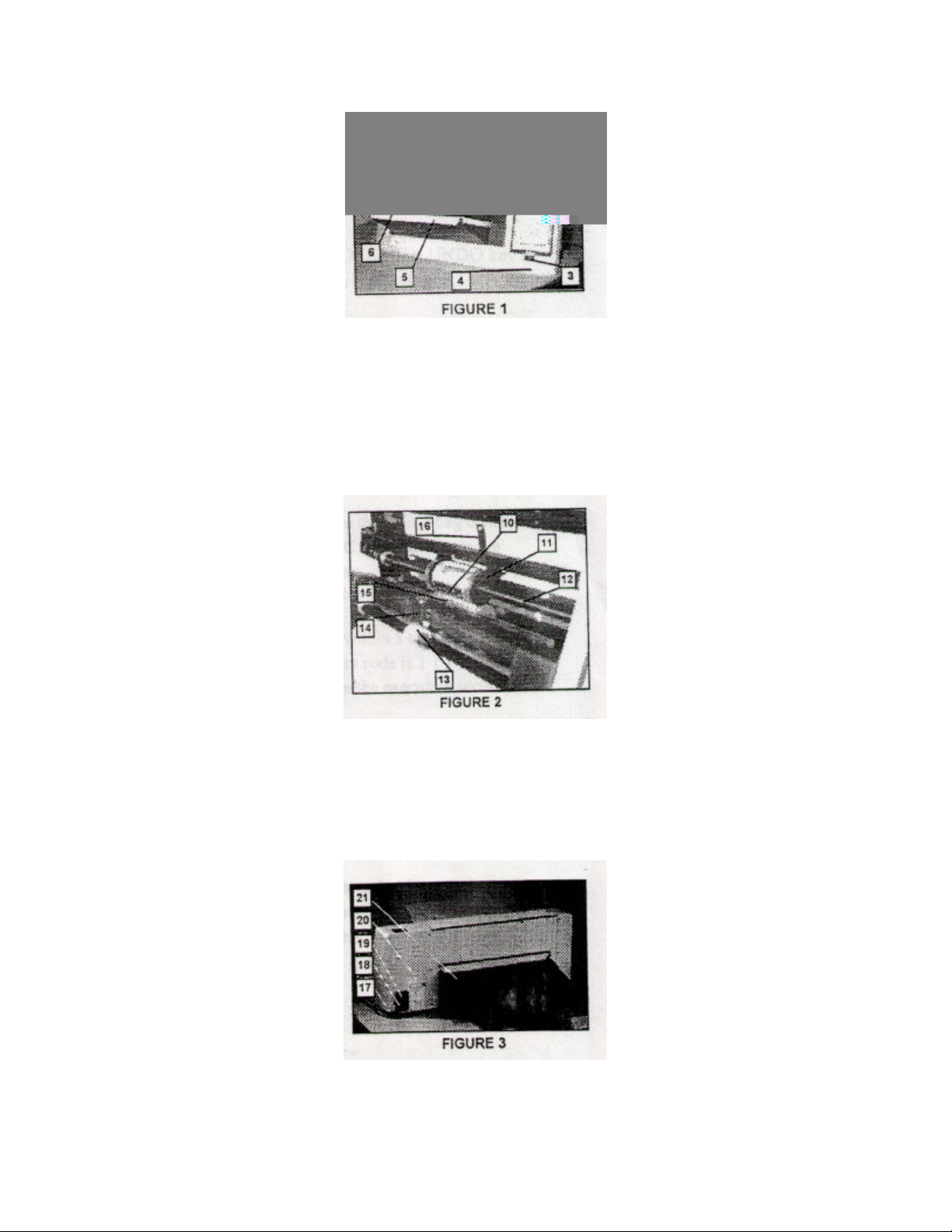

Nomenclature (see figures 1, 2 and 3)

1. Ink Rollers – is saturated with fast-drying permanent ink and rotates freely on the ink roller shaft.

The ink roller guide holds the ink roller in position. The ink roller shaft is spring-loaded into

floating brackets.

2. Control Panel – has a 20 -character by 2-line display at the top and a keypad below.

3. Power Switch – has international symbols. 0 for OFF and | for ON.

4. Bezel – durable, flame -retardant ABS

5. Feed Table – supports the document to be signed

6. Paper Guides – maintain document alignment during feeding

7. Bracket – one each side supports the ink roller shaft

8. Ink Roller Adjustment Screw – one each side, determines the amount of contact between the ink

roller and signature plates.

9. Cover Lock – one on each side of the cover

Page 3

3

10. Signature Plate Holder – clamp is spring-loaded for easy installation and removal of signature

plates.

11. Idler Wheels – a pair of rollers that feed the paper after the paper leaves the drive rollers.

12. Signature Plate Shaft – supports and drives the signature plate holder

13. Feed Roller – feeds the document from the bottom of the stack into the drive rollers one at a time.

14. Retarder – adjusts to allow only one document to feed at a time

15. Platen – supports the paper during impression

16. Idler Tension Spring – puts tension on the idler disc.

17. Line Cord – connects the signer to the AC power source.

18. Fuseholder – contains the replaceable power fuse

19. Key Switch – is used only to program the security codes and the stored setup parameters.

20. Serial Label – shows the serial number, electrical ratings, and agency approvals.

21. Receiving Tray – catches the signed documents. The backstop adjusts to different document

lengths.

Page 4

4

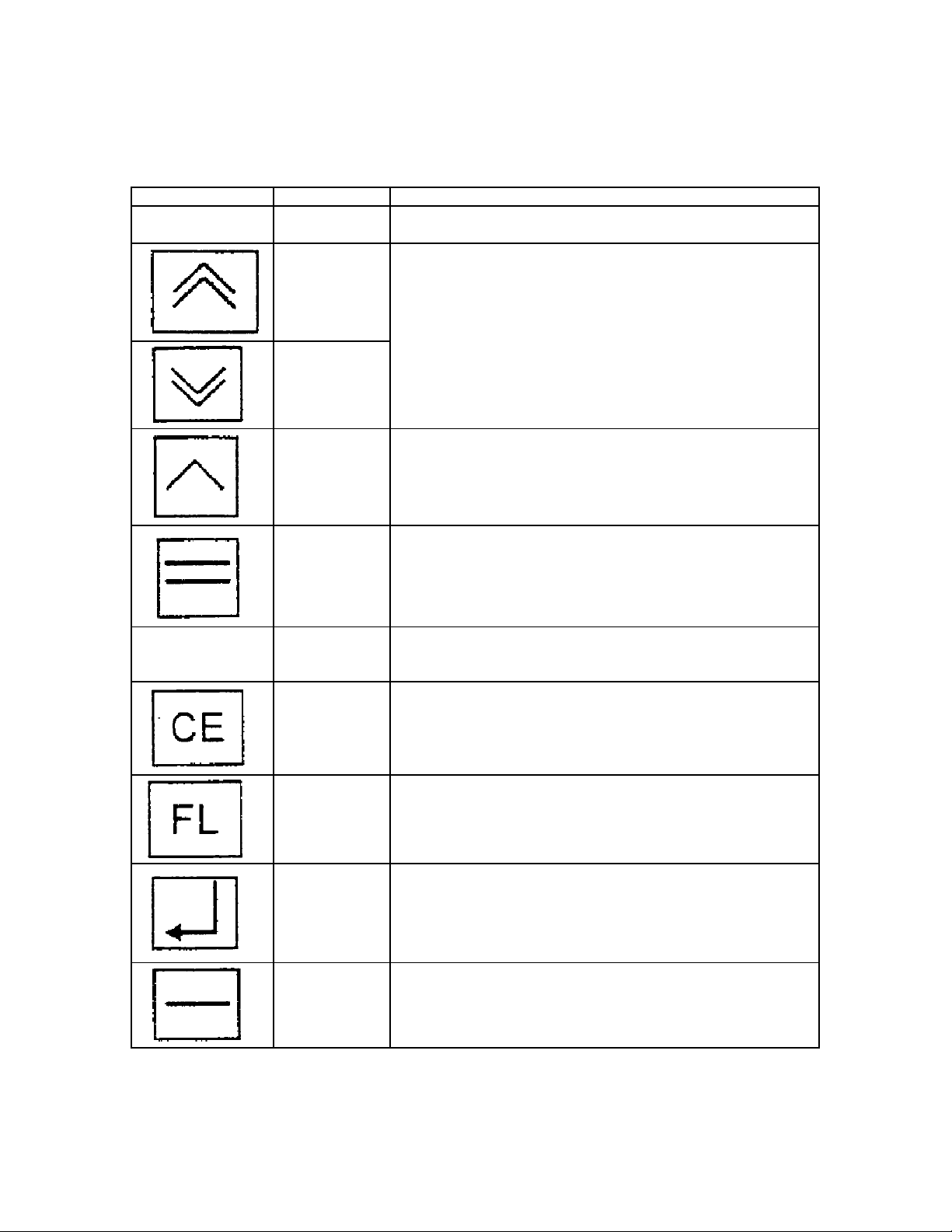

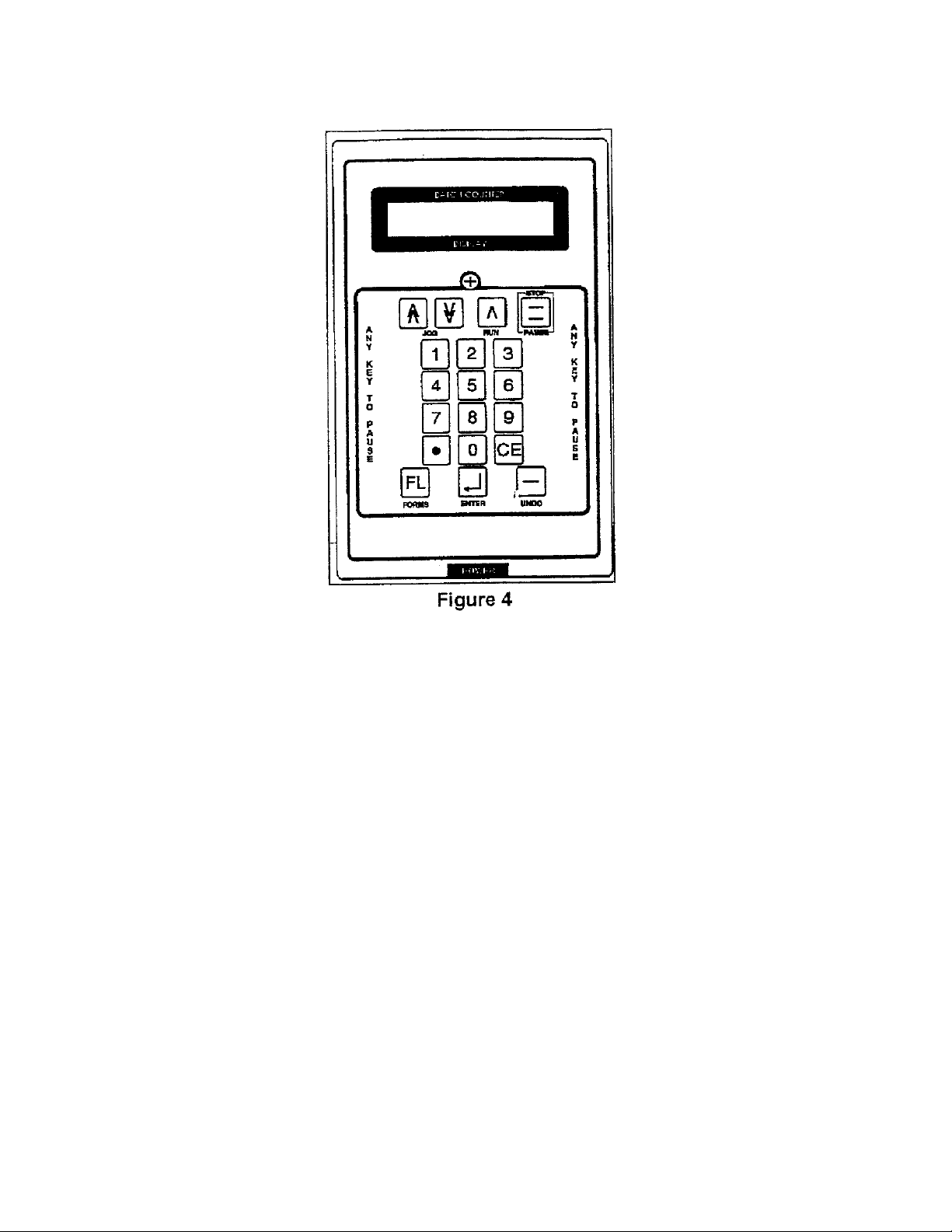

The control panel (see figure 4)

Key Name Function

Batch Counter

Display

Jog Forward

Key

Jog Reverse

Key

Run Key Is used at the last step in setup to start the signing process

Pause / Stop

Key

Keeps a running count of documents signed. During setup, this

display informs and prompts the operator

Are used during setup to align the signature line with the

reference line. Each jog step is approximately 1/16”

Is used during operation to stop or pause the signing process.

Any other key will do the same.

Number and

Decimal Point

Keys

Clear Entry

Key

Forms Length

Key

Enter Key Is used to define signature locations, and to skip the five second

Undo Key Is used to back up one step during setup or programming. Note –

Are used to enter security codes and respond to choices offered

by the prompts

Is used to clean an incorrect entry

Is used at any time to have the signer display the current setup

cover access period.

The UNDO Key is not used to clear an incorrect numerical entry,

because it will back up to the previous mode choice.

Page 5

5

Installation

After careful unpacking, place the 912 on a flat level surface for operation. Remove the plastic

bag containing the programming keys and hex key (Allen) wrench. Plug the power cord into an

AC outlet and press the POWER switch. Make sure the programming key is out of the key switch

in the rear. Note – In this manual, prompts and messages are shown in quotation marks, e.g.,

“New Executive Code?”.

When prompted for the executive code, press the “1” key 5 times. Open the cover within 5

seconds. If a mistake is made, press CE and re-enter 11111. (The factory preset executive

security code is 11111. If the display shows invalid code when this number is used, use the lock

key to reprogram the executive security code. See Programming Secti on of this manual)

The platen (backup roller) is normally held in place by friction. For shipping, the platen has been

tightened down at the factory. Adjust the platen’s sliding friction by using the Allen wrench

provided to turn the platen setscrew 3 / 4 turn counterclockwise from snug. Remove the brown

packaging tape that is holding the signature plate holder and platen in place. Also remove the tape

from the Plexiglas reference guide.

1. Positioning the signature plate holder

Remove the ink roller shaft by grasping each end and sliding the shaft to the left or right until it

clears the bracket. Set the assembly (ink roller, guide and shaft) aside, with the flat side of the ink

roller guide down. Note – Be careful to keep the shaft horizontal so the ink roller does not slide

off the end of the shaft. Rotate the signature pate shaft manually until the setscrew in the signature

Page 6

6

plate holder is accessible. Use the hex key (Allen) wrench provided to loosen the setscrew. Slide

the signature plate holder left or right to the approximate location of the signature block on the

documents. * Note – The idler disk assembly moves with the signature plate holder. Retighten

the setscrew.

Slide the platen into plate directly beneath the signature plate holder. The platen is held in place

by friction.

Caution – Do not tighten the setscrew in the platen.

2. Installing the signature plates

The 912 requires two identical signature plates to be installed on the signature plate holder.

Install a signature plate by sliding the plate holder clamp to the left and slipping the notch in the

signature plate onto a pin in the right end of the plate holder. Release the plate holder clamp.

Manually rotate the signature plate shaft backwards until the signature plate touches the platen

from behind. Slight contact between the signature plates and the platen prevents the first signature

plate from falling off when the opposite signature plate is installed or removed. Install the second

signature plate in the same manner as the first. Ensure that both signature plates are seated

correctly, flat against the signature plate holder.

3. Installing the ink roller

Caution – The ink roller is saturated with permanent ink. Always use the protective glove

supplied with your 912 (or similar hand protection) when working with ink rollers.

Put the ink roller back onto the machine by first positioning the ink roller guide so that it straddles

the signature plate is facing the ink roller guide at the top. Insert the ink roller shaft first into one

brackets, then the other. The springs inside the brackets hold the shaft in place. The ink roller

adjustment screws determine the inking of the signature plates.

4. Adjusting the ink roller

The depth of inking is adjusted at the factory. If readjustment is necessary, first rotate the

signature plate shaft so that a signature plate is facing the ink roller. Look in from the side to see

the gap between the signature plate and the ink roller. Adjust the ink roller adjustment screws

with a crosspoint (Phillips) screwdriver until the ink roller just contacts the rubber stamp evenly.

Turn each screw one more turn counter clockwise.

5. Installing the feed tray

At each end of the retarder bar, raise the feed tray latches and use the 3/32” hex key (Allen)

wrench provided to snug the screws. Tilt the feed tray up and slide the top black hook on each

side of the feed tray onto its respective support pin. Lower the feed tray into position. Release the

tray latches and tighten the screws to lock the tray latches in position.

6. Installing the receiving tray

Slide the receiving tray hooks into the slots in the rear panel window and lower the receiving tray.

Install the backstop on the receiving tray in the shortest position that will allow a sample form to

lay flat on the receiving tray. Note that the tabs on either end of the backstop fit into the slots in

the receiving tray, providing length adjustment from 3” to 17” in 2” increments.

7. Adjusting the retarder

Page 7

7

Select a sample sheet of the thinnest paper to be processed through the 912. Slide the feed tray

paper guides apart to the stops. Use the Diagnostic Test #9 to run the paper drive motor as

follows. Restart the 912 by turning it off and back on again. Insert the key into the lock in the

rear panel and turn the key clockwise. At the prompt “or 2 to Change Stored Forms”, press STOP

and then press the 9 key 5 times. At the prompt “Diagnostic Tests, Depress 1-9”, press the 9 key.

After 2 seconds, press the RUN key.

Pull out the Feed Tray Extension. Hold the sample form by the trailing edge, 5” above the feed

tray. Feed the leading edge of the sample form into the machine to just below the retarder bar (1 /

2” past the line of contact between the feed wheel and the retarder). Turn the retarder thumbwheel

clockwise until the feed wheel exerts a constant pull on the sample form. Release the form and let

it pass through the 912. Press the STOP key.

Programming

Two features of the 912 can be programmed. One is the executive and operator security codes that

allow the 912 to operate. The other feature is the setup parameters of signature locations and

batch control. Note – In this manual, prompts and messages are shown in quotation marks e.g.,

“New Executive Code?”.

Page 8

8

program number. Those parameters are: number of signatures per sheet, the location of each

signature, and the batch mode. If that stored setup is to be kept under that program number, press

CE and enter another program number.

Press the “Enter Key to Re-Define” if you wish to modify that stored setup. The display will

prompt “Define New Signature Locations”. Follow instructions at “Load One Sheet; Use Jog

Forward Key” to advance a sample form into the signer. When the signature line on the form is

under the reference line, press the ENTER Key. Follow the prompts to define other signature

locations on the form. After the last signature location has been defined, press STOP. The signer

will feed out the sample form and prompt for a “Batch Mode?”.

Select “Count Up” if the signer is to sign and count without limit. Select “Count Down” if the

signer is to sign a predetermined quantity. If desired, follow the prompts to select another form

number to re-define.

Operation

Follow the display prompts to enter codes (passwords). Open the cover to install signature plates

or adjust the horizontal location of the signature block. Select a stored setup or enter a setup

manually by jogging a sample from though the 912 to define the new signature locations. Select

the batch mode (count down from a preset quantity or count up until paper is depleted), and

initiate the signing process.

At each step, the 912 displays a prompt for an entry or action. At some of the steps, supplemental

messages are displayed.

Note – In this manual, prompts and messages are shown in quotation marks e.g., “New Executive

To eliminate supplemental messages, press any key immediately after power is switched on,

before the prompt “Enter Executive Code” appears.

1. Setup Steps

The display prompts and messages are self-explanatory. For reference, here is a list of steps for

setup and the choices available at each step.

a. “Enter Executive Code” – Enter the 5-digit code that has been programmed as the

b. “Cover May Be Opened” – If you are installing or removing the signature plates, or if

executive security code. Each digit entered will be acknowledged by the moving cursor

in the display. If you make an incorrect entry, press CE and try again. If the code is not

accepted, use the lock key to reprogram the executive security code. (See programming

Section of this Manual.) The factory preset executive code is 11111.

If a form is in the Model 912 and blocking the paper sensor while the prompt “Enter

Executive Code” is displayed, remove any forms from the feed tray and press RUN to

pass the form out quickly. This method of clearing the Model 912 is faster than using the

JOG Keys.

you need to adjust the signature plate holder horizontally, open the cover within 5

seconds. To proceed to the next step, press ENTER at this prompt. The 912 will

sequence to the next step automatically if this prompt is displayed for 5 seconds, or if the

cover is opened and closed. Once the cover is opened, it may be left opened indefinitely.

Once the cover is closed, it will be locked until the executive code is entered again.

Page 9

9

c. “Press 1 for Stored or 2 for Manual” If you desire to use the most recent setup again,

press CE at this time. The 912 will skip this step and the next two steps. To select a

stored setup, press key 1, then press a key 1-5 for the setup number. The 912 will then

skip the next two steps. To “Define New Signature Locations” for the current setup,

press key 2.

d. “Load One Sheet. Use Jog Forward Key” On the feed tray, adjust the paper guides for

the width of a sample form. Place it in the feed tray and use the JOG FORWARD Key to

advance the sample form until the first signature line is directly below the reference line

on the clear plastic bar. Press ENTER to define that location. Repeat the JOG

FORWARD and ENTER procedure until the last signature location has been defined. To

feed out the sample form, press STOP.

Note – The retarder must be adjusted for correct paper feeding. Section Installation

section 7, Adjusting the Retarder.

e. “Press 1 for Count Up or 2 for Count Down” When the count up mode is chosen, the

BATCH COUNTER keeps a running total of signatures. The 912 will continue to run

until it is out of paper. When the count down mode is chosen, the desired number of

signatures must be entered to preset the counter before each batch is run.

f. “Enter Batch Amount” – If the count up mode was chose, the 912 will skip this step. If

the count down mode was chosen, a quantity must be entered, followed by ENTER.

g. “Enter Operator Code” – Enter the operator code if it has been programmed to be

different from the executive code. The factory preset operator code is 22222. If the

operator code has been programmed to be the same as the executive code, the 912 will

skip this step. (To reprogram the operator code, see Programming Section of this

manual.)

h. “To Begin, Press the RUN Key” – Fan the stack of forms so the stack is tilted away from

the 912. (See figure 5.) Place the stack on the feed tray with the bottom form at the line

of contact between the feed roller and the retarder roller. To begin the signing process,

press the RUN key. The 912 will run until another key is pressed, or the paper is

depleted, or the count is down to zero (count down mode). After a few forms have been

signed, you may want to pause the 912 to verify the signature alignment and to ensure the

forms are stacking correctly. When paused, the 912 displays “Batch Count _, HOLD

RUN to Continue”, with the HOLD flashing. Press RUN to continue.

The 912 automatically terminates the run if no paper feeds in 8 seconds, or if the count is

down to zero (count down mode). To manually terminate the run, press STOP, then press

UNDO. The 912 then displays “Final Batch_, Press Any Key”. To return to the prompt

“Enter Executive Code”, press UNDO again. If a form has been left in the Model 912,

removed the stack from the feed tr ay and press RUN to pass the form out quickly, or use

a JOG Key.

Insert image here

2. Adjusting the signature locations

To adjust a signature location during a run, first press STOP to pause the 912. Then, press the

number of the signature you wish to move. For example, press the 2 key to select the 2nd signature

on the form. The 912 prompts “Adjust Signature Number 1 (2, 3, or 4)”. To move the selected

signature up, press the JOG FORWARD Key. To move the selected signature down, press the

JOG REVERSE Key. The 912 acknowledges “Sig #1 (2, 3, or 4) Moved Up (Down) 1/16 of an

Note – Only one signature location adjustment can be made during each pause.

3. Storing the adjusted signature locations

Page 10

10

To program the new signature locations into a stored setup, first complete the run. Pres UNDO

twice to return to the prompt “Enter Executive Code”. Press the FL Key. Insert the lock key into

the lock on the rear panel and turn the key clockwise. The 912 prompts “Form Number (1-5) to be

Updated”. Press the number of he stored setup to be updated. The 912 acknowledges

“Programmed Form Number 1 (2, 3, 4 or 5) Updated”. Then the 912 reminds you to “Turn Key to

Continue”. Turn the lock key to the vertical position and remove it.

Operator’s Troubleshooting Guide

If an error is made during setup or programming, the 912 display a specific message describing the

error and prescribing a corrective action. Follow the prompt to retry the last step. If the error

message is repeated, turn the 912 off and on again, and repeat the setup or programming steps. To

clear an error message, press CE. Following is a listing of possible and corrective actions. Also

see Section Diagnostic Tests and Section Error Code Explanations.

1. No message in the display – Make sure the power cord is plugged into a live AC outlet.

Check the power fuse in the rear panel for an open filament or a burnt spot. If necessary,

replace the fuse with the same type and rating.

2. Any error message in the display – Press CE and try again. If the error message repeats call

your service technician for assistance.

3. First prompt after power on is not “Enter Executive Code” Check to see that the lock key is

out of the rear panel switch.

4. Security code is not recognized – Press CE and re-enter your se curity code. If the security

code is still not recognized, reprogram it by the procedure in the Programming Section of this

manual.

5. Display indicates “Cover May Be Opened”, but cover is stuck Rock the cover up and down

at both sides while the message is displayed. If necessary, press UNDO and re-renter the

security code.

6. Signature plate holder won’t slide Check to make sure that the setscrew is loose. Gently tap

the right end of the signature plate holder.

7. Platen won’t slide – Gently tap either end of the platen. Slide the platen back and forth

several times. If necessary, loosen, but do not remove, the setscrew using the hex key (Allen)

wrench provided. (The factory setting for proper tension is 3 / 4 turn counterclockwise from

snug.)

8. Cover won’t close completely – Check to see that the ink roller assembly was installed with

the flat side of the ink roller guide at the top.

9. “Cover is OPEN” message when cover is closed Jiggle cover slightly.

10. Paper skews to one side during feeding – Tap the paper guide away from the paper, at the end

of the paper guide closest to the feed roller.

11. No signature on the paper – Make sure the platen is beneath the signature plate holder. Make

sure the signature plates and the ink roller have been installed.

12. Every other signature is out of alignment – Determine which signature plate has a misaligned

rubber pad and realign it as follows. Viewing a signature plate with the notch to the right, the

signature will be upside down and the imaginary signature line should align with the top edge

of the notch. The signature should be centered left to right. If a rubber pad is not positioned

correctly, remove it and realign the rubber pad.

13. Signature is consistently too high or too low – Check alignment of the rubber pads of the

signature plates. See above.

14. Signature placement is not consistent – Call your service technician for assistance.

15. Signature impressions smeared or slow to dry – Check ink roller adjustment (see section

Installation and Cleaning I of this manual.)

16. Signature impressions too light or uneven – Check ink roller adjustment. Replace the ink

roller if the ink roller has been in use for 50,000 impressions or 18 months.

Page 11

11

17. Every other signature is light – Determine which signature plate needs to be raised. Install a

piece of masking tape under each end of that signature plate directly on the signature plate

holder.

18. Machine rattles while running – Open the cover and check the tightness of the signature

plates. If one signature plate is loose, put a small strip of masking tape on the beveled end of

the signature plate.

19. Machine squeaks – Oil sparingly with one drop of light machine oil in each bearing.

20. Machine makes a growling sound or squeals continuously – Spot the machine and

immediately call your service technician for assistance.

Maintenance

Maintenance information included in this manual consists of an Operators Troubleshooting Guide,

Diagnostic Tests, Parts Diagram with a Parts List, and a Wiring Diagram.

Caution – Make sure power to the machine is disconnected and locked out before attempting any

maintenance procedures.

I. Cleaning

1. General

As often as needed (but at least weekly), vacuum paper dust and other contaminants from

the 912. Clean the main body of the machine with a soft dry cloth.

2. Feed Roller and Jog Roller

As often as needed (but at least weekly), clean the feed roller and the jog roller (located

on the feed tray) with a cloth dampened with a mild soap and water solution.

3. Idle Roller

As often as needed (but at least weekly), clean the long idle roller with a Roller Cleaner.

Spray roller cleaner on a dry cloth and clean until no residue remains on the idle roller.

4. Optical Sensor

As often as needed (but at least weekly), clean the optical sensor with a soft cloth

dampened with a mild soap and water solutions.

5. Platen and Signature Plates

Caution – The ink roller is saturated with permanent ink. Always use the protective

glove supplied with you 912 (or similar hand protection) when working ink rollers.

Warning – Never use cleaning solvents near fire or f lame. Always wear eye and skin

protection when using cleaning solvents.

When the quality of signatures begins to noticeably deteriorate, clean the platen and

signature plates. To clean the signature plates, remove them from the signature plate

holder. Clean the plates with a cloth dampened with alcohol. Wipe the signature plate

holder, idler wheels, and platen with a cloth dampened with alcohol.

II. Lubrication

After each eight hours of running time, lubricate all accessible bearings with one drop of

light machine oil that contains no detergent or wax. Do not use a penetrating oil; it will

displace the existing oil and evaporate. Also lubricate gears and plastic bearings with

lithium grease or other synthetic grease.

Diagnostic Tests

Note – These te sts should only be preformed by qualified personnel.

Page 12

12

In the diagnostic test mode, a series of tests can be performed on the subsystems of the

912. There are two methods of entering into the diagnostic test mode. If the right side

cover has been removed for servicing, press the small push button switch on the logic

board. To enter the diagnostic test mode from the keypad, repeatedly press UNDO until

the prompt “Enter Executive Code” is displayed. Turn the lock key clockwise, as though

entering the progr amming mode. At the prompt “or 2 to Change Stored Forms”, press

STOP, then press 9 five times. The 912 will acknowledge “Diagnostic Tests, Depress 09”. To return to the signing mode from this point, turn the lock key back to the vertical

position and press UNDO. TO select a diagnostic test, press the number of the test. To

return to the diagnostic tests entry section from any diagnostic test, press UNDO.

Following are the diagnostic tests and explanations for each.

I. Diagnostic Test 0

Test 0 is used to “Change System Parameters” of logo and double sheet checking. Use

the JOG FORWARD and JOG REVERSE Keys to scroll through the choice or Logo On

or Off, and Double Sheet Checking On or Off. To have the manufacturer’s logo and

model number displayed at start up, press ENTER while “Logo On” is displayed. To

have a different model number displayed, press ENTER while “Logo Off” is displayed.

“Insert Model Number” by typing in your desired model number, up to six digits, and

pressing ENTER. The logo on/off option only affects the logo and model number

information displayed when the 912 is first activated.

The double sheet checking feature works as follows. When a setup is performed

manually by jogging a single sheet through the 912 and pressing ENTER to define the

signature locations, the 912 measures the length of the sample form. During a run, the

912 checks for double sheet feeding by measuring the length of each form as it passes

over the photoelectric sensor. If any form appears to be longer than the sample form, the

912 stops and displays “Sheet-Feed-ERROR, Reload Missed Sheet”. To turn on or off

this double sheet checking feature, press ENTER while your choice is displayed.

II. Diagnostic Test 1

Test 1 is used to view and alter the values stored in the non-volatile RAM (Random

Access Memory. The non-volatile RAM stores signature locations, security codes, and user selectable options in the diagnostic tests. User -selectable options in Test 1 are:

a. Calibration of the signature placement.

b. Reloading the default values into the non-volatile RAM.

These values are preset and should not be changed.

If you suspect the non-volatile RAM values have been corrupted, e.g., the actual signature

location is grossly different from the signature location displayed, then the non-volatile RAM

can be reloaded with default values. To do so, first press 0 to jump to address 00. Press 1 to

change the value from AB to AC. Press ENTER, then press UNDO. The microprocessor

checks the value at address 00 when returning to the diagnostic test entry screen. If the value

at address 00 is not AB, the microprocessor reloads the non-volatile RAM with default values

from the EPROM (Electronically Programmable Memory). While the default values are

being reloaded the 912 asks that you “Please Wait.”

III. Diagnostic Test 2

Test 2 is used to check the switch and sensor inputs and the keypad. When both the left and

right cover switches are pushed down, the “Cvr” value changes from 0 to 1. When the

photoelectric sensor sees an object within 6 millimeters, the “Pap” value changes from 0 to 1.

When the key is turned to the horizontal position, the “Key” value changes from 0 to 1.

Page 13

13

When the diagnostic test switch except UNDO is pressed, that keypad switch is displayed.

When UNDO is pressed, the 912 returns to the diagnostic tests entry screen.

IV. Diagnostic Test 3

Test 3 is used to test the paper feeding system. The paper drive motor will run in the forward

direction with or without speed control (tracking). To toggle the speed control on or off, press

CE. Set the motor speed by selecting the average period of the encoder disk pulses as

follows. Press 1 for a 1000 microsecond period, press 2 for a 1100 microsecond period, press

3 for a 1200 microsecond period. To run the motor, press JOG FORWARD. The period is

continuously read and displayed. To take an instantaneous reading, press RUN. TO stop the

motor, press STOP.

The paper drive motor will run in the reverse direction, but only without speed control, by

pressing JOG REVERSE. To stop the motor, press STOP.

Test the paper feeding system as follows. In Diagnostic Test 3, press CE to turn off the speed

control (tracking). Press FL to toggle to “Display Measured Paper While Running”. Load 10

sheets of 8-1/2” by 11” copier paper onto the feed tray. Press JOG FORWARD. Observe the

measured values, in encoder pulses, for the individual sheets of paper. When the last sheet of

paper has fed through, press STOP. For 11” paper, the values should be 1056+ / - 5. (Each

encoder pulse equal s 1/96” of paper). If the values differ by more than 10, check the roller

pressure. To check the minimum gap between sheets, press 5. The time between sheets

should be no less than 70 msec. To check the maximum paper length in microseconds, press

6. To check the maximum paper length in encoder pulses, press 7. To check the number of

sheets, press 8.

V. Diagnostic Test 4

Test 4 is used to calibrate and test the stepper motor system, including the signature plate

shaft. In Test 4, the display shows the values for the home flag sensor, the setting for the

stepper motor current (power), and the phase code (step).

When the flag sensor sees one of the two flags, the “Home” value will be 1.

A “Current” value of 11 means the stepper motor power is set to zero. To set the stepper

motor power to 1/3 press 1 (“Current” value of 10). To set the power to 2/3, press 2

(‘Current” value of 01). To set the power to 3/3 (full power), press 3 (“Current” value of 00).

The “Phase” value simply tells into which of the four repeating steps the stepper motor is

locked.

To single-step the stepper motor in the forward direction, press 4. To single-step the stepper

motor in the reverse direction, press 5. If the stepper motor only steps at every other key

press, one of the two stepper motor windings is not being energized. To check the stepper

motor windings, unplug the stepper motor and check continuity.

To set the home orientation, first press 3 to set full power for the stepper motor. Then use the

4 and 5 keys to step the signature plate shaft until the index pins for the signature plates are

horizontally in the line with the center of the signature plate shaft. Press 4 seven times.

Loosen the setscrews in the flag hub and rotate the flag and the hub assembly unti l a flag is

centered in the flag sensor. Tighten the setscrew in the flag hub. Check the centering of the

flag in the sensor by rocking the signature plate shaft slightly out of détente until the “Home”

value changes to 0. Release the shaft and check to make sure the “Home” value goes back to

1. Rock the shaft out of détente in the other direction until the “Home” value again goes back

to 1. If the flag is not centered in the sensor, reposition the flag and hub assembly, or loosen

Page 14

14

the mounting screws for the flag sensor. Move it slightly in the appropriate direction, and

retighten the mounting screws. Check the other flag by rotating the signature plate shaft 180

degrees and repeating the centering check. In a extreme case, it may be necessary to bend one

flag.

To run the stepper motor, first ensure the signature plates are not installed. The normal

running speed of the stepper motor is 140 pulses per second. To run the stepper motor in the

forward direction at 100 pulses per second, press 7. At 100 pulses per second, (full power),

the stepper motor will run with moderate torque, but it will be noisy. To run the stepper

motor at 200 pulses per second, press 8. At 200 pulses per second, (full power), the stepper

motor will run with moderate torque, smoothly and quietly. To activate the stepper motor at

400 pulses per second, press 9. The stepper motor normally will not run at 400 pulses per

second.

VI. Diagnostic Test 5

Test 5 is used to test the logic board outputs, including the homing routine for the signature

plate shaft, and the photoelectric sensors on the encoder board.

To pulse (100 msec duration) the non-resettable counter, press 1. To retract the cover latching

solenoids for two seconds, press 2. To test the inking routine, press 3.

To test the homing routine, first turn the signature plate shaft by hand to get it out of home

position (“Hme” value = 0), then press RUN. The stepper motor should search for and find

one of the two home positions (“Hme” value = 1).

The two photoelectric sensors in one package on the encoder board form a quadrature

detector. Each sensor, primary and auxiliary, sends a 1 when it sees a tooth of the encoder

disk and a 0 when it sees a gap between teeth. The latch is set to 1 when the encoder disk

rotates in the forward direction and 0 when the encoder disk rotates in the reverse direction.

To test the encoder board sensors, reach over the roller guard on the retarder bar and contact

the top drive roller (idle roller) with your fingers. Slowly push the back of the roller down,

which will rotate the roller in the reverse direction. The primary and auxiliary signals should

change one at a time, and the latch signal should change to 0. Slowly pull the back of the

roller up to rotate the roller in the forward direction. Again, the primary and auxiliary signals

should change one at a time, but the latch signal should change to 1. If either sensor fails to

change, check the encoder cable and check the duty cycle settings in Test 9.

VII. Diagnostic Test 6

Test 6 is used to check the values stored in the microprocessor internal RAM. The meaning

of the values stored there is beyond the scope of this maintenance procedure.

VIII. Diagnostic Test 7

Test 7 is used to adjust the jog speed. Both the duty cycle and the frequency of the pulse train

that is sent to the paper drive motor during jogging can be adjusted. Use the decimal point

key to toggle between to two parameters, jog speed (duty cycle) and jog frequency. The

default values are 15 and 02, respectively. In both, the JOG FORWARD key increase the

hexadecimal value for faster jogging and the JOG REVERSE key decreases the value for

slower jogging. To test the current value, press RUN. The paper drive motor will run briefly

at the new speed. To load the new value into the non-volatile RAM, press ENTER. Martin

Yale recommends the jog speed be adjusted in preference to jog frequency.

IX. Diagnostic Test 8

Page 15

15

Page 16

16

Error Reference 01

No forms length set. Go through setup again.

Error Reference 02

Sensor is blocked when it shouldn’t be. Remove whatever is blocking the se nsor.

Error Reference 03

Signature location is off the form. Redefine the signature locations.

Error Reference 04

Signature plate was moved during HOLD. Restart the batch of forms.

Error Reference 05

No quantity set for countdown mode. Go through setup again.

Error Reference 06

Second signature location invalid (repeat spacing). Redefine signature locations.

Error Reference 07

Third signature location invalid (repeat spacing). Redefine signature locations.

Error Reference 10

Flag on signature shaft not seen. Remove any obstruction that may prevent the signature shaft

from rotating. With power off, check to make sure the signature shaft rotates freely. Use

Diagnostic Test 8 to activate the homing routine.

Error Reference 11

Signature step missed during a run cycle. Remove any obstruction.

Error Reference 12

Paper sensor intermittent during a run cycle. Clean the paper sensor. Use Diagnostic Test 2 to

check the paper sensor.

Error Reference 13

Stored setup has invalid signature locations. Program new signature locations.

Error Reference 14

Signing routine during HOLD. Restart the batch of forms.

Error Reference 15

No encoder pulses seen while paper drive motor should be running. Use Diagnostic Test 9 to

check the encoder pulses.

Error Reference 16

Page 17

17

Accelerate routine during HOLD. Restart the batch of forms.

Error Reference 17

Missed signature interrupt signal. Remove any obstruction and restart the batch of forms.

Error Reference 19

Encoder pulses slowed or stopped. Remove any obstruction and restart the batch of forms. Use

Diagnostic Test 9 to check the encoder pulses.

Error Reference 20

Signature shaft lost synchronization with the paper drive system. Remove any obstruction and

restart the batch of forms.

Error Reference 21

Invalid routine during a run cycle. Restart the batch of forms.

Error Reference 22

Too many steps needed to reach home during a run cycle. With power off, check that the

signature shaft rotates freely.

Error Reference 23

Invalid run routine when home is reached. Clean the encoder disk and its sensor.

Error Reference 24

Insufficient paper left when entering first dwell. Check paper length and feeding.

Error Reference 25

Invalid routine during run cycle. Clean the encoder disk and its sensor.

Error Reference 27

Out of paper before last signature. Check paper length and feeding.

Error Reference 30

Non-volatile RAM did not write. Use Diagnostic Test 1 to reload the default values.

Error Reference 31

Non-volatile RAME did not acknowledge. Use Diagnostic Test 1 to reload the default values.

Parts Diagram

Loading...

Loading...