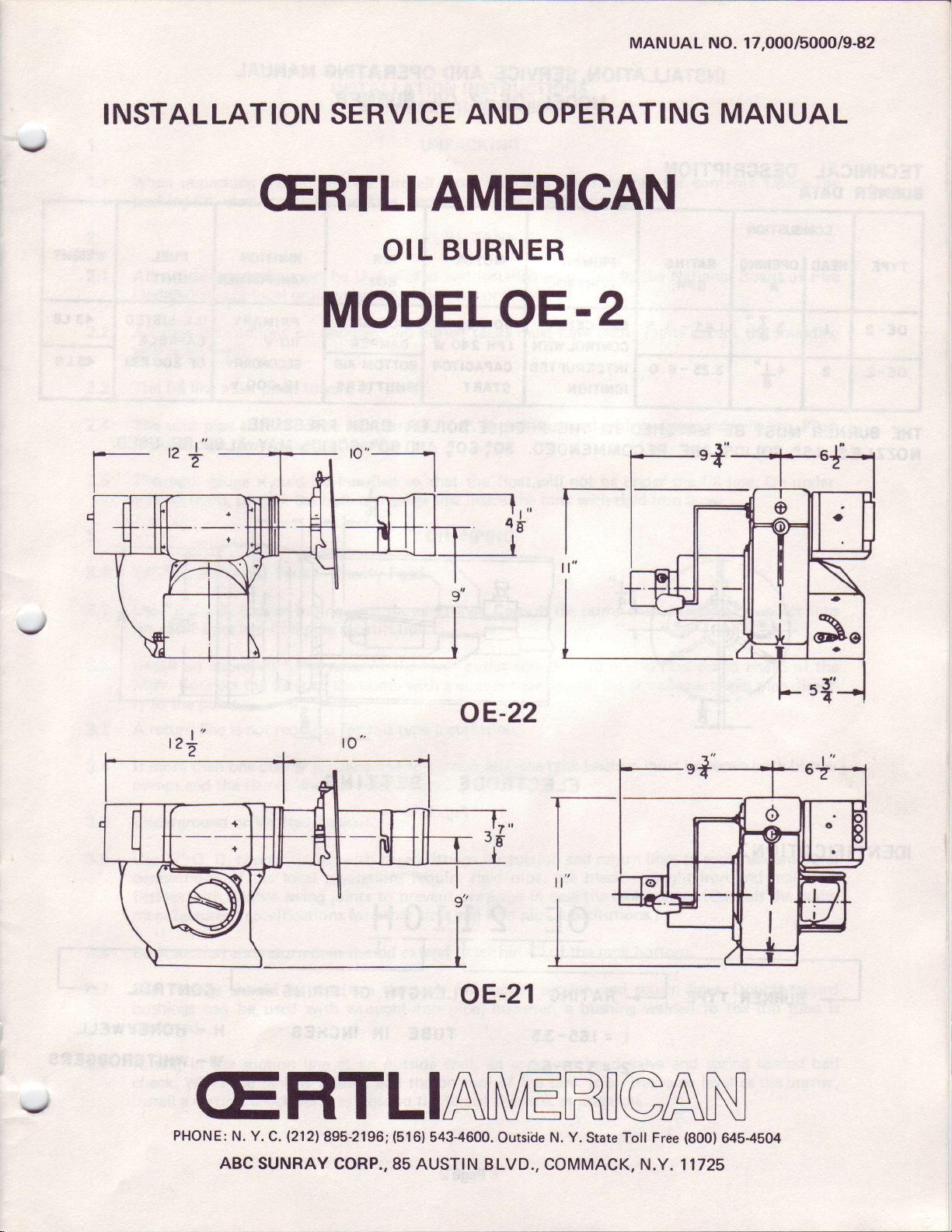

OERTLI AMERICAN OE-22, OE-2, OE-21 Service Manual

MANUAL NO. 17,000

lSOOOlg-82

YI

INSTALLATION

SERVICE

CERTLI

MODELOE.z

AMERICAN

OIL

AND

OPERATING

BURNER

MANUAL

,+'--1-5{

I

e

o

\

rFl

J

J

I

I

tDng

r

,a

5{'

oE-22

oE-21

J

CERTLIANtrRIGAN

PHONE:

N. Y.

ABC

C.

.2121895-2196;

SUNRAY CORP.,85

{516)

543-4600.

AUSTIN BLVD.,

Outside

N. Y.

State Toll Free

COMMACK, N.Y. 11725

(800)

645-4504

INSTALLATION.

SERVICE

ltiODEL

AND

OE-z

OPERATING

BURNER

OIL

IIANUAL

v

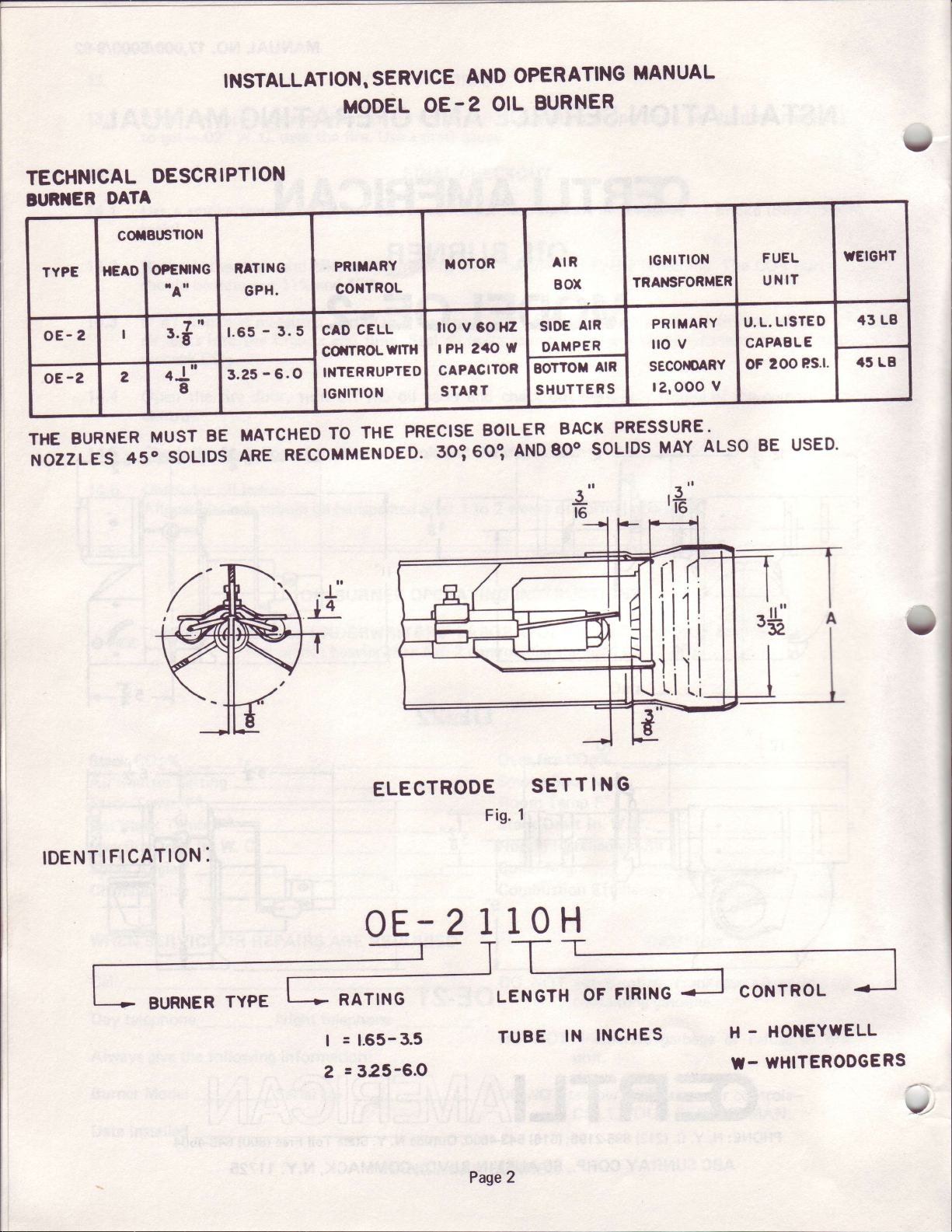

TECHNICAL

IUR]IER

BURNER

THE

NOZZLES

DESCRIPTION

DATA

MUST

450

BE

soLlDs

LISTED

L.

-

t.65

3.5

MATCHEDToTHEPREc|sEBo|LERBACKPRESSURE.

ARERECoMMENDED.So?600'ANDEoosoL|DsMAYALSoBEUSED.

CELL

CAD

COfTROLWITH

INTERRUPTED

IGNITION

lto

tPH240W

CAPACITOR

START

v 60

Hz

U.

CAPABLE

Ps.l.

200

oF

1

I

9

IDENTIFICATION:

BURNER

TYPE

ELECTRODE

0E-

RATING

=

1.65-3.5

|

:325-6.O

2

2

SETTING

1

Fig.

10H

1

LENGTH

TUBE

-

OF

INCHES

IN

FIRING

l

I

I

CONTROL

-

HONEYWELL

H

WHITERODGERS

U-

I

-

Page2

INSTALLATION

FUEL OIL

# 2

INSTR UCTIONS

BURNERS

1.

1.1

When unpacking

packing

list, electrical

2.

All oil storage

2.1

Underwriters

2.2

2.3

2.4

2.5 The

3.

3.A 275-Gal.

pipe

All

(stick

well

The filf line

The vent

the vent

ground

pipe

tank

tanks,

UNPACKING

the burner,

rating

tanks must be U.

local

or

connections on underground

well).

must

pipe

should not be lessthan

toward tank Yo"

gauge

protect

Basement

ordinances,

pitch

toward

should be

the

Tanks-Gravity Feed.

be sure all

(voltage,

To"

per

installed so that the

and

bulb

hertz) and for concealed

listed

L.

whichever

buried

per

tt.

1y4" l. P. S. and equipped

ft.

gauge

packages

loose

FUEL

TANK

installed according

and

precedence.

has

tanks must have sruing

float

vvill

inside the tank with rigid

line

PIPING

OIL

inspected

are

damage.

with an approved vent

not be

for

to the National Board of Fire

joints

under

iron

contents. Gheck

except

the fill

pipe.

the sounding

cap. Pitch

line.

On

the

under-

3.1 UseYz" O. D.

for

other

3.2 Install an approved

filter. Connect the filter to the

ly to the

3.3

3.4

3.8

3.5

3.6

3.7

A return

more than one

lf

pumps

Underground

l)se

connections.

fittings with

manufacturer's specifications

Both

Slip

bushings

preferred.

and

Tr" O.

suction and return

fittings should

copper tubing with

sizes and iron

pump.

not required for

line is

burner is connected

the size of

Vaulted

or

D. copper

tf the

double sruing

can be used

flared fittings. Consultthe

pipe

substitution.

hand

line and

Tanks.

tubing

local regulations

lines should

be used on

with wrought-iron

in the

valve

pump

this type

filter

with flared

joints

to

for other

the

with

to suction

must be increased.

require

prevent

sizes and

extend

tank for copper

tank

outlet

a copper

installation.

line,

fittings

for suction

rigid

breakage

iron

to within

pipe;

however, a

pump

and close

tube

the tank bottom

pipe,

in case the

pipe

4"

to burner

pigtail.

use

of

suction

Do

return lines

and

black wrought

tank settles.

substitutions.)

the tank

and return

bushing

manufacturer'sspecifications

pump

fuel

not connect rigid

be above both

must

to

bottom.

lines. Double-tapped

welded to the

ahead of the

pipe

underground

avoid

iron

and

(Consult

dip tube

direct-

burner

malleable

pump

the

is

valve and spring

3.8

J

Install,

check. When

install a vertical check valve

in the suction

the

line at an outside

is

tank

vaUlted

as close

and

to the

wall, an approved

the bottom of

top

of

Page

the tank

3

the tank

hand

is on the

practical'

as

same level

loaded ball

as the burner,

3.g

3.10

1

3.1

g.12

3.13

4.

thetank

bottom

the

lf

highest

the

at

lnstall

filter

lnsta

Avoid

hangers

A separate

provided , ,pting-jouJed

an

the

to

a copper

ll

fastening

with

of

Point.

approved

pump

with

tube

suction

rubber

so-ft

suction

hand

a

pigtail

line should

is above

close

valve

copper

and

lining

ball check

tube

between

return

prevent noise

to

be

levelof

the

to

pigtail'

pu

the

lines

used

installed

is

FUEL

the

burner

the

mp and

floor

to

transmission.

each

for

in the

FILTER

OIL

anti-siphon

burner,

spring-loaded

beams'

burner.

an

pump,

lf

A common

return

ahead

necessary

pipe

from

of

ball

valve

filter,

the

check

to do

return

each

is usually

and

return

in the

use

so,

line

fuel unit'

required

connect

line'

fitting

loose

be used'

may

the

4.1

4.2

4.3

5.

5.1

5.2

5.3

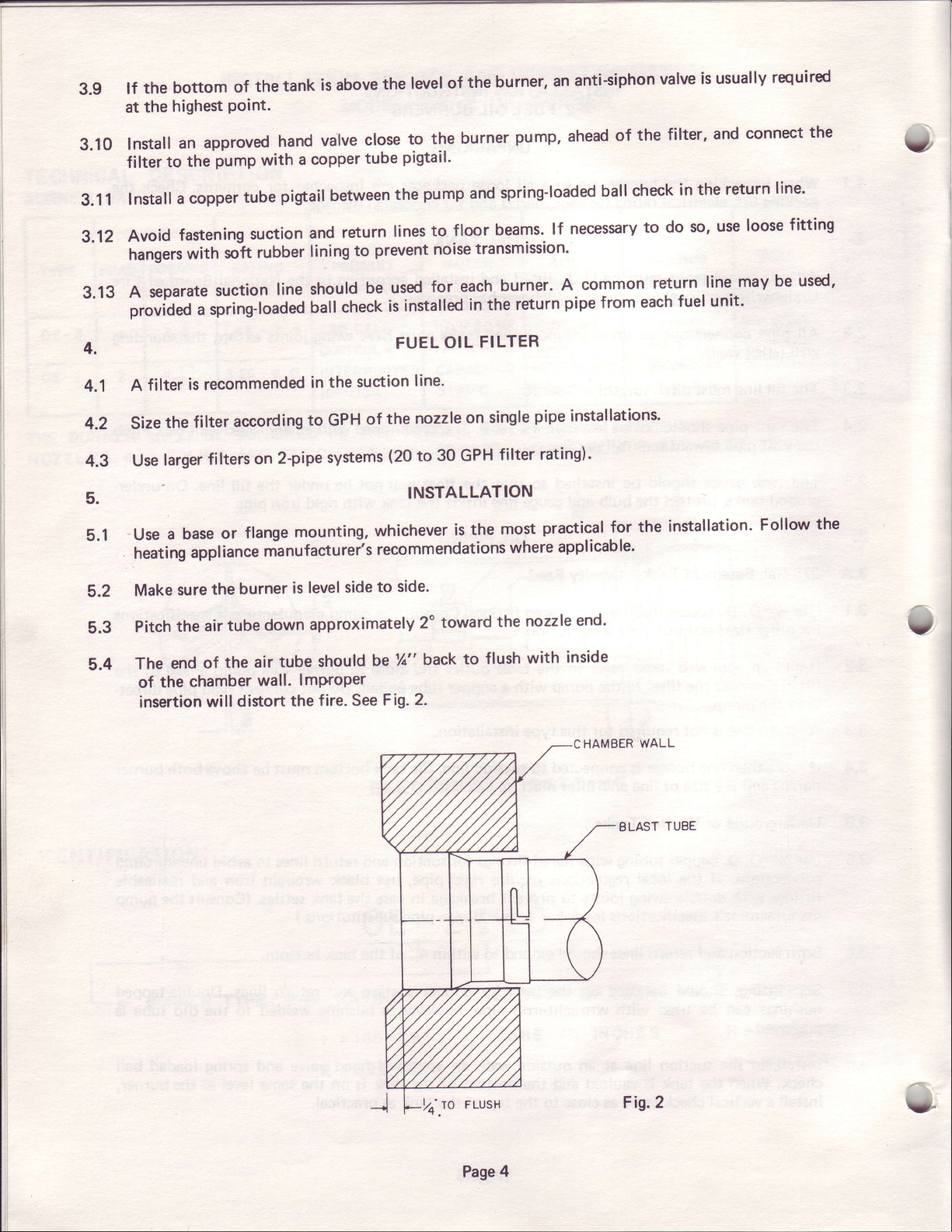

5.4

A filter

size

Use

Use

heati

Make

Pitch

The

of

insertion

is recommended

the

larger

base

a

appl

ng

sure

the

end

chamber

the

according

filter

on

filters

flange

or

iance

burner

the

tube

air

the air

of

wall.

willdistort

suction

in the

to GPH

2-pipe

mounting,

mi nufacturei's

level

is

approximately

down

tube should

lmProPer

the fire.

of

systems

whichever

recommendations

to

side

be

See

line'

toward

2o

back

is

on

the

to

nozzle

the

(20

to 30 GPH

INSTALLATION

side.

Tt"

2.

Fig.

single

filter

most

where

nozzle

the

flush

pipe

installations.

rating).

practical for

icab

appl

end.

inside

with

CHAMBER

the

le.

WALL

ELAST

installation'

TUBE

Follow

the

3

Page

Fig.2

4

v

Loading...

Loading...