OERTLI PK 550 Assembly Manual

PK 550

Fuel oil/gas boilers

300020196-02

en

Assembly

Instructions

D000913

2

PK 550 18/03/2016 - 300020196-02

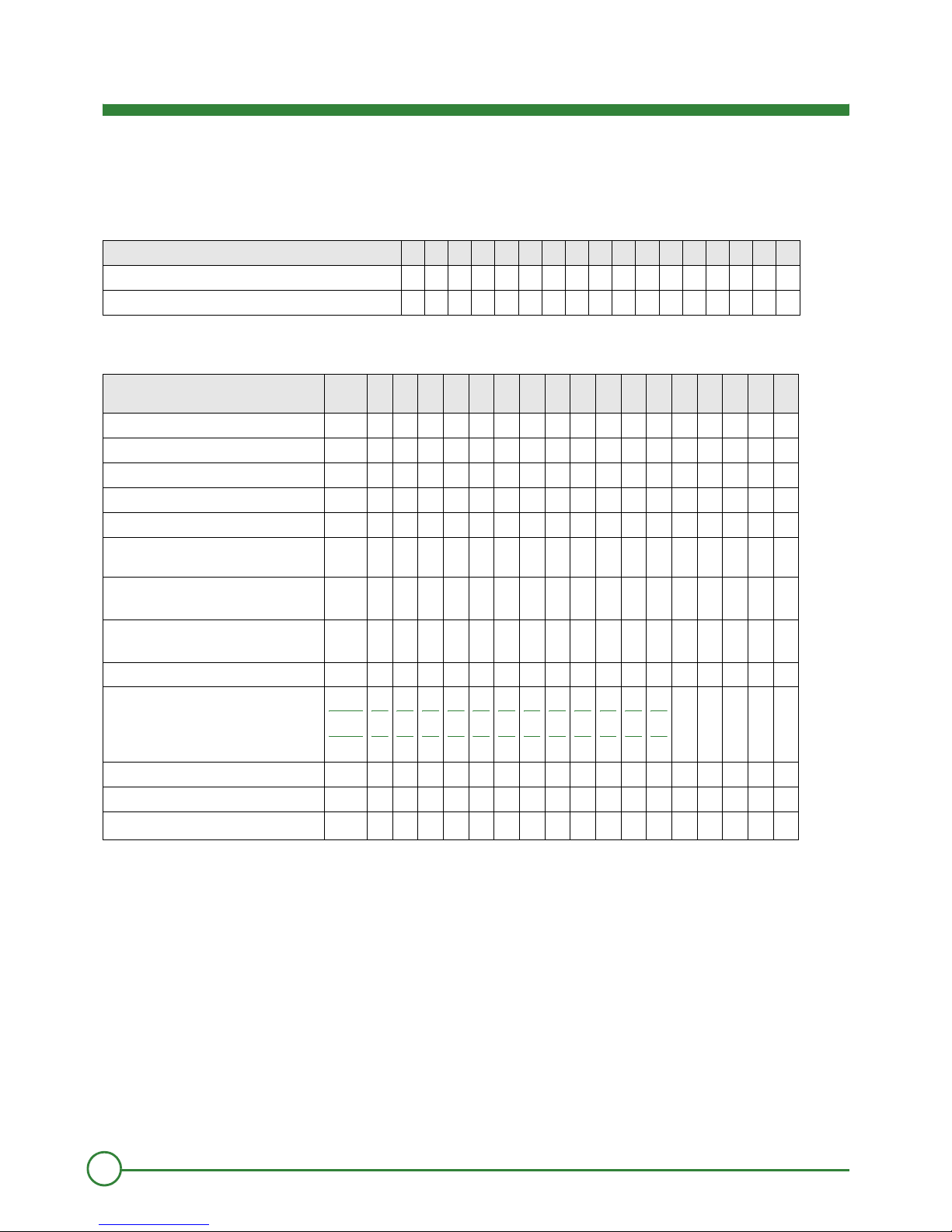

1. Package list

1 Package list

Before starting to assemble the boiler, refer to the table below to check if you have received all the packages required.

• Boiler body + Accessories

- Boilers supplied with an assembled body

- Boilers supplied with an unassembled body

(1)

The distributing tube fitting for PK 550 boilers with 15 to 19 sections is included in the accessory package.

(2)

The diaphragm for PK 550 , 13 and 14 section boilers is delivered in the additional accessory kit package.

Boiler PK 550- Number of sections 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Assembled boiler body (contents depend upon model) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Cleaning tool kit (contents depend upon model) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Boiler PK 550- Number of sections

packag

e

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Base frame (dimensions depend upon model) 1 1 111111111111111

Rear section 11111111111111111

Normal intermediate section 4567891011121314141516171819

Special intermediate section 33333333333444444

Front section 11111111111111111

Set of assembly rods + Cleaning tools (contents

depend upon model)

11111111111111111

Standard accessory kit

(contents depend upon model)

1

FA 44

FA 45

FA 46

FA 47

FA 48

FA 49

FA50

(1)

FA51

(1)

FA52

(1)

FA53

(1)

FA54

(1)

FA55

FA56

FA57

FA58

FA59

FA60

Additional accessory kit (contents depend upon

model)

(2)

1

FA63

FA64

FA65

FA66

FA67

(2)

FA68

(2)

FA69

FA70

FA71

FA72

FA73

FA74

FA75

FA76

FA77

FA78

FA79

Plain furnace plate 11111111111111111

Flue gas connection plate with opening

Ø 300

Ø 350

Ø 400

1

1 1 1 1

1 1 1 1 1 1 1

Plain flue gas connection plate 11111

Flue gas box 11111111111111111

Distributing tube fitting

(1)

(1) (1) (1) (1) (1)

111111

3

18/03/2016 - 300020196-02 PK 550

1. Package list

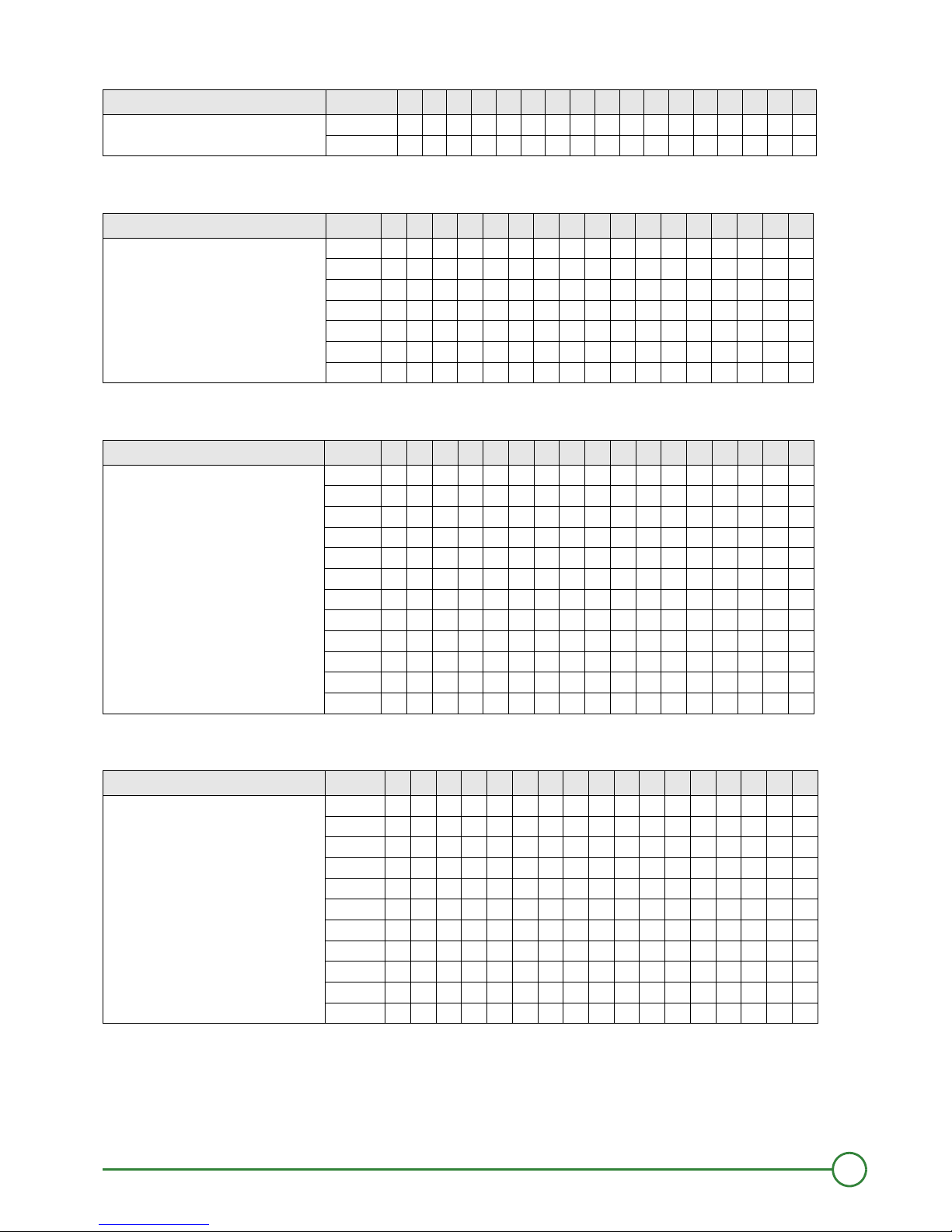

• Baffles

• Casing fittings

• Casing, variable parts

• Insulating material for body

Boiler PK 550 - Number of sections package 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Baffles CM 22 1 11111

CM 23 1111111111222222

Boiler PK 550 - Number of sections package 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Casing fittings MS1 111111111

MS2 11111111

MR3 1

MR4 1 1 1 1 1 1 1 1

MR5111 11 111

FA10 1 22 221 2211

FA11 11 222112332233

Boiler PK 550 - Number of sections package 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Casing, variable parts FA16 11111111

FA17 1

FA18 1

FA19 1 1

FA20 1 1

FA21 1 1

FA22 1 1

FA23 1 1

FA24 1 1

FA25 1

FA26 1

FA27 1

Boiler PK 550 - Number of sections package 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Insulation FA31 1

FA32 1

FA33 1 1

FA34 1 1

FA35 1

FA36 1 1

FA37 1 1

FA38 1

FA39 1 1

FA40 11

FA41 1

4

PK 550 18/03/2016 - 300020196-02

1. Package list

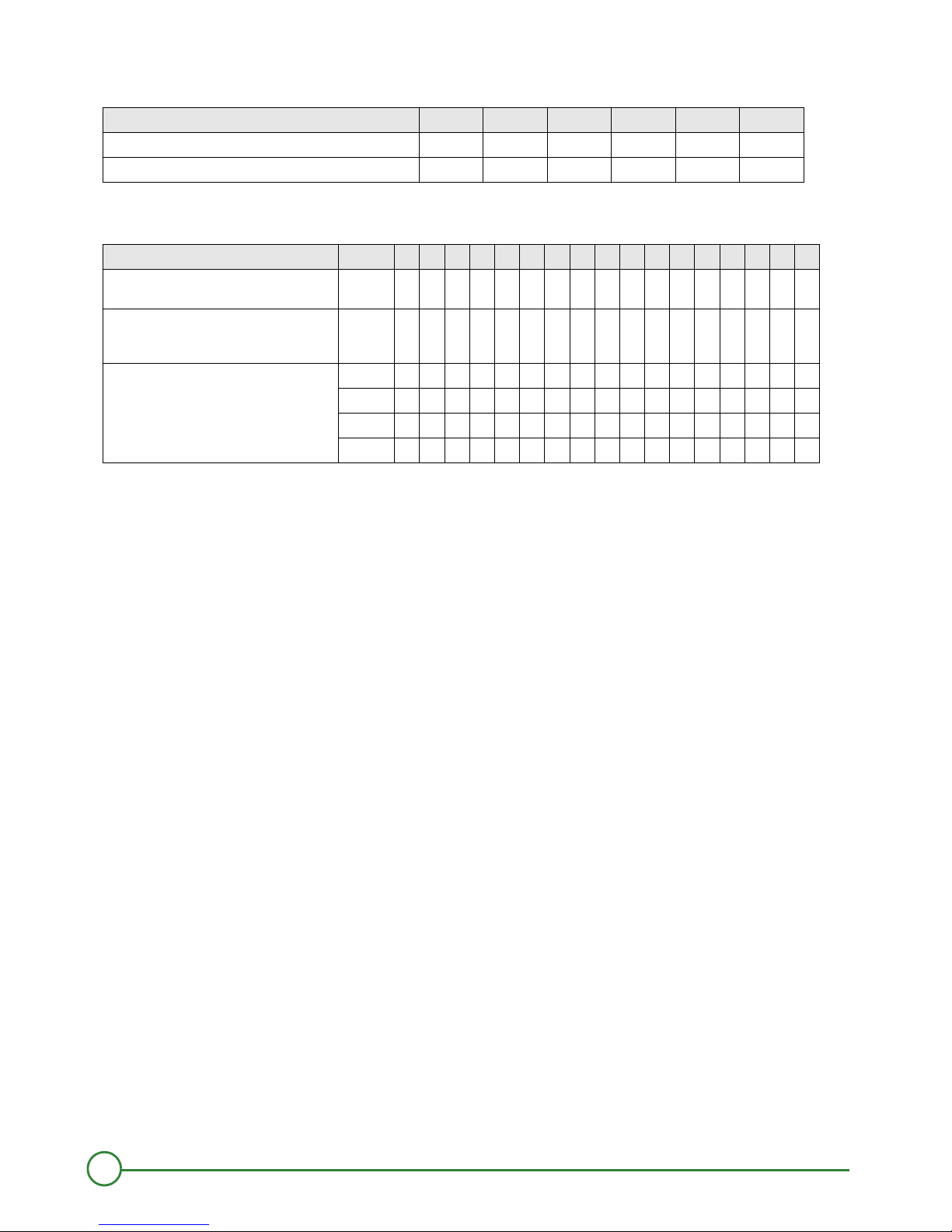

• Control panel

All models can be equiped with one of the following control panels:

• Accessories - Available as an option*

* Refer to the applicable price list for the other optional features (control units etc.) which may be used with these boilers.

Boiler PK 550 - Number of sections 9 10 11 12 13 14

Standard control panel - X 1 Package MG1 MG1 MG1 MG1 MG1 MG1

R control panel 1 Package MG2 MG2 MG2 MG2 MG2 MG2

Boiler PK 550 - Number of sections 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Furnace plate with hole

Ø 165 / 186 / 210 / 240 or Ø 295

11111111111111111

Connecting plate with opening or plain connecting

plate - Ø 300

or Plain connection plate

11111111111111111

Set of anti-vibration studs 8208-7757 1

8208-7758 1111111

8208-7759 1111

8208-7760 11111

5

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

2 Mounting PK 550

2.1 Introduction

Warning: Assemble the boiler in the order given by the numbers of each figure, in compliance with all the instructions.

Refer to the applicable price list for any optional features used.

Tools required

- 1 JD-TE or JD-TE Plus assembly tool

- 1 Flat screwdriver

- 1 "n°2 posidrive" screwdriver

- 1 10, 13, 16, 17 spanners, 18, 19

- 1 22 tubular box spanner

- 1 27 tubular box spanner

- 1 electric screwdriver + 1 "n°2 Philipps" screwdriver bit

- 1 Stanley knife

- Silicone filler (Supplied)

Boilers supplied with an assembled body

- Hydraulic test: See fig. 17

- Mounting: start assembly from figure 34

6

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

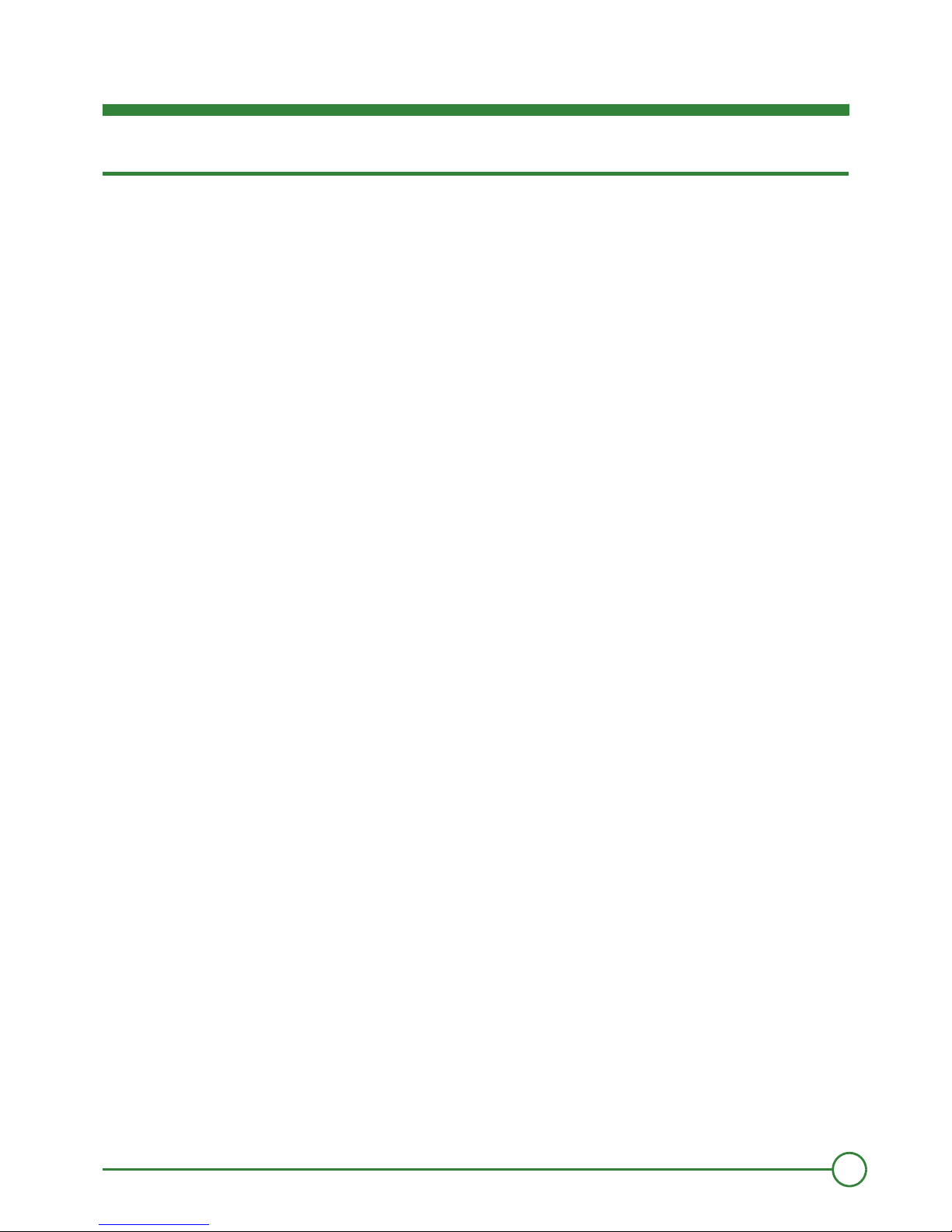

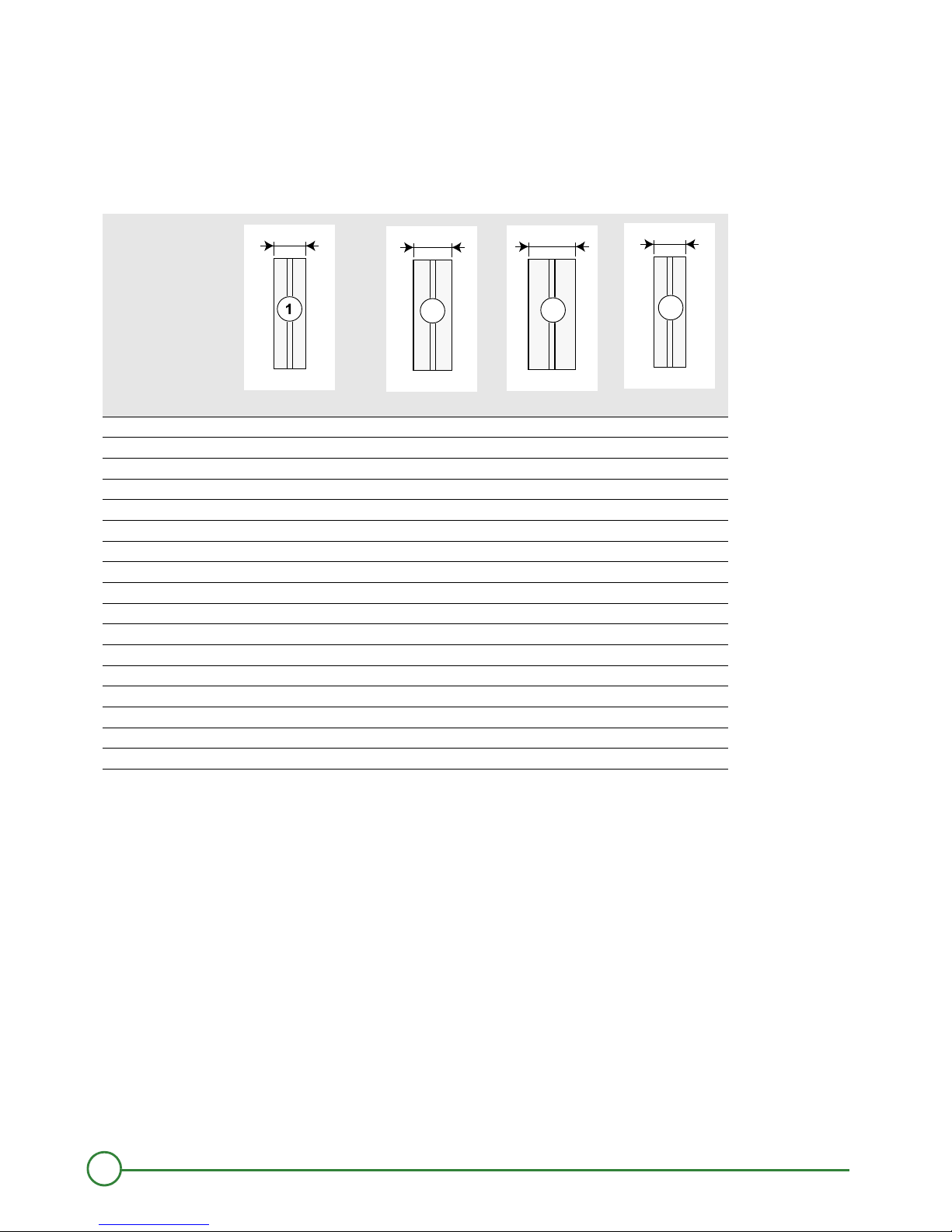

Assemble the boiler body from the rear to the front:

- assemble the rear section,

- assemble all the normal intermediate sections,

- assemble all the special intermediate sections,

- assemble the front section.

The number of sections of each type is provided in the table below

Rear section

Normal intermediate section

Special intermediate section

Front section

Section type

PK 550-9 1431

PK 550-10 1531

PK 550-11 1 6 3 1

PK 550-12 1731

PK 550-13 1831

PK 550-14 1931

PK 550-15 11031

PK 550-16 11131

PK 550-17 11231

PK 550-18 11331

PK 550-19 11431

PK 550-20 11441

PK 550-21 11541

PK 550-22 11641

PK 550-23 11741

PK 550-24 11841

PK 550-25 11941

104

8228-0004

8228-0001

111

2

8228-0002

151

3

8228-0003

104

4

7

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

2.2 Mounting PK 550

1

`

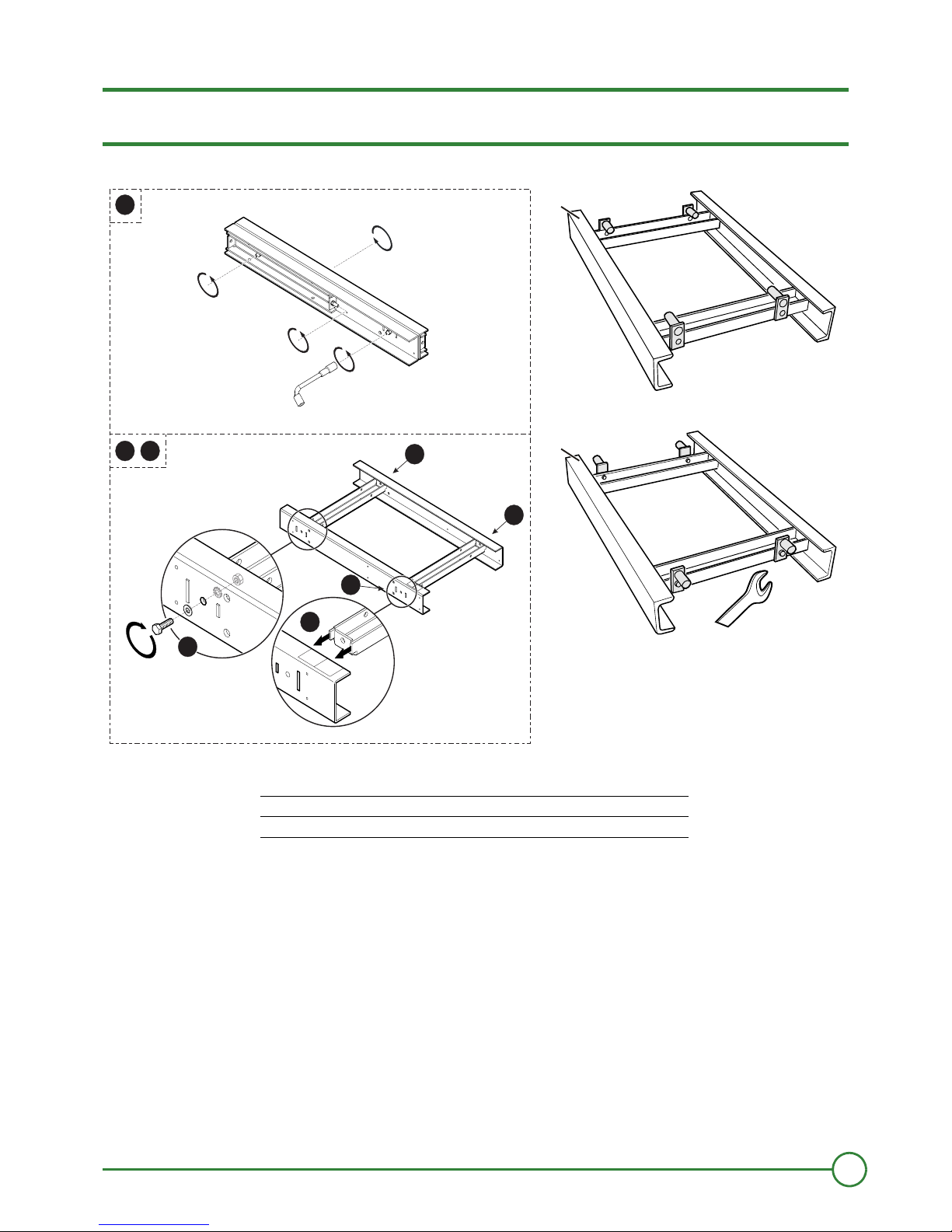

to : Assembly of the base frame, delivered unassembled.

` Place the frame on the floor, taking care to note the TOP and FRONT positions

` Fit the fastening brackets as shown, depending on the type of boiler (1 Screw Ø 12x40 - 19 spanner)

DESS

US

NOBE

TOP

NAVA T

VORN

FRONT

DE

SSU

S

O

BE

N

TOP

ANTA

V

VORN

F

OR

NT

3

3

M000309

3

1

2

3

2

3

E

D

S

S

U

S

O

B

E

N -

T

O

P

DE

S

S

U

S

OBEN

TOP

DES

S

U

S

O

B

EN

T

O

P

D

E

SS

U

S

O

B

E

N

- TO P

48555N0 2A

F

R

ONT

V

O

R

N

A

V

A

NT

FR

O

N

T

VO

RN

A

V

ANT

F

R

O

N

T

V

O

R

N

A

V

A

N

T

F

R

O

N

T

V

OR

N

A

V

A

N

T

19

A

B

A Boilers: 10, 12, 14, 16, 18, 20, 22, 24 sections

B Boilers: 9, 11, 13, 15, 17, 19, 21, 23, 25 sections

8

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

2

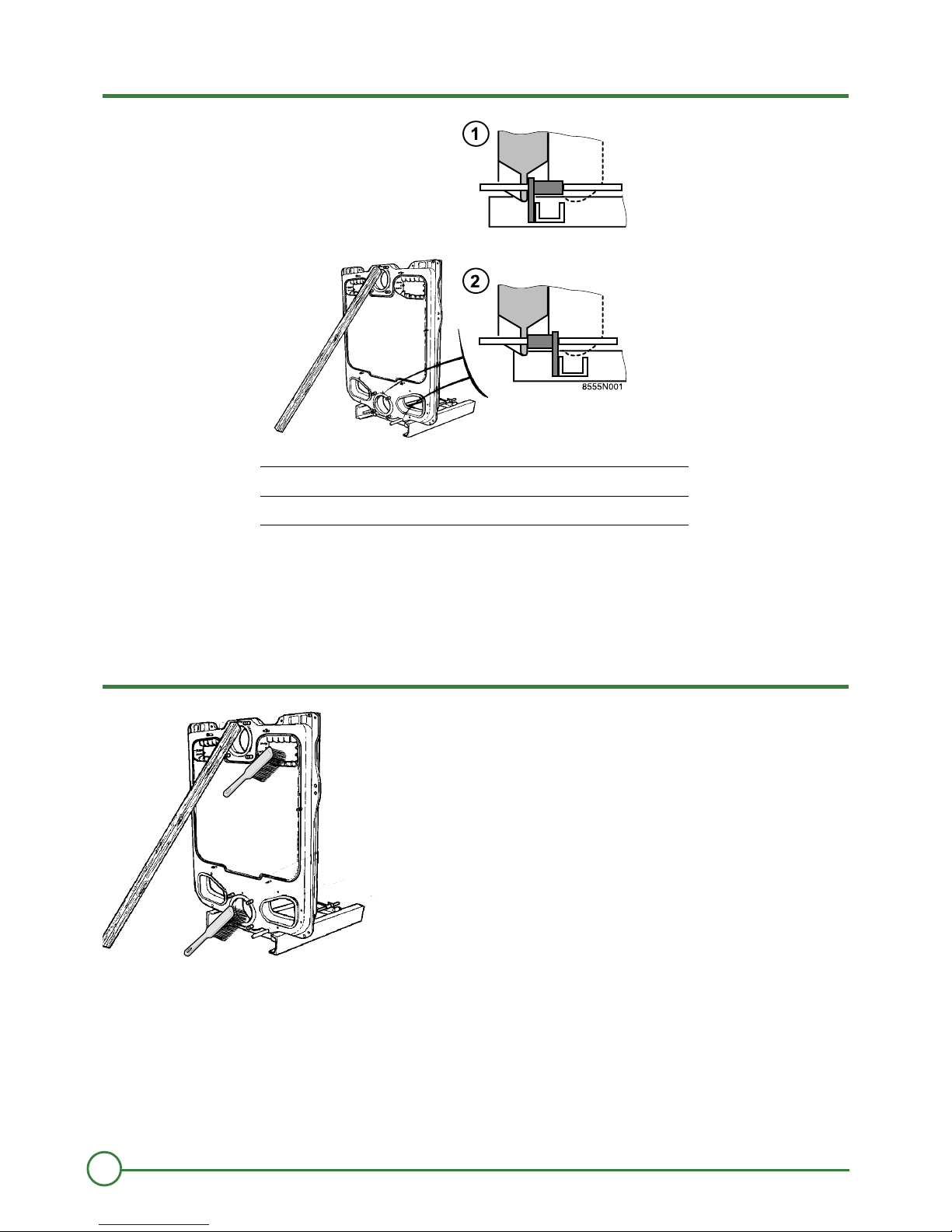

` Establish the location of the frame on the basis of the opening direction of the furnace door and the length of the burner. Leave enough

clearance at the rear of the boiler for water connections and the distributing tube.

` Fit the rear section on the frame, behind the fastening brackets (see detailed drawing) and prop it up.

` Insert the lower assembly rods in the holes of the rear section and the fastening brackets of the frame, in order to position the rear section

correctly according to the frame

3

` Clean all the openings in the section with a brush. Remove any deposit on the bottom of the section.

Boilers: 10, 12, 14, 16, 18, 20, 22, 24 sections

Boilers: 9, 11, 13, 15, 17, 19, 21, 23, 25 sections

00 8

M00 5

9

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

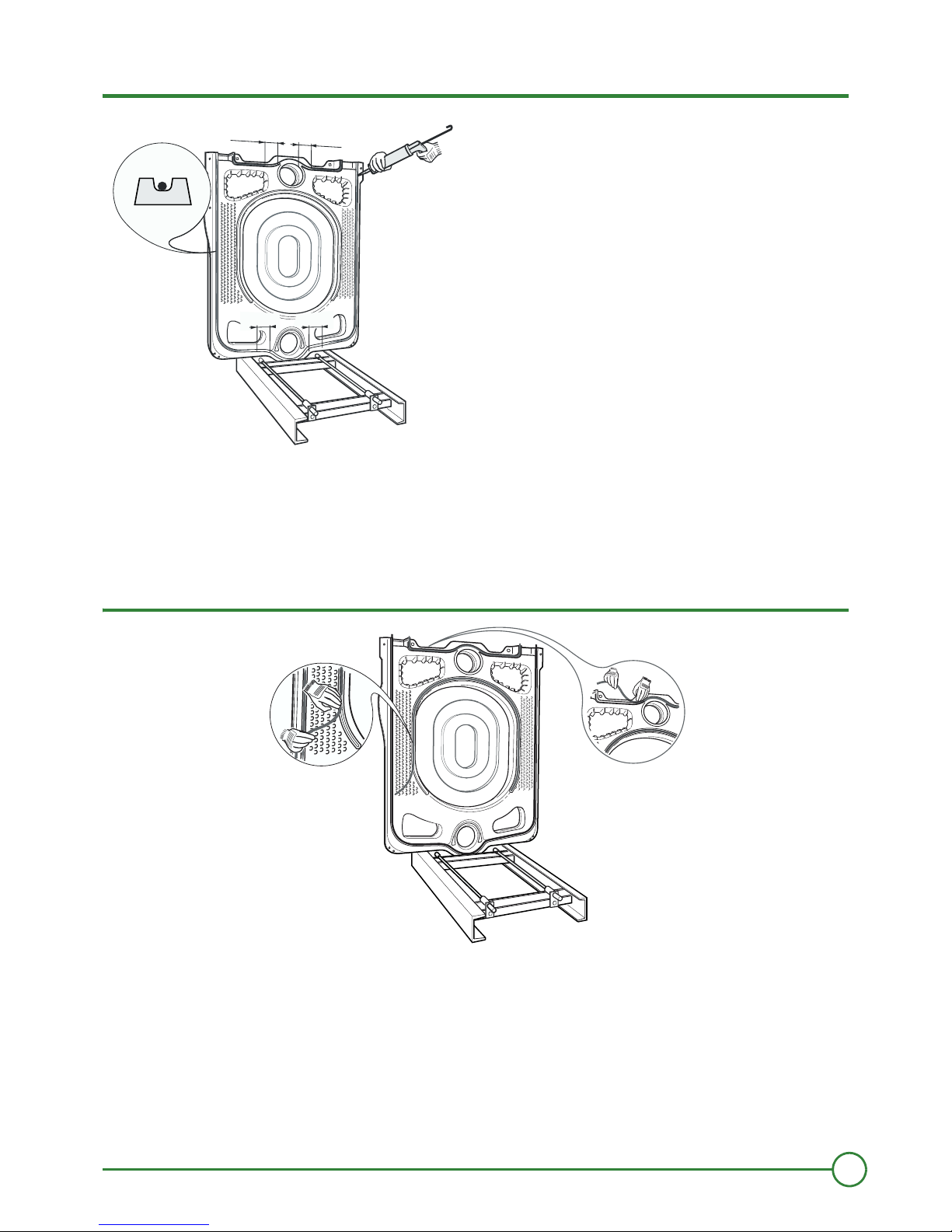

4

` Fill the bottom of the U groove (located on the periphery of the section) with a continuous bead of DOW CORNING silicon, diameter

approximately Ø 5 mm.

silicon must not be applied 100 to either side of the connection (nipple assembly area).

Dimensions are given in millimeters.

5

` Fit the Ø 10.5 mm diameter thermocord into this U groove and into the groove which circles the furnace.

Note: Do not pull on the seal while inserting it. Otherwise, you may stretch it and reduce its thickness.

M000059

100

100

001

100

a

M000060

10

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

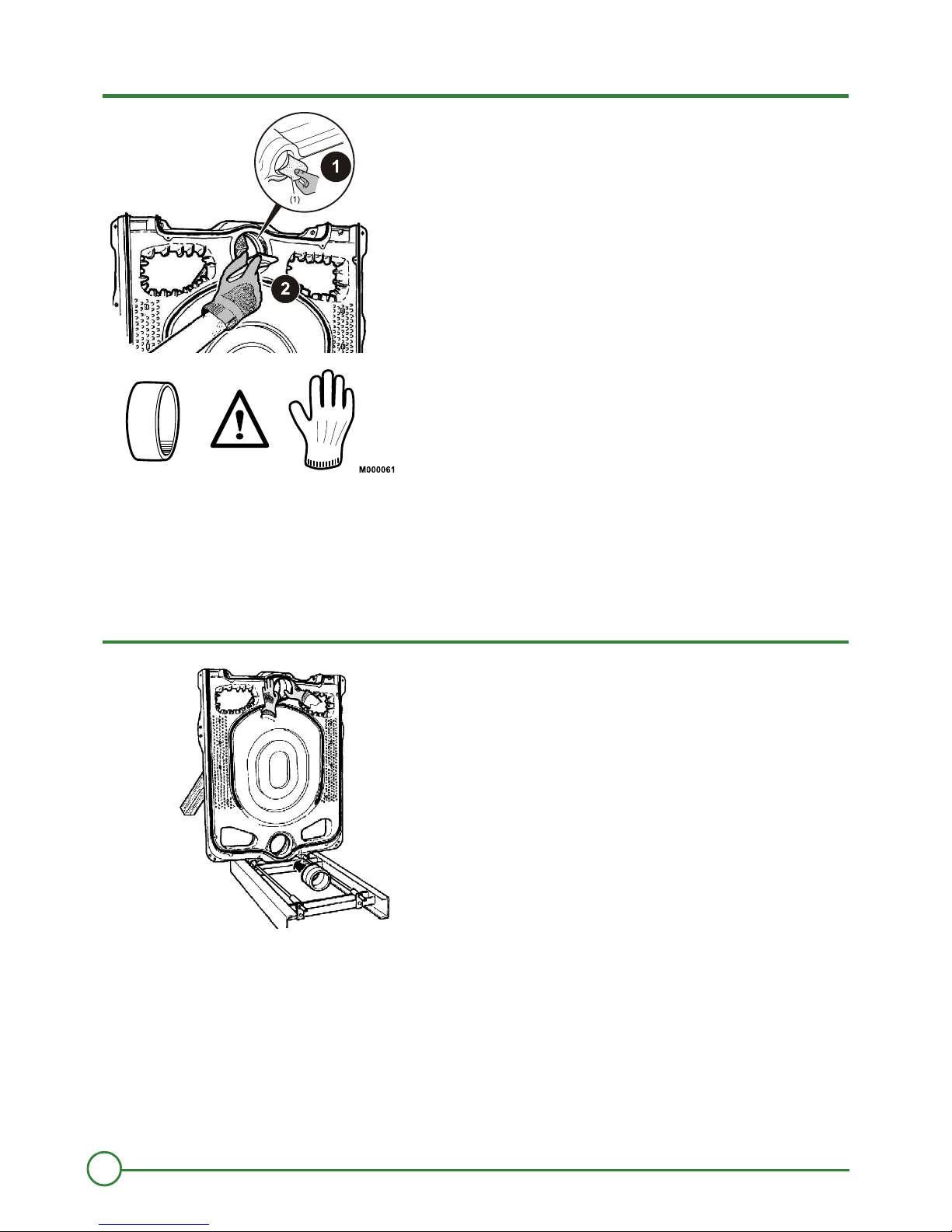

6

(1) Sandpaper

Handle the nipples with gloves, there might be sharp edges.

Remove any traces of rustprotective paint so that the surface is perfectly smooth.

Smear the nipples with the greasing product provided.

7

` Gently push in the 2 nipples.

A

R

R

I

ÈR

E

D

ES

S

US

O

B

E

N

T

O

P

VA

A

N

T

A

R

R

I

R

È

E

DE

S

S

U

S

O

EB

N

T

OP

A

V

A

NT

M000062

11

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

8

` Fill the bottom of the W groove opposite the U groove for the intermediary parts (located on the periphery of the section) with a continuous

bead of DOW CORNING silicon, diameter approximately Ø 5 mm.

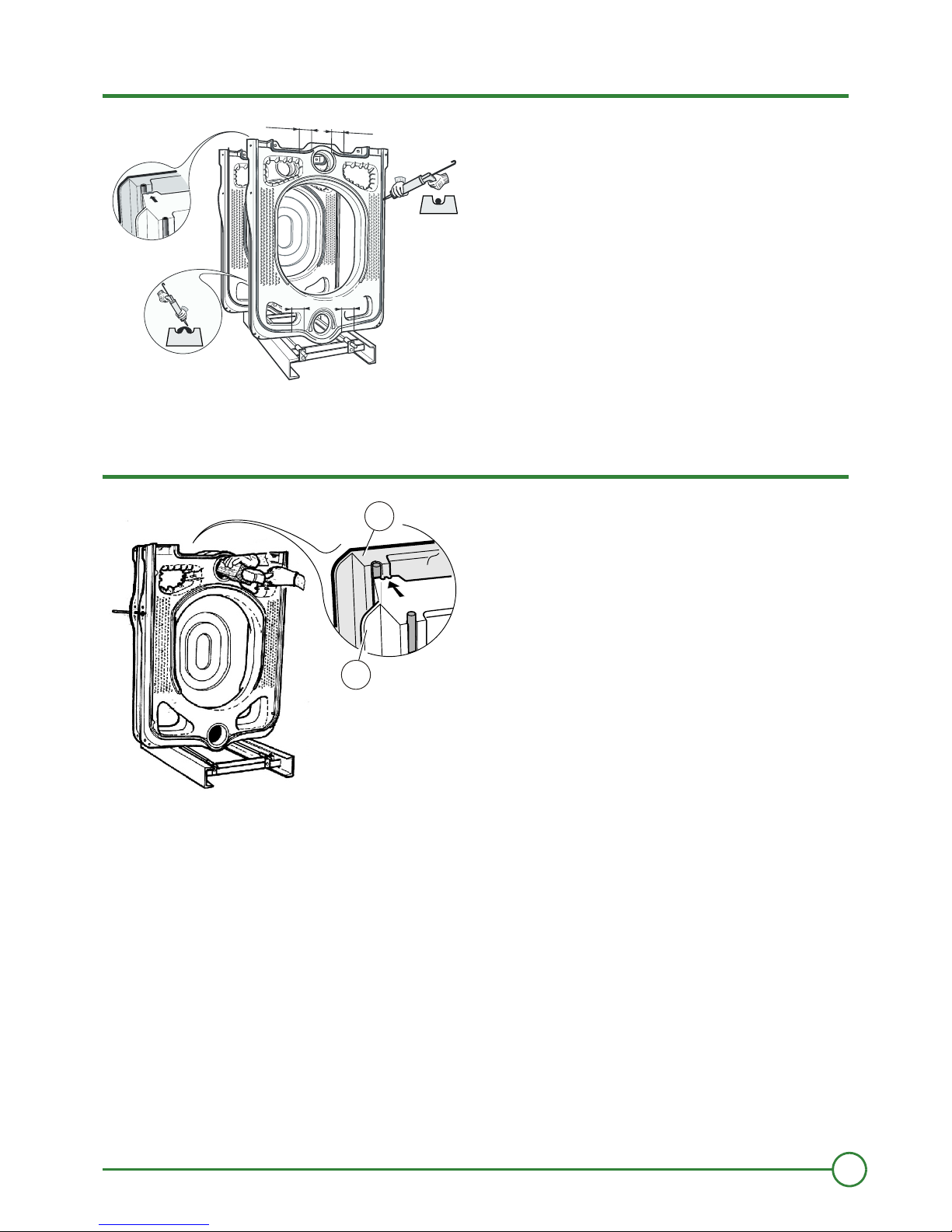

9

Rear section

Intermediate section

` Place the first normal intermediate section, making sure that it is turned in the right direction, i.e. with the flattening groove against the

thermocord.

` For safety, insert a lateral assembly rod (supplied) in the holes of the 2 sections.

` Push the section gently and simultaneously on the 2 nipples of the rear section with a hammer and a piece of wood positioned in line with

the bores.

100

100

010

010

M000063

a

M000064

1

2

12

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

10

` Put the assembly tool in position.

` Tighten gradually so as to bring together the upper and lower connections evenly and simultaneously.

11

` Assemble the remaining intermediate sections one by one, to the procedure stated in figures 3, 4, 5, 6, 7, 8, 9,, and 10.

` First assemble the normal intermediate sections, then the special ones.

Leave the assembly tool in place.

M000065

M000066

13

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

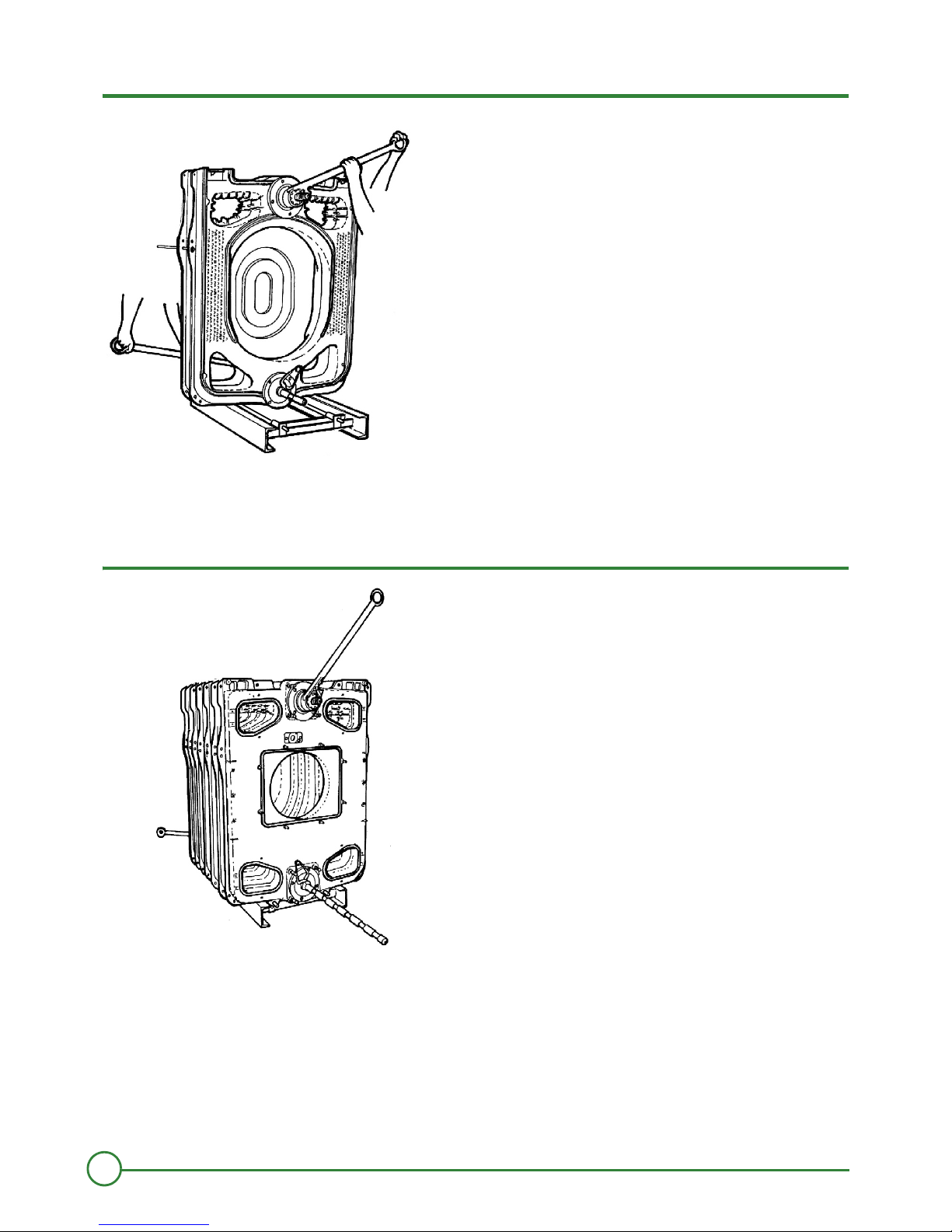

12

` Trim off any projecting ends of the thermocords the sweeping covers.

13

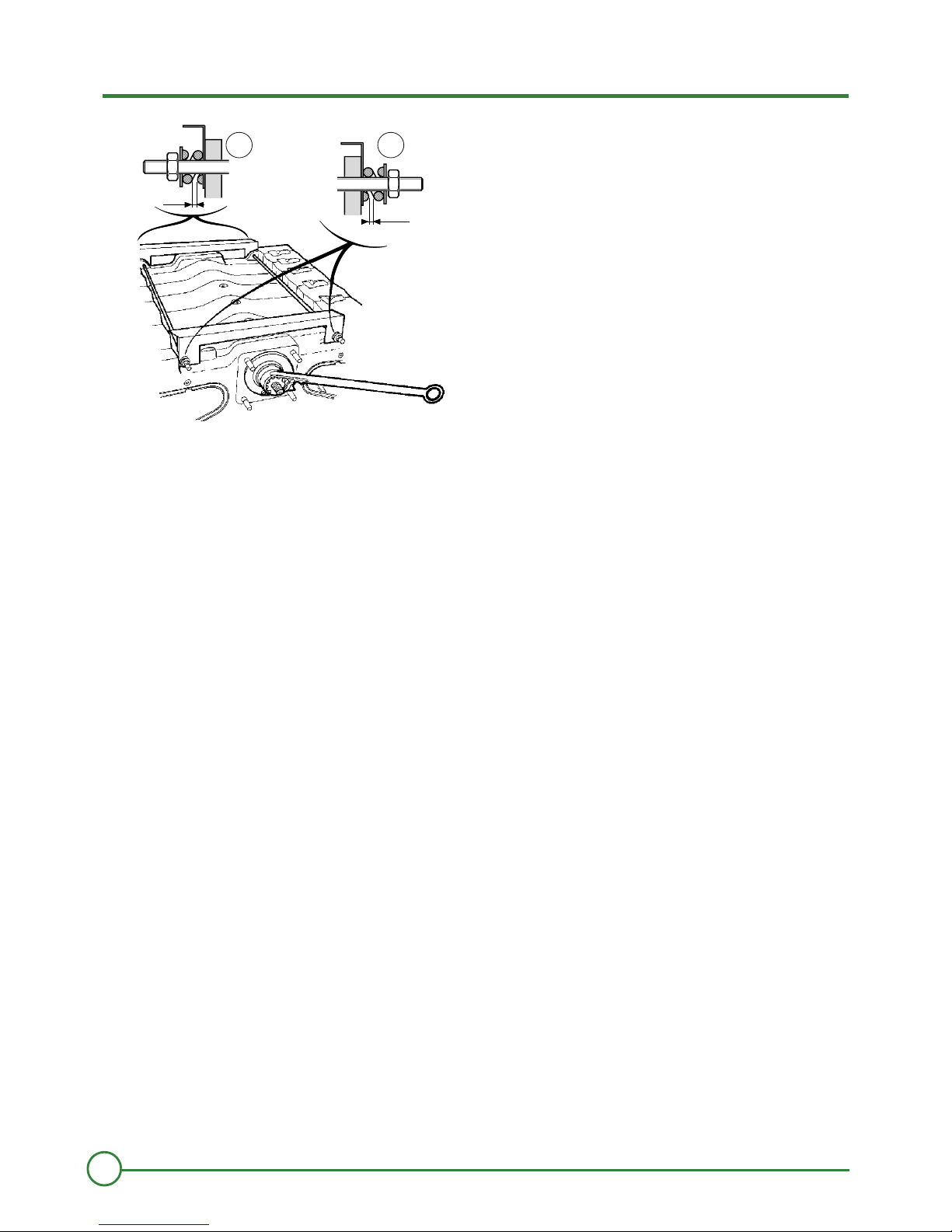

Fitting the upper and lower assembly rods

` On the lower assembly rods, fit the following at each end in the given order : an expansion spring, a washer and a nut (the holes of the

front lugs must be aligned with the holes of the frame brackets as the assembly rods are used to make the boiler body integral with the

frame).

` Stop tightening as soon as the gap between the spring spires is equal to about 2 mm.

M000067

M06000 8

2

14

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

14

Rear

Front

` Put in place the upper assembly rods in the two front and rear lugs.

` Mount the 2 crosspieces (supplied in package MS1/MS2) with their bends turned backwards and fasten them to the rods with an

expansion spring, 1 nut and 1 washer

` Remove the assembly tool.

00069M0

2

2

21

15

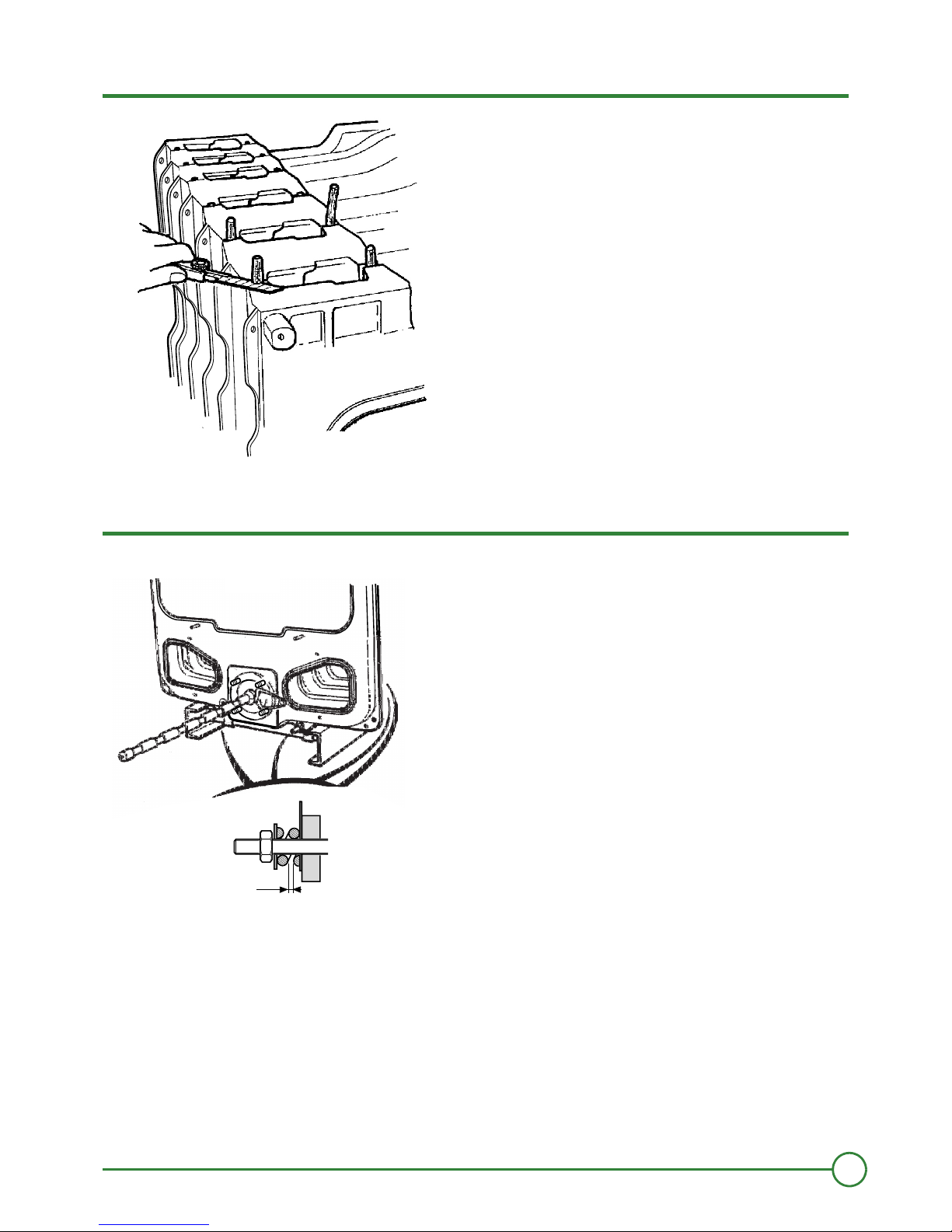

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

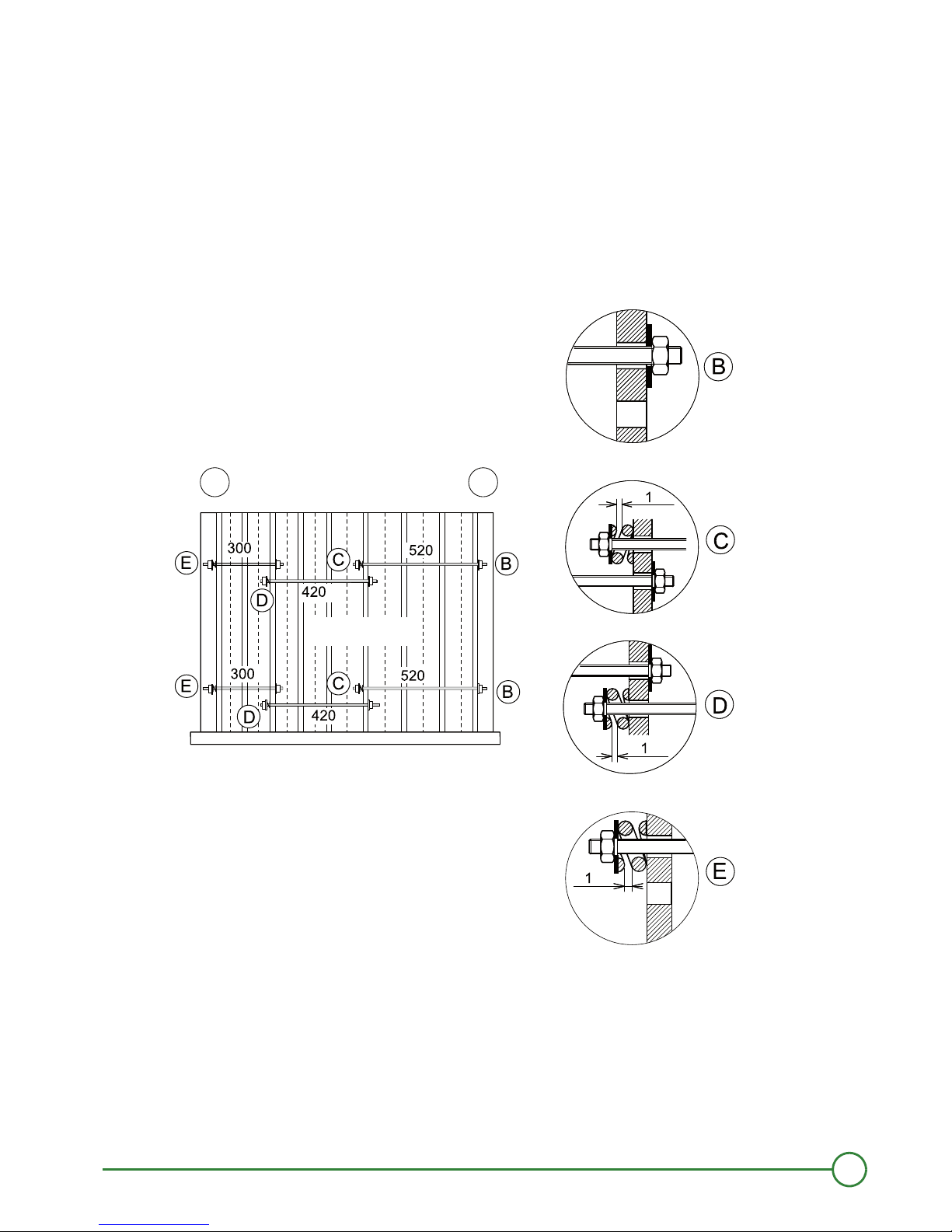

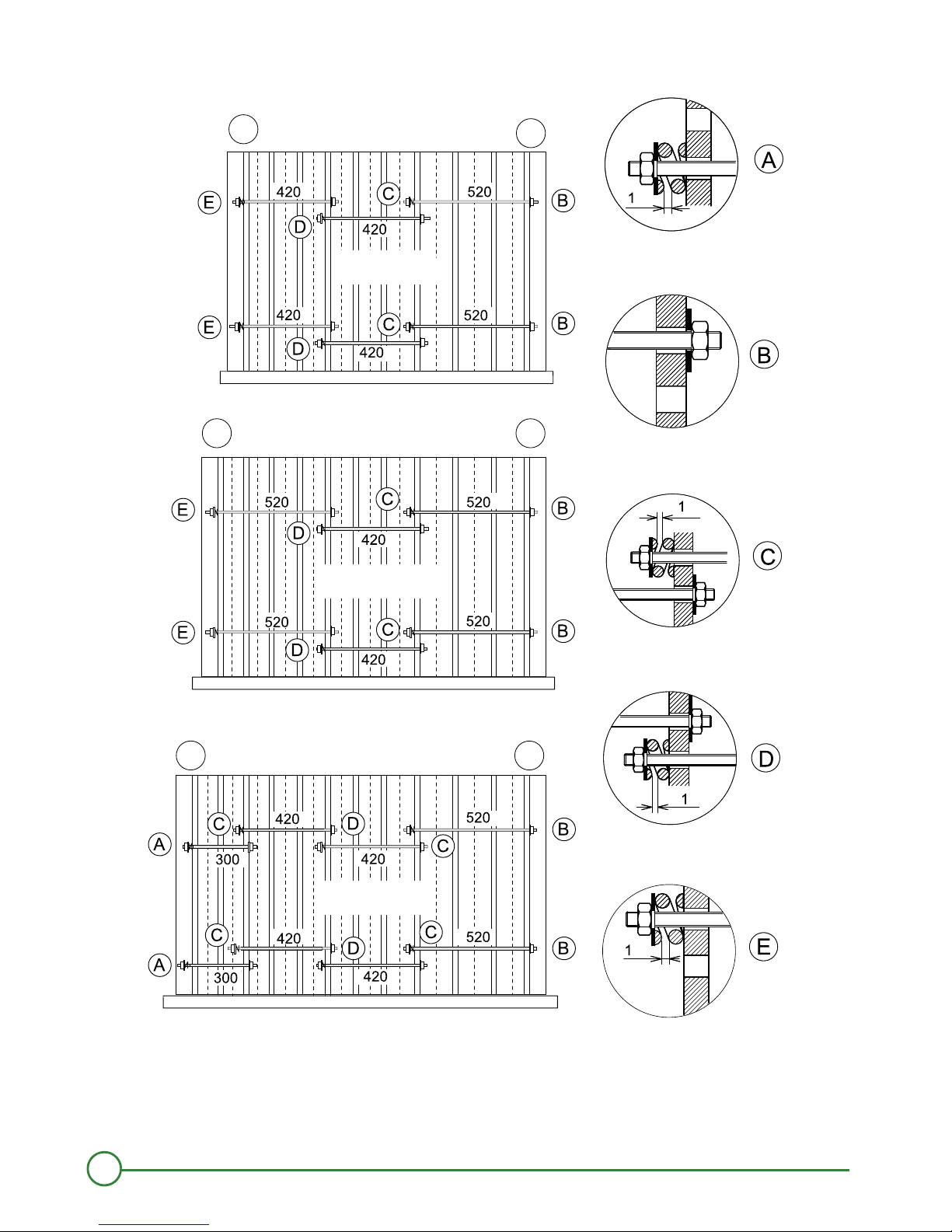

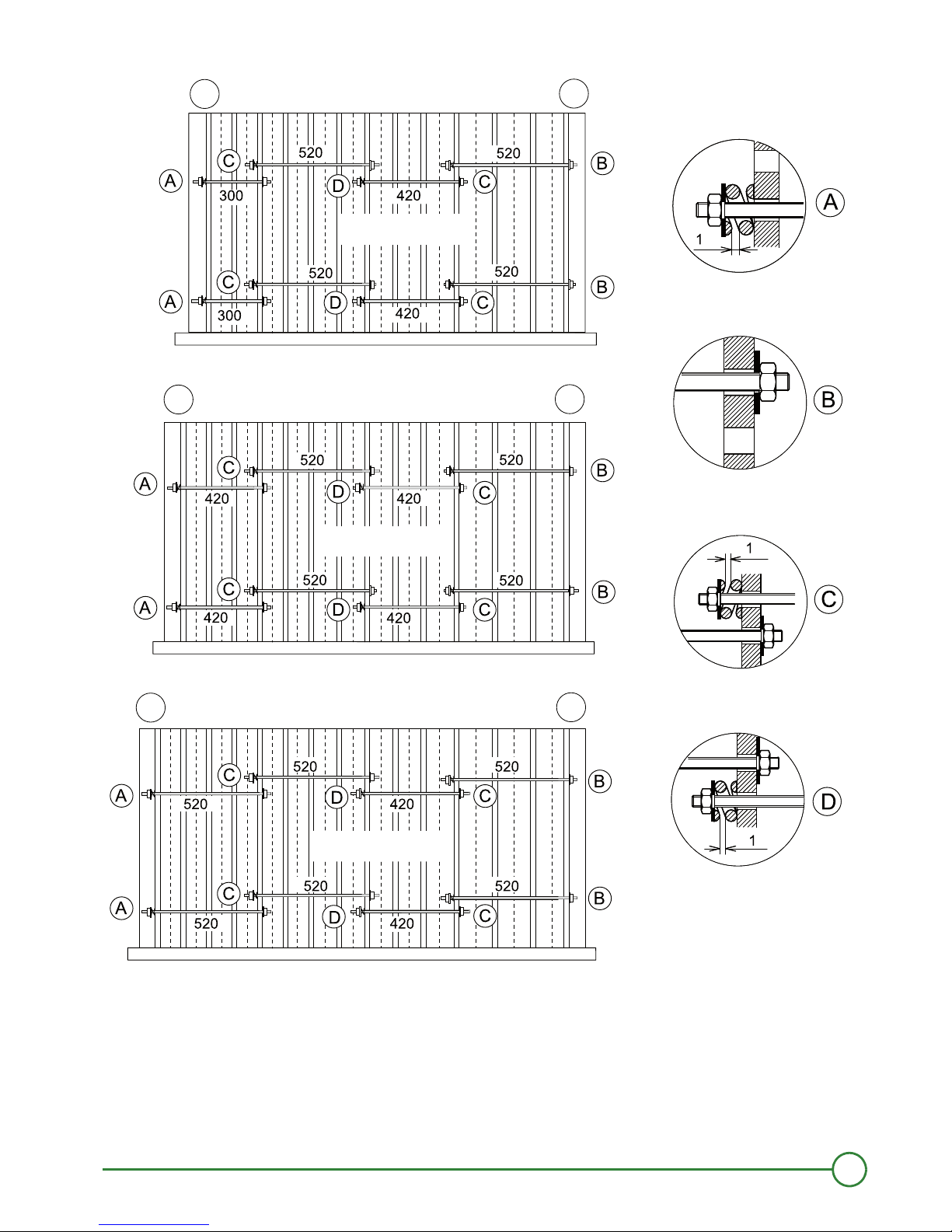

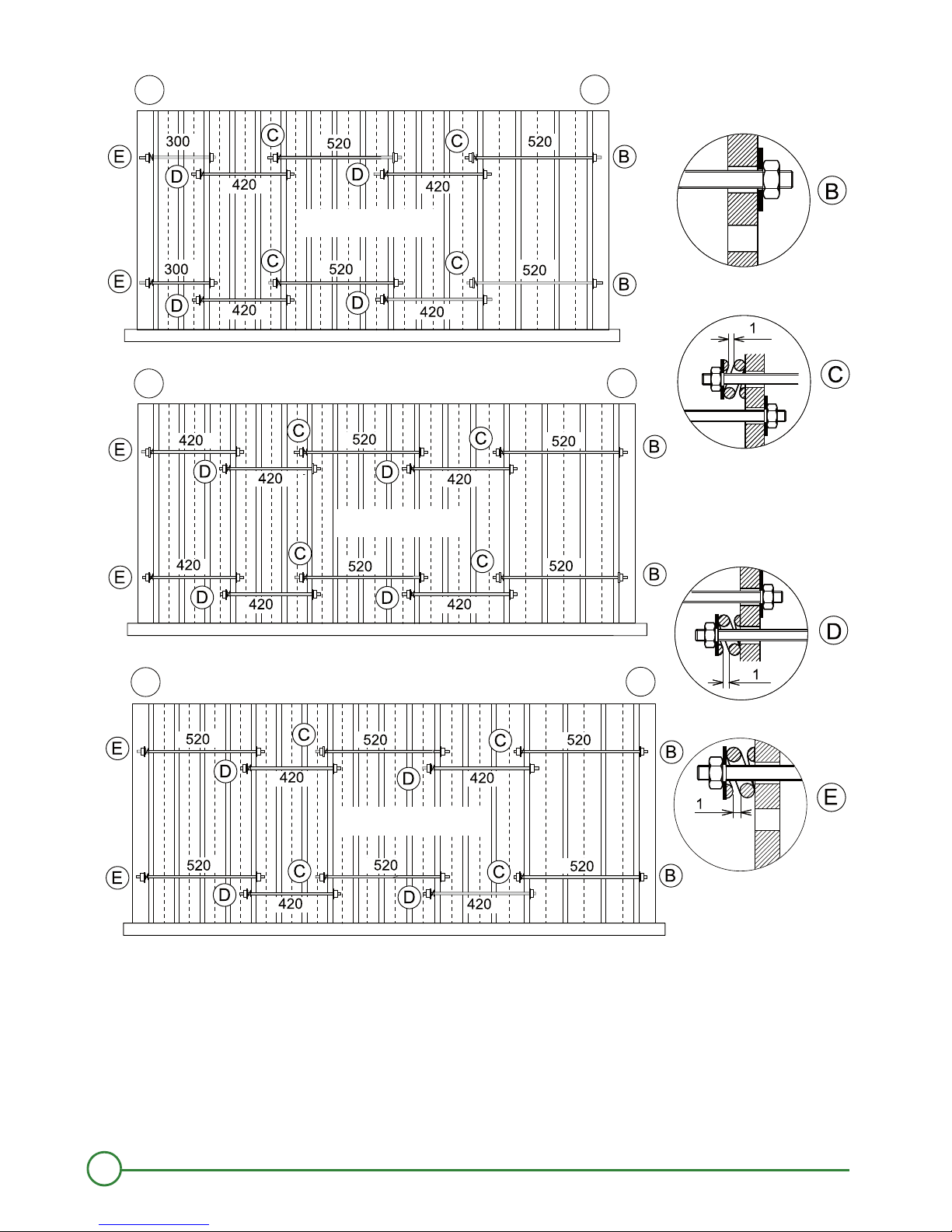

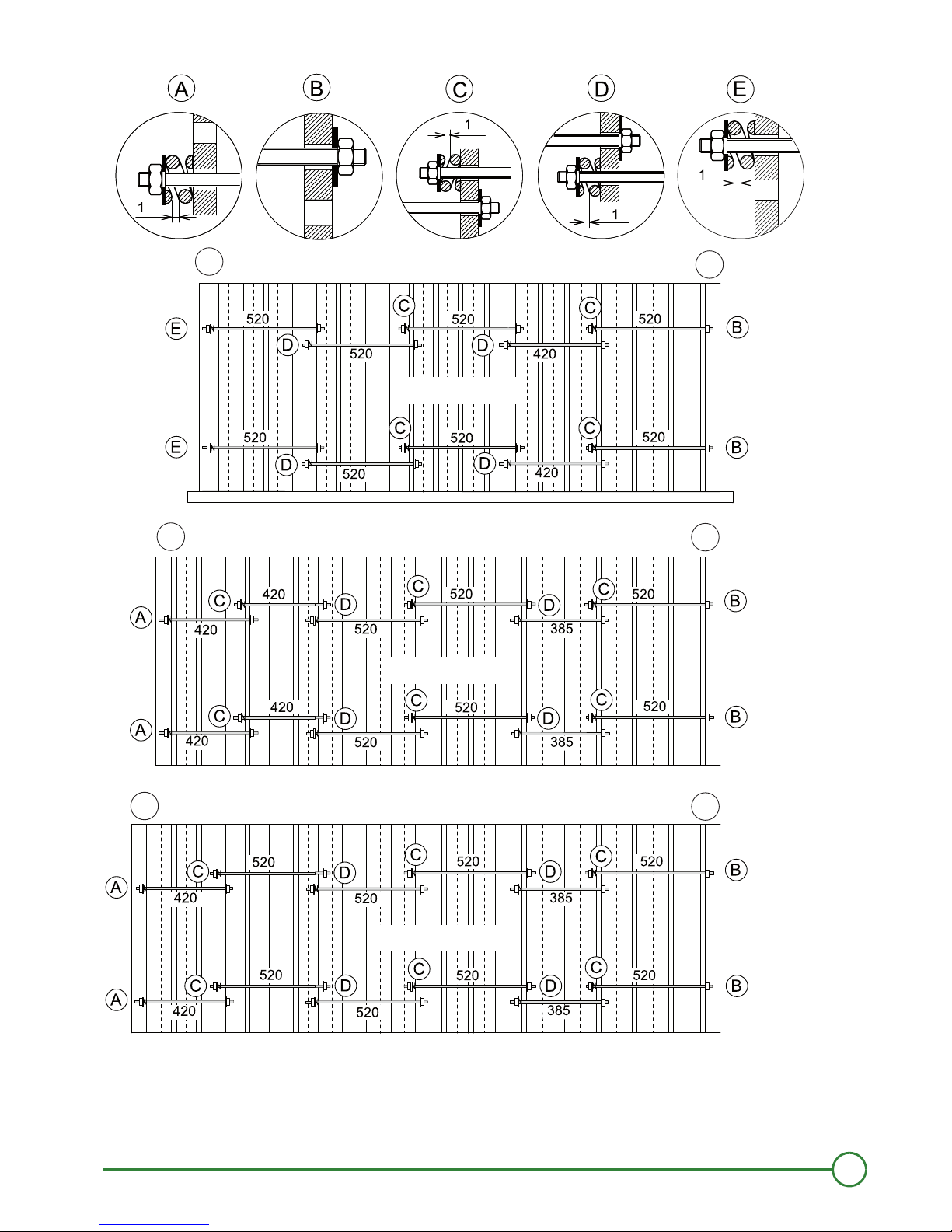

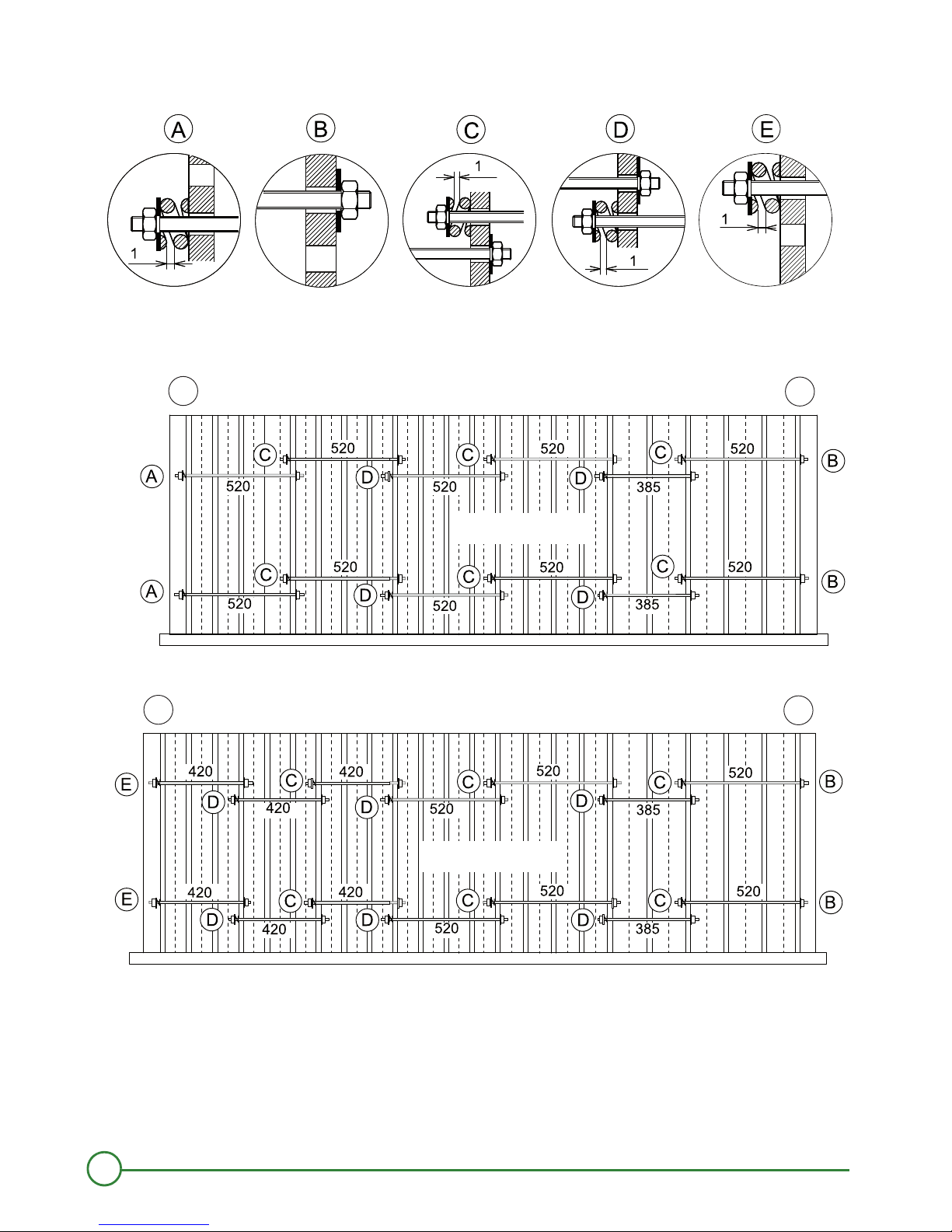

Assembling the side assembly rods

The side assembly rods must be assembled from the rear to the front.

The rods must be inserted in the holes stated in the diagrams (the lugs of the sections in which the assembly rods are to be

inserted have 2 holes).

` Place the expansion spring and washer on the rear of each rod.

` Stop tightening the nuts as soon as the gap between the spires of the springs is about 1 mm

Rear

Front

Dimensions are given in millimeters.

D000915A

1

2

PK550-9

16

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

Rear

Front

Dimensions are given in millimeters.

PK550-10

PK550-11

PK550-12

D000916A

1

2

1

2

1

2

17

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

Rear

Front

Dimensions are given in millimeters.

PK550-13

PK550-14

PK550-15

D000917A

1

2

1

2

1

2

18

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

Rear

Front

Dimensions are given in millimeters.

PK550-16

PK550-17

PK550-18

D000918A

1

2

1

2

1

2

19

18/03/2016 - 300020196-02 PK 550

2. Mounting PK 550

Rear

Front

Dimensions are given in millimeters.

PK550-19

PK550-20

PK550-21

D000919A

2

1

2

1

2

1

20

PK 550 18/03/2016 - 300020196-02

2. Mounting PK 550

Rear

Front

Dimensions are given in millimeters.

PK550-22

PK550-23

D000920A

2

1

2

1

Loading...

Loading...