Page 1

Operating Instructions

OS3 Vitrex VC830201

VV016031E

0297

29.05.09 VV016031E 1

Page 2

Instructions for using the Oertli OS3 VC830201 Vitrex Module

Contents Page

1 Application and description.........................................................................................................3

2 Important points and hazards .....................................................................................................3

3 The control panel ........................................................................................................................4

3.1 Arrangement of control and indicator elements..........................................................................4

4 Foot switch and pedal.................................................................................................................5

4.1 Foot-operated switch (stand-alone operation) ............................................................................5

4.2 Duallinear pedal (interconnected operation)...............................................................................5

5 Supply connections / power on-off..............................................................................................5

5.1 Compressed air connection ........................................................................................................5

5.2 Electrical connection ...................................................................................................................5

5.3 Replacing fuses...........................................................................................................................5

6 Operation ....................................................................................................................................5

6.1 AIR ..............................................................................................................................................5

6.2 VISCO.........................................................................................................................................6

6.3 LUM light source .........................................................................................................................6

6.3.1 Changing lamps ..........................................................................................................................7

7 ParaProg settings........................................................................................................................7

8 System communication...............................................................................................................7

8.1 Visual displays ............................................................................................................................7

8.2 Acoustic signals ..........................................................................................................................7

8.3 Voice confirmation.......................................................................................................................7

9 Choice of set values....................................................................................................................7

10 Cleaning and sterilisation instructions.........................................................................................7

10.1 Cleaning......................................................................................................................................8

10.2 Sterilisation..................................................................................................................................8

11 Accessories and replacement parts............................................................................................8

12 Authorised service centres..........................................................................................................8

13 Technical data.............................................................................................................................8

14 Overview of messages, warnings and error messages..............................................................9

15 Explanation of symbols...............................................................................................................10

16 Calibration and maintenance ......................................................................................................10

17 Disposal ......................................................................................................................................10

18 OS3 Vitrex VC830201, Overview................................................................................................11

29.05.09 VV016031E 2

Page 3

1 Application and description

The OS3 Vitrex operating unit is used for surgical

procedures in the posterior segment of the eye. It can be

used as a stand-alone unit or, preferably, in conjunction

with the OS3 VC830100 base unit.

The functional features offered by the instrument include

inter-ocular lighting, an air pump to maintain inner eye

pressure and a pump for the injection and extraction of

visco-elastic substances.

IMPORTANT!

Alterations and repairs may only be undertaken by persons

authorised by the manufacturer, otherwise the proper

functioning of the unit may be impaired.

CAUTION!

The unit must never be used in areas containing

inflammable anaesthetics!

The unit actuates and controls the accompanying

instrumentation and consumable materials within the

performance limit values selected by the operator in each

case, and as set on the control panel. A foot pedal is used

for the fine adjustment of these values within the specified

range. The unit is extremely easy to operate. Frequently

used settings can be stored and recalled.

The unit may only be used with the Oertli instruments and

consumable materials recommended and supplied by the

manufacturer (see Section 11).

The unit may only be operated by trained personnel. The

surgeon is responsible for defining the correct settings.

The unit is not suitable for surgical interventions outside the

eye. If in doubt, please contact the manufacturer.

2 Important points and hazards

IMPORTANT!

Please read these instructions very carefully before using

the apparatus for the first time!

IMPORTANT!

When setting up the unit, ensure that neither the rear

ventilation holes nor the top of the unit are covered.

CAUTION!

Never look directly into the lamps when they are lit!

IMPORTANT!

Mobile telephones and other appliances that use radio

frequencies may cause unexpected or undesirable

behaviour of the unit or system!

IMPORTANT!

Never place the unit or system next to or on top of other

appliances when operating it. If it is necessary to arrange

the appliances in this way, it must be checked in each case

that the unit or system is working correctly.

NOTE!

In order to avoid the risk of electric shock, this unit may

only be connected to mains supplies with a protective earth

connection.

IMPORTANT!

The user is responsible for ensuring compliance with and

fulfilment of IEC 60601-1

IMPORTANT!

Before connecting the unit, check that the voltage shown

on the rating plate is the same as that of the operating

room!

CAUTION!

The Visco instrument connections (INJCT and EXTR) must

never come into direct contact with the eye! If a syringe is

to be used as a silicone container, care must be taken to

ensure that there is no air in the syringe reservoir!

IMPORTANT!

While in the EXTR mode, ensure that liquid is never sucked

into the unit at the Visco instrument connection, especially

during the application of substances with a lower viscosity.

IMPORTANT!

The correct choice of equipment settings is the

responsibility of the surgeon!

Settings given in this instruction manual are suggestions

only.

IMPORTANT!

Only those instruments and accessories supplied by the

manufacturer and listed in Section 11 may be used!

29.05.09 VV016031E 3

Page 4

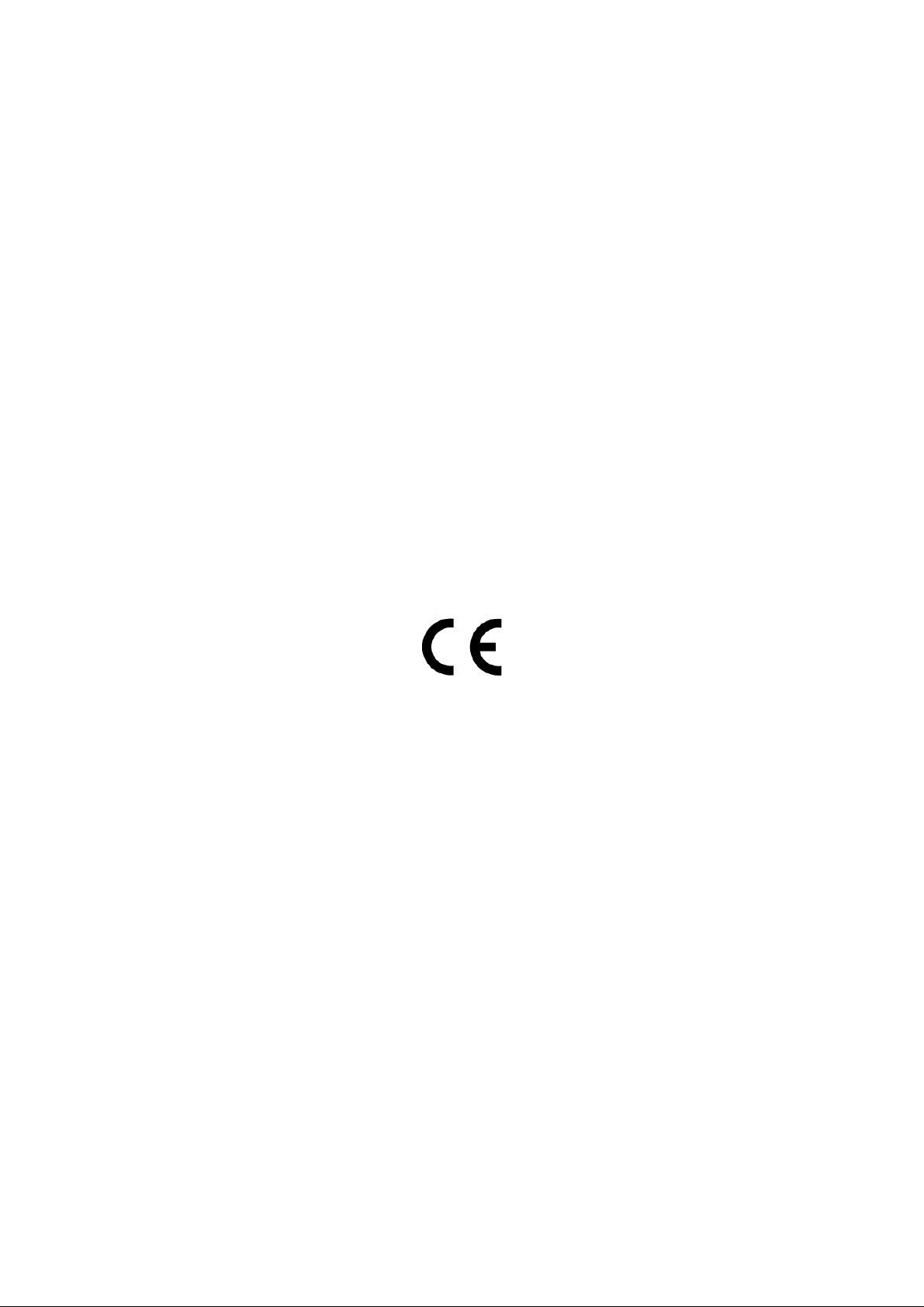

The control panel

40 mmHg

0.50 bar

0.10 bar

All settings for operating the OS3 Vitrex unit can be entered

on the control panel (pre-settings are entered in ParaProg,

see Section 7). A visual display shows at a glance the

operating state of the system and the current values.

The buttons respond to gentle pressure which can also be

applied either with a sterile swab or the sterile operating

pen (VE850003) available from the manufacturer.

Depending on the stage of the operation or the position of

the control pedal, certain buttons will be disabled. This

feature offers increased protection against improper use.

The execution of a command is accompanied by

corresponding changes in the display field. If a disabled

button is pressed, no change is shown on the display.

The control panel cannot be separated from the unit. If you

are using it in combination with the OS3 VC830100 base

unit, a VE830020 remote controller can be attached.

2.1 Arrangement of control and indicator elements

Diplay and

setting area

Function

selection area

Injection pressure indicator

Displays the selected limit value (current value flashes

when active) of the injection pressure at the VISCO (B)

outlet. The unit of measurement can be set using ParaProg

(mmHg, PSI, kPa).

Extraction vacuum indicator

Displays the selected limit value (current value flashes

when active) of the extraction vacuum at the VISCO (B)

outlet. The unit of measurement can be set using ParaProg

(mmHg, PSI, kPa).

Arrow buttons

The arrow buttons can be used to reduce (down arrow) or

increase (up arrow) the value shown in the display field

immediately above. Exert normal pressure to change the

value slowly or in individual increments, or fully depress for

rapid value setting.

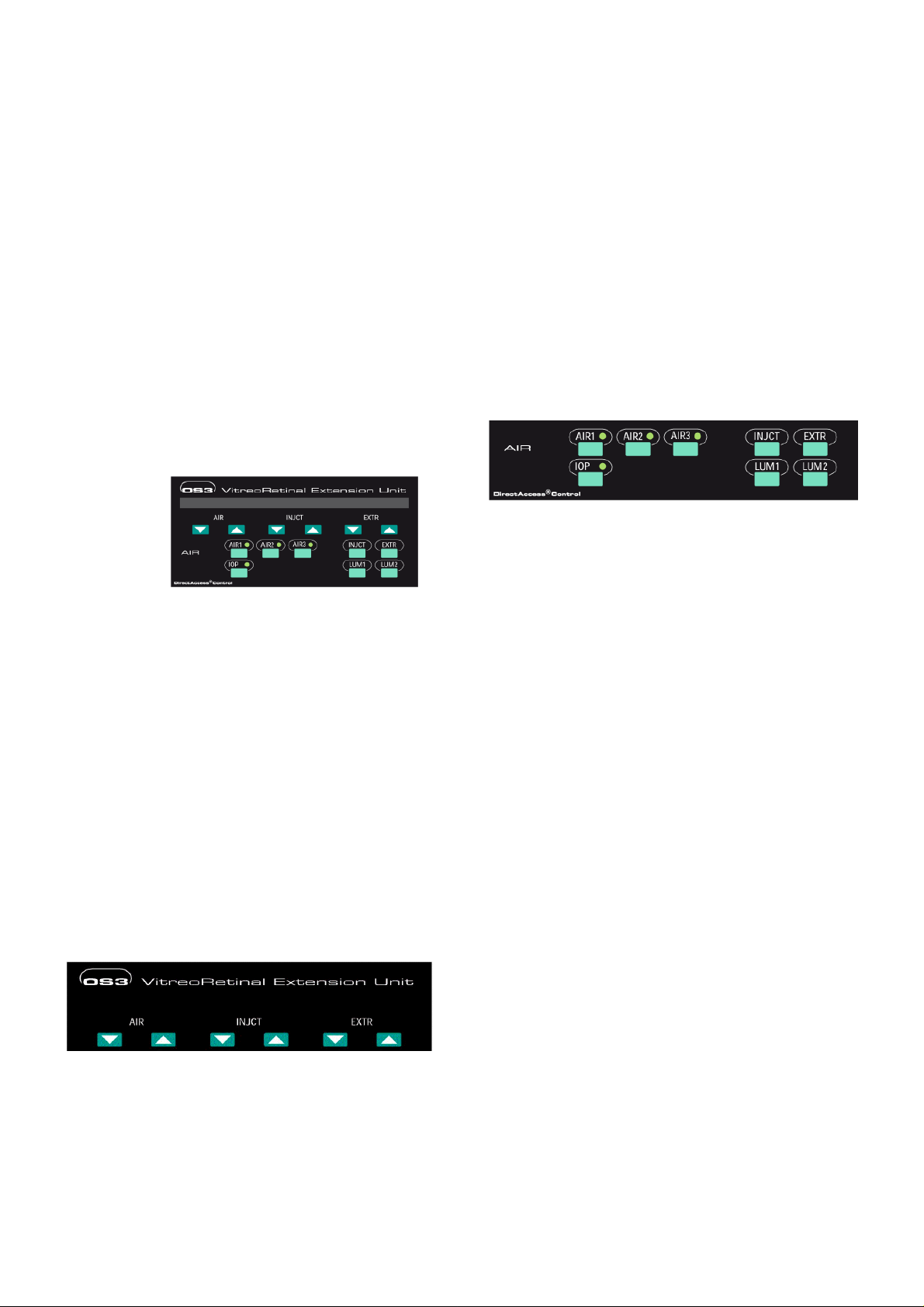

The function selection area

AIR1 button and indicator light

Activates the AIR function with the pressure value stored in

memory 1. The indicator lamp lights up.

Press again to activate the pump and reduce pressure.

Pressing once more will deactivate the pump and the

function and switch off the indicator lamp.

The control and indicator elements are grouped in such a

way that they can be operated after only a short period of

familiarisation, even in semi-darkness. The top half of the

control panel is the indicator and setting area. It is designed

to show at a glance the operating state of the unit and the

current values. The values displayed can be increased or

reduced using the dark green arrow buttons directly below

the value displays.

The lower half of the control panel houses the function

selection buttons.

Please familiarise yourself thoroughly with this ergonomic

arrangement of the control elements; it will enable you to

operate the equipment quickly almost "blind"!

The display and setting area

Air pressure indicator Injection pressure Extraction vacuum

indicator Indicator

Air pressure indicator

Displays the selected limit value (current value flashes

when active) of the air pressure at the AIR (A) outlet. The

unit of measurement can be set using ParaProg (mmHg,

PSI, kPa).

AIR2 button and indicator light

Activates the AIR function with the pressure value stored in

memory 2. The indicator lamp lights up.

Press again to activate the pump and reduce pressure.

Pressing once more will deactivate the pump and the

function and switch off the indicator lamp.

AIR3 button and indicator light

Activates the AIR function with the pressure value stored in

memory 3. The indicator lamp lights up.

Press again to activate the pump and reduce pressure.

Pressing once more will deactivate the pump and the

function and switch off the indicator lamp.

INJCT button

Activates the Visco injection function with the limit value

last used for the injection pressure. Press again to switch

off the function.

EXTR button

Activates the Visco extraction function with the limit value

last used for the extraction vacuum. Press again to switch

off the function.

IOP button and indicator light

Enables the control of AIR functions via a duallinear pedal

(illuminated display) when operated in combination with the

OS3 VC830100 base unit

When the unit is operated in stand-alone mode this button

has no function.

29.05.09 VV016031E 4

Page 5

LUM1 button

QOP

Switches the left-hand light source (LUM1) on and off.

If no pressure is detected, the message "CHECK

COMPRESSED AIR!" appears.

LUM2 button

Switches the right-hand light source (LUM2) on and off.

Note: If the light source is ON the display shows an

asterisks * between the values for Extraction and Injection

3 Foot switch and pedal

When used as a stand-alone unit, pneumatic foot switches

control the Vitrex. When used in combination with the OS3

VC830100 base unit, it is controlled by the duallinear pedal.

3.1 Foot-operated switch (stand-alone operation)

The hoses for the pneumatic foot-operated switches INJCT

(no. 1), EXTR (no. 2) and AIR (no. 3) can be inserted into

the rear of the Vitrex unit. Ensure that the foot-operated

switches are not depressed whilst the hoses are being

inserted.

3.2 Duallinear pedal (interconnected operation)

In interconnected operation, the INJCT, EXTR and AIR

functions can be controlled by the duallinear pedal. See

operating instructions VV016011D for the OS3 base unit.

4 Supply connections / power on-off

4.1 Compressed air connection

Connect the compressed air connector K to the

compressed air network using a NIST EN 397 air fitting

(VX100911).

IMPORTANT!

The compressed air supply must have a pressure of 6.5 –

10 bar!

NOTE: The LUM (light) and AIR functions can be operated

even without a pressure connection.

4.2 Electrical connection

IMPORTANT!

The mains supply voltage in the operating area must be

100 - 240 V AC / 50 - 60 Hz!

After a successful test, the message "SYSTEM READY!"

appears, and the installed software version is displayed in

weakly illuminated lettering.

The unit is now ready and can be prepared for the

operation.

4.3 Replacing fuses

Press clip on fuse holder P to the right, until it pops out.

Use a small screw driver if need be. Fully pull out holder.

Insert new fuse and push holder P back in again.

The correct fuse value is printed above the holder P on the

rear panel of the unit.

5 Operation

5.1 AIR

Connect an air delivery line with filter (VV690100) or an

alternative Oertli original air feed accessory (see Section

11) to the AIR (A) port. Observe the instructions on the

packaging note.

IMPORTANT!

Only Oertli original accessories should be used. A filter

should always be attached to the AIR port. Accessories

must not be re-used!

Press one of the buttons AIR1, AIR2 or AIR3. The stored

pressure value and the indicator lamp for the respective

memory will light up in the air pressure display field.

Use the arrow button to change the pressure value. The

range is 1-120 mmHg, unless otherwise limited in

ParaProg.

The air supply can be switched on and off in the following

ways:

With the active (light indicator) AIR1, 2, 3 button

With the AIR foot switch (pneumatic)

With the TOP right pedal switch1), if used in

conjunction with the OS3 base unit

With the active AIR1, 2, 3 button (light indicator) on the

remote controller if used in conjunction with the base

unit.

1)

If specified in ParaProg for the base unit

NOTE: If the Vitrex unit is in standby or System Ready

mode, the AIR1 function will be switched on just by

activating the foot switch or the TOP right switch.

Plug the supplied mains cable into the mains connection

socket O (on the rear panel of the unit), and connect to the

mains supply socket.

Set the mains switch Q to position I.

As soon as it is switched on, the unit performs an autotest

to check the functioning of the circuits, voltages and

pressure system.

The display will flash continuously while the air supply is

active, and it is possible to change between memories

AIR1, AIR2 or AIR3 at any time.

The AIR function can be operated in parallel with all of the

other functions of the OS3 system (Vitrex and base unit).

IOP function (only in interconnected operation)

When the IOP button is active (indicator light on), air

pressure can be changed using the HEEL switches of the

duallinear pedal (stepless, or by changing between AIR 1,

2 and 3, depending on the ParaProg setting). The air

pressure is shown in the display for the bottle height (OS3

29.05.09 VV016031E 5

Page 6

operating panel), and the corresponding arrow buttons are

functional.

The IOP function is used mainly in conjunction with the

accessories for active infusion.

Warning tone

An alarm threshold for the pressure value can be defined in

ParaProg (Section 7). When the specified pressure value is

reached, an alarm tone sounds regardless of memory

AIR1, 2 or 3.

Storing values

Press the desired button AIR1, 2 or 3. Set the pressure to

the required value using the arrow buttons. Hold down the

active button AIR1, 2 or 3 until "VALUE SET" appears. If

the button is not depressed long enough, "NOT SET" will

appear.

NOTE: When used in conjunction with the OS3 base unit,

the value stored will apply only for the surgeon whose

number has been entered.

5.2 VISCO

Connect a silicone application set, VV690210 or VV690211

or other Oertli original Visco accessory to the VISCO (B)

port. Observe the instructions on the packaging note

precisely.

IMPORTANT!

Only Oertli original accessories should be used. Always

attach the VISCO connection to an infusion syringe, and

never bring it into direct contact with the eye!

INJCT/EXTR function

Both the INJCT and EXTR functions can be operated

simultaneously. Press the INJCT and EXTR buttons to do

this. When using the duallinear pedal, INJCT is to the left

and EXTR to the right.

NOTE: In interconnected operation with the OS3 base unit,

the aspiration function may also be operated during the

INJCT and EXTR function. To do this, set the required flow

rate (venturi rate) and aspiration vacuum on the base unit.

The values used last will appear. To aspirate, move the

duallinear pedal to position 2.

5.3 LUM light source

IMPORTANT!

Never operate the light source with the cover open – risk of

being dazzled!

Always connect a light instrument to the light output before

switching on to avoid being dazzled!

Never use light instruments with other connectors and

never push foreign objects into the light output socket.

Reduce the brightness using the rotary knob before

switching on.

Connect a light instrument with Oertli original light

connector to each of the light outputs LUM1 and LUM2.

INJCT function

Press the INJCT button. The value used last appears in the

injection pressure display field (surgeon-specific in

interconnected operation). Use the arrow buttons to change

the pressure value. The range is 0.05 – 5.0 bar unless

otherwise limited in ParaProg (Section 7).

The injection pressure is switched on or off by pressing the

pneumatic foot switch (left). The display will flash and an

acoustic signal will sound. When used in conjunction with

the OS3 base unit, the injection pressure is regulated

linearly by moving the duallinear pedal to the left or right.

To exit the INJCT function, press the INJCT button or, in

interconnected operation, a function button on the OS3

base unit.

EXTR function

Press the EXTR button. The value used last appears in the

extraction vacuum display field (surgeon-specific in

interconnected operation). Use the arrow buttons to change

the vacuum value. The range is 0.01 – 1.0 bar unless

otherwise limited in ParaProg (Section 7).

The extraction vacuum is switched on or off by pressing the

pneumatic foot switch (right). The display will flash and an

acoustic signal will sound. When used in conjunction with

the OS3 base unit, the vacuum value is regulated linearly

by moving the duallinear pedal to the left or right.

The VX100940 adapter can be used to connect disposable

light instruments.

The light source is suitable for both disposable and

autoclavable light instruments.

Insert the light instrument into the connection socket until

fully engaged.

Switch on the lamps with the LUM1 and LUM2 buttons. To

switch off, press the respective button again. The cooling

fan will continue to run for a time.

The desired brightness can be set smoothly using the

rotary knobs for light dimming. The two light sources are

independent of each other.

NOTE: Hot lamps must be allowed to cool down before

they can be switched on again. The cooling time is around

30 seconds. A message will appear if an attempt is made

to switch on the lamp again within this period of time.

NOTE: If a lamp begins to flicker during operation, it has

reached the end of its service lifetime. The lamp must be

replaced before the next operation.

NOTE: if both lamps fail to light up, switch the unit off for at

least 15 seconds. Then try again to light the lamps.

To exit the EXTR function, press the EXTR button or, in

interconnected operation, a function button on the OS3

base unit.

29.05.09 VV016031E 6

Page 7

5.3.1 Changing lamps

If a lamp does not light up after frequent attempts to do so

or does not light up at all within one minute, it has reached

the end of its service life and must be replaced.

Allow the unit to cool until the fan switches off, then

switch off the mains switch Q.

Remove the middle screw from the sliding cover.

Open the sliding cover on top of the unit in the

direction of the arrow.

Remove the clamping screw next to the socket and

separate the plug halves.

Pull out the socket together with the lamp and insert a

new lamp.

Insert the clamping screw and connect the plug halves

together.

IMPORTANT!

- Risk of burns

- Do not touch the metal halide lamps with your bare hand!

Hold the lamp by the metal socket only. Use only original

VV300004 lamps.

6 ParaProg settings

Several important basic settings can be entered in the

ParaProg. These settings only affect the Vitrex unit, and

have nothing to do with the ParaProg settings for the OS3

base unit. However, if the Vitrex unit is being used in

conjunction with the OS3 base unit, the ParaProg settings

will apply only for the surgeon selected in the base unit.

The respective parameter appears in the AIR display field.

Selectable options are shown in the INJCT field. The

Illuminated value is the one previously selected; the

flashing value may be selected by pressing the ↵ -button.

To exit ParaProg, press the AIR1 function button.

7 System communication

7.1 Visual displays

Selected, stored and current values and important

information about the status of the unit are indicated by

light displays on the control panel. Warnings and

instructions appear in the language selected in ParaProg.

See Section 7.

7.2 Acoustic signals

The unit uses acoustic signals to inform you about the

generation of vacuum and pressure.

INJCT pressure: slow repeating beep tone

EXTR vacuum: slow repeating high/low acoustic signal

Volume control

The volume can be set between 0 - 100 % in ParaProg.

The volume is not surgeon-specific when used in

combination with the OS3 base unit.

7.3 Voice confirmation

If the unit is being operated in conjunction with the OS3

base unit, the voice confirmation function of the OS3 base

unit will also include the Vitrex unit. See operating

instructions VV016011D for the OS3 base unit for detailed

information.

IMPORTANT!

For ParaProg settings in interconnected operation, it is

essential that the surgeon number in the base unit is

observed!

To access the ParaProg function, switch off the Vitrex unit

at the mains switch Q Then press and hold down the

INJCT button whilst switching on the mains switch Q again.

Release the INJCT button as soon as "ParaProg" is

displayed.

ParaProg Vitrex

To page forward in the program, press the ↓ button.

Alternatively, the arrow buttons beneath AIR can be used

to page forwards or backwards.

The ParaProg parameters are defined in the VV016032D

appendix. Make sure that they agree with the installed

software.

UnitAIR mmHg

8 Choice of set values

Every surgeon develops his own preferred operating

technique, which also requires specific set values for the

various stages of the operation.

The OS3 unit enables a high level of compatibility with

these individual requirements.

The unit is supplied with the values set during the last trial

or internal works test. These values are certainly not

recommended or suggested values. The correct choice of

equipment settings is the responsibility of the surgeon!

Please also note that set values cannot necessarily be

transferred from other makes of operating equipment to the

OS3 unit.

As a general principle, we recommend that you work

initially with moderate set values.

Our sales consultants will be pleased to advise you on the

basis of our experience during the trial and induction

period.

9 Cleaning and sterilisation instructions

IMPORTANT!

Under no circumstances may accessories for air supply,

active infusion and visco application be reused!

29.05.09 VV016031E 7

Page 8

9.1 Cleaning

Autoclavable light instruments must be immersed in BSS or

distilled water and thoroughly rinsed immediately after the

operation!

The cleaning instructions supplied with the instruments

should be strictly observed!

Consumable material, AIR/VISCO (disposable)

VV690100 Air delivery line with filter, pack of 10

VV690110 Air application set for IOP control, anterior

VV690111 Air application set for IOP control, posterior

VV690210 Silicone application set, 20 cc, pack of 10

VV690211 Silicone application set, Opsia, pack of 10

Use only distilled or de-ionised water, neutral detergents

and a soft lint-free cloth or a soft sponge!

Ensure that all instruments are free of blood, tissue and

impurities caused by saline deposits or other substances.

Rinse carefully and thoroughly with distilled water, and

carefully clean with compressed air.

Do not use oxygen or other gases!

9.2 Sterilisation

Steam sterilisation is the prescribed method for light

instruments. ETO sterilisation is not recommended, and

gamma sterilisation is not permitted owing to the instability

of the materials!

IMPORTANT!

The user is responsible for the proper application of

sterilisation methods including precautions taken to ensure

bacteriological safety.

After cleaning (as described in Section 10.1), the

instruments must be sterilised in the autoclave with the

supporting air extraction device.

The recommended values are: temperature 134°C - 138°C,

minimum cycle duration of 3 minutes.

When the instruments are removed from the sterilisation

unit, they should be cooled to room temperature before

operating.

IMPORTANT!

Instruments must always be sterilised before every use!

10 Accessories and replacement parts

IMPORTANT!

The use of accessories other than those listed, or of other

converters and cables may lead to increased interference

emission or reduced interference immunity of the unit or

system!

IMPORTANT!

Accessories, converters and cables are listed in the

following table for which the manufacturer guarantees EMC

compatibility!

Consumable material, light (disposable)

VV300101 Endo illuminator, straight, pack of 10,

microconnection

VV300131 Endo illuminator, 30°, pack of 10,

microconnection

VV300201 Endo illuminator with microhook, pack of 10,

micro-connection

Light instruments, autoclavable

VE201728 Endo illuminator with diathermy, "plug-on"

VE301005 Endo illuminator with microhook, 2 m cable

VE302003 Light sleeve for SDS instruments, 1.6 mm

VE302004 Light sleeve for SUS instruments, 1.6 mm

VE308130 Endo illuminator, 30°, 2 m cable

VE308160 Endo illuminator, 60°, 2 m cable

VE308190 Endo illuminator, straight, 2 m cable

11 Authorised service centres

Switzerland Oertli Instrumente AG

(Manufacturer) Hafnerwisenstr. 4

CH–9442 Berneck

Phone: +41–71–7474200

Germany Domilens GmbH

Holsteiner Chaussee 303a

D–22457 Hamburg

Phone: +49–40–5598800

Austria Mositech GmbH

Schwefel 93

A–6850 Dornbirn

Phone: +43–5572–34534

Information about other service centres can be obtained

from the manufacturer.

Authorised representative in the EU

Germany Oertli Instrumente GmbH

Magnolienweg 14

D–63741 Aschaffenburg

Unit accessories

VC830100 OS3 base unit

VE830001 Unit trolley with infusion pole drive

VE830010 Programmable duallinear pedal

VE830020 Remote control with illumination

VX100940 Light adapter for disposable leads

VX100907 Pneumatic foot switch AIR

VX100908 Pneumatic foot switch INJCT/EXTR (VISCO)

VX100911 Pressure hose with NIST air connection

VX100912 OS3/Vitrex pneumatic connection cable

VX100913 OS3/Vitrex COM connection cable

VV300004 Replacement metal halide lamps

VX520010 3.15 AT fuses, high breaking capacity

12 Technical data

Supply pressure* Air 6.5 - 10 bar, max. 25l/min

NIST EN-739 connection

Supply voltage 100 – 240 V AC

Supply voltage frequency 50 – 60 Hz

Power consumption 320 VA

Fuses 3.15 AT, high breaking

capacity

Operating mode continuous

Application parts non-electrically powered

Protection class I

CE classification IIb

Visco injection 0.05 - 5 bar ±0.2 bar

Visco extraction 0.01 - 1 bar ±0.05 bar

Air pump 1 - 120 mmHg ±10 mmHg

29.05.09 VV016031E 8

Page 9

Light Metal halide

24 V/21 W

2 x 1460 Lumen

Noise emission < 70 dB (A)

Dimensions 380 x 110 x 340 mm (W/H/D)

Weight 8.7 kg

Transport and Temperature 20°C - +55°C

storage conditions Atmos. pressure 500hPa -

1060hPa

Relative humidity

10% - 95%

non-condensing

Operating conditions Temperature 10°C - 35°C

Atmos. pressure 700hPa -

1060hPa

Relative humidity 20% - 80%

non-condensing

*If there is no compressed air connection, the INJCT and EXTR functions

cannot be operated

13 Overview of messages, warnings and error

messages

Pressure deviation

The actual value deviates considerably from the desired

value.

Automatic safety venting.

No pressure

Pressure at the compressed air connection is too low.

Check supply pressure (min. 6.5 bar).

Not set.

Values were not stored.

System ready

The autotest has been successfully completed.

Values set

Values were stored.

Set values

Values will be stored.

Temperature too high

Allow the light to cool.

Replace lamp 1

Lamp 1 is defective, replace it.

Replace lamp 2

Lamp 2 is defective, replace it.

Call Service Error 101

Call service (internal voltages defective).

Unit cannot be operated.

Adjust Unit Error 102

Call service (pressure measurement incorrect).

Unit cannot be operated.

Extr Deviation Error 103

Pressure instead of vacuum.

Call service.

HW Lum Error 104

Incorrect light source set.

Call service.

29.05.09 VV016031E 9

Page 10

14 Explanation of symbols

COM

Use only mains fuses with the specified

value

Risk of burns!

Follow the operating Instructions

Dangerous voltages.

Do not open the unit!

Footswitch connection

Grounding pin

Operating Instructions

WEEE – have the appliance disposed of

correctly

Connection for communication with OS3

base unit

15 Calibration and maintenance

The unit requires the following calibration and

maintenance:

Yearly calibration:

Adjustment of the pressure sensor as described in the

service manual

Yearly maintenance:

Checking of electrical cables (instrument and power

leads) for signs of wear and tear, and replacement as

necessary.

16 Disposal

This unit should be disposed of in accordance with local

regulations for the disposal of electronic equipment, or it

should be returned to the manufacturer for disposal.

Items designed for single use should be disposed of in

accordance with local regulations for the disposal of

contaminated medical waste.

Instruments for repair should be cleaned and sterilised prior

to their return to the service centre.

29.05.09 VV016031E 10

Page 11

17 OS3 Vitrex VC830201, Overview

Front view

Rear view

A Air hose connection (air pump)

B Visco application set connection (INJCT/EXTR)

C Light cable connections (Oertli standard)

D Rotary knobs for light dimming

E Sliding cover for replacing lamps

F Control panel

G Connection for injection footswitch

H Connection for extraction footswitch

J Connection for air footswitch

K Compressed air connection (see service manual)

L Slot for smart card (see service manual)

M Connection for data cable to the base module

N Grounding pin

O Mains connection socket

P Fuse holder

Q Mains switch

29.05.09 VV016031E 11

Page 12

Table 201:

Guidelines and manufacturer’s declaration – electromagnetic compatibility

The unit is intended for operation in the electromagnetic environment described below. The customer or the user of the

unit should ensure that it is used in such an environment.

Emission measurement Conformity Electromagnetic environment - guidelines

HF emissions

according to CISPR 11

HF emissions according to

CISPR 11

Group 1 The unit uses HF energy exclusively for its own

internal functions. Its HF emission level is therefore

very low and it is unlikely that adjacent electronic

equipment will be affected.

Class B The unit is intended for use in all facilities including

residential areas and those directly connected to

public supply networks that also supply residential

buildings.

Table 202:

Guidelines and manufacturer’s declaration – electromagnetic immunity

The unit is intended for operation in the electromagnetic environment described below. The customer or the user of the unit

should ensure that it is used in such an environment.

Immunity

tests

Electrostatic discharge

(ESD)

according to IEC 610004-2

Fast transient electrical

interference

variables/bursts according

to IEC 61000-4-4

Surge voltages

(Surges)

according to IEC 610004-5

Voltage drops, short

interruptions and

fluctuations of the supply

voltage

according to IEC 610004-11

Magnetic field at the

mains supply frequency

according to IEC 610004-8

NOTE: UTis the mains AC voltage before application of the test level

IEC 60601

Conformity level Electromagnetic environment - guidelines

test level

± 6kV

contact discharge

± 6kV

contact discharge

Floor should be made of wood or concrete or

covered by ceramic tiles. If the floor is

covered with synthetic material, the relative

± 8kV

air discharge

± 2kV

for mains cable

± 8kV

air discharge

± 2kV

for mains cable

humidity must be at least 30 %.

The quality of the supply voltage should be

equivalent to that in a typical commercial or

hospital environment.

± 1kV

for input and output

cables

± 1kV

voltage external

conductor – external

conductor

± 2kV

voltage external

conductor – earth

< 5 % U

T

for ½ cycle

(> 95 % drop)

40 % U

T

for 5 cycles

(60 % drop)

70 % U

T

for 25 cycles

(30 % drop)

< 5 % U

T

for 5 sec.

(> 95 % drop)

± 1kV

for input and output

cables

± 1kV

voltage external

conductor – external

conductor

± 2kV

voltage external

conductor – earth

< 5 % U

T

for ½ cycle

(> 95 % drop)

40 % U

T

for 5 cycles

(60 % drop)

70 % U

T

for 25 cycles

(30 % drop)

< 5 % U

T

for 5 sec.

(> 95 % drop)

The quality of the supply voltage should be

equivalent to that in a typical commercial or

hospital environment.

The quality of the supply voltage should be

equivalent to that in a typical commercial or

hospital environment.

3 A/m 30 A/m Magnetic fields at the rated frequency should

be equivalent to the typical values found in

commercial and hospital environments.

29.05.09 VV016031E 12

Page 13

Table 204:

Guidelines and manufacturer’s declaration – electromagnetic immunity

The unit is intended for operation in the electromagnetic environment described below. The customer or the user of the

unit should ensure that it is used in such an environment.

Immunity

tests

Conducted

HF interference

variables

according to IEC

61000-4-6

Radiated

HF interference

variables

according to IEC

61000-4-3

IEC 60601

test level

3 V eff

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

Conformity level Electromagnetic environment - guidelines

Portable and mobile radio devices are not used at a

distance closer to the unit including its cables than

the recommended safe distance calculated by

means of an equation appropriate for the

transmission frequency.

Recommended safe distance:

10 V eff

Pd 35.0

10 V/m

Pd 35.0 80MHz to 800MHz

Pd 70.0 800MHz to 2.5GHz

Where P is the rated power of the transmitter in

Watts (W) according to the transmitter

manufacturer’s specifications and d is the

recommended safe distance in metres (m).

The field strength of all stationary radio transmitters

is less than the conformity levelbfor all frequencies

according to a local examination3.

Table 206:

Recommended safe distances between portable and mobile

HF telecommunication devices and the unit

The unit is intended for operation in the electromagnetic environment described below, in which the HF interference

variables are controlled. The customer or the user of the unit can help to avoid electromagnetic interference by

maintaining the recommended minimum distance between portable and mobile HF telecommunication devices

(transmitters) and the unit as given in the table below according to the maximum output power of the communication

device.

Rated power

of the transmitter (P) W

0.01 0.035 0.035 0.070

0.1 0.11 0.11 0.22

1 0.35 0.35 0.70

10 1.1 1.1 2.2

100 3.5 3.5 7.0

For transmitters whose maximum rated power is not given in the above table, the recommended safe distance d in metres

(m) can be determined using the equation given in the respective column, where P is the maximum rated power of the

transmitter in Watts (W) according to the transmitter manufacturer’s specifications.

NOTE 1 Thehigher value applies at 80 MHz and 800 MHz.

NOTE 2 These guidelines may not apply in all situations. The propagation of electromagnetic waves is affected by

absorption and reflection from buildings, objects and persons.

Safe distance in metres depending on the transmission frequency

150kHz to 80MHz

Pd 35.0

80MHz to 800MHz

Pd 35.0

800MHz to 2.5GHz

Pd 70.0

Interference is possible in the vicinity of equipment

NOTE 1: The higher value applies at 80 MHz and 800 MHz.

NOTE 2: These guidelines may not apply in all situations. The propagation of electromagnetic waves is affected by

a

b

absorption and reflection from buildings, objects and persons.

The field strength of stationary transmitters, e.g. base stations for radio telephones and mobile agricultural broadcast

services, amateur radio stations, AM and FM radio and television transmitters cannot be precisely determined

theoretically in advance. In order to determine the electromagnetic environment resulting from stationary transmitters,

an examination of the location is recommended. If the field strength determined at the location of the unit exceeds the

conformity level stated above, the unit must be observed with regard to its normal operation at each place of use. If

unusual performance characteristics are observed it may be necessary to take additional measures, such as realigning

or moving the unit.

The field strength should be smaller than 10 V/m above the frequency range from 150 kHz to 80 MHz.

bearing the following symbol.

29.05.09 VV016031E 13

Loading...

Loading...