Oerlikon Leybold Vacuum Sogevac SV300 B Operating Instructions Manual

Part Numbers

960 700 to 960 703

960 706 to 960 708

960 711 to 960 713

960 716 to 960 718

Sogevac SV300 B

Single-stage, oil-sealed

Rotary Vane Pump

Operating Instructions GA02330_002_06

Document 300270042/002/06

Important Safety Information 3

1 Description 4

1.1 Design and function 4

1.2 Standard specification 5

1.3 Technical data 6

1.4 Connection fittings 11

1.5 Accessories 12

1.6 Spare parts 13

1.7 Lubricants and grease 13

1.8 Manipulation and stock 13

2 Operation 14

2.1 Installation 14

2.2 Connection to system 14

2.3 Electrical connections 17

2.4 Start-up 19

2.5 Operation 19

2.6 Shutdown 21

2.7 Pump ultimate pressure 21

3 Maintenance 22

3.1 Maintenance schedule 22

3.2 Checking the oil 23

3.3 Oil change, Replacing the Oil Filter 24

3.4 Cleaning the dirt trap 25

3.5 Checking the anti-suckback valve 25

3.6 Cleaning the gas ballast intake filter 26

3.7 Disassembly of electrical motor 26

3.8 Radiator cleaning 26

3.9 Exhaust filter exchange 26

3.10 Heat exchanger cleaning 27

4 Troubleshooting Guide 28

EC Declaration of Conformity

Declaration of contamination

Spare Parts list

Sales and Service

Contents

2 GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Page

Important Safety Information

It is mandatory that these operating instructions be read and understood prior

to the vacuum pump installation and start-up.

The SOGEVAC vacuum pumps have been manufactured according to the

newest technical standards and safety regulations. If not installed properly or

not used as directed, dangerous situations or damages might occur.

Under certain operating conditions, dangerous situations may occur when

running the vacuum pump. If this happens, please contact our local office.

Indicate procedures that must be strictly observed to prevent hazards to

persons.

Indicate procedures that must be strictly observed to prevent damage to, or

destruction of the appliance.

The references to figures, e. g. (2/10) consist of the Fig. No. and the item No. in

that order.

We reserve the right to alter the design or any data given in these Operating

Instructions.

When working on the pump system, always observe the Operating Instructions.

Disconnect the unit from the power supply before starting any work. Take

appropriate precautions to ensure that the pump cannot start.

If the pump has pumped hazardous gases, it will be absolutely necessary to

determine the nature of the hazard involved and take the appropriate safety

precautions.

Observe all safety regulations !

Take adequate safety precautions prior to opening the intake or exhaust port.

If you send a pump to Oerlikon Leybold Vacuum, indicate whether the pump

is free of substances damaging to health or whether it is contaminated. If it is

contaminated also indicate the nature of hazard.

For this you must use the form we have prepared and which will be provided

upon request.

A copy of this form, «Declaration of Contamination of Vacuum Instruments and

Components» is reproduced at the end of the Operating Instructions.

Please attach this form to the pump, or enclose it with it. This Declaration is

required to meet the law and to protect our personnel.

Oerlikon Leybold Vacuum will return any pump received without a "Declaration

of Contamination" to the sender's address.

The pump must be packaged in such a way that it will not be damaged during

shipping, and so that no harmful substances can escape from the package.

Safety Information

3

GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Warning

Warning

Warning

Caution

Notes

Figures

Oerlikon Leybold

Vacuum Service

Warning

1 Description

1.1 Design and function

The SOGEVAC SV300 B are single- stage, oil-sealed rotary vane pumps. The antisuckback valve, gas ballast valve (optional), exhaust filter, oil return circuit and

oil cooling oil are integrated functional elements. The pumps are driven by a

directly flanged motor.

The rotor mounted eccentrically in the pump cylinder has three vanes which

divide the pump chamber into several compartments. The volume of each changes periodically with the rotation of the rotor.

As the rotor rotates, the intake portion of the pumping chamber expands and

sucks gas through the intake port. The gas passes through the dirt trap and the

open anti-suckback valve and enters the pump chamber. As the rotor rotates

further, the vane separates part of the pump chamber from the intake port.

This part of the pump chamber is reduced, and the gas is compressed. At slightly above atmospheric pressure the gas is expelled from the chamber via the

exhaust valve.

Oil injected into the pump chamber serves to seal, lubricate and cool the pump.

The oil entrained with the compressed gas is coarsely trapped in the oil case by

deflection. Then fine filtering occurs in the exhaust filter elements. The proportion of oil in the exhaust gas is thus reduced below the visibility threshold (over

99 % entrapment rate).

Oil trapped in the exhaust filters is returned to the inlet chamber via an oil

return transfer. To prevent gas flowing at atmospheric pressure from the oil

reservoir into the intake port, the oil return line is controlled by a float valve.

The oil cycle is maintained by the pressure difference existing between the oil

case (pressure above or equal to atmospheric pressure) and the intake port

(pressure below atmospheric pressure).The ball bearings are greased for 30 000

hours.

A fan running on the pump shaft generates the necessary cooling air. The oil

cools down through a radiator.

Water cooled pumps with en oil-water heat exchanger and thermostatic valve

are also available (as specific variants).

By opening the gas ballast valve, a controlled amount of air so called «gas

ballast» is admitted into the pump chamber. This gas ballast prevents condensation (up to the limit of water vapor tolerance specified in the Technical Data)

when pumping condensable gases or vapors.

There are different types of gas ballast :

- small gas ballast ( 4 m

3

/h)

- standard gas ballast ( 7.5 m3/h)

- large gas ballast ( 15 m3/h)

- gas ballast with electromagnetical valve ( 10 m3/h) - See § 2.5.2

On pumps supplied without gas ballast valve, the valve can be retrofitted. The

gas ballast flows are indicative and valid at ultimate pressure.

Description

4

GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Description

5

GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Unintentional venting of the vacuum chamber as well as oil suckback when

shutting down the pump are prevented by the integrated anti suck-back valve .

In applications where an oil suckback must be avoided by all means, it is

recommended to install a dedicated valve.

1.1.1 Range of use

SOGEVAC pumps are designed for pumping of inert gases in the range of rough

vacuum, between atmospheric pressure and ultimate pressure of the pump.

SOGEVAC pumps are not designed for pumping of agressive, corrosive,

flammable or explosive gases. By presence of agressive, flammable, corrosive

or explosive gases, contact Oerlikon Leybold Vacuum. These pumps are not

designed for working in flammable or explosive environment.

In case of doubt, contact Oerlikon Leybold Vacuum for the ATEX pump range.

The pumps are not suitable for pumping liquids or media which contain dust.

Corresponding protective measures must be introduced.

In case of doubt, contact Oerlikon Leybold Vacuum.

Before pumping greater than atmospheric concentrations of oxygen (> 20 %)

or other highly reactive gases, the pump must be modified, degreased and a

special oil (such as PFPE) must be used

Take adequate safety precautions. Contact Oerlikon Leybold

Vacuum for important safety instructions.

1.2 Standard Specification

The pump is supplied with drive motor in ready-to-use condition. It is supplied

with GS77 mineral oil, which is filled in.

Specific variants are delivered with different oils. In any case, the oil type is indicated on the pump. No warranty claims could be accepted with use of another

oil than specified.

The connection ports are blanked off by plastic protective caps.

Take these caps away before turning on the pump.

Warning

Caution

Description

6

GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

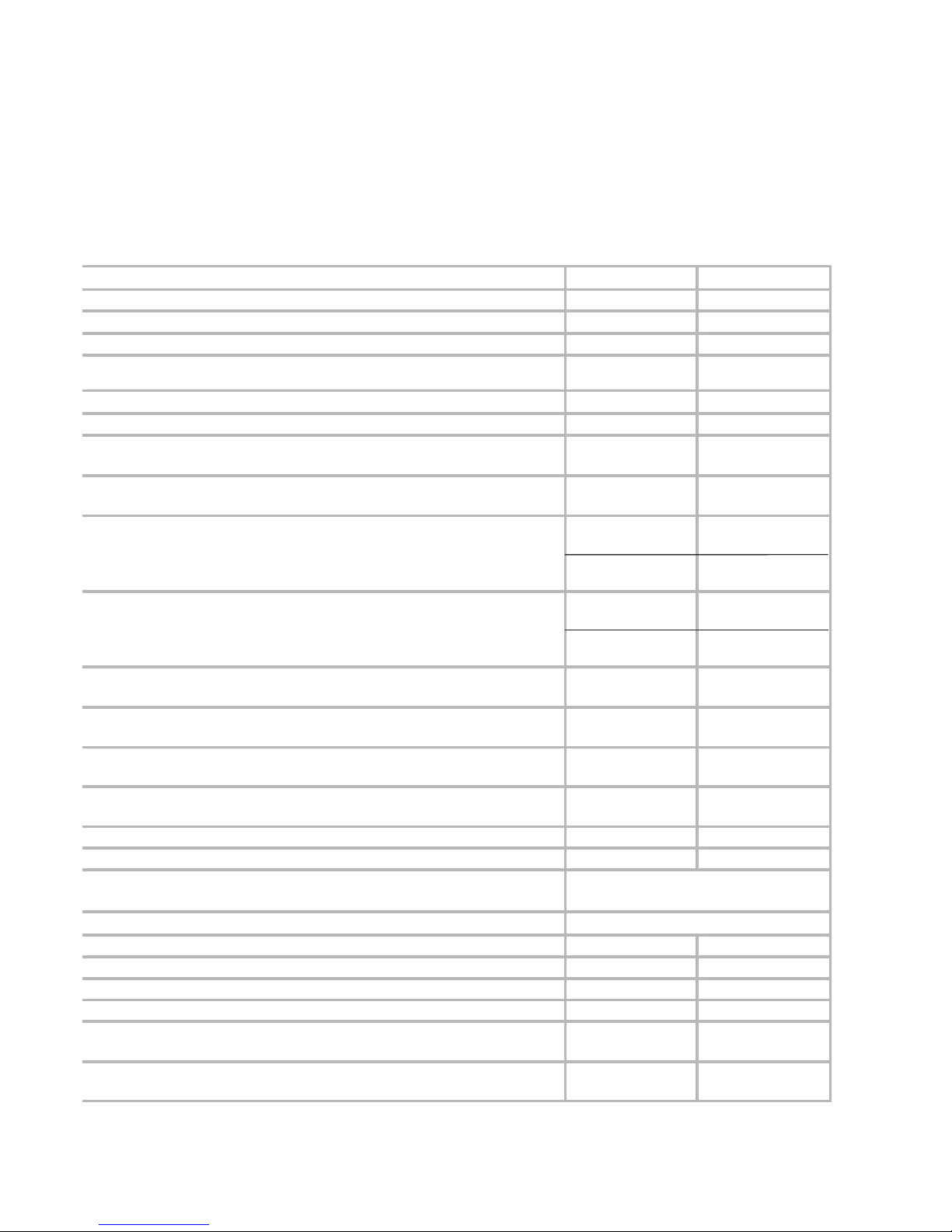

50Hz 60Hz

Nominal speed

1)

m3.h

-1

280 340

Pumping speed

1)

m3.h

-1

240 290

Ultimate partial pressure without gas ballast mbar

≤ 8.10

-2

≤ 8.10

-2

Ultimate total pressure with small gas ballast 4 Nm3/h mbar ≤ 0,5 ≤ 0,5

Ultimate total pressure with standard gas ballast 7.5 Nm3/h

also for EM gas ballast 10 Nm

3

/h

mbar

≤ 0,7 ≤ 0,7

Ultimate total pressure with big gas ballast 15 Nm3/h mbar

≤ 2,0 ≤ 2,0

Ultimate total pressure with two big gas ballasts 28 Nm3/h mbar

≤ 3,0 ≤ 3,0

Water vapour tolerance with small gas ballast 4 Nm3/h mbar

4

with turbine 220 mm5with turbine 220 mm

Water vapour capacity with small gas ballast 4 Nm

3

/h kg.h

-1

0,4

with turbine 220 mm

0,6

with turbine 220 mm

Water vapour tolerance with standard gas ballast 7.5 Nm

3

/h

also for EM gas ballast 10 Nm

3

/h

mbar

10

with turbine 220 mm

40

with turbine 150 mm

12

with turbine 220 mm

50

with turbine 150 mm

Water vapour capacity with standard gas ballast 7.5 Nm

3

/h

also for EM gas ballast 10 Nm

3

/h

kg.h

-1

1,3

with turbine 220 mm

6,0

with turbine 150 mm

1,8

with turbine 220 mm

8,0

with turbine 150 mm

Water vapour tolerance with big gas ballast 15 Nm

3

/h mbar

70

with turbine 150 mm70with turbine 150 mm

Water vapour capacity with big gas ballast 15 Nm

3

/h kg.h

-1

11

with turbine 150 mm14with turbine 150 mm

Water vapour tolerance with two big gas ballasts 28 Nm

3

/h mbar

95

with turbine 150 mm95with turbine 150 mm

Water vapour capacity with two big gas ballasts 28 Nm

3

/h kg.h

-1

15

with turbine 150 mm17with turbine 150 mm

Noise level

2)

dB(A) 70 74

Leak rate mbar.l.s

-1

≤ 1.10

-3

≤ 1.10

-3

Mains voltage (std) - for other voltages please contact Oerlikon Leybold

Vacuum

V

See

Ordering data

Motor power kW

See Ordering data

Type of protection IP55 IP55

Rated rotational speed min.-1 1450 1750

Weight (with oil filling) kg 200 200

Oil capacity (min./max.) l 8,5/11,5 8,5/11,5

Intake connection

G2 G2

NPT2

3)

nN

Exhaust connection G2 G2

NPT2

3)

1.3 Technical Data

1) according to DIN28400 and following numbers, with standard gas ballast

2) operated at ultimate pressure without gas ballast, free-field measurements at a distance of 1m

3) please contact Oerlikon Leybold Vacuum

7GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

WATER COOLING

WATER QUALITY

TH(°F)

0°

CORROSION

(WATER TOO SOFT)

4° 8° 12° 20°

CARBONAT CONTENT

PPm

0

CORROSION

(AGRESSIVE WATER)

30 90 160 300

PH

CORROSION

(AGGRESSIVE WATER)

5 7.5

PRESSURE OF WATER NETWORK : 2 Bar MINI / 8 Bar MAXI

MINIMUM WATER SUPPLY : 600 L/H FOR WATER TEMPERATURE 15°C

VALVE REGULATION ON 2 FOR WARM AMBIANCES 40°C

MAX . WATER TEMPERATURE : 30°C

SERVICE AREA

INCRUSTING WATER

(DEPOSIT OF SCALE

SERVICE

AREA

INCRUSTING

WATER

VERY INCRUSTING

WATER

SERVICE AREA

INCRUSTING WATER

Description

Ordering data Ref. No. SV300 B

Pump with three-phase motor CEI w/o gas ballast

230 V/400 V, +/-10% , 50 Hz, 5,5kW

460 V, +/-10% , 60Hz, 6,3 kW

960 700

Pump with three-phase motor CEI and integrated gas ballast valve

230 V/400 V, +/-10% , 50 Hz, 5,5kW

460 V, +/-10% , 60Hz, 6,3 kW

960 702

Pump with three-phase motor NEMA and integrated gas ballast

208V +/-10% and 230/460 +/-10%, 60Hz, 10 hp

400V +/-10% 50Hz, 10 hp

960 707

Pump with three-phase motor JIS and integrated gas ballast valve

200V +10% -15%, 50/60Hz, 7,5 kW

960 712

Pump with wide range motor and integrated gas ballast valve

200V -15% ... 230V +10% / 380 ... 400 V +/-10%, 50Hz, 5,5 kW

200V -15% ... 230V +10% / 380 ... 400 V +/-10% & 460 +/-10%, 60Hz, 6,6 kW

960 717

Other gasballast variants available.

8 GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Description

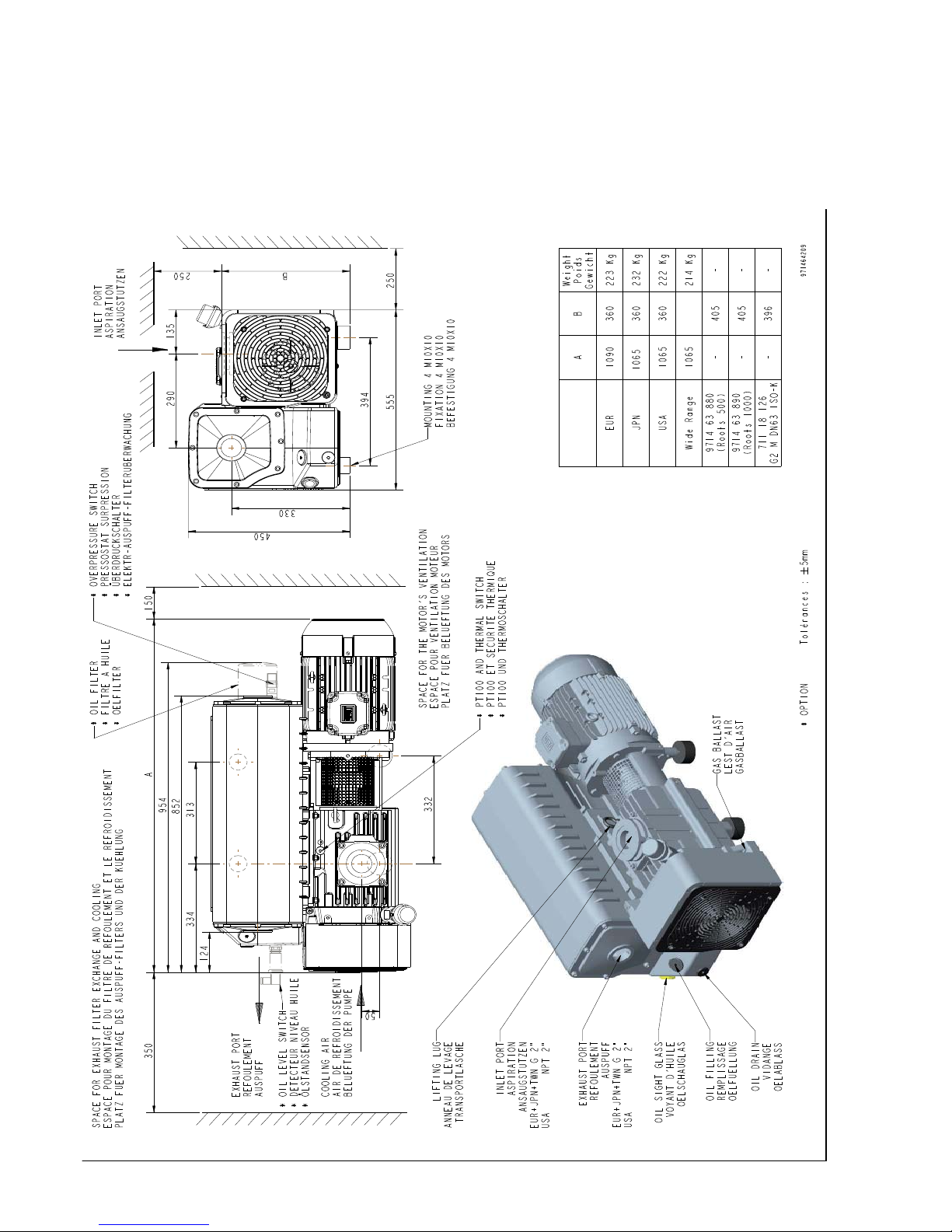

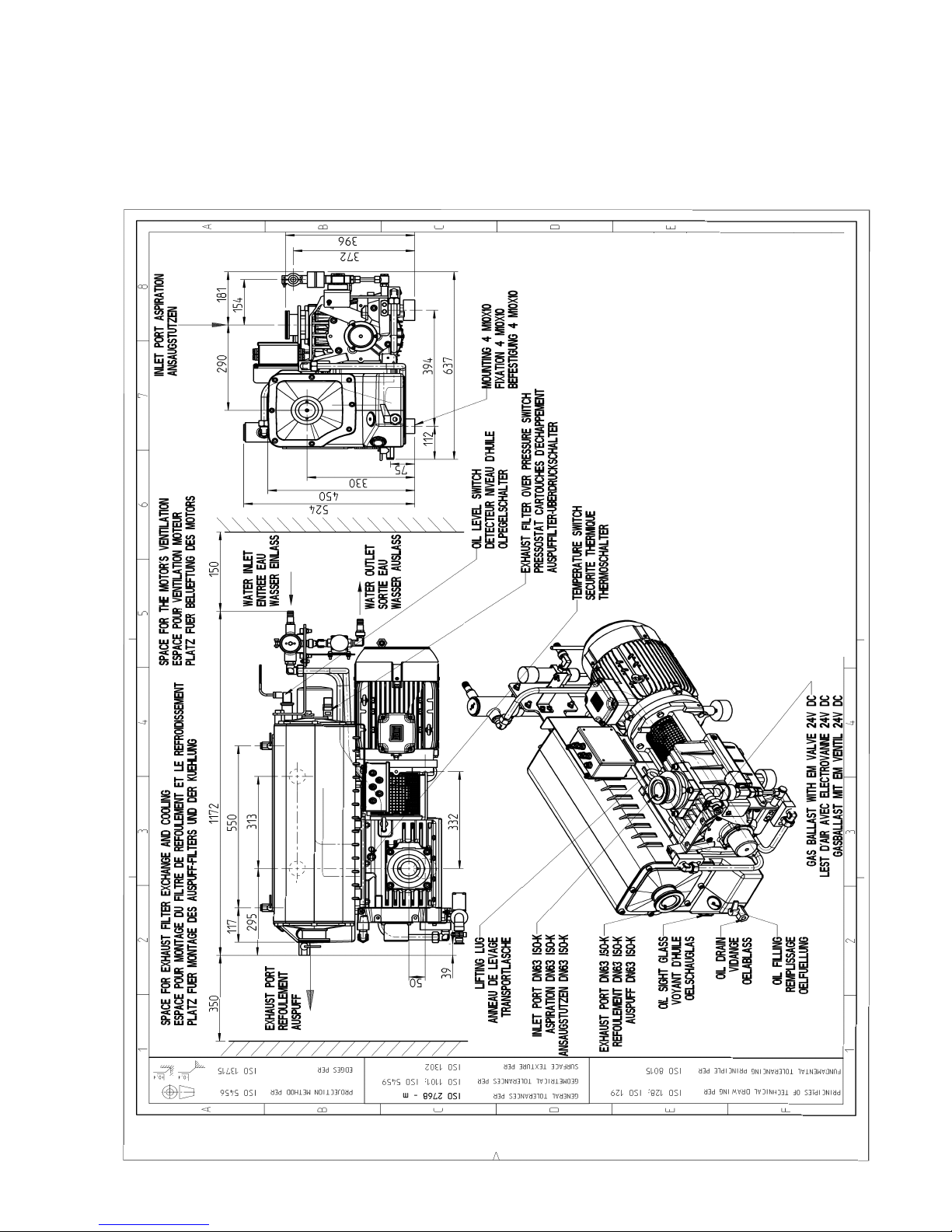

Fig. 1a

384

9GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

Description

Fig. 1b

1 0 GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

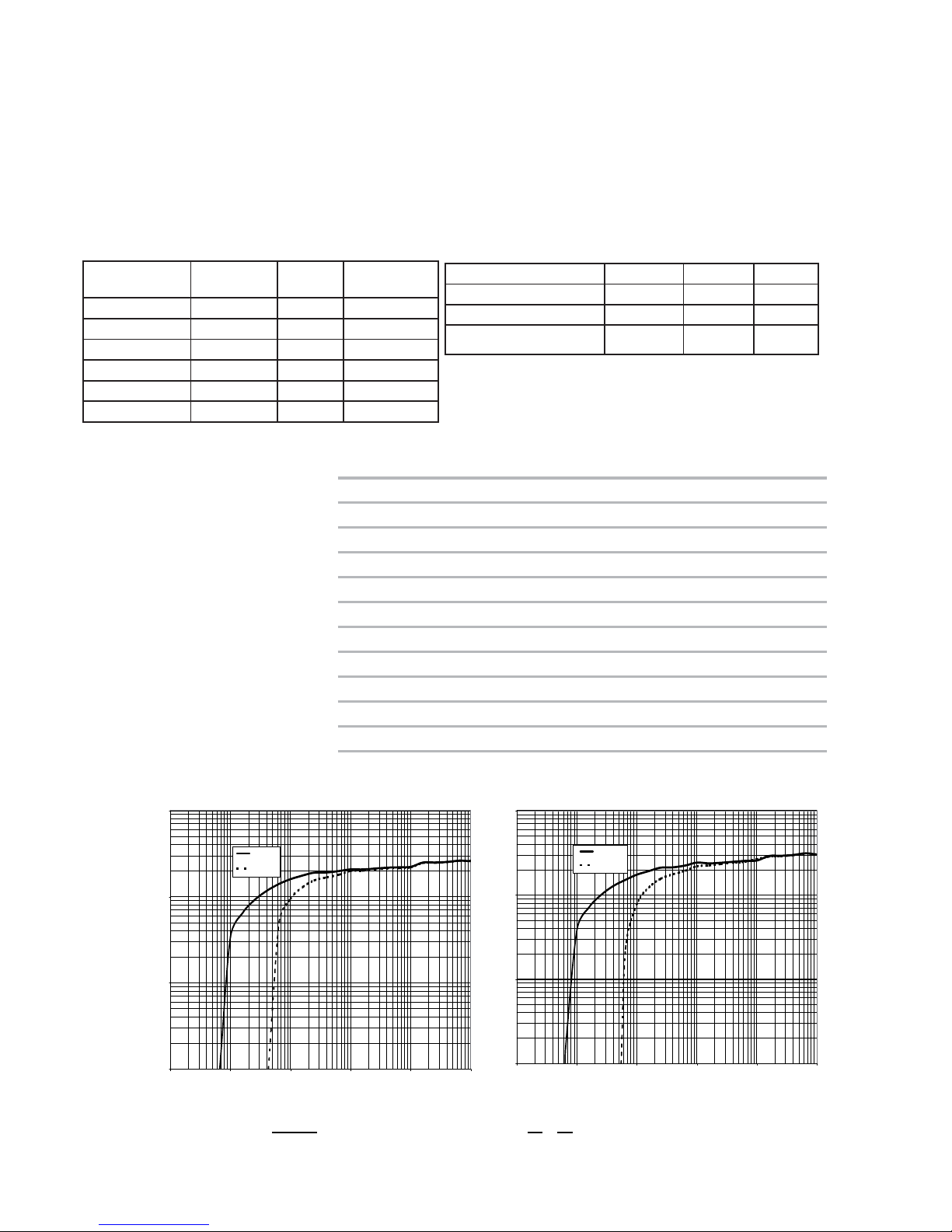

Description

without gas ballast with gas ballast

at 60Hz

mbar (millibar) torr

inches Hg

vacuum

1lb = 0.453 kg 1013 760 0

1 qt = 0.946 l 400 300 18.12

1 hp = 0.735 kW 133 100 25.98

1 inch = 25.4 mm 4 3 29.80

1 r.p.m. = 1 min - 1 0,75 29.89

0,1 0,75 29.92

1 atm (atmosphere) = 1013 mbar

1 Pa (pascal) = 0.01 mbar =10-2 mbar

1 bar = 1000 mbar

1 torr = 1.33 mbar

Different pressure units Different pumping speed units

m

3

.h-1 l.s

-1

cfm

m3. h-1 = m3/h 1 1 0.278 0.589

I.s-1 = I/s 3.60 1 2.12

cfm (cubic feet per minute) 1.699 0.472 1

Example : 1m

3.h-1

= 0.589 cfm

Note : the nominal pumping speed of a pump at 60Hz is

20% higher than at 50Hz

Conversion factors

at 50Hz

1

10

100

1000

0,01 0,1 1 10 100 1000

Pressure (mbar)

Pumping speed (m3/h)

60 Hz

GB 7,5 m3/h

1

10

100

1000

0,01 0,1 1 10 100 1000

Pressure (mbar)

Pumping speed (m3/h)

50 Hz

GB 7,5 m3/h

Fig. 2

60Hz

Nominal speed

1)

cfm 200

Pumping speed

1)

cfm 171

Ultimate partial pressure without gas ballast Torr

6.10

-2

Ultimate total pressure with gas ballast Torrr

0.5

Water vapour tolerance with standard gas ballast standard

1)

Tor r ≤ 30

Motor power hp 10.5

Rated rotational speed rpm 1750

Weight (with oil filling) lb 430

Oil capacity (min./max.) qt 9/12.2

Intake connection NPT (F) inches NPT2

Exhaust connection NPT (F) inches NPT2

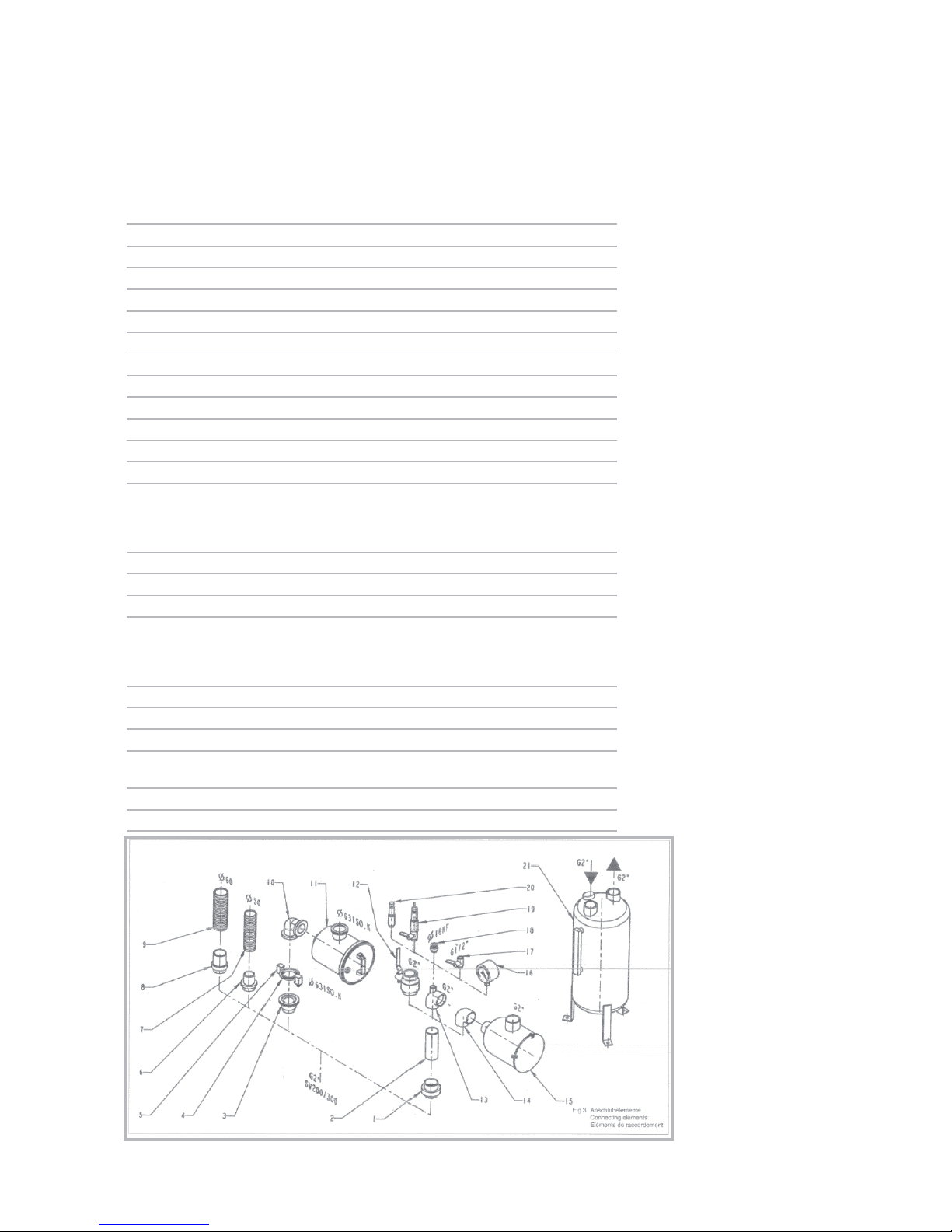

Item Description Size Cat. Nr.

1 Union coupling + seal G2 F/M 711 18 025

2 Nipple G2 M/M - 150 mm long 711 18 035

3 Threaded flange adapter G2 M - DN 63 ISO-K 711 18 126

4 Centering ring 63 ISO-K AL/NBR 268 07

5 Set of 4 clamps for M10 x 24 267 01

ISO-K flanges

6 Adapter for tubing G2 DN 50 711 18 015

7 PVC tubing 50 mm, 1 m long 711 18 325

8 Adapter for tubing G2 DN 60 711 18 016

9 PVC tubing 60 mm, 1 m long 711 18 326

10 Right-angle bend 90° 63 ISO K 887 25

11 Dust filter, paper

Dust filter, charcoal

Dust filter metal

Dust filter polyester

63 ISO K 951 68

711 27 125

711 27 126

711 27 127

12 Ball valve G2 F/F 711 30 107

13 Tee reducer bush G2-G2-G1/2 F/F/F 711 18 265

14 Elbow 90° G2 F/F 711 18 215

15 Dust filter, paper

Dust filter, charcoal

Dust filter, metal

Dust filter polyester

G2 M/F 951 65

711 27 122

711 27 123

711 27 124

16 Vacuum gauge G1/2 M 951 92

17 Ball valve G1/2 M/F 711 30 113

18 Threaded flange adapter G1/2 M - DN 16 KF 711 18 120

19 Regulation valve

with isolation valve

G1/2 M 951 87

20 Regulation valve G1/2 M 951 86

21 Condensate Trap G2 F -G2 F 951 44

Fig. 3

1 1GA02330_002_06 - 01/2010 - © Oerlikon Leybold Vacuum

1.4 Connection fittings

Description

Loading...

Loading...