Page 1

Table of Contents

INTRODUCTION.........................................................................................................................................2

WARNING....................................................................................................................................................2

GENERAL DESCRIPTION........................................................................................................................3

UPERFLEX

S

IGISENSOR

D

PTIMIZER

O

UNCTIONS

F

ONTROLLER

4 C

............................................................................................................................. 3

..................................................................................................................................................... 4

....................................................................................................................................................... 5

...................................................................................................................................................... 5

INSTALLATION................................................................................................................... ....................... 6

OUNTING THE

M

YPICAL WIRING

T

ONTROLLER

SF4 C

.................................................................................................................. 6

............................................................................................................................................. 6

Joystick Controllers.................................................................................................................................... 7

Valves.......................................................................................................................................................... 8

Superflex 4 Controller.................................................................................................................................8

Power.......................................................................................................................................................... 9

Optimizer .................................................................................................................................................... 9

IRING (APPENDIX

W

5) ..................................................................................................................................... 9

OPERATION..............................................................................................................................................10

ENERAL

G

UNCTIONS FOR THIS APPLICATION (APPENDIX

F

PTIMIZER

O

....................................................................................................................................................... 10

1).......................................................................................... 10

..................................................................................................................................................... 10

Adjustments ............................................................................................................................................... 11

Diagnostic Menus..................................................................................................................................... 12

Customized Display (Appendix 2)............................................................................................................. 13

DJUSTMENTS AND CALIBRATION

A

................................................................................................................. 13

Active Adjustments.................................................................................................................................... 13

Bench / Static Adjustments........................................................................................................................ 16

Factory Default Values (Appendix 3)....................................................................................................... 16

TROUBLESHOOTING............................................................................................................................. 17

S ON SUPERFLEX

LED’

PTIMIZER DIAGNOSTICS

O

IGISENSOR

D

ONNECTORS

C

................................................................................................................................................... 19

................................................................................................................................................. 19

................................................................................................................................... 17

............................................................................................................................... 18

OPTIMIZER MENU FUNCTION DIAGRAM....................................................................................... 20

APPENDIX.................................................................................................................................................. 21

PPLICATION SPECIFIC FUNCTIONS

1. A

USTOMIZED OPTIMIZER DISPLAY

2. C

ACTORY DEFAULTS AND ADJUSTMENT LIMITS

3. F

NPUTS AND OUTPUTS CONNECTION TABLE

4. I

IRING DRAWING

5. W

file: SF4MAN.DOC -

..................................................................................................................................... 21

............................................................................................................ 21

............................................................................................................. 21

........................................................................................ 21

.............................................................................................. 21

1 -

December 30, 1996

Page 2

Introduction

The quality and versatility of your joystick control system can make a critical difference in the performance

of your machinery. That is why OEM Controls Inc. products are the controllers of choice for mobile

equipment manufacturers.

OEM, the largest manufacturer of controls for electrohydraulic valves, offers the industry’s most advanced

line of high-quality products. Their compact design, rugged performance, and expanded application

versatility can help improve the performance and capabilities of your equipment. Sophisticated electronic

control methods help create a responsive interface between the equipment and its operators.

For over 28 years, OEM has developed winning products by solving specific application challenges and

anticipating the ongoing needs of the industries we serve. We are prepared to help you meet your

performance requirements.

OEM configures each product to individual customer specifications, utilizing field-proven components, a

long list of options, and industry-leading engineering expertise. We can provide completely customengineered systems to most precisely match your configuration, control, and performance criteria, from

basic on/off functions to multi-axis joystick control.

Compatible with most electrohydraulic valves, OEM controllers feature heavy-duty construction in a

compact design. Metal internal structures and industrial-grade electronics are used to ensure long-term

reliability.

Warning

WARNING: IT IS THE PURCHASER'S RESPONSIBILITY TO DETERMINE T HE

SUITABILITY OF ANY OEM CONTROLS PRODUCT FOR AN INTENDED

APPLICATION, AND TO INSURE THAT IT IS INSTALLED AND GUARDED IN

ACCORDANCE WITH ALL FEDERAL, STATE, LOCAL AND PRIVATE SAFETY

AND HEALTH REGULATIONS, CODES AND STANDARDS.

Due to the unlimited variety of machines, vehicles and equipment on which our controls are used, and the

numerous standards which are frequently the subject of varying interpretation, it is impossible for OEM

Controls personnel to provide expert advice regarding the suitability of a given controller for a specific

application. The flexibility of our products allows us to offer thousands of custom configurations. We can

advise you of the various features that are available and you can examine models to see what meets your

needs. We believe our customers' engineering departments should be the qualified experts in their own

product field. If the product will be used in a safety critical application, the customer must undertake

appropriate testing to prevent injury to the ultimate user.

SHOULD YOU HAVE ANY QUESTIONS, OR IF ANY OF THIS WARNING IS UNCLEAR, PLEASE

CONTACT OEM CONTROLS, INC., 10 CONTROLS DRIVE, SHELTON, CT 06484 (203) 929-8431.

file: SF4MAN.DOC -

2 -

December 30, 1996

Page 3

General Description

The Superflex 4 System consists of joysticks and a stand alone controller that electrically drives

electrohydraulic valves. Typical applications include operating crane booms, fire truck ladders, track

driven machines and other hydraulic equipment with electrohydraulic valves and pumps.

Superflex 4 Controller

The Superflex 4 Controller is a rugged, micropro cessor controll ed device that can directly operat e four bidirectional electrohydraulic valves. The Superflex 4 receives inputs from Digisensors, switches, and other

transducers, and converts these signals into proportional PWM outputs to drive the valves. Each output

signal may be independently fine-tuned and calibrated by using the hand held Optimizer .

Figure 1

Figure 1 shows a Superflex 4 Controller. The Superflex 4 has three 12 pin connectors for inputs, outputs,

and power / Optimizer connections. (Revision B and later Superflexes also have two 4 pin connectors).

The connec tors are designa ted “BT1” to “BT5” throughout this manual. Three red LEDS p rovide the user

with status and diagnostic information. A user friendly label identifies the connectors and provides simple

troubleshooting information.

The Superflex 4 Controller is a versatile and flexible control device. It may be factory programmed by

OEM Controls Inc. to include many different options. A few examples of its flexibility include -

!"

The Superflex 4 is supplied with factory default settings for the electrohydraulic valves used. However, the

customer may select other default values and adjustment limits. This factory programmed data allows the

Superflex 4 to be installed and ready to use as delivered from the factory. Please contact OEM Controls

Inc. for details on customizing the Superflex 4 Controller for your particular application.

Single or dual coil valves with PWM frequencies from 33 to 1000 Hz.

"

Single or dual axis joysticks. Arotrack drive (convert dual axis to left and right track drive).

"

Discrete digital inputs for High / Low ranges, start up interlocks, ramp disable shutdown, etc.

"

Auxiliary outputs (2) for dump valves, alarms, multiplexed output selection, etc.

"

Various “belly” curves to modify the joystick controller’s characteristics.

file: SF4MAN.DOC -

3 -

December 30, 1996

Page 4

Digisensor

The Digisensor (Figure 2) is a small, rugged device that c onverts joystick handl e movement into an

electrical signal. The Digisensor requires only two wires, and can transmit its signal to a Superflex

controller up to 500 feet away. Figure 18 (on page 19) shows the various features of the Digisensor.

A potentiometer embedded in the Digisensor measures

the joystick controller’s movement (usually with a gear).

The potentiometer is also used for mounting the

Digisensor. Two red LEDS indicate the Digisensor

position (whenever power is applied). The “Direction

A” LED turns on when the potentiometer shaft is turned

counter-clockwise, and the “Direction B” LED turns on

when rotated clockwise. When the Digisensor’s shaft is

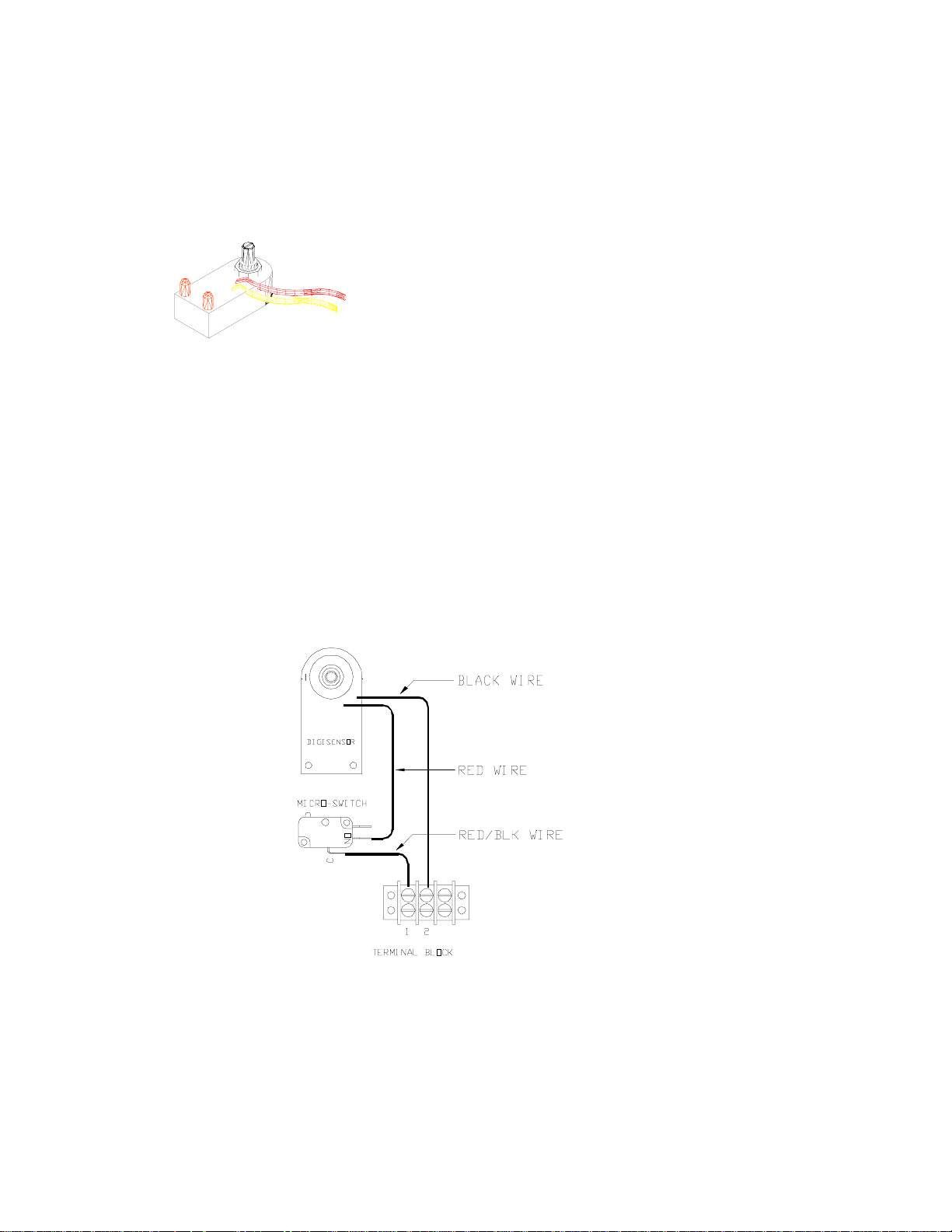

Figure 2

Two wires connect the Digisensor to the system. The red wire connects to the +12 or +24 volt power, and

the black wire connects to one of the Superflex inputs. Figure 3 shows typical wiring for a single axis

joystick controller. In this example, a microswitch turns on the Digisensor when the joystick handle is

moved from its center or “off” position.

centered (turned halfway between its ends) both LEDS

will be on. The section titled “Troubleshooting Digisensor” has additional details.

Figure 3

file: SF4MAN.DOC -

4 -

December 30, 1996

Page 5

Optimizer

The OPT4 Optimizer is a hand held user interface with a keypad and an alphanumeric display. It is used as

a calibration and diagnostic tool, to display various system values, and to make adjustments to the Superflex

4 Controller.

Figure 4 shows the Optimizer and its connecting

cable. The Optimizer cable length should be

limited to 120 feet.

Figure 4

Functions

A typical system application uses four single axis, bi-directional joysticks as inputs and controls four bidirectional channels. Each channel has two proportional PWM (pulse width modulated) output signals, and

each signal has independently adjustable threshold, maximum output and ramp time adjustments. The AUX

output turns on whenever any of the joysticks are operated. Four digital inputs can be used to select high or

low range (dual speed option) for the 4 channels. Diagnostic indicator LEDS show the Superflex system’s

status and can be used for easy checkout. An Optimizer may be connected for calibration and

troubleshooting.

file: SF4MAN.DOC -

5 -

December 30, 1996

Page 6

Installation

Mounting the SF4 Controller

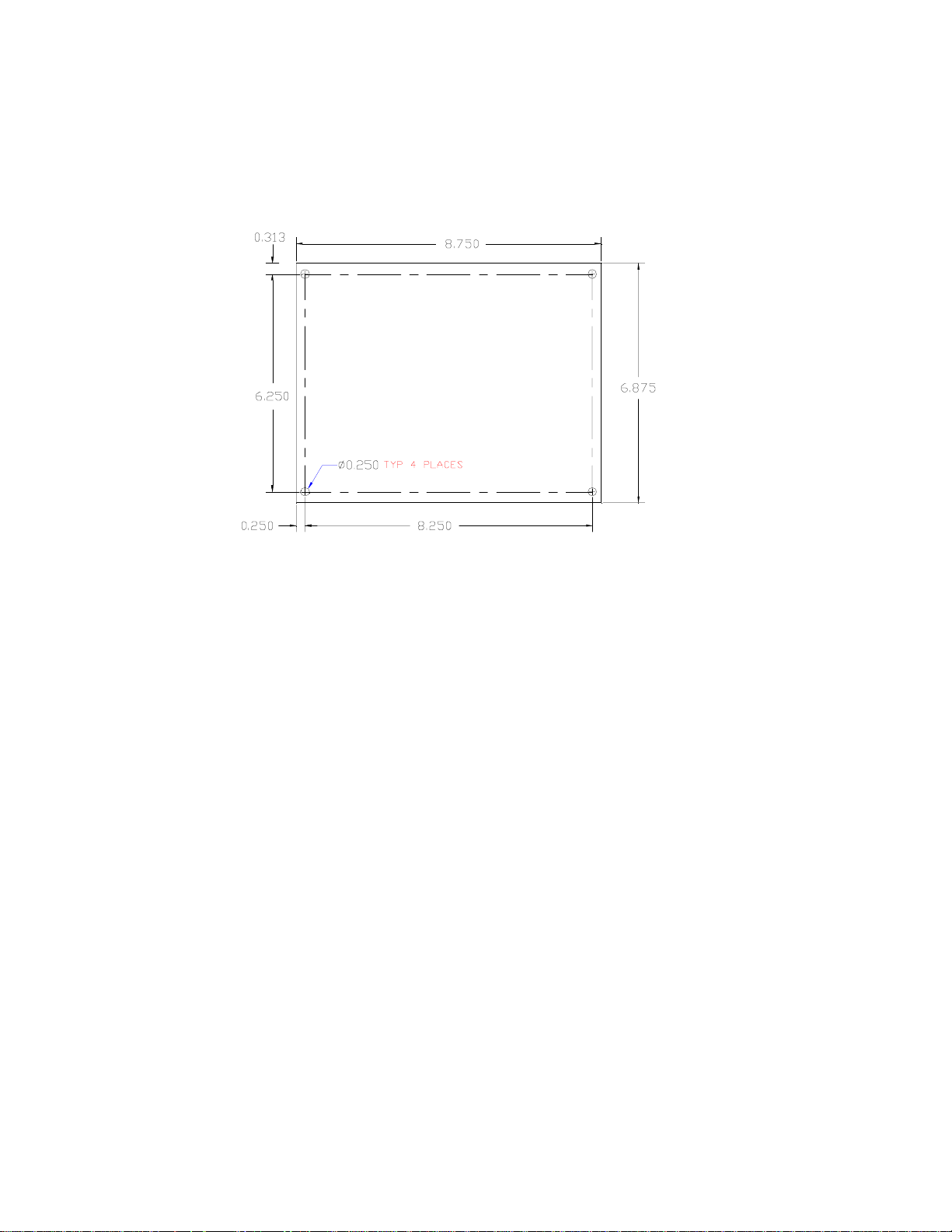

Figure 5

The Superflex Controller is an electronic circuit board assembly mounted on an aluminum plate. The

device can be mounted in standard enclosures or in another protected area. Mounting dimensions are

shown in figure 4. Allow at least 9 by 7 inches to mount the Superflex 4, and provide at least 3 inches of

clearance above it for the wire connectors and cable routing. (The Superflex 4 is approximately 1 inch in

height).

Since the Superflex 4 Control System is installed at the site of the machine’s final assembly there are many

installation variations. Follow these guidelines when installing or replacing the Controller -

"

Place the Superflex 4 in a metal enclosure, protected from rain and other fluids.

"

Be sure there are weep holes or one way drains at the bottom of the enclosure.

"

Use a minimum of 18 AWG wiring, especially on the power and output connections.

"

Install the wiring per SAE Specification J-1121.

"

Use 3 amp flyback diodes on all relay coils and non-proportional solenoid valves to prevent

EMI. Refer to the wiring drawing in appendix 5.

"

CAUTION

connectors from the Superflex 4 before welding to prevent damage to the system or to its wiring.

- Provide external current paths when welding on the machine. Disconnect all of the

Typical Wiring

Inputs and outputs are controlled by the particular application’s software program that is built into the

Superflex 4. The function of various terminals are dependent on the application. The following sections

provide general guidelines for wiring the system.

file: SF4MAN.DOC -

6 -

December 30, 1996

Page 7

Joystick Controllers

Figures 6 and 7 show typical single and dual axis joystick controllers with Digisensors. Typically, the

Digisensors are pre-wired to terminal blocks on the joystick. (Refer to instructions that come with your

custom joystick co ntroller for p roper mounting and gr ounding proced ures).

Figure 7

There are six inputs on the Superflex 4 Controller that may be connected to Digisensors mounted on

joystick controllers. (Usually, only the first four inputs are used). Figure 8 shows the wiring of a typical

single axis joystick. This device is connected to the Superflex 4 as follows -

"

Terminal 1 is connected to power (the +12 volt battery).

"

Terminal 2 is connected to one of the Digisensor inputs on the Superflex connector BT2.

The joystick controller may be located up to 500 feet from the Superflex 4 Controller.

Figure 6

Figure 8

file: SF4MAN.DOC -

7 -

December 30, 1996

Page 8

Valves

There are eight high current outputs on the Superflex 4 designed to drive four dual coil (bi-directional)

valves. Each output is rated at 3 amps maximum, and has built in short circuit protection. Figure 9 depicts

a typical connection. This example shows the channel 1 valve’s two coils connected to BT3 terminals 12

and 6 for the “A” and “B” directions. In general -

"

An output from Superflex connector BT3 is connected to the plus side of the valve.

"

The minus side of the valve is connected to the machines ground or battery minus terminal.

Figure 9

There are two AUX (auxiliary) high current outputs on BT3. Depending on the Superflex 4 application,

these outputs may control the machine’s dump valve, throttle, etc. The AUX outputs are connected in a

similar fashion as the valves shown above.

Superflex 4 Controller

The Superflex 4 has three 12 pin connectors: BT2 is used for inputs, BT3 for outputs and BT1 for power

and Optimizer connections (see figure 10 on the next page for the connector locations). Cables and / or

wiring harnesses may be purchased from OEM Controls in any desired length. Appendix 4 shows the

terminal pin number s and wiring for your par ticular application. The BT pin numbers are idendified in

figure 11 on t he next page.

Revision B and later Superflex 4 Controllers have two additional 4 pin connectors, BT4 and BT5.

Connector BT5 has power and ground connections, and BT4 has Optimizer connections. Either BT1, or

both BT4 and BT5 may be used for your application.

A label on the Superflex 4 Controller also identifies all connector pins and their functions.

file: SF4MAN.DOC -

8 -

December 30, 1996

Page 9

Power

Figure 10

The Superflex System requires a DC

voltage of 10 to 16 volts to operate

properly. This range covers machines

with a nominal 12 volt power source.

Figure 12 shows how connector BT1

connects to power and ground. Be

sure the power wire is of sufficient

size to provide current to the

Superflex and to all of the external

valves connected to the system. The

total system current is not to exceed

12 amps, including all active outputs.

Optimizer

Figure 12 also shows the wiring between Superflex connector BT1

and the Optimizer.

Wiring (Appendix 5)

A wiring diagram, included in appendix 5, gives additional

information on hooking up the input and output signals for your

specific application. Also refer to appendix 4 for the signal names

and BT pin numbers.

Figure 12

Figure 11

file: SF4MAN.DOC -

9 -

December 30, 1996

Page 10

Operation

This section only describes basic operation of the Superflex 4 System. Refer to the machine manufacturer’s

instructions for additional information on operating your equipment.

General

The Superflex 4 System essentially converts joystick handle movement into an electrical output signal to

drive the electro-hydraulic valve. The output signal increases proportionally to the amount of joystick

movement.

The dual range digital (switched) input provides two independently adjustable output ranges. The low

range is an adjustable percentage of the maximum output.

In a typical application, the AUX1 (auxiliary) output turns on whenever any of the eight valve outputs are

active.

Functions for this application (Appendix 1)

Refer to the information in appendix 1 for any additio nal features and functions that have been included in

your specific application. (This does not apply to the typical application described above).

Optimizer

Figure 13 on the next page identifies the display and important keys. The key functions will be described

below. To use the Optimizer, plug its cable into the Superflex Controller.

The Optimizer display will look like this, assuming that no joysticks are

operated (and the Superflex outputs are off).

When a joystick is operated, the Optimizer display will change to this. The

upper right portion identifies the active channel or function, and the lower

right portion indicates the actual output value. In this example, function 1

direction B (Fn1B) is active, with an output PWM duty cycle of 72.5%. This channel has been customized

to read “Rotate Left”. As the joystick is moved, the displayed value will change. If more than one joystick

is operated at the same time, so that several outputs are active, the Optimizer display will show the channel

who’s joystick was most recently moved.

There are five adjustment select keys - Threshold, Maxout, Low Range, Ramp Up and Ramp Down. These

keys are used to select one of these 5 parameters to adjust.

The Direction Select key toggles (alternates between) the A and B direction. This key only functions when

all joystick controllers are off. The Optimizer automatically selects the direction when a joystick is

operated; this makes active adjustments easy to perform.

The Function Select chooses one of the 4 channels for adjusting. This key only operates when all

controllers are off. Each time this key is pressed, the next function (or channel) is selected, that is 1 ... 2 ...

3 ... 4 ... 1 ... etc. The Optimizer automatically selects the function (channel) whenever a joystick is

operated, making active adjustments easy to perform.

RUN MODE, NORMAL

FUNCTIONS OFF

RUN: ROTATE L

Fn1B 72.5 %

file: SF4MAN.DOC -

10 -

December 30, 1996

Page 11

Figure 13

Figure 14 identifies various items that are displayed

when you are making an adjustment. The “value” is

flashing (blinking on and off) and will change as the

Plus or Minus keys are pressed. The Channel

(Function) and Direction are displayed generica lly on

the bottom line, and as the actual machine’s functions

on the top line. The parameter being adjusted (in this

example threshold) is shown at the upper left.

CAUTION -

Be sure to press the RUN key after

making an adjustment or the new setting will be lost

Figure 14

The Menu key accesses

less frequently used items,

other information and

diagnostics. A “three key

menu” system allows

additional functions and

features to be easily added

to SF4 while still having a

universal Optimizer. The

Enter key is used to step

through the various menu

items. The section

“Diagnostic Menus” below

describes the Menu and

Enter key functions.

The Plus and Minus keys

are used for changing the

various adjustments

(threshold, ramp, etc.).

The process is described

below. The Run key must

be pressed after making an

adjustment so the new

value is saved.

Adjustments

Threshold is the amount of output that causes the machine to just start to move or operate. The Threshold

value represents a PWM percent duty cycle, which corresponds to the initial voltage signal driving the valve

when the Joystick handle is moved slightly from its off position.

Max Out

desired speed. The Max Out value also represents a percent duty cycle, corresponding to the voltage signal

driving the valve when the Joystick handle is fully deflected (and high range is selected).

Low Range

ange setting rep resents a percent age of the Maximum Output value.

file: SF4MAN.DOC -

or maximum output is the amount of output that causes the machine to operate at maximum

sets the limited amount of output signal when the Joystick handle is fully deflected. The Low

11 -

December 30, 1996

Page 12

Threshold, Max Out and Low Range adjustments are made in 0.5 % steps.

Ramp Up

adjustment is made in te nt hs of a second.

Ramp Down

Ramp Down adjustments are also in tenths of a second.

sets the time the machine’s function will take to increase (accelerate) from off to full on. This

sets the time required for the machine’s function to decrease (decelerate) from full on to off.

Diagnostic Menus

Various pieces of information are available in the Diagnostic Menu mode.

This mode is started by pressing the “Menu” key. The Optimizer displays the

first menu item. Press the Enter key to step through all of the menu items.

The first four menu items display fixed data. Two examples are shown at the right.

The valve PWM frequency for the first two outputs (channels 1 and 2) is

followed by the valve frequency for the second two outputs (cha nnels 3 and

4). Next the OEM part number and serial number are shown.

The next three menu items are active displays

showing input and output signals. These

screens are useful for troubleshooting. The

switched digital inputs (see figure15) can be

tested on this display. If an input is On, the

display is a “1” and if it is Off or 0 volts, the

display is a “0”. Likewise the AUX outputs

and Digisensor inputs can be displayed. The

Troubleshooting guide has additional

information.

Figure 15

The next menu item is “Restore Factory Defaults” and is used to reset all of

the adjustable parameters to the settings that were programmed in by the

factory. The display looks like this, with the bottom line flashing. Pressing

the Plus key will restore the default values. Pressing the Enter key will step

to the next menu item.

The final three menu selections go together. They provide an alternate method of choosing adjustments,

channels and the direction for making changes. At each of these screens, the selected item (e.g.: TH, MX,

RU, RD or LR) will flash. Use the Plus key to select and the Enter key to go to the next menu. After

proceeding through these 3 menus, you will be able to adjust the selected variable.

FREQUENCY 1 2

100 Hz

OEM PART NUMBER

SF4-4-200.001x

RESTORE DEFAULT?

Yes=+ No=Enter

CONTROL ADJUST

TH MX RU RD LR

file: SF4MAN.DOC -

FUNCTION SELECT

Fn1 Fn2 Fn3 Fn4

12 -

DIRECTION

DIR A DIR B

December 30, 1996

Page 13

Customized Display (Appendix 2)

Your particular Superflex 4 System application may be customized to easily identify the machine’s

function. Nine characters may be specified for each function, channel and direction. For example - you

might choose “DRIVE FWD” for the machines drive forward, “BOOM LIFT” and “ROTATE R” for

boom functions, etc. Refer to the customized data located in Appendix 2 of this manual.

Adjustments and Calibration

Two different methods may be used to calibrate the system: 1) Active or 2) Bench / Static. In the Active

mode, the equipment is actually operated with the joystick controllers while making the adjustments. The

Bench / Static mode does not requir e operating the equipment or moving the joystick handles. For best

results, the Active method is recommended.

NOTE

- After making an adjustment, always press the RUN key

not pressed, the new settings will be lost as soo n a s the Optimizer is unplugged or the Superflex 4 power is

turned off.

to save the new value. If the RUN key is

Active Adjustments

WARNING

locate the machine in an area which is suitable for safe operation.

NOTE

operated. Plug in the Optimizer and turn on power. Follow any additional procedures specified by the

equipment manufacturer.

"

"

- The Action (Channel) and the Direction are automatically selected when a Joystick controller is

To adjust THRESHOLD (initial starting or creep speed) -

Move the jo ystick handle (of the function to adjust) just far enough so that the Optimizer display

changes from “Run Mode Functions Off” to “RUN: ... Fn...” At this point, the channel is

operating. Continue to hold the joystick handle in this position and perform the following steps.

Press the Threshold key. The Threshold value is displayed, and it blinks (flashes) to indicate that

it can be adjusted.

Press the Plus key to start or speed up this function if it does not move. OR Press the Minus key

to stop or slow down the function if it moves too fast.

Press the RUN key to sa ve the new value.

Repeat these steps for adjusting the Threshold in the opposite direction.

To adjust MAXOUT (full speed) -

If the machine has two speeds (Dual Range), make sure the High range is selected. (If this is not

possible, then temporarily adjust the Low Range to 100%.

Move the joystick handle fully on (to the end of its travel) in the direction to be adjusted, and hold

it there. Allow time for the machine function to accelerate to full speed.

Press the Maxout key. The Maximum Output value is displayed and flashes.

- Your machine will be operated during this calibration procedure. Be sure to

file: SF4MAN.DOC -

13 -

December 30, 1996

Page 14

Press the Plus key to increase the function speed. OR Press the Minus key to decrease the

function speed .

Press the RUN key to sa ve the new value.

Repeat these steps for adjusting Maxout in the opposite direction.

"

To adjust LOW RANGE (a slower speed range) -

NOTE - the Maxout adjustment should be made first. The Low Range speed is affected by the

Maxout setting; low range is actually a per centage of the maximum output.

Select the “low range” machine function. This may be a selector switch or other device.

Move the joystick handle fully on (to the end of its travel) in the direction to be adjusted, and hold

it there. Allow time for the machine function to accelerate to full speed.

Press the Low Range key. The Low Range value is displayed, and will be flashing.

Press the Plus key to increase the function speed. OR Press the Minus key to decrease the

function speed .

Press the RUN key to sa ve the new value.

Repeat these steps for adjusting Low Range in the opposite direction.

"

To adjust RAMP UP (acceleration time) -

Ramp Up determines the time it will take for the machine function to accelerate from off to full on

when the joystick handle is moved abruptly. Ramp up time is used to prevent sudden jerky

movements of the machine. Ramp up (and ramp down) time is adjustable in tenths of a second

increments.

If the machine has two speeds (Dual Range), make sure the High range is selected. (If this is not

possible, then temporarily adjust the Low Range to 100%.

Press the Ramp Up key. The Ramp Up value is displayed and flashing.

Move the joystick handle very quickly to its fully on position (to the end of its travel) in the

direction to be adjusted. Observe the machine’s response.

If the machine starts too quickly and/or is jerky, press the Plus key to increase the ramp up time.

OR If the machine takes too long to start up, press the Minus key to decrease the ramp up time.

Press the RUN key to sa ve the new value.

Repeat these steps for adjusting the Ramp Up time in the opposite direction.

"

To adjust RAMP DOWN (deceleration time) -

file: SF4MAN.DOC -

14 -

December 30, 1996

Page 15

Ramp Down determines the time it will take for the machine function to decelerate from full on to

off when the joystick handle is moved abruptly. Ramp down time is used to prevent sudden jerky

movements of the machine and allow smooth stopping.

CAUTION

function to stop.

If the machine has two speeds (Dual Range), make sure the High range is selected. (If this is not

possible, then temporarily adjust the Low Range to 100%.

Press the Ramp Down key. The Ramp Down value is displayed and will flash.

Move the joystick handle fully on in the direction to be adjusted. Allow the machine to reach full

speed. Then quickly move the joystick handle to its off position. Observe the machine’s

response.

If the machine slows down too quickly and/or is jerky, press the Plus key to increase the ramp

down time.

OR If the machine takes too long to stop, press the Minus key to decrease the ramp down time.

Press the RUN key to sa ve the new value.

Repeat these steps for adjusting the Ramp Down time in the opposite direction.

After all adjustments have been made for the desired machine performance, it would be helpful to record all

of these settings for future reference. The following table can be used to record the settings.

Threshold

Maxout

Low Range

Ramp up

Ramp down

- Setting the Ramp Down time too high will increase the time it takes for the machine

1A 1B 2A 2B 3A 3B 4A 4B

file: SF4MAN.DOC -

15 -

December 30, 1996

Page 16

Bench / Static Adjustments

Any adjustment can be made without operating the machine. This process is known as “static” or “on the

bench” calibration. Use the following steps -

Provide power to the Superflex 4 Controller. Connect the Optimizer.

Select a “function” (channel) by pressing the Function Select key one or more times, until the

desired channel (1 through 4) is d isplayed.

Select a direction (A or B) by pressing the DIR A/B key.

Select a contr oller adjustment by pressing one of Thresho ld, Maxout, Low Range, Ramp Up or

Ramp Down keys.

Use the Plus and Minus keys to make the adjustment.

Press RUN to sa ve the changes before powering down or disconne cting the Optimizer.

Factory Default Values (Appendix 3)

All defaults (preset values) as well as upper and lower limits to each adjustment range may be specified by

the customer. These setting are installed by OEM Controls when your Superflex 4 Controller is

manufactured. After making adjustments with the Optimizer, it may be desirable to return to these default

values. This task is easily accomplished with the Optimizer.

Apply power to the Superflex 4 Controller and connect the Optimizer.

Press the Menu key. Then press the Enter key several times, until the Optimizer displays “Restore

Defaults?”.

Press the Plus key to restore the default values. The Optimizer displays “BUSY” while the

original values are copied. This may take several seconds, depending on how many values need to

be restored. Then the Optimizer will momentarily display “DONE” and return to the default run

screen. Be sure to wait

to the Superflex 4 Controller.

for this to happen before disconnecting the Optimizer or turning off power

file: SF4MAN.DOC -

16 -

December 30, 1996

Page 17

Troubleshooting

The Superflex 4 System has been designed to perform in the harsh environments of the mobile equipment

industry. Most of the common problems encountered are external to the Superflex 4 Controller. Problems

may include: broken wires, loose or corroded or defective connections, wiring errors, wiring shorts, and

improper power supply voltages. The Superflex 4 Controller has several built in features that can assist

with testing and troubleshooting your system.

Check for the following machine related problems -

LED’s on Superflex

Figure 16 shows the location of three red indicator LEDS. These indicators provide the following

information.

"

Power is turned on and supplied to the Superflex. Supply voltage is OK (batteries aren’t weak).

"

Make sure all cables and wiring are connected properly.

"

Be sure the ground wiring is good.

"

Are there any machine interlocks (or “enable” signals) that are preventing operation?

Figure 16

"

The middle or CPU LED flashes if system is OK. This LED is off if there is no power being supplied to

the Superflex. If this LED is on constantly (not flashing) there is a CPU failure, and the Superflex 4

Controller must be replaced or repaired by OEM Controls, Inc.

"

The INPUT LED flashes whenever one or more joysticks (Digisensors) are operated. This LED is off if

all microswitches (Digisensors) are off. If this LED remains off when a joystick is operated, check the

wiring, and make sure there is power to the joystick. This LED will be on continuously (not flashing) if one

of the Digisensor wires is shorted to +12 volts.

file: SF4MAN.DOC -

17 -

December 30, 1996

Page 18

"

The OUTPUT LED flashes when any of the PWM outputs are active. It will turn off when all of the

outputs are off (this may take several seconds if a long Ramp Down time is used). If the output LED is on

continuously (not flashing) then one of the 8 PWM outputs is shorted to ground. Operate one joystick at a

time while observing this LED to determine the output. Then check the wiring and correct the short circuit.

Optimizer Diagnostics

The Optimizer can be used for system testing and troubleshooting. When the

Optimizer is plugged into the Superflex, it will start by displa ying the “RUN”

screen. If the display is blank, then check the power and ground wires to the

Optimizer. If the display looks like the example shown here, there is a

communication problem between the Superflex 4 Controller and

the Optimizer. This is most likely a connector or wiring problem.

Digisensor operation may be checked by using one of the diagnostic menu displays. Press the Optimizer’s

MENU key, and then press the ENTER key several times, until the display’s top line reads “DS1 DS2 DS3

DS4”. Below each of these indicators is the actual data being sent by a particular Digisensor. By moving

the joystick handle, the data will change.

The displayed Digisensor data will decrease to 0 when the joystick is moved in the “A” direction

(Digisensor potentiometer shaft rotates counterclockwise). Likewise, the displayed data will increase to

511 when the joystick handle is moved in the “B” direction (Digisensor shaft rotates clockwise). When the

joystick is centered, the Optimizer’s data will be approximately 255.

Four digital inputs can be tested (see figure17).

Press the Optimizer’s MENU key and then press

the ENTER key several times to reach this menu

item. Then observe the Optimizer display while

operating the machine controls that correspond to

these inputs. A “1” is displayed when the input is

at a high voltage ( at least 10 volts ) or “on”. A

“0” is displayed when the input is at ground or

“off”.

INITIALIZING

SYSTEM

Figure 17

file: SF4MAN.DOC -

18 -

December 30, 1996

Page 19

Digisensor

There are two LEDS on a Digisensor. To check for proper operation, apply power to the Digisensor and

observe these LEDS. See Figure 18.

Power may be supplied by the machine or by using a fresh 9 Volt transistor radio battery. Connect the

battery plus to the red wire, and the battery minus to the black wire. One or both LEDS should be on. If

neither LED turns on, replace the Digisensor.

Next, rotate the Digisensor’s potentiometer shaft.

When it is turned fully counter-clockwise, the left

“direction A” LED turns on. When the shaft is turned

fully clockwise, the right “direction B” LED turns on.

There is a small area when the potentiometer shaft is

turned about halfway where both LEDS are on. This is

important for aligning the Digisensor to the Joystick

controller.

Whenever a Digisensor is mounted to a joystick

controller, the mechanical alignment must be checked

and adjusted if necessary. This is important as the

Superflex 4 Controller depends on proper Digisensor

signals to operate the valves. Check the Digisensor

LEDS when the Joystick handle is in its center or “off”

position. NOTE - it may be necessary to operate the

joystick’s on/off micro-switch to apply power to the

Digisensor. Both LEDS must be ON when the handle

Figure 18

is centered. If this is not the case, rotate the shaft until

both LEDS turn on, and then tighten all mechanical

hardware.

Connectors

Replacement connectors are available from OEM Controls, Inc. or the connector manufacturer.

Superflex 4 Controller connectors BT1, BT2 and BT3 -

OEM part number EPCN/932 (body) and EPWT/835 (pins, also for BT5)

AMP Inc. 770581-1 (body) and 171637-1 (pins, also for BT5)

Superflex 4 Controller connectors BT4 and BT5 -

OEM part number EPCN/938 (body) and EPWT/839 (gold pins for BT4 only)

AMP Inc. 172167-1 (body) and 171637-3 (gold pins for BT4 only)

Optimizer Connector

OEM part number EPCN/859

Curtis Industries, Inc. PA256/5.08/4

file: SF4MAN.DOC -

19 -

December 30, 1996

Loading...

Loading...