Page 1

OptiMizer 4

Users Manual

For SuperFlex 4 Systems

Optimizer

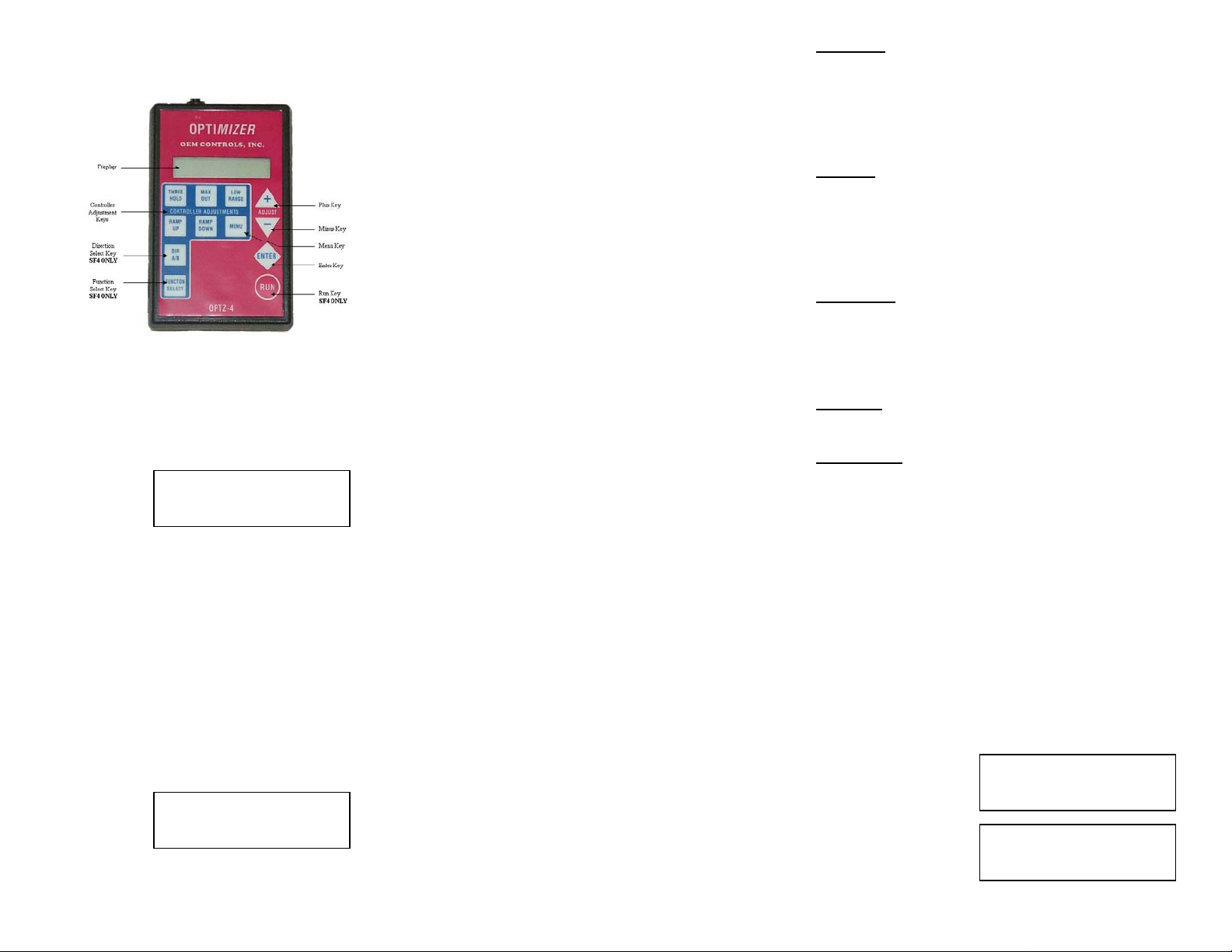

The OPT4 Optimizer is a hand held user

interface with a keypad and an alphanumeric

display. It is used as a calibration and diagnostic

tool, to display various system values, and to

make adjustments to the SB family of controllers.

When a joystick is operated, the Optimizer

display will change to this. The upper right

portion identifies the active channel or function,

and the lower right portion indicates the actual

output value. In this example, function 1

direction B (Fn1B) is active, with an output PWM

duty cycle of 72.5%. This channel has been

customized to read “Rotate Left”. As the joystick

is moved, the displayed value will change. If

more than one joystick is operated at the same

time, so that several outputs are active, the

Optimizer display will show the channel who’s

joystick was most recently moved.

RUN MODE, NORMAL

FUNCTIONS OFF

RUN: ROTATE L

Fn1B 72.5%

There are five adjustment select keys - Threshold,

Maxout, Low Range, Ramp Up and Ramp Down.

These keys are used to select one of these 5

parameters to adjust.The Direction Select key toggles

(alternates between) the A and B direction. This key

only functions when all joystick controllers are off. The

Optimizer automatically selects the direction when a

joystick is operated; this makes active adjustments easy

to perform.

The Function Select chooses one of the 4 channels for

adjusting. This key only operates when all controllers

are off. Each time this key is pressed, the next function

(or channel) is selected, that is 1 ... 2 ... 3 ... 4 ... 1 ...

etc. The Optimizer automatically selects the function

(channel) whenever a joystick is operated, making

active adjustments easy to perform.

The Menu key accesses less frequently used items,

other information and diagnostics. A “three key menu”

system allows additional functions and features to be

easily added to SF4 while still having a universal

Optimizer. The Enter key is used to step through the

various menu items. The section “Diagnostic Menus”

below describes the Menu and Enter key functions.

The Plus and Minus keys are used for changing the

various adjustments (threshold, ramp, etc.). The

process is described below. The Run key must be

pressed after making an adjustment so the new value is

saved.

Figure 14 identifies various items that are displayed

when you are making an adjustment. The “value” is

flashing (blinking on and off) and will change as the

Plus or Minus keys are pressed. The Channel

(Function) and Direction are displayed generically on

the bottom line, and as the actual machine’s functions

on the top line. The parameter being adjusted (in this

example threshold) is shown at the upper left.

CAUTION - Be sure to press the RUN key after making

an adjustment or the new setting will be lost

FRONT

Adjustments

Threshold

machine to just start to move or operate. The

Threshold value represents a PWM percent duty

cycle, which corresponds to the initial voltage

signal driving the valve when the Joystick handle

is moved slightly from its off position.

Max Out

output that causes the machine to operate at

maximum desired speed. The Max Out value

also represents a percent duty cycle,

corresponding to the voltage signal driving the

valve when the Joystick handle is fully deflected

(and high range is selected).

Low Range

signal when the Joystick handle is fully deflected.

The Low ange setting represents a percentage of

the Maximum Output value.

Threshold, Max Out and Low Range adjustments

are made in 0.5 % steps.

Ramp Up

take to increase (accelerate) from off to full on.

This adjustment is made in tenths of a second.

Ramp Down

machine’s function to decrease (decelerate) from

full on to off. Ramp Down adjustments are also in

tenths of a second.

Diagnostic Menus

Various pieces of information are available in the

Diagnostic Menu mode. This mode is started by

pressing the “Menu” key. The Optimizer displays

the first menu item. Press the Enter key to step

through all of the menu items. The first four menu

items display fixed data. Two examples are

shown at the right.

The valve PWM frequency for the first two outputs

(channels 1 and 2) is followed by the valve

frequency for the second two outputs (channels 3

and 4). Next the OEM part number and serial

number are shown.

is the amount of output that causes the

or maximum output is the amount of

sets the limited amount of output

sets the time the machine’s function will

sets the time required for the

FREQUENCY 1 2

100HZ

OEM PART NUMBER

SF4-4-200.00X

A8906 rev B

Page 2

PO Box 894

10 Controls Dive

Shelton, CT 06484

Telephone (203)929-8431

Fax (203)929-3867

www.oemcontrols.com

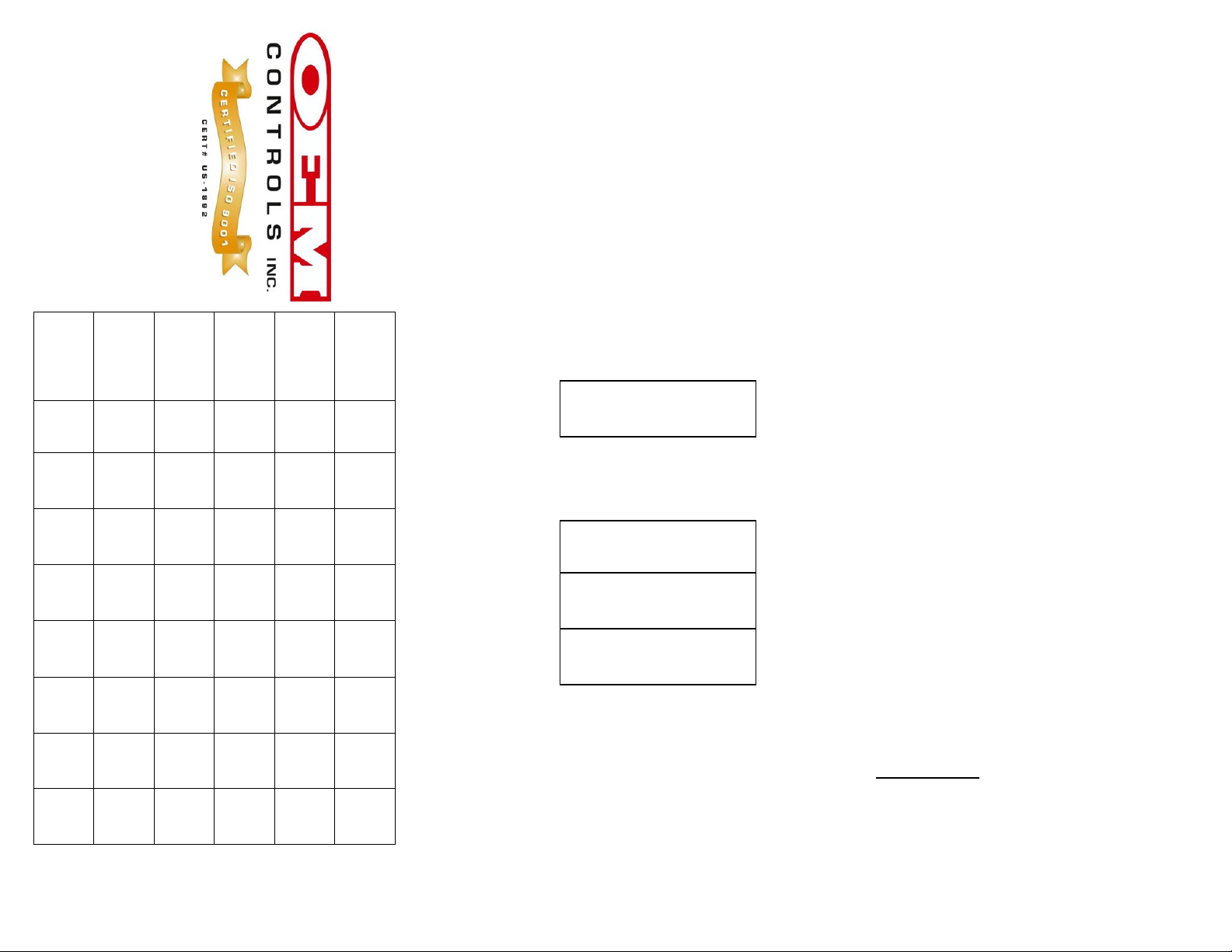

Ramp

Down

Ramp

Up

Range

Low

Maxout

Threshold

1A

1B

2A

2B

3A

3B

4A

4B

The next three menu items are active displays

showing input and output signals. These screens

are useful for troubleshooting. The switched

digital inputs (see figure15) can be tested on this

display. If an input is On, the display is a “1” and

if it is Off or 0 volts, the display is a “0”. Likewise

the AUX outputs and Digisensor inputs can be

displayed. The Troubleshooting guide has

additional information.The next menu item is

“Restore Factory Defaults” and is used to reset all

of the adjustable parameters to the settings that

were programmed in by the factory. The display

looks like this, with the bottom line flashing.

Pressing the Plus key will restore the default

values. Pressing the Enter key will step to the

next menu item.

The final three menu selections go together.

They provide an alternate method of choosing

adjustments, channels and the direction for

making changes.

At each of these

screens, the

selected

item (e.g.: TH, MX, RU, RD or LR) will flash. Use

the Plus key to select and the Enter key to go to

the next menu. After proceeding through these 3

menus, you will be able to adjust thE selected

variable.

Customized Display (Appendix 2)

Your particular Superflex 4 System application

may be customized to easily identify the

machine’s function. Nine characters may be

specified for each function, channel and direction.

For example - you might choose “DRIVE FWD”

for the machines drive forward, “BOOM LIFT”

and “ROTATE R” for boom functions, etc. Refer

to the customized data located in Appendix 2 of

this manual.

RESTORE DEFAULT?

YES=+ NO=ENTER

CONTROL ADJUST

TH MX RU RD LR

FUNCTION SELECT

Fn1 Fn2 Fn3 Fn4

DIRECTION

DIR A DIR B

BACK

Bench / Static Adjustments

Any adjustment can be made without operating

the machine. This process is known as “static” or

“on the bench” calibration. Use the following

steps -

1) Provide power to the Superflex 4 Controller.

Connect the Optimizer.

2) Select a “function” (channel) by pressing the

Function Select key one or more times, until the

desired channel (1 through 4) is displayed.

3) Select a direction (A or B) by pressing the DIR

A/B key.

4) Select a controller adjustment by pressing one

of Threshold, Maxout, Low Range, Ramp Up or

Ramp Down keys.

5) Use the Plus and Minus keys to make the

adjustment.

6) Press RUN to save the changes before

powering down or disconnecting the

Optimizer.

Factory Default Values (Appendix 3)

All defaults (preset values) as well as upper and

lower limits to each adjustment range may be

specified by the customer. These setting are

installed by OEM Controls when your Superflex 4

Controller is manufactured. After making

adjustments with the Optimizer, it may be

desirable to return to these default values. This

task is easily accomplished with the Optimizer.

1) Apply power to the Superflex 4 Controller and

connect the Optimizer.

2) Press the Menu key. Then press the Enter key

several times, until the Optimizer displays

“Restore Defaults?”.

Press the Plus key to restore the default values.

The Optimizer displays “BUSY” while the original

values are copied. This may take several

seconds, depending on how many values need to

be restored. Then the Optimizer will momentarily

display “DONE” and return to the default run

screen. Be sure to wait

disconnecting the Optimizer or turning off power

to the Superflex 4 Controller. After all

adjustments have been made for the desired

machine performance, it would be helpful to

record all of these settings for future reference.

The table at the right can be used for this.

for this to happen before

A8906 rev B

Loading...

Loading...