English

Contents

Important User Information .................................................................................4

Safety Instructions ................................................................................................5

Installation Environment ......................................................................................7

NX7 Product List ...................................................................................................8

Base Module ...................................................................................................8

Expansion Module .........................................................................................8

Programming Software .................................................................................8

Cables..............................................................................................................8

Hardware Features................................................................................................9

Specifications ......................................................................................................10

General Specifications.................................................................................10

Power Supply Specifications.......................................................................10

Performance Specifications.........................................................................11

Input Specifications......................................................................................12

Output Specifications...................................................................................13

Communication Specifications ...................................................................15

Installing and Wiring...........................................................................................16

Product Dimensions.....................................................................................16

Installation Dimensions ...............................................................................16

Installation Space .........................................................................................17

Terminal Block Dimensions.........................................................................17

Power Supply Wiring ...................................................................................18

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Because of this difference, and also because of

the wide variety of uses for solid state equipment, all persons responsible for

applying this equipment must satisfy themselves that each intended application

of this equipment is acceptable.

In no event will OE Max Controls be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, OE Max Controls cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by OE Max Controls with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of OE Max Controls is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

WARNING

Identifies information about practices or

circumstances which may lead to serious personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

4

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or

circumstances that can lead to minor personal

injury, property damage, economic loss, or product

malfunction. However, depending on situation,

failure to follow the directions accompanying this

symbol may also lead to serious consequences.

Safety Instructions

Please read this manual and the related documentation thoroughly and

familiarize yourself with the directions before installing, operating,

performing inspection and preventive maintenance. Make sure to follow

the directions correctly to ensure normal operation of the product and

your safety.

• When designing a system using this product, consider proper

prevention against external environmental fluctuations, power failure

and noise, etc., in accordance with installation requirements. Design

and implement an external circuit that allows your system to operate

continually and safely in any system failure.

• Make sure to disconnect the external power to the product before

performing mounting, wiring, inspection, maintenance and cleaning.

Never touch the power terminal when the power is on. Otherwise, it

may cause an electrical shock.

• Do not connect AC-powered products to a DC I/O terminal. Do not

connect externally- powered products to an internal 24V DC output

terminal.

• If you need to perform a special operation during run, such as program

editing, operation control or forced output, make sure to perform it after

ensuring safety.

• Do not connect an external device or a hand-held programmer (HHP)

that uses internal power to the product when runnig. Make sure to stop

the system and ensure safety before connecting them.

• Make sure to use an external device to PLC when configuring the

protective circuit breakers for emergencies.

• When the self-diagnostics functionality detects an error, such as internal

arithmetic error, watchdog time error, and/or connection failure, power

continues to be provided to the controller’s power supply so that your

system still works. Design and configure the circuits so that your system

runs safely under those conditions.

• The internal 24V DC power supplied to the circuits inside the PLC may

have voltage fluctuations, depending on the volume of load. These

voltage fluctuations may cause malfunction of the PLC or I/O devices

connected. Therefore, use the internal power within the allowed rating.

• Do not apply an impact to the terminal blocks or the product itself when

the power is on. Otherwise, it may cause malfunction and failure of the

product, or electrical shock.

5

• Operate and keep the product under the allowed conditions directed in

product specifications. During installation, be sure that all debris (metal

chips, wire stands, etc.) is kept from falling into the product.

Do not expose the product to high temperature, high humidity, dusty

conditions, salt, metal chips, corrosive gas, inflammable gas, solvents,

abrasive oil, and/or direct sunlight.

Avoid vibrations and crashes with other objects. Otherwise, it may

cause a fire, damage, malfunction or aging to the product.

• Fix cables as directed in the wiring instructions. We recommend you do

not connect the line to the terminals marked with the symbol

When wiring with the termi

•

Screw: 3.0 M, Torque: 0.5 N.m (5 kgf.cm)

Terminal width: 6.35 mm or less (0.25 in)

• Input/output and communication cables should be separated from

power cables. Give at least 200 mm space between them. Otherwise,

generated noise may cause product malfunction.

• We recommend installibng an insulation transistor near the front of the

PLC. Make sure to use twisted cables to prevent input noise.

• For frame grounding, perform class 3 grounding at 100Ω or less ground

resistance or independent class D grounding using a 2mm

perform common grounding to high voltage devices.

• Do not disassemble or remodel the product. If you need to repair the

product, contact the service center.

• This manual does not include detailed explanation on all of the

instructions and functions supported by the product. Please refer to

other related manuals for more information.

• Use the product only for the purposes stated on the product or in this

user manual.

• When disposing the product, make sure to follow your local regulations

and guidelines on industrial waste disposal.

nal block, use the following specifications:

'

●

2

. Do not

'

.

6

Installation Environment

ATTENTION

Do not install your PLC system if any of the following

conditions are present.:

• Ambient temperature outside the range of 0 to 55° C

(32 to 131° F).

• Direct sunlight.

• Humidity outside the range of 30% to 85% (noncondensing)

• Chemicals that may affect electronic parts.

• Excessive or conductive dust, or salinity.

• High voltage, strong magnetic fields, or strong

electromagnetic influences.

• Direct impact and excessive vibration.

ATTENTION

ATTENTION

ATTENTION

ATTENTION

Electrostatic Discharges

Under dry condition, excessive electrostatic discharges

may occur. Make sure to remove electrostatic discharges

by touching a grounded metal piece before touching your

controller system modules.

Cleaning

Never use chemicals such as thinner because they melt,

deform or discolor PCB boards.

Precautions for use of power

• Run your PLC system only after the I/O devices and

motor devices have started. (For example, first power

on in the PROG mode, then change the operation mode

to RUN.)

• Make sure to power off I/O devices after ensuring PLC

operation is stopped.

If you power on/off I/O devices when the PLC system is in

operation, the system may malfunction because input

signal noises may be recognized as normal inputs.

Before powering on

• Make sure to follow these directions before powering

on your PLC system.

• When installing the system, ensure that there are no

metal chips or conductive fragments that stick to wiring

cables.

• Ensure that power supply and I/O wirings and power

supply voltage are all correct.

• Securely fasten installation and terminal screws.

• Set the operation mode switch to PROG mode.

7

NX7 Product List

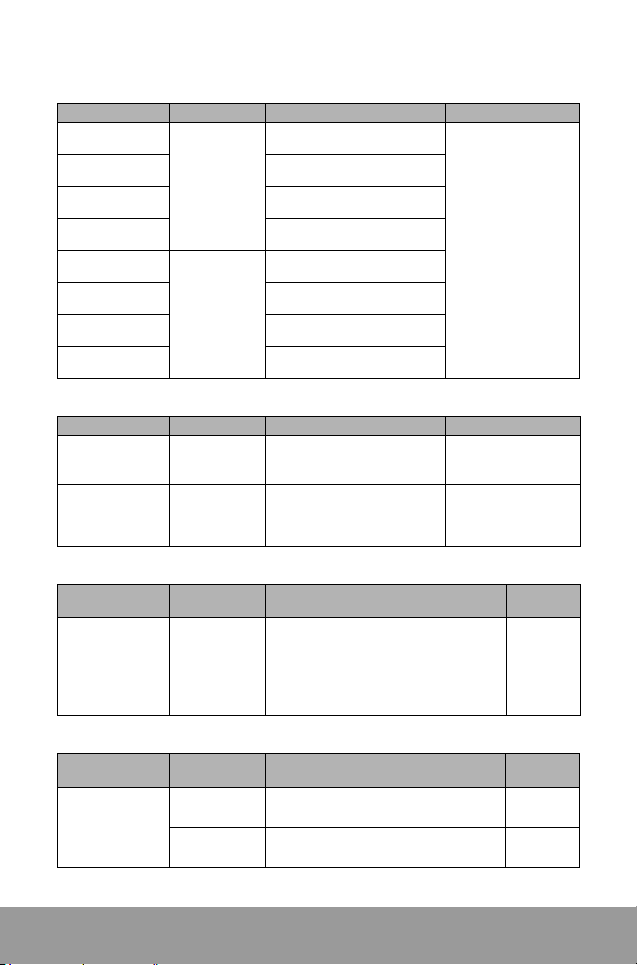

Base Module

Catalog number Input power I/O specifications Remarks

NX7-28ADR

NX7-28ADT

NX7-48ADR

NX7-48ADT

NX7-28DDR

NX7-28DDT

NX7-48DDR

NX7-48DDT

100 to 220V ac

power supply

24V dc

power supply

Expansion Module

Catalog number Input power I/O specifications Remarks

NX7-28EDR

NX7-28EDT

24V dcb power

supply

24V dc power

supply

Programming Software

Programming

software

WinGPC 3.5

(Windows)

Catalog

number

16-point dc input/12-point relay

output

16-point dc input/12-point

transistor output

28-point dc input/20-point relay

output

28-point dc input/20-point

transistor output

16-point dc input/12-point relay

output

16-point dc input/12-point

transistor output

28-point dc input/20-point relay

output

28-point dc input/20-point

transistor output

16-point dc input/12-point relay

output

16-point dc input/12-point

transistor output

Specifications Remarks

Allows you to perform the following tasks

on a remote computer:

PLC program editing and monitoring, file

-

management, program backup, online

editing, error and status check-up, network

status check-up, I/O mapping, time chart

monitoring

Built-in 9k steps

memory,

Several

µ

s per step

processing speed

Built-in 1 HSC input

channel,

Built-in 2 pulse output

channels built in,

2 communication ports

(NOTE: Some relevant

contacts are unavailable

when HSC input or

pulse output channels

are used.)

16-point 24V dc input

12-point relay output

2A per point

16-point 24V dc input

12-point transistor

output

4A per point

For

Windows

95/98/

2000/NT

Communication

cable for both

RS232 and

RS485

8

Item

Cables

NX_CBLCPU2

NX_CBLCPU5

Catalog

number

Specifications Remarks

PLC to PC communication (WinGPC)

2 m

Same functions with NX _CBLCPU2

5 m

Loading...

Loading...