Odyssey LI-COR Owner's Manual

ii

CE Marking:

This product (model number 9120) is a CE-marked product. For

conformity information, contact LI-COR Support at biosupport.licor.com.

Outside of the U.S., contact your local sales office or distributor.

Note on Safety

LI-COR products have been designed to be safe when operated in the manner described in this manual. The safety of

this product can not be guaranteed if the product is used in any other way than is specified in this manual.

Equipment markings:

The product is marked with this symbol when it is necessary for you to refer to the manual or accompanying

documents in order to protect against damage to the product.

The product is marked with this symbol when a hazardous voltage may be present.

iii

The product is marked with this symbol for a Chassis Ground connection.

Warnings must be followed carefully to avoid bodily injury.WARNING

CAUTION Cautions must be observed to avoid damage to your equipment.

Manual markings:

Warnings must be followed carefully to avoid bodily injury.WARNING

CAUTION Cautions must be observed to avoid damage to your equipment.

NOTE Notes contain important information and useful tips on the operation of your equipment.

iv

Notice

The information contained in this document is subject to change without notice.

LI-COR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL,

INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. LI-COR shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

This document contains proprietary information which is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without prior written consent of LI-COR, Inc.

Printing History

Publication Number 984-11712

Printed March 2011

Revised: April 2014

The Odyssey System and LI-COR chemical reagents are produced and distributed for research

purposes only. In no instance is any product offered for drug or clinical use in humans.

LI-COR is an ISO9001 registered company. © 2011 LI-COR, Inc. Specifications subject to change.

LI-COR, Odyssey, MousePOD, In-Cell Western, and IRDye are trademarks or registered trademarks of LI-COR,

Inc. in the United States and other countries. All other trademarks belong to their respective owners. The

Odyssey Infrared Imager and IRDye reagents are covered by U.S. patents, foreign equivalents, and patents

pending.

Federal Communications Commission

Radio Frequency Interference Statement

WARNING: This equipment generates, uses, and can radiate

radio frequency energy and if not installed in accordance with

the instruction manual, may cause interference to radio communications. It has been tested and found to comply with the limits

for a Class A computing device pursuant to Subpart J of Part 15

of FCC rules, which are designed to provide a reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment in a

residential area is likely to cause interference in which case the

user, at his own expense, will be required to take whatever

measures may be required to correct the interference.

v

4647 Superior Street

International: 402-467-0700 • 402-467-0819

LI-COR GmbH, Germany

LI-COR UK Ltd., UK

All other countries, contact LI-COR Biosciences or a local LI-COR distributor:

(Serving Europe, Africa, and the Middle East)

• P.O. Box 4000 • Lincoln, Nebraska 68504 USA

Technical Support: 800-645-4260

North America: 800-645-4267

: +49 (0) 6172 17 17 771

(Serving UK, Ireland, and Scandinavia)

: +44 (0) 1223 422104

http://www.licor.com/distributors

www.licor.com

Table of Contents

vii

Chapter 1: Safety and

Operational Information

In This Manual ............................................ 1

Safety Considerations .................................. 1

Laser Safety .............................................. 1

Safety Interlocks ....................................... 4

Chemical Safety........................................ 4

Placement in the Laboratory........................ 4

Ambient Laboratory Conditions................ 5

Ventilation................................................ 5

Space Requirements ................................. 5

Moving the Odyssey System..................... 5

Electrical Considerations ............................. 7

Power Cords............................................. 7

Power Switch ........................................... 7

Fuse Replacement .................................... 8

Routine Maintenance .................................. 8

Networking Cables ...................................... 9

Chapter 2: Overview and

General Description

Overview .................................................. 11

Hardware Description .............................. 12

Scanning Surface.................................... 13

General Description of Scanning ............... 13

Continuous Operation ............................... 15

Powering Off the System ........................... 16

Power Button.......................................... 16

Shutdown via the Browser Interface........ 16

Resetting the Instrument ............................ 16

Chapter 3: Operation

Before You Begin .......................................17

Cleaning the Scanning Surface...................17

Using Membranes......................................18

Using Gels .................................................19

Using Microplates......................................20

Using the MousePOD

Positioning Membranes and Gels...............22

Positioning Microplates..............................24

Scanning Multiple Microplates ...............25

Front Panel Controls...................................26

Setting the Network Address From the

Front Panel .............................................27

Starting Scans From the Front Panel........27

Downloading Scans................................28

File Size and Storage Capacity ...................29

Scanning Limitations ..............................31

Software Options .......................................32

Odyssey Application Software ................32

Browser Interface....................................32

®

Accessory..............21

Chapter 4: Connecting the

Odyssey Imager to a Network

Introduction ...............................................33

Firewall Recommendations........................ 34

Installing the Odyssey

Software.....................................................34

Adding Users ............................................... 36

Installing Optional Modules ........................36

Configuring the Windows System for the

Odyssey Software.....................................37

Assembling the Basic Hardware

Configuration............................................. 44

Assembling the Networked Configuration ..46

®

Application

viii

Connecting to a Network Using an Ethernet

Switch ....................................................... 49

Setting a Static or Automatic (DHCP) IP

Address...................................................... 50

Configuring the Odyssey

®

Imager with a

Static or Automatic (DHCP) IP Address .. 50

Configuring the Computer with a Static or

Automatic (DHCP) IP Address ................ 54

Connecting Other Computers on the

Network .................................................... 56

Chapter 5: Accessing the

Odyssey Imager With an

Internet Browser

Overview................................................... 59

Connecting to the Odyssey Imager Using

a Browser ................................................. 59

Checking Instrument Status........................ 61

Chapter 6: User and Scan

Group Administration

Adding User Accounts................................ 65

Changing User Account Rights .................. 69

Changing Your Own Password .................. 70

Changing Other Users’ Passwords ............. 72

Deleting User Accounts............................. 73

Deleting the Original Admin Account........ 74

Creating and Changing Groups.................. 74

Creating a New Scan Group.................. 74

Changing Access Permission of a

Scan Group............................................ 75

Deleting Scan Groups................................ 77

Viewing and Deleting Scans Within a Scan

Group........................................................ 78

Chapter 7: Starting Scans

Using an Internet Browser

Using the Scan Setup Window ...................81

Naming the Scan ................................... 82

Entering Scan Parameters........................83

Starting a Scan........................................86

Stopping a Scan......................................88

Saving and Deleting Preset Parameters.......88

Chapter 8: Importing and

Editing Scanned Images

Opening the View Page............................... 89

Opening a Scan Stored on the Odyssey

Imager .......................................................90

Changing the Appearance of an Image.......92

Zooming In and Out ...............................92

Cropping an Image .................................93

Changing Image Appearance ..................94

Inverting the Grayscale Map ...................95

Changing Image Orientation ...................... 96

Rotating the Image..................................96

Flipping the Image ..................................97

Showing and Hiding Image Channels ........97

Displaying Scan Information ...................... 99

Saving Changes to Images........................100

Printing Image Files..................................101

Chapter 9: Instrument Utilities

and Diagnostics

Instrument Status ......................................103

Instrument Shutdown ...............................104

Editing Network Addresses.......................105

DHCP vs. Static Addressing ................. 106

Using Host Names................................106

Entering a Gateway Address .................106

Setting Date and Time..............................107

Updating the Odyssey® Instrument

Software .................................................. 108

Opening the Update Scanner Page....... 108

Starting the Update .............................. 110

User Diagnostics ..................................... 112

Browser Test............................................ 113

Technician Diagnostics ............................. 115

Chapter 10: Appendices

Specifications ............................................ 117

Error Messages........................................... 118

Scan Setup.............................................. 118

Scan Console.......................................... 119

Imaging .................................................. 119

Software Upgrade Errors......................... 119

Time Setup ............................................. 120

Utilities: Change Password..................... 120

Utilities: Manage Groups........................ 120

Utilities: User/Technician Diagnostics,

View System Log, View Scan Log........... 121

ix

Chapter 1: Safety and Operational

Information

In This Manual...

The following topics are discussed in this manual:

•

Safety considerations.

•

Instrument placement and power considerations.

•

Description of detection optics and signal processing.

1

•

Odyssey® Infrared Imaging System operation.

•

Use and maintenance of the Odyssey scanning bed.

•

Troubleshooting for the Odyssey Infrared Imaging System.

Safety Considerations

Laser Safety

The Center for Devices and Radiological Health (CDRH) was established in October, 1982, by the U.S. Food and Drug Administration

(FDA) to protect the public health in the fields of medical devices and

radiological health.

Manufacturers of products subject to performance standards under

the Radiation Control for Health and Safety Act of 1968 are required

to furnish various reports to the CDRH.

CHAPTER 1

2

Operational Information

The Odyssey® Infrared Imager is certified as a Class I laser product,

containing a Class IIIb laser. This means that hazardous laser

radiation is

not

emitted outside the instrument. Radiation emitted

inside the instrument is confined within protective housings and

external covers. A series of safety interlocks ensures that the laser

beam cannot escape during any phase of user operation.

The CDRH implemented regulations for laser products on August 1,

1976 (CDRH radiation performance standard 21, Code of Federal

Regulations Chapter 1, Subchapter J). Compliance for products

marketed in the United States is mandatory. The label that must be

attached to laser products marketed in the United States is Figure

1-1 and is located on the rear panel of the Odyssey System,

indicating compliance with CDRH regulations.

CAUTION:

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

LI-COR, INC.

4421SUPERIOR ST.

LINCOLN, NE 68504 USA

DISCONNECT POWER BEFORE SERVICING

THIS DEVICE COMPLIES WITH PART 15 OF

THE FCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS: (1)

THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST

ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY

CAUSE UNDESIRED OPERATION.

THIS PRODUCT COMPLIES WITH CDRH

RADIATION PERFORMANCE STANDARD 21

CFR CHAPTER 1 SUB-CHAPTER J.

Made in U.S.A. Patents Pending

Model: 9120

S/N: ODY-

INPUT

100-127V

~

8A

200-240V ~ 5A

50/60HZ

Figure 1-1.

The Odyssey® Infrared Imaging System contains two lasers; one

emitting at 785 nm, and one at 685 nm. Each laser has a peak power

rating of up to 80 milliwatts. The 685 nm laser emits visible laser

radiation

– direct exposure to either beam may cause eye damage

.

Laser radiation is emitted through apertures at the top of the Odyssey

microscope assembly. Because the microscope assembly moves in

both planes relative to the glass scanning surface, laser radiation

could be focused at any position on this surface. Safety interlocks

(below) automatically turn the lasers off when the Odyssey lid is

opened.

The label shown below is affixed to the inside of the Odyssey

instrument case at two locations; one near the laser/microscope

assembly scanning bed, and the second on the cover that is used to

seal the above mentioned assembly:

3

DANGER:

DANGER:

VISIBLE AND INVISIBLE LASER

RADIATION WHEN OPEN

AVOID DIRECT EXPOSURE TO BEAM

RAYONNEMENT VISIBLE ET

INVISIBLE LASER EN CAS

D'OUVERTURE

EXPOSITION DANGEREUSE AU

FAISCEAU

Figure 1-2.

CHAPTER 1

4

Operational Information

Safety Interlocks

The Odyssey® Infrared Imager has two safety interlocks that prevent

access to the laser when the instrument lid is opened during

operation.

Do not attempt to defeat these interlocks.

The interlocks

are located on the front of the instrument bezel as shown below.

Audible tones sound when the lid is opened and closed.

Chemical Safety

LI-COR Biosciences recommends that all biochemicals be handled

carefully, and that safe laboratory procedures be followed at all

times. Be aware of the hazards associated with any chemical before

using it.

The Odyssey Imager should not be used with any radioactive

materials.

The Odyssey Infrared Imaging System weighs approximately 33 kg

(72 lb). The system should be placed on a level laboratory bench that

is sufficiently sturdy to bear its weight.

Interlocks

Figure 1-3.

Placement in the Laboratory

Ambient Laboratory Conditions

Place the Odyssey® System away from external heat sources

(furnaces, windows, etc.). Additional heating can cause high temperatures within the enclosure, resulting in instrument shut down. Place

the instrument away from sinks or other sources of water that pose a

shock hazard. Recommended operating conditions are 15-35°C and

a dew point not greater than 19°C to prevent condensation on the

laser/microscope assembly during operation.

Ventilation

The instrument enclosure and circuit boards are cooled with two

internal fans. There are no restrictions regarding placement of the

instrument with respect to the fan cover; the fan shrouds are not

filtered, and the cover serves only as an exhaust outlet.

5

Space Requirements

The Odyssey System requires an area approximately 54 cm W (21.3")

×

62 cm D (24.4"). With the hood fully open, the Odyssey Imager

requires 74 cm (29") of vertical clearance.

Moving the Odyssey System

Be cautious when moving the instrument. Always be sure to move

the motor lock switch on the instrument back panel to the

Up (Transport)

a pen or a small screwdriver to move the motor lock switch. After

position before moving the instrument. Use the tip of

CHAPTER 1

6

Operational Information

moving the instrument, return the motor lock switch to the

Down (Operate)

position. The following label is located next to

the motor lock switch:

Use a minimum of two people when moving the Odyssey

®

System,

as it weighs about 33 kg (72 pounds). Lift under the metal enclosure

on each side of the unit, and keep the unit as near vertical as

possible. Gently set the Odyssey Imager at its new position.

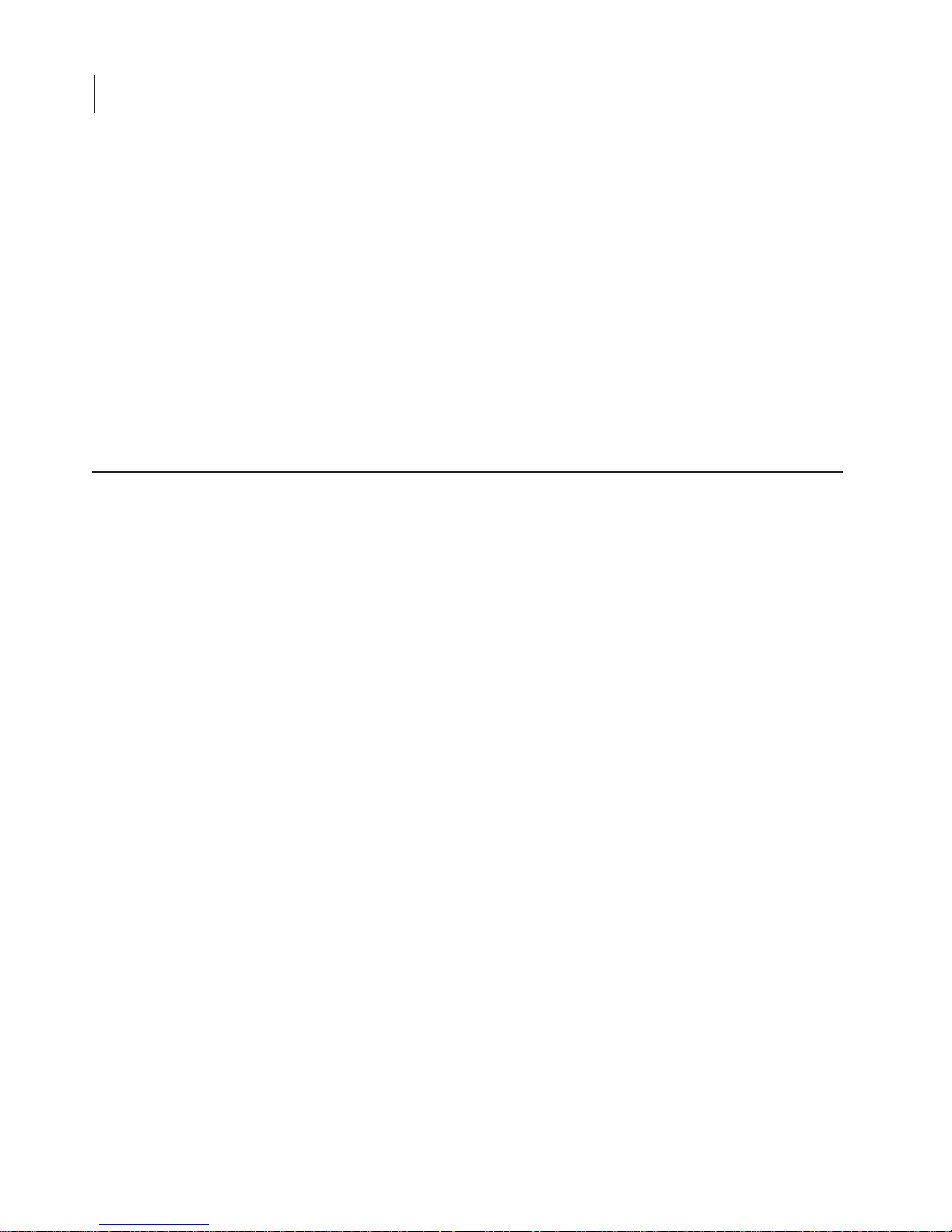

The instrument can be leveled after it is moved, if necessary. The

instrument does not need to be level for proper operation; it may be

helpful, however, if the laboratory bench is not level, to prevent

moistened membranes from sliding on the scanning surface.

Each of the 4 plastic feet on the bottom of the instrument case has a

threaded metal insert that can be turned in either direction to adjust

its height. Adjust the feet as necessary, until the instrument is level.

TRANSPORT

MOTOR LOCK

OPERATE

10BASE-T or

100BASE-TX

Figure 1-4.

Instrument base

Metal insert

Plastic foot

Figure 1-5. Turn the metal inserts on the feet to adjust the height.

Electrical Considerations

Power Cords

The Odyssey® Imager is equipped with a 3-wire grounding-type plug.

This plug will only fit into a grounding-type outlet. This is a necessary

safety feature. If you are unable to insert the plug into the outlet, you

will need to replace the outlet. Do not defeat the purpose of the

grounding-type plug.

Do not locate the Odyssey Imager where the power cord will be

walked on or exposed to water or chemical spills.

7

The Odyssey Imager draws approximately 3 amperes at 120V. If an

extension cord is used, make sure the total of the ampere ratings on

the instruments plugged into the extension cord does not exceed the

extension cord ampere rating. Also make sure the total amperage of

instruments plugged into the wall outlet does not exceed the

amperage capacity for the outlet. In the U.S., this is usually 15 or 20

amperes.

Power Switch

After March 2010, a power switch will be located above the power

cord input. Push ‘ ’ to turn on the instrument or ‘

O

’ to turn it off.

CHAPTER 1

8

Operational Information

Fuse Replacement

Caution:

Replace fuses only with fuses of the specified type and

current ratings.

The power supply fuses are located inside the sealed instrument

power supply, and

are not user serviceable

. If the instrument fails to

power up, and you suspect that a fuse has blown, contact LI-COR

Biosciences or a LI-COR

®

representative. A single 5A fast blow fuse

protecting the Digital Signal Processor (DSP) is located on one of the

printed circuit boards (PCB). This fuse is also not user-serviceable.

The Odyssey

®

Imager requires only minimal maintenance. However,

as with any equipment utilizing electrical voltages, there is a danger

of fire or electrical shock if the equipment is not properly maintained.

LI-COR Biosciences recommends that you routinely inspect the

system and the scanning surface. The following are some general

maintenance guidelines:

•

Wipe all chemical spills from the case and/or scanning surface to prevent

damage to the surface coating.

•

Inspect all cables and power cords for evidence of fraying, exposed wire,

or loose connections.

•

Keep the scanning surface free of organic solvents and other combustibles.

•

Clean the exterior case parts with warm water and a damp cloth. The

exterior case parts are painted with a durable urethane coating that is

resistant to chemical spills. Do not use scouring compounds, solvents such

as acetone, benzene, carbon tetrachlorides, lacquer thinner, or alcohol to

clean the case.

Routine Maintenance

Networking Cables

Multiple Cat. 5 networking cabes are provided with the Odyssey®

Imager. Do not use networking cables other than the ones provided.

The use of other networking cables may result in improper electrical

performance.

9

Chapter 2: Overview and General

Description

Overview

The Odyssey® Imager is a network server device that is connected to

a network, and ultimately to a computer, via TCP/IP. This allows

access to the Odyssey Imager via the Odyssey Application Software

or an Internet browser. The Odyssey Imager can also be connected

directly to the computer in stand-alone (non-network) configurations.

11

Image data, run parameters, and security protocols can be viewed

and/or changed over the network; finished scans are then

downloaded from the Odyssey hard disk to local drives for storage

and analysis.

Note:

Although the Odyssey Imager has an internal hard disk, it should be used for

temporary storage only; when the hard disk is full, the oldest files are overwritten to

make space.

Files can also be erased from the hard disk using the browser

interface; see Chapter 5,

Group

Unique, password-protected User Accounts allow access rights to be

established for multiple users.

.

Viewing and Deleting Scans Within a Scan

CHAPTER 2

12

Odyssey Overview and General Description

Two solid state

diode lasers

simultaneously provide light excitation

at 685 and 785 nm.

Collimating lenses, optical bandpass filters

, and

a

focusing lens

focus and tune the laser beams to produce an

excitation spot on the scanning surface. The microscope electronics

then modulate the laser beams to discriminate the infrared (IR) dye

signal fluorescence from background fluorescence. The scanner

detection optics

focus on the excitation spot and collect light from

the fluorescing IR dyes.

After collection by the

microscope objective

, the light is passed to a

dichroic mirror

. The mirror splits the light and essentially sorts the

fluorescent signals by transmitting the light above 810 nm and

reflecting light below 750 nm. Transmitted and reflected light travels

two independent paths through optics designed to remove scattered

and stray light. The light is ultimately focused onto one of two

avalanche photodiodes

that converts the light to an electrical signal

for processing by the microscope detection electronics.

In the microscope electronics, the signal is amplified, filtered, and

finally converted to a digital value by an analog-to-digital converter.

The digital signal is demodulated, filtered again, and coordinated

with the microscope position by a

Digital Signal Processor

(DSP) to

produce the image file.

The entire compact laser/microscope assembly travels on a platform

that moves beneath the scanning surface (below) along both the

X- and Y-axes.

Hardware Description

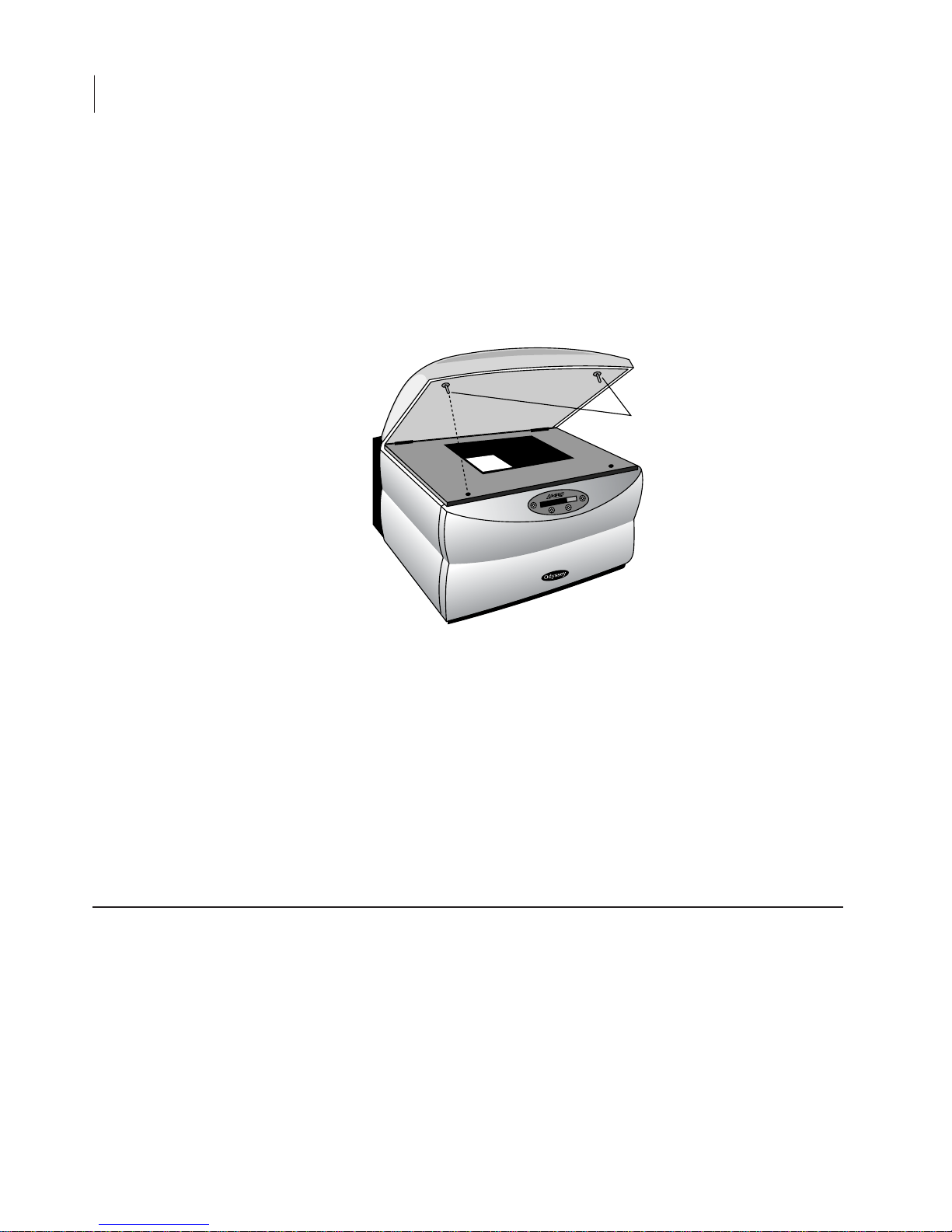

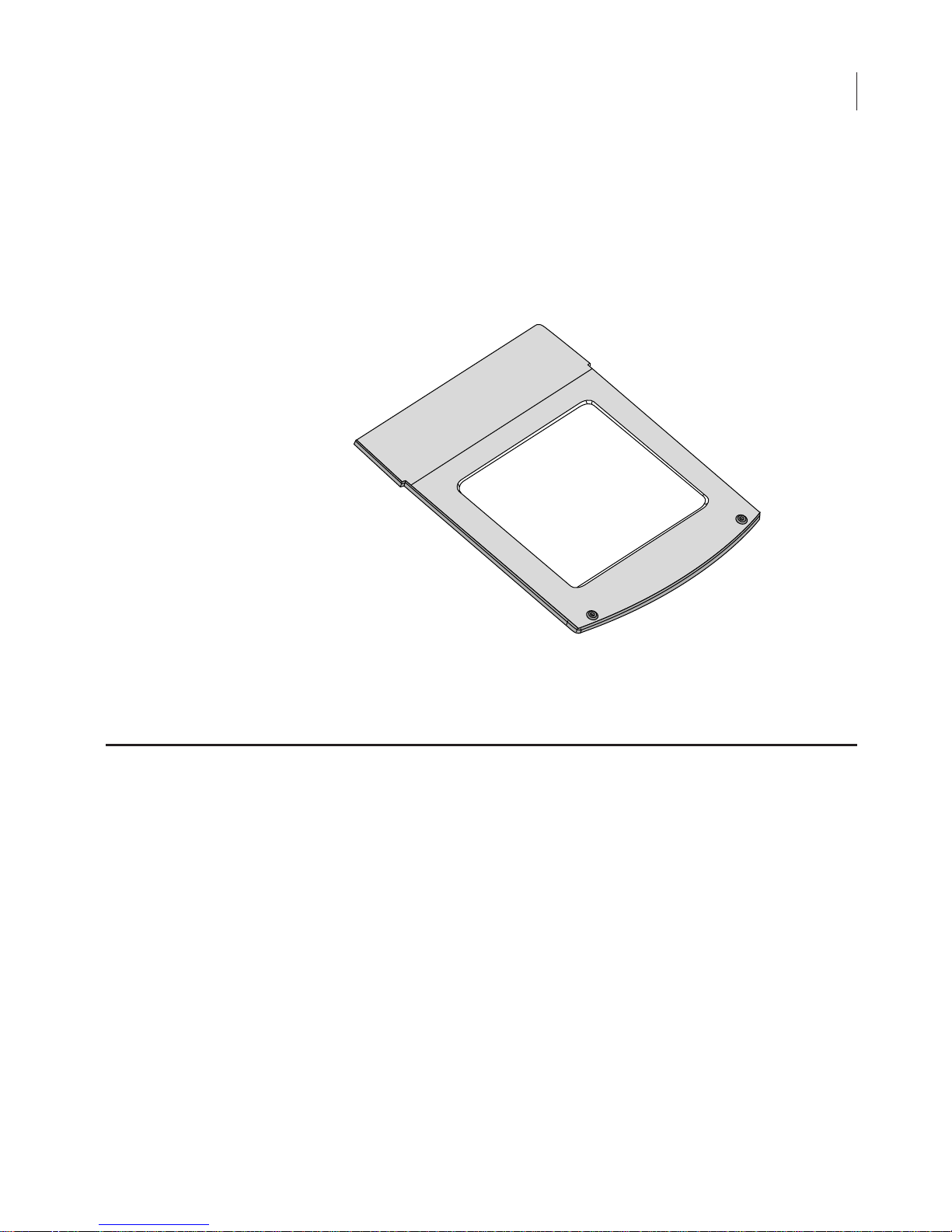

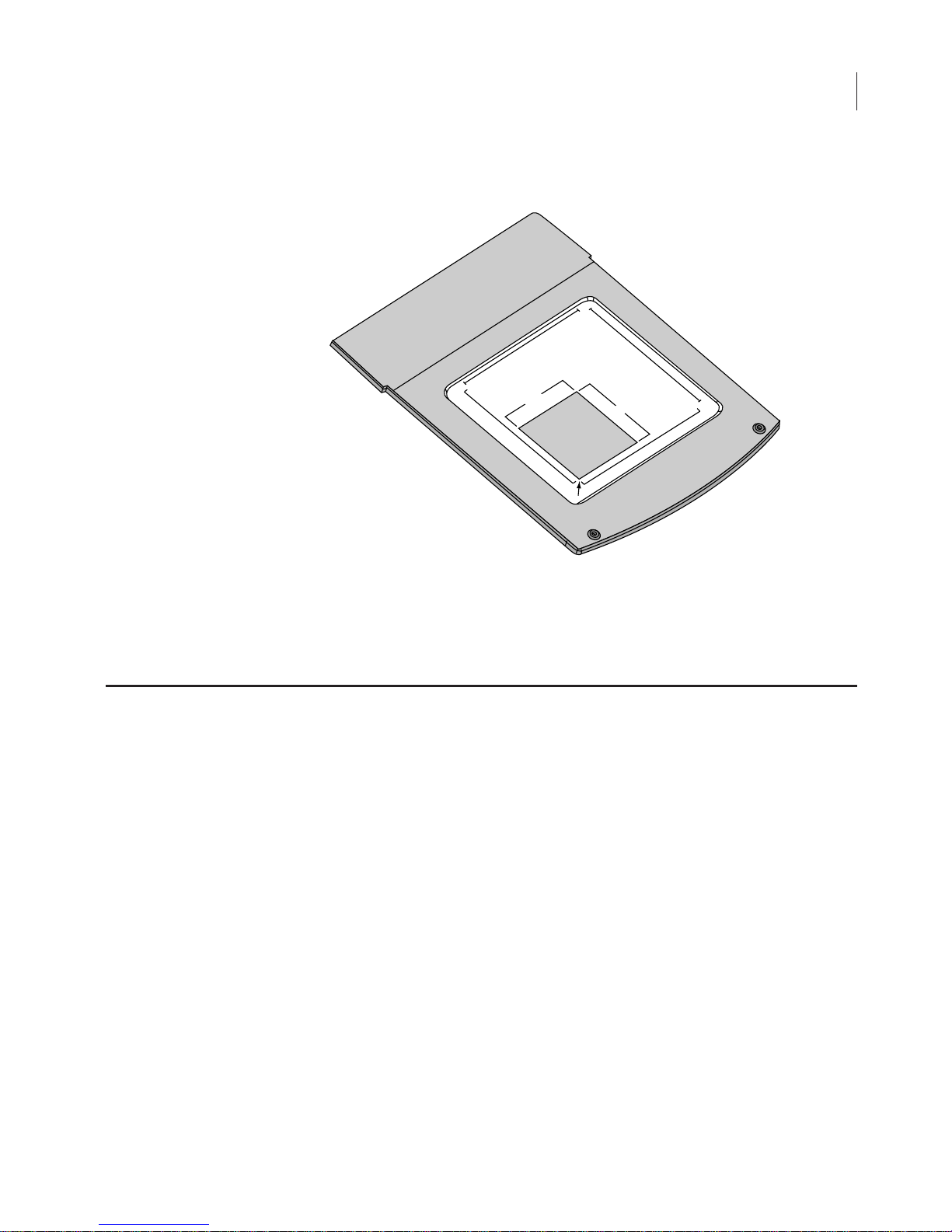

Scanning Surface

The scanning surface is a 25 cm × 25 cm glass plate (below), upon

which the samples to be scanned are placed. The scanning surface is

sealed from the instrument interior so no moisture can penetrate to

the detection optics and electronics below.

Scanning

Surface

13

Figure 2-1. Scanning surface on the Odyssey Imager.

General Description of Scanning

Scans can be initiated in any of three ways; 1) using the Odyssey

Application Software; 2) using an Internet browser, or 3) from the

Odyssey keypad.

®

CHAPTER 2

14

Odyssey Overview and General Description

When scanning is initiated from the Odyssey® Application Software

or an Internet browser, the user is presented with a representation of

the scanning surface, from which the origin of the scan and the size

of the area to be scanned are chosen.

Scanning starts at the lower left hand corner of the scanning surface

(when facing the front of the instrument), and progresses first across

the X axis, and then steps up incrementally along the Y axis of the

scanning surface, as shown in Figure 2-3. The scan will again

progress along the X axis until the specified area has been scanned.

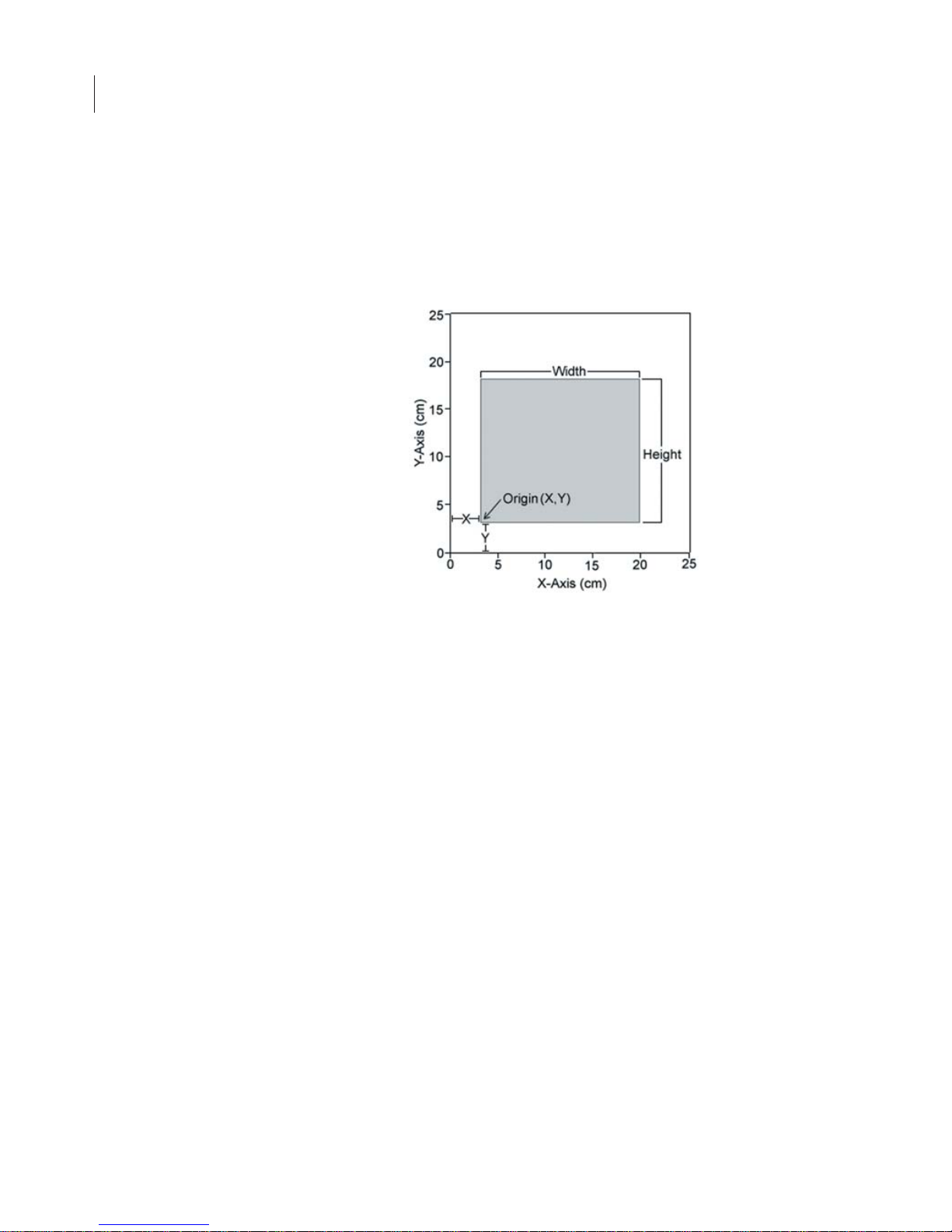

Figure 2-2. Scan origin and size of sample are chosen in the software.

15

Figure 2-3. Scans start at the lower left hand corner of the scanning

surface and progresses across the X-axis and up the Y-axis.

Continuous Operation

The Odyssey® Imager and network switch are designed to operate

continuously. During idle times, the Odyssey Imager can remain

powered on or be powered off at your discretion. When idle, the

Odyssey Imager uses approximately 0.5 amp of power, about the

same as a light bulb. If the Odyssey Imager needs to be powered off

(when moving it, for example), see

25

Width

Y-Axis (cm)

Sample

Origin (X,Y)

0

Height

X-Axis (cm)

0

25

Powering Off The System

below.

CHAPTER 2

16

Odyssey Overview and General Description

Note:

After powering off the system, the Odyssey® Imager may take up to 30 minutes

to reboot when power is restored.

Power Button

Briefly press the

Power

button on the front panel keypad to shut

down the Odyssey Imager. You will be asked to confirm that you

want to shut down. Press the

Y (start)

button to shut down.

Shutdown via the Browser Interface

The Odyssey instrument can also be shutdown using the browser

interface as described in Chapter 8. An account with

Administrator

access is required to use the Shutdown function.

Note:

Do not

attempt to turn off the instrument by unplugging the power cable, or by

pushing ‘O’ on the rear power switch (if applicable).

In the event that the front-panel keypad is unresponsive and you

cannot connect to the instrument using an Internet browser, the

instrument can be reset by holding down the

Power

key for at least 4

seconds until the instrument turns off. This procedure cuts power to

the instrument and internal hard disk, so it should only be used when

communication cannot be established by any other means. The

Odyssey instrument should resume normal operation after the

Power

key is pressed again to turn the instrument back on,

though start up

may take several minutes or up to 30 minutes.

Powering Off the System

Resetting the Instrument

Chapter 3: Operation

Before You Begin...

The following procedure is recommended before every scan:

1) Thoroughly wash the glass scanning surface with ultrapure water

and wipe with a lint-free tissue.

2) Repeat the wash with isopropanol to remove any visible smears.

Use ethanol to remove any remaining residues. If dye contamination continues to be a problem, slightly wet a cloth with

acetone and wipe the glass.

contact anything other than the glass. The paint can be damaged

by acetone.

Important:

17

the acetone must not

3) If the silicone mat is being used, rinse it under warm water.

Gentle lab soap may be used, but the soap must be completely

rinsed away before use. The silicone mat may also be rinsed with

isopropanol if needed. Dry the silicone mat with a lint-free tissue.

Cleaning the Scanning Surface

The scanning surface is plate glass, which can be cleaned with any

non-abrasive glass cleaner. Warm, soapy, distilled water or isopropanol can also be used. Do not use scouring compounds or abrasive

scouring pads; the glass can scratch, which can affect the scanned

image.

CHAPTER 3

18

Operation

It is very important that the glass and silicone mat be free of smudges,

dust, and dye before placing membranes or gels onto the Odyssey

®

Imager. Contaminated surfaces in contact with the membrane

surface may cause blotches and streaks that cannot be removed with

further washing.

For Western blotting methods, nitrocellulose or PVDF membranes

may be used (see

www.licor.com

for the latest membranes and kits).

For best performance, pure cast nitrocellulose membranes are

recommended. Detailed blotting protocols can be found in the

Odyssey Application Protocols. There are some general tips,

however, for using membranes with the Odyssey Imager.

•

Do not touch the membrane – handle only with a clean, smooth-edged

forceps. Lift the membrane only by the corners. Fingerprints, even from a

glove, will show clearly when imaged.

•

Use the silicone mat included to cover the membrane(s) before scanning.

Use the 4" soft roller included to remove any air bubbles that may be

present. These optional steps help keep the membrane flat against the

scanning surface for optimum imaging.

•

Protect the membrane from light until it has been scanned.

•

Keep the membrane wet if it is to be stripped and re-used. For Western

blots, store dry or in PBS buffer at 4°C.

•

Use clean containers to avoid cross-contamination and reduce

background.

•

Multiple membranes can be washed together, provided there is ample

volume so each membrane moves freely.

•

If the signal on the membrane is too strong, re-scan at a lower intensity

setting.

•

The fluorescent signal on the membrane will remain stable for several

months or longer if protected from light.

Using Membranes

Using Gels

A protocol for In-Gel Westerns is provided in the Odyssey® Application Protocols manual. Coomassie-stained gels can also be

scanned since Coomassie Blue dye can be seen clearly in the 700 nm

channel, and faintly in the 800 nm channel (see the Western Blot

Analysis protocol for details). As well, nucleic acids stained with

®

Syto

60 and separated in a gel can be imaged in the 700 nm channel

(see the Syto 60 Staining of Nucleic Acids in Gels protocol for more

information). To scan a gel, follow these procedures:

1) Thoroughly rinse the gel with destaining solution or water to

remove dye particulates.

19

2) When placing the gel on the scanning surface, take care not to

trap air bubbles underneath. Cover the gel with plastic wrap to

prevent drying, if desired.

3) Scan the gel in the 700 nm channel.

4) Adjust the focus offset for the gel thickness. The correct focus

offset is 1/2 the thickness of the gel; for a 1 mm gel, set the focus

offset to 0.5 mm. The maximum offset is 4 mm in the most current

edition of the Odyssey Infrared Imaging system, allowing gels of

up to 8 mm to be scanned.

Note:

Early versions of the Odyssey Imager were limited to a 2.0 mm focus offset, but

can be upgraded by installing the Odyssey Server Software version 2.0.0 or above.

5) After removing the gel, clean the glass surface to remove any

residual dye by following the instructions in the section

You Begin...

above.

Before

CHAPTER 3

20

Operation

Microplates that meet certain physical characteristics can be

scanned directly on the Odyssey

®

scanning surface. Proper selection

of microplates significantly affects the results of your analysis as each

plate has its own characteristics including well depth, plate autofluorescence, and well-to-well signal crossover. Some general considerations for microplate selection are provided below.

•

Plate dimensions must be such that the distance from the Odyssey

scanning surface to the target detection area of the plate is 4.0 mm or less.

•

In order to avoid well-to-well signal spread, black-walled, clear bottom

plates should be used for assays that involve imaging of a liquid. Since

In-Cell Western

™

assays use detection at the well surface with no liquid

present, both clear and black-walled plates can be used. Consult protocols

in the Application Protocols manual or on the LI-COR

®

website

(

http://biosupport.licor.com

) for specific recommendations.

•

Do not use plates with white walls because the autofluorescence from the

white surface will create significant noise.

•

For In-Cell Western assays requiring sterile plates for tissue culture growth,

the following plates are recommended by LI-COR Biosciences.

96-well format Nunc

®

(P/N 161093) Clear

96-well format Nunc (P/N 165305) Black

96-well format Falcon

™

(P/N 353075) Clear

96-well format Falcon (P/N 353948) Black

384-well format Nunc (P/N 164688) Clear

384-well format Nunc (P/N 164730) Black

384-well format Falcon (P/N 353961) Clear

384-well format Falcon (P/N 353962) Black

•

Before plate scanning, clean the bottom plate surface with a moist, lintfree paper to remove any obstructions. Additionally, the Odyssey scanning

surface should be thoroughly cleaned using the procedures described

earlier in this chapter.

Using Microplates

Loading...

Loading...