Page 1

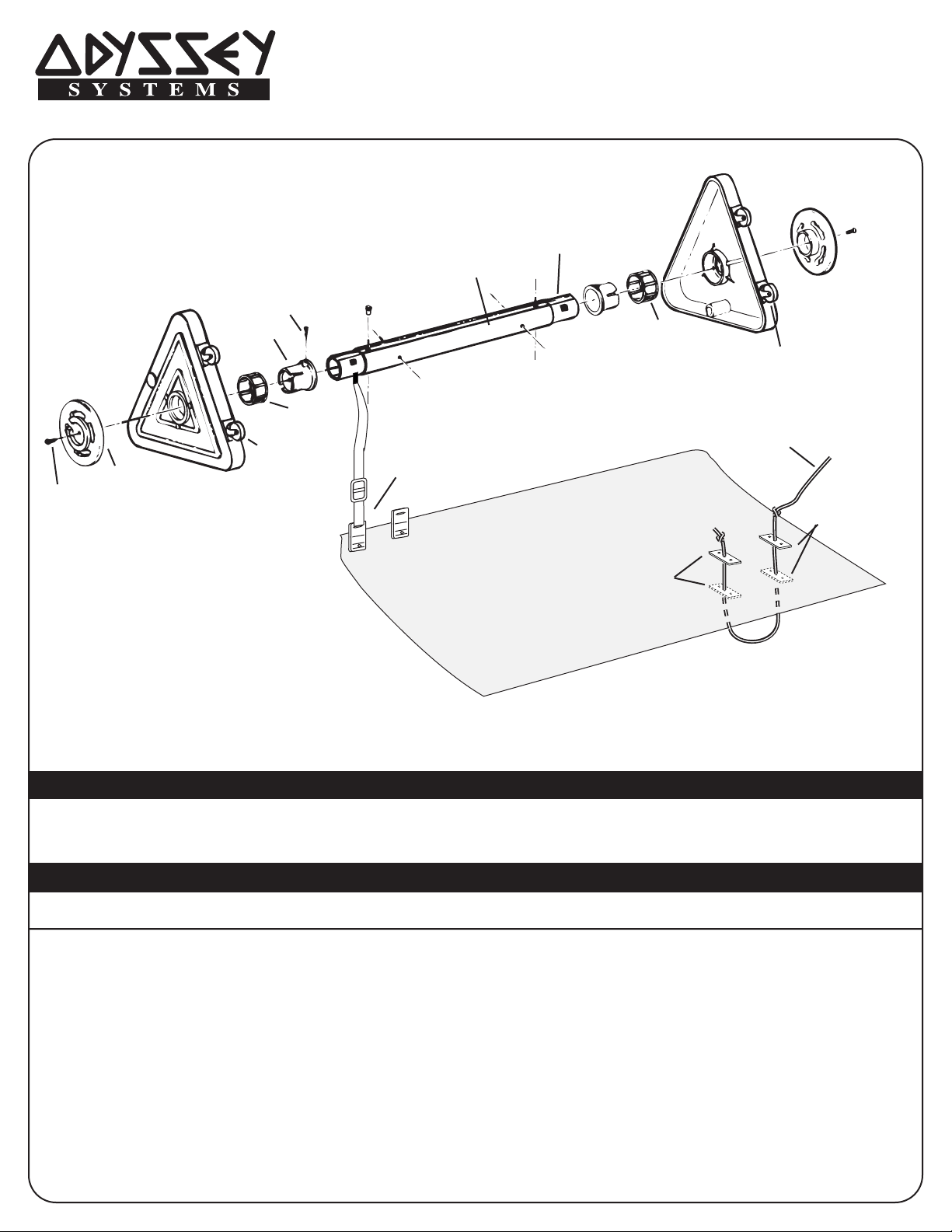

FREEDOM SERIES

(4.) 2 PLACES

(7.) 8 PLACES

(9.) 1 PLACE

(3.) 2 PLACES

(2.) 2 PLACES

(1.) 2 PLACES

(5.) 2 PLACES

(8.) 2 PLACES

SEE BLANKET

ATTACHMENT KIT

INSTALLATION

INSTRUCTIONS

(6.) 2 PLACES

(10.) CORD SET

(11.) 5 FT. CORD

(10.) CORD SET

TIE A DOUBLE KNOT

AT BOTH ENDS

(12.)

(13.)

(14.)

(15.)

M700 INST. 3/03

M700S2 COMMERCIAL REEL SYSTEM

Assembly and Operation Instructions

For Solar Covers up to 26’ x 75’ (Max 12 Mil Thickness)

Power Drill Hex Socket Wrench w/ 7/16” hex socket

Drill bits for cutting metal – 1/2” & 13/64” sizes Phillips Screwdriver

PARTS DESCRIPTION PART# QTY PARTS DESCRIPTION PART# QTY

1. 1-1/4” Flat Head Screw 430 2

2. Handwheel 517 2

3. Main Frame w/4” Casters 507 2

4. Bearing Race Assembly 620 2

5. End Cap 527 2

6. 3/4” Philips Head Screw 440 2

7. Neoprene Tube Insert 476 8

8. 10’ 6” Aluminium Tube (Inner) 200 2

TOOLS REQUIRED

PARTS LIST

9. 10 ’6” Aluminium Tube (Outer) 201 1

10. Cord Plate (Set) 610 2

11. 5’ Return Cord 840 1

12. Velcro Hook Piece 880 8

13. 6’ Blue Strap 890 8

14. Strap Buckle 800 8

15. Quick Clip Cover Plate 600 8

Page 2

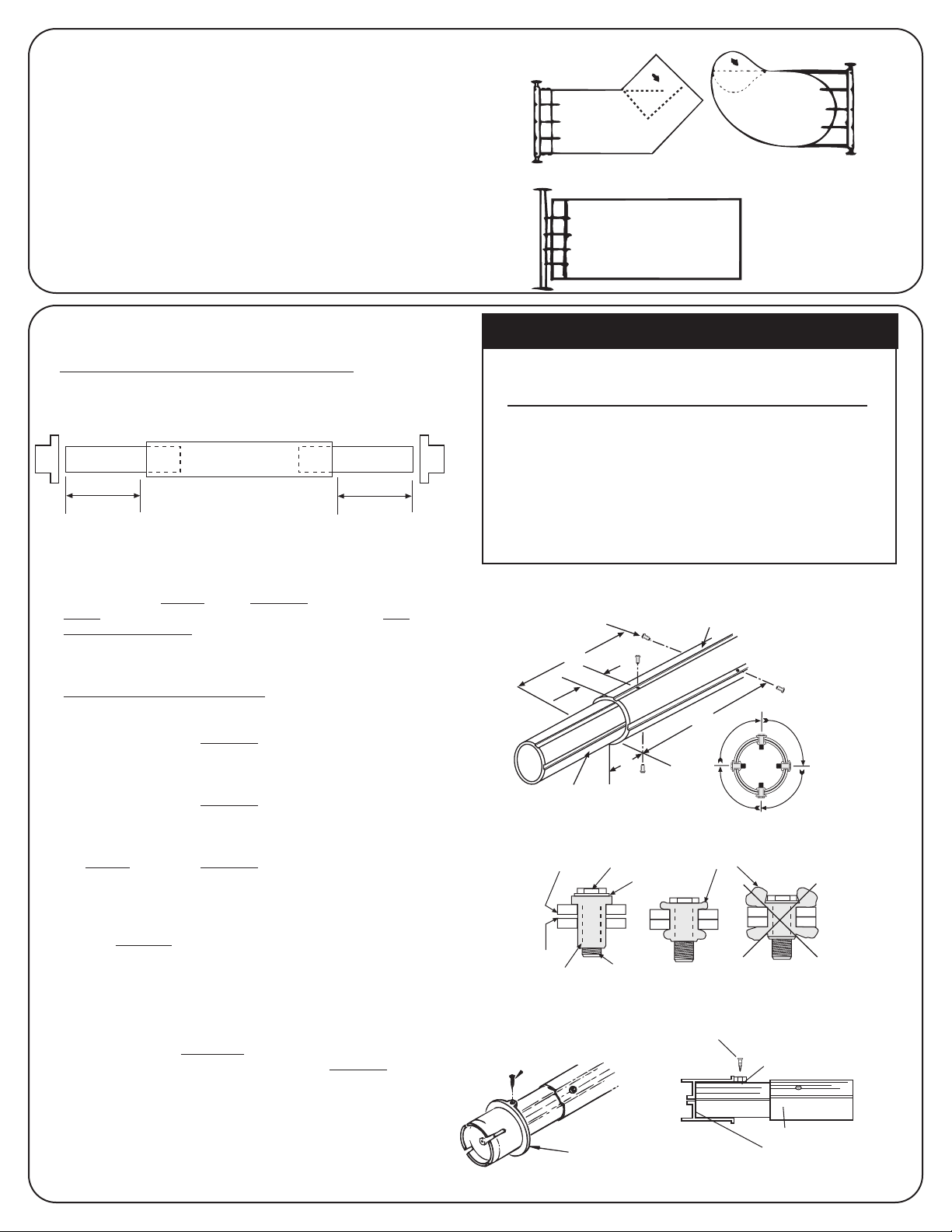

WASHER

HEX HEAD BOLT

OUTER TUBE

INNER

TUBE

NEOPRENE INSERT BODY

HEX HEAD BOLT

NEOPRENE WILL

MUSHROOM AS TIGHTENED

PERFECT

TIGHTNESS

TOO TIGHT

STEP 2

STEP 3

STEP 4

OUTER TUBE

SECTION 2

INNER TUBE

SECTION 1 OR 3

STEP 5

NEOPRENE

INSERT

3”

14”

STEP 4

STEP 2

STEP 3STEP 5

END

VIEW

90°

90°

90°

90°

3”

14”

DRILL 13/64” HOLE INT

TUBE (ONE PLACE)

TUBE NO. 1 OR N

FULLY INSERT TUBE

TO BACK WALL OF

END CAP

3/4” PHILLIPS HEAD SCREW

END CAP FULLY

SEATED ON TUBE

PHILLIPS HEAD

SCREW

SECTION-1

END

CAP

LENGTH-A

SECTION-3

END

CAP

SECTION-2

LENGTH-A

OVAL WITH EXTENSION

LAZY “L”

RETANGULAR

INITIAL PREPARATIONS

1. Prior to assembly, select the most suitable location for the reel,

normally 2 ft. from either end of the pool. However, on irregular pools,

a location closer to the center of the pool may be preferred and at the

pools maximum width. Other considerations are obstructions (diving

boards, hand rails, etc). When in doubt, consult your dealer or call

Odyssey for an evaluation of your reel placement.

2. BLANKET PREPARATION: In order for your solar blanket to roll up

neatly on the solor reel, allow the blanket to relax on the pool for a

day or two and let the heat of the sun iron out the folds and creases

of the blanket.

M700 INST. 3/03

ASSEMBLY INSTRUCTIONS

1. Remove all Tube Sections and place on a flat ground as in (FIG. 1).

SECTION 1 IS STORED INSIDE OF SECTION 2. Slide sections 1

and 3 out to the desired total tube length. (Usually pool width plus

two feet). Refer to Table #1 and (FIG. 1).

(FIG. 1)

NOTE: Step 2-9 must be followed or

tube sagging will occur

2. To attach the LEFT SIDE of section 1 & 2 tubes.

Using (FIG. 2), with a power drill and a sharp 1/2” bit, Drill a

hole 3” from the left end

center

of the groove cut in the tube. Drill through both sec-

tion 1 and section 2.

3. Place neoprene tube insert into the hole. Using a hex

socket wrench and a 7/16” socket, rotate hex head

two (2) complete turns and stop

4. Rotate tube sections 90° and drill a hole 14” from

the left end of the tube section 2

Repeat all instructions in #3 above.

of the section 2 tube and in the

(Refer to Step 2)

.

(Refer to Step 2)

.

(Refer to Step 3)

TABLE #1

POOL WIDTH TOTAL TUBE LENGTH A

FEET LENGTH FEET

FEET

20 22’6” 6

22 24’6” 7

24 26’6” 8

26 28’6” 9

NOTE: Under no circumstances should the system

be operated if Length A exceeds 9 ft.

Tubes may be cut in size in order to accomadate

smallerpool widths. It is recommended to cut an

equal amount off sections 1 & 3.

(FIG. 2)

5. Rotate tube sections 90° and drill a hole 3” from

the

left end

of the tube section 2.

(Refer to Step 4)

Repeat all instructions in #3 above.

6. Rotate tube sections 90° and drill a hole 14” from

7. Rotate tube sections 90°. Using a hex socket

the left end

Repeat all instructions in #3 above.

of the tube section 2.

wrench and a 7/16” socket, to tighten each hex

head an additional

8. Continue to rotate tubes and tighten hex heads until all are

tight and neoprene insert body mushrooms.

Do not overtighten. (SEE FIG. 3)

9. To attach the RIGHT SIDE of section 2 & 3 tubes.

Repeat instructions #2 thru #8

measurements from the RIGHT END of tube section 2

10.ATTACH END CAPS TO TUBE – Place end caps on end of

tube sections 1 and 3, rotate them to make certain that the

(Refer to Step 5)

two (2) complete turns.

above, but taking all hole

aluminum tube is making contact with the back wall of each

end cap (Refer to STEP 7).

the end cap as a guide, drill a 13/64” hole through each

tube and fasten with 3/4” inch PhillipsHead screw,

(SEE Step 8).

Using the pre-drilled hole in

.

STEP 7

(FIG. 3)

(FIG. 4)

STEP 8

Page 3

MAIN FRAME

BEARING

HAND WHEEL

1-1/4”

FLAT HEAD

SCREW

PLACE ON POOL DECK

POOL WIDTH

POOL LENGTH

(FIG. 1)

(FIG. 2)

PUNCH SMALL HOLE

WITH SHARP OBJECT

PUSH SHARP POST

AND SNAP INTO RECEIVER HOLE

3”

POSITION COVER

ON LAST RAISED BAR

ON INSIDE OF CLIP

(FIG. 3)

FOLD AND DISTRIBUTE

8 CLIPS

3”

3”

BUCKLE

CLIP

TO VELCRO

12”

VELRO

24”

INSERT

BUCKLE FROM

THIS END

CLIP POSITION

AND FOLD LINE

12”

(FIG.4)

(FIG. 5)

VELCRO

ON STRAP

VELCRO

ON POLE

IN A STRAIGHT LINE

DOWN THE POLE

(FIG. 6)

VELCRO

ON POLE

ASSEMBLY INSTRUCTIONS (Cont.)

11. Place the main frames in contact with the pool

deck (SEE FIG. 5), insert end caps through the center

opening. (SEE STEP 9).

12.Slide bearing race assembly over each end cap and

seat in main frame bushing. (center opening).

(SEE STEP. 10).

13.Align the keys in the handwheel collar with the cor

responding key ways in the end cap. Screw hand wheel securely in place, using 1-1/4” long flathead Phillips screw (Step 11).

ATTACHING THE COVER FOR IN-GROUND

POOLS

STEP 9

M700 INST. 3/03

(FIG. 5)

STEP 10

STEP 11

14. The reel system should be positioned at the end of

the pool, perpendicular to the center line of the pool

(SEE FIG. 1). The cover should be on the pool and

properly trimmed.

15. Starting at a point approximately 3” from one edge of

the end of the cover to which the reel will be

connected, attach a plastic cover clip (SEE FIG. 2) to

the cover. The sharp pointed post on the clip will pierce

the cover (or use a knife or other sharp tool for ease of

installation). Continue across the edge of the cover

attaching the remaining seven clips, evenly spaced.

The last clip should be positioned approximately 3”

from the opposite edge of the blanket.

(SEE FIG. 3)

16. Assembly of strap and buckle: With the ridged

crossbar of the buckle facing up, slide the buckle onto

the strap from the end opposite the Velcro end. Move

the buckle at least 24” up from the end of the strap.

(SEE FIG. 4) Feed the end of the strap through the slot

on the plastic clip then thread the strap end back

through the buckle as indicated by the dotted lines in

the diagram. Repeat the process at each clip position.

(SEE FIG. 5)

17. Position the Velcro end of the strap as straight as possible over the tube of the reel system. Place a Velcro

tab on the tube at the Velcro strap end by removing the

protective backing. The tube must be dry and clean

where the Velcro tab is being placed.(SEE FIG. 6)

Attach the Velcro end of the strap to the Velcro tab.

Repeat this process in a straight line along the tube for

each of the seven remaining straps. Using the buckles,

adjust each strap so that each has equal tension on

the cover. This is necessary for proper roll-up

alignment.The extra length should wrap around the

tube to facilitate pulling the blanket off the pool

and on to the tube. The Velcro tabs alone are not

strong enough to pull the blanket up off the pool.

Page 4

18. For ease of re-covering your pool after use, install the return

TOWARD POOL

POOL

HOLD

TOWARD POOL

OPERATING

POSITION

cord provided at the opposite end of the pool cover using the

white cord and two sets of male/female cord plates. Locate

the plates about 3” apart and at least 6” from the edge of the

cover (SEE FIG. 7) . To install plates, use the plate with three

holes as a guide to punch three holes through the cover. Snap

the posts on the male plate through the two holes on the female

plate with the cover sandwiched between the two plates.

(SEE FIG. 8) Thread the return cord through the top center hole of

plate #1 and plate #2 as shown in the diagram and then tie a

double knot at both ends. (SEE FIG. 7)

OPERATING INSTRUCTIONS

19. Roll the reel system so that it straddles the pool, and is 2 ft from

end of pool as in (SEE FIG. 11). More distance may be required for

irregular pools. If your pool IS NOT rectangular shape, merely fold

the cover in the irregular areas back on itself so that the entire pool

cover can pass between the two end main frames of the system.

20. Standing behind the tube, place foot or hold base of triangular

frame and pull the top of the frame toward you to rotate system into

operating position, (SEE FIG. 9).

21. Lock casters on both frames. Rotate handwheel slowly. The

straps will move the cover away from possible damage on the

coping and fold back into itself. Continued rotation of the hand

wheel will transport the cover underneath the tube and then up,

over and onto the tube. In the unlikely event that the main frame

“creeps” during this operation, use a free hand to hold main

Frame until the entire cover is removed from pool. Attempt to

keep seams straight and avoid misalignment. If system has

retrieved the cover with ease, you are operating the system

correctly. It is suggested that you mark the position of the main

frames during operation on the pool decking for future use of the

system. To remove the system from the pool area, unlock caster

brakes. MANUFACTURER IS NOT RESPONSIBLE FOR

DAMAGE OR ACCIDENT RESULTING FROM IMPROPER OR

UNSAFE STORAGE OR MOVEMENT

PLACING THE COVER ON THE POOL

22. Roll the reel system to a straddling position 2’ from the

end of the pool, onto the deck marking suggested in

(SEE FIG. 11), lock casters down prior to unrolling over.

23. Hold white return cord and walk down the

length of the pool, allowing the system to “free wheel”

(SEE FIG. 10) the cover back onto the pool surface.

Replace folded-back cover into irregularly shaped areas.

24. Your cover is now installed and operational. If you wish to

remove the reel system from the pool while the cover is

on the pool, detach the straps using the lift-off velcro tabs,

and roll empty system to storage area (SEE FIG. 11).

SOME HELPFUL HINTS

1. Make sure the cover is not dragging against the side of the pool

coping.

2. If tube is sagging: refer to assembly instruction on drilling tubing

and tighten neoprene inserts.

3. If tubes discolors, they can be restored using Flitz metal polish

available at hardware/marine stores.

4. Place a white protective cover over blanket and secure to protect

blanket from the sun when rolled up.

5. Do not use lubricants on any plastic parts.

6. Remove handwheels at the beginning of each season, or every 12

months. Clean yoke bushing, bearing race, and end cap with

warm soapy water. Rinse, dry and reassemble.

7. Always store the reel with an eye for safety.

M700 INST. 3/03

(FIG. 8)

SNAP TOGETHER

PUNCH 3 HOLES WITH

SHARP INSTRUMENT

(FIG. 7)

PLATE #1

TIE DOUBLE KNOT

AT BOTH ENDS OF CORD

3”

PLATE #2

(FIG. 9)

(FIG. 10)

STRAP

CLIP

ODYSSEY warrants the reel system to be free of

workmanship/material defects for a period of three

(3) years from the date of purchase. Any claims must

be supported by invoice/proof of purchase.

EXCLUDED FROM THIS WARRANTYARE ALL

CONSUMABLES: straps, cord, velcro, plastic plates

and clips.

ODYSSEY WILL not be liable for any incidental or

consequential damages resulting from any defects in

workmanship or material, nor for personal injury

resulting from improper placement of reel system

when not in use.

220 South Ola Vista, Suite C, San Clemente, CA 92672

TURN REEL

THIS WAY

TUBE

POOL COVER

LIMITED WARRANTY

ODYSSEY SYSTEMS

(949) 498-9454 • Fax (949) 361-0608

www.odysseysystems.com

© ODYSSEY SYSTEMS 2003

(FIG. 11)

POOL

COVER

STRAPS

2 FT

POOL END

6”

Loading...

Loading...