Odyssey CT80-250, CT80.3F9A1, CT120.3G9A, CT215.1H9A, CT80.3P9A1 Installation And Operation Instructions Manual

...Page 1

Odyssey

Danger Sign: Indicates a hazardous situation which, if not avoided, will result in

Warning Sign: Indicates a hazardous situation which, if not avoided, could result

bol: Indicates a hazardous situation which, if

Caution Sign without Safety Alert Symbol: Indicates a hazardous situation

es a hazardous situation which, if not avoided, could result

H

Model Numbers: CT80-250

Version Date: 2013-03-15

NEW – OUTDOOR SENSOR

Meets Sept. 2012 requirements for

“Automatic Means”

INSTALLATION AND OPERATION INSTRUCTIONS

ODYSSEY OIL BOILER

Venting Applications: Natural Draft or Direct Vent (Balanced Flue)

TABLE OF CONTENTS

1.0 INTRODUCTION...............................................................................................................3

2.0 SPECIFICATIONS..............................................................................................................6

3.0 BOILER LOCATION..........................................................................................................8

4.0 BOILER ASSEMBLY.........................................................................................................9

5.0 GENERAL VENTING......................................................................................................14

6.0 NATURAL DRAFT APPLICATIONS.............................................................................15

7.0 DIRECT VENT APPLICATIONS....................................................................................19

8.0 BOILER PIPING...............................................................................................................26

9.0 FIELD WIRING................................................................................................................28

10.0 INSTALLATION CHECKLIST .......................................................................................34

11.0 ANNUAL MAINTENANCE AND INSPECTION ..........................................................36

12.0 PARTS LIST .....................................................................................................................39

13.0 WARRANTY....................................................................................................................43

Odyssey CT80-250

HAZARD SYMBOLS AND DEFINITIONS

serious injury or death.

in serious injury or death.

Caution Sign plus Safety Alert Sym

not avoided, could result in minor or moderate injury.

which, if not avoided, could result in property damage.

Notice Sign: Indicat

in property damage.

This Boiler must be installed by a licensed and trained Heating Technician or

the Warranty is Void. Failure to properly install this unit may result in

property damage, serious injury to occupants, or possibly death.

NTI # 84944

Page 2

Odyssey

Read Before Proceeding

│

Installation and Operation Instructions CT80-250

If you do not follow these instructions exactly, a fire may result causing property

damage, serious injury or death.

FOR YOUR SAFETY, READ BEFORE OPERATING_

BEFORE OPERATING:

A. Do not start burner unless the smoke hood, clean out door, HydroStat 3250, flue breeching, and burner

door (if applicable) are secured in place and the boiler is filled with water.

B. Do not attempt to starter burner when excess oil has accumulated in combustion chamber, when unit is

full of vapour, or when combustion chamber is very hot.

C. Do not use gasoline, crankcase drainings, or any oil containing gasoline.

D. Never burn garbage or paper in the unit and never leave combustible material around it.

E. Always keep the oil supply valve shut off if the burner is shut down for an extended period of time.

F. Do not tamper with the unit or controls - call your service personnel for service and maintenance.

G. Do not use this boiler if any part has been under water. Immediately call a qualified service technician to

inspect the

under water.

boiler and to replace any part of the

OPERATING INSTRUCTIONS_

control system and any oil control which has been

1. STOP! Read the safety information above very carefully.

2. Initial start-up and start-ups after periods of extended/seasonal shutdown must be performed by a

qualified service technician.

3. Check the boiler area for proper clearances.

4. Turn the thermostat(s) up.

5. Turn the emergency power isolation switch on.

6. If ignition does not occur, follow the instructions “To Turn Off Oil Boiler” and call a qualified service

technician.

TO TURN OFF OIL BOILER_

1. STOP! Read the safety information above very carefully.

2. Turn off emergency power isolation switch. Should be mounted on the wall near entrance to boiler room.

Void Warranty - This boiler must have water in it whenever the burner is on or it will

damage the unit and void the warranty. Failure to follow these instructions may result in

serious injury or death.

Fuel Oil - Use only No. 2 fuel oil for boiler models listed in this manual. Failure to follow

these instructions may result in severe personal injury, property damage, or death.

Low Water Cut Off (LWCO) - To take advantage of the HydroStat’s LWCO feature, the

Odyssey is equipped with a special immersion well call the Electro-well™. Failure to use

the Electro-well™ provided with the boiler will over-ride the LWCO feature and allow the boiler to operate

during low water conditions which may result in over heating, fire, serious injury, or death.

Oil Supply Valve - Always keep the oil supply valve shut off if the burner is shut down

for an extended period of time.

2

Page 3

CT80-250 Introduction - Installation & Operation Instructions

1.0 INTRODUCTION

│

Odyssey

General Installation Requirements

The installation of your NTI Odyssey oil boiler shall be in accordance with these instructions and the regulations

of the authorities having jurisdiction and must comply with the following codes and standards:

United States

State and local plumbing, heating, and electrical codes

NFPA 70 National Electric Code

NFPA 31 Installation Code for Oil Burning Equipment

Standard ANSI/ASME CSD-1, Controls and Safety Devices for Automatically Fired Boilers (if applicable)

Canada

Provincial and local plumbing, heating, and electrical codes

CSA C22.1 Canadian Electrical Code Part One

CSA B139 Installation Code for Oil Burning Equipment

The Odyssey is a knock-down boiler constructed of cast iron. The venting application needs to be decided in

advance, either Natural Draft or Direct Vent, prior to ordering the boiler as burner packages will vary depending

on the venting application. The boiler package comes in three sections and requires field assembly. Check your

boiler package when it arrives and ensure it includes the following:

1. Boiler

2. Jacket

3. Burner Kit

This document pertains to the correct installation and operation of NTI Odyssey oil boilers for Natural Draft and

Direct Vent models. The instructions detailed in this document supersede any and all previous instructions

provided by NTI, written or otherwise. The warranty is included in the Installation and Operation manual. Each

unit comes complete with the following documentation:

1. Installation and Operating Instructions

2. Users Manual

Read and understand this entire document prior to proceeding with the installation of the

Odyssey. Failure to follow the instructions outlined in this document will result in

property damage, serious injury or death.

User Responsibilities

This boiler must be installed and serviced by a qualified installer or service technician. This boiler must be

serviced and inspected annually. As the User/Owner of this equipment, you are responsible for ensuring the

maintenance is performed at the required intervals. See “Users Manual”.

Failure to have the boiler properly serviced and inspected on a regular basis by a qualified

service technician may result in property damage, serious injury or death.

Installer Responsibilities

As the installing technician it is your responsibility to ensure the installation is performed in accordance with this

instruction manual as well as any applicable local or National installation codes. It is also your responsibility to

inform the User/Owner of their obligation with respect to the above description under “User Responsibilities”.

Failure to follow this warning could result in fire, serious injury, or death.

3

Page 4

Odyssey

Natural Draft Applications

│

Installation and Operation Instructions - Introduction CT80-250

Natural Draft Applications - All Odyssey models are certified as Natural Draft boilers

which require a “Chimney System”. The exhaust gases must be vented directly to the

chimney. Failure to follow these instructions will result in serious injury or death.

Blocked Vent Switch - All Natural Draft Odyssey boilers require a Blocked Vent Switch

which is factory supplied and packaged with the burner kit and is mandatory in Canada.

The Block Vent Switch must be field installed as per the instructions in this manual and the manufacturers

instructions included with the switch. Failure to follow the specified instructions may result in fire, property

damage, personal injury, or death.

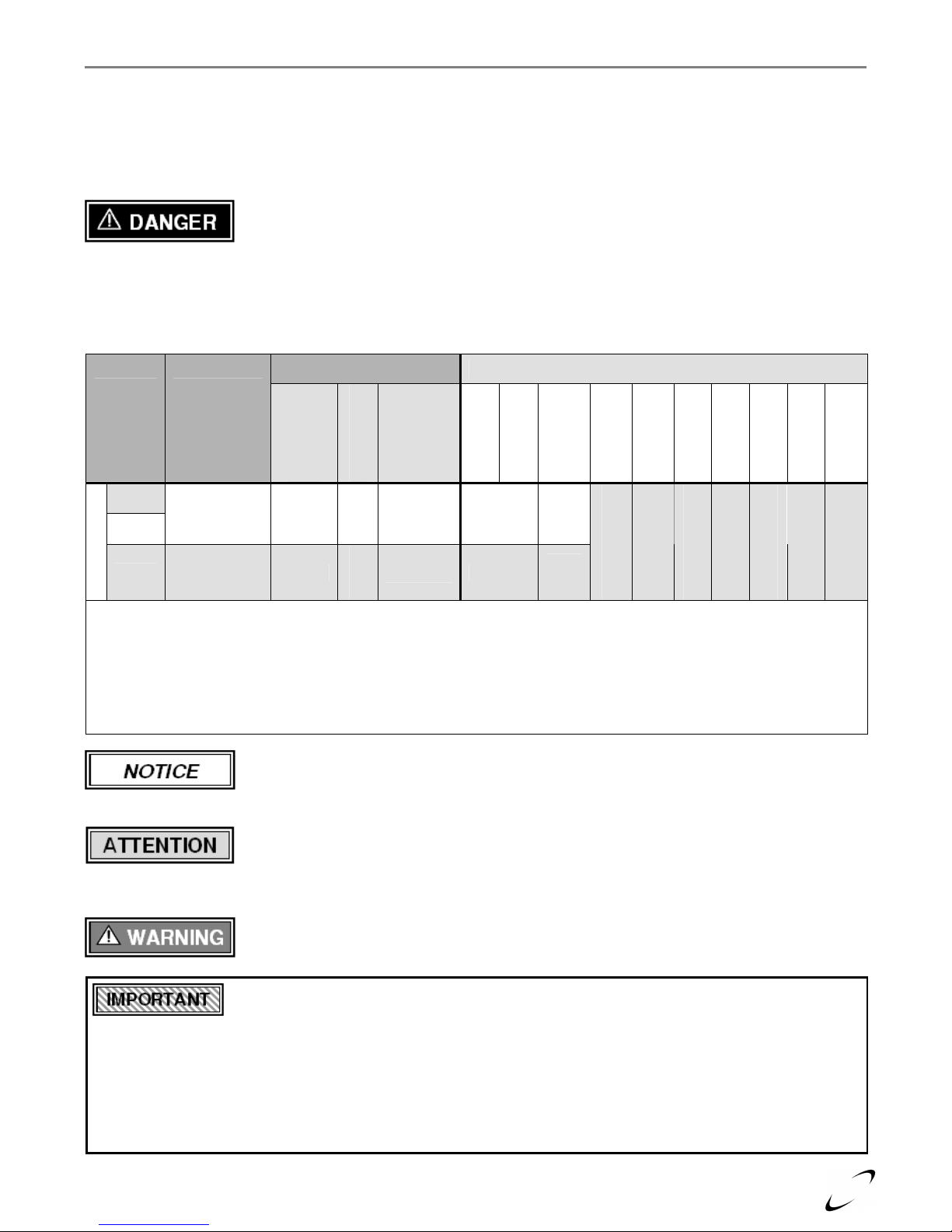

Table 1-1 Odyssey Boiler Packages (Natural Draft)

MODEL

4

CT80

4

CT90

4

CT100

BOILER PACKAGE

BOILER

PART

NUMBER

Boiler

CT80.3F9A1 CT80

Burner Kit

Jacket

Natural

Draft 1

Only

Burner

82002

F3.CT

10618

Burner Kit Contents (Natural Draft)

2

Blast Tube

Nozzle

HydroStat

3250

Hydrolevel

0.65

o

60

84024

W

Tridicator

Electro-Well

OD Sensor

Relief Valve

Supply Tee

Block Vent

CT120

84654

0.85

60oB

1.5

60o W

0.75

70oB

84787

84788

81342

83604

13701

84829

CT150

CT180

Riello Burner

CT215

CT230

CT250

CT80

CT90

CT100

CT120.3G9A

1

4

CT215.1H9A1 CT215

4

4

CT80.3P9A1 CT80

4

CT120

F5.CT

3

10630

82003

F10.CT

82004

NYC601CT 81031

10632

82002

CT120

CT150

CT180

Becket Burner

CT215

CT230

CT120.3P9A1

4

CT215.3P9A1 CT215

CT120

CT250

Notes:

1

Boiler manual packaged with the Burner Kit.

2

Nozzle size included in Burner Kit. See below, “Attention: Nozzle Sizes”.

3

Burner and blast tube comes assembled c/w nozzle specified in this table. Nozzle may need to be changed depending on boiler output.

4

Models CT80-100 and CT180 are no longer offered as they do not meet new minimum efficiency regulations.

NYC602C

T

82003

NYC602C

T

82004

81032

81032

1.10

60oB

1.10

60oB

Nozzle Sizes - The nozzle sent with each respective boiler burner kit is for the minimum

firing rate specified for that burner. To obtain a different firing rate, replace the factory

supplied nozzle with the appropriate nozzle that meets the desired output. Refer to Tables 2-1 to 2-2 in Section

2.0 for nozzle specifications and performance ratings for Natural Draft boilers.

Manufacturer’s Instructions - For complete instructions on installation and control

operations, refer to the manufacturer’s instructions included with the Fuel Smart

HydroStat 3250, Burner Package, and Blocked Vent Switch.

Switch

82905

4

Page 5

CT10

0

CT80-250 Introduction - Installation & Operation Instructions

│

Odyssey

Direct Vent Applications

There are four Odyssey models, CT90-120, certified for installation as a Direct Vent boiler. This balanced flue

system requires a special venting system in order to pressurize and essentially equalize the inlet and outlet

pressure to ensure normal operation. Refer to section “General Venting” and “Specifications” for more details on

Direct Vent applications and termination kits.

Balanced Flue Applications - Models CT90-120 are also certified as Direct Vent boilers

and must be ordered as such. Balance flue systems must use the NTI approved venting

system. Note that the Direct Vent Terminal and Insulated Flex Pipe are sold separately (see Table 7-2 Direct

Vent Kit Components for more details). This “Special Venting System” is designed for pressurized venting with

NTI Direct Vent boilers. The exhaust gases must be piped directly to the outdoors using the vent materials and

rules outlined in these instructions. Failure to follow these instructions will result in serious injury or death.

Table 1-2 Odyssey Boiler Packages (Direct Vent)

BOILER PACKAGE

Burner Kit Contents (Direct Vent)

Jacket

82002

82003

Burner

Kit

Direct

Vent

BF5.CT

BF5.CT

2

1

3

3

Burner

Blast Tube

Nozzle

HydroStat

3250

Hydrolevel

Electro-Well

Tridicator

OD Sensor

Relief Valve

81122

81122

0.85

60oB

0.85

60oB

84787

84788

81342

83604

13701

4

Supply Tee

Direct Vent

84829

Table 7-2

BOILER

MODEL

CT90

PART

NUMBER

6

Only

Boiler

CT90.3T9A4 CT80

6

CT120

Riello Burner

Notes:

1

Boiler manual packaged with the Burner Kit.

2

Nozzle size included in the Burner Kit. See below, “Attention: Nozzle Sizes”.

3

Burner and blast tube comes assembled c/w nozzle specified in this table. Nozzle may need to be changed depending on boiler output.

4

Direct Vent Terminal not included in Kit. Refer to Table 7-2 for a list of components that must be ordered separately.

5

Riello BF5 burners are single line gravity feed. See burner manufacturers’ instructions for more details.

6

Models CT80-100 are no longer offered as they do not meet new minimum efficiency regulations.

CT120.3T9A4 CT120

Manufacturer’s Instructions - For complete instructions on installation and control

operations, refer to the manufacturer’s instructions included with the Fuel Smart

HydroStat 3250, Burner Package, and Direct Vent Terminal.

Nozzle Sizes - The nozzle sent with each respective boiler burner kit is for the minimum

firing rate specified for that burner. To obtain a different firing rate, replace the factory

supplied nozzle with the appropriate nozzle that meets the desired output. Refer to Table 2-3 in Section 2.0 for

nozzle specifications and performance ratings for Direct Vent boilers.

Intakes/Vents - Failure to keep the Vent and Combustion Air Intake clear of ice, snow,

and other debris may result in property damage, serious injury, or death.

which is provided primarily to permit the use of an external energy management system that serves the same function.

THIS OVERRIDE MUST NOT BE USED UNLESS AT LEAST ONE OF THE FOLLOWING CONDITIONS IS TRUE :

An external energy management system is installed that reduces the boiler water temperature as the heating load

decreases.

This boiler is not used for any space heating.

This boiler is part of a modular or multiple boiler system having a total input of 300,000 BTU/hr or greater.

This boiler is equipped with a tankless coil.

Energy Saving Feature - This boiler is equipped with a feature that saves energy by reducing the

boiler water temperature as the heating load decreases. This feature is equipped with an override

Kit

5

Page 6

Odyssey

2.0 SPECIFICATIONS

Natural Draft Application

│

Installation and Operation Instructions - Specifications CT80-250

Draft Settings (Natural Draft) - The Odyssey is designed to operate with -.03” w.c. draft

in the flue breaching. For proper operation, there must be enough natural or mechanical

draft. Due to the design of the Odyssey, it may operate at a positive over fire pressure up to +.20 at -.03 draft. Due

to installation and equipment variations, recommended air settings are a guideline and will require alteration. See

Tables 2-1 and 2-2.

Insertion Depth (Natural Draft) - See General Notes section in Tables 2-1 and 2-2.

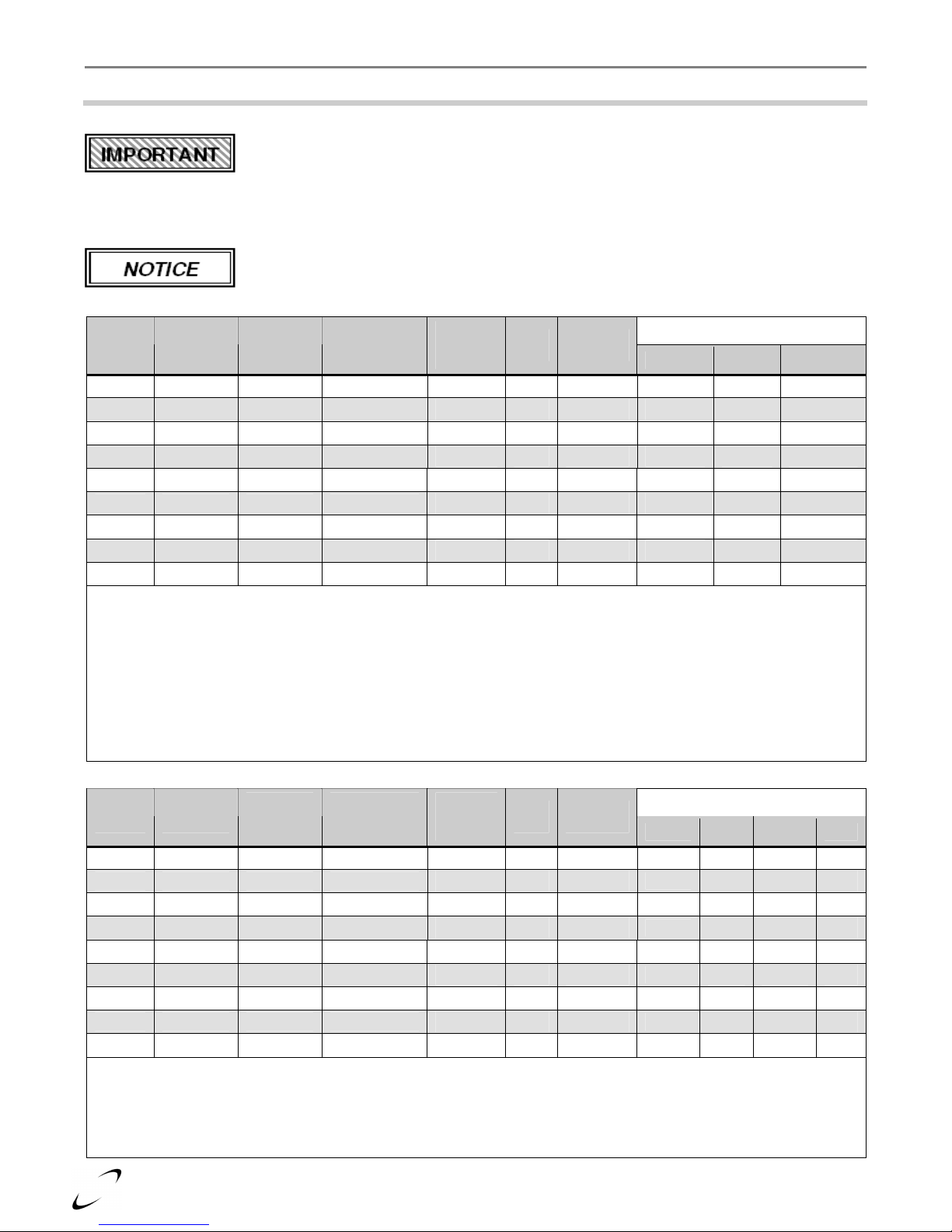

Table 2-1 Riello Burners with Odyssey Boilers (Natural Draft)

Boiler

Model

CT80

CT90

CT100

8

8

Input

GPH (US)

0.65 77 67

0.75 88 77

8

0.85 99 86

CT120 1.00 121 105

CT150 1.25 149 130

8

CT180

1.50 176 153

CT215 1.75 212 184

CT230 1.85 223 194

CT250 2.00 240 209

General Notes:

1

Output is “Heating capacity” for models CT80-250.

2

Models CT80-250 use Riello 40 series burners.

3

Energy ratings for C85-250 have been confirmed by AHRI.

4

Models C80-100 - F3 burners have an insertion depth of 2.375”.

5

Models C120-180 - F5 burners come assembled with an insertion depth of 2.375”.

6

Models C215-250 - F10 burners have an insertion depth of 2.75”.

7

F10 burner heads - If head carbons on models CT215-250, reduce turbulator setting and increase air a little.

8

Models CT80-100 and CT180 are no longer offered as they do not meet new minimum efficiency regulations.

Table 2-2 Beckett Burners with Odyssey Boilers (Natural Draft)

Boiler

Model

CT80

CT90

CT100

4

4

Input

GPH (US)

0.65 77 67

0.75 88 77

4

0.85 99 86

CT120 1.00 121 105

CT150 1.25 149 130

4

CT180

1.50 176 153

CT215 1.75 212 184

CT230 1.85 223 194

CT250 2.00 240 209

General Notes:

1

Models CT80-250 use Beckett AFG50 series burners.

2

Energy ratings for C85-250 have been confirmed by AHRI.

3

Models CT80-250 - MDL1 (NYC601) burners and MDV1 (NYC602) have an insertion depth of 3.75.

4

Models CT80-100 and CT180 are no longer offered as they do not meet new minimum efficiency regulations.

Heating

Capacity

MBH

Heating

Capacity

MBH

Net I=B=R

Rating Water

MBH

Net I=B=R

Rating Water

MBH

AFUE

Efficiency

%

83.6% 117

Pump

PSIG

Delevan

Nozzle

0.60 60oW

83.0% 133 0.65 60oW

82.4% 128 0.75 60oW

85.1% 138 0.85 60oW

84.0% 156 1.00 60oW

82.8% 144 1.25 60oW

85.8% 136 1.50 60oW

85.5% 152 1.50 60oW

85.0% 178 1.50 60oW

AFUE

Efficiency

%

83.6% 117

83.0% 133 0.65 60oW

82.4% 128 0.75 60oW

85.1% 138 0.85 60oW

84.0% 156 1.00 60oW

82.8% 144 1.25 60oW

85.8% 136 1.50 60oW

85.5% 152 1.50 60oW

85.0% 178 1.50 60oW

Pump

PSIG

Delevan

Nozzle

0.60 60oW

Recommended Burner Settings

Burner Air Turbulator

F3 5 0

F3 7 0

F3 7 2

F5 3 2

F5 5 2

F5 9 3.5

F10

F10

3.5

7

2

2

F10 6 3

Recommended Burner Settings

Burner

MBL1

MBL1

MBL1

MDV1

MDV1

MDV1

MDV1

MDV1

MDV1

Head Shutter

- 5 0.5

- 6 1

- 10 0

0 5 1

1 6 2

2 8 3

3 10 6

4 10 5

4 8 7

Band

6

Page 7

CT80-250 Specifications - Installation & Operation Instructions

Direct Vent Application

│

Odyssey

Draft Settings (Direct Vent) - Due to the design of the balanced flue system, the Odyssey

will operate at a positive draft pressure and a positive over fire pressure at all times. It is

designed to operate with a maximum stack draft of 0.25” w.c. and a maximum over fire draft of 0.33” w.c. when

little or no wind is present. In extreme wind conditions, the maximum stack draft is 0.35” w.c. and the maximum

over fire draft is 0.45” w.c. Due to installation and equipment variations, recommended air settings are a guideline

and will require alteration. See Table 2-3.

Insertion Depth (Direct Vent) - See General Notes section in Table 2-3.

Table 2-3 Riello Burners with Odyssey Boilers (Direct Vent)

Boiler

Model

CT90

CT100

4

4

Input

GPH (US)

0.75 88 77

0.85 99 86

CT120 1.00 121 105

General Notes:

1

Models CT90-120 use Riello 40 series burners.

2

Energy ratings for CT90-120 have been confirmed by AHRI.

3

Models CT90-120 - BF5 burners come assembled with an insertion depth of 2.375”.

4

Models CT80-100 are no longer offered as they do not meet new minimum efficiency regulations.

Heating

Capacity

MBH

Net I=B=R

Rating Water

MBH

AFUE

Efficiency

%

83.0% 133

82.4% 128

85.1% 138

Pump

PSIG

Delevan

Nozzle

0.65 60oW

0.75 60oW

0.85 60oW

Recommended Burner Settings

Model Air Turbulator

BF5 4

BF5

BF5

5

6

0

0

1.5

Boiler Characteristics

Table 2-4 Odyssey Boiler Characteristics

Description

CT80-100 CT120-180 C215-250

Boiler Shell Weight [lbs] 260 390 500

Fuel Type No. 2 Oil

Water Connections – NPT [in.] 1.25 1.25 1.25

Dimensions H x W x D [in.]

Approx. Boiler Weight with Water [lbs]

Approx. Boiler Water Content [usg]

Stack Size

Electrical Rating

30 x 17.5 x 15.5 30 x 25.5 x 15.5 30 x 33.5 x 15.5

290 435 560

3.6 5.4 7.3

5 5 5

120V / 1Ph / 60Hz / < 12A

Boiler Shell

7

Page 8

1, 2

Odyssey

3.0 BOILER LOCATION

│

Installation and Operation Instructions - Boiler Location CT80-250

In all cases, the Odyssey must be installed indoors in a dry location where the ambient temperature must be

maintained above freezing and below 100°F [38°C]. All boiler components must be protected from dripping,

spraying water, or rain during operation and servicing. Consider the proximity to the following when

determining the best boiler location.

System Water Piping

Oil Supply

Electrical Power

Combustion Air / Ventilation Air

Chimney

Components - Water or flood damaged components must be replaced immediately with

new components (see parts list). Failure to do so may result in fire, serious injury, or death.

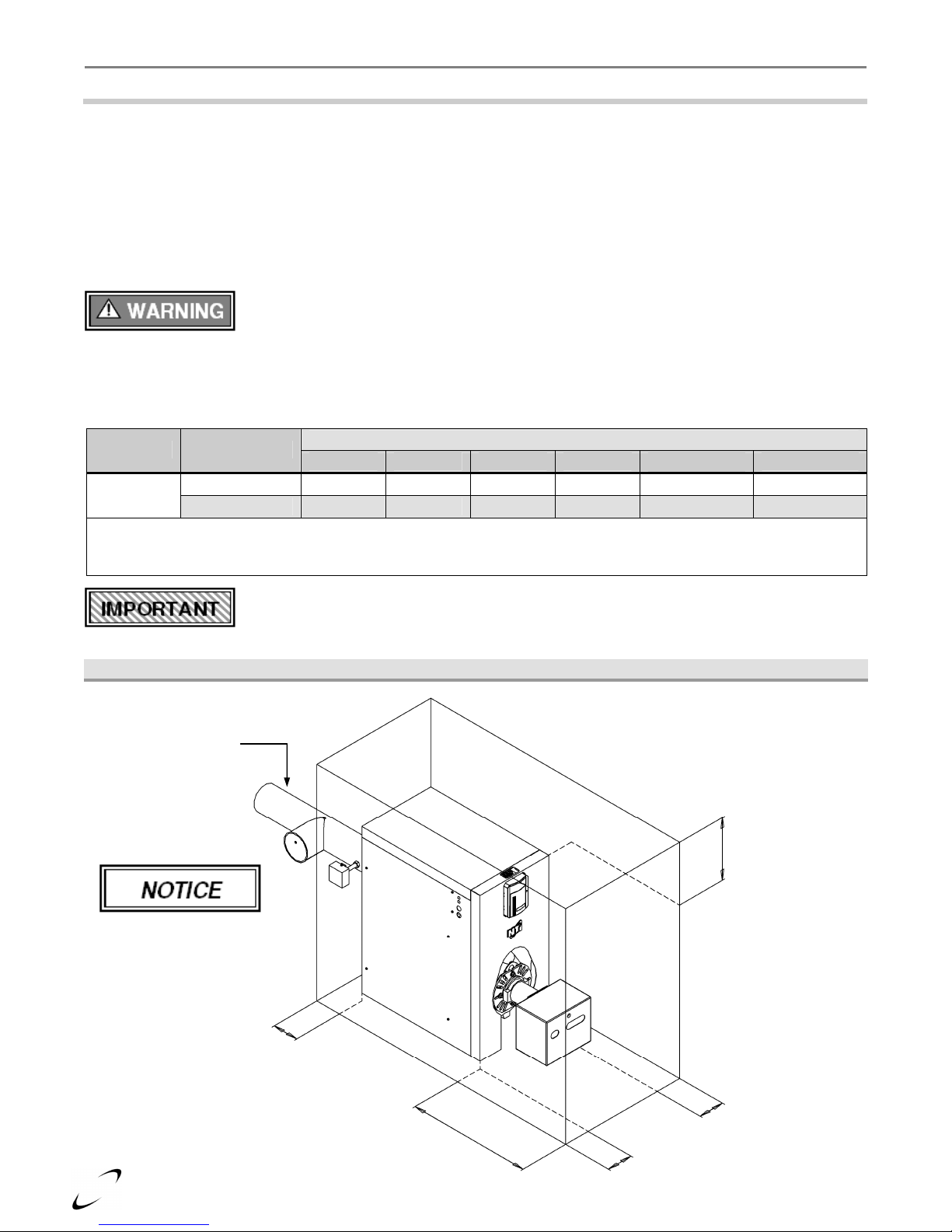

Clearances - Clearances to combustibles represent the minimum clearances required for safety and service.

Recommended clearances are for ease of piping installation, annual maintenance, and service access. Refer to

Table 3-1 and Figure 3-1.

Table 3-1 Minimum Clearances for Installation and Service

Model Clearances

CT80-250

Notes:

1

Minimum clearances from flue pipe to combustibles is 9” for single-wall pipe; 6” for double-wall pipe (Type-L).

2

Flue pipe clearances take precedence over all other clearances.

To Combustibles 24 [610] 5 [124] 12 [305] 5 [124] 9 [228] Combustible

Recommended 36 [915] 24 [610] 24 [610] 24 [610] 9 [228] Combustible

Front Rear Top Sides

Dimensions - inches [mm]

Flue Pipe

Floor

Boiler Location - Even if all installation codes are met, good judgment and common

sense must also be used when selecting a boiler location. Refer to minimum clearances in

Table 3-1 and vent clearances for chimney or direct vent applications.

Figure 3-1 Minimum Clearances to Combustibles

Flue Pipe

9” minimum

Flue pipe clearances

take precedence over

all clearances, refer to

Table 3-1.

Rear 5”

8

Top 12”

Right Side 5”

Front 24”

Left Side 5”

Page 9

nuts and washers at

the rear of the boiler

C 85-340 Boiler Assembly - Installation & Operation Instructions

4.0 BOILER ASSEMBLY

│

Odyssey

The installation of the boiler shall be in accordance with the authorities having jurisdiction and must comply with

Standard CSA B139 (Canada) or NFPA 31 (USA).

Fiberglass Materials - Before installing the insulation, read “Handling Instructions” in

Section 11.0 and the protective measures recommended when handling fiberglass.

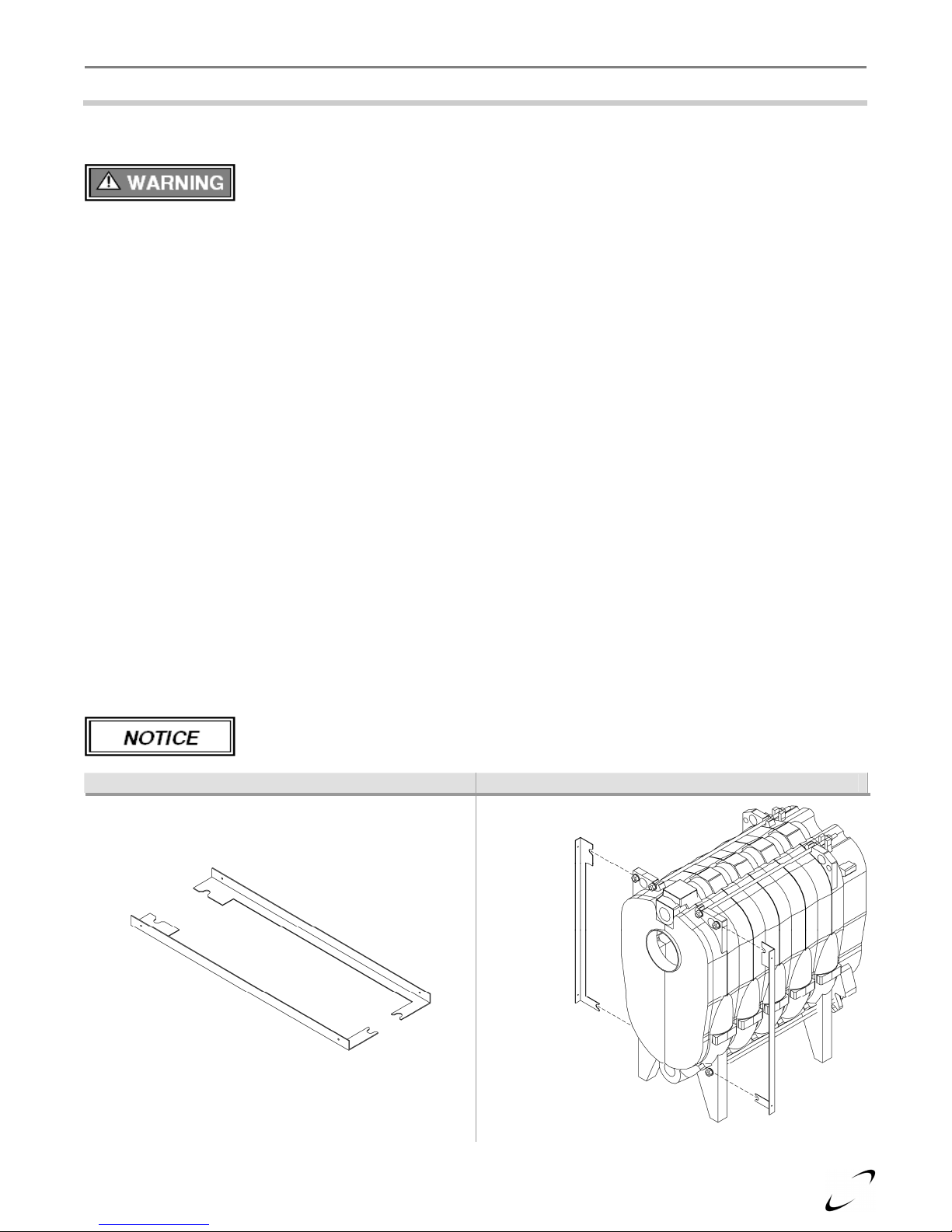

Assembly Procedure

The boiler assembly procedure is to be completed in sequence and in conjunction with the illustrated assembly

diagrams, Figures 4-1 through 4-12.

1. Do not fully tighten screws until jacket assembly is complete.

2. Level the boiler before commencing jacket installation.

3. Install rear brackets on the boiler, secure by tightening nuts (Figures 4-1 to 4-3).

4. Install front brackets on the boiler, secure by tightening nuts (Figures 4-4 to 4-6).

5. Install fiberglass insulation on the boiler by wrapping it around the heat exchanger. Secure with factory

supplied twine (Figure 4-7).

6. Remove all protective plastic film on the jacket panels before installing.

7. Attach side panels to front and back brackets (Figure 4-8).

8. Install control panel between side panels, secure with screws provided (Figure 4-9).

9. Mount HydroStat 3250 by sliding it down over the tabs on the control panel. Secure in place with hold down

bracket as shown (Figure 4-10).

10. Mount bottom back panel to boiler (Figure 4-10); Recommend installing top back panel after flue breeching

connected, sealed, and supported. (See also Figure 6-1 Flue Breeching).

11. Fully tighten all jacket screws to secure panels in place.

12.

Insert sensor fully into the Electro-well or boiler overheating may occur (Figure 4-11). See “Danger”

warning on page 11.

13. Feed the green wire, connected to the boiler ground screw, through the knockout in the back of the HydroStat.

Connect the other end of the wire to the HydroStat ground screw inside the control (green screw).

14. Installation of burner and completion of wiring must be done with front cover removed.

15. Install top cover. Align the top panel clips into the slots in the top of the side panels and slide cover forward

to lock clips in place (Figure 4-12).

HydroStat 3250 Instructions - For complete installation and operation instructions, refer

to the manufacturer’s instructions included with the Fuel Smart HydroStat 3250.

Figure 4-1 Rear Brackets Figure 4-2 Mount Rear Brackets

Top

Bottom

Slide the rear

brackets behind the

as shown.

9

Page 10

Tighten the nuts,

Before installing the insulation, read the

Remove protective

plastic coating from

Odyssey

│

Installation and Operation Instructions - General Venting CT80-250

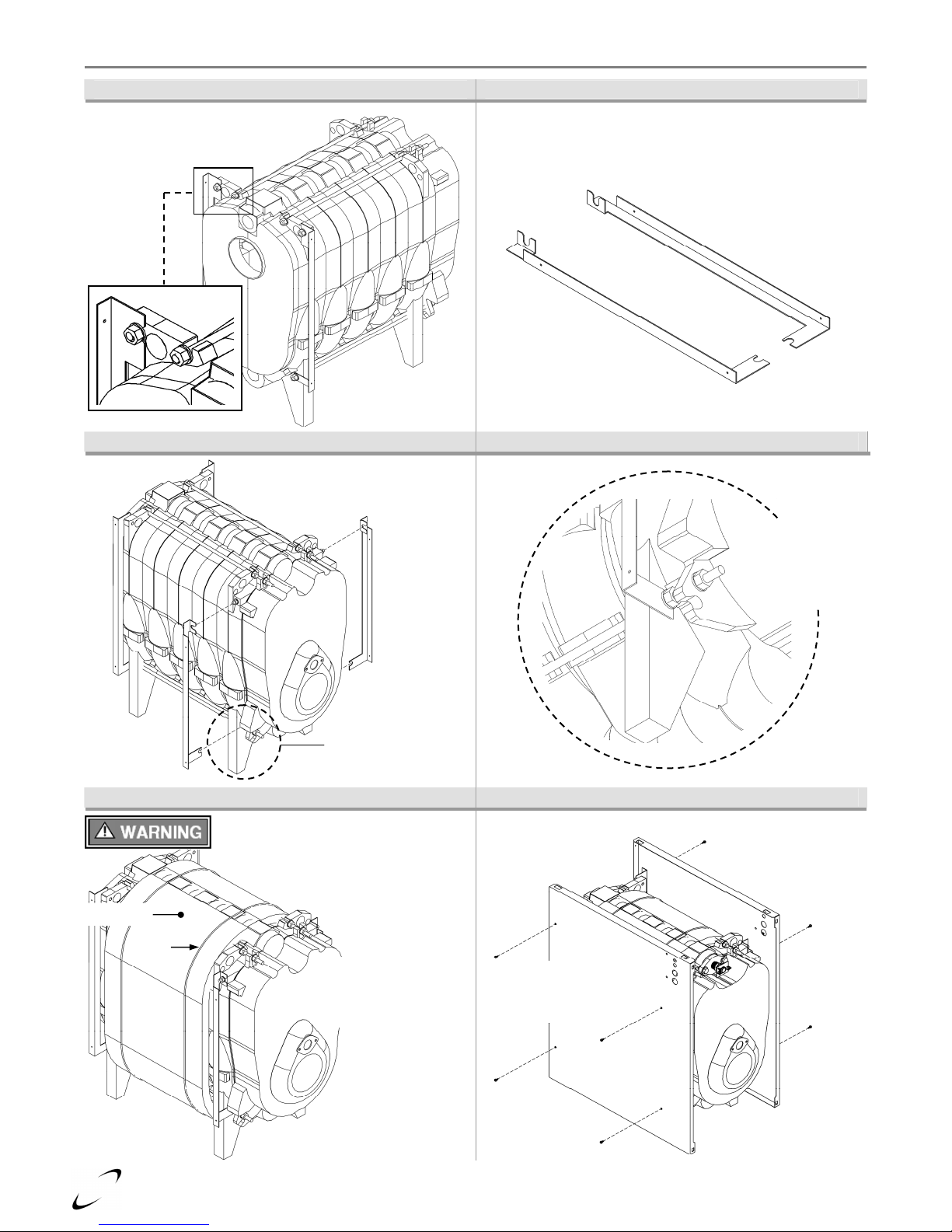

Figure 4-3 Tighten Bracket Nuts (Rear) Figure 4-4 Front Brackets

Tighten nuts, top and bottom,

to secure the rear brackets to

the boiler.

Figure 4-5 Mount Front Brackets Figure 4-6 Tighten Bracket Nuts (Front)

Top

Bottom

Slide the front brackets

behind the nuts and washers

at the front of the boiler.

Insulation

Twine

top and bottom,

to secure the

front brackets to

the boiler.

See Figure 4-6

Figure 4-7 Insulate Heat Exchanger Figure 4-8 Attach Side Panels To Brackets

“Handling Instructions” in Section 11.0.

all jacket pieces

before installing.

Install insulation around

the heat exchanger and

secure in place with

factory supplied twine.

Attach both side panels

to brackets using sheet

metal screws provided.

10

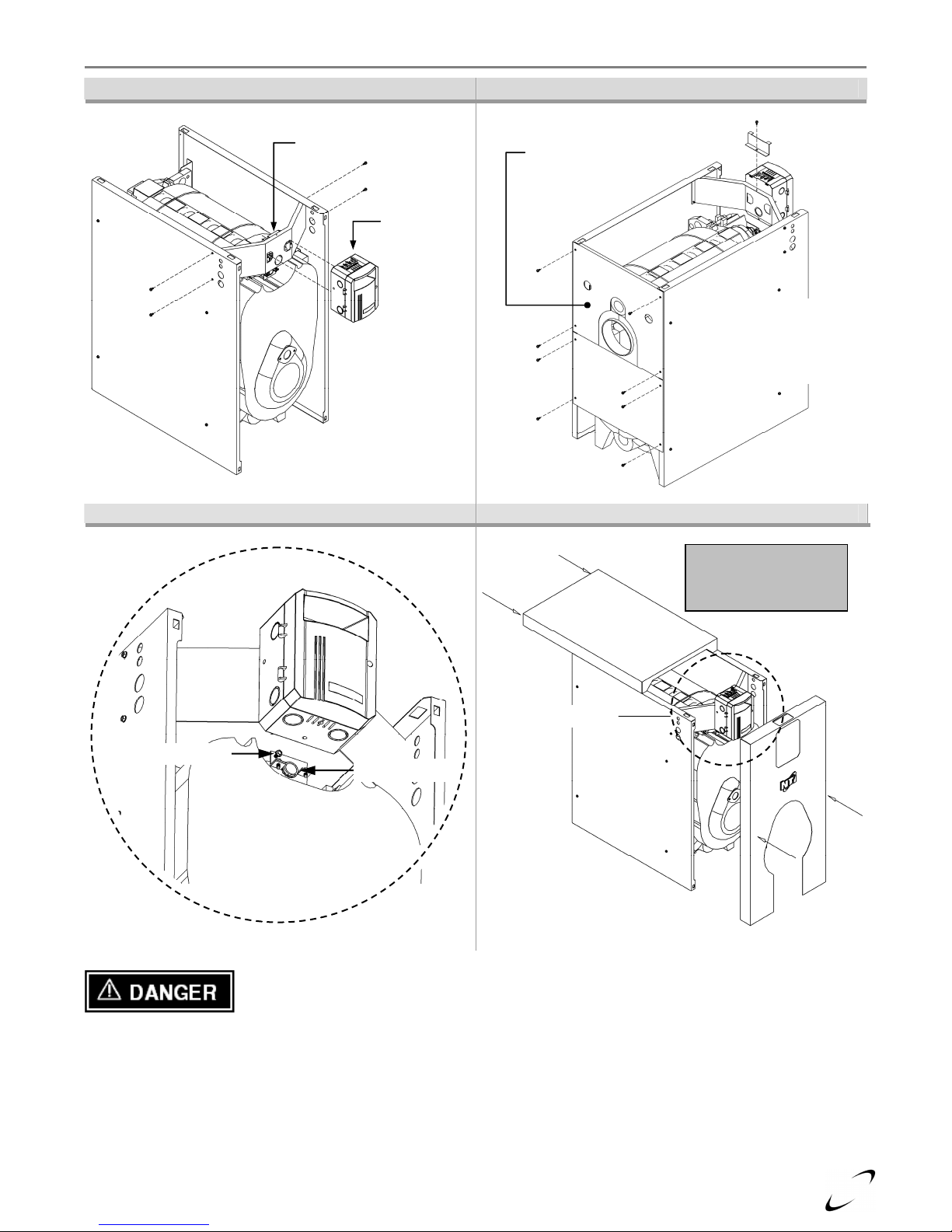

Page 11

C 85-340 Boiler Assembly - Installation & Operation Instructions

side panels, secure

the HydroStat 3250

to the control panel

Secure bottom back panel.

Ground Wire

- Connect green

wire between ground screw

Installation of burner and

Figure 4-9 Attach HydroStat 3250 Bracket Figure 4-10 Attach Back Panels & Electro-well

│

Odyssey

Control Panel

Recommend installing

top back after flue

breeching connected

and sealed.

Hold Down

Bracket

HydroStat

3250

Attach hold down bracket

Attach the control

panel between the

as shown.

Figure 4-11 Install Ground Wire and Sensor Figure 4-12 Install Top and Front Covers

to top edge of HydroStat

control panel to secure it

in place.

completion of wiring

must be done with front

cover removed.

See Figure 4 -11

Ground Screw

Electro-well

and HydroStat ground screw.

Sensor - Insert fully into the

Electro-well or overheating

may occur. See “Danger”.

Sensor - Insert the sensor fully into the Electro-well or the boiler may overheat resulting

in fire, property damage, serious injury, or death.

11

Page 12

Odyssey

│

Installation and Operation Instructions - General Venting CT80-250

Burner Installation

The Odyssey boiler is designed to work with burners described in this manual. The use of other nozzles, and/or

burners, may cause unsafe operation and will void any and all responsibility by NY Thermal for the safety and

reliability of the system.

The burner kit should be installed in accordance with the instructions in this manual and the burner

manufacturer’s instructions included with the burner. Refer to specification Tables 2-1 to 2-3 for nozzle sizes,

burner settings, insertion depths, and air setting guidelines.

Fuel Oil - Odyssey boilers operate with No. 2 oil as their only approved fuel source. DO

NOT USE GASOLINE, CRANKCASE DRAININGS, OR ANY OIL CONTAINING

GASOLINE. Failure to follow these instructions may result in severe personal injury, property damage, or death.

Combustion Analyzer -

capable of measuring CO

To calibrate burner operation, use a calibrated combustion analyzer

2

and O2 from oil burning boilers

Smoke Test - All tests must be done with the burner covers or air intakes in place to

simulate normal operation.

Smoke Pump - A reliable, certified smoke pump is required to correctly set up this

equipment.

Avoid Condensation - Due to the high combustion efficiencies and low stack gas

temperatures, great care must be taken to ensure the chimney isn’t subjected to flue gas

condensation. The gas temperature where the flue pipe enters the chimney must be a minimum of 240oF.

Burner Installation Procedure:

1. Burner Package:

a. Prepare the burner in accordance with the burner manufacturers instructions included with the burner.

b. Refer to specification Tables 2-1 to 2-3 to determine the appropriate nozzle size for the boiler output. See

“Attention: Nozzle Sizes” in Section 2.0.

c. Riello Burners (extra step required): Mount the burner gasket and burner flange to the boiler. Secure to

the boiler using washers and nuts provided (Figure 4-5). Seal around the burner gasket and the blast tube

ring with high temperature silicone (i.e. 83ml tube of silicone included in the burner kit).

d. Mount prepared burner package to the boiler. Seal around burner flange with high temperature silicone.

Combustion Air Settings - Refer to Section 10.0 Installation Checklist for instruction

regarding adjusting combustion air settings.

Oil Supply Tank and Oil Piping

The oil supply tank and piping should be installed in accordance with the instructions in this manual; the burner

and pump manufacturer’s instructions; National codes NFPA 31 (USA) or CSA B139 (Canada), and local codes.

General Installation Guidelines:

1. Install the oil supply tank as per tank manufacturer’s instructions.

2. Install oil supply piping from the tank to the burner.

3. Recommend installing a low pressure-drop fuel oil filter to prevent burner nozzles plugging at low flow rates.

4. Shut-off valves should be installed to control the flow during operation and to avoid spills during servicing.

5. Oil can be fed from the supply tank by gravity (single pipe system) or by transfer pump (two-pipe lift system).

6. Refer to burner manufacturer’s instructions before installing oil piping systems as some burner packages are

not equipped to work with two-pipe lift systems (i.e. Riello BF5).

7. Connect oil supply piping to the fuel oil pump as per the pump manufacturer’s instructions and system type.

Pipe Dope / Teflon Tape - DO NOT use on direct oil connection to the fuel pump. Failure

to follow instructions may cause valve failure and dangerous operating conditions.

12

Page 13

C 85-340 Boiler Assembly - Installation & Operation Instructions

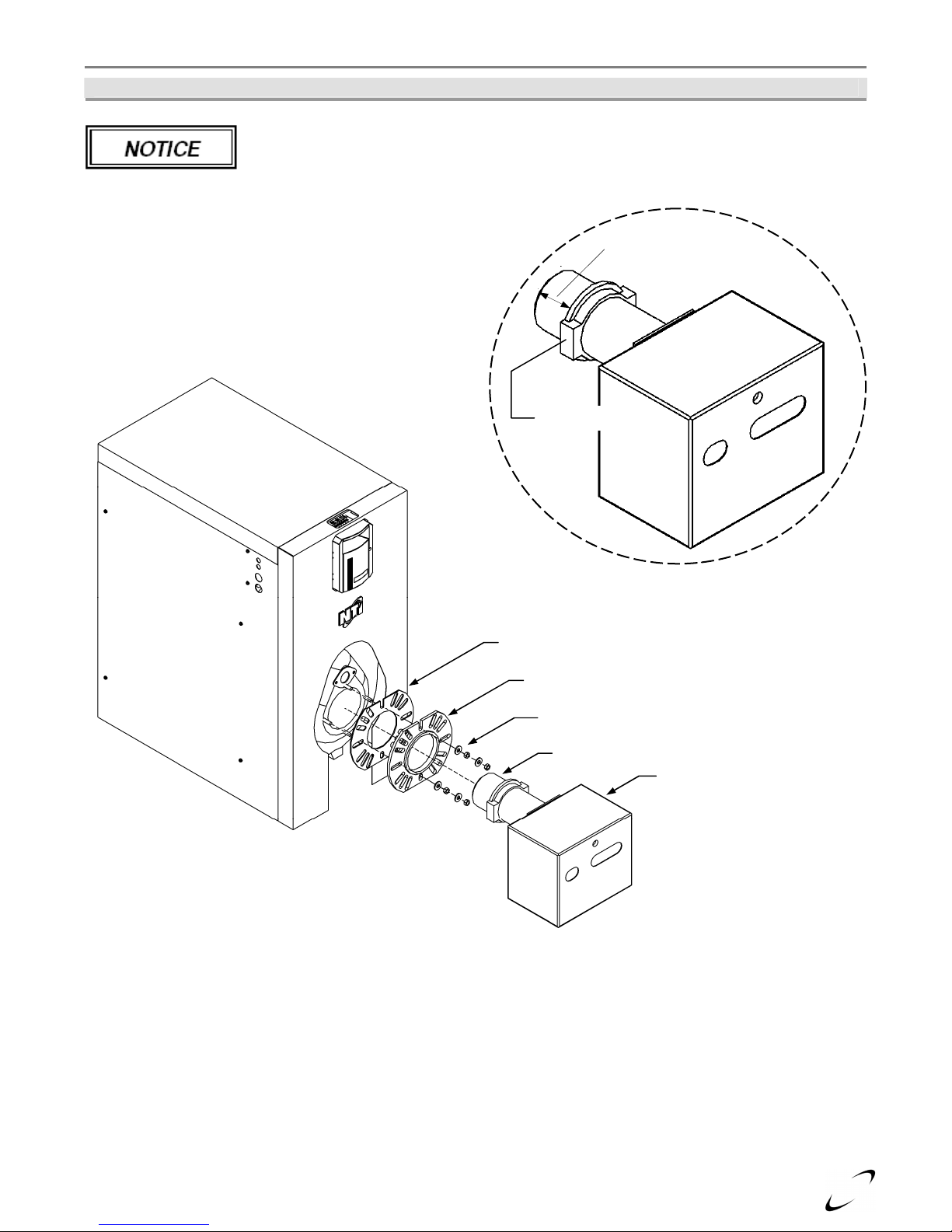

Figure 4-5 Burner Installation

Prepare the burner as per the burner manufacturer’s instructions. Refer to Tables 2-1 to

2-3 for nozzle sizes, burner settings, insertion depths, air settings, and specifications.

Set insertion depth

(Tables 2-1 to 2-3)

Blast Tube Ring

│

Odyssey

Burner Gasket

Burner Flange

Washers and Nuts

Blast Tube

Burner

13

Page 14

Odyssey

5.0 GENERAL VENTING

│

Installation and Operation Instructions - General Venting CT80-250

Natural Draft Applications

All Odyssey models are certified as Natural Draft boilers. The Natural Draft installation draws combustion air

from the room and uses the stack effect and draft system to exhaust flue gases using a chimney.

Air Supply - Allowances for combustion air must be supplied to the appliance space, due to the fact that the

heating appliance consumes large volumes of combustion air. In most instances, a permanent opening with an

unobstructed or “free area” of 1 square inch for every 1000 BTU’s of input will provide a sufficient amount of

combustion air for the boiler to operate properly. If the building is fairly new and relatively air tight, compensate

for the air tightness by using a “free area” that is 15% larger that what was calculated above. Do not place the

boiler in, or adjacent to, a room where an exhaust fan is operating. Refer to “Combustion Air” in Section 6.0

Natural Draft Applications for more details. Installation must comply with Standard CSA B139 (Canada) and

NFPA 31 (USA).

Stack Draft - Sufficient draft by natural or mechanical means is necessary for ensuring optimal and consistent

operation. The appliance should have a stack draft sufficient to support stable operation. See Draft Settings

(Natural Draft).

Avoiding Condensation - Due to the high combustion efficiencies and low stack gas

temperatures, great care must be taken to ensure that the chimney isn’t subjected to gas

condensation. The exhaust gas temperature where the flue pipe enters the chimney must be a minimum of 240oF

or condensation may occur.

Draft Regulator - A draft regulator must be used and set to regulate the draft of the boiler. Make sure that the

damper is free to operate without sticking, for this will affect the boiler’s combustion system. It is important that

the draft be adequate because poor draft conditions will cause poor operation and a possible hazardous condition.

Draft Settings (Natural Draft) - The Odyssey is designed to operate with a -.03” w.c.

draft in the flue breaching; therefore, ensure there is enough natural or mechanical draft

for proper operation. Due to the design of the Odyssey it may operate at a positive over fire pressure up to +.20 at

a -.03 draft.

Direct Vent Applications

Odyssey models C85-150 are also certified for direct vent applications. The Direct Vent installation uses a special

venting system where exhaust gases are vented directly to the outside using a special venting system which

equalizes the pressure between the air inlet and the flue outlet resulting in a balanced flue system. Refer to Section

7.0 Direct Vent Applications for more details. Installation must comply with Standard CSA B139 (Canada) and

NFPA 31 (USA).

Draft Settings (Direct Vent) - Due to the design of the balanced flue system, the Odyssey

will operate at a positive draft pressure and a positive over fire pressure at all times. It is

designed to operate with a maximum stack draft of 0.25” w.c and a maximum over fire draft of 0.33” w.c. when

little or no wind is present. In extreme wind conditions, the maximum stack draft is 0.35” w.c. and the maximum

over fire draft is 0.45” w.c.

14

Page 15

CT80-250 Natural Draft - Installation & Operation Instructions

6.0 NATURAL DRAFT APPLICATIONS

│

Odyssey

Natural Draft Rules and Guidelines

1. Acceptable Venting Material - Use vent material approved by National Standards NFPA 31 (USA) or CSA

B139 (Canada) and local codes.

2. Venting Application - Venting must be connected to a chimney for models operating with Natural Draft.

3. Chimney Condition - Inspect existing chimney before installing new boiler. Deterioration of mortar joints

should be repaired prior to using.

4. Chimney Height - Chimney must extend 3’ above the highest point where it exits the roof and 2’ higher than

any part of the structure within 10’.

5. Cleaning - Clean chimney, if required; ensure it is clear of any blockages before connecting breeching.

6. Liner Condition - Damaged liner or pipe should be repaired before commencing installation.

7. Minimum Clearances - Observe clearances to combustibles illustrated in Figure 3-1 and Table 3-1:

8. a) Double-wall vent (Type-L) 6 "

9. b) Single-wall vent 9 "

10. Chimney Sizes - Minimum chimney sizes should be used. See Table 6-1.

11. Combustion Air - An adequate supply of combustion air must be available to ensure proper combustion.

12. Interlock - If a damper is used to provide make-up air for combustion, it must be interlocked with the burner

to prevent the burner starting before the damper is opened.

Potential Condensation - Oversized chimneys, outside masonry chimneys, and/or de-

rated inputs can result in flue gases condensing in the chimney.

Combustion Air

Natural Draft boilers require an adequate amount of combustion air to sustain proper combustion and prevent

flue gas leakage. The appliance’s air-inlet draws combustion air from Indoors or Outdoors depending on whether

there is a sufficient natural infiltration (air changes) occurring to sustain combustion. If the building is newer and

relatively air tight, outdoor air should be considered. For recommended practice, refer to NFPA 31 (USA) or

CSA B139 (Canada).

Air Circulation - The boiler shall be located so as not to interfere with proper circulation

of combustion, ventilation, and dilution air.

Make-up Air - The operation of exhaust fans, kitchen ventilation systems, clothes dryers,

and fireplaces must be considered in determining the adequacy of a space to provide

combustion air requirements. Failure to ensure adequate make-up air to all appliances may result in flue gas

leakage, personal injury or death.

Permanent Openings for Combustion Air

The appliance space or boiler area requires a permanent opening(s) capable of providing adequate combustion air

to the boiler. If using two permanent openings, one opening must be within 12 inches of the ceiling, the other

within 12 inches of the floor. The minimum dimension of air openings to the appliance space shall not be less

than 3 inches in any one direction, including rectangular ducts. Round ducts are connected to the permanent air

openings, duct sizes must have a minimum cross-sectional area of 3 inches. See “Sizing Combustion Air

Openings” for more details.

The minimum size of permanent openings and how combustion air is supplied to them depends on three factors:

1. What is the input capacity of the boiler in Btu/hr?

2. How is the Combustion Air being supplied?

3. Is make-up air required for other appliance in the room competing for the same air?

15

Page 16

Odyssey

│

Installation and Operation Instructions - Natural Draft CT80-250

Sizing Combustion Air Openings

The following sections detail the three (3) methods for determining the minimum opening size and location

required for providing combustion air:

1. Indoor Air - Opening Sizes: Older buildings typically have sufficient ventilation due to air leakage around

single pane windows, poorly weather-stripped doors, and non-existent vapour barrier. Indoor air can be used

to supply combustion air to the boiler area if the air infiltration rate is adequate, i.e. greater than 0.4 ACH (air

changes per hour) or when the boiler area and communicating spaces have a minimum volume of 50 cubic ft

per 1000 Btu/hr. If the air infiltration rate is known to be less that 0.4 ACH, refer to the Installation Code for

Oil-Burning Equipment for further guidance.

a. Combined spaces on the same story

minimum free area of openings = 1 in.2/1000 Btu/hr of total input rating of all appliances in the space.

not less than 100 sq. in.

two openings required - one within 12 in. from ceiling, other within 12 in. from floor or bottom of the

enclosure.

minimum dimension of air openings shall be not less than 3 in.

b. Combined spaces in different stories

Volume of spaces in different stories shall be considered as communicating spaces where spaces

connected by one or more openings in doors or floors having a total minimum free area of 2 in.2/1000

Btu/hr of total input rating of all appliances.

2. Outdoor Air - Opening Sizes: When outdoor air is used to supply combustion air to the appliance space,

both openings must connect directly to the outdoors via ducts or connect to a crawl space or attic that

connects freely to the outdoors. Outdoor combustion air provided through opening(s) to the outdoors must be

made in accordance with the methods detailed below.

a. Two Permanent Openings Method - Two permanent openings shall be provided, one commencing

within 12 in. of the top, and the other within 12 in. of the bottom of the enclosure. The openings shall

communicate directly, or by ducts, with the outdoors or spaces that freely communicate with the

outdoors, as follows:

vertical ducts, minimum free area = 1 in.2/4000 Btu/hr of total input rating of all appliances in the

space.

horizontal ducts, minimum free area = 1 in.2/2000 Btu/hr of total input rating of all appliances in the

space.

b. One Permanent Opening Method - One permanent opening, commencing within 12 in. of the top of

the enclosure, shall be provided. The appliance shall have clearances of at least 1 in. from the sides and

back and 6 in. from the front of the appliance. The opening shall directly communicate with the outdoors

or shall communicate through a vertical or horizontal duct to the outdoors or spaces that freely

communicate with the outdoors and shall have a minimum free area of the following:

1 in.2/3000 Btu/hr of the total input rating of all appliances located in the enclosure.

Not less than the sum of the areas of all appliances’ vent connectors in the space.

3. Combination Indoor and Outdoor Air - Opening Sizes: The use of a combination of indoor and outdoor

combustion air shall be in accordance with the following:

a. Indoor Air - Where used, openings connecting the interior spaces shall comply with opening sizes

calculated in accordance with “Indoor Air Opening Sizes” described previously.

b. Outdoor Air - Outdoor opening(s) shall be located and sized in accordance with “Outdoor Air Opening

Sizes” described previously.

c. Outdoor Opening(s) - The outdoor opening(s) size shall be calculated in accordance with the following:

The ratio of interior spaces shall be the available volume of all communicating spaces divided by the

required volume (i.e. 50 cubic ft per 1000 Btu/hr if 0.4 ACH or greater).

The outdoor size reduction factor shall be 1 minus the ratio of interior spaces.

The minimum size of outdoor opening(s) shall be the full size of outdoor opening(s) calculated in

accordance with “Outdoor Air Opening Sizes” described previously, multiplied by the reduction

factor. The minimum dimension of air openings shall not be less than 3 in.

16

Page 17

CT80-250 Natural Draft - Installation & Operation Instructions

Connect Breeching & Blocked Vent Switch

│

Odyssey

Restrictions - Use the minimum vent length and number of elbows possible to ensure

flow of combustion gases are not restricted. Failure to follow instructions may result in

severe personal injury or death.

Blocked Vent Switch - For complete installation details, refer to the manufacturer’s

instructions included with the Blocked Vent Switch.

The steps for connecting breeching to a chimney are illustrated in Figure 6-1 and should be read in conjunction

with the sizes specified in Table 6-1. Restricted flow can result in condensation, flue gas leakage, and/or carbon

monoxide emissions.

Breeching Installation:

1. Chimney Clearances - Observe clearances to combustibles for breeching and chimney connections.

2. Supports - Install flue pipe brackets according to local codes or as needed.

3. Breeching Sizes- Connect breeching to the boiler flue collar. Use full size breeching when possible. Refer to

Table 6-1 for minimum sizes.

4. Potential Restrictions - Keep breeching lengths and elbow-tee combinations to a minimum to avoid

restricting the flow of combustion gases. See warning titled “Restrictions”.

5. Chimney Connections - Use thimble or slip joint where breeching enters chimney to allow for removal for

cleaning and servicing.

6. Avoiding Obstructions - Ensure breeching does not protrude so far into the chimney that it will cause

obstruction. Avoid connecting near the bottom of chimney as blockages may result.

7. Draft Regulator - Ensure damper is level. See instructions included with regulator.

8. Normal Draft Settings - When properly installed, Odyssey models are designed to operate with -.03” w.c.

draft in the flue breaching. For proper operation, there must be enough natural or mechanical draft. Due to the

design of the Odyssey, it may operate at a positive over fire pressure up to +.20 at -.03 draft.

9. Draft Gauge (if applicable) - A barometric control can be used to adjust the draft opening by installing it in

the breeching. This is optional and typically only done when excessive draft conditions exist which must be

relieved or to comply with applicable codes or regulations.

10. Sealing - Seal all vent joints.

11. Blocked Vent Switch - Install switch 6-8” from boiler breeching (Canada). See manufacturer’s instructions.

12. Interlock Set-up - Interlock burner with fan operation before start-up if using a motorized damper to supply

outdoor combustion air or induced draft.

17

Page 18

Blocked Vent Switch

8” from the boiler

breeching, refer to instructions included

Top Back Panel

-

with high temperature silicone.

Odyssey

Table 6-1 Minimum Chimney Sizes

Model

│

Installation and Operation Instructions - Natural Draft CT80-250

Minimum

Breaching

Diameter

Minimum I=B=R Chimney

Rectangular Round

Minimum

Chimney

Height

Boiler Flue

Collar Size

C80

C90

C100

6 "

15 '

C120

C150

5 "

8 " x 8 "

C180

C215

C230

C250

Notes:

1

6-3/4" x 6-3/4" inside liner.

2

Excessive breeching length or too many elbows and/or tee will cause restriction.

1

7 "

8 "

15 '

15 '

Figure 6-1 Breeching & Blocked Vent Switch

5"

Recommend

installing top back after flue

breeching connected and sealed

Secure breeching using a

minimum of two screws,

equally spaced. These two

screws must past through

the support tabs on either

side of the breeching.

Draft Regulator

Support Tabs

Blocked Vent Switch

Install the switch 6-

18

with kit (mandatory in Canada).

Page 19

CT80-250 Direct Vent - Installation & Operation Instructions

7.0 DIRECT VENT APPLICATIONS

│

Direct Vent Rules and Guidelines

1. Vent Material: Use approved venting material. Refer to Direct Vent Termination Kit in this section.

2. Continuous Vent: The vent must be in one continuous piece with no joints.

3. Balance: Combustion air intake and vent must be installed on the same wall using the specified vent terminal

to ensure the system is balanced.

4. Prevailing Winds: Ensure the vent is located where it will not be exposed to normal prevailing winds.

5. Combustion Air-inlet Contamination: Air for combustion must be drawn from an area free of dust and

contaminants. Combustion air containing chemicals such as chloride, fluoride, bromine, iodine, or dust and

debris will cause corrosion damage of the heat exchanger voiding your NTI warranty.

6. Snow Level Allowance: 24” is the recommended snow level allowance above grade or any surface that will

support snow, debris, or ice required for air-inlet / vents in balanced flue systems. If living in a snowfall

region, consult your local weather office for the maximum typical snowfall in your area.

Example: New Brunswick Canada - typical maximum snowfall is 19”, thus the inlet must be (12”+19”) = 31”

above grade.

7. Wall Flashing: Under normal operating conditions this boiler will produce a plume of white gases, and

should be taken into consideration when selecting an adequate location. A 36” [915 mm] diameter stainless,

plastic, or vinyl shield can be used to flash the exterior of the residence.

8. Flue Gas Hazard: Position the vent termination where vapors cannot make accidental contact with people

and pets, damage property, or adjacent buildings.

9. Condensate Hazard: Do not locate vent over public walkways, driveways or parking lots. Condensate could

drip and freeze resulting in a slip hazard or damage to vehicles and machinery.

10. Wall Thickness: Direct Vent terminations are designed to work with any standard wall thickness.

Installation guidelines for min/max wall thickness are as follows: Min.= 1” [25mm], Max.= 20” [0.5m].

Standard Vent Terminal is 8” long (p/n 81522-1) and Extended Vent Terminal is 20” long (p/n 81522-2).

11. Venting Options: Due to potential moisture loading (build-up) along the exterior wall, sidewall venting may

not be the preferred venting option.

Odyssey

19

Page 20

Odyssey

Direct Vent Clearances

│

Installation and Operation Instructions - Direct Vent CT80-250

Table 7-1 is a quick reference table that is to be read in conjunction with the numbered

notes in the table, the Direct Venting Rules and Guidelines, and Figure 7-1. The

instructions detailed in this section are a combination of Odyssey specific and National Code restrictions.

Compliance alone doesn’t ensure a satisfactory installation as good common sense must also be applied. Failure

to follow these instructions may result in fire, property damage, serious injury or death.

Table 7-1 Termination Clearances Quick Reference Table

Clearances to Vent Termination

A Vent Terminal above grade, snow level, or an object that can support snow/ice 3 12 in. 305 mm 12 in. 305 mm

B Flue gases directed toward / causing damage to masonry, siding, or construction 6

C To exhaust from any other appliance 4 6 ft. 1.8 m 12 in. 305 mm

D

From combustible materials, surrounding building openings, or property lines 9

E Below / adjacent operable window or building opening 6 ft. 1.8 m 4 ft. 1.2 m

F Above window, door, or building opening. 6 ft. 1.8 m 12 in. 305 mm

G To combustion air inlet from any other appliance 6 ft. 1.8 m 12 in. 305 mm

H Under a veranda, porch, deck, or balcony 8 6 ft. 1.8 m

I Mechanical air supply inlet to building 5 6 ft. 1.8 m 3 ft. 1.0 m

J Soffit, overhang, eave or parapet 2 ft. 610 mm 12 in. 305 mm

K Soffit vent; vent opening in overhang 6 ft. 1.8 m 12 in. 305 mm

L Inside corner of an L-shaped structure (including walls and fences) 3 ft. 1.0 m 3 ft. 1.0 m

Minimum distance from the oil supply tank’s vent or fill pipe (inlet)

M

N Above a gas meter, gas meter / regulator assembly 4 3 ft. 1.0 m

P Each side of center line above or below meters, regulators and vent/relief devices 4 6 ft. 1.8 m

Q Above or adjacent to a paved sidewalk /driveway, or parking lot

7

7 ft. 2.1 m 7 ft. 2.1 m

R Above a sidewalk, driveway, or parking lot on public property

S Above a sidewalk, driveway on private property between / serving both dwellings

T Into a canopy or carport

U Above, under or near exterior stairs

Notes:

1 - Canadian installations must comply with the current CSA B139 Natural Oil Installation Code and local codes.

2 - US installations must comply with current Standard NFPA 31 Installation of Oil Burning Equipment and local codes.

3 - 24” is the recommended snow level allowance above grade or any surface that will support snow, debris, or ice (i.e.

deck). Minimum distance is 12” above grade or above snow level (which ever is greater). If living in a snowfall region,

consult your local weather office for the maximum typical snowfall for your area.

4 - Within 3’ of the vertical centerline.

5 - For US installations, an exhaust vent may be 3 ft above a mechanical air supply inlet if within 10 ft. [3 m] horizontally.

6 - The vent terminal shall not terminate where flue gases are directed toward brickwork, siding, or construction in such a

manner that can cause damage from heat or condensate from the flue gases.

7 - Exit terminals of mechanical draft systems must maintain this minimum distance when located above or adjacent public

walkways, driveways or parking lots. Flue gases cannot drip, freeze, or create a hazard.

8 - Only permitted if a minimum of two sides are fully open beneath.

9 - Vent terminal must terminate so flue gases maintain the stated clearances from combustibles, property line, and

surrounding building openings.

X

- Not permitted by National code(s) and/or recommended by boiler manufacturer.

Canada 1 USA 2

Min. Distance Min. Distance

X X X X

6 ft. 1.8 m

- -

- -

3 ft. 1.0 m

5 ft. 1.5 m

- -

- -

X X X X

X X X X

X X X X

X X X X

20

Page 21

CT80-250 Direct Vent - Installation & Operation Instructions

Figure 7-1 Termination Clearance Quick Reference Diagram

│

Odyssey

21

Page 22

1

,3

DV Burner Kit.

3

5

Odyssey

│

Installation and Operation Instructions - Direct Vent CT80-250

Direct Vent Termination Kit

When installed as a Direct Vent boiler the combustion air-inlet must also be piped directly to the outdoors using

the methods described in this section and in accordance with the CSA B139 (Canada) or NFPA 31 (USA) and

local code requirements.

Venting Options - Due to potential moisture loading (build-up) along the exterior wall,

sidewall venting may not be the preferred venting option.

The majority of the balance flue components required for Direct Vent installations are included with the

Burner Kit. Remaining components must be ordered separately. Refer to the components listed in Table

7-2 and illustrated in Figure 7-2.

Table 7-2 Direct Vent Components

Item Part # Description

Included with Direct Vent Burner Kit

1 81764

2 81098

3 81138

5” to 3” Ported Adapter

3” Insulated Flex to Pipe Adapter

3” Flex, 10’ long 3

4 81625 Hose Clamps, 3” (2)

6

2

4

Direct Vent Terminal 1

5 81522-1 Direct Vent Terminal, 8”

Insulated Flex

1

81109 5’ Insulated Flex

81097 10’ Insulated Flex

6

81110 15’ Insulated Flex

81111 20’ Insulated Flex

Optional Components 2

- 81522-2 Extended Direct Vent Terminal, 20”

- 81453 Silicone, High Temp., 302 (83ml)

- 81847 3” Direct Vent 90o Elbow

- 81633 Adapter3” x 20’ Flex Aluminum

- 83026

Notes:

1

Required for Direct Vent installation but not included with boiler package; therefore, must be ordered separately.

2

Optional components available from NTI. Must be ordered separately.

3

The vent and air intake maximum length is 20’ (6m).

5” to 3” 90o Elbow Ported

Components required for Direct Vent installation:

Items 1-4 included with the boiler’s

Items 5-6 must be ordered separately.

Figure 7- 2

4

22

Page 23

Connection

Flange

CT80-250 Direct Vent - Installation & Operation Instructions

Direct Vent Installation Instructions

│

Odyssey

Vent Location - Under normal operating conditions, the boiler will vent plumes of white

flue gases; therefore, code restrictions and potential hazards associated with thru-wall

installations should be considered before selecting a location for the Direct Vent terminal.

To install the Direct Vent Termination Kit for the balanced flue system, complete the steps listed below in

sequence. Note there are two parts to the install, outside prep work and inside connections:

PART A: Outside

1. Vent Location - Select a suitable location for the

vent terminal. It is highly recommended that the

vent terminal be located where it will not be

Support Bracket

Heat Shield

exposed to normal prevailing winds. See NFPA 31

(USA), CSA B139 (Canada) for code clearances.

2. Exterior Surface - Ensure that the outside wall

Mounting Tabs

surface is flat and meets the installation clearances.

See Table 7-1 and Figure 7-1.

3” Hole

3. Vent Hole - Cut a rectangular hole, 5.5” wide, and

6.5” in height in the exterior wall.

4. Orientation - Insert the vent terminal through the

rectangular hole into the building so that the 3”

diameter hole for the air intake is facing downward.

See Figure 7-3.

5. Slope - When installed correctly, the vent terminal

pipe should point slightly uphill in order to drain

Figure 7- 3

water to the outside. If it is not sloped to the outside, flue gases will condense and drain back into the boiler.

6. Mounting Tabs - Secure the mounting tabs on either side of the vent terminal to the outside of the structure

using 4 x #10 stainless steel screws (field supplied).

7. Sealing - Using a suitable silicone sealant, seal the gap between the structure and the vent terminal.

PART B: Inside

8. Bend Bracket Support - Using a screwdriver, bend up the support

bracket located on the top of the unit as shown in Figure 7-4.

9. Support - Support the back end of the vent terminal by connecting

the support bracket to a joist, or other solid structure, by means of

metal strapping or wire.

10. Air Inlet Connections - Using the screws provided, attach the air

inlet connection flange to the bottom of the vent terminal. Figure 7-4.

11. Heat Shield - The back of the vent terminal is equipped with a

flexible heat shield, bend the flaps to the side, and then bend the heat

Air Inlet

Connection

shield up, and out of the way as shown in Figure 7-5.

12. Silicone - Seal the space between the vent terminal and the structure.

Refer to “Sealing” section for more detailed instructions.

13. Flex Piping - Install air inlet flex piping (3” flex 10’) over air inlet

connection (Figure 7-5). Secure with a 3”gear clamp included in the

Figure 7- 4

burner kit. Connect other end of flex piping directly to the Riello

burner (or increaser if using a Beckett burner). See Figure 7-7.

14. Insulated Flex - The boiler can now be connected to the vent

terminal with the help of insulated flex piping. The flex piping is

available in lengths of 5 ft, 10 ft, 15ft, and 20 ft. Ensure the flex

piping is long enough to form long radius bends (no smaller than 1 ft

in radius). If the flex is too long, it can be cut with a hacksaw.

15. Direct Vent - Assemble Direct Vent as detailed in following section

titled “Sealing”. Use only high temperature silicone provided or

referenced in instructions.

Air Inlet

Figure 7- 5

23

Page 24

Odyssey

Sealing

│

Installation and Operation Instructions - Direct Vent CT80-250

Proper Sealing - This Balanced Flue system will leak if the following sealing procedures

are not followed. It’s easier to seal the entire system properly the first time than return at a

later date and have to remove the connections to reseal it.

The adapters are multi-start, left hand thread, with one thread twice the width of the

others. Therefore, care must be taken to ensure that the correct threads are engaged before

tightening in a counter clockwise direction.

Clearances to Combustibles - The vent must have 9” clearance to combustible within 36” of the appliance

breech. The remaining section of the vent to the terminal can have a minimum of 1” clearance. The terminal is

rated for 0” clearance.

Recommended Sealing Method - Because the balanced flue system operates with a positive pressure in the

exhaust at all times, the sealing has to be done properly to prevent leaks at the joints. The type of sealant used

throughout this installation is critical to the operation of the balanced flue system. A tube of high temperature

silicone is provided with the installation kit (#81453). This tube should be sufficient for the whole installation,

but if more sealant is needed buy one of the following: GE 106, Dow Corning 736 Heat Resistant Sealant,

Perimeter 248 High Temp or RTV Silicone Gasket.

It’s the installer’s responsibility to ensure that combustion products do not enter the home.

To obtain a good seal between the Vent Terminal and the building wall, follow Steps “A” through “J”

illustrated in Figure 7-6:

PART 1: Boiler

A. Seal the 5” smoke collar to the smoke hood on the boiler with the high temperature silicone. Inspect all boiler

openings (sight door, burner connection, pipe joints, Etc) during initial operation, to verify there are no leaks.

Flex Pipe - Make sure that it’s long enough to form long radius bends (no smaller than 1 ft

in radius). If the flex is too long, it can be cut with a hacksaw.

Flex Adapter Collar - It is recommended to remove the collar on the 81098 & 81112 flex adapters that secure

the insulation and outer foil of the flex pipe. This can be accomplished by removing the pop rivet at the base of

the collar, and backing off the gear clamp completely. After removing the collar, you will get an unobstructed

view of the pipe joint. To reinstall, put the collar back into place and install a #8 x ½” screw in rivet hole, and rethread the gear clamp.

PART 2: Flex Pipe

B. Pull the outer foil sheathing and insulation back to give an unobstructed view of the pipe joints. Put 1 bead of

silicone on both inside ends of the insulated flex pipe, approximately 1” wide and ½” from the end. Put 1

bead of silicone on both outside ends of 81098 & 81112 connectors, approximately 1” wide and 1” from the

bottom of the threads. Screw in part number 81089 & 81112 adapters into the insulated flex and pull the

insulation and the outside flex over the collar and tighten the gear clamp.

C. Apply a wide bead on top of the flex joint.

D. Reinstall the collars on the vent connectors using a #8 x ½” screw in rivet hole, and re-thread the gear clamp

E. Apply silicone between the vertical overlap joint of the 5” to 3” adapter.

F. Apply silicone on inside surface of the 5” to 3” adapter.

G. Apply silicone on outside surface of the boiler cast collar, and slide 5” to 3” adapter over the smoke hood and

tighten the gear clamp.

H. Perform steps D-G to install the 3” adapter #81098 over the 3” vent terminal, and tighten gear clamp.

I. Fold the vent terminal heat shield flaps back into position.

J. Refer to Figure 7-7 for an illustration of a typical balanced flue installation for an Odyssey boiler (CT90-120).

24

Page 25

CT80-250 Direct Vent - Installation & Operation Instructions

Vacuum

Secure

│

Odyssey

Seal with silicone where shown.

Step G

Smoke Hood

Step B

5” to 3”

Ported Adapter

Insulated Flex

Step D

Step E

Step F

Step C

Important Warning - It is the responsibility of the installing contractor to ensure that:

1. The boiler and venting system are totally sealed from products of combustion.

2. The homeowner is advised of their responsibility of keeping the vent terminal clear of snow and ice.

3. That the home is equipped with a carbon monoxide detector.

Figure 7 -6

Insulated Flex

5” to3”

Ported

Adapter

Typical Balanced Flue Installation for CT90-120

3” Insulated Flex

to Pipe Adapter

Seal

Hose Clamp

using Tabs

Hose Clamp

3” Flex (10’)

Hose Clamp

Direct Vent

Terminal

Breaker

Air Inlet Piping

3” Flex (10’)

Figure 7 -7

Tilt down

after sealing

Direct Vent Terminal Installation

Seal with silicone where shown.

25

Page 26

Odyssey

8.0 BOILER PIPING

│

Installation and Operation Instructions - Field Wiring CT80-250

Boiler Water

Pressure - Odyssey boilers are intended to solely for use in pressurized closed-loop heating systems operating

with a “fill pressure” between 12-15 psi at the boiler outlet and a Relief Valve pressure of 30 psi (maximum

working pressure of the boiler).

Oxygen Elimination - The Odyssey boiler is designed to operate in a pressurized closed-loop heating system,

free of air and other impurities. To avoid the presence of oxygen, ensure all of the air is removed from the system

during commissioning via strategically placed, adequately sized air-removal devices located throughout the

heating system and the boiler piping (Figure 8-1). Immediately repair any leaks in the system plumbing to avoid

the addition of make-up water; make-up water provides a source of oxygen and minerals that may lead to heat

exchanger failure, poor performance, unnecessary wear of system components, and premature failure.

Closed System - The Odyssey is not approved for operation in an “open system”, thus it

cannot be used for direct potable water heating or process heating of any kind.

Antifreeze - If using antifreeze, use an inhibited propylene glycol specifically designed for hydronic systems.

NTI recommends against exceeding 35% concentration of glycol.

Near Boiler Plumbing

Install boiler piping for central heat and domestic hot water as shown in Figure 8-1.

Gauges - The temperature and pressure gauges (Ttridicator) is factory supplied and must be field installed in the

front of the boiler or on the coil plate.

Relief Valve - A 30 psi relief valve is factory supplied and must be field installed.

Piping - The closed loop piping system must be in accordance with the central heat piping illustration. All piping

joints must be secure and water tight or the boiler warranty is void.

Water Supply - Pressure regulating “fill valve” (12-15 psi) and back flow preventer are required (Figure 8-1).

Boiler Venting - Hot waters boilers are designed to operate with the airless water in the system. The NY Thermal

boilers are designed with a built-in air trap, to purge air at the ¾” relief valve nipple. An air vent must be installed

here or the boiler warranty is void.

Low Water Cut Off (LWCO) - To take advantage of the HydroStat’s LWCO feature, the

Odyssey is equipped with a special immersion well call the Electro-well™. Failure to use

the Electro-well™ provided with the boiler will over-ride the LWCO feature and allow the boiler to operation

during low water conditions which may result in over heating, fire, serious injury, or death.

Verify LWCO is Active - Ensure the LWCO active light is illuminated on the HyrdroStat

3250 when using the Electro-well™. If the indicator light is not illuminated than the

LWCO feature is not active. Refer to manufacturer’s instructions included with the HydroStat 3250.

Removing Air - Do not fill the boiler with water until you are ready to fire the burner.

Once filled with water, bring the boiler up to temperature and remove the air.

Removing Air from the Boiler:

1. Open automatic air vent 1 turn.

2. Bleed air from system. Starting at the lowest point in the building, open air vents one at a time and leave them

open until water comes out. Close all air vents, except the automatic air vent.

3. Refill to correct pressure, 12-15 psi.

26

Page 27

CT80-250 Field Wiring - Installation & Operation Instructions

Tee

(below

Figure 8-1 Near Boiler Piping

Central Heat

Relief

Valve

Outlet

Tridicator

│

Odyssey

Heating

Supply

Heating

Return

Bypass Line

(optional)

* Circulator location

may vary from one

application to another.

Pump *

Automatic Air Vent

Air Eliminator (mandatory)

Isolation/Throttle Valve

Water

Supply

Expansion Tank

Boiler

Drain

burner)

Inlet

27

Page 28

Odyssey

9.0 FIELD WIRING

│

Installation and Operation Instructions - Field Wiring CT80-250

All wiring and electrical grounding must be in accordance with local codes and the applicable National Electrical

Code, NFPA 70 (USA) or CSA C22.2 (Canada). Ensure that the wiring complies with this manual.

Avoid Shocks - To Avoid Electrical Shock, turn off electrical power to the boiler prior to

opening any electrical box within the unit. Ensure the power remains off while any

wiring connections are being made. Failure to follow these instructions may result in component failure, serious

injury or death.

Wire Protection - When passing any wiring through the casing of any component or

electrical box, the installer must use wire grommets suitable for securing the wiring and

preventing chafing. Failure to follow instructions may result in component failure, serious injury or death.

Burner Primary Safety - Blocked Vent Switch and any other limit device must break

power to the burner primary (B1). Failure to follow these instructions may result in

serious injury or death.

Labeling - Label all wires prior to disconnecting them when servicing controls. Wiring

errors can cause improper and dangerous operation. Failure to follow instructions may

result in property damage or personal injury.

Connection Description

T-T

WWSD

Heat Demand Input (Dry Contact) - from heating thermostat or zone controller. Contact closure

indicates to the controller that there is a heating demand, controller will apply Thermal Targeting

Outdoor Temperature Sensor (Factory Supplied) – Connecting the OD Sensor to WWSD and C enables

the Warm Weather Shutdown feature of the controller. Control will not respond to T-T demands when the

C

outdoor temperature is above the WWSD setting.

Outdoor Temperature Sensor (Factory Supplied) – Connecting the Outdoor Sensor to OR and C

OR

disables Thermal Targeting and enables full Outdoor Reset functionality, including Warm Weather

Shutdown.

Table 9-2 Electrical Field Connections - Line Voltage

Connection Description

Power Supply Hot – 120VAC input for the controller. Installation codes require the installation of a

L1

service switch to break line voltage to the appliance. Power supply must be protected with 15 Amp circuit

breaker or fuse.

L2 Power Supply Neutral – Location for connecting the Neutral of the power supply.

C2 Circulator Neutral – Location for connecting the Neutral to the circulator.

C1 Circulator Hot – 120VAC output to circulator (5.8 FLA max.)

B1

Burner Hot – 120VAC output to burner (7.4 FLA max.). Additional safety limits, i.e. LWCO and/or

Blocked Vent Switch, must be installed in series with this circuit. B1 is the Burner Primary.

B2 Burner Neutral – Location for connecting the Neutral to the burner.

ZC

Priority Zone Output (120VAC) – Power supply for priority zone, power is always present at ZC unless

the LO TEMP temperature is not attained.

Priority Zone Input (120VAC) – When power is applied to ZR from ZC, via a contact closure of an

Indirect Tank Thermostat, when Zone/Indirect Switch is set to “I”, the control overrides Thermal Targeting

ZR

and Outdoor Reset functions, and operates to the HI TEMP setting. When Zone/Indirect Switch is set to

“Z”, the control interprets the call as an end switch from Priority Zone relay, and operates as a central heat

demand performing Thermal Targeting or Outdoor Reset functions.

28

Page 29

CT80-250 Field Wiring - Installation & Operation Instructions

Figure 9-1 Odyssey Wiring Diagram

│

Odyssey

Burner Primary Safety - The Blocked Vent Switch and any other limit device must

break power to the burner primary (B1). Failure to follow these instructions may result in

serious injury or death.

29

Page 30

Odyssey

│

Installation and Operation Instructions - Field Wiring CT80-250

Fuel Smart HydroStat Model 3250

The Fuel Smart HydroStat 3250-Plus is manufactured by HydroLevel Company. It is a Temperature Limit and

Reset Control for oil and gas fired boilers. It meets the September 2012 requirements for “Automatic Means” of

adjusting boiler temperature. The HydroStat provides only temperature and reset functionality when installed on a

standard immersion well used on Caprice models.

Temperature Limit – In lieu of the HydroStat 3250 the Honeywell Aquastat models L7248A, L7224U or

L8148A can be used on Odyssey boilers.

Low Water Cut Off (LWCO) - To take advantage of the HydroStat’s LWCO feature, the

Odyssey is equipped with a special immersion well call the Electro-well™. Failure to use

the Electro-well™ provided with the boiler will over-ride the LWCO feature and allow

the boiler to operation during low water conditions which may result in over heating, fire, serious injury, or death.

Verify LWCO is Active - Ensure the LWCO active light is illuminated on the HyrdroStat

3250 when using the Electro-well™. If the indicator light is not illuminated than the

LWCO feature is not active. Refer to manufacturer’s instructions included with the HydroStat 3250.

Infloor Radiant Heating Applications - When the heating system incorporates low

temperature radiant heating, external mixing controls must be used to regulate the

temperature. Failure to follow these instructions may result in property damage.

HydroStat 3250 - For complete installation details and instructions on controls operation,

refer to the manufacturer’s instructions included with the Fuel Smart HydroStat 3250.

Table 9-3 HydroStat 3250 Control Settings

Parameter Default Recommended Settings

HI TEMP 190ºF 140-210ºF

LO TEMP OFF OFF

ECONOMY (Thermal Targeting) 1 See Thermal Targeting Method

ECONOMY (Outdoor Reset) 1.00 See Outdoor Reset Method

Thermal Pre-Purge OFF ON

Warm Weather Shutdown (WWSD) 70ºF 70ºF

Zone/Indirect Switch I See Zone/Indirect Switch

General Notes:

1 – LO TEMP must be set at least 10ºF below the HI TEMP.