O'Donnell Z01T Assembly Instructions Manual

ASSEMBLY INSTRUCTIONS

TM

®

i

O’DONNELL HISTORY

Every dream has a beginning and an end. This one just happened

to start out in the O’Donnell family garage back in 1980. Young

Steve O’Donnell wasn’t satisfi ed with the mediocre products

that the RC industry had to offer, so he set out to build the best

engineered and manufactured products available. Lucky for us, his

dream is far from over…

O’Donnell took his vast knowledge of nitro engine tuning and soon

designed products that would complement his talents. First came

his custom designed and machined aluminum cooling heads for

the on-road racing scene. Finding another void in the industry, he

also began producing custom tuned pipes to better utilize all of the

power these nitro burning monsters could produce.

The efforts of O’Donnell did not go overlooked. Some of the major

R/C manufacturers went to O’Donnell Manufacturing to have their

trick aluminum parts machined. O’Donnell’s meticulous standards

and overwhelming knowledge of the products made it a natural fi t.

Over the past 24 years, O’Donnell Manufacturing has produced parts

for such notable companies as Team Associated and Team Losi.

O’Donnell Manufacturing took another major step forward in 1988

when they introduced O’Donnell Racing Fuel…the name that

made them famous with racers around the world. Once again,

O’Donnell saw a need — for a high-quality fuel specifi cally blended

for the demands of nitro burning car engines. From that point on,

O’Donnell Racing Fuel became synonymous with winning. To this

day, no other fuel has won as many national championships as

O’Donnell Racing Fuel.

O’Donnell’s dreams moved to the next level when he embarked

on the ultimate journey…the design and creation of a new 1/8

off-road nitro racing buggy. The plan was simple: Don’t try to “reinvent the wheel”, just refi ne it…all of it.

Now all of the development, refi nement and on-track performance

of the O’Donnell Z01-B Buggy can be found in the Z01-T Truggy.

To complement the racing fuel, O’Donnell set out in 2000 to design

a glow plug that would out-perform and out-last all the competitors.

The result? Two U.S. patents and a World Championship. Not

bad for someone who started out in his parents’ garage. Today,

O’Donnell glow plugs are the choice of champions worldwide.

ii

• O’Donnell® guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. O’Donnell will

warranty this kit for 90 days after the purchase date. O’Donnell

will repair or replace, at no charge, the incorrectly made part.

• Make sure you save the receipt or invoice you were given when you

bought your model! It is your proof of purchase and we must see

it before we can honor the warranty. Further, O’Donnell reserves

the right to change or modify this warranty without notice.

• In that O’Donnell has no control over the fi nal user assembly or

material used for fi nal user assembly, no liability shall be assumed

nor accepted for any damage resulting from the use by the user

of the fi nal user-assembled product. By the act of using the userassembled product, the user accepts all resulting liability.

WARRANTY

To return your Z01T for repairs covered under warranty you should

send your truggy to:

Hobby Services

3002 N. Apollo Drive Suite 1

Champaign, Illinois 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am-5:00 pm Central Time M-F

E-mail: hobbyservices@hobbico.com

www.hobbyservices.com

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the place

of purchase.

2

iii

SAFETY PRECAUTIONS

Use care and good sense at all times when operating this radio

controlled truggy. Failure to use this vehicle in a safe, sensible

manner can result in injury or damage to property. You and you

alone must insure that the instructions are carefully followed and

all safety precautions are obeyed.

• Do not operate the Z01T near people. Spectators should be

behind the driver or at a safe distance away from the vehicle.

• Water can cause the electronics to short out and can cause

permanent damage.

• Always turn on the transmitter before turning on the receiver.

• Fully extend the transmitter antenna before operating your vehicle.

• Before turning on your radio system, check to make sure that no

one else is running on the same frequency.

• The engine and exhaust produce quite a bit of noise. Do not run

this vehicle when or where it can disturb others.

• The engine and exhaust can become very hot. Avoid touching

any of these parts during use and until they have cooled down.

• Model engine fuel is poisonous. Make sure you read and follow

all of the precautions on the fuel container. Keep fuel out of the

reach of children.

• Model engine fuel is fl ammable and when ignited has a fl ame

that is diffi cult to see. Avoid sparks, fl ames, smoking, or any

other ignition source when fuel is near.

• The engine emits harmful fumes just like real vehicles. Do not

operate this model indoors.

• Avoid running the truggy in cold weather. The plastic and metal

parts can become brittle at low temperatures. In addition,

grease and oil become thick, causing premature wear and

poor performance.

iv

• Read the instructions carefully before starting assembly.

• We recommend building the kit on a towel to help prevent small parts and screws from rolling off your work surface.

• Before turning on your radio system, check to make sure that no one else is running on the same frequency.

• Do not use an electric screwdriver/drill for assembling the kit. This could cause parts to strip out from overtightening.

• Use a quality threadlock where specifi ed in the manual.

• Parts for step included in this parts bag.

• Apply grease to part(s) indicated. Note: Always use black moly grease on areas indicated.

• Apply threadlock to screw(s) indicated. IMPORTANT: Clean oil or fi lm from screws before applying threadlock.

G

re

Threadlock

1

a

s

e

GENERAL BUILDING TIPS

3

v

REQUIRED ACCESSORIES

Transmitter

Receiver

High Torque

Steering Servo

Servo

5-Cell Receiver

Hump Pack

Glow Plug

(and spares)

Tires

Engine

Header & Pipe

Tire Inserts

4

vi

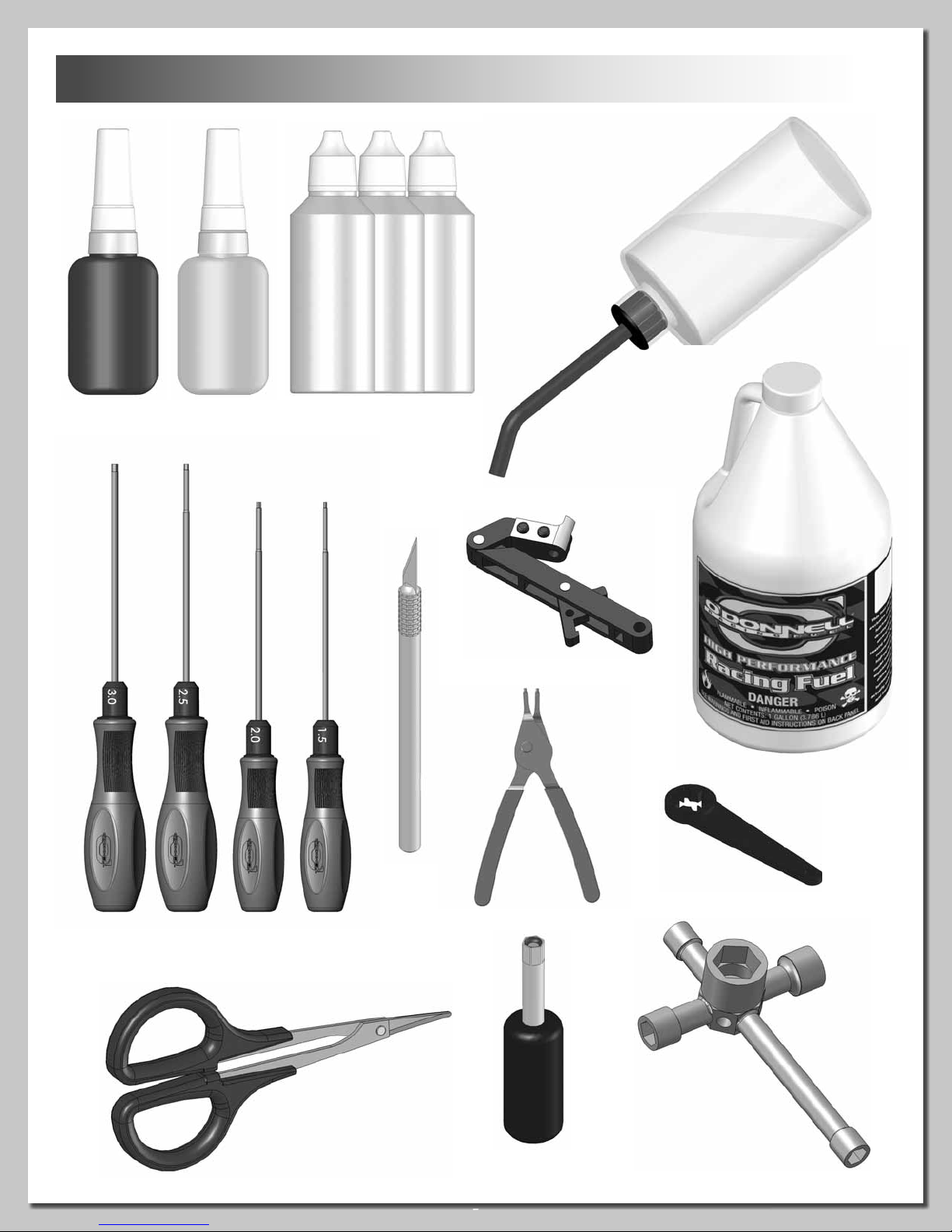

REQUIRED TOOLS & TRACK EQUIPMENT

Threadlock CA Tire Glue

Diff, Shock & Air Filter Oils

Clutch Tool

Snap Ring

Pliers

Fuel

Bottle

Fuel

3.0mm Hex

Wrench

2.5mm Hex

Wrench

2.0mm Hex

Wrench

1.5mm Hex

Wrench

Body

Scissors

Hobby

Knife

Flywheel

Wrench

4-Way

Wrench

Glow Plug

Ignitor

5

1

Grease

Grease

HARDWARE

DIFF HOUSING

(x3)

8x16mm Bearing

(x3)

Diff Outdrive O-Ring

(x3)

Sun Backing Washer

Front/Rear (x2)

Center (x1)

Apply grease in the groove

and a light fi lm of grease

on the shaft of all outdrives.

Make sure the bearing is fully

seated on the diff housing.

Slide the pin in place using

needle-nose pliers.

Apply a small amount of included

grease to the O-ring before installing.

This will help prevent damage to the

O-ring when installing the drive joint.

1

2

HARDWARE

Satellite Backing

Washer

DIFF PLANETARY GEARS

(x12)

Make sure the fl at spots on

the planetary gear shafts

interlock when installing.

1

6

3

DIFF OIL

Grease

Grease

HARDWARE

(x3)

8x16mm Bearing

(x3)

Diff Outdrive O-Ring

Apply a small amount of the included

grease to the O-ring before installing.

This will help prevent damage to the

O-ring when installing the drive joint.

Make sure the bearing is

fully seated on the gear.

SPUR/DIFF GEARS

Center (x1)

(x3)

Sun Backing Washer

4

HARDWARE

(x12)

3x12mm FH

Screw

Apply grease in the groove

and a light fi lm of grease

on the shaft of all outdrives.

Front/Rear (x2)

1

DIFF OIL

Build the front, rear and center diffs.

Fill the diff until the planetary

gear shafts are completely

covered with diff oil. When

using heavy oils, you need to

allow the oil to settle and add

oil if necessary. Do not overfi ll!

(Note: See set-up sheet for

recommended diff oils.)

DIFF OIL

1

4

Finish tightening the diff

gear screws in order. This

will help make sure the gear

is mounted fl at on the diff

housing and the housing is

properly sealed.

3

2

1

7

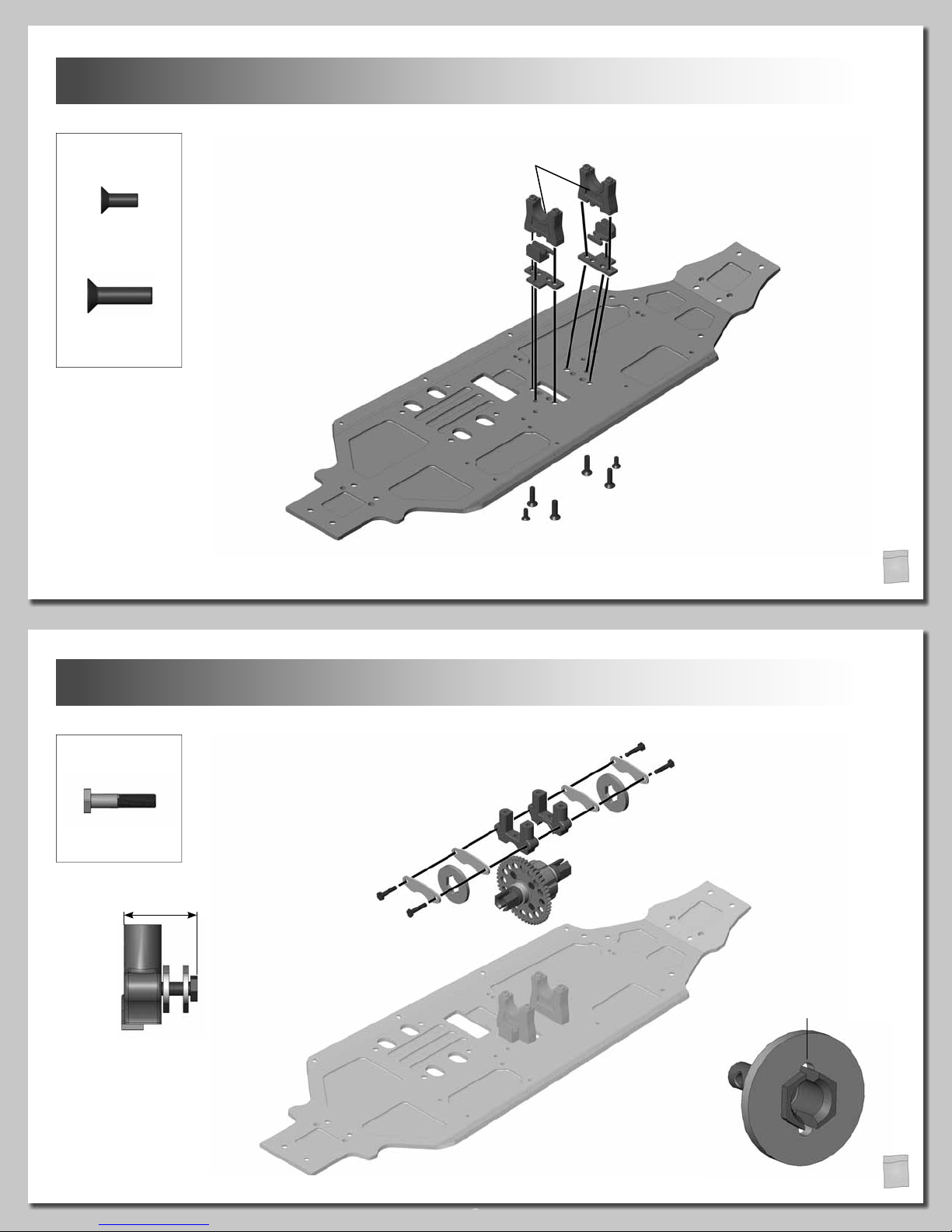

5

IMPORTANT!

IMPORTANT!

HARDWARE

3x8mm FH

Screw

4x14mm FH

Screw

(x2)

(x4)

IMPORTANT!

The grooves for the diff

bearings face inward.

Make sure the brake disc guides

are interlocked with the diff

mounts before installing.

4x14mm FH

CENTER DIFF MOUNTS

3x8mm FH

4x14mm FH

2

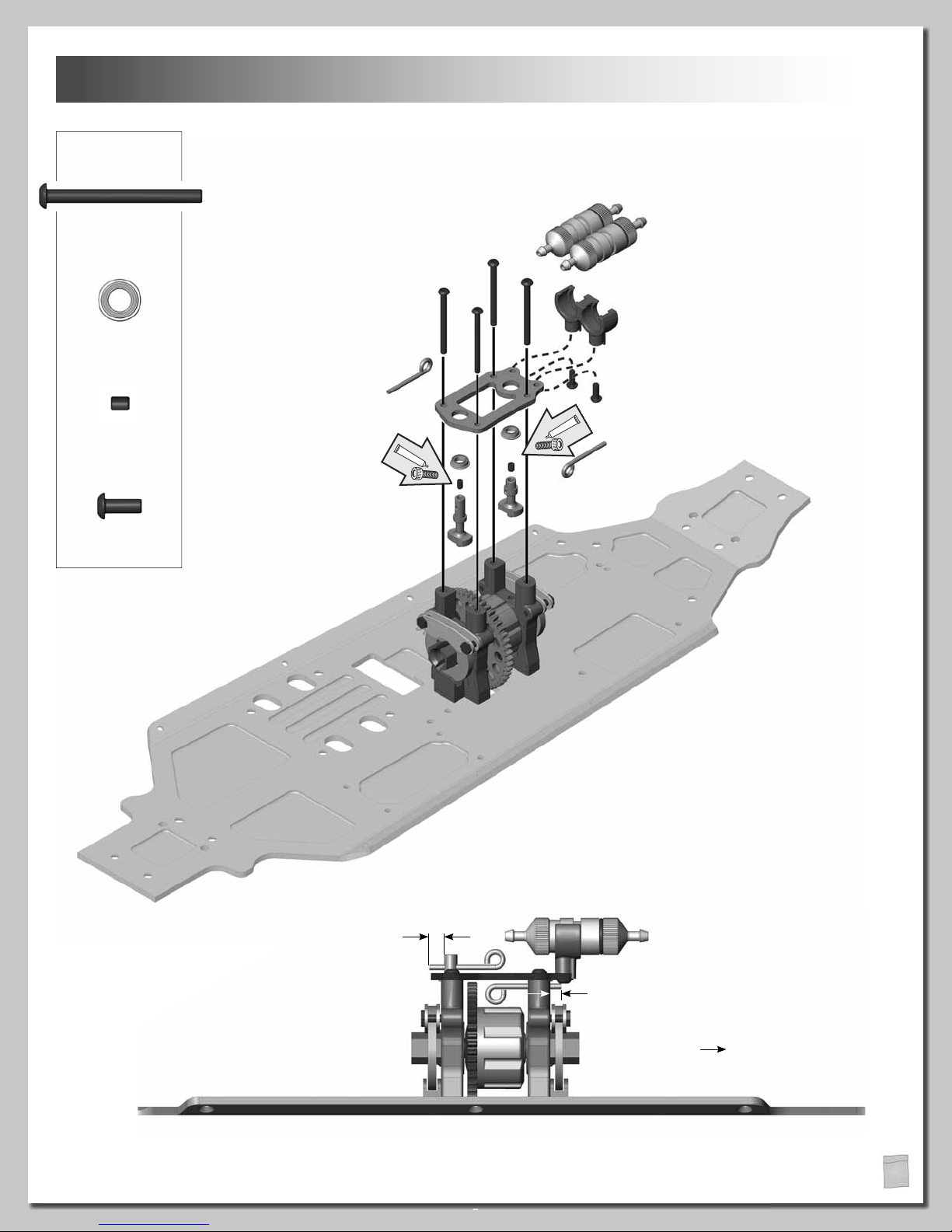

6

HARDWARE

(x4)

Brake Pad Bolt

16.75mm

IMPORTANT!

Brake pad bolt adjustment

must be correct and equal

front and rear.

MOUNT THE CENTER DIFF

Large

Front

Small

Line up brake disc notch.

2

8

7

IMPORTANT!

IMPORTANT!

T

h

re

a

d

lo

c

k

T

h

r

e

a

d

l

o

c

k

HARDWARE

3x35mm BH

Screw

5x8mm Flanged

Bearing

3x4mm Set

Screw

(x4)

(x2)

(x2)

3x35mm BH

BRAKE ACTUATOR & FUEL FILTER MOUNT

IMPORTANT!

Mount the fuel fi lter mount to the center

upper brace before installing the center

upper brace to the center diff mounts.

IMPORTANT!

Make sure the brake actuators move

freely in the mounts.

3x8mm BH

Screw

(x2)

The angled side of the brake

actuator faces the brake plate.

Short

Long

5.5mm

4.25mm

Front

2

9

8

IMPORTANT!

IMPORTANT!

T

h

re

a

d

lo

c

k

G

re

a

se

G

re

a

se

G

re

a

s

e

G

re

a

s

e

IMPORTANT!

HARDWARE

REAR DIFF JOINT

3x14mm FH

4x14mm FH

(x2)

Screw

(x2)

8x16mm Bearing

(x1)

5x5mm Set

Screw

(x2)

Pinion Shaft Shim

(x2)

3x14mm FH

Screw

IMPORTANT!

Place a small amount of the included

black grease around the outside of the

bushing before installing.

4x14mm FH

Make sure the bearings are

fully seated in the case.

3

9

HARDWARE

IMPORTANT!

4x40mm FH

(x2)

Screw

Apply a 1/4" strip of the included

grease to three locations on the

ring gear.

(x2)

4x8mm Set Screw

(x2)

4x16mm BH Screw

Refer to the

setup sheets for

droop settings.

(x2)

Silver (Thick)

Diff Shim

(x2)

Gold (Thin)

Diff Shim

Left

10

REAR DIFF HOUSING

4x8mm SS

Right

G

re

a

se

4x14mm BH

4x14mm BH

IMPORTANT!

Use the included shims to space gears properly

in the diff case. Adjust the gear mesh for smooth

rotation without excessive play. The number of

shims needed, and the side on which they must

be placed, may vary.

4x40mm FH

4x40mm FH

3

10

T

h

r

e

a

d

lo

c

k

HARDWARE

4x14mm FH Screw

REAR SHOCK TOWER

3x14mm FH

(x2)

3x14mm FH Screw

3x14mm BH Screw

11

(x4)

4x14mm FH

3x14mm BH

(x2)

3

REAR OUTDRIVES

HARDWARE

Wheel Hub Pin

8x16mm Bearing

5x5mm Set Screw

O-Ring

(x2)

(x4)

(x2)

(x2)

Make sure the bearings are

fully seated in the hub.

Secure the axle pin in the drive

hub using the 5mm set screw.

Place the O-ring in the

groove after installing

the wheel hub pin.

3

11

Loading...

Loading...