Page 1

1

ENGINE

E N G I N E

Page 2

2

TABLE OF CONTENTS

Thank you for purchasing the O’Donnell SS .21 engine. Many years

of engine expertise were used to develop an engine with maximum

performance and reliability. This engine was manufactured using the

highest quality standards, materials and manufacturing processes.

When properly used and maintained, it will perform at the highest

level of racing. Carefully read through the entire instruction manual

before starting your SS .21 engine.

Safety Precautions .......................... 3

Important Information ...................... 4

Fuel ................................................. 5

Fuel Tubing ...................................... 5

Fuel Filter ........................................ 5

Air Filter ........................................... 6

Glow Plug ........................................ 6

Tuned Pipe ...................................... 7

Carburetor Restrictors ..................... 7

High Speed Needle ......................... 8

Low Speed Needle .......................... 8

Throttle Stop Screw ......................... 8

Factory Carburetor Settings ............ 8

Priming the Engine .......................... 9

Engine Break-In ............................ 10

Engine Maintenance ..................... 12

Page 3

3

SAFETY PRECAUTIONS

• Model engine fuel is poisonous. Make sure you read and follow all

of the precautions on the fuel container.

• Keep fuel out of the reach of children.

• Model engine fuel is fl ammable and when ignited has a fl ame

that is diffi cult to see. Avoid sparks, fl ames, smoking or any other

ignition source when fuel is near.

• The engine emits harmful fumes just like a real vehicle. Do not

operate the engine indoors.

• The engine and its exhaust can become very hot during operation.

Avoid touching these parts during use and until they have cooled

down completely.

• The engine and exhaust produce quite a bit of noise. Do not run

your vehicle when or where it can disturb others.

• Avoid running the engine in cold weather. Running the engine in cold

weather can result in premature wear and poor performance.

Page 4

4

IMPORTANT INFORMATION

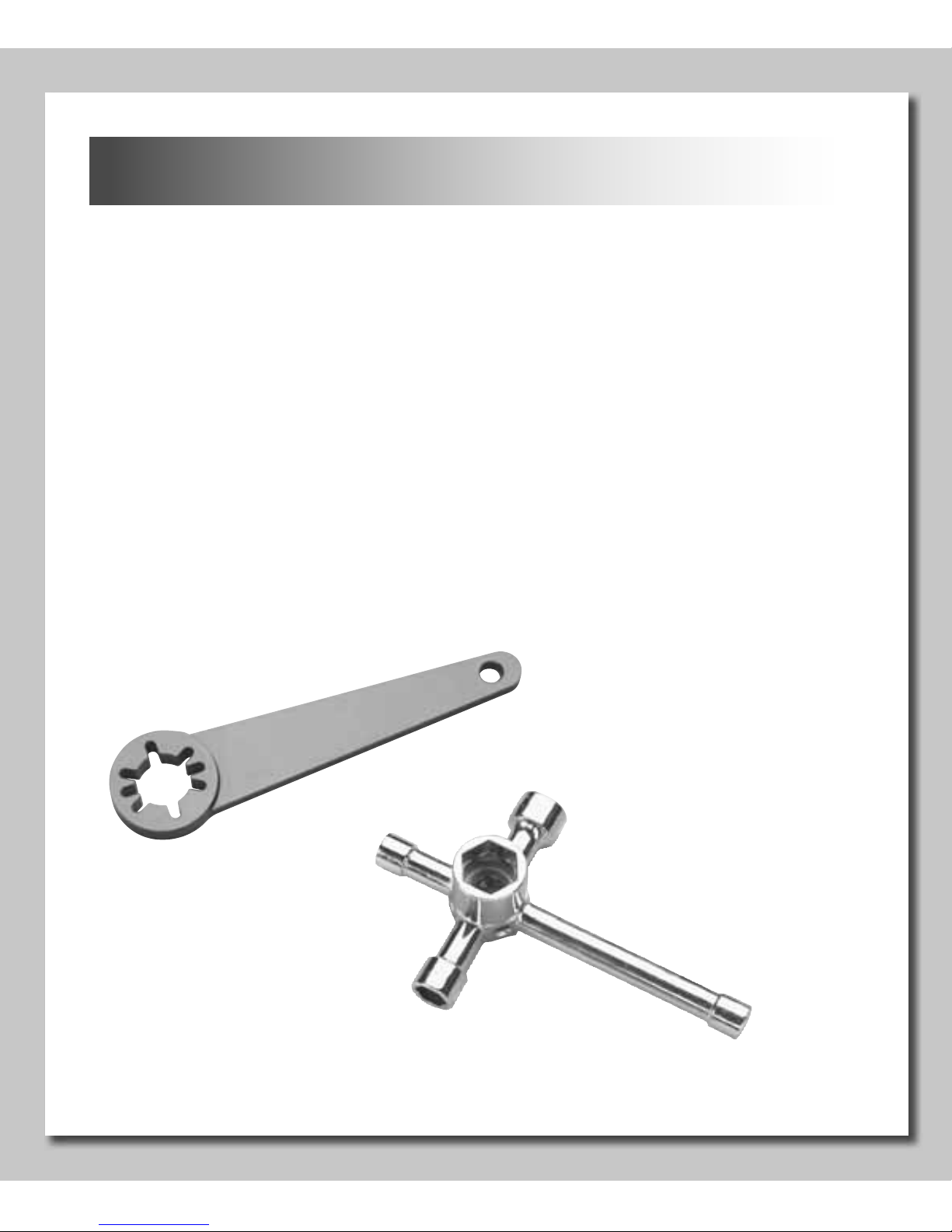

• Make sure you properly tighten the fl ywheel/collet onto the engine.

We recommend using a fl ywheel wrench and a 10mm socket. DO

NOT put something in the exhaust to prevent the engine from

turning over.

• Make sure you keep your vehicles fuel tank free of dirt and debris.

• Make sure your vehicle’s clutch is in good working order before

installing it onto the SS .21. Periodically check your clutch to

ensure optimal performance.

Page 5

5

FUEL

• We recommend O’Donnell 20% or 30%

racing fuel be used whenever possible. If

at any time during the life of the engine

you change fuel, either the percentage of

nitromethane or brand, we recommend

that you set the carburetor needles back to

the stock settings to help prevent possible

damage or premature engine wear.

• Whenever possible, do not allow the fuel

container to sit in direct sunlight or opened.

Always close the container promptly after

each use. Do not store on a concrete fl oor.

Doing so will decrease the quality of the

fuel and could cause the engine to perform poorly.

• We recommend that you install new fuel tubing on your vehicle

before installing the SS .21. This will help prevent problems related

to old or torn fuel tubing.

• We highly recommend a quality fuel fi lter be used between the

vehicle’s fuel tank and the SS carburetor. This will help keep out

dirt and debris that could be detrimental to the life of the engine.

Page 6

6

AIR FILTER & GLOW PLUGS

• It is very important that you use a quality air fi lter like the O’Donnell

ODOC1525 air fi lter. It is also just as important that you properly

maintain it. Using an air fi lter that is overly dirty, torn, improperly

oiled or worn out could allow dirt to be ingested, which will cause

premature wear and failure. We recommend that you clean and

re-oil your air fi lter regularly and always use a quality air fi lter oil.

• The SS .21 comes with an O’Donnell 97T glow plug. After

extensive testing, Steve O’Donnell has found that this plug gives

you maximum performance and superb durability.

• We recommend that you always keep a spare

O’Donnell 97T (ODOG0497) on hand so that you

can replace the plug when needed. You can check

your glow plug by pulling it out of the engine and

install it onto a charged glow starter. If the glow

plug glows bright orange it should still be good. If

it does not glow it is time to replace the plug. You can also check to

make sure that the coils are not distorted. If the coils are distorted,

replace the plug.

• Important: If you change plug types or brands, you will have to

re-tune your engine.

Page 7

7

TUNED PIPE

CARB RESTRICTORS

• The SS .21 comes with a 7mm restrictor installed in

the carburetor.

• For increased performance, install the included 8mm

restrictor. The engine will need to be re-tuned after

changing the carburetor restrictor (richer mixture).

After extensive testing Steve O’Donnell has

developed the R2 tuned pipe for the SS .21. The

R2 tuned pipe helps the engine achieve maximum

performance, with a smooth, broad power band.

ODOG8000

Page 8

8

NEEDLE SETTINGS

The high speed needle (A) controls the

amount of fuel entering the engine when

the carburetor is fully open. Turning the

high speed needle counterclockwise

(richer) allows more fuel to enter the

engine. Turning the high speed needle

clockwise (leaner) allows less fuel to

enter the engine.

The low speed needle (B) controls the amount of fuel entering

the engine during idle to the mid range. The low speed needle

affects your low end power. Turning the low speed needle

counterclockwise (richer) allows more fuel to enter the engine

and turning the low speed needle clockwise (leaner) allows less

fuel to enter the engine.

The throttle stop screw (C) adjusts the idle of the engine. Turning

the stop screw clockwise will increase the idle. Turning the stop

screw counterclockwise will lower the idle. Setting the idle too high

can cause damage to the clutch. Setting the idle too low can cause

the engine to stall frequently.

The factory needle settings for the SS .21 are:

High Speed: 2-1/2 turns out

Low Speed: 1-1/2 turns out

Page 9

9

PRIMING THE ENGINE

We recommend that you prime your engine before starting it. While

holding the throttle open, place your fi nger over the muffl er outlet

on the tuned pipe and turn the engine over using a starter box for

3–5 seconds or until fuel reaches the carburetor. DO NOT install

your glow starter during priming. Turn your transmitter and receiver

on, install your glow starter and then start your engine. Do not hold

the throttle wide open while starting, use only 1/4-throttle. Allow the

engine to idle for 10–15 seconds before increasing the throttle. If

the engine does not start within 8–10 seconds, remove the glow

plug and check that it and your glow ignitor are working properly.

Note: If you are having problems tuning your engine, we recommend

that you return the needles to the factory settings and make small

tuning adjustments until you achieve the optimal settings for the

particular conditions.

To reset the needles to factory settings, gently close (clockwise) the

needles. Then open (counterclockwise) the needles the designated

number of turns.

Important: Make sure when closing the needles you do not

overtighten. Overtightening the needles can cause damage to

the carburetor.

Page 10

10

ENGINE BREAK-IN

It is critical that you properly break-in your SS .21. Proper breakin will help ensure optimal fi t between critical engine components

and help prevent premature wear. Proper break-in will help obtain

maximum performance.

• It is recommended to NOT run the body on your vehicle during

break-in.

• DO NOT run the engine at full throttle until the break-in procedure

is complete and the needles are set for your current conditions.

• We DO NOT recommend that you idle your engine on a starter

box for break-in.

• Do not allow the engine to run out of fuel during break-in. This will

cause the engine to lean out possibly causeing engine damage.

• We highly recommend the use of a quality temperature gauge like

the O’Donnell TGX1 (ODOP0900) to monitor engine temperature.

The high and low speed needles are preset at the factory. The

factory needle settings are a safe (rich) starting point.

Find a large, fl at, open area to perform the break-in procedure.

Make sure you are in an area where you will not disturb others or

have to worry about traffi c.

When leaning the engine during break-in, only

make adjustments of 1-hour increments. This will

help prevent over leaning the engine during breakin and causing damage to your engine.

6

12

93

1 hour = 1/12 turn

Page 11

11

Tanks 1-4: Start the engine and run the vehicle approximately 100

feet back and forth or in a fi gure eight. Do not squeeze the throttle

more than 1/2-way. Every 4-6 passes check the engine temp

making sure that it does not go over 170° Fahrenheit. Continue this

procedure for the fi rst four tanks, making sure you do not allow the

engine to run out of fuel.

Tanks 5-6: Continue running the vehicle approximately 100 feet

back and forth. Now you can squeeze the throttle 3/4 of the way.

Continue to temp the engine every 4-6 passes, making sure that

the engine temperature does not go over 190° Fahrenheit. After

tank 6 you are ready to fi ne tune in your engine. After tank 6 allow

the engine to cool down. Then restart the engine.

Tanks 7-8: You can now run the vehicle approximately 150-200

feet, pulling the trigger to full throttle the last 50 feet of each pass.

Continue to temp the engine every 4-6 passes, making sure that

the engine temperature is close to 200° Fahrenheit but no more

than 210° Fahrenheit.

During tanks 7-8 bring the vehicle to a stop and allow it to idle for 10

seconds. Then pull full throttle for approximately 100 feet. Take note

of how much smoke comes out during acceleration. Optimum is a

small amount of smoke from stop to approximately 100 feet. Once

this is achieved do the same thing only go 150-200 feet. Continue

to check the engine temperature every 4-6 passes. The fi nal head

temp after break-in should be approximately 210° Fahrenheit.

After the 8th tank, your engine should be ready to race. Additional

tuning may be necessary at the track for optimal performance.

Page 12

12

ENGINE MAINTENANCE

To increase the life of your SS .21 it is critical that you properly

maintain your engine.

• Before each run check that your air fi lter is clean and properly oiled.

• Occasionally check your fuel fi lter and remove any dirt or debris

that may have accumulated.

• Keep the outside of your engine clean and do not allow large

amounts of dirt to accumulate on the engine. This can act as

an insulator and cause the engine to run excessively hot. It is

recommended to use a brush to remove most of the debris. If

using a spray cleaner, be careful not to allow dirt or debris to enter

the front bearing or carburetor.

• After each day of running, remove any excess fuel from the

vehicle’s fuel tank. Then start the engine and allow it to idle off any

fuel left in the fuel lines and carburetor. DO NOT give the engine

throttle input during this procedure.

• After each day of running make sure the fuel tubing is not

damaged or torn. If you fi nd any potential problems with the fuel

line, replace it before your next run.

• Properly maintain your clutch, replacing any worn out or

damaged parts.

• Warranty: This engine is warrantied against manufacturer defect for

90 days from the date of purchase. Due to the extreme conditions

of racing we are unable to extend any other type of warranty.

Page 13

13

CARB PARTS & VIEW

Carburator Assembly Complete ........................... ODOG6010

1 Carb Slide Ball Clamp ..........................................ODOG6025

2 Low Speed Needle w/O-Rings .............................ODOG6095

3 Low Speed Needle O-Ring...................................ODOG6105

4 Slide Valve ............................................................ODOG6024

5 Carb Slide Boot ....................................................ODOG6027

6 Carburetor Body ...................................................ODOG6010

7 Carburetor O-Ring ................................................ ODOG6105

8 Carburetor Drawbar w/O-Ring ..............................ODOG6020

9 Carburetor Spraybar w/O-Rings ...........................ODOG6030

10 Idle Screw w/O-Ring.............................................ODOG6090

11 High Speed Needle Housing w/Inlet & Seal .........ODOG6085

12 High Speed Needle w/O-Ring ..............................ODOG6086

13 Carburetor Restrictor Set ..................................... ODOG6023

14 Carburetor Restrictor O-Ring ............................... ODOG6105

Page 14

14

REPLACEMENT PARTS

20 Cylinder Head Screw 3.5 x 14mm (4) ..................ODOG6120

21 Cylinder Head ......................................................ODOG6056

22 Cylinder Head Button Turbo ................................. ODOG6061

22 Cylinder Head Button Standard ...........................ODOG6062

23 Cylinder Head Shim (2) ........................................ODOG6068

24 Cylinder Sleeve & Piston .....................................ODOG6071

25 Wrist Pin Set ........................................................ODOG6150

26 Connecting Rod ...................................................ODOG6032

27 Crankcase Assembly ............................................ODOG6041

28 Bearing Front 7 x 19 x 6mm .................................ODOG6001

29 Bearing Rear 14 x 25 x 6mm ...............................ODOG6005

30 Crankshaft SG ......................................................ODOG6051

31 Backplate w/O-Ring..............................................ODOG6115

32 Backplate Screw 2.5 x 8mm (4) ........................... ODOC6120

33 Exhaust Coupler ...................................................ODOG6078

34 Backplate O-Ring ................................................. ODOG6105

Page 15

15

EXPLODED VIEW

Page 16

Copyright © 2009 ODOG5010Mnl v1.1

WARRANTY & REPAIR SERVICE

O’Donnell will warrant this engine for 90 days after the purchase from

defects in materials or workmanship. O’Donnell will either repair or

replace, at no charge, the incorrectly made part. (Please note: O’Donnell

engines are manufactured to the highest standards using only the very

best materials. However, since this engine will be used in high level racing

conditions using high Nitro fuels, wear and tear and/or damage as a result

will not be covered under this warranty.)

Make sure you save the receipt or invoice you were given when you bought

your engine! It is your proof of purchase and we must see it before we can

honor the warranty.

Repair service is available anytime. You can have your engine repaired for a

small charge by the experts at O’Donnell’s authorized repair facility, Hobby

Services, at the address listed below. To speed up the repair process,

please do the following:

1. Under all circumstances, return the entire engine.

2. Send written instructions that include a thorough explanation

of the problem, the service needed and your phone number

during the day. (If you expect the the repair to be covered

under warranty, be sure to include proof of purchase.

3. Be sure to send your full return address

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, Illinois 61822

Attn: Service Department

(217) 398-0007

9:00 am-5:00 pm Central Time M-F

E-mail: hobbyservices@hobbico.com

www.hobbyservices.com

Loading...

Loading...