ODM TTK-720, VIS 300C-PM-02-V, DLS 355 User Manual

TTK 720

Wireless Industry Fiber Test Kit

User Guide

Introduction

The TTK 720 test kit is an all-in-one solution for performing ber inspection, insertion (dB) loss

testing, and red laser continuity testing. This kit has been specically designed to meet the needs of

technicians working in the wireless communications eld.

Kit Overview

Item Description

All-in-one test platform for ber scoping, dB loss testing, and red laser continuity testing. Includes

VIS 300C-PM-02-V

DLS 355 Dual laser source - outputs 1310 and 1550nm wavelengths for dB loss testing singlemode ber.

AC 029 LC adapter for OPM port on VIS 300C unit.

touchscreen monitor with customized software and high-denition inspection probe. Power meter and

VFL included.

AC 107B

AC 048B 1.25mm universal inspection adapter for VIS 300C probe.

AC 049B 2.5mm universal inspection adapter for VIS 300C probe.

AC 040B SC bulkhead inspection adapter for VIS 300C probe.

AC 044B LC bulkhead inspection adapter for VIS 300C probe.

AC 4500 Loopback module - single mode. Used to loop signal at tower top in order to test both bers in the pair.

AC 523

AC 602 LC duplex bulkhead. Used to connect AC 523 to trunk bottom.

AC 089 One-click cleaner for all 1.25mm ferrules. Dry-clean method.

AC 092 Fiber cleaning pad and pen for all exposed ferrules. Wet/Dry clean method.

AC 802 USB cable for data transfer to computer.

AC 015 Large hard carry case.

LC 60-degree bulkhead inspection adapter for VIS 300C probe. May be used to scope dicult bulkheads,

such as those in tower-top enclosures.

Loopback test jumper - plugs into DLS 355 and OPM port on VIS 300C unit in order to plug onto the

ber trunk pair at the tower bottom.

M-UM010-02 TTK 720 06/18

Page 2

Kit Overview

VIS 300C-PM-02-V*

*VFL , OPM, and Scope included

DLS 355

AC 4500

AC 602

AC 523

AC 044B

AC 048B

AC 049B

AC 107B

AC 040B

AC 092

M-UM010-02 TTK 720 06/18

AC 089

Page 3

Test Procedures Overview

The following section will provide an overview of the workow and recommended procedures for

each test that can be performed with the TTK 720 kit. Some procedures may have more importance

placed on them by the carrier: please use these procedures only as a guideline. Wireless carrier

requirements supersede ODM’s recommended procedures in all circumstances.

1

Proper Equipment Care Between Uses

This section explains how to properly maintain the TTK 720 test kit components between uses.

VIS 300C charging, equipment cleaning, and storage are discussed.

Creating a New Folder in VIS 300C Software

2

When arriving at a new test site or when starting a new project, the user should create a new “Project

Folder” on the VIS 300C unit. This stores all relevant site information (scope images, loss readings, etc.

in one place. This section covers setting up for a new test site.

Fiber Scoping

3

Fiber inspection should be performed before making any connections onsite. Analysis and saving of

images may be required for closeout packages. This section explains how to inspect and clean ber.

dB Loss Testing

4

Also known as “insertion loss” or “ber sweep” testing, dB loss testing allows the technician to validate

that all ber pairs are in working condition. Saving of dB loss test results may be required for closeout

packages. This section explains the necessary steps for testing ber.

VFL Testing

5

An onboard red laser allows users to verify proper continuity of ber cables. This is a troubleshooting

task only. This section gives an overview of the VFL functionality.

Creating and Sharing Reports

6

The VIS 300C has built-in report creation software. This section explains how to create reports for

closeout packages.

M-UM010-02 TTK 720 06/18

Page 4

1

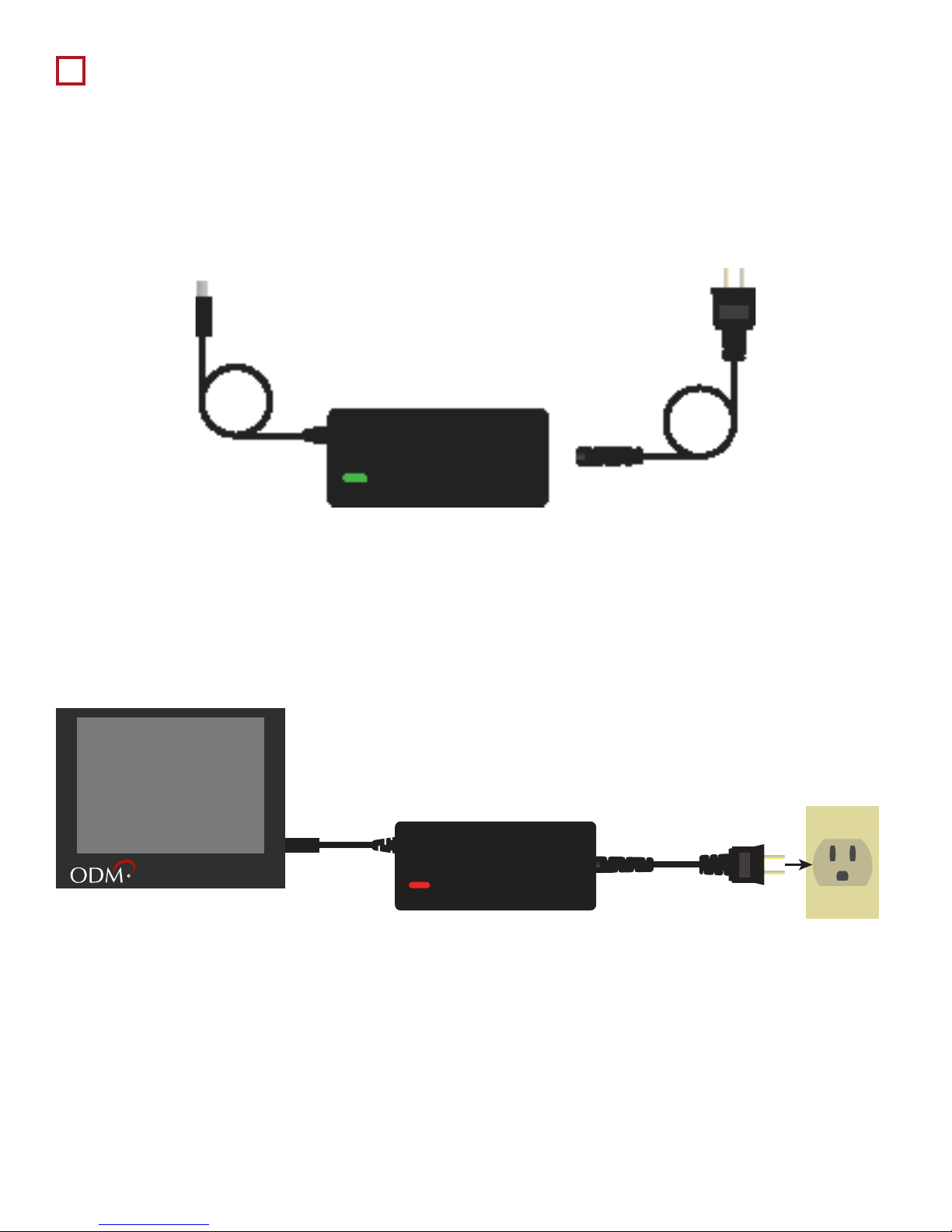

Wall Plug

Green when fully charged

Proper Equipment Care Between Uses

1a - Charging the VIS 300C

The VIS 300C charger comes in two pieces. See diagram below. The cable on the right will be

plugged into the power brick to create the charging device.

Allow the VIS 300C to charge fully between uses. The VIS 300C can be used while charging;

please be aware that an internal fan may activate to regulate temperature. 4-5 hours battery

life typical for a single charge.

VIS 300C

Light on Charger:

Red when charging

M-UM010-02 TTK 720 06/18

Page 5

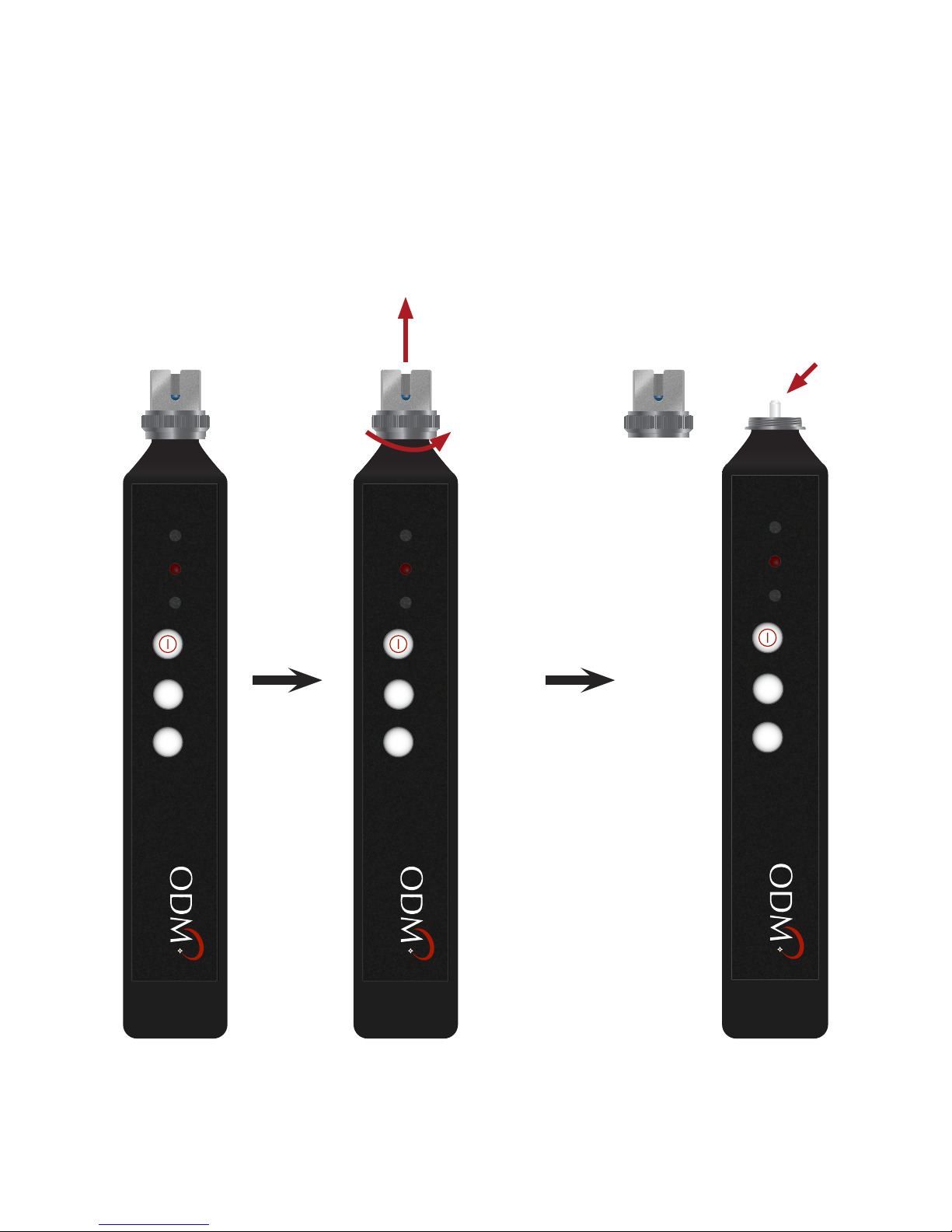

1b - Cleaning the DLS 355

The DLS 355 laser source is a high-end test laser, capable of outputting 1310 and 1550nm

wavelengths. The output port of this unit utilizes a physical connection, which means that it

can become soiled if used improperly. When needed, the DLS 355 adapter may be removed for

inspection and cleaning of the ber ferrule.

DLS 355 is stored with

adapter ON to protect

ferrule inside.

1310

1550

LOW

BAT

2kHz

1310

1550

Remove adapter by

unscrewing until it spins

freely, then pull o.

LOW

BAT

2kHz

Inspect ferrule with

VIS 300C and clean

with appropriate tools.

Always replace adapter.

1310

1550

LOW

BAT

2kHz

λ

DLS 355

Dual Laser

Source

Optical Design Manufacturing Inc.

www.odm-inc.com

λ

DLS 355

Dual Laser

Source

Optical Design Manufacturing Inc.

www.odm-inc.com

λ

DLS 355

Dual Laser

Source

Optical Design Manufacturing Inc.

www.odm-inc.com

Regular inspection and cleaning of the output port of the DLS 355 may not be necessary if

appropriate procedures are followed. Always inspect test jumpers before they are plugged into

the DLS 355 and store it properly to ensure continued performance.

M-UM010-02 TTK 720 06/18

Page 6

1c - Inspecting and Cleaning Fiber Jumpers and Loopback

Special care should be taken to ensure the continued function of all test jumpers and

loopbacks. A regular inspection and cleaning regimen will keep kit components functional for a

longer period of time.

AC 4500

1d - Equipment Storage

All equipment should be stored in the airtight case provided by ODM. Keep the case in a cool,

dry location and remove battery from the DLS 355 if it must be stored for over 6 weeks.

Each arrow in the diagram at left

indicates a ber ferrule that should be

inspected and cleaned between uses.

AC 523

M-UM010-02 TTK 720 06/18

Page 7

Creating a New Folder in VIS 300C Software

2

The VIS 300C platform saves all test information in a folder system onboard. The internal memory is

capable of saving thousands of images and power meter readings. Follow the steps below to create a

new folder when beginning a project.

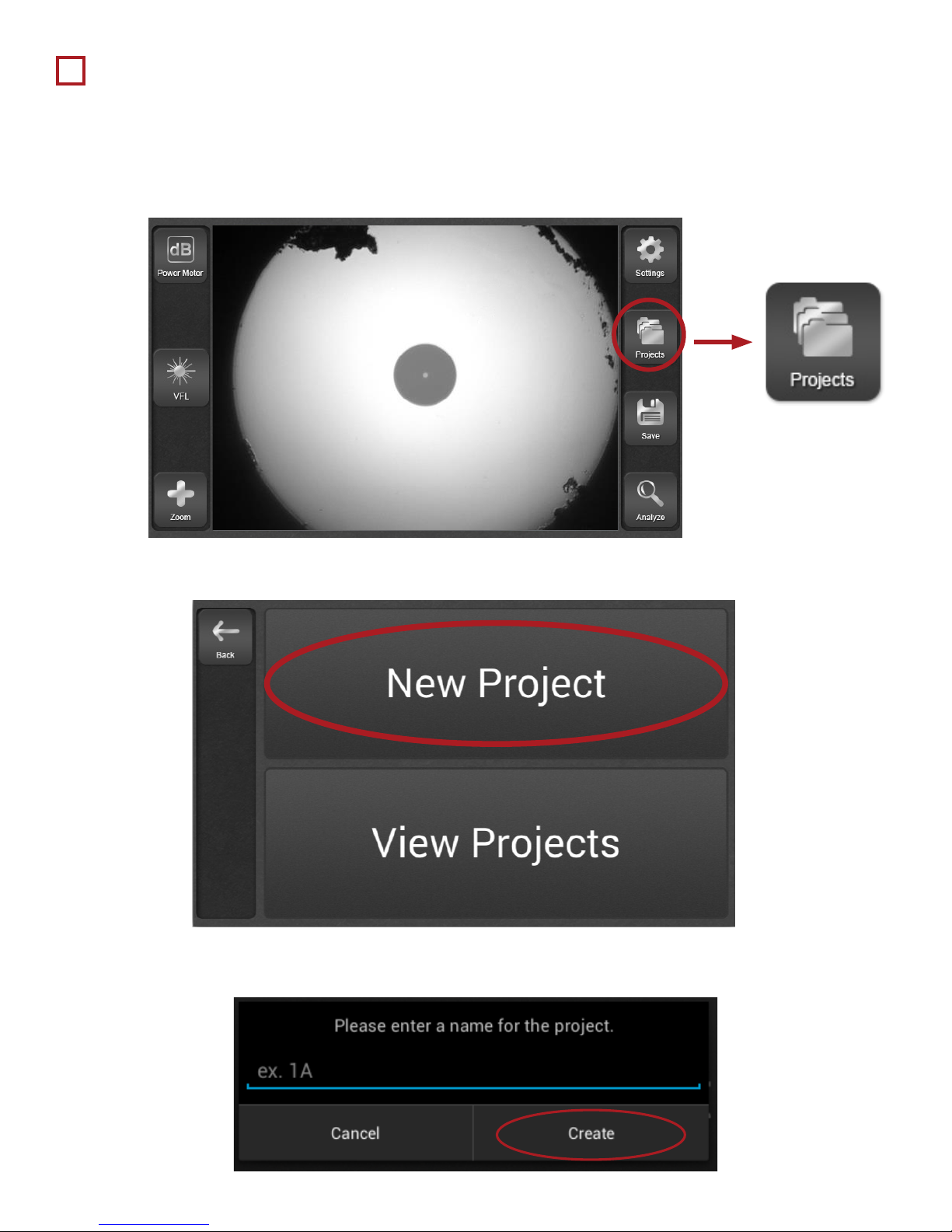

2a - Create a New Project

Touch

“Projects” Button

Main Inspection

Screen

Touch

“New Project”

Give the project a name using the onscreen keyboard. Touch “Create” to make the project folder.

Enter Project

Name

Touch

“Create”

M-UM010-02 TTK 720 06/18

Page 8

The next screen contains several text elds which help make the project unique. Fill out these elds

using the onscreen keyboard as appropriate, then touch “OK”. You’ll be taken back to the Main

Inspection Screen.

Enter all

Project Details

Touch

“OK”

2b - Change Project Information

If you ever need to change this information, touch “Projects” on the main screen of the unit,

then touch “View Projects,” then choose the appropriate project name. The screen shown below

will appear. Touch the settings icon in the top right of the window to make changes to this

information.

Touch

Settings Icon

M-UM010-02 TTK 720 06/18

Page 9

Loading...

Loading...