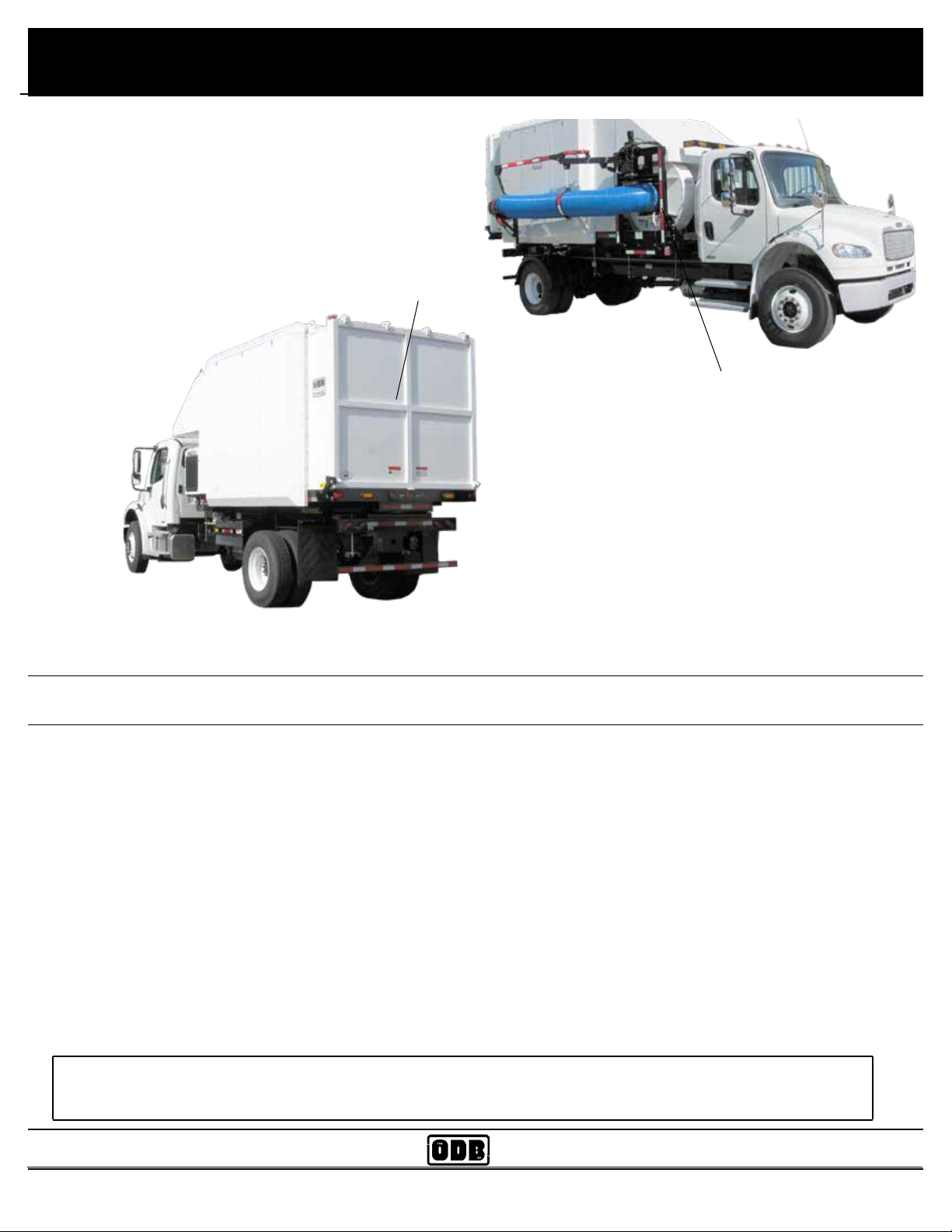

SCL800SM-3X

SCL800SM-3X

Automated Self Contained

Automated Self Contained

Leaf Collector

Leaf Collector

Pre-Operating Manual

Operating Manual

Maintenance Manual

2018 Diesel Edition

ODB Company

5118 Glen Alden Drive

Richmond, VA 23231

800-446-9823

www.leafcollector.com

Owner's Manual

Safety Manual

Service Manual

Parts Catalog

Front Cover

816210

DO NOT ATTEMPT TO OPERATE

OR REPAIR

THE LEAF COLLECTOR WITHOUT FIRST

READING AND UNDERSTANDING THIS

MANUAL

IF YOU HAVE ANY QUESTIONS CONCERNING THE

INSTALLATION OR OPERATION OF THIS UNIT, PLEASE CALL

ODB FOR ASSISTANCE BEFORE ATTEMPTING TO REPAIR OR

OPERATE THE UNIT.

IMPROPER USE OF ANY MACHINE CAN

RESULT IN SERIOUS INJURY!

STUDY AND FOLLOW ALL SAFETY

PRECAUTIONS BEFORE OPERATING OR

REPAIRING UNIT

THIS MANUAL IS AN INTEGRAL PART OF THE LEAF COLLECTOR AND SHOULD

BE KEPT WITH THE UNIT WHEN IT IS SOLD.

ODB COMPANY

5118 Glen Alden Drive

Richmond, VA 23231

800-446-9823

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Safety Section

If the decal above is missing or damaged call ODB immediately and we will send you a replacement free of

charge. Never operate a unit with damaged or missing safety decals.

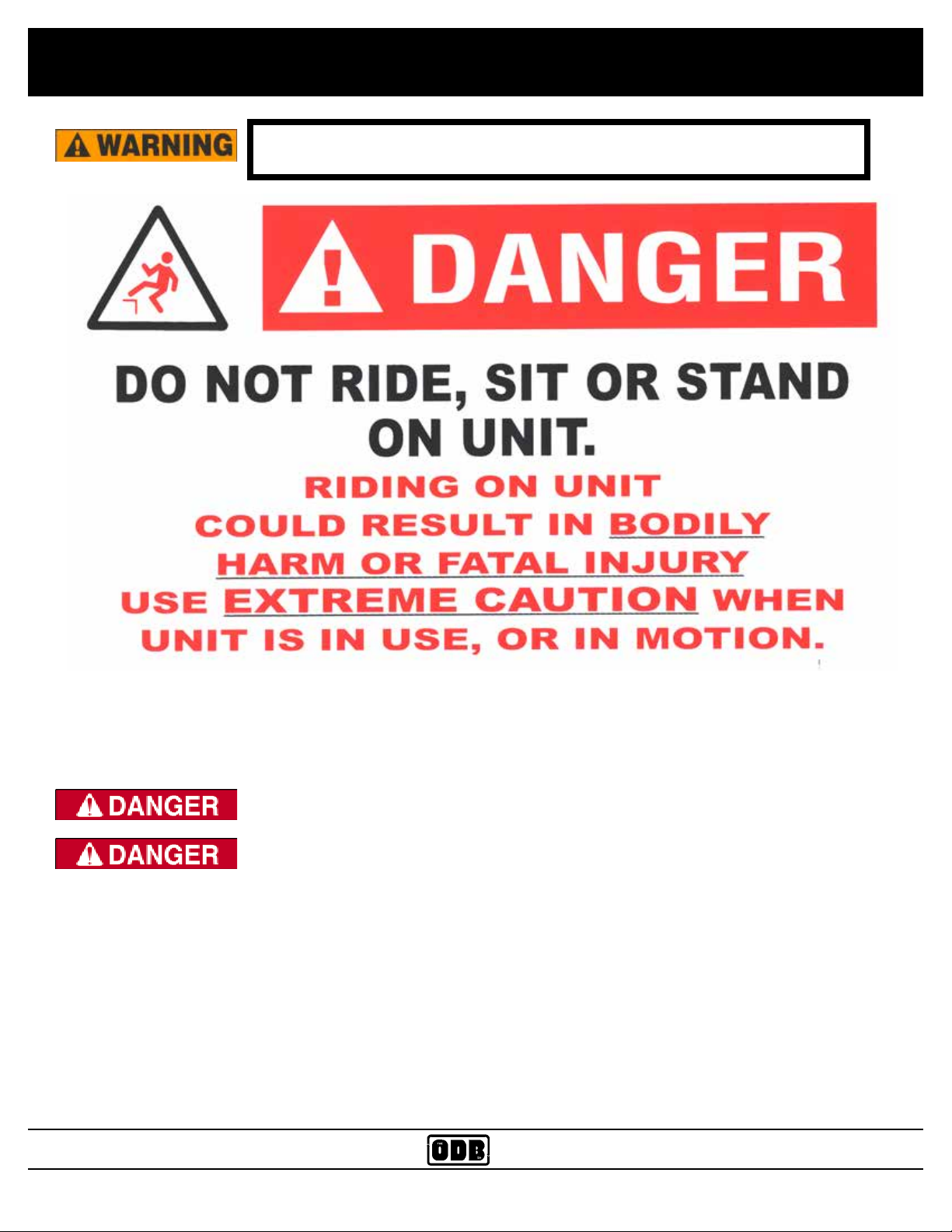

DO NOT RIDE, SIT OR STAND ON UNIT

DO NOT MODIFY THE UNIT FOR RIDERS IN ANY

WAY. SERIOUS INJURY OR DEATH MAY OCCUR

ODB’s leaf collectors are NEVER to be used to accommodate riders. If your unit has been modied

to accommodate riders, remove these modications immediately as this can result in serious injury or

death.

ODB COMPANY

800-446-9823 SCL800SM3X

3

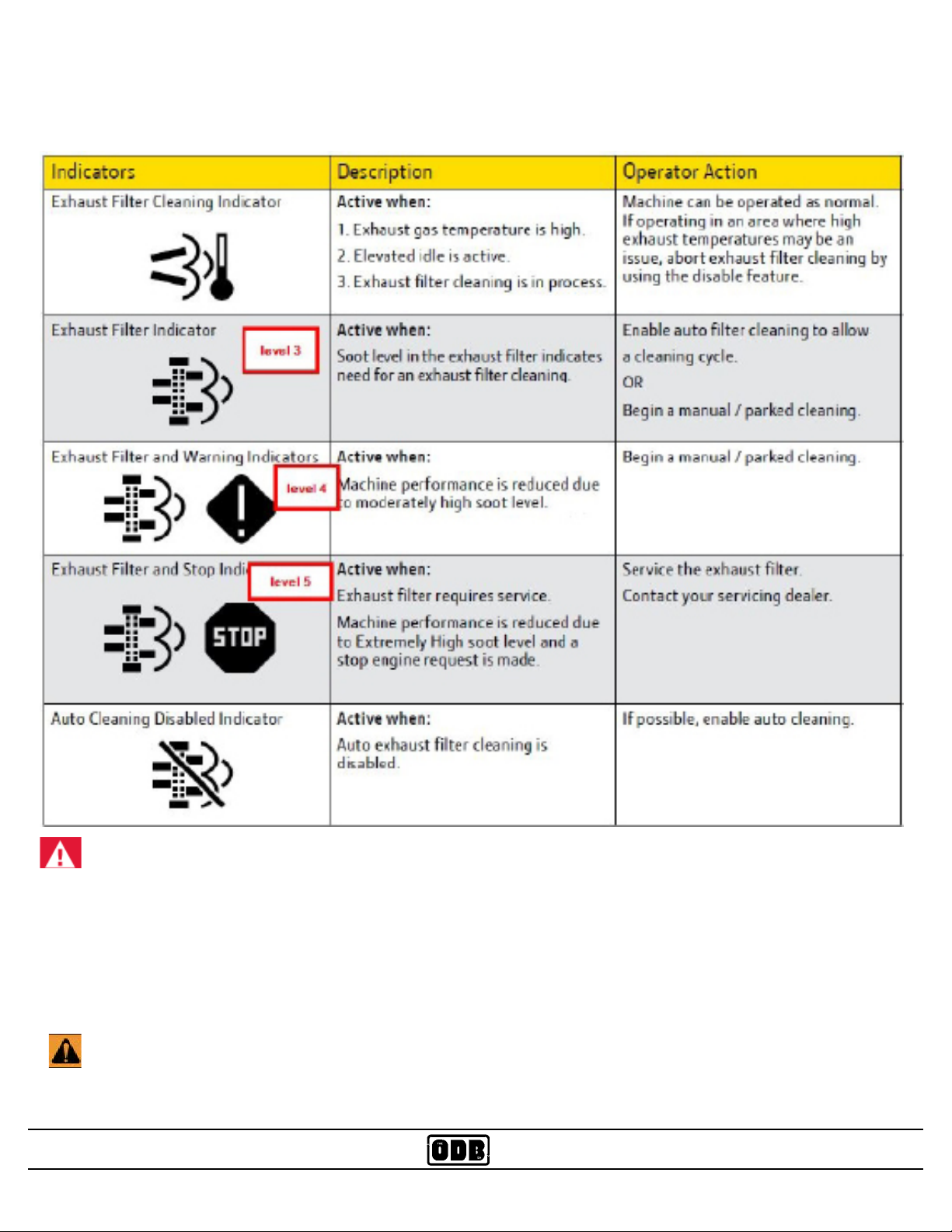

DIESEL REGEN CHART

WHEN THE UNIT IS UNDERGOING REGEN, WHETHER IT BE AUTOMATIC OR MANUAL, DO

NOT TURN THE MACHINE OFF! THIS IS HIGHLY DETRIMENTAL TO THE UNIT. ALLOW IT TO

FINISH ITS PROCCESSES.

IF YOU NEED TO STOP THE CLEANING, USE THE INHIBIT BUTTON TO STOP THE REGEN

PROCCESS AND MOVE TO A SAFE AREA TO RESUME

IF YOU HAVE A 74HP OR BELOW: THERE WILL BE A "LOW DEF FLUID" ICON ON THE SCREEN, THIS IS

NORMAL.

75HP AND ABOVE: THE SCREEN CAN MONITOR YOUR DEF LEVELS AND NOTIFY YOU WHEN IT IS BELOW

OPTIMAL LEVELS

ODB COMPANY

800-446-9823 SCL800SM3X

4

Municipal Products

Municipal Products

Since 1910

ODB COMPANY

5118 Glen Alden Drive

Richmond, VA 23231

800-446-9823

www.odbco.com or

www.leafcollector.com

Since 1910

THANK YOU

Thank you and Congratulations on your purchase of your ODB Leaf Collector. Your ODB leaf collector has been carefully designed and manufactured to give you a maximum amount of dependability and years of trouble-free operation. Take comfort in the fact the ODB has been manufacturing

municipal products since 1910 and takes pride in our product's quality and our customer service.

Please take the time to thoroughly read this manual, as well as the engine manual, in its entirety before operating, maintaining, servicing or repairing your leaf collector. Please thoroughly review and

follow all the safety procedures located in this manual.

Whenever you need replacement parts, service information or any question regarding your ODB

product please feel free to contact us at 800-446-9823 or www.odbco.com.

Please record the following information for future reference:

Model No.:

Serial No.:

Vin No:

Engine Serial No.:

Date of Purchase:

ODB COMPANY

800-446-9823 SCL800SM3X

5

Table of Contents

TABLE OF CONTENTS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Table of Contents

Contents

Front Cover ...................................................................................................................................................1

Table of Contents ..........................................................................................................................................5

1.0 GENERAL SAFETY

1.1 Safety Symbol Denitions .................................................................................................................... 11

1.2 Do’s and Do Not’s:.................................................................................................................................12

1.3 Training: .................................................................................................................................................14

1.4 Safety Decals ......................................................................................................................................15

1.5 Serial Number Location ......................................................................................................................... 17

2.0 PRE-OPERATING SECTION

2.1 IQAN Display System and Controls - Overview ................................................................................... 19

2.1 IQAN Display System and Controls - Overview ................................................................................... 20

2.1 IQAN Display System and Controls - Overview ................................................................................... 21

2.2 Joystick Controls: ..................................................................................................................................22

2.2 Safe Operations: ..................................................................................................................................... 23

2.3 Preparation For Operation ......................................................................................................................25

2.4 Pre-Transport Checks .............................................................................................................................26

2.5 Personal Protective Equipment and Clothing ........................................................................................27

2.6 Work Site Preparation ............................................................................................................................28

3.0 OPERATING SECTION

3.1 Starting Engine .......................................................................................................................................30

3.1 Starting Engine, continued; .................................................................................................................... 31

3.2 Engaging the Standard PTO ................................................................................................................... 32

3.3 Fluid Drive Coupler (if equipped) .........................................................................................................33

3.4 Hose Boom Operation - 3 Axis .............................................................................................................. 34

3.4 Hose Boom Operation - 3 Axis, cont. .................................................................................................... 35

3.4 Hose Boom Operation - 3 Axis, cont. .................................................................................................... 36

3.4 Hose Boom Operation - 3 Axis, cont. .................................................................................................... 37

3.5 Dumping the Body ................................................................................................................................. 38

3.5 Dumping the Body, continued ...............................................................................................................39

3.5 Dumping the Body, continued ...............................................................................................................40

4.0 MAINTENANCE SECTION

4.1 Maintenance Overview: ......................................................................................................................... 42

4.2 Maintenance and Lubrication ...............................................................................................................43

4.3 Lubrication: ............................................................................................................................................ 44

4.3 Lubrication, continued; ......................................................................................................................... 45

4.3 Lubrication, continued; ......................................................................................................................... 46

4.3 Lubrication, continued; ......................................................................................................................... 47

4.4 Preventative Maintenance ...................................................................................................................... 48

4.5 Torque Values ........................................................................................................................................ 53

4.6 Quick Reference Chart ........................................................................................................................... 54

4.7 Kraft Fluid Drive Maintenance (Optional) ............................................................................................55

ODB COMPANY

800-446-9823 SCL800SM3X

6

TABLE OF CONTENTS

Table of Contents

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

5.0 SERVICE SECTION

5.1 Removing Blower Housing Face ................................................................................................................ 59

5.2 Replacing the Drive Belt (if equipped) ....................................................................................................... 60

5.2 Replacing the Drive Belt (if equipped), ..................................................................................................... 61

5.3 Replacing the Drive Bearings(if equipped) ................................................................................................ 62

5.3 Replacing the Drive Belt (if equipped), ..................................................................................................... 63

5.3 Replacing the Drive Bearings (if equipped), continued .............................................................................. 64

5.4 Impeller Installation and Removal .............................................................................................................. 65

5.4 Impeller Installation and Removal, continued ............................................................................................ 66

5.5 Replacing the Blower Housing Liners ........................................................................................................ 67

5.5 Replacing the Blower Housing Liners; continued, ..................................................................................... 68

5.6 Auto Mfg. Clutch Adjustment - 2008 and after .......................................................................................... 69

5.20 HYDRAULIC DIAGRAM

5.20.1 Hoist Hydraulic Diagram ....................................................................................................................... 71

5.20.2 Valve Body Hydraulic Diagram ............................................................................................................. 72

5.30 IQAN ADVANCED SCREENS

5.30.1 Adjust Menu ........................................................................................................................................... 74

5.30.1 Adjust Menu ........................................................................................................................................... 75

5.30.2 Measure Menu ....................................................................................................................................... 76

5.30.2 Measure Menu ....................................................................................................................................... 77

5.30.3 Preferences Menu ................................................................................................................................... 78

5.30.4 Info Menu ............................................................................................................................................... 79

5.30.4 Info Menu ............................................................................................................................................... 79

5.30.4 Info Menu, continued ............................................................................................................................. 80

5.30.5 IQAN Error Codes ................................................................................................................................. 81

5.30.5 IQAN Error Codes, continued ............................................................................................................... 82

5.30.5 IQAN Error Codes, continued ............................................................................................................... 83

5.30.5 IQAN Error Codes, continued ............................................................................................................... 84

5.40 WIRING DIAGRAMS

5.40.1 Wiring Harness Overview Diagram ....................................................................................................... 86

5.40.2 Engine Wiring Harness Diagram ........................................................................................................... 87

5.40.3 Valve Body Wiring Harness Diagram .................................................................................................... 88

5.40.4 XA2 and XS2 Module Wiring Harness Diagram .................................................................................. 89

5.40.5 Engine Side Rail Wiring Harness Diagram ........................................................................................... 90

5.40.6 IQAN MD3 Display Wiring Harness Diagram ...................................................................................... 91

5.40.7 IQAN E-Stop,Relay,Joystick & Door Lock Diagrams .......................................................................... 92

5.40.8 IQAN Power Switch and E-Stop Wiring Diagrams ............................................................................... 93

6.0 ENGINE GROUP

6-0 ..................................................................................................................................................................... 95

6.1 Air Cleaner Group ....................................................................................................................................... 96

6.2 Sheet Metal Group, SCL 3X ....................................................................................................................... 97

6.3 Engine Mount Group .................................................................................................................................. 98

ODB COMPANY

800-446-9823 SCL800SM3X

7

TABLE OF CONTENTS

Table of Contents

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

6.4 Mufer (Exhaust) Assembly ......................................................................................................................... 99

6.5 Radiator Assembly Group ........................................................................................................................... 100

6.6 Engine Senders / Switch Group ................................................................................................................. 101

6.7 Battery Group .............................................................................................................................................. 102

6.8 Engine Miscellaneous Parts Group ............................................................................................................. 103

6.9 John Deere Common Engine Parts Group .................................................................................................. 104

6.10 Remote Clutch / Throttle Circuit Board Assembly ................................................................................... 105

6.11 Remote Clutch and Remote Throttle Assembly ........................................................................................ 106

6.12 Chaffe Eliminator Assembly, hinged ........................................................................................................107

7.0 CLUTCH GROUP

7-0 ..................................................................................................................................................................... 108

7.1 AutoHD PTO Clutch Group ........................................................................................................................ 109

7.2 AutoHD PTO Assembly Group .................................................................................................................. 110

7.3 AutoHD PTO Linkage Group ..................................................................................................................... 111

7.4 Clutch Assist Group .................................................................................................................................... 112

7.5 Kraft Fluid Drive Group (Optional) ............................................................................................................ 113

7.6 Kraft Fluid Drive Installation (Optional) .................................................................................................... 114

7.7 Kraft Fluid Drive Breakdown (Optional) ................................................................................................... 115

7.8 Kraft Fluid Drive Common Parts (Optional) .............................................................................................. 116

8.0 BLOWER HOUSING GROUP

8-0 ..................................................................................................................................................................... 117

8.1 Blower Housing Face Group ...................................................................................................................... 118

8.2 Belt Drive Assembly ................................................................................................................................... 119

8.3 Blower Housing Group - Belt Drive ........................................................................................................... 120

9.0 Hydraulic Group

9-0 ..................................................................................................................................................................... 121

9.1 Hydraulic Tank Assembly - 3X ................................................................................................................... 122

9.2 Valve Body Group ....................................................................................................................................... 123

9.3 Valve Body Mounting Group ...................................................................................................................... 124

10.0 Chassis and Hopper Group

10-0 ................................................................................................................................................................... 125

10.1 Fuel Tank Group ....................................................................................................................................... 126

10.2 Box Container Screens .............................................................................................................................. 127

10.3 Chassis Group ........................................................................................................................................... 128

10.4 Light and Reector Group ........................................................................................................................ 129

10.5 Box Interior Group .................................................................................................................................... 130

10.6 Automated Door Latch Group .................................................................................................................. 131

10.7 Manual Top Hinged Door (Optional) ........................................................................................................ 132

10.8 Bottom Exhaust Group (Optional) ............................................................................................................ 133

10.9 Hood Scoop Group (Optional) .................................................................................................................. 134

10.10 Chipper Door Group (Optional) .............................................................................................................. 135

ODB COMPANY

800-446-9823 SCL800SM3X

8

TABLE OF CONTENTS

Table of Contents

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

10.11 Light Bar Group (Optional) ....................................................................................................................136

10.12 Backup Camera Group (Optional) .......................................................................................................... 137

10.13 Rear Chipper Hitch Package (Optional) .................................................................................................138

11.0 HOSE BOOM GROUP

11-0 ...................................................................................................................................................................139

11.1 Boom Assembly, 3 Axis ............................................................................................................................ 140

11.2 Hinged Boom Frame Assembly - 3 Axis ..................................................................................................141

11.3 Auburn Gear Drive Assembly - 3 Axis .....................................................................................................142

11.4 In-Cab Controls Mount - 3 Axis ...............................................................................................................143

INDEX

Index .................................................................................................................................................................145

ODB COMPANY

800-446-9823 SCL800SM3X

9

SAFETY PRECAUTIONS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Safety Section

GENERAL

SAFETY

1.0

1.0 GENERAL SAFETY

Contents

Front Cover ....................................................................................................... 1

Table of Contents .............................................................................................. 5

1.0 GENERAL SAFETY

1.1 Safety Symbol Denitions .........................................................................11

1.2 Do’s and Do Not’s:..................................................................................... 12

1.3 Training: ..................................................................................................... 14

1.4 Safety Decals .......................................................................................... 15

1.5 Serial Number Location ............................................................................. 17

ODB COMPANY

800-446-9823 SCL800SM3X

10

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Safety Section

If the decal above is missing or damaged call ODB immediately and we will send you a replacement free of

charge. Never operate a unit with damaged or missing safety decals.

DO NOT RIDE, SIT OR STAND ON UNIT

DO NOT MODIFY THE UNIT FOR RIDERS IN ANY

WAY. SERIOUS INJURY OR DEATH MAY OCCUR

ODB’s leaf collectors are NEVER to be used to accommodate riders. If your unit has been modied

to accommodate riders, remove these modications immediately as this can result in serious injury or

death.

ODB COMPANY

800-446-9823 SCL800SM3X

11

SAFETY PRECAUTIONS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Safety Section

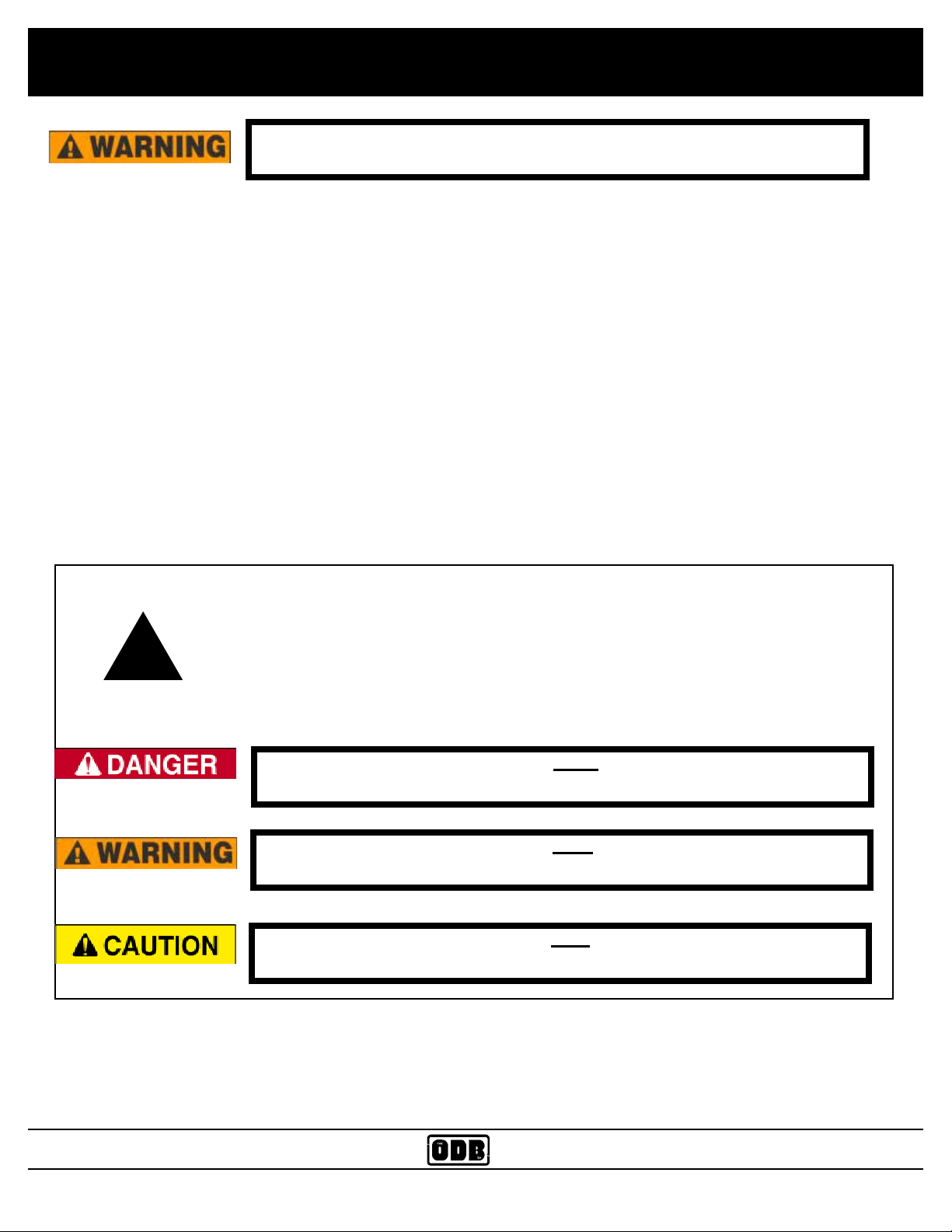

1.1 Safety Symbol Denitions

This manual provides the owners/operator with procedures for safe operation, maintenance and repair of your leaf collector. As with any machine,

there are hazards associated with their operation. For this reason safety is

emphasized throughout this manual. To highlight specic safety information

the following safety denitions are provided to assist the reader.

The purpose of safety symbols are to attract your attention to possible

dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not by themselves

eliminate any danger. The instructions or warnings they give are not substitutues for proper accident prevention measures.

SYMBOL

!

MEANING

SAFETY ALERT SYMBOL:

tention is required in order to avoid serious personal injury. May be used in

conjunction with other symbols or pictographs.

Disregarding this safety warning WILL result in serious equipment

damage, injury or possible death.

Disregarding this safety warning CAN result in serious equipment

damage, injury or possible death.

Disregarding this safety warning MAY result in minor or moderate

injury or property damage.

Indicates danger, warning or caution. At-

ODB COMPANY

800-446-9823 SCL800SM3X

12

SAFETY PRECAUTIONS

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Safety Section

1.2 Do’s and Do Not’s:

This section contains some general safety precautions to do and not to do.

This is not an all inclusive list and and it is the responsibilty of the operator to

have proper training and use common sense in work situations.

DO NOT:

1. DO NOT operate, maintain or repair this unit without having fully read

and understood ALL the aspects of this manual.

2. DO NOT ride, sit or stand on unit at anytime.

3. DO NOT modify the leaf vacuum for any reasons to allow for riders.

4. DO NOT operate the unit in a state of disrepair.

5. DO NOT operate the unit with ANY guards or safety devices broken,

missing, or inoperable.

6. DO NOT operate the unit without wearing proper safety equipment.

7. DO NOT operate this unit while under the inuence of any alcohol or

medication.

8. DO NOT operate this unit if you have a record of mental instability or diz-

ziness which could result in injury to yourself or others.

9. DO NOT operate this unit if you are under 18 years of age.

10. DO NOT operate this unit without fully inspecting the unit for any damage

or leakage.

11. DO NOT operate if the unit has any excessive vibration.

12. DO NOT operate unit with the inspection door limit switch damaged or

missing.

13. DO NOT operate unit unless it is properly connected to a leaf collection

box.

14. DO NOT operate unit unless it is properly attached to the tow vehicle.

15. DO NOT tow unit without using all the safety chains.

16. DO NOT tow unit with a damaged tongue.

17. DO NOT ll fuel tank with engine running. Allow engine to cool for 5 min-

utes before refueling.

18. DO NOT operate unit if fuel is spilled or with fuel cap off.

19. DO NOT smoke or weld near the unit.

20. DO NOT run engine in an enclosed area.

21. DO NOT place hands or feet near moving or rotating parts.

ODB COMPANY

800-446-9823 SCL800SM3X

13

SAFETY PRECAUTIONS

Safety Section

Do Not, continued;

22. DO NOT operate engine with an accumulation of grass, leaves or other

debris on the engine.

23. DO NOT run engine with air cleaner removed.

24. DO NOT leave leaf machine unattended while in operation.

25. DO NOT park machine on steep grade or slope.

26. DO NOT vacuum a leaf pile without looking for foreign objects such as

metal, glass, plastic or large pieces of wood.

Do’s:

1. DO completely read and understand the owner’s manual before operating,

maintaining or repairing the leaf collector.

2. DO follow engine and PTO manufacturer operating and maintenance instructions.

3. DO check fuel lines and ttings frequently for cracks or leaks. Replace if

necessary.

4. DO completely inspect the unit before leaving the service garage.

5. DO check the tow tongue each day for cracks.

6. DO inspect and be attentive to what is being vacuumed.

7. DO check the impeller, liners and blower housing for cracks or holes daily.

8. DO wear proper safety equipment as described in this manual.

9. DO watch for pedestrians, animals and other foreign material when vacu-

uming leaves.

10. DO replace any worn or missing safety stickers immediately.

ODB COMPANY

Battery posts, terminals and related accessories contain lead and leaf compounds, chemicals know to the state of California to cause cancer and birth

defects or other reproductive harm. Wash Hands after handling

Engine Exhaust, some its constituents and certain vehicle components contain

or emit chemicals known to the state of California to cause cancer and birth defects or other reproductive harm.

012213

800-446-9823 SCL800SM3X

14

SAFETY PRECAUTIONS

Safety Section

1.3 Training:

Improper use of the ODB leaf collector CAN result in severe personal injury or death. All personnel using this leaf vacuum must

be trained and qualied with all the operations, maintenance, repair

and safety procedures dened in this manual.

The warnings and procedures regarding safety in this manual are to be used

as a guideline only. It is impossible to cover all the events that could happen

in the vacuuming process. For this reason, it is vital that the owner accept the

responsibility to implement a training program that will provide every operator

or mechanic the basic skills and knowledge to make good judgement in all situations.

This training program must include the entire scope of hazards, precautions

and government regulations encountered in the vacuuming process. The program should stress the need for regularly scheduled preventive maintenance

and detailed equipment safety checks.

It is strongly recommended that all training programs be documented to ensure

all operators and mechanics receive initial training on not just the operation but

the safety features of the leaf collector.

ODB COMPANY

800-446-9823 SCL800SM3X

15

SAFETY PRECAUTIONS

1.4 Safety Decals

*Read and Follow all Safety

Sticker Warnings--Replace

all damaged or missing

stickers immediately.

Safety Section

2,8,9

1,2,3,4,5,6,9,

10,11,15

*Not in TruckDK

Kit

ITEM

NO.

*

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Decals shown on next page

PART

NUMBER

TRUCKDK

200183

200106

200192

200193

200194

200178

Call

200195

200181

200109

200179

Call

Call

200177

200182

*200190

*200187

*Call

DESCRIPTION

Decal Kit - Trucks (includes 1 -15)

Danger--Rotating Parts

Caution- Pinch Point

Caution - Do Not Operate ... without reading manual

Caution - Allow Engine to Idle

Caution - Do not use Dielectric grease

Danger - Explosion hazard

SCL800 oval sticker

Clean Hopper screens

Warning - Head, Eye and Ear Protection

Do Not Over-Lubricate

Danger - Do Not Ride, Sit or Stand

ODB Big Sticker

ODB wide sticker

Warning - Flammable

Warning - Do not open cover while in operation

Caution - Unload Body Prop

Caution - Body must be braced

Caution - Operation of body prop

ODB COMPANY

800-446-9823 SCL800SM3X

16

1

3

5

SAFETY PRECAUTIONS

Safety Section

6

2

4

7

8

11

13

14

9

10

12

17

15

ODB COMPANY

16

18

800-446-9823 SCL800SM3X

17

SAFETY PRECAUTIONS

Safety Section

1.5 Serial Number Location

Thoroughly read and understand the safety and preoperating sections of this manual before starting the

engine.

Make sure each operator knows and understands the

load ratings of the towed vehicle and that he/she is

qualied to tow the vehicle.

The serial number tag is located on the chassis on boom

side of the unit. It should be in front of the fenders going

toward the front of the unit. (See gure 1.5a).

gure 1.5a

ODB COMPANY

800-446-9823 SCL800SM3X

18

2.0 PRE-OPERATING SECTION

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

Pre-Operating

2.0

Section

2.0 PRE-OPERATING SECTION

2.0 PRE-OPERATING SECTION

2.1 IQAN Display System and Controls - Overview ..............................................19

2.1 IQAN Display System and Controls - Overview ..............................................20

2.1 IQAN Display System and Controls - Overview ..............................................21

2.2 Joystick Controls: .............................................................................................22

2.2 Safe Operations: ................................................................................................23

2.3 Preparation For Operation .................................................................................25

2.4 Pre-Transport Checks ........................................................................................26

2.5 Personal Protective Equipment and Clothing ...................................................27

2.6 Work Site Preparation .......................................................................................28

ODB COMPANY

800-446-9823 SCL800SM3X

19

Pre-Operating Section

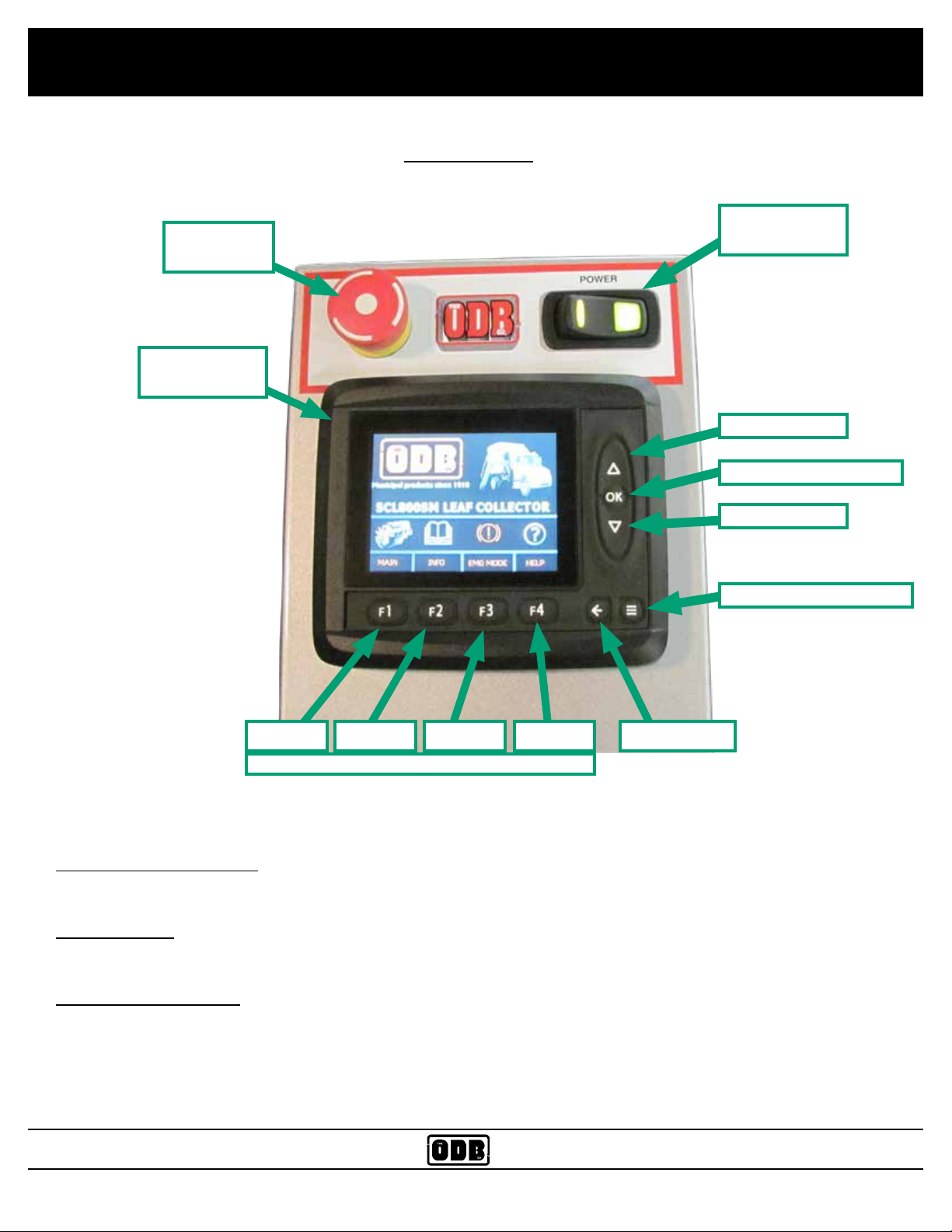

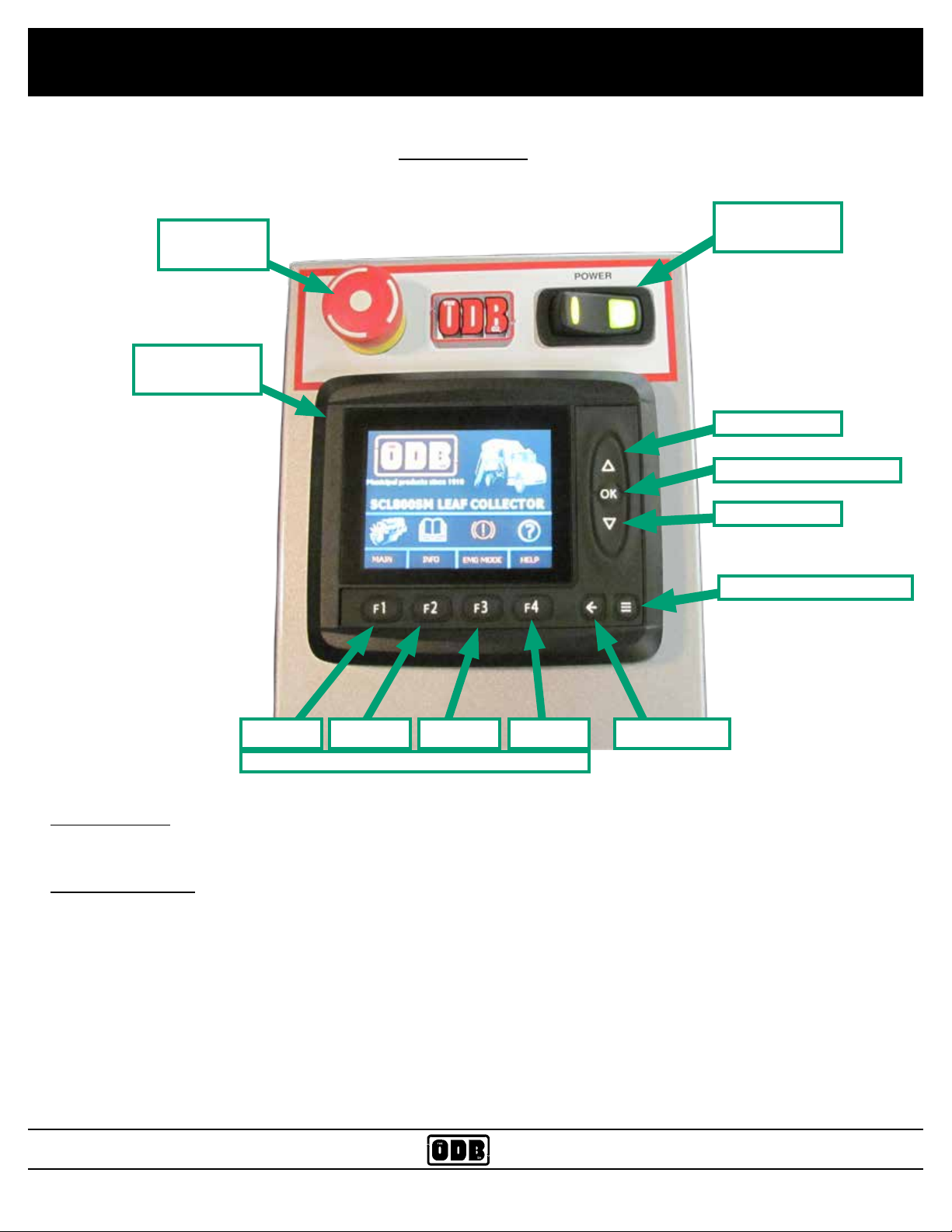

2.1 IQAN Display System and Controls - Overview

Control Station:

Emergency

Stop Button

IQAN Display

System

Figure 2.1A

Power Switch

Up Button

OK Button /Greeting

Down Button

System Menu Button

F1 Button

**This is a just a brief overview of the controls of the IQAN system, please see Section 3.1 for more

detailed instructions on using the system.

Emergency Stop Button:

This button shuts down the system immediately in case of an emergency situation.

Power Switch:

This button turns the IQAN Display system on and off.

IQAN Display System:

This is the heart of the SCL800SM-3X system. It controls and monitors the engine, PTO, dump and 3

Axis boom systems.

ODB COMPANY

F2 Button

Function Buttons

F3 Button F4 Button

Return Button

800-446-9823 SCL800SM3X

20

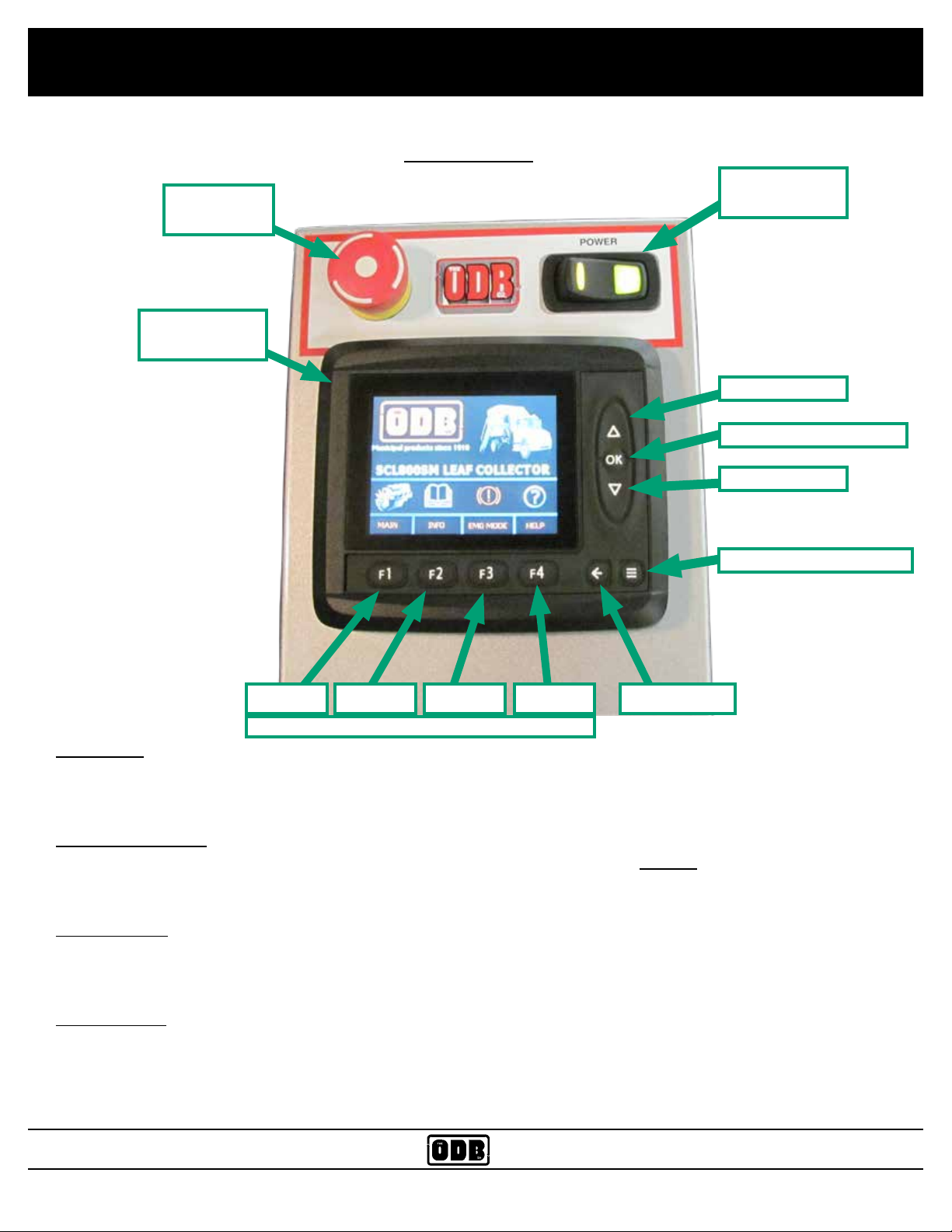

Pre-Operating Section

2.1 IQAN Display System and Controls - Overview

Control Station:

Emergency

Stop Button

IQAN Display

System

Figure 2.1A

Power Switch

Up Button

OK Button /Greeting

Down Button

System Menu Button

F1 Button

Up Button:

This button is used to navigate through the various display pages, menus and lists. Also used to increase the throttle of the engine.

OK Button Switch:

This button is used to conrm selections as well as go the main menu. NOTE: Pressing the OK button

when take you to the Startup Greeting page (Shown above) on most screens.

Down Button:

This button is used to navigate through the various display pages, menus and lists. Also used to decrease the throttle of the engine.

Menu Button:

This button is used to access the System menu.

F2 Button

Function Buttons

F3 Button F4 Button

Return Button

ODB COMPANY

800-446-9823 SCL800SM3X

21

Pre-Operating Section

2.1 IQAN Display System and Controls - Overview

Control Station:

Emergency

Stop Button

IQAN Display

System

Figure 2.1A

Power Switch

Up Button

OK Button / Greeting

Down Button

System Menu Button

F1 Button

Return Button:

This button is return to the previous screen.

Function Buttons:

These Four (4) buttons have different functionality depending on the screen. These are the main buttons that the user uses to select the screen or function they desire. The function key corresponds to

the menu choice above the function key.

ODB COMPANY

F2 Button

Function Buttons

F3 Button F4 Button

Return Button

800-446-9823 SCL800SM3X

22

Figure 2.2a

Deadman

Pre-Operating Section

BOOM MODE

2.2 Joystick Controls:

Throttle Fast

Throttle Slow

Joystick Controls:

The joystick is used to control the boom actions,

engine throttle, rear door lock and body dump. The

joystick works in two different modes, Boom mode

and Dump mode.

Right

Boom In

Left

Never tamper with the Deadman switch such

as taping it down, serious equipment damage

or bodily harm could occur.

DUMP MODE

Figure 2.2b

Deadman

Boom Up/Down

Boom Out

Door Lock

Door Unlock

NOTE:

In order for the boom to move, the "Deadman" must

be pressed rst, but it doesn't need to be continously held (except when when dumping box in dump

mode).

Boom Mode: (Figure 2.2a)

Pushing the joystick ...

Forward - boom moves In towards the truck

Backward - boom moves Out away from the truck

Left - Boom moves Forward to the front of truck

Right - Boom moves Backward to rear of unit.

Top Yellow Button - throttle fast

Bottom Yellow Button - throttle slow

Red Slide Up - Boom Up

Red Slide Down - Boom Down

Dump Mode: (Figure 2.2b)

Pushing the joystick ...

Forward - Lowers Dump Body

Backward - Raised Dump Body

Note: Deadman button must be pressed!

Top Yellow Button - Rear Door Lock

Bottom Yellow Button - Rear Door Unlock

Dump Down

Deadman must be held at all

times during dump.

ODB COMPANY

Dump Up

PROPORTIONAL CONTROLS

The 3 Axis boom on the ODB leaf collector is proportional

which allows the operator the greatest control of the boom

possible.

What does that mean? It means that the harder you move

the joystick in a direction the faster the boom moves and

the softer you move the joystick in a direction the slower the

boom moves. For instance, if you need to move the joystick

slowly forward you slightly move the joystick forward and the

boom will slowly move forward. The harder you press the

joysick forward the faster the boom will go.

800-446-9823 SCL800SM3X

23

Pre-Operating Section

2.2 Safe Operations:

ALL personnel using, maintaining or servicing this unit must be

trained in all safety procedures outlined in this manual. Improper

or careless use of this equipment CAN result in personal injury or

death.

Operations shall be restricted to:

1. Properly trained, qualied and experienced operators and/or qualied and

experienced maintenance and test personnel.

2. Trainees under the direct supervision of qualied and experience

personnel.

3. Qualied and experienced maintenance and service personnel.

Operators who qualify to operate this equipment under the above restrictions shall also comply with the following physical requirements:

1. Have good vision and the ability to read and understand this manual as well

as all safety and operational decals on the equipment.

2. Be capable of hearing, with or without a hearing aid, at a level needed to

safely operate this equipment.

3. A record of mental stability with no history of epileptic seizures, dizziness, or

any other disability that may result in injury to himself or others.

If any of these requirements are not satised at any time, the person failing to

meet these requirements MUST NOT OPERATE THIS EQUIPMENT.

ODB COMPANY

800-446-9823 SCL800SM3X

24

Pre-Operating Section

2.2 Safe Operations (continued):

Additional Requirements:

1. Each operator must demonstrate competence to understand all safety

decals, operator’s manuals, safety codes, applicable government regulations, and all other information applicable to the safe and proper operation of the leaf vacuum.

2. Each operator must demonstrate the ability to recognize an emergency

situation that may arise during vacuuming operations and the knowledge

and procedures to implement corrective action.

3. Each operator must demonstrate or provide evidence of qualicatation

and experience prior to operating the leaf vacuum.

4. Each operator must be able to recognize existing or potential problems

regarding the mechanical integrity of the leaf vacuum and report any

maintenance requirements to the supervisor in charge.

5. Each operator must wear the proper personal clothing and safety gear.

(Refer to SAFETY PRECAUTIONS Section 5.4)

6. Operators must not be physically or mentally fatigued.

7. Operators must not be under the direct or indirect inuence of alcohol

and/or drugs. This includes prescription drugs that could cause drowsiness, dizziness, or any other condition that would impair their ability to

operate or use this equipment in a safe manner.

ODB COMPANY

800-446-9823 SCL800SM3X

25

Pre-Operating Section

2.3 Preparation For Operation

Before your leaf vacuum is put into operation it is very important

to read and follow the procedures outlined in the engine owner’s

manual. (EOM).

For specic information regarding the following checks please refer to the

“Maintenance” section of this manual and the engine owner’s manual.

DISENGAGE the clutch and remove the negative battery cable before performing the following checks.

NEVER place any part of the body under or behind guards or any

other area in which you cannot see.

IMPORTANT CHECKS:

NOTE: The following checks contained in the next three sections should be

performed prior to leaving the storage area.

1. Check engine fuel, coolant and oil levels. (see EOM)

2. Check engine air lter

3. Check all bolts and nuts to ensure they are tight.

4. Check all controls for free and proper operation.

5. Check main drive belt (if equipped) for proper adjustment.

6. Inspect the fan blades to ensure that they are not bent , deformed, fatiqued or cracked. Replace fan if any damage is present.

7. Inspect the intake hose ange to make sure it is connected correctly to the

blower housing.

8. Inspect the leaf vacuum frame and structure for any bent, broken, cracked,

missing or loose parts.

9. Check all guards to ensure they are undamaged, in place and properly

secured.

10. All decals must be in place and legible prior to operating the leaf vacuum.

See the decal section for decal replacement.

ODB COMPANY

800-446-9823 SCL800SM3X

26

Pre-Operating Section

2.4 Pre-Transport Checks

Failure to verify the road worthiness of the leaf vacuum and the

truck and verify all equipment is properly stowed, may cause serious injury or death to yourself or others.

Do not tow the leaf vacuum unless all important checks listed below

are completed.

IMPORTANT CHECKS:

1.

The hose boom is properly secured.

a. Be sure nozzle is in the cradle securely.

2.

The unit's lighting is operating properly.

3.

Check the general condition of the tires, tire pressure and ensure that

all lug nuts are securely fastened.

4.

Visual examination of the leaf vacuum frame, suspension and structure to determine if all components are correctly positioned and secured for travel.

5.

Check the intake hose boom to verify that it is securely fastened to the

leaf vacuum and can not swing free.

6.

Verify there are no loose tools or materials on the unit, inside the intake and exhaust hoses, or inside the engine sheet metal.

7.

Check all cones, wheel-chocks, signs or other support tools and materials to ensure proper stowage.

ODB COMPANY

8

Verify the driver of the unit is qualied to tow the type and weight of

the unit.

800-446-9823 SCL800SM3X

27

Pre-Operating Section

2.5 Personal Protective Equipment and Clothing

Always wear proper safety equipment as outlined below, not wearing such equipment CAN result in serious personal injury or possible death.

IMPORTANT CHECKS:

Anyone operating the leaf vacuum equipment MUST wear appropriate pro-

tective equipment and clothing to protect them from injury during operations.

PROTECTIVE EQUIPMENT:

1. Head Protection: Hard hats without under-chin strapping.

2. Eye Protection: Wraparound goggle type eye protection held in place

with an elastic band around the head or a hard hat mounted face shield,

which provides full protection of the face.

3. Eye protection must meet ANSI Z87.1 standards.

4. Hearing Protection: plug type or “muff type” ear protection should be

worn at all times while operating the unit.

5. Breathing Protection: Paper lter type dust masks should be worn to

protect from dirt and dust particles during the vacuuming process.

6. Reective Vests: Highly visible vests should be worn so motorists can

see see the operator in all weather and lighting conditions.

7. Work Gloves: Gloves should be worn to protect the hands and wrists

from debris.

8. Steel Toed Boots: should be worn to protect the feet.

Work clothes MUST be close tting, but not restrictive of movement, without any loose parts that could be entangled in any parts

of the leaf vacuum. This includes items such as jewelry, chains

and backpacks.

ODB COMPANY

800-446-9823 SCL800SM3X

28

Pre-Operating Section

2.6 Work Site Preparation

Never place any part of the body under or behind guards or any

other visually obscured area.

Making sure the leaves are clear of possible dangerous material is

critical to safe vacuuming. Vacuuming up metal, glass, rocks or

other dangerous material CAN cause serious damage to the equipment or personal injury.

The following guidelines must be followed to insure safety.

1. An inspection of the leaves to be vacuumed must be done prior to the

vacuuming process. We realize that it is impossible to completely inspect

every inch of leaves being vacuumed, but it is imperative that all leaves be

inpsected for obvious dangerous material before vacuuming.

2. The operator should never be in the line of trafc, the operator should work

on the shoulder whenever possible.

3. The operators should place cones or other barriers to provide adequate

warnings to vehicles and pedestrians that vacuuming is in progress.

4. Strobe lights on the leaf vacuum and on the tow vehicle should be on at all

times for high visibility.

5. Conrm that all operators are wearing proper clothes and personal protective equipment.

6. Restrict all personnel, except the operator from the area near the leaf vacuum. DO NOT allow pedestrians, children or animals near the work area.

7. Make sure that the exhaust hose (if equipped) ts properly into the box container so that all debris is blown into the box container.

ODB COMPANY

800-446-9823 SCL800SM3X

29

3.0 OPERATING SECTION

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

3.0 OPERATING SECTION

3.0 OPERATING SECTION

3.1 Starting Engine .............................................................................................. 30

3.1 Starting Engine, continued; ........................................................................... 31

3.2 Engaging the Standard PTO ..........................................................................32

3.3 Fluid Drive Coupler (if equipped) ................................................................ 33

3.4 Hose Boom Operation - 3 Axis ..................................................................... 34

3.4 Hose Boom Operation - 3 Axis, cont. ........................................................... 35

3.4 Hose Boom Operation - 3 Axis, cont. ........................................................... 36

3.4 Hose Boom Operation - 3 Axis, cont. ........................................................... 37

3.5 Dumping the Body ........................................................................................ 38

3.5 Dumping the Body, continued ...................................................................... 39

3.5 Dumping the Body, continued ...................................................................... 40

ODB COMPANY

800-446-9823 SCL800SM3X

30

Operating Section

Figure 3.1A

Main (F1)

Figure 3.1B

Power Switch

3.1 Starting Engine

Check your surroundings before starting unit and

make sure people and objects are clear of unit.

Thoroughly read and understand the

safety and pre-operating sections of

this manual before staring the engine.

DO NOT start the engine in an enclosed building.

Proper ventilation is required before starting the

engine.

Start (F1)

Figure 3.1C

Throttle

Throttle

Up

Throttle

Down

Review the Engine Operating Manual supplied with your

leaf vacuum for specic start-up, maintenance and operating instructions. It is especially important to review

break-in service procedures for brand new units.

Starting Procedure (refer to gure 3.1A):

1.

2.

3.

4.

5.

Perform all the pre-starting, pre-operating checks

outlined in the EOM and in this manual.

Turn on power to the IQAN station by pressing

the power switch to the right.(Fig. 3.11A)

Depress F1 key to access the "Main" Menu

Then Depress the F1 key to start the engine. (Fig.

3.1B)

The engine throttle is controlled using either the

arrow buttons on the IQAN or the Yellow Buttons

on the Joystick. (Figure 3.1C)

ODB COMPANY

800-446-9823 SCL800SM3X

31

Operating Section

Figure 3.1A

Main (F1)

Figure 3.1B

Power Switch

Throttle

Up

3.1 Starting Engine, continued;

IMPORTANT: Do not operate the starter for

more than 30 seconds at a time. To do so

may overheat the starter. If the engine does

not start the rst time, wait at least 2 minutes

before trying again. If the engine fails to start

after 4 attempts, see the trouble shooting section of the EOM and this manual.

5.

6.

Check all gauges for normal engine operation.

If operation is not normal, stop the engine and

determine the cause.

IMPORTANT: To assure proper lubrication,

operate the engine at or below 1600 rpm with

no load for 1 -2 minutes. Extend this period

2 - 4 minutes when operating at temperatures

below freezing.

Watch the coolant temperature gauge. Do

not place engine under load until it is properly

warmed up. The normal engine coolant temperature range is 180 - 202 degrees F.

Start (F1)

Figure 3.1C

ODB COMPANY

Throttle

Down

Throttle Fast

Throttle Slow

800-446-9823 SCL800SM3X

32

Operating Section

Figure 3.2A

Vac On(F2)

Throttle Fast

Throttle Slow

Throttle

Up

Throttle

Down

3.2 Engaging the Standard PTO

Thoroughly read and understand the safety and

pre-operating sections of this manual before staring the engine.

Make sure the intake hose is properly attached

and make sure the front of the hose is clear of

any objects which could be inadvertently vacuumed during the PTO engagement process.

Review the Engine Operating Manual supplied with your

leaf vacuum for specic start-up, maintenance and operating instructions. It is especially important to review

break-in service procedures for brand new units.

Figure 3.2B

Engaging the PTO (refer to Figure 3.2A):

1.

2.

3.

4.

IMPORTANT: If the unit experiences any heavy vibrations or makes any unusual

noises, shut the engine down and after following the necessary safety guidelines,

have a qualied technician investigate the cause. DO NOT operate a unit that is in a

state of disrepair.

Perform all the pre-starting, pre-operating checks

outlined in the EOM and in this manual.

Start the engine as previously discussed in this

manual and in the EOM.

Once the engine has been allowed to thoroughly

warm up (engine temperature gauge should read

at least 180 degrees) increase the throttle control

until the engine reaches 1800 rpm.

Press F2 button "VAC ON" Fig. 3.2A) to engage

the clutch. Use the F3 button "VAC OFF" to disengage the clutch.

ODB COMPANY

800-446-9823 SCL800SM3X

33

Operating Section

Figure 3.3A

3.3 Fluid Drive Coupler (if equipped)

Thoroughly read and understand the safety and

pre-operating sections of this manual before staring the engine.

Make sure the intake hose is properly attached

and make sure the front of the hose is clear of

any objects which could be inadvertently vacuumed at any time.

There is no PTO engagement when the unit is equipped

with a Fluid Drive Coupler. The impeller is ALWAYS engaged and rotating.

The suction impeller is ALWAYS rotating when the engine is running

and for a few minutes after the engine is shut off. Exercise caution

whenever the unit is running.

IMPORTANT: If the unit experiences any heavy vibrations or makes any unusual

noises, shut the engine down and after following the necessary safety guidelines,

have a qualied technician investigate the cause. DO NOT operate a unit that is in a

state of disrepair.

ODB COMPANY

800-446-9823 SCL800SM3X

34

Operating Section

3.4 Hose Boom Operation - 3 Axis

Thoroughly read and understand the safety, pre-operating and operating sections of this manual before vacuuming. Wear the proper

safety equipment as outlined in this manual.

Visually inspect the area around the hose boom for any objects,

trees, telephone poles, persons or animals which could possibly be

in the path of the moving hose boom.

Visually inspect the leaves before vacuuming any for any material

that could be harmful to the leaf vacuum of people. This includes

bottles, wood, steel, glass, stone or other hard or breakable objects.

Figure 3.3A

Deadman

Boom In

BOOM MODE

Left

Throttle Fast

Throttle Slow

Right

Boom Up/Down

Boom Out

Boom Operation:

1.

2.

3.

4.

Start the engine using the procedures stated earlier in this manual.

Set the engine throttle to around 1,600-1,800.

NOTE: Always vacuum leaves using the lowest

rpm as possible. This saves fuel and decreases

the amount of dust escaping the box container. It

also decreases the chance of picking up undesirable material.

Check again for any objects in the path of the

moving hose boom

Grasping the joystick, press the "Deadman" button (Fig. 3.3A) and then slide the red Slide button

up to raise the boom (Fig. 3.3A) to raise the hose

out of the cradle.

ODB COMPANY

NOTE: The "Deadman" (Fig. 3.3A) must be

depressed rst for any of the boom functions to

work.

800-446-9823 SCL800SM3X

35

Operating Section

3.4 Hose Boom Operation - 3 Axis, cont.

Visually inspect the area around the hose boom for any objects,

trees, telephone poles, persons or animals which could possibly be

in the path of the moving hose boom.

Visually inspect the leaves before vacuuming any for any material

that could be harmful to the leaf vacuum or people. This includes

bottles, wood, steel, glass, stone or other hard or breakable objects.

Boom Operation, continued:

Never tamper with the Deadman switch such

as taping it down, serious equipment damage

or bodily harm could occur.

Figure 3.3A

BOOM MODE

Deadman

Boom In

Left

Throttle Fast

Throttle Slow

Right

Boom Up/Down

Boom Out

Joystick Controls: (Figure 3.3A)

Pushing the joystick ...

Forward - boom moves In towards the truck

Backward - boom moves Out away from the

truck

Left - Boom moves Forward to the front of

truck

Right - Boom moves Backward to rear of

unit.

Top Yellow Button - throttle fast

Bottom Yellow Button - throttle slow

Red Slide Up - Boom Up

Red Slide Down - Boom Down

PROPORTIONAL CONTROLS

The 3 Axis boom on the ODB leaf collector is proportional which allows the operator the greatest control of

the boom possible.

What does that mean? It means that the harder you

move the joystick in a direction the faster the boom

moves and the softer you move the joystick in a direc-

tion the slower the boom moves. For instance, if you

need to move the joystick slowly forward you slightly

move the joystick forward and the boom will slowly

move forward. The harder you press the joysick for-

ward the faster the boom will go.

ODB COMPANY

800-446-9823 SCL800SM3X

36

Operating Section

3.4 Hose Boom Operation - 3 Axis, cont.

Visually inspect the area around the hose boom for any objects,

trees, telephone poles, persons or animals which could possibly be

in the path of the moving hose boom.

Visually inspect the leaves before vacuuming any for any material

that could be harmful to the leaf vacuum or people. This includes

bottles, wood, steel, glass, stone or other hard or breakable objects.

Boom Operation, continued:

Never tamper with the Deadman switch such

as taping it down, serious equipment damage

or bodily harm could occur.

Figure 3.3A

BOOM MODE

Deadman

Boom In

Left

Throttle Fast

Throttle Slow

Right

Boom Up/Down

Boom Out

5.

Carefully and slowly maneuver the hose

to the leaf pile.

6.

Engage the clutch fully using the steps

outlined earlier in this manual.

7.

Always keeping the hose nozzle at a 45

degree angle. This allows proper air ow

and will reduce clogging. DO NOT bury

the nozzle into the leaf pile, this will cut

off the air ow and will make vacuuming

much more difcult and will increase the

chance of clogging.

8.

If leaves are not vacuuming, increase

the engine rpm to 2,000 - 2,200 and try

vacuuming again.

NOTE: Wet leaves will need higher

rpm's to vacuum whereas dry leaves will

only need minimal rpm's.

ODB COMPANY

9.

Continue moving the nozzle slowly and

carefully in a sweeping motion above the

leaves while vacuuming.

800-446-9823 SCL800SM3X

37

Figure 3.3B

Operating Section

3.4 Hose Boom Operation - 3 Axis, cont.

Visually inspect the area around the hose boom for any objects,

trees, telephone poles, persons or animals which could possibly be

in the path of the moving hose boom.

Visually inspect the leaves before vacuuming any for any material

that could be harmful to the leaf vacuum or people. This includes

bottles, wood, steel, glass, stone or other hard or breakable objects.

Boom Speed Control:

10.

If you want to adjust the speed of the

boom in any or all directions you can access the boom speed control by pressing

the Escape key. (Fig. 3.3B)

Figure 3.3C

Speed

Control

11.

Press the direction that you wish speed

up or slow down.

12.

This will take you to another screen with

a dial. Use the navigation buttons to

increase or decrease the speed. Press

OK at the desired setting. (Fig. 3.3D)

Figure 3.3D

Navigation Buttons

Up

OK

Down

ODB COMPANY

800-446-9823 SCL800SM3X

38

Operating Section

3.5 Dumping the Body

Make sure all people and animals

are completely clear of the unit during the dumping process.

Always operate the dump body

controls from the front of the unit,

standing beside the tongue.

Figure 3.4A

Thoroughly read and understand the safety and

pre-operating sections of this manual before starting the engine.

Make sure the unit is properly attached to the tow

vehicle and the surface is level and solid before

raising the body .

Watch for any overhead obstacles such as power

lines and tree limbs before dumping.

Review the Engine Operating Manual supplied with your

leaf vacuum for specic start-up, maintenance and operating instructions. It is especially important to review

break-in service procedures for brand new units.

Figure 3.4B

Dump(F4)

Dumping the body (refer to gures 3.3a and 3.3b):

1.

2.

3.

4.

5.

Perform all the pre-starting, pre-operating checks

outlined in the EOM and in this manual.

Start the engine as previously discussed in this

manual and in the EOM. Make sure the PTO is

disengaged.

Do a thorough inspection of the entire area around

and above the unit, looking for any object that could

get in the way of the body dumping.

Make sure the surface is level and the ground is

solid before dumping.

Increase the throttle to 1,600 -1,800 rpm. Do not

race the engine while using the hoist.

ODB COMPANY

800-446-9823 SCL800SM3X

39

Figure 3.4A

Operating Section

3.5 Dumping the Body, continued

Figure 3.4B

Dump(F4)

6.

7.

8.

9.

Press the F4 "Dump" button from the IQAN display (Fig. 3.4A) to enter "Dump" mode.

In order for the dump body to dump the rear door

locks must be released. Press either the F3

"Unlock" button from the IQAN screen (Fig. 3.4B)

or use the bottom yellow button on the Joystick.

(Fig. 3.4C)

Raise the body only as high as it is needed to

dump the load.

Shut off all power, raise the body prop(s) (Fig.

3.4D) to a free standing position. Lower the body

slowly until the long beam bracket contacts the

prop arm saddle (Fig. 3.4E). DO NOT POWER

HOIST DOWN.

Figure 3.4D

Unlock (F3)

Figure 3.4C

Deadman

Dump Down

Deadman must be held at all

times during dump.

ODB COMPANY

Door Lock

Door Unlock

Dump Up

Figure 3.4E

800-446-9823 SCL800SM3X

40

Figure 3.4C

Operating Section

3.5 Dumping the Body, continued

Door Lock

Door Unlock

Lowering the body:

Deadman

Dump Down

Deadman must be held at all

times during dump.

Figure 3.4D

Dump Up

Before lowering the body, walk completely

4.

around the unit and thoroughly inspect the area

between the body and the unit’s frame. Look for

any object, person or animal that could potentially

get between the dump body and the frame. DO

NOT go under the body while inspecting.

Once the area has been inspected, start the en-

5.

gine as described in section 3.1. DO NOT race

the engine.

Slowly raise the body just enough to clear the

body prop saddle, lower the body prop to the storage position (g 3.3c) and slowly lower the body.

The dump body may stop approximately 12”

from the bottom due to the safety check valve. If

it does, slowly raise the body a few inches and

SLOWLY lower the body down. The body needs

to be lowered extremely slow the last 12 inches or

the check valve will stop the body.

Figure 3.4E

ODB COMPANY

Once the body is completely down close the latch

hooks using the joystick top yellow button or the

F2 Lock button on the IQAN display.

800-446-9823 SCL800SM3X

41

4.0 MAINTENANCE SECTION

Read and understand this entire manual before operating, maintaining or repairing the leaf vacuum.

4.0 MAINTENANCE SECTION

4.0 MAINTENANCE SECTION

4.1 Maintenance Overview: .................................................................................................. 42

4.2 Maintenance and Lubrication ........................................................................................43

4.3 Lubrication: ..................................................................................................................... 44

4.3 Lubrication, continued; .................................................................................................. 45

4.3 Lubrication, continued; .................................................................................................. 46

4.3 Lubrication, continued; .................................................................................................. 47

4.4 Preventative Maintenance ............................................................................................... 48

4.5 Torque Values ................................................................................................................. 53

4.6 Quick Reference Chart .................................................................................................... 54

4.7 Kraft Fluid Drive Maintenance (Optional) .....................................................................55

ODB COMPANY

800-446-9823 SCL800SM3X

42

Maintenance Section

4.1 Maintenance Overview:

Only properly trained personnel should perform maintenance or repair on this equipment. Consult ODB before performing any main-

tenance procedures that is not specically covered in this manual.

Improper maintenance or repair may void any and all warranties on

this equipment.

Improper maintenance or repair CAN result in equipment damage

and/or personal injuries.

BEFORE CONTINUING, please read and understand the Safety, Preoperating and Operating sections of this manual before doing any

procedures in this section.

A properly maintained leaf vacuum will dramatically extend the life of the

unit and will create a safer work place as well. For the general safety and

welfare of all personnel it is important to create a scheduled maintenance

program that covers all the elements in this manual as well as the engine,

PTO and axle owner’s manuals provided with this unit.

Use the chart on the following page as a guide for your scheduled maintenance program. If there are any questions concerning any of these procedures please call ODB.

ODB COMPANY

800-446-9823 SCL800SM3X

43

Maintenance Section

4.2 Maintenance and Lubrication

This chart is only a reference, always consult the Owners Manual of the Engine, PTO, etc for actual recommendations

(Use Hour Meter as a Guide)

INTERVAL

MAINTENANCE

Check and add engine oil, coolant, fuel and

Hydraulic uid (hoist and boom)*

Check for loose nuts or bolts

Check for fuel, oil, coolant and hydraulic leakage*

Check or clean radiator screen

Lubricate impeller shaft ange bearings(if equipped)

Check lug nuts and tire pressure / condition

Check trailer safety chains and hitch

Check tow bar for damage or wear

Check and clean instrument panel and circ. board

Clean pre-cleaner

Check air lter for dirt or debris*

Check trailer lighting and trailer brake operation

Change engine oil* (for break in oil see EOM)

Clean and check battery and connections*

Check power band tension (if equipped)

Check power band condition (if equipped)

Check impeller for damage, cracks or wear

Grease (non-conductive) circuit board connectors

Clean hydraulic pump motor/connections

Lubricate throttle and choke cables

Check blower housing liners for cracks or wear

Check Clutch/PTO linkage adjustment

Change hoist hydraulic uid and lter

Change boom hydraulic uid

Inspect intake and exhaust hoses for damage

Check exhaust duct gasket for wear

Replace oil lter*

Replace air lter primary element*

Inspect radiator and hoses*

Check fan belt conditions and tension*

Inspect all duct work for cracks, holes or wear

Grease / Inspect wheel bearings for corrosion

Change engine coolant*

Check fuel tank for leaks

Lubricate Hoist and Hinge Fittings

Daily

First

8

Hours

Every

25

Hours

Every

50

Hours

Every

100

Hours

Every

200

Hours

* = see the engine owner's manual for complete details

ODB COMPANY

800-446-9823 SCL800SM3X

44

Figure 4.3A

Maintenance Section

4.3 Lubrication:

Remove the negative battery terminal before attempting any lubrication procedures.

Thoroughly read and understand the safety and

pre-operating sections of this manual before performing any lubrication procedures.

The following are general lubrication procedures for our

standard units. Any special or custom built units may

have other lubrication procedures not directly mentioned

in this manual. Please consult ODB before any lubricat-

ing procedures not specically mentioned in this manual.

NOTE; DO NOT mix different

types of grease. The old grease

MUST BE purged before a different type of grease is used. Mixing grease WILL cause premature

failure to the bearings.

Proper lubrication of your unit correlates directly to how

long your unit will last. A properly maintained unit will last

much longer than a unit that is not maintained properly.

NOTE: Always lubricate bearings at the end of each work

day. This will displace any moisture in the bearings. Also

lubricate thoroughly before extended shutdown or storage.

Lubrication Points:

1. Drive Bearings (if equipped) (gure 4.3a): These

bearings are critical components of the belt-driven

units. These bearings should be greased every 10

hours with approximately two strokes from the average hand pump grease gun. The type of grease used

in these bearings are also critical to the performance

of the bearings. A multi-purpose, heavy-load, hightemperature, moisture resistant #2 grease is required

for the drive bearings. ODB recommends Mantek Elite

Supreme #1 WG Extreme Duty multi-purpose grease..

Other premium quality grease that matches the above

requirements may be used but after years of testing

ODB recommends the Elite Supreme grease.

ODB COMPANY

800-446-9823 SCL800SM3X

45

Figure 4.3b

Figure 4.3c

Maintenance Section

4.3 Lubrication, continued;

Lubrication Points, continued;

2. Aubur Gear Oil (gure 4.3b): Fill Auburn gear with

90W gear oil. Undue plug as shown and ll. There is a

plug at the bottom for draining if necessary.

3. Boom Swivel (gure 4.3c): Grease the boom bear-

ings once every week with a multi-purpose moisture

resistant #2 grease.

4. PTO Bearing & PTO Shaft Fitting (gure 4.3d): The

End Cap PTO bearings should be greased after every

50 hours of operation with a high grade, high temperature lithium base #2 lubricant having an operating tem-

perature of 200 degrees F. Three to ve pumps with a

hand operated grease gun is sufcient.

Figure 4.3d

5. The PTO cross shaft and linkage should be lubricated

with high temperature lithium base #2 lubricant after

200 hours of operation.

6. Hinge and Friction Points: Leaf vacuum operation

and longevity can be improved by keeping hinges and

friction points lubricated. ODB recommends that lubrication be performed weekly. Use SAE30 weight oil on

hinges and a premium grade, high temperature lithium

based EP#2 grease on friction points.

7. Door Latch Hook (gure 4.3e): Grease both hooks

with high temperature lithium based EP#2 grease once

a week.

ODB COMPANY

800-446-9823 SCL800SM3X

46

Figure 4.3e

Maintenance Section

4.3 Lubrication, continued;

Lubrication Points, continued;

Never go under the dump body unless the body is

empty and the body prop(s) is in the proper position.

The body prop is designed and intended to support an EMPTY truck body in the raised position.

Unload the body before using the body prop(s).

Figure 4.3f

8. Hydraulic Hoist Fittings (gure 4.3e): Raise

and support the dump body as detailed in section

3.2. Lubricate the ttings at least every 200 hours

of operation with a #2 high grade grease. There are

tremendous forces on the bearing surfaces within the

hoist frame. It pays to be generous with the grease

gun, to insure proper operation and long life.

9. Hoist Hinge and Body Prop(s) Fittings (gure

4.3f): Each hinge pivot has a grease tting that

needs lubricating every 200 hours. The body prop(s)

has a tting at the pivot area as shown in gure 4.3h.

Figure 4.3f

ODB COMPANY

800-446-9823 SCL800SM3X

47

Figure 4.3g

Maintenance Section

4.3 Lubrication, continued;

Lubrication Points, continued;

Never go under the dump body unless the body is

empty and the body prop(s) is in the proper position.

Grease

Fitting

The body prop is designed and intended to support an EMPTY truck body in the raised position.

Unload the body before using the body prop(s).

10. Latch Shaft Pillow Block Bearings (gure 4.3h): Each

pillow block bearing should be greased with a high temperature lithium based EP#2 grease once a week.

11. Boom Cylinders (gure 4.3i): Grease the pivot joints of

the boom cylinder with a high temperature lithium based

EP#2 grease once a weak.

ODB COMPANY

800-446-9823 SCL800SM3X

48

Maintenance Section

4.4 Preventative Maintenance

Remove the negative battery terminal before attempting any maintenance procedures.

Thoroughly read and understand the safety and pre-operating sections of this manual before performing any maintenance procedures.

The following are general preventative maintenance procedures for our standard units. Any special or custom built units may have other preventative

maintenance procedures not directly mentioned in this manual. Please consult ODB before doing any preventative maintenance procedures not specically mentioned in this manual.

Proper preventative maintenance of your unit, just like lubrication, correlates

directly to how long your unit will last. A properly maintained unit will last

much longer than a unit that is not maintained properly.

Preventative Maintenance:

1.

2.

NEVER check the engine coolant when the engine is hot. Allow the

engine to cool at least one hour before checking the coolant. Check