www.odacore.com

Programmable DC Power Supply

OPS Series

User Manual

Manual Part NO. 018OPS-2.0

Legal Notices

© ODA Technologies.,Co.Ltd 2004

No part of this document may be photocopied, reproduced, or translated to another language without

the prior another language without the prior agreement and written consent of ODA agreement and

written consent of ODA Technologies.,Co.Ltd. as governed by Korea and international copyright laws.

Warranty Certification

The material contained in this document is provided “as is,” and is subject to being changed, without

notice, in future editions. Further, to the maximum extent permitted by applicable law, ODA disclaims

all warranties, either express or implied, with regard to this manual and any information contained

herein, including but not limited to the implied warranties of merchantability and fitness for a particular

purpose. ODA shall not be liable for errors or for incidental or be liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of

any information contained herein. Should ODA and the user have a separate written agreement with

warranty terms covering the material in this document that conflict with these terms, the warranty terms

in the separate agreement shall control.

Assistance

This product comes with the standard product warranty. Warranty options, extended support contacts,

product maintenance agreements and customer assistance agreements are also available.

Contact your nearest ODA Technologies. Sales and Service office for further information on

ODA Technologies. full line of Support Programs. Refer to below information.

www.odacore.com

oda@odacore.com

82-2-1800-8644

Waste Electrical and Electronic Equipment

The affixed product label (see right) indicates that you must not discard

this electrical/electronic product in domestic household waste. Do not

dispose in domestic household waste. To return unwanted products,

contact our local ODA distributors, or call us for more information.

Manual Editions

Manual Part Number: 018OPS-2.0 Edition 2, February, 2018 Printed in ROK

Reprints of this manual containing minor corrections and updates may have the same printing date.

Revised editions are identified by a new printing date.

Safety Notices

p

d

p

y

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings or instructions elsewhere

in this manual violates safety standards of design, manufacture, and intended use of the instrument.

ODA Technologies assumes no liability for the customer's failure to comply with these requirements.

eneral Do Not Modify the Instrument

G

Do not use this product in any manner not

specified by the manufacturer. The protective

features of this product may be impaired if it is

used in a manner not specified in the operation

instructions.

Do not install substitute parts or perform any u

nauthorized modification to the product. Return

the product to an ODA Sales and Service Office

for service and repair to ensure that safety

features are maintained.

round the Instrument

G

This product is a Safety Class 1 instrument

(provided with a protective earth terminal).

To minimize shock hazard, the instrument unintended o

chassis and cover must be connected to an qualified service personnel.

electrical ground. The instrument must be

connected to the ac power mains through

a grounded power cable, with the ground

wire firmly connected to an electrical ground

(safety ground) at the power outlet. Any attention to an operating procedure, practice, or

interruption of the protective (grounding) the like that, if not correctly

conductor or disconnection of the protective to, could result in damage to the product or loss

earth terminal will cause a potential shock

hazard that could result in personal injury. C

Before Applying Power are fully understood and met.

Verify that all safety precautions are taken.

Make all connections to the unit before W

applying power. Note the instrument's A WARNING notice denotes a hazard. It calls

external markings described under attention to an operating procedure, practice,

Fuses death. Do not proceed beyond a WARNING

The instrument contains an internal fuse, which notice until the indicated conditions are fully

is not customer accessible.

n Case of Damage

I

Instruments that appear damaged or defective

should be made inoperative and secured against

eration until they can be repaired b

AUTION

C

AUTION notice denotes a hazard. It calls

A C

erformed or adhere

of important data. Do not proceed beyond a

AUTION notice until the indicated conditions

ARNING

rofrep yltcerroc ton fi ,taht ekil eht ro "slobmyS ytefaS" med or

adhered to, could result in personal injury or

understood and met.

D

o Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence

of flammable gases or fumes.

D

o Not Remove the Instrument Cover

Only qualified, service-trained personnel who

are aware of the hazards involved should

remove instrument covers. Always disconnect

the power cable and any external circuits before

removing the instrument cover.

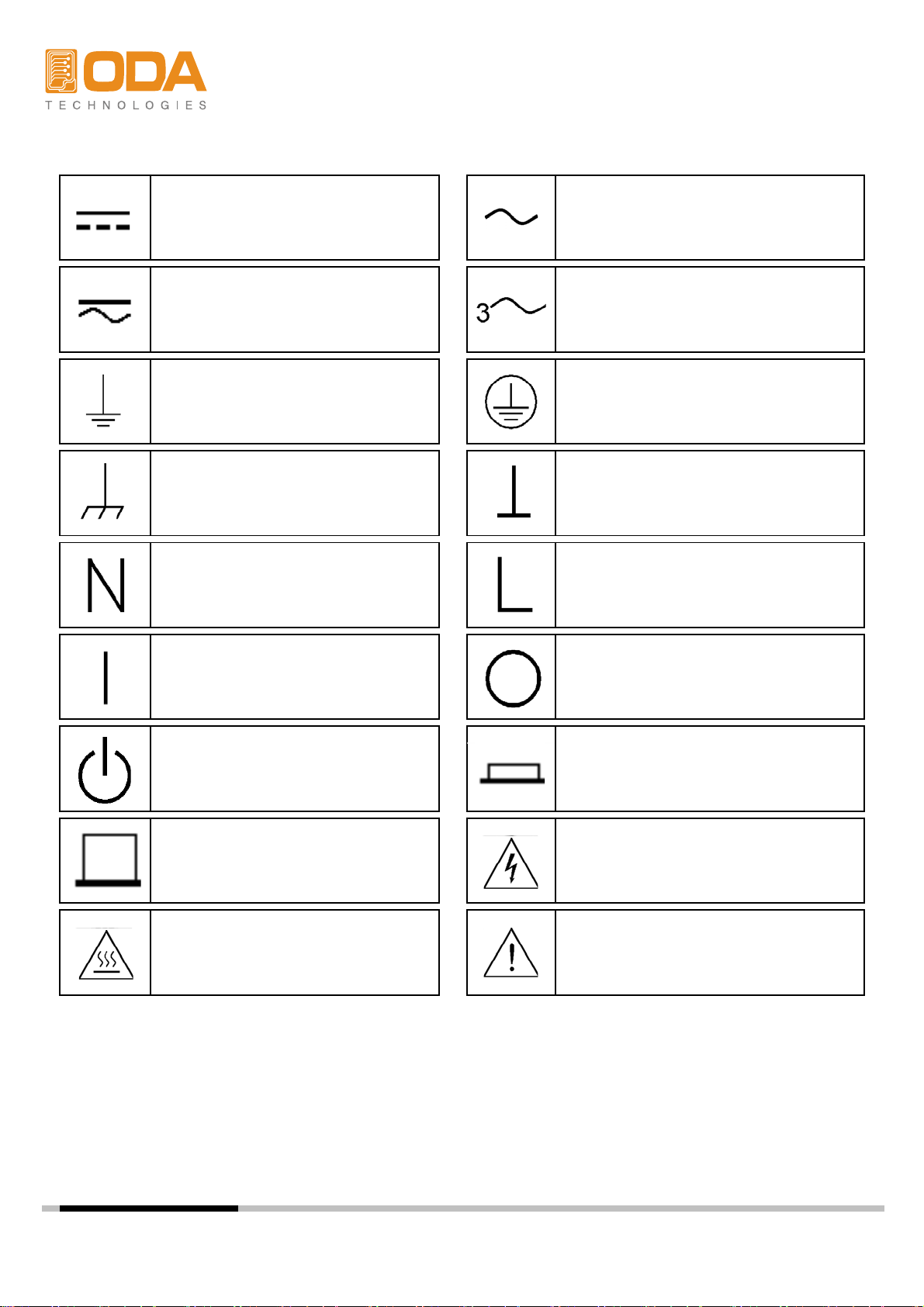

Safety Symbol

Direct current

Both direct and alternating current Three phase alternating current

Earth (ground) terminal

Frame or chassis terminal

Neutral conductor on

permanently installed

equipment

Alternating current

Protective earth ground terminal.

Terminal is at earth potential.

Line conductor on

permanently installed equipment.

Standby supply. Unit is not

completely disconnected

from ac mains when switch

is off

Out position of a bi-stable

push switch

Caution, hot surface

ylppus ffO ylppus nO

In position of a bi-stable push

switch

Caution, risk of electric shock

Caution, refer to accompanying

documents

CONTENTS

-

R

p

-

-

n

-

-

Default Setti

-

-

-

-

-

-

gp

1. General Information

1-1. Feature

General Feature

emote Interface

Calibration

Factory Option

Cycling Mode

Self Testing

---------------------------------------------

--------------------------------------

1-2. Accessories and Options

Accessories

O

tions

1-3. Check

Instrument Check

electrical Check

1-4. Operating Conditions

------------------------------------------------

-------------------------------------

1-5. Check Before Power On

Output Terminal check

Power Cord check

Input Power Line Check

1-6. Check After Power O

Display Procedure on the LCD

ng Values

1-7. Installation

Cooling

Bench Operation

Rack Mounting

---------------------------------------------

-------------------------------------

---------------------------------

-----------------------------------

6

6

7

8

8

9

11

12

2. Front Panel, Rear Panel Composition & Function

2-1. Front Panel Voltage & Current Setting

2-2. Display & Condition Indicator LAMP

2-3. Rear Panel Composition

2-4. Output Check

Voltage Output Check

Current Output Check

-------------------------------------------

-----------------------------------

- 2 -

----------------------

------------------------

---------

14

17

18

19

20

3. Front Panel Operating

-

-

33. Remote Voltage Sensing

24

-

3-5. P

(OCP)

29

-

37. KEY LOCK

36

F

-

LMT DISPLAY Function

-

SEQUENCE Number input

-

-------------------------------------- 21

Over view

3-1. Constant Voltage Operating(CV)

3-2. Constant Current Operating(CC)

-

CV Regulation

Output Rating

Output Noise

Stability

Connecting Remote Voltage Sensing

-----------------------------------

---------------------------

---------------------------

3-4. Programming Over Voltage Protection(OVP)

rogramming Over Current Protection

3-6. I/O Config & LOCAL

RS232C Setting

RS232C Setting(Option)

GPIB Setting

GPIB Setting(Option)

-

---------------------------------------------

3-8. STORE / CALIBRATE

3-9. RECALL / FACTORY

3-10. OUTPUT ON/OF

3-11. V/I & LMT DISPLAY

V/I Function

--------------------------------------

--------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------

-----------------

-----------------

22

23

26

31

37

38

38

39

3-12. CYCLING MODE

Feature

Preparing Record Table

STEP

STEP Setting

SEQUENCE

REPEAT

REPEAT input

RUN / STOP

RUN / STOP Proceed

3-13. ERROR

ERROR Check

3-14. ESC

------------------------------------------------

---------------------------------------------------

----------------------------------------

40

47

47

- 3 -

4. CALIBRATION

g

-

-

-

44. Calibration Technique

49

Positioning Calibrating Location

Positioning Calibrating Location

-

4-6. Calibration(for GPIB) Using REMOTE INTERFAC

57

-

Y

-

-

-

-

E

-

-

4-1. Function

4-2. Preparing for Detailed Setting

---------------------------------------------

------------------------------------------------

-------------------------------48

4-3. Required Efficiency for Detailed Settin

-

Instrument Connection

Electronic Load

Current-Monitoring Resistor(shunt)

DVM(Digital Volt Meter)

Programming

--------------------------------------

----------------------

48

48

49

4-5. Calibration Using Front Panel

CALIBRATE KEY Structure

CALIBRATE Setting Area

Voltage CALIBRATE Operating

Current CALIBRATE Operating

Conneting Instrument

Remote Calibration Command Sequence

Voltage CALIBRATE Operating

Current CALIBRATE Operating

5. FACTOR

5-1. Feature

------------------------------------------------

------------------------------------------------

5-2. FACTORY KEY Structure

5-3. CYCLING CLEAR

CYCLING CLEAR Operating

5-4. USER-MEM CLEAR

USER-MEM CLEAR Operating

5-5. CALI-RESTOR

CALI-RESTORE Operating

5-6. CALI-BACKUP

CALI-BACKUP Operating

----------------------------------------

--------------------------------------

-------------------------------------------

-------------------------------------------

---------------------------

---------------

---------------

-----------------------------------

51

59

59

59

59

60

61

62

- 4 -

6. SCPI Command

s

x

-

-

-

65

-

-

64. Output Voltage & Current & Operating Commands

65

d

d

-

-

-

-

r

o

-

-

-

-

-

7-5. Calibrati

r

77

-

-

-

-

-

-

-

-

-------------------------------------------

6-1. Commands Synta

6-2. Commands

Output Setting Commands

Measurement Commands

Calibration Commands

Factory Commands

System Commands

6-3. Apply Comman

---------------------------------------------

-------------------------------------------

6-5. Measure Commands

6-6. Calibration Comman

6-7. Factory Comman

6-8. System Command

----------------------------------------

------------

-------------------------------------

-------------------------------------

----------------------------------------

----------------------------------------

63

63

63

65

69

70

71

71

7. Error Messages

7-1. Running Error

7-2. Hardware Error

-------------------------------------------

-------------------------------------------

-------------------------------------------

7-3. Remote Calibration Erro

7-4. Cycling Mode Err

on Erro

----------------------------------------

----------------------------------------

7-6. Fixed Memory Check Error

7-7. Interface Commands Error

8. Option

8-1. Analog Input

8-2. Rear Output

9. Specifications

-------------------------------------------

-------------------------------------------

-------------------------------------------

-------------------------------------------

-----------------------------------

--------------------------------

--------------------------------

75

75

75

76

77

78

78

80

80

81

82

10. Caution

------------------------------------------------

- 5 -

85

1. General Information

instrument) protocol. In addition, It is designed to be equipped in 3U*19inch Half-Rack

▌

▌Insulation with instrument & Floating Logic realization

▌Store Voltage, Current, Slope time, Delay time each step up to 100 slots

▌

1-1. Feature

ODA Technologies's OPS-Series are high efficiency, high performance programmable DC power supply

RS232C & GPIB(IEEE-488.2) interface based on SCPI (Standard Commands for Programmable

*

General Functional Features

▌Simple setting using jog & shutttle.

▌Output voltage, current block & restore function (Output ON/OFF)

▌Front panel's key lock function

▌Caution alarms on events

High accuracy & High limit of resolution

▌Built-in Remote Sensing for Load Voltage(V-Sensing)

▌Over Voltage Protection(O.V.P) / Over Current Protection(O.C.P) Secure Function

▌Excellent Load Regulation & Line Regulation

▌Operating condition(Voltage,Current,OVP,OCP) Store & Recall up to 10 slots.

▌Store Error message (up to 10 messages)

▌3U * 19inch Half-Rack compatible

Remote Interface Features

▌GPIB(IEEE-488.2) & RS232C Interface

▌SCPI(Standard Commands for Programmable Instruments) compatible

▌High speed setting & measument

▌plenty of Commands equipped

▌Simple interface setting using front panel I/O config

▌Insulation with instrument & Floating Logic realization

▌SCPI programming grammatical order check options equipped

-

.

Calibration Features

▌adopted Software Calibration do not requires inside correction

▌Simple calibration operating using Independence or PC Interface

Factory Function Features

▌Initialization memory function up to 10 memories

▌Initialization mamory function up to 100 cycling mode memories

▌Calibration restoration function

▌Calibration back up function

Cycling mode Features

▌Operating realization by instrument itself

▌Safe storation used by permanent memories

▌Cycling mode tests available using sequence panel

Self Test Features

▌Front panel Test ▌ADC H/W Error Test

▌Remote interface Test ▌UnRegulated condition Test

Memory data verification Tes▌ADC/DAC Calibration verification Test

- 6 -

1-2. Accessories and Options

Function that blocks Voltage/Current in OUTPUT OFF Mode

Accessories

▌1 Power Cord

▌Output load (+), (-) 1 each. (Part number : OE-LW-BCW-2.0)

▌2 pcs metal short-bar for voltage sensing. (Part number : OM-S20)

▌1 User's Manual

▌DEMO Software CD (Windows application manual included)

Option

▌GPIB Module

▌GPIB Calbe 1M, 2M, 4M

▌RS232C Cable 1M, 2M, 4M, 10M

▌100V ± 10% , 50~60Hz AC input power

▌115V ± 10% , 50~60Hz AC input power

▌230V ± 10% , 50~60Hz AC input power

▌Rear output

▌Rack mount support

▌Block system when it is overlapped.

Function that blocks Voltage/Current in "**OUTPUT OFF**" Mode.

.

- 7 -

1-3. Check

Technologies in the future. If you return the power supply for service, attach a tag

▌Check the panel surfaces are free of dents and scratches

▌Wh

ODA

▌

▌Relative Humidity : Less than 80%

When you receive your power supply, inspect it for any obvious damage that may have

occurred during shipment. If any damage is found, notify the carrier and the nearest ODA

Sales Office immediately. Warranty information is shown in the front of this manual. Keep

the original packing materials in case the power supply has to be returned to ODA

identifying the owner and model number. Also include a brief description of the problem.

Mechanical Check

▌Check the broken key, encoder switch, power switch.

▌Check the broken output terminals.

.

▌Check the cabinet is free of scratches.

▌Check the LDC display is not scratched or cracked.

Electrical Check

en turning on the power, it shows instrument model and

▌Check the model Number is matched with displayed model number.

website at first.

▌After, it shows "**OUTPUT OFF**" message, verifies to a high level of confidence

that the power supply is operating in accordance with its specifications.

Note

Service Center : 82-32-623-5454

Home page : www.odacore.com

1-4. Operating Conditions

This instrument is designed for following environmental conditions in other to use

optimized condition

▌Environment Temperature : 0 ∼ 40℃

Relative Humidity : Less than 80%

▌Operating Altitude : Less than 2000m

▌No Vibration

▌Avoid Electric Magnetic Field

- 8 -

1-5. Check Before Power On

electric shock hazard to the operator

pp

a

a

and the worker

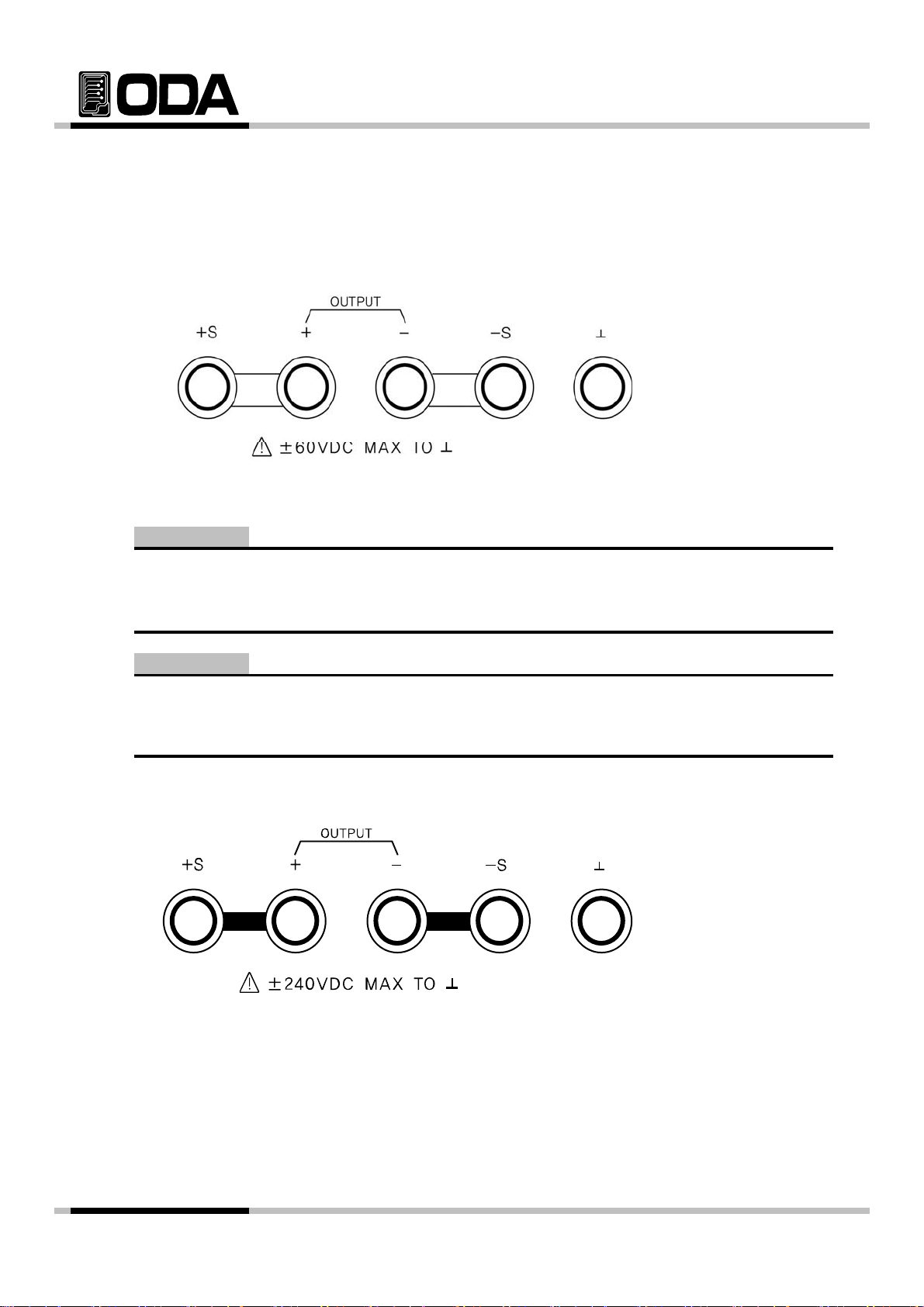

<Diagram 12>

Output Terminal Check

▌Check the front panel two fixed outputs two variable output terminals and GND terminal.

Metal Short-bar

<Diagram 1-1>

WARNING

Floating the power supply output more than ±60 Vdc from the chassis presents an

.

WARNING

If metal short bar that is su

floated. Please make sure that there should be no contact between insulated output termin

.

insulate-bar

lied from our company excluded, maximum ±240Vdc output c

-

- 9 -

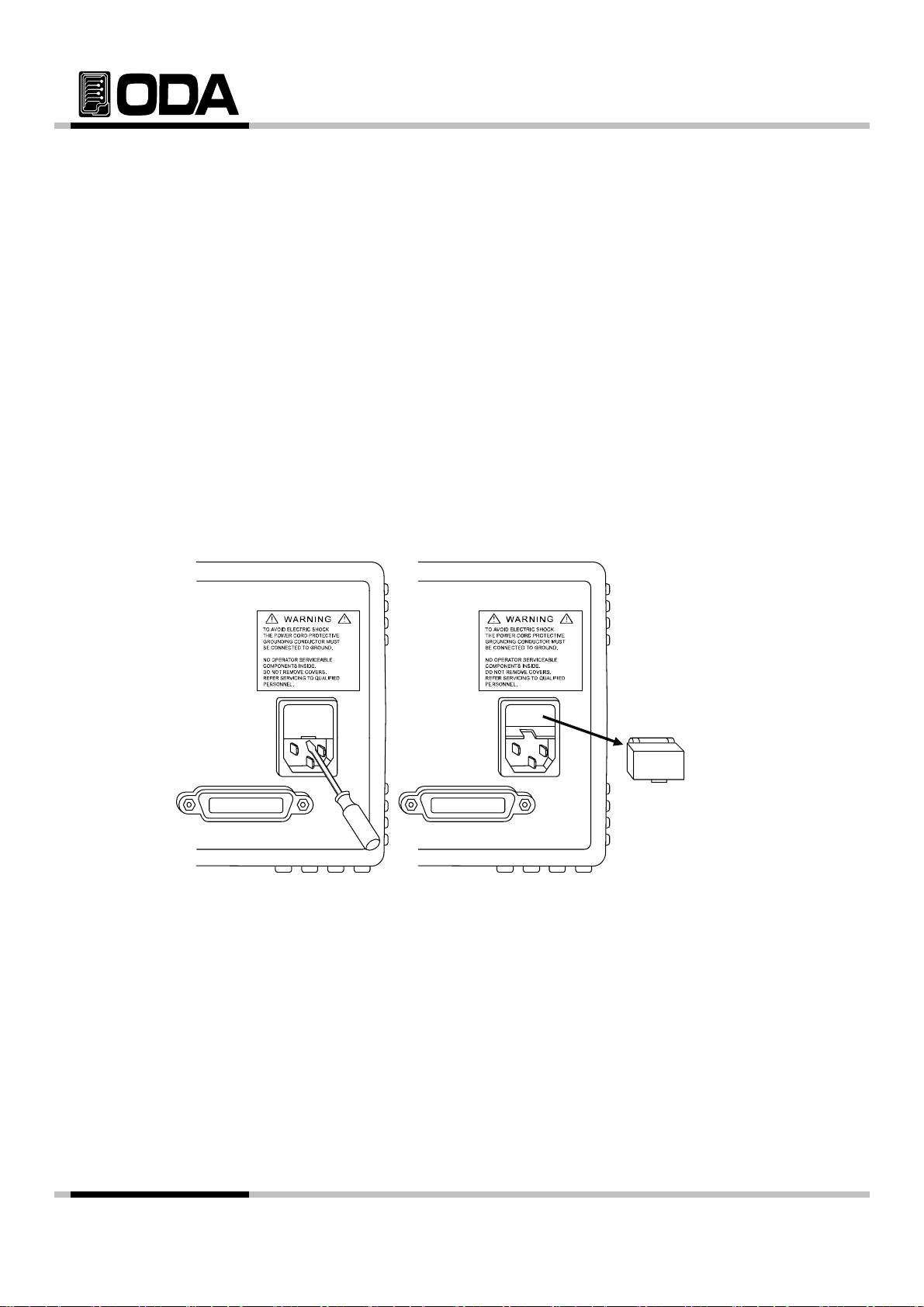

Power Cord Check

▌In other to prevent the instrument severe damage from overload, fuse is installed

▌Your power supply is equipped with a 3-wire grounding type power cord; the third

conductor being the ground. The power supply is grounded only when the powerline

cord is plugged into an appropriate receptacle. Do not operate your power

supply without adequate cabinet ground connection.

Input Power Line Check

▌You can operate your power supply from a nominal 198~242 V single phase ac

power source at 47 to 63 Hz. AC100V, 110V, 115V, 230V input power is optional.

Refer to chapter "1-2. Accessories & Options"

in inlet case. If the fuse is also repeatedly when power turns on, check the

input power line or broken braker and then call to nearest ODA Technologies A/S Center

Input power connection is following.

<Diagram 1-3>

- 10 -

1-6. Check After Power On

t

▌Output Voltage : 0V

▌Cursor Location : Default Voltage Select

pppypp

When turning on the power switch, the front-panel display will light up briefly while the

instrument performs its power-on default value setting. And also keep the ex-remote

interface setting mode, voltage value is zero and current value is max value.

OVP & OCP will be set on maximum output value.

Display Procedure on LCD

▌Homepage "WWW.ODACORE.COM" will be displayed.

Visit our homepage and we will provide various service and info about upgrading, manual and software.

▌Also, Front lamp OVP, OCP, LOCK, RMT will be all lighted.

CV & CC are not included.

▌"INITIALIZING. . ." Message will be displayed.

There will be a reset using non-volatile memory.

▌Also, Front lamp OVP, OCP, LOCK, RMT lights will be turned off.

CV & CC are not included.

▌"SELF-TESTING. . ." Message will be displayed.

While self-testing, message below will be displayed.

Front panel Tes

Remote interface Test Check Remote interface for PC network

Memory data verification Test Check Instrument's info & setting

ADC H/W error Test Check ADC controlling

UnRegulated condition Test Check Output voltage Floating

ADC/DAC Calibration Test Check ADC & DAC Calibration Data

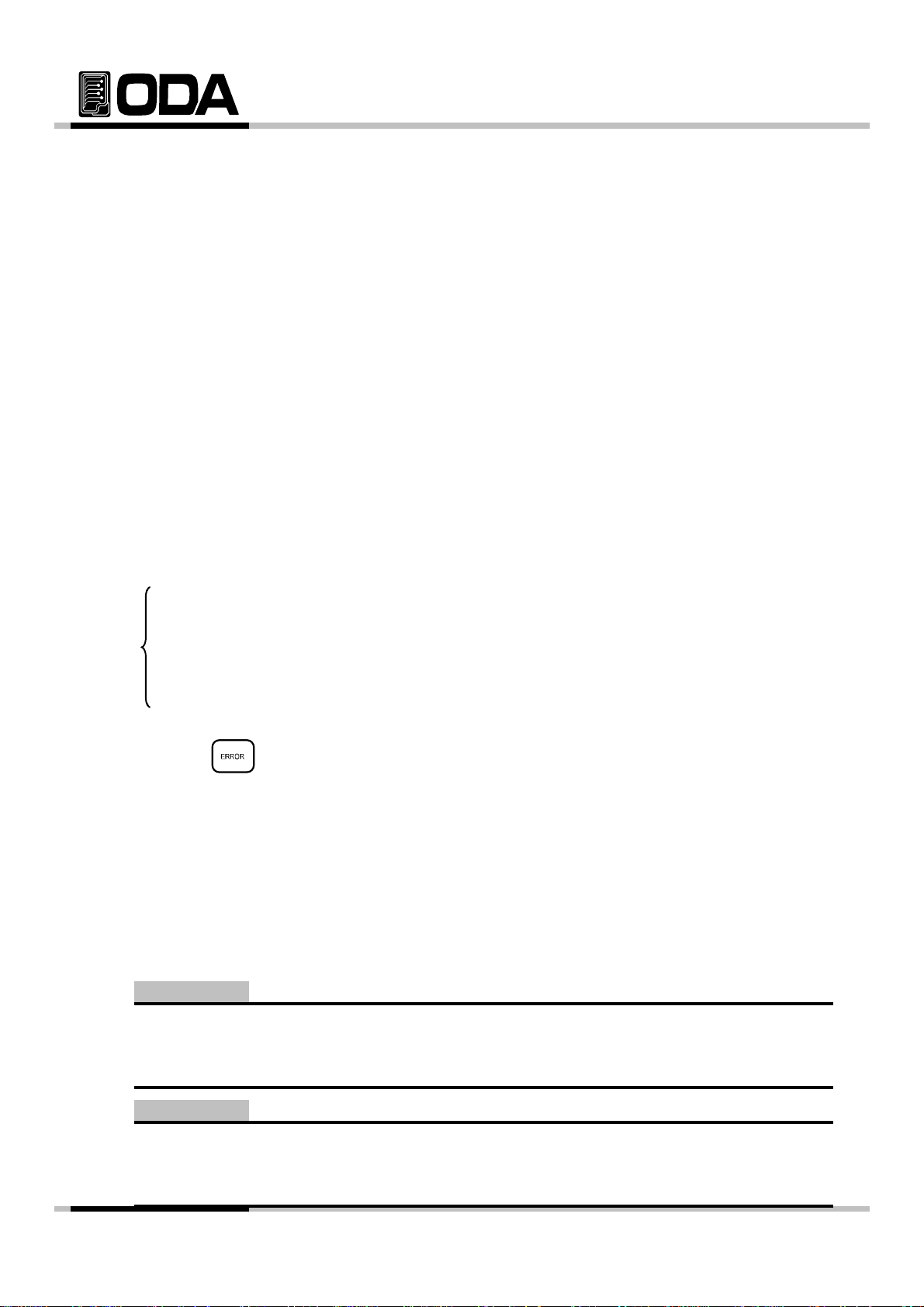

When an error occurs, there will be a alarm sound from instrument, and error No will be stored.

Check Front panel's connection

Press Key to check error code.

Please read “7. Error Messages” to check details about error code.

Default Setting Value

▌OVP : OVP Max value, OVP setting ON ▌Remote Interface : maintain previous setting

▌OCP : OCP Max value, OCP setting ON

▌Output Current : Limit setting max value Voltage : 1V scale

▌KEY LOCK : OFF Current : 5A > 100mA scale

▌Condition after Self-testing : "**OUTPUT OFF**"

50A > 1A scale

Note1

The RS232C is attached in the instrument when the power supply is shipped from the

factory for remote interface configuration and baudrate is set 9600bps at first time.

In case of choosing RS485 interface, address no. is 05 when this is shipped from the factory.

Note2

It has the option function that is last setup stated memory & recall. This function, when you

turn down the instrument, the device store the last state(voltage, current and state) and after

then the operator turn on again, this starts from last state.

- 11 -

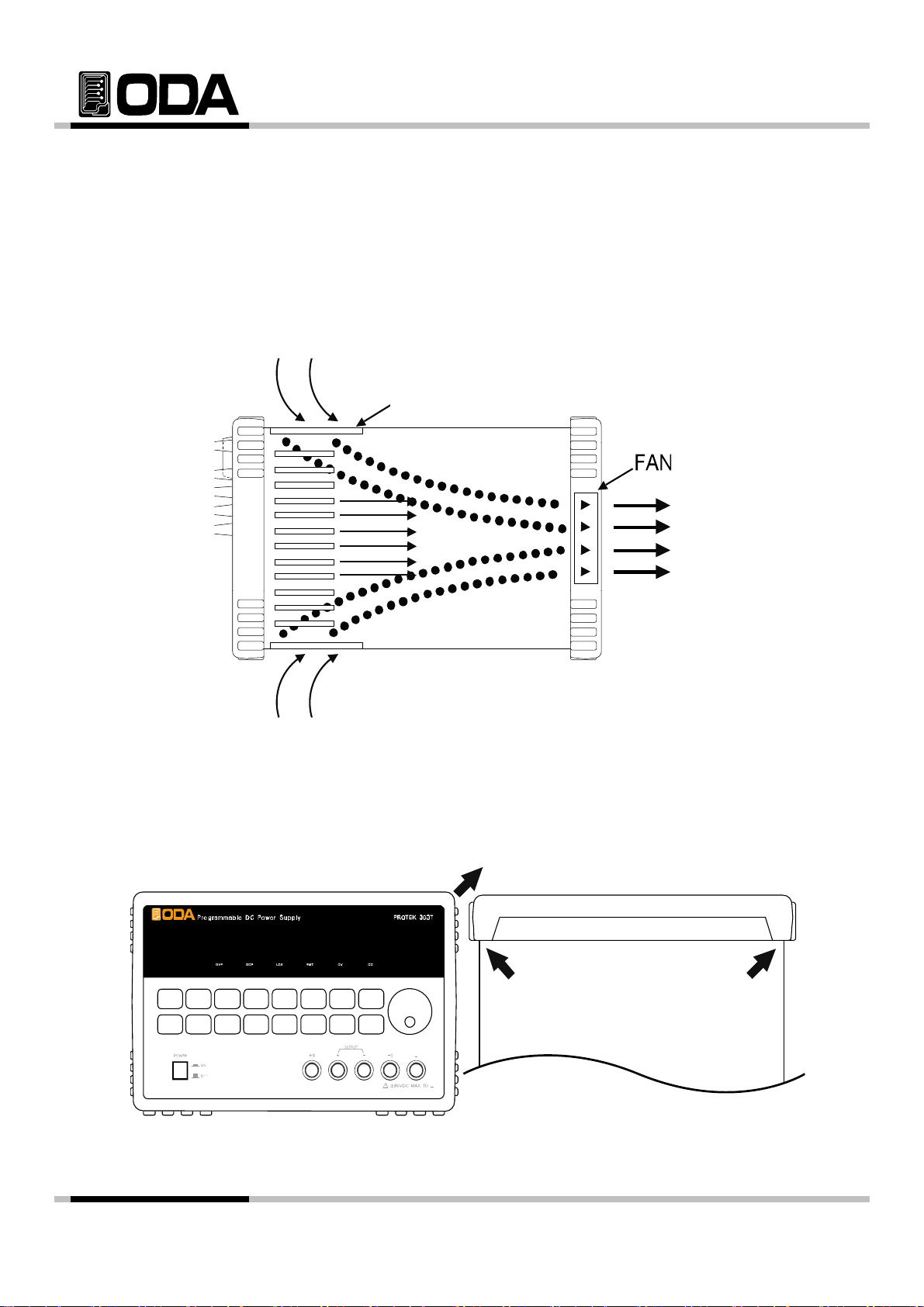

1-7. Installation

40 °C

pply by d

▌Y

ppl

fficient sp

Cooling

▌The power supply can operate without loss of performance within the

temperature range of 0 °C to 40 °C, and with derated output current from

to 55 °C. A fan cools the power su

panel and exhausting it out the sides. Using an ODA rack mount will not

impede the flow of air.

Draft

rawing air through the rear

<Diagram 1-4 Bottom view>

Bench Operation

our power su

at the sides and rear of the power supply for adequate air circulation.

y must be installed in a location that allows su

ace

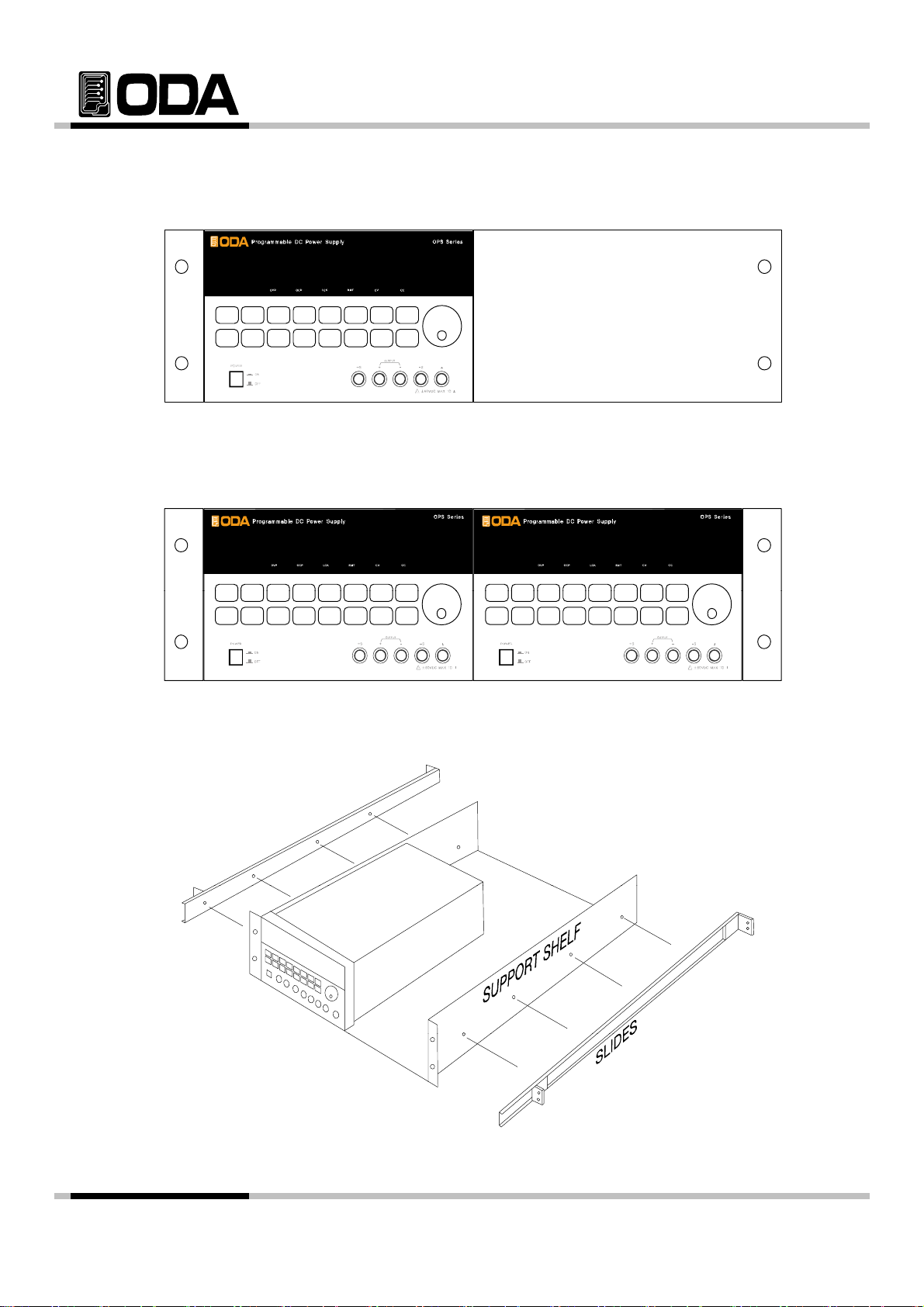

Rack Mounting

▌It is designed to be compatible in 3U * 19inch, please desort bumper (diagram below)

<Diagram 1-5>

- 12 -

▌It is convenient to equip OM-3U19-FS(Option) supported by Power Supply indenpence

on the rack.

<Diagram 1-6>

▌It is convenient if you equip power supply double on a rack with OM-3U19-FD(option).

<Diagram 1-7>

▌It is simpler to use instrument if you use inside cabinet & slider OM-3U19-SS(Option).

<Diagram 1-8>

- 13 -

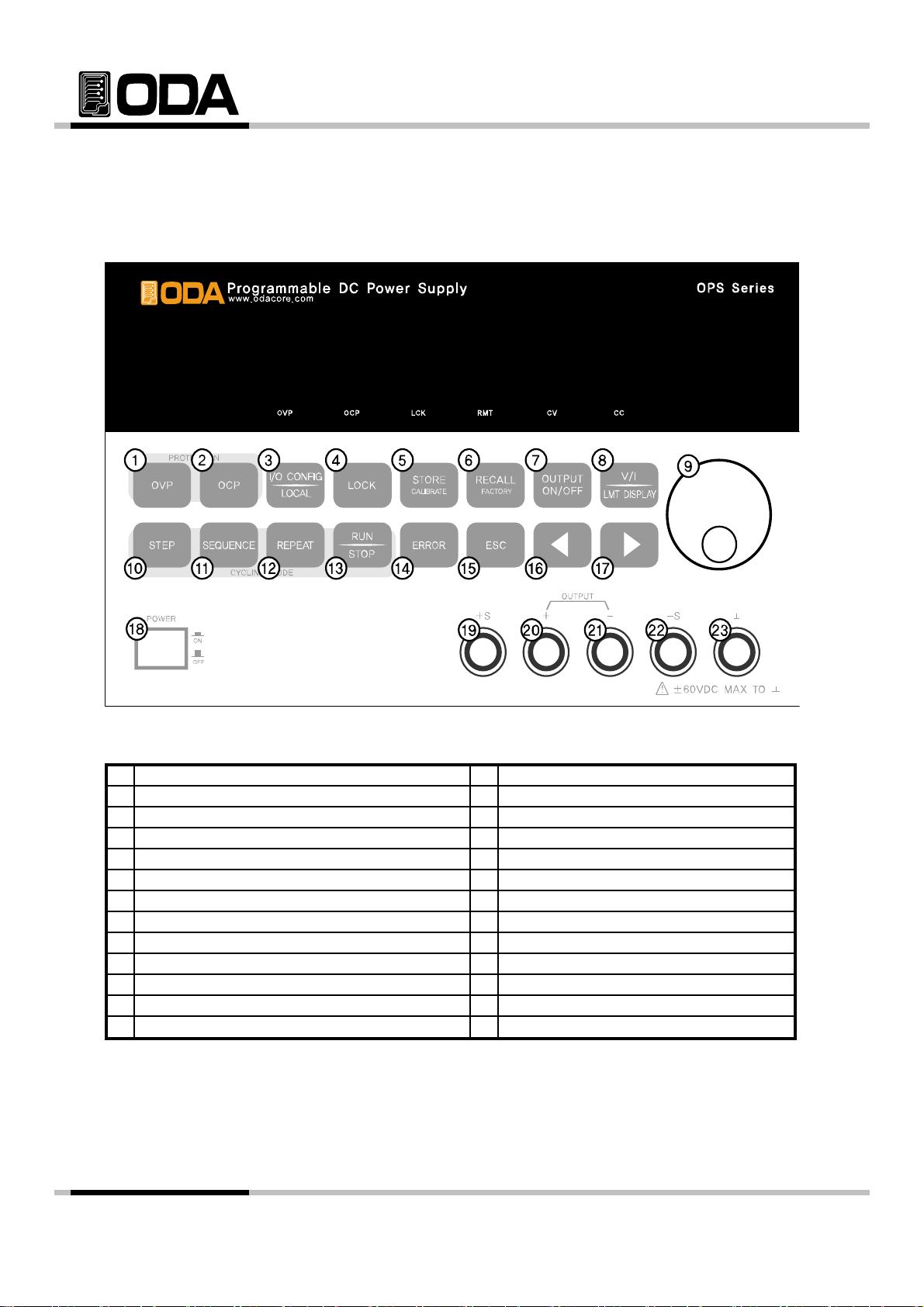

2. Front Panel, Rear Panel Composition & Function

y

e

p

6

19

13

Restore memory save slot or Factory Key

K

i

y

y

+ output terminal

13 Cycling mode s RUN/STOP Key

Over Voltage Protection Key Error message Display Key

114

Over Current Protection Key

215

I/O CONFIG or LOCAL Key

316

LOCK Key

417

Store present condition or Calibration K

518

Restore memory save slot or Factory Ke

Output Voltage/Current ON/OFF

720

Choice Voltage/Current or Limit Display

821

922

Cycling mode's STEP setting Key

10

Cycling mode's Sequence control Key

11

Cycling mode's repeating Key

12

C

cling mode's RUN/STOP Ke

Menu Escape Key

Voltage/Current Cursor or Menu Key

Main Power ON/OFF Switch

Remote V+ Sensing Input terminal

+ out

- output terminal

Remote V- Sensing Input terminal

Earth GND terminal Voltage/Current/Numbering Encorder Sw

ut terminal

- 14 -

1. Over Voltage Protection Key

yp

i

pp

t

Over voltage protection function. On/Off selectable, able to change OVP Level value.

2. Over Current Protection Key

Over current protection function. On/Off selectable, able to change OCP Level value.

3. I/O CONFIG or LOCAL Key

Configures the power supply for remote interfaces. Set baudrate of RS232C. If remote

interface is RS485, it can be used for setting baudrate & address. Also under Remote Interface

situation, in other to recover bench top using, this key operate to local from remote.

4. LOCK Key

Lock/Unlock Key on the Front panel

5. Store current condition or Calibration Key

Store Voltage, Current, OVP / OCP Setting value. Press Power button while holding this key. Th

lead you in Calibration mode, voltage/current Calibration.

6. Memory save slot restoration or Factory Key

Saved Voltage, Current, OVP/OCP Setting value can be a

while holding this key. This will lead you in Factory mode, which allows you to restore or reset

calibration.

lied to instrument. Press Power but

7. Output Voltage/Current ON/OFF

Enables or disables the power supply output. This key toggles between on and off.

8. Voltage/Current select or Limit Display Key

Shows voltage and current limit values on the display and allows knob adjustment for setting

limit values.

9. Voltage/Current Cursor or menu changing key

Move the blinking digit to the left. In the menu mode, it can change menu tree.

Under the **OUTPUT OFF** mode, this key work on recall key.

10. Cycling mode's STEP setting Key

Appoint 1~100 slots, Set Voltage, Current, Slope Time and Delay Time.

11. Cycling mode's Sequence control Key

Setting repeating panels from ( )slot to ( )slot.

12. Repeating setting key of Cycling mode

Setting No. of repetition.

13. Cycling mode's RUN/STOP Key

Operate or Cancel Cycling mode after setting 10 → 11 → 12.

- 15 -

14. Error message Display Key

g

gggy

When error occurs from Self-testing, Alarm sound will come out from the instrument, and will b

up to 10 memories slot

15. Menu Escape Key

Canceling while in the Menu.

16. Voltage/Current Cursor or menu changing Key

Move the blinking digit to the left.

In menu mode, it can change menu tree.

Under the "**OUTPUT OFF**" mode, this key work on store key.

17. Voltage/Current Cursor or menu changing Key

Move the blinking digit to the left.

In menu mode, it can change menu tree.

Under the "**OUTPUT OFF**" mode, this key work on store key.

18. Main Power ON/OFF Switch

This switch allows to disable AC Power.

19. Remote V+ Sensing input terminal

+ Output Voltage sensing input terminal

20. + Output terminal

+ Output terminal.

21. - Output terminal

- Output terminal.

22. Remote V- sensing input terminal.

- Output Voltage sensing input terminal.

23. Earth GND terminal

GND terminal, it is able to connect to earth terminal of the DUT

- 16 -

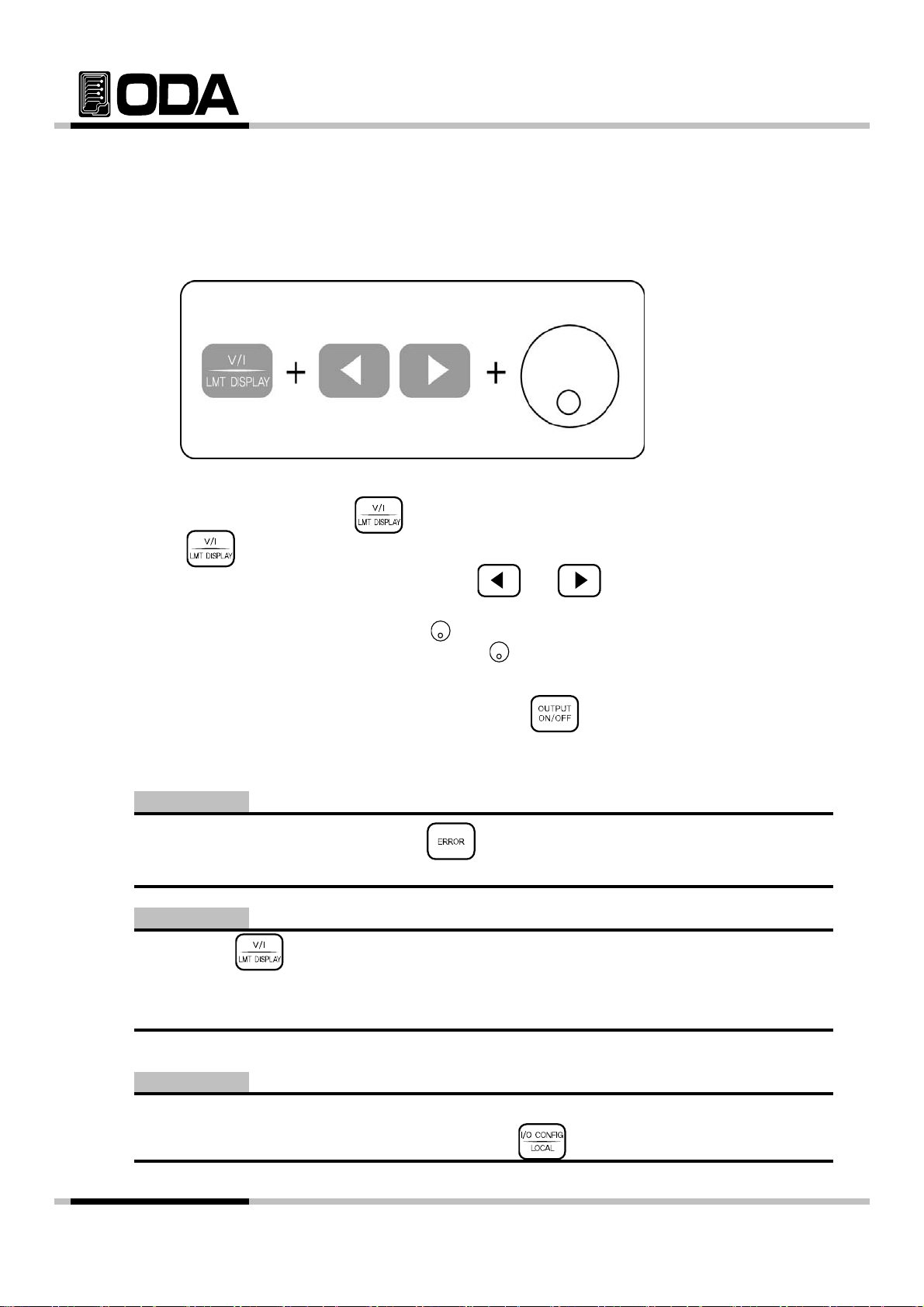

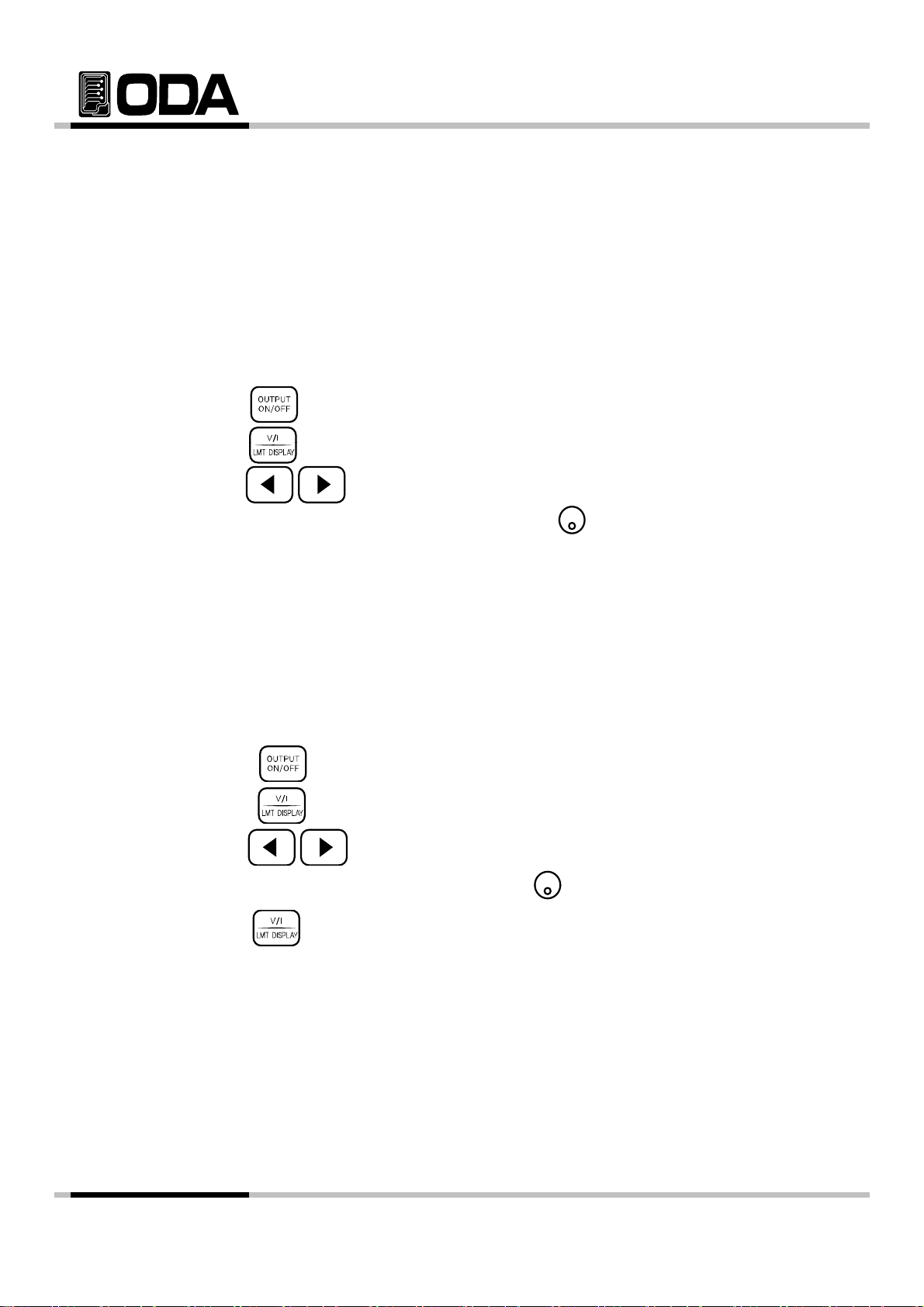

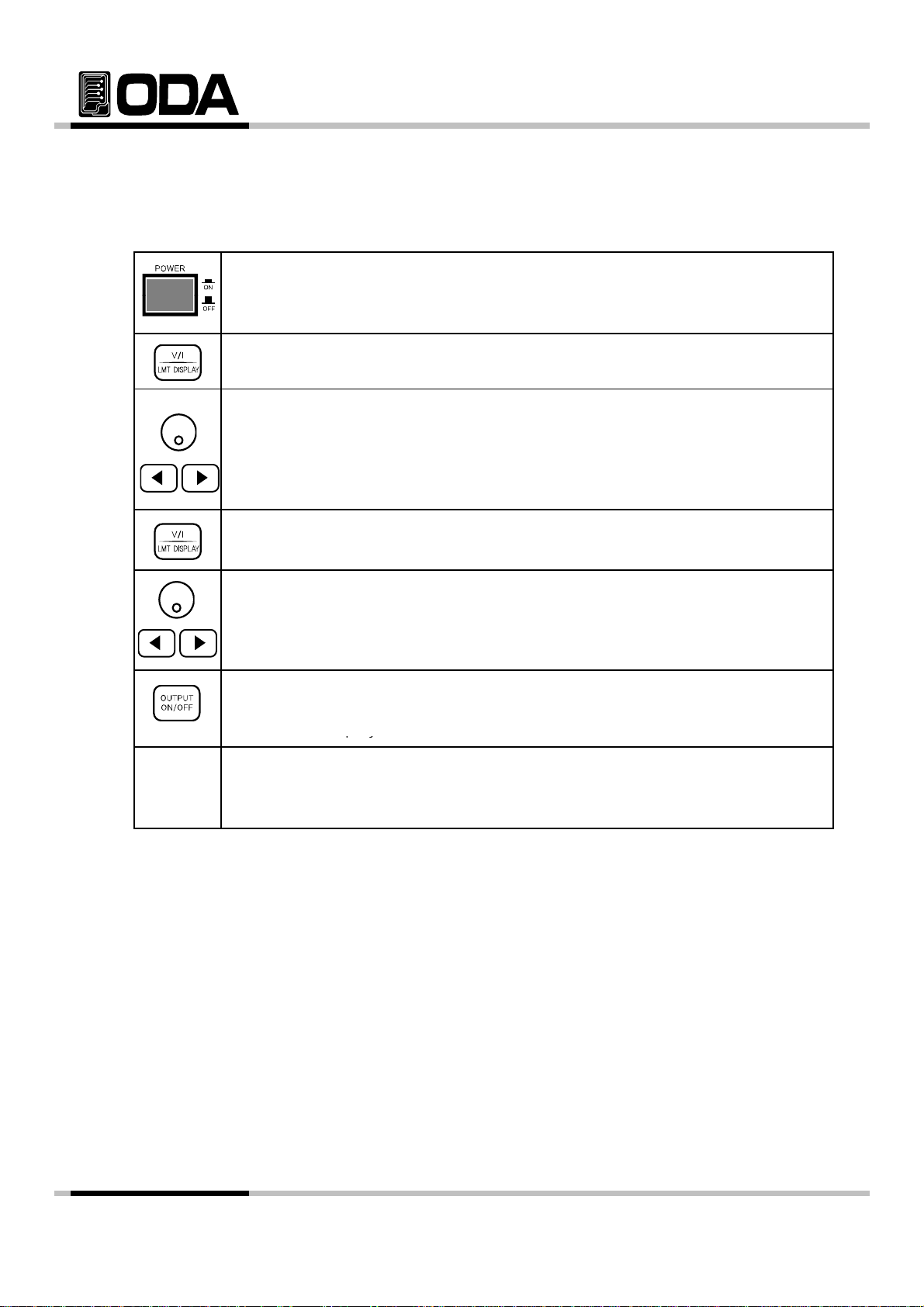

2-1. Front-Panel Voltage & Current Setting

Use the method below to change limit value of voltage and current.

1. Check "**OUTPUT OFF**" When the instrument turned on

2. Press V/I & LMT DISPLAY key to switch Limit Mode.

3. Press key to select Voltage and Current

4. To select incresing or decreasing digit, press or and position cursor key.

5. In other to increase limit value, turn the encoder clockwise.

In other to decrease limit value, turn the encoder anti-clockwise.

6. Confirm the change of setting value at VFD Display

7. In other to output the setting voltage & current, press key.

Note1

If there is a problem in "Self-test" Press key to confirm the error code.

Please check "7. Error Messages" for Error code.

Note2

When press key, disappear the message of "**OUTPUT OFF**" and then change to limit

display state, and cursor is blinking. At that time, if let the display time-out after 3 seconds,

**OUTPUT OFF** display at the LCD.

Note3

If it is under remote control, key and encoder switch on the front panel won't operate.

If turning to local mode from remote control, press key to change to local mode.

- 17 -

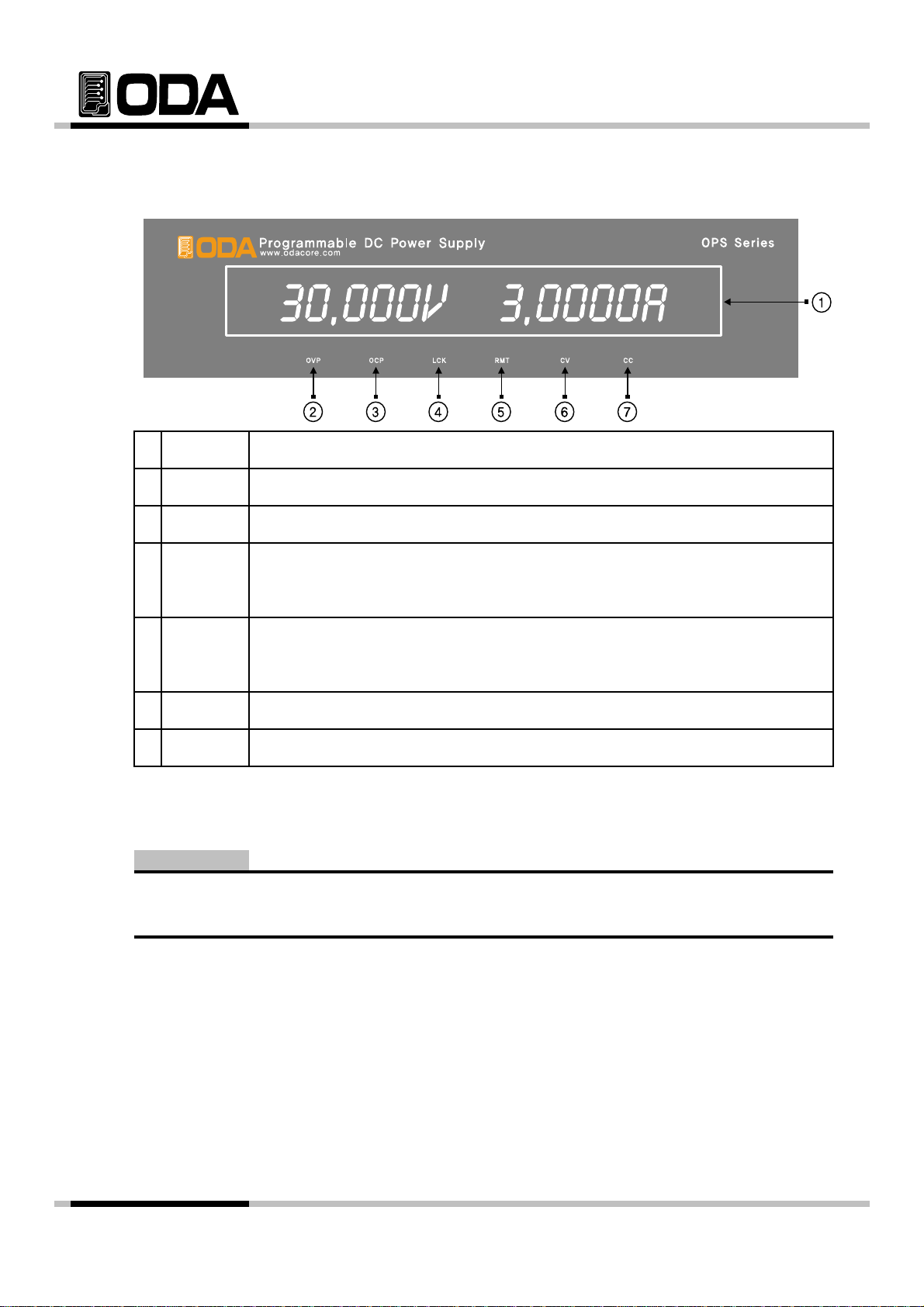

2-2. Display & Condition Indicator LAMP

p

e

p

e

1

2

3

4 LOCK

5 RMT

6

7

VFD

OVP

OCP

CV

Voltage Current & Message Display module

OVP Setting mode "Brightened bulb"

OCP Setting mode "Brightened bulb"

When it is

the light will go out and ables Key & Encoder.

In other to switch the dis

while the light bulb is ON.

Lights ON while Constant Voltage Mode.

Lights ON while Constant Current Mode.CC

ressed, Key & Encoder will disabled, when it is pressed onc

lay to Local, set Remote Interface and press k

Note

When the instrument turned on the first time, OVP, OCP, LOCK, RMT LAMP will lightened for 300ms

and will be turned off. CV & CC are not included.

- 18 -

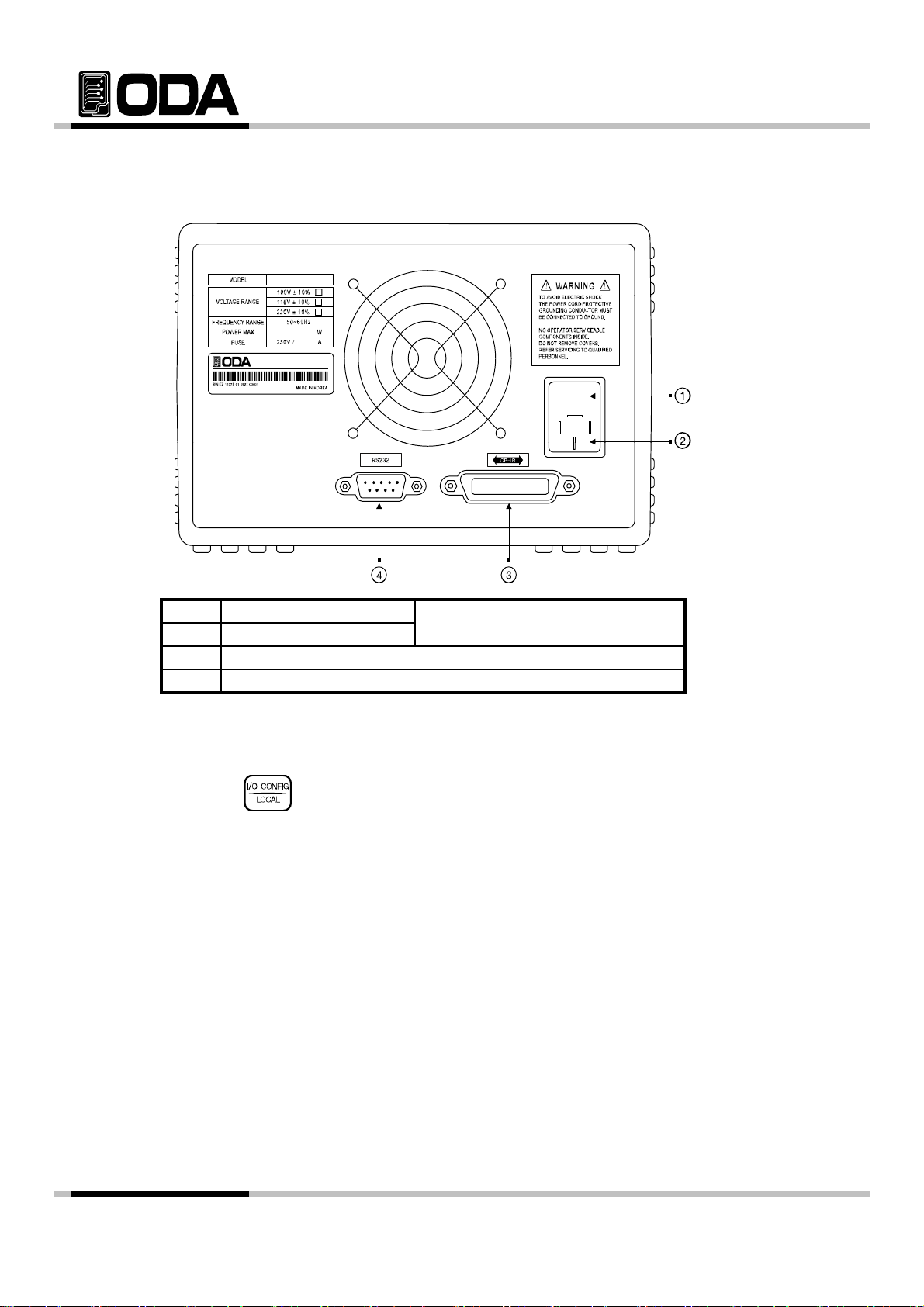

2-3. Rear Panel Composition

1

Fuse Holder

2

AC inlet

3 GPIB (IEEE-488) interface connector

RS-232C interface connector4

Power-line module

PC Interface Method

Press key on the front panel in other to set PC interface.

("Refer to chapter 3-3. I/O Config & LOCAL")

- 19 -

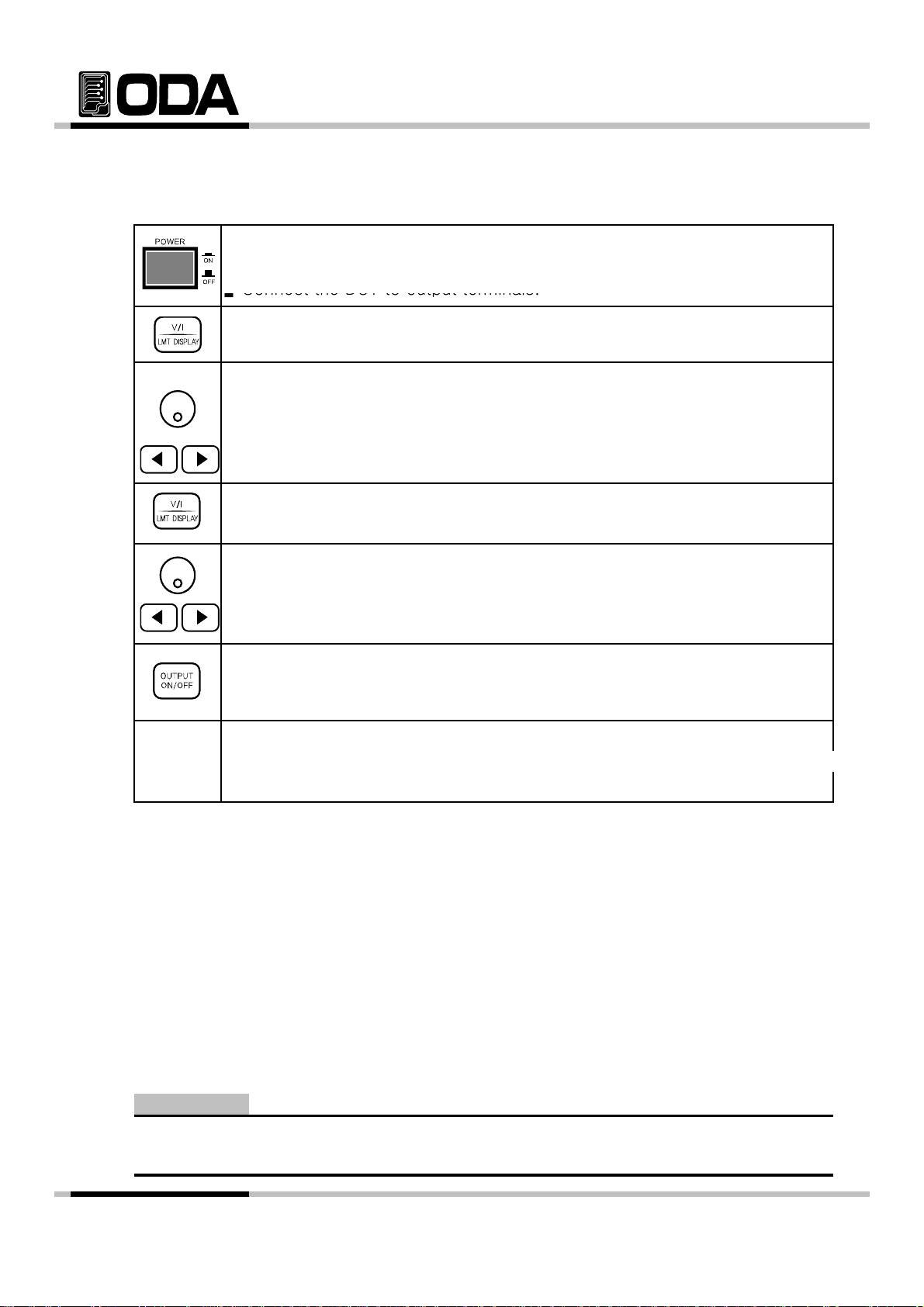

2-4. Output Check

d

prop

n

Press the

key and move the blinking cursor to voltage value

Set the current upto 5A by using encoder switch

clockwise

The following procedures check to ensure that the power supply develops its rated outputs an

erly responds to operation from the front panel. Forr complete performance and verificatio

refer to belows procedure.

Voltage Output Check

▌The following steps verify basic voltage functions with no load.

1. Turn on the power supply

2. The output is disabled (the OUTPUT OFF annunciator turns on)

3. In other to measure the voltage, connect the DVM to output terminals properly

4. Press the key in other to output the voltage.

5.

6. Press the key and select the voltage resolution what you want.

7. In other to increase or decrease, turn on the switch CW or CCW.

8. Compare between LCD display real voltage value and DVM annunciator.

.

Current Output Check

▌The following steps check basic current functions with a short across the

power supply's output.

1. Turn on the power supply

2. The output is disabled (the OUTPUT OFF annunciator turns on)

3. Press the key in other to output the current.

4. Press the key and move the blinking cursor to current value.

5. Press the key and select the current resolution what you want.

6.

.

7. Press the key in other to output the current.

8. Compare between LCD display real current value and DAM annunciator.

- 20 -

3. Front-Panel Operating

6. I/O Config & LOCAL

So far you have learned how to install your power supply and perform initial operation.

During the initial operation, you were briefly introduced to operating from the front

panel as you learned how to check basic voltage and current functions. This chapter

will describe in detail the use of these front panel keys and show how they are used to

accomplish power supply operation.

Overview

1. Constant Voltage (CV)

Explanation about constant voltage output mode operation.

2. Constant Current (CC)

Explanation about constant current output mode operation.

3. Remote Voltage Sensing

Explanation about load's voltage sensing.

4. Programming Over Voltage Protection(OVP)

Explanation about over voltage protection.

5. Programming Over Current Protection(OCP)

Explanation about over current protection.

Explanation about remote interface setting and recovering to local mode.

7. KEY LOCK

Explanation about Front panel's locking function.

8. STORE / CALIBRATE

Explanation about User memory store.

9. RECALL / FACTORY

Explanation about how to use & apply the stored 『user memory』store.

10. OUTPUT ON/OFF

Explanation about the output disable or enable.

11. V/I 및 LMT DISPLAY

Explanation about voltage/current select or limit display.

12. CYCLING MODE

Explanation about Cycling mode.

13. ERROR

- 21 -

3-1. Constant Voltage Operating(CV)

▌

▌Connect the DUT to output terminals.

play

▌Pl

OUTPut[:STATe] {OFF|ON|0|1}

To set up the power supply for constant voltage (CV) operation, proceed as follows.

▌Turn ON the power supply

After turned on, check the power supply displays "**OUTPUT OFF**" .

Connect the DUT to output terminals.

▌In other to set the limit value, press the LMT key.

▌Adjust the knob & resolution button for the desired voltage limit.

▌Move the cursor to current.(Press the V/I Key once more)

▌Adjust the knob & resolution button for the desired current limit.

▌Enable the output.(Press the output ON/OFF key.)

After about 2.5 seconds later, power supply changes to readback display

from limit dis

ease check CV lamp is on, CC lamp is off.

If it is on and off opposite, check the load giving enough current, and raise

current limit value.

≫ Related Remote Interface Command

[SOURce:]VOLTage{<voltage>|UP|DOWN}

[SOURce:]CURRent{<current>|UP|DOWN}

:

Refer: OUTPUT OFF Block output

VOLT 10 Set voltage 10V

CURR 5 Set current 5A

OUTPUT ON Output Voltage & Current

.

Note

1. Select scale of increasing or decreasing voltage & current using cursor key.

2. ReadBack Display? It refers to displaying voltage & current 's output.

- 22 -

3-2. Constant Current Operating(CC)

After turned on, check the power supply displays

OUTPUT OFF

play

py

[SOURce:]CURRent{<

t>|UP|DOWN}

To set up the power supply for constant current (CC) operation, proceed as follows.

▌Turn on the power supply

"**

▌Connect the DUT to output terminals

▌In other to set the limit value, press the LMT Display key.

▌Adjust the knob & resolution button for the desired voltage limit.

▌Move the cursor to current.(Press the V/I Key once more)

▌Adjust the knob & resolution button for the desired current limit.

**"

.

≫ Related Remote Interface Command

[SOURce:]VOLTage{<voltage>|UP|DOWN}

OUTPut[:STATe] {OFF|ON|0|1}

Application :

▌Enable the output.(Press the output ON/OFF Key.

After about 2.5 seconds later, power supply changes to readback display

from limit dis

▌Check the CC annunciator is lit

If the CC annunciator turn off of twincle, choose a higher voltage limit.

curren

OUTPUT OFF Block output

VOLT 10 Setting voltage 10V

CURR 5 Setting current 5A

OUTPUT ON Voltage & Current OUTPUT ON

.

- 23 -

3-3. Remote Voltage Sensing

o

a

a

p

y

and power supply will be unregulated mode. Also, when each load leadline rise more than 1

When a electric load is connected from power supply's output terminal, voltage regulation will

from output terminal. Therefore, to supply accurate power to load, Remote Voltage Sensing

(V-Sensing) can be used. Please read below to use V-sensing correctly.

CV Regulation

Specification's voltage Load Regulation attribute.

While using V-Sensing, because of the change from current, 5mV should be added to this

between+S Point and +output terminal. Because, sensing lead line is power supply's feedb

It will stable when the resist value is below 0.5Ω.

Output Rating

Please read below about specification's output voltage & current.

When you use V-Sensing, the load leadline's voltage drop point will be added to it's load.

Therefore if you

the instrument will be unregulated not related to maximum voltage.

rint out more than maximum voltage, V-sensing mode will not guarantee

Note

What is UnRegulated mode? Disabled power supply's CC and CV

Output Noise

Noise from power supply's output can lead to a serious problem in Load Regulation.

Please follow the steps below :

▌twist sensing leadlines togeter to decrease noise from outside.

▌connect in a straight line with sensing leadline, when it's near load leadline.

▌cover sensing leadline when it's disclosed.

▌Noise cover equipment should be connected to GND in the closest location.

- 24 -

Stability

s

p

e

Al

ill be feedback

pply'

When load leadline is long and contains a lot of capacity, it can lead to a problem using VIt will act like a filter on a part of voltage feedback roof which is problem on sensing.

This will decrease the liablity of

so, this un-reliable roof w

To decrease these probablity, please follow steps below :

▌Connect Load & Sensing leadline as short as possible.

▌twist Load leadline to use.

▌Sensing leadline should be connected to load safely.

▌Do not connect load leadlines to sensing terminal.

ower supply, and voltage terminal supply could be instabl

to lead to power su

s erruption.

Remote Voltage Sensing Connection

Connect V-Sensing carefully checking +,- from coutput terminal to load.

If you connect load with sensing terminal, it can turn to unregulated condition, and its very

dangerous that voltage & current can be different from displaying value.

Note

To connect V-Sensing, please take out metal short-bar, and put it back on

if V-Sensing is not using.

< Diagram 3-1 >

- 25 -

3-4. Programming Over Voltage Protection(OVP)

▌P

▌

, p

▌

In OVP ON

condition, press OVP button once more

V

Disables Voltage when output voltage is higher than user set up.

Read below to set up OVP Level.

the OVP Level below can be diffierent from others

ower Switch On

After turning on, check "**OUTPUT OFF**" is displayed on the screen.

▌Press OVP key to Level & Set up.

VFD Display Description

In "OVP ON" condition

VFD Display Description

▌Change value using cursor keys.

▌Use encoder switch to change level value.

▌When the setting is done, press OVP key.

VFD Display Description

Message will be Displayed and return to front page.

▌To cancel, press ESC key.

There is no cancelling message, return to front page.

▌To disable OVP, press OVP Key

OVP ON

ress OVP button once more.

OVP-LEVEL 32.0

CHANGED

.

VFD Display Description

▌Press Left or Right cursor key while "OVP ON" displayed.

VFD Display Description

▌To save "OVP OFF" press OVP Key.

VFD Display Description

Message will be Displayed and return to front page.

▌To cancel, press ESC key.

There is no cancelling message, return to front page.

OVP ON

OVP OFF

CHANGED

- 26 -

≫ Related Remote Interface Command

OVP Level,

message will be displayed.

If output voltage is higher than

OVP Level

OVP TRIPPED

message will be displayed

Second, when you used load that causes counter-electromotive force from coil & motor.

Second, when you used load that causes counter electromotive force from coil & motor

[SOURce:]VOLTage:PROTection{<voltage>}

[SOURce:]VOLTage:PROTection:STATe {0|1|OFF|ON}

Refer: VOLT:PROT 20 OVP Level Setting

VOLT:PROT:STAT ON 또는, OVP On

VOLT:PROT:STAT OFF OVP Off

Note

Read reference "1-6. Check after power on" for more info about first OVP Setting

If output voltage is higher than

It disables output voltage & current from sources.

If you wish to output voltage & current, please remove the load and used the method below

the causes of trip occuring Trip are :

First, The different OVP Level can cause trip. Therefore raise level value to

get resolution.

Can be protected as below diagram

Third, When sources used by load also can cause tripping. This happens when

source one is used from load

"OVP TRIPPED"

,

NOTE : Connect +S Diode

Anode while using Remote

.

.

< Diagram 3-2 >

- 27 -

OVP TRIPPED

V

g

VFD Display Description

OVP

OFF

VOLT:PROT:CLE

OVP Trip Cl

▌When voltage rise more than OVP Level, "OVP TRIPPED" will be displayed

on VFD.

▌To clear OVP Trip, raise OVP Level first.

To raise OVP Level, press OVP Key.

VFD Display Description

▌Press OVP Key once more when "OVP ON" is displayed.

VFD Display Description

▌Use cursor key to change value.

▌Use encorder switch to raise Level.

▌When the setting is done, press OVP Key.

VFD Display Description

Message above will be displayed, and return to condition before trip.

▌Second method to clear OVP Trip.

To clear OVP, Press OVP Key.

VFD Display Description

▌Press Left or Ri

ht while "OVP ON" is displayed.

OVP ON

OVP-LEVEL 10.0

CHANGED

OVP ON

OVP OFF

▌To apply changes, press OVP Key when "OVP OFF" is displayed.

VFD Display Description

Message above will be displayed, and return to condition before trip.

≫ Related Remote Interface Command

[SOURce:]VOLTage:PROTection{<voltage>}

[SOURce:]VOLTage:PROTection:STATe {0|1|OFF|ON}

[SOURce:]VOLTage:PROTection:TRIPped?

[SOURce:]VOLTage:PROTection:CLEar

Refer: Method to raise level value when there is a trip

VOLT:PROT:TRIP? Return value "1" Check whether it is OVP Trip

VOLT:PROT 32 OVP Level Setting

VOLT:PROT:CLE OVP Trip Clear

Method to disable OVP

VOLT:PROT:TRIP? Return value "1" Check whether it is OVP Trip

VOLT:PROT:STAT OFF Disables OVP

CHANGED

ear

- 28 -

3-5. Programming Over Current Protection(OCP)

g

,

play

After turning on, check

OUTPUT OFF

displayed on the screen.

A

▌When the setting is done, press OCP Key

▌To disable OCP, press OCP Key.

▌To disable OCP, press OCP Key

g

VFD Displ

ipti

CHANGED

[SOURce ]CURRent PROTection{ current }

Disables current when output current is higher than user set up.

Read below to set up OCP Level.

the OCP Level below can be diffierent from others

▌Power switch ON

After turnin

▌To set up OCP Level & Panel press OCP Key.

on

check "**OUTPUT OFF**" is dis

is

ed on the screen.

VFD Display Description

▌Press OCP button once more while "OCP ON" is displayed.

VFD Display Description

▌Use cursor key to change value.

▌Use encorder switch to change level.

VFD Display Description

Message above will be displayed and return to previous condition.

▌To cancel, press ESC Key.

There is no message for cancelling, return to previous condition.

VFD Display Description

▌Press left or right cursor while "OCP ON" is displayed.

VFD Display Description

OCP ON

CP-LEVEL 11.0

.

CHANGED

.

OCP ON

OCP OFF

▌To save chan

Message above will be displayed, return to previous condition.

▌To cancel, press ESC Key.

There is no message for cancelling, return to previous condition.

≫ Related Remote Interface Command

[SOURce:]CURRent:PROTection{<current>}

[SOURce:]CURRent:PROTection:STATe {0|1|OFF|ON}

Refer: CURR:PROT 6 OCP Level Setting

CURR:PROT:STAT ON OR, OCP Sensing condition

CURR:PROT:STAT OFF OCP Disable

Note

First OCP set-up Reference : 1-6

es, press OCP Key while "OCP OFF" is displayed.

ay Descr

on

- 29 -

If output current is higher than OCP Level, "OCP TRIPPED" message will be displayed.

pg

A

▌

OCP, p

OCP K

g

g

VFD Displ

ipti

CHANGED

[SOURce:]CURRent:PROTection:CLEar

CURR:PROT:STAT OFF

Disable OCP

It disables output voltage & current from sources.

If you wish to output voltage & current, please remove the load and used the method below

the causes of trip occuring Trip are :

First, The different OCP Level can cause trip. Therefore raise level value to get resolution.

Second, when you used load that causes counter-electromotive force from coil & motor.

Can be protected as below diagram

Third, When sources used by load also can cause tripping. This happens when

source one is used from load

OCP TRIPPED

▌When OCP Trip occurs, "OCP TRIPPED" will be displayed on VFD.

▌To clear OCP Trip, raise OCP Level in the first step.

To set up Level, press OCP Key.

VFD Display Description

OCP ON

▌Press OCP button once more while "OCP ON" is displayed.

VFD Display Description

CP-LEVEL 10.0

▌Use cursor key to change value.

Use encorder switch to raise level.

▌When the setting is done, press OCP Key.

VFD Display Description

CHANGED

Message above will be displayed, and return to condition before trip.

▌Second step to clear OCP Trip.

To disable

VFD Display Description

▌Press left or ri

VFD Display Description

▌To save chan

ay Descr

ress

ey.

OCP ON

ht cursor while "OCP ON" is displayed.

OCP OFF

es, press OCP key while "OCP OFF" is displayed.

on

Message above will be displayed, return to condition before trip.

≫ Related Remote Interface Command

[SOURce:]CURRent:PROTection{<current>}

[SOURce:]CURRent:PROTection:STATe {0|1|OFF|ON}

[SOURce:]CURRent:PROTection:TRIPped?

Refer: Method to raise level value when there is a trip

CURR:PROT:TRIP? Return value "1" Check whether it is OCP Trip condition

CURR:PROT 10 OCP Level Setting

CURR:PROT:CLE OCP Trip Clear

Method to disable OCP when there is a Trip

CURR:PROT:TRIP? Return value "1" Check whether it is OCP Trip condition

:

CURR:PROT:CLE OCP Trip Clear

:

- 30 -

3-6. I/O Config & LOCAL

▌

▌Turn on the power supply

displayed

p

s

0

0

▌To save changes, press I/O CONFIG Key

To configure the power supply for the RS-232 and RS485 interface, proceed as follows.

RS232C interface is standard, in case of RS485, it is optional and remove the RS232C module.

If interface is RS485 when it is shipped, address default is no. 05.

Baud rate default is 9600bps and setting of RS232C & RS485 is able to set on front panel.

The RS-232 baud rate and parity selections are stored in non-volatile memory,

and does not change when power has been off or after a remote interface reset.

▌If remote interface works, the lamp of RMT on front panel lits and power supply is

remotely controlled preferentially.

▌If you want to control power supply on local mode, at first finish remote nterface

and then press the "I/O & LOCAL" key. Lamp of "RMT" turn off and you can contorol.

RS232C Setting

Sequence of RS232C Setting.

After turned on, check the power supply displays "**OUTPUT OFF**".

▌Press "I/O" key in other to set RS232C interface.

LCD Display

▌RS232C or GPIB will be displayed following previous condition.

If "I/O - GPIB" displayed, press cursor key once more to "I/O - RS232C"

is

When VFD Dis

and change into

If previous Display description is "I/O - RS232C" , perss I/O CONFIG Key.

VFD Display Description

▌Baud rate is divided into 4800bps, 9600bps, 19200bps, 38400bps.

It must be the fitted with PC Interface and Baud rate.

For instance, to select 19200bps, press right cursor key twice.

VFD Display Description

VFD Display Description

Now, Interface would be RS232C and Baud rate is 19200bps.

I/O - RS232C I/O - GPIB

.

lay

I/O - GPIB

press cursor key

I/O - RS232C

AUD-RATE 480

AUD-RATE 1920

.

CHANGE SAVED

Note

What is bps? The initial of Bit per Second, data transmission unit of 1bit per one second.

- 31 -

RS232C Setting(Option)

pyp

▌

▌RS232C is fixed as below.

Data Bit : 8

Stop Bit : 1

Parity Bit : None

▌RS232C Data frame structure

Start

Bit

▌To connect product and PC, Female type cross cable is required. Diagram below is

explanation when both side is all female type cross cable.

Read "1-2. Accessories & Instrument Option" for more information.

Equipmen

8 Data Bits

< Diagram 3-3 >

Stop

Bit

It is convenient when you use separated adapter cable. (If you wish to use DB25PIN from

Read "1-2. Accessories & Instrument Option"" for more information.

Equipmen

< Diagram 3-4 >

- 32 -

GPIB Setting

o

play

play

will be displayed.

/O S3C

A

5

4

CHANGE SAVED

Including PC, maximum 15 connection is enabled. Network is fast and creates critical affects t

production.

Draw below is how to set up GPIB.

▌Power Switch ON

After turning on, check "**OUTPUT OFF**" is displayed on the screen.

▌Press "I/O CONFIG Key to set up GPIB.

VFD Displays

▌GPIB will be displayed on previous setting.

If VFD is displaying "I/O - RS232C" press cursor key once to make I/O-GPIB

displayed.

When VFD Dis

I/O - RS232C

I/O - RS232C

OR,

Press cursor key, and

I/O - GPIB

Note

OR

I/O - RS232C

IF the first display description is "I/O-GPIB", press I/O CONFIG key.

VFD Display Description

▌GPIB's Address can be selected 00 ~ 30, PC Interface

should be the same as GPIB Address.

For instance, to set 04 adress, press left cursor key once.

VFD Display Description

▌To save changes, press I/O CONFIG Key.

VFD Display Description

Now, GPIB is selected for Interface, and address is set to 04.

will be dis

DR-SELECT 0

DR-SELECT 0

ed.

RS232C port is female type, must be a cross type.

Please read "1-2. Accessories & Instrument Option" for more information.

- 33 -

GPIB Installation & Setting

not use more than 3 IEEE488.2 connecter block

GPIB connecter is regular 24pin, located on the rear panel of our instrument.

Only available when you have selected the option.

regular 24pin

GPIB Connector

< Diagram 3-5 >

▌GPIB PC Interface Installation

When you connect each equipment, use shield line, and line should be less than 2m.

Also, do not connect more than 15 devices including PC.

Do

<A> <B>

.

OR

< Diagram 3-6 > < Diagram 3-7 >

Note

If conneting cable is more than 4M, Please read IEEE488.2 warning.

- 34 -

▌General GPIB 24pin Shield cable

< Diagram 3-8 >

▌Structure of power supply & load, devices below :

< Diagram 3-9 >

- 35 -

3-7. KEY LOCK

[]{|}

Function to disable all the keys on Front panel.

Can protect customers making mistakes while running the instrument.

▌Power Switch ON

After turning on, check "**OUTPUT OFF**" is displayed.

▌Press LOCK Key once to disable front panel keys.

LOCK lamp will be lighted and other keys will be disabled.

▌To allow controling Front panel, press LOCK Key once.

LOCK lamp light will be off and allows front panel control.

≫ Related Remote Interface Command

KEYLock[:STATe] {OFF|ON}

KEYLock[:STATe]?

Refer: Checking KEY LOCK, Checking KEY UNLOCK

KEYL? Check Lock ON

KEYL ON Lock Setting

Return value "0"

- 36 -

3-8. STORE / CALIBRATE

p

pp

OVP & OCP s Level is stored, not On.OFF condition.

py p

A

You can store the operating states that are total five voltage, current in non-volatile memory.

In case of this function, the mode must be in "**OUTPUT MODE**". If the mode of

is output on mode, store key is used the left move key of cursor. Proceed as follows.

OVP & OCP 's Level is stored, not On.OFF condition.

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

▌To save user's memory, press STORE Key.

ower su

VFD Display Description

▌Use cursor key to change slots.

For instance, press right key to select 02 slot or use encorder switch

또는

VFD Display Description

▌To save slot, press STORE Key once.

VFD Display Description

▌

fter STORE DONE displayed, return to previous condition.

≫ Related Remote Interface Command

*SAV {1|2|3|4|5|6|7|8|10}

Refer: *SAV 4 User's memory

Note

STORE NO, 01

STORE NO, 02

STORE DONE

User's memory can be reset. Please read reference "5-4" USER-MEM CLEAR.

- 37 -

3-9. RECALL / FACTORY

Under tracking mode, if you use recall function, cancelled the tracking mode

p

q

s

You can recall the saved operating states that are total five voltage, current in

non-volatile memory. In case of this function, the mode must be in "**OUTPUT MODE**".

If the mode of power supply is output on mode, recall key is used the right move key of

cursor. Proceed as follows.

.

▌Power Switch ON

After turning on, please check "**OUTPUT OFF**" is displayed.

▌To bring back saved slots, press RECALL Key.

VFD Display Description

▌Use encorder switch or cursor key to select saved slots.

For instance, if you wish to bring back 02 slot,

OR or use trun the encorder switch clock-wise.

VFD Display Description

▌To save changes, press RECALL Key once.

VFD Display Description

▌After displayed "RECALL DONE", return to previous condition.

≫ Related Remote Interface Command

*RCL {1|2|3|4|5|6|7|8|10}

Refer: *RCL 4 User's Memory

RECALL NO, 01

ress right cursor key once,

RECALL NO, 02

RECALL DONE

3-10. OUTPUT ON/OFF

Enables or disables the power supply output. This key toggles between on and off.

At the output off mode, voltage and current output is 0V and 50mA, therefore

you can ac

uire the effect of output off without remove the connected DUT. Proceed as follow

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

▌To allow general output, press OUTPUT ON/OFF Key once more.

▌To block again, press OUTPUT ON/OFF Key once more.

≫ Related Remote Interface Command

OUTPut[:STATe] {OFF|ON|0|1}

OUTPut[:STATe]?

Refer: Check Output condition, Method to turn it ON

OUTP? Return value "0" Check output condition

OUTP ON Allow output

- 38 -

3-11. V/I & LMT DISPLAY

current side

▌

press LMT DISPLAY Key

n

2. Wh

hile blinki

ill be last. Whil

blinki

Shows voltage and current limit values on the display and allows knob adjustment

for setting limit values. Also you can choose between voltage limit set or current limit set.

V/I Function

▌Power Switch ON

After turning on, please check "**OUTPUT OFF**" is displayed.

▌To set up voltage & current limit, press OUTPUT ON/OFF Key.

▌Cursor will blink to voltage. When it is blinking, press V/I to move

it to

▌To move back to voltage side, press V/I Key once more.

LMT DISPLAY Function

Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

.

▌To display voltage, current limit, press OUTPUT ON/OFF Key.

▌Wait for 2.5 seconds approximately, when the blinking cursor disappears,

.

▌Return back to Limit Display condition after blinking

▌Press LMT DISPLAY Key once more to move back to V/I Selection.

Note

1. If you turn encorder switch while cursor is blinking, Limit Display will be last. While cursor is not blinki

turn to ReadBack Display.

en you press cursor key w

turn to ReadBack Display.

ng, Limit Display w

e cursor is nott

ng,

- 39 -

3-12. CYCLING MODE

Attributes

Attributes

CURR

SLOPE TIME

STEP

VOLT

DELAY TIME

p

s

Aft

REPEAT i

p

n

Simple function for implement of a load. Can set repeating time, Slope Time, Delay.

Also, this function do not need any PC interfaces & software, can be operated by itself.

▌Operates independently

▌Safe saving using infinit memory

▌Voltage, Current, Slope Time, Delay Time can be saved up to 100 slots

▌Cycling mode test available using sequence panel

▌Support repetition up to 1500 times.

Record Tabel

▌Create Record Table below to use it with convenience.

STEP

CURR

1 4.5 6010

255 10

SLOPE TIMESTEP VOLT DELAY TIME

5

510

60

603 5.5

SEQUENCE

START NUMBER

13

REPEAT

100

>step 1 : If it was 0V before operating, voltage will rise up to 4.5V within 10seconds.

Current will be 5A at the same time.

When the Slope Time is done, 4.5V will maintain for 60seconds.

After 60 seconds, go on to step 2.

>step 2 : After setting current 5A, Voltage will be rise up to 5V within 10seconds.

When the Slope Time is done, 5V will maintain for 60seconds.

After 60 seconds, go on to step 3.

>ste

When the Slope Time is done, 5.5V will maintain for 60seconds

> After 100 times, message will be dis

3 : After setting current 5A, Voltage will rise from 5V up to 5.5V within 10second

FINISH NUMBER

er 60 seconds, repeat step 1 to step 3 that

CYCLING FINISH

s set.

layed and finish cycli

- 40 -

▌Power Supply's output Scope

5.5

▌STEP s Structure

Setting Time

100 ms

24Hours (86,400 seconds)

Pretend output voltage is 0V before Start.

[V]

6

5

4.5

0

1 Cycling 2 Cycling

70 80 [s]

STEP

▌Step Number, Voltage, Current, Slope Time, Delay Time can be entered in STEP

'

STEP NUMBER

VOLTAGE

CURRENT

SLOPE

DELAY

◆ NUMBER

Setting memory range for Voltage, Current, Slope Time, Delay Time

> Memory Range 1~100

◆ VOLTAGE

Set step's voltage value from number.

> Voltage rang Full Range

◆ CURRENT

Set current value from Number Selected.

> Current rang Full Range

280140 15010 290210 220

◆ SLOPE

Set step's voltage rise or decrease time from number

>

◆ DELAY

Maintaining time for selected set from number.

Delay Time is activated when Slope Time is finished.

> Setting Time 100 ms ~ 24Hours (86,400 seconds)

~

- 41 -

Setting STEP

▌

G

play

V

V

VFD Display Description

VOLTAGE

04.500

G

▌To set up current, press right cursor key once

N

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

Press STEP Key.

VFD Display Description

▌To set up Step Number, press STEP Key once more.

VFD Display Description

▌To change Step Number, use cursor key or encorder switch.

For instance, to change to 002, press right cursor key once or turn

encorder switch clock-wise.

VFD Display Description

▌To set up, press STEP Key once. Changed value will be displayed.

TEP 001 - NUMBE

- NUMBER 001

- NUMBER 002

VFD Display Description

▌To set Voltage, press right cursor key.

VFD Display Description

▌Press STEP Key.

VFD Display Description

▌For instance, to set 4.5V, use encorder and cursor key to change.

VFD Dis

▌To set up, press STEP Key.

VFD Display Description

VFD Display Description

Description

TEP 002 - NUMBE

EP 002 - VOLTA

OLTAGE 00.000

OLTAGE 04.500

EP 002 - VOLTA

EP 002 - CURRE

.

- 42 -

▌Press STEP Key.

0

0

N

▌To set up SLOPE TIME

press right cursor key once

E

0

E

Y

0

▌

VFD Displ

ipti

STEP 002

DELAY

VFD Display Description

▌For instance, to set 5A, use encorder and cursor key to change.

VFD Display Description

▌To set up, press STEP Key.

VFD Display Description

URRENT 00.00

URRENT 05.00

EP 002 - CURRE

,

VFD Display Description

▌Press STEP Key.

VFD Display Description

▌For instance, to set up 5seconds, use encorder and cursor key to change.

VFD Display Description

▌To set up, press STEP Key once.

VFD Display Description

▌To set up DELAY TIME, press right cursor key once.

VFD Display Description

▌Press STEP Key.

VFD Display Description

TEP 002 - SLOP

SLOPE 00000.

- SLOPE 00005.0

TEP 002 - SLOP

STEP 002 - DELA

DELAY 00000.

.

For instance, to set up 60seconds, use encorder and cursor key to change

VFD Display Description

▌To set up, press STEP Key once.

▌After saving changes above, press ESC Key to go back to previous page.

ay Descr

- DELAY 00060.0

on

-

- 43 -

SEQUENCE

e

Note

FINISH NUMBER

g

▌

R

▌T

SEQUENCE K

▌Repeat & operate starting point and finish point. If Start Number is higher than

Finish Number, it causes error immediately.

When an error occurs, please read "7. Error Messages"

Not

It is convenient to control many other test modes dividing 100 step range using Start number and

Finish number in Sequence menu.

▌SEQUENCE Structure

SEQUENCE START NUMBER

◆ START NUMBER

Set Step Starting point.

> Selection range 1~100

◆ FINISH NUMBER

Set Step Finishing point.

> Selection range 1~100

SEQUENCE Number Input

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

Press SEQUENCE Key.

VFD Display Description

▌To set up START Number, press SEQUENCE Key.

VFD Display Description

▌Use cursor key or encorder switch to select 0~99 STEP.

For instance, to set starting point number 002, press right cursor key or

turn encorder switch clock-wise.

VFD Display Description

o save, press

After "CHANGE SAVED" Message Displayed, VFD will go back to

previous Sequence.

EQUENCE - STA

START NO. 001

START NO. 002

ey.

- 44 -

▌To set up FINISH Number, press SEQUENCE Key.

R

VFD Display Description

FINIS

003, p

h

▌P

ON

▌

h

0

0

previous Sequence

VFD Display Description

▌To select FINISH Number, press cursor key once.

▌To set up, press SEQUENCE Key once more.

VFD Display Description

▌Use cursor key or encorder switch to change steps from 2~100.

For instance, to set

clock-wise.

VFD Display Description

▌To save, press SEQUENCE Key.

After "CHANGE SAVED" Message Displayed, VFD will go back to

previous Sequence.

EQUENCE - STA

-

-

FINISH NO. 100

ress right cursor key or turn encorder switc

FINISH NO. 003

REPEAT

This is third step after entering Voltage, Current, Slope Time, Delay Time. This step sets numbe

Repetition in the cycling mode.

◆ REPEAT

Set REPEAT Number.

> Selection number 1~15 million

INPUT REPEAT NUMBER

ower Switch

After turning On, please check "**OUTPUT OFF**" is displayed.

▌Press REPEAT Key.

VFD Display Description

To set up number of repeating value, use cursor key or turn encorder switc

clock-wise. For instance, to set 200 repeat, press right cursor key once or

turn encorder switch clock-wise.

VFD Display Description

EPEAT 0000010

EPEAT 0000020

▌To save, press REPEAT Key.

After "CHANGE SAVED" Message Displayed, VFD will go back to

.

- 45 -

RUN / STOP

p

o

Operationg Step Number

When you have done above steps, use RUN/STOP Key to start testing.

When you

will be cancelled and error message will be saved with alarm.

If there is an error, please refer "7. Error Messages".

ress RUN/STOP Key, it will start testing the first data. If an error occurs, Cycling m

RUN / STOP OPERATING

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

▌Press RUN / STOP Key.

▌Display Description

CYC - 00000000 - 001

Number of repeating value Sequence's Start, Finish

- 46 -

3-13. ERROR

p

▌Error message will be stored max 10, from 11th message, first saved message will be dele

R

VFD Displ

ipti

200

?

Note

Error found in self-testing mode, calibration, SCPI Program, will be saved in volatile memory u

Read reference "7. Error Messages" for more information

▌ERROR's memory is stack-structured, and the latest error will be accessed.

▌When you check message by pressing ERROR Key, messages from last will be deleted.

▌There will be a alarm everytime when an ERROR occurs.

Check ERROR

▌Power Switch ON

After turning On, please check "**OUTPUT OFF**" is displayed.

▌To check ERROR message, press ERROR Key.

If there is no Error, below description will be displayed for 2 seconds

and return to previous page.

VFD Display Description

If there is an Error, Error number will be displayed

ay Descr

RROR NO ERRO

on

NO, -

▌To check next ERROR number, press ERROR Key.

If there is an Error the Error number will be displayed.

VFD Display Description

▌To check next ERROR code, press ERROR Key.

≫ Related Remote Interface Command

SYSTem:ERRor?

Refer: Check Error

SYST:ERR

Return value :-222,"Out of data"

Able to check Error number and message

ERROR NO, -10

1. Only ERROR Numbers can be check from Front panel, and message discription can be checked

from remote interface.

2. Stack memory? FILO(First In Last Out)-structured

Queue memory? FIFO(First In First Out)-structured

3-14. ESC

Move on to local mode when you cancel entering menu and low menu.

Note

If you do not panel about 10seconds on front panel, esc key will be activated by itself.

- 47 -

4. CALIBRATION

▌PC based calibration from Remote Interface

▌Humidity should be below 80%

Warning

Do not use calibrate function without person with knowledge.

Calibration should be done > every 180 days for accuracy

cyclically. > every 365 days to be activated properly

4-1. Attributes

▌Calibrate without opening case

▌Calibration using Front panel Key

▌PC based calibration from Remote Interface

▌Store in fixed memory

▌Support Calibration data Backup & Value Backup

4-2. Preparing for accurate calibration

▌Use measuring instruments should measure spec of power supply.

▌Give more than 1 hour in temp 20~30 degree to warm up.

.

▌Connect Power Supply's output terminal to load instrument.

▌Other instruments that causes magnetic field should be off.

- 48 -

4-3. Required efficiency for accurate calibration

n

g

PC based Calibration

/

GPIB Controller

Full GPIB capabilities

Transient On/Off

4-4. Calibrati

e

▌g , , p

Instrument recommendatio

Digital Voltmeter Voltage Calibration

Electronic Load Agilent 6063B

Current

monitoring

Required Efficiency

Resolution: 0.1 mV

Accuracy: 0.01%

Voltage Range: 50 Vdc

Current Range: 10 Adc

Open and Short Switches

Transient On

0.01Ω , 0.01%

100 MHz with

20MHz bandwidth

Off

Agilent 82341C

Interface card

Agilent 34401A

Tektronix

TDS3014

Usage

Current Calibration,

Power Supply Protection

while Current Calibration

Monitoring Voltage

ripple & noise MeasuringOscilloscope

on Techniqu

Technical description about calibration below :

Instrument Connection

▌Connect output terminal and measuring instrument as below.

▌While Voltage Calibration, Switch OFF electric load, or remove from output terminal.

< Diagram 4-1 >

- 49 -

Electronic Load

▌,gp

▌gg g

▌

%

▌Use measuring instrument which displays more than Resolution 0.1 mV , Accuracy 0.01%

pp

GPIB Connection below :

▌Use electronic load which changes resitor from power supply's current calibration

▌Must be able to short Load with On/Off function.

▌Must be suitable with GPIB network, using pc calibration.

Current-Monitoring Resistor(shunt)

▌Use current monitoring resistor for general current measuring

▌Make less TCR 10ppm.

▌Use 0.01% standard resist.

DVM(Digital Volt Meter)

▌Used in Voltage Calibration & Current monitoring Sensing measurement.

Use measuring instrument which displays more than Resolution: 0.1 mV , Accuracy: 0.01

▌Must be suitable with GPIB network, using pc calibration.

Programming

This instrument supports PC Interface based Calibration.

Connect Power Su

and allow accurate calibration data.

ly, DVM, Ammeter, Electric Load using GPIB, and there will be no error

< Diagram 4-2 >

- 50 -

Measuring Location

If you wish to get accurate result of load regulation, pk-pk voltage and response time,

Follow as below :

< Diagram 4-3 >

4-5. Calibration using Front Panel

Explanation about Front panel using CALIBRATE Key to fix manual.

CALIBRATE KEY Structure

STORE /

CALIBRATE

POWER

ON

TIME

LEFT 30s

CAL VOLTAGE V - LOW

CURRENT A - LOW

V - HIGH

A - HIGH

- 51 -

CALIBRATE Setting Range

p

OPS-915

OPS 1815

OPS 502

▌Voltage & Current Calibration is divided into LOW and HIGH.

▌It is range chart for each model below.

MODEL

OPS-95

OPS-97

OPS-910

-

OPS-920

OPS-930

OPS-183

OPS-185

OPS-187

OPS-1810

-

OPS-302

OPS-303

OPS-305

OPS-307

OPS-3010

OPS-501

OPS-502

OPS-503

OPS-505

LOW

Low High High

0.00VVoltage

Current 0.00A

Voltage 0.00V 0.90V

Current 0.00A 0.70A

Voltage 0.00V

Current 0.00A 1.00A

Voltage 0.00V 0.90V 8.70V 9.60V

Current

Voltage 0.00V

Current

Voltage 0.00V 0.90V

Current 0.00A 3.00A

Voltage 0.00V 1.80V

Current

Voltage 0.00V 1.80V

Current 5.25A

Voltage 0.00V 1.80V

Current

Voltage 0.00V 1.80V

Current

Voltage 0.00V 1.80V

Current 15.75A

Voltage 0.00V 3.00V

Current

Voltage 0.00V 3.00V

Current

Voltage 0.00V 3.00V

Current

Voltage 0.00V 3.00V

Current

Voltage 0.00V 3.00V

Current

Voltage 0.00V 5.00V

Current

Voltage 0.00V 5.00V

Current 2.1A

Voltage

Current

Voltage

Current

0.00A

0.00A 0.30A 2.90A 3.20A

0.00A 0.50A 4.80A 5.30A

0.00A 0.70A 6.80A 7.50A

0.00A 1.00A 10.00A 11.00A

0.00A 1.50A 14.50A 16.20A

0.00A 0.20A 2.00A 2.20A

0.00A 0.30A 2.90A 3.20A

0.00A 0.50A 4.80A 5.30A

0.00A 0.70A 6.80A 7.50A

0.00A 1.00A 10.00A 11.00A

0.00A 0.10A 1.00A 1.10A

0.00A 0.20A 2.00A 2.20A

0.00V 5.00V

0.00A 0.30A

0.00V 5.00V

0.90V

0.50A

0.90V

1.50A 14.50A 16.20A

Low

8.70V

4.80A 5.30A

8.70V 9.60V

6.80A 7.50A

8.70V

10.00A

8.70V

8.70V

29.00A

17.70V

17.70V

17.70V

17.70V

17.70V

29.00V

29.00V

29.00V

29.00V

29.00V

48.00V 53.00V

48.00V 53.00V

48.00V 53.00V

2.90A 3.20A

48.00V

HIGH

9.60V

9.60V

11.00A

9.60V0.90V

21.50A0.00A 2.00A 19.50A

32.00A

19.50V

19.50V

19.50V

19.50V

19.50V

32.00V

32.00V

32.00V

32.00V

32.00V

53.00V

MAX

Output

9.45V

5.25A

9.45V

7.35A

9.45V

10.5A

9.45V

15.75A

9.45V

21A

9.45V9.60V

31.5A

18.9V

3.15A

18.9V

18.9V

7.35A

18.9V

10.5A

18.9V

31.5V

2.1A

31.5V

3.15A

31.5V

5.25A

31.5V

7.35A

31.5V

10.5A

52.5V

1.05A

52.5V

52.5V

3.15A

52.5V

5.25A0.00A 0.50A 4.80A 5.30A

- 52 -

OPS-801

OPS-1501

g

OPS-802

OPS-803

OPS-1001

OPS-1002

OPS-1003

OPS-1502

OPS-2001

OPS-3001

Voltage

Current 0.00A 0.10A

Voltage

Voltage

Current 0.00A 0.30A

Voltage 0.00V 10.00V 96.00V 107.00V

Current 1.00A 1.10A

Voltage

Current

Voltage 0.00V 10.00V 96.00V 107.00V

Current 0.00A

Voltage 0.00V 15.00V 144.00V 160.00V

Voltage

Current

Voltage

Current

Voltage 0.00V

Current

CALIBRATE Voltage

85.00V0.00V 8.00V 77.00V

1.00A

0.00V

0.00ACurrent

0.00V

0.00A 0.10A

0.00V

0.00A 0.20A

0.00ACurrent

0.00V

0.00A

0.00V

0.00A 1.10A

0.00A 0.10A 1.00A 1.10A

8.00V 77.00V 85.00V

0.20A

8.00V 77.00V 85.00V

10.00V 96.00V 107.00V

0.30A

0.10A 1.00A

15.00V 144.00V 160.00V

0.20A

20.00V

0.10A

2.00A

2.90A 3.20A

2.00A

2.90A 3.20A

2.00A

192.00V

1.00A

288.00V 320.00V30.00V

1.10A

2.20A

2.20A

1.10A

2.20A

215.00V

84V

1.05A

84V

2.1A

84V

3.15A

105V

1.05A

105V

2.1A

105V

3.15A

157.5V

1.05A

157.5V

2.1A

210V

1.05A

315V

1.05A

Holding

30초 대기

▌Connect instrument before calibration.

▌Keep pressing CALIBRATE key and turn on the power.

▌Power Switch ON

▌When the self-testing mode is done, "LEFT 30" Message will be displayed.

Let go CALIBRATE Key.

▌After 30 seconds, it will enter CALIBRATE Mode.

VFD Display Description

▌Press CALIBRATE Key while "CAL - VOLTAGE" is displayed.

VFD Display Description

CAL - VOLTAGE

V-LOW 00.000V

- 53 -

▌Wait for voltage on the DVM meter to be settled.

V

▌Use cursor key and encorder switch to input voltage value on DVM Meter

T

▌Use cursor key and encorder switch to input voltage value on DVM Meter.

For instance, if it is 154.1mV, set as below :

VFD Display Description

▌When it is done, press CALIBRATE Key to go on to High Range.

V-LOW 00.154V

VFD Displays

▌Waith for voltage on the DVM meter to be settled.

For instance, if it is 30.123V, input data as below :

VFD Display Description

▌When it is donw, press CALIBRATE Key to save.

VFD Displays