Page 1

Mesotest II b

Instruction Manual

Copyright by G/62800/0607/e

Page 2

Page 2

Instruction Manual Mesotest II

___________________________________________________________________

0. Foreword

Thank you for the confidence which you

have placed in us by buying this OCULUS

product. With this unit you have made your

decision for a modern, thoroughly thoughtout product which has been manufactured

and tested according to the highest quality

standards.

Ongoing research and development at

OCULUS, which are certainly in your

interests as well, may lead to changes in the

design and scope of standard equipment.

The illustrations shown in this Instruction

Manual may therefore differ in some

respects from the unit as delivered.

Our company can look back on a history

extending more than 100 years into the past.

OCULUS today is a medium-sized company

whose only focus is to support physicians

and optometrists in their demanding work

with a line of top-quality products for ocular

examinations and operations.

Your Mesotest II is a free-space unit for

testing mesopic vision and glare sensitivity.

In the early 1960s, OCULUS cooperated

with the University Eye Clinic in Tübingen to

develop and build the world's first unit for

testing mesopic vision and glare sensitivity.

At the beginning of the 1980s, this unit was

further developed even with the help of a

new optical system.

The latest generation, the Mesotest II, has

been further improved by the application of a

new functional principle. The use of an

electronic control system has made it

possible to substantially streamline the unit's

use and operation, which can now optionally

be carried out from a PC. This also permits

the processing of patient data and

examination results.

The instrument´s weight has also been

greatly reduced, facilitating mobile use.

Proper use is indispensable for safety in

working with the unit. Therefore, please

familiarize yourself thoroughly with the

contents of this Manual before using the unit

for the first time.

Should you have questions or desire further

information on your unit, give us a call or

send us a telefax message. Our service

team will be happy to help.

OCULUS Optikgeräte GmbH The Management and Staff

Page 3

Instruction Manual Mesotest II

Page 3

___________________________________________________________________

1. Table of Contents

Page

0. Foreword ................................................. ............2

1. Table of contents..................................................3

2. Standard equipment list........................................4

3. Safety precautions ...............................................5

4. Description of the unit and its functions ....... .......6

4.1. Components of the unit...................................6

4.2. Description of the unit .....................................8

4.3. Description of the control unit .......................10

4.4. Warning signs and labels on the unit …........12

5. Proper use..........................................................12

6. First use of the unit.............................................12

6.1. Before first use………... ................................12

6.2. Installation and adjustment ...........................12

6.3. Instructions on transport and storage ...........13

7. Operating the unit...............................................14

7.1. Before each use................................ ............14

7.2. Preparation of the examinee ........................14

7.3. The examination procedure ..........................15

7.4. Additional examinations................................ 16

7.5. Evaluation of results .....................................16

7.6. After each use .................................... ..........16

8. Maintenance.......................................................17

8.1. Care, cleaning and disinfection.....................17

8.2. Replacing the viewing aperture lining……....18

8.3. Replacing fuses.............................................19

8.4. Replacing the workplace light bulb................19

8.5. Solving problems and malfunctions.......... ....20

8.6. Maintenance: description and intervals.........20

9. Disposal..............................................................20

10. Terms of warranty and service ........................21

10.1. Terms of warranty ......................... .............21

10.2. Liability for malfunctions or damage............22

10.3. Manufacturer's and service address........... 22

11. Appendix...........................................................23

11.1. Literature references ..................................23

11.2. Declaration of compliance...........................24

11.3. Order information, accessories and

replacement parts.......................................24

11.4. Technical data ............................................25

Page 4

Page 4

Instruction Manual Mesotest II

___________________________________________________________________

2. Standard Equipment List

- Mesotest II

- Control unit with LCD module and work

area illumination

- Mains cable

- Instruction Manual

- Notepad for test results (100 pages)

- Dust cover

- Metal covering for viewing aperture

If you have also acquired the software

module (cf. Chapter 10.3.), please see the

separate Instruction Manual for this product

and its accessories.

Right reserved to change the scope and

design of standard equipment when

technical development so requires.

Page 5

Instruction Manual Mesotest II

Page 5

___________________________________________________________________

3. Safety Precautions

The manufacturer is required by law to

inform the user explicitly on safety aspects

involved in dealing with this unit. This

chapter contains a summary of the most

important points to be noted regarding

technical safety.

Other safety precautions are found in the

text of this Instruction Manual

and are designated by

Please pay special attention to these

instructions as well.

Store this Instruction Manual with care in a

place where it is accessible for persons

using the unit at all times; also, give due

attention to Instruction Manuals of the unit's

other accessories as required.

The unit may only be used for its intended

purpose, as described in this Instruction

Manual (chapter 5), and by persons whose

proper use of the unit is ensured by their

training and practical experience.

Use the unit only with original parts and

accessories delivered by us and in a

technically flawless condition. Do not

attempt to use a damaged unit, but contact

your supplier.

Please abide by accident prevention laws

where applicable, and be especially careful

to observe the instructions and information

printed on the unit.

The unit may be used in medical areas only

if these rooms are equipped according to

VDE norms or the equivalent (Association of

German Electrotechnical Engineers).

Always disconnect all mains plugs from their

power outlets before carrying out

maintenance or cleaning work.

Disconnect the mains plug at once if you

notice smoke, sparks, or unusual sounds

coming from the unit. Do not use the unit

again until the problem has been corrected

by our service personnel.

Do not connect electrical plugs and sockets

by force. If it is not possible to connect them,

verify whether the plug is correct for the

socket. If you find damage in either the plug

or the socket, have them repaired by our

service personnel.

Do not disconnect electric plugs from their

sockets by pulling on the cable, but rather

on the plug.

Auxiliary equipment connected to the analog

or digital interfaces of the unit must have

proven compatibility with the EN and/or IEC

specifications of these interfaces.

Furthermore, all configurations must meet

IEC Systems Norm 601-1.

Do not attempt to configure electro-medical

systems by combining the Mesotest II with

non-medical electrical equipment (e.g. data

processing equipment) if this might reduce

the level of patient safety below that

recommended by IEC Norm 601-1. Where

permissible levels for leakage current may

be exceeded due to such combinations,

protective disconnecting devices must be

present.

Do not use the equipment named in the

Standard Equipment List in the following

situations:

- Where there is danger of explosion.

- In the presence of flammable anesthetics

or volatile solvents such as alcohol, benzine

or the like.

Do not store or use the unit in damp rooms.

Avoid placing the unit near dripping,

gushing, or splashing water, and make

certain that no fluid can enter the unit. For

this reason, please do not place any

containers full of liquid on top of the unit,

and also take care when cleaning the unit

with a damp cloth that no fluid gets into the

unit.

Do not cover the ventilation openings.

This unit is a high-quality technical product.

To ensure that it performs flawlessly and

safely, we recommend having the unit

inspected regularly every two years by our

service personnel. Should any problem arise

which you cannot solve using the enclosed

checklist of errors, label the unit "Out of

Order" and contact our service department.

Page 6

Page 6

Instruction Manual Mesotest II

___________________________________________________________________

4. Description of the Unit and Its Functions

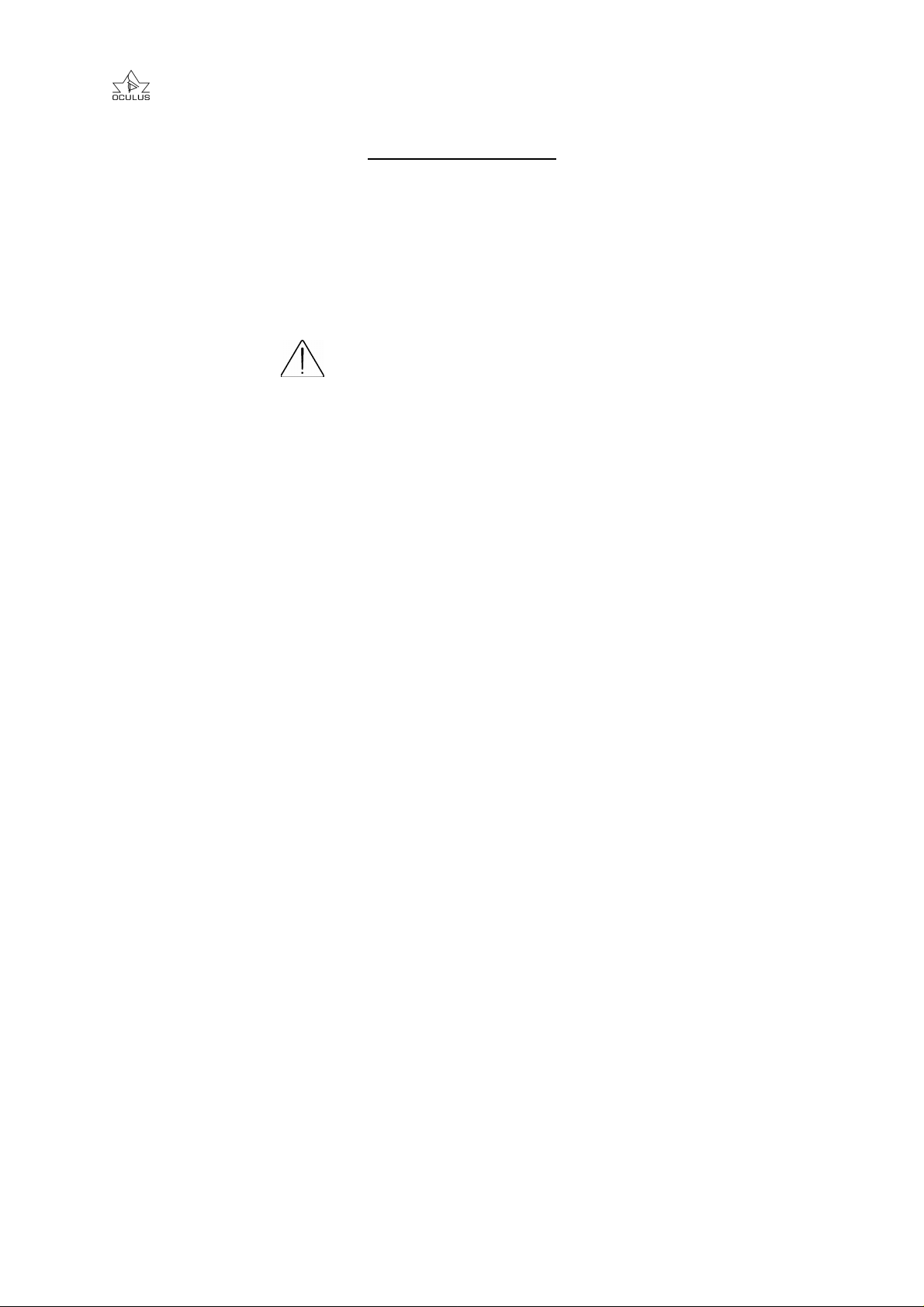

4.1. Components of the Unit

3 4 5

2

1

Figure 1 - Mesotest II, front view

No.1 - Front shell of the housing

No.2 - Lining of the viewing aperture

No.3 - Ventilation openings

No.4 - Clip spring

No.5 - Viewing aperture

Page 7

Instruction Manual Mesotest II

Page 7

___________________________________________________________________

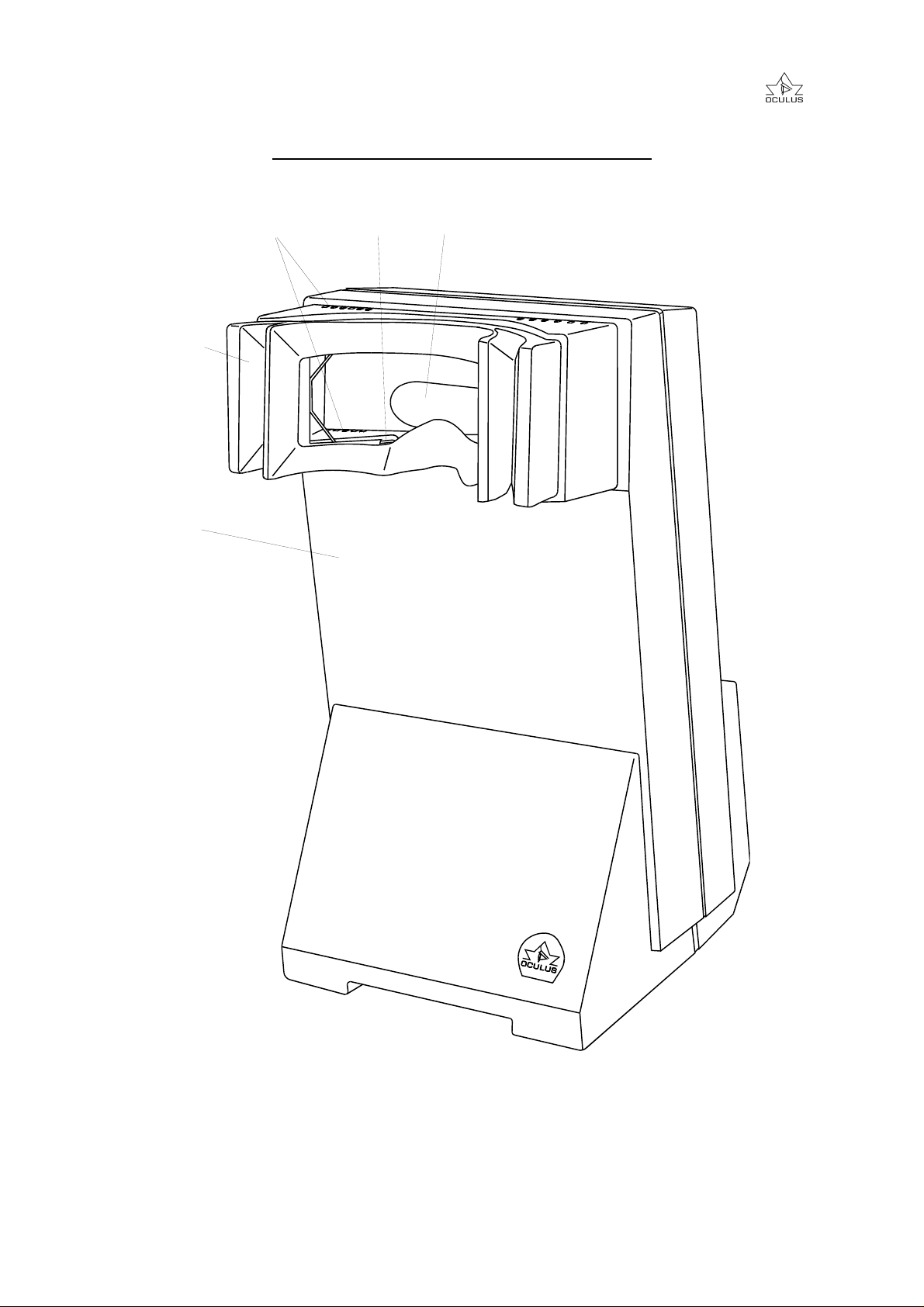

7

6

11 10 9 8

No.6 - Rear wall of housing

No.7 - Tinted window

No.8 - Mains plug with fuse holder

No.9 - Socket of the serial interface

No.10 - Mains switch

No.11 - Type plate

Figure 2 - Mesotest II b, rear view

Page 8

Page 8

A

Instruction Manual Mesotest II

___________________________________________________________________

4.2. Description of the Unit

Tests for mesopic vision and glare sensitivity

are an important supplement to tests of

photopic visual acuity, especially when

evaluating the ability to drive at night. Preand postsurgical examination is also to be

recommended for patients undergoing IOL

or refractive surgery, or when tinted lenses

are prescribed.

The Mesotest II is a PD-independent, freespace unit for testing mesopic vision and

glare sensitivity.

"Free-space" means that the test objects

appear under natural visual conditions.

Instrument myopia is eliminated for the most

part, since the eyes accommodate and

converge as in normal vision.

The comfortable, cushioned lining around

the viewing aperture ensures freedom of

viewing and optimum adjustment for all

examinees. The complete elimination of light

from other sources ensures correct

examinations even when room conditions

are only moderately dark.

The ventilation openings of the viewing

aperture lining ensure that condensation

cannot cloud the examinee's glasses or the

unit's occluder.

The test is carried out with optotypes of

different contrast levels. These optotypes

are presented in front of a low-brightness

backdrop.

The light intensity of the backdrop is 0.032

cd/m2 without and 0.10 cd/m2 with glare.

This corresponds to the brightness of

automobile traffic at twilight or at night.

Landolt rings acc. to DIN Norm No. 58220T1 are used as optotypes. Since visual

acuity decreases with decreasing

brightness, acuity level 0.1 is used. The

optotypes can be presented in six different

positions, and one position is preselected

automatically at the beginning of each test.

The Landolt ring positions which are

available for selection are:

LO - Top Left

O - Top

RO - Top Right

LU - Bottom Left

U - Bottom

RU - Bottom Right

Four different contrast levels are available.

They are:

1:23 / 1:5 / 1:2,7 / 1:2.

Here contrast level 1:23 corresponds to the

highest contrast, i.e. this level is the most

easily recognized.

Contrast 1:23 is the ratio between light

intensity of the optotypes and the backdrop.

The contrast levels are presented in each

case with and without glare (=BLEND). This

results in a total of eight tests which run

successively during the course of a test

routine.

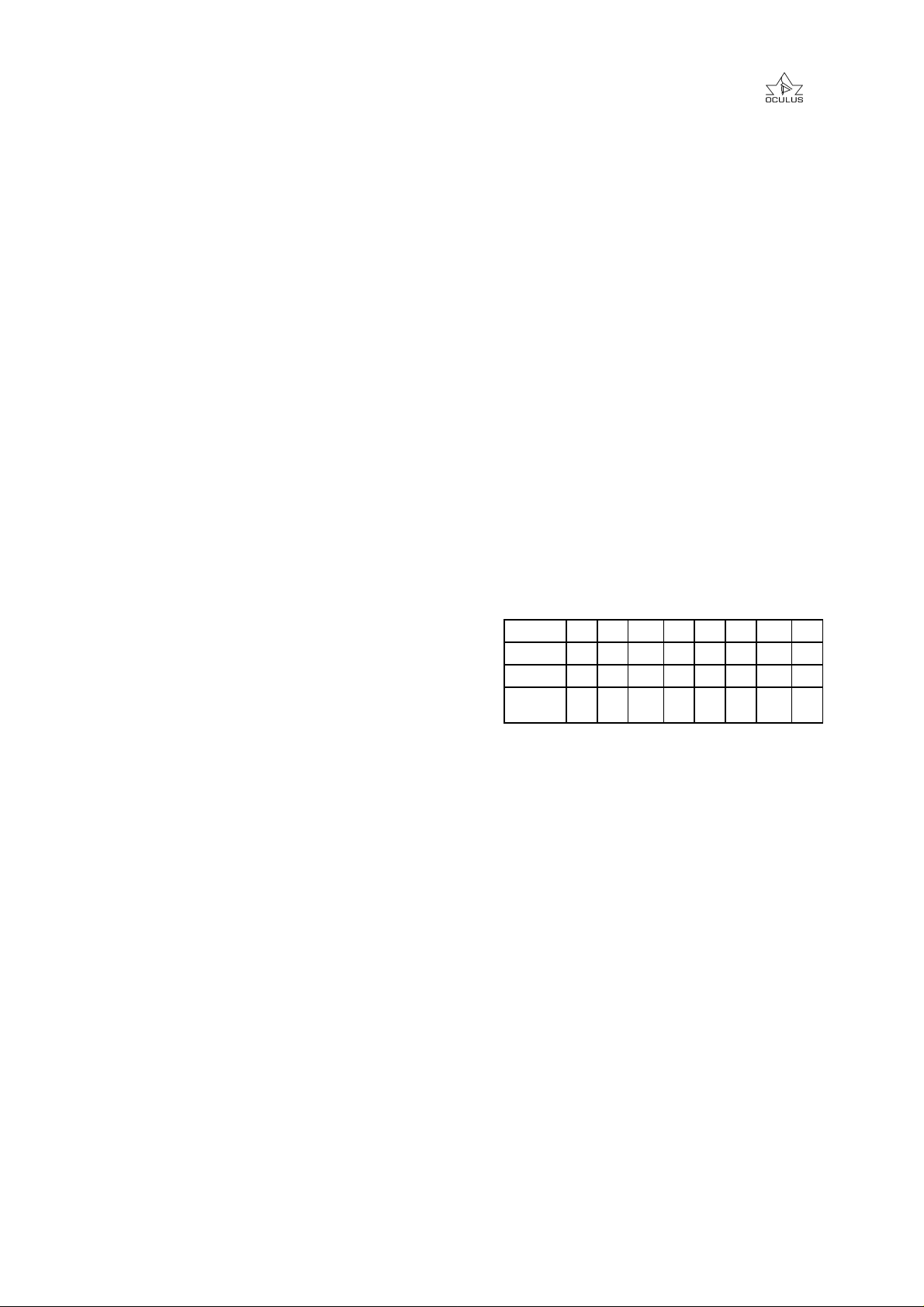

Table 1 shows the course of the test routine.

Table 1

Test-No. 1 2 3 4 5 6 7 8

Contrast 1:23 1:5 1:2,7 1:2 1:23 1:5 1:2,7 1:2

Glare Off Off Off Off On On On On

utomatic

Land.sett.

LO RO O U RU U LU O

The viewing screen of the test panel is seen

through an optical system via a

semitransparent viewing mirror. The

optotypes are presented in front of this

viewing screen. Their virtual image appears

at a distance of 5 meters from the eye.

The optotypes are vacuum metallized onto a

glass disk. The projection disk is

manufactured to very tight tolerances for the

various contrast levels.

Page 9

e

F

ixat

ionAssist

e

Instruction Manual Mesotest II

Page 9

___________________________________________________________________

anc

Landolt Ring

Surrounding

GlareLight

Figure 3 - Test panel

The glare light source is situated at the left,

next to the test panel, at a visual angle of 3°

(cf. Figure 3). It is activated automatically in

accordance with test selection.

The glare light source simulates glare

created by an oncoming vehicle with its

headlights on dipped beam. The glare

intensity is 0.35 lux at the pupils.

The light sources are two white LED´s, one

for the surrounding and one for glare.

A stand-by function switches the illumination

off whenever there has been no operating

input for a certain period of time.

A projection device above the test panel

assists in fixation. It can be used to project

two red dots onto the test panel (cf. Figure

3).

This fixation assistance is turned off

automatically when the next test or

optotypes appear.

The Mesotest II is available with 3 sets of

minus lenses as an option. These make it

possible to determine the presence of night

myopia and thus to compensate for this form

of myopia, i.e. to improve nocturnal vision as

far as possible.

An integral part of this option is the

possibility of monocular examinations.

Fixation Assist anc

Page 10

Page 10

Instruction Manual Mesotest II

___________________________________________________________________

4.3. Description of the Control Unit

-0,5

Landol t r ing position: Top Left (LO)

2nd funct ion: i nt erpose -0.5 D minus lenses (Option)

-1,0

Landol t r ing position: Top (O)

2nd funct ion: i nt erpose -1.0 D minus lenses (Option)

-1,5

Landol t r ing position: Top Right (RO)

2nd funct ion: i nt erpose -1.5 D minus lenses (Option)

Landol t r ing position: Bot t om Left (LU)

Plug lock:

Press lever to

to c onnect

or r e lease !

FIX

R/L/BIN

-DPT.

START

STOP

Landol t r ing position: Bot t om (U)

0

Landol t r ing position: Bot t om Right (RU)

2nd funct ion: r eset minus lenses to 0 D (Opt ion)

Turns Fixati on A ssist ance on and off

Select an eye fo r Ex am i n ati o n

(Option)

Activ it at es 2nd f unc t ion (mi nus lenses)

Next pat ient , or stop current t ests and

return to beginning

TEST

NR.

CONTRAST

1 :____

R/L/BIN

-1,0 -1,5-0,5

-DPT.

BLEND

FIX

Workplace

light

0

R/L/BIN

TEST

<

TEST

>

Return to previous test

Proceed to next t est

FIX

START

STOP

TEST

<

MESOTESTII

-DPT.

TEST

>

Figure 4 - Control unit

Page 11

Instruction Manual Mesotest II

Page 11

___________________________________________________________________

The Mesotest II is operated via the external

control unit and the illuminated LCD module

(Figure 4). The control unit has its own work

area illumination to permit note-taking in

darkened rooms.

The unit can also be controlled from a PC by

means of an optional software module.

In this case, it is not the control unit but

rather the PC which is connected to the

serial interface of the Mesotest II.

Following are a few displays which are

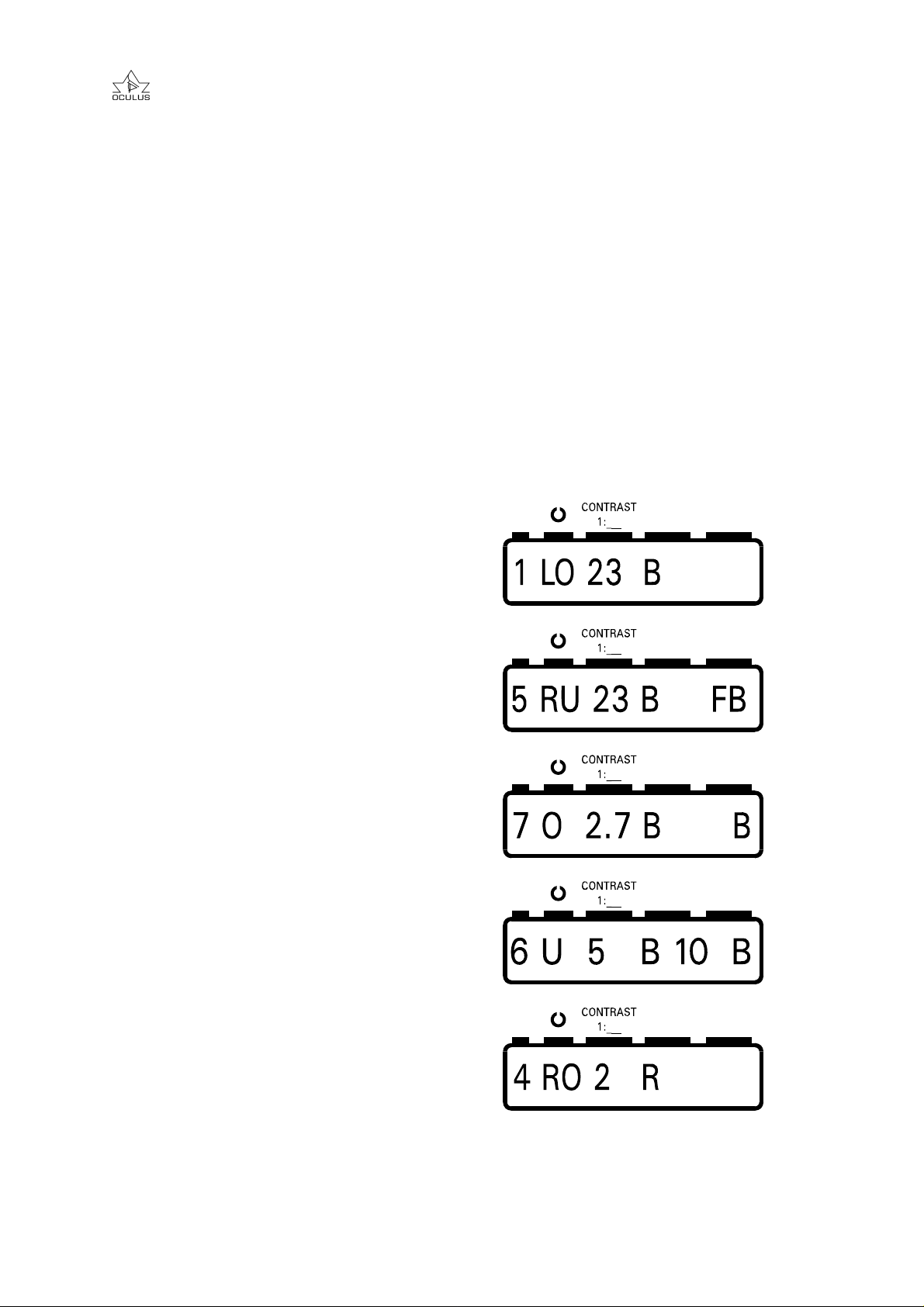

possible on the LCD module:

TEST

NR.

-DPT.

R/L/BIN

BLEND

FIX

Test No. 1: Display after the unit is turned on

B: Binocular examination

TEST

NR.

-DPT.

R/L/BIN

BLEND

FIX

Test No. 5: B: Binocular examination

F: Fixation assistance: On.

B: (=BLEND) = Glare: Active

TEST

NR.

-DPT.

R/L/BIN

BLEND

FIX

Test No. 7: B: Binocular examination

B: (=BLEND) = Glare: Active

TEST

NR.

-DPT.

R/L/BIN

BLEND

FIX

Test No. 6: -1.0 D minus lenses are

interposed (Option)

TEST

NR.

-DPT.

R/L/BIN

BLEND

FIX

Test No. 4: R: Monocular examination of

the right eye (Option).

Figure 5 - Sample displays of the LCD module

Page 12

Page 12

Instruction Manual Mesotest II

___________________________________________________________________

4.4. Warning Signs and Labels on the Unit.

Caution! Disconnect the mains plug

before opening the unit.

Caution! See the enclosed information sheets.

.

5. Appropriate Use

This unit is designed only for the purposes

described in this Instruction Manual. It is

designed for testing visual performance of

the human eye in the mesopic range.

This unit may be used only by persons

whose training and practical experience

ensure that they will work with the unit in an

appropriate manner.

Operate the unit only with original parts

and accessories delivered by us and in a

technically flawless condition.

Run the unit only on an electric power

supply system whose supply voltage is

within the voltage range given on the rating

plate.

Please abide by the safety precautions

given above.

6. First Use of the Unit

6.1. Before First Use

Please remove the unit and its accessories

from their packing and store the latter. You

can then send or transport the unit correctly

should service or repairs ever be required.

Before connecting the unit to the electric

power supply system, check whether the

supply voltage of the electric power supply

system is within the range given on the

rating plate.

This optical unit is to be handled with care.

Do not subject it to shocks, impacts, dirt or

high temperatures.

6.2. Installation and Adjustment

The Mesotest II should be set up in a

moderately bright or moderately darkened

room (room brightness between 2 and 5

lux).

tinted window of the unit should be

closed with the enclosed metal covering

in order to avoid falsification of the

examination results.

For example, if the unit must be

set up in a bright room due to

lack of available space, the

Page 13

Instruction Manual Mesotest II

Page 13

___________________________________________________________________

Proceed as follows to install this covering

(cf. Figure 6):

- Insert the metal covering on either side into

the slit between the viewing aperture and

the housing.

- Hold the metal firmly by the recessed grips

with one hand.

- Bend the metal with the other hand and let

it snap into the opposite slit.

To remove the metal covering, simply grasp

the recessed grips and pull it out.

However, closing the light

admission opening of the unit

increases the risk of instrument

myopia. This must be taken into account

when evaluating the examination results.

Avoid the vicinity of heating units or sources

of moisture which might enter the unit.

To put the unit into operation for the first

time, connect the control unit (or the serial

cable of the PC) to the socket (Figure 2, No.

9).

Figure 6 - Installing the metal covering

6.3. Instructions for Transport and Storage

A carrying bag is available for purposes of

transportation, e.g. for mobile use. If you

have decided not to acquire this, please

transport the unit only in its original packing

in order to avoid unnecessary damage and

expenses.

Avoid shocks when relocating the unit, since

they can have a negative effect on

calibrations.

Inspect the unit for damage after every

relocation. Do not under any circumstances

attempt to use a damaged unit, but please

contact our service personnel.

If you keep the unit in an automobile during

the cold season of the year, its optical

Connect the mains cable (to No. 8 in Figure

2).

Switch on the mains switch (Figure 2, No.

10). The unit is ready for use after a brief,

automatic self- test.

The LCD module, the work area light, and

the light in the mains switch light up to show

readiness for use.

components may become fogged with

condensation after being brought into much

warmer surroundings.

Please give the unit time to adjust to the

new surroundings before turning it on.

The conditions prescribed for transportation

and storage by IEC Norm 601-1 are:

- Surrounding temperature: -40° C to

+70°C.

- Relative humidity: 10% to 100%

including condensation.

- Air pressure: 500 hPa to 1060 hPa

If the unit is kept in its corresponding

packing, these values apply for a period of

15 weeks maximum.

Page 14

Page 14

Instruction Manual Mesotest II

___________________________________________________________________

7. Operating the Unit

7.1. Before Each Use

Please inspect the unit prior to each use to

make sure that:

- The unit is in flawless technical

condition.

- All cables and plugs are free of defects.

- You have connected the unit with the

mains cable which is intended for the

unit.

- You have inserted the mains plug into a

power outlet with a flawless protective

earth conductor.

7.2. Preparation of the Examinee

This poses no problem if the Mesotest II

has been set up in a darkened room. If it

has been set up in a brightly lit room, the

examinee has to be adapted by having

him look into the unit for a

corresponding period of time.

If the person being tested wears spectacles

or contact lens, the examination is then

carried out with the spectacles or contact

lenses.

This should be noted on the test form sheet

(also the presence of tinted lenses, if any).

The eyes of the person to be

examined must be adapted to

darkness for ca. 5 minutes

before the examination.

Page 15

Instruction Manual Mesotest II

___________________________________________________________________

Page 15

7.3. The Examination Procedure

Turn on the unit. After carrying out an

automatic calibration, the Mesotest II begins

Test No. 1.

A specific Landolt ring setting is pre-selected

for each test (cf. Table 1, Page 8). Test 1,

with contrast level 1:23, is the most easily

recognized and can therefore be used to

instruct the examinee.

After giving instructions, show the examinee

at least 5 different Landolt ring positions.

You can select these as desired with the

keys. The visual requirements are regarded

as fulfilled when the examinee has

Carry out the rest of the tests (Nos. 5 to 8) in

the same manner as Nos. 1 to 4.

Fill out all other spaces on the test form

sheet.

In order to start the examination again, e.g.

for a new patient, press the START/STOP

key. The program then restarts with Test

No.1.

Figure 7 - Test form sheet No. 62855 (reduced in

scale)

recognized at least 3 of 5 positions (60%

criterion). Mark these correspondingly on the

form sheet (No. 62855, cf. Figure 7).

Pressing the TEST> key as often as

required brings you to each subsequent test

(Nos. 2 to 4), with contrast levels 1:5, 1:2,7

Name

First Name

Street

City

Examinat ion

TestNo.12345678

Contrast 1:23 1:2 1:23 1:5 1:2,7 1:21:2,71:5

wears no visual ai d

with contact l enses

Date of birt h

Sex m f

tinted lenses

clear l enses

binocular

monoc. right

monoc. left

and 1:2. The contrast diminishes with each

test. Level 1:2 is the most difficult to

recognize.

In presenting the Landolt ring positions,

proceed as during the first test. Mark these

results on the form sheet as well.

In case of uncertainty, the previous test can

be repeated by pressing the TEST< key.

Tests 5 to 8 are presented at the same

contrast levels as tests 1 to 4, but in brighter

surroundings and with continuous glare.

Before continuing the examination with Test

No. 5, turn on the fixation assistance with

the FIX key. Ask the examinee to direct his

gaze between the two red lights.

If the examinee does not do this and looks

directly into the glare light source during the

change to Test No. 5, he will recognize no

optotypes at first. This can cause a delay in

the examination, since he requires some

time (ca.10-30 seconds) for readaptation.

You can turn the fixation assistance off

again with the FIX key. However, it is

automatically turned off after each change of

tests or optotypes in order to prevent a

falsification of the examination results.

Now press the TEST> key again.

Visual performance improves

with differentlensepowers

Qualified for Night Driving Yes No

City, date Examiner

Mesotest II fort estingmesopie vision

Typ 62800

and glaresensitivity

The unit switches to "Standby" whenever ca.

7 minutes have elapsed with no change in

settings. Press any key to turn the

illumination on again.

If you have interrupted the examination,

show the examinee a different Landolt ring

position or a different test after taking up the

examination again.

-0.5 D -1.0 D -1. 5 D

Test form sheet No.62855

Optikgerät eGmb H

D-35549 Wetzlar

Tel.+ + 49/641/2005-0

Fax + + 49/641/2005-55

Page 16

Page 16

Instruction Manual Mesotest II

___________________________________________________________________

7.4. Additional Examinations

Provided that your Mesotest II is equipped

with minus lenses and an eye cover, you

have the option of carrying out additional

examinations.

You can use the minus lenses to determine

whether night myopia is present.

Activate the minus lenses for the last test

number which the examinee just barely

recognized.

To interpose a minus lens, first press the DPT.- key, then the key with the desired

lens power (marked in red on the control

unit).

If the examinee's visual performance

improves, night myopia is possibly present

and should be corrected with a

corresponding visual aid.

The degree of night myopia can be

determined by interposing different lens

powers (-0.5/-1.0/-1.5 D).

The eye cover also permits monocular

examinations to be carried out.

This is very important, e.g. for IOL patients

or excimer laser patients.

To swing the eye cover into place, press the

R/L/BIN key on the control unit. The cover is

advanced farther each time the key is

pressed. The screen display shows which

eye is being examined ( R / L / B ).

7.5. Evaluation of Results

The test with the least contrast which is still

correctly recognized constitutes the basis for

evaluating visual performance.

For the evaluation of the ability to drive at

night the German Ophthalmological society

(DOG) gives following recommendations:

Driver's licence in classes: A, A1, B, BE, M, L

and T

without glare: contrast level 1 : 5 (Test 2)

with glare: contrast level 1 : 5 (Test 6)

Driver's licence in classes: C, C1, CE, C1E,

D, D1, DE, D1E and passenger transport

without glare: contrast level 1 : 2,7 (Test 3)

with glare: contrast level 1 : 2,7 (Test 7)

Minimum requirements concerning the

mesopic vision and glare sensitivity according

to “Berufsgenossenschaft Principle G 25”

(Berufsgenossenschaft: Institution for Statutory

Accident Insurance and Prevention):

Requirement level 2 (only for increased

requirement)

without glare: contrast level 1 : 5 (Test 2)

with glare: contrast level 1 : 5 (Test 6)

Requirement level 1 (only for increased

requirement)

without glare: contrast level 1 : 2,7 (Test 3)

with glare: contrast level 1 : 2,7 (Test 7)

As a test criterion you must operate with a

criterion to interrupt just like the DIN 58220

(visual acuity). 3 out of 5 test-signs must be

recognized correctly.

Mark an "X" in the proper space on the

"Qualified for Night Driving" line of the form

sheet. If appropriate, also give the desired

driver's licence class.

7.6. After Each Use

Turn off the unit after using it, and use the

dust cover to protect it against foreign

matter.

Page 17

Instruction Manual Mesotest II

___________________________________________________________________

Page 17

8. Maintenance

8.1. Care, Cleaning and Disinfection

General Remarks

Disconnect the mains plug

before cleaning the unit!

Always observe the product

descriptions and instruction manuals for any

agents and equipment which are used in

caring for, cleaning, and disinfecting the unit

or its accessories.

Do not use agents which are aggressive,

contain chlorine, are abrasive, or may attack

the finish of the unit.

Cleaning Painted Surfaces and the Housing

Take care that no cleaning agents get inside

the unit.

In general, we recommend the use of a

cleaning agent with antistatic action for

plastic surfaces (to reduce subsequent static

attraction of dust particles).

Otherwise, clean the outer surfaces of the

unit by wiping them with a damp cloth.

If there are residues, you can wipe them off

with a mixture of equal parts of alcohol and

distilled water. You can also add a few drops

of a standard commercial dishwashing liquid

to this fluid.

Cleaning the Glass of the Viewing Aperture

Soiling caused by dust or fingerprints may

affect the examination. You can clean the

glass of the viewing aperture with a soft

cloth or an optical brush, using alcohol or a

lens cleaner if necessary.

Cleaning and disinfecting the lining of the Viewing Aperture

You can clean the lining of the viewing

aperture with mild soapsuds.

We recommend alcohol or spirits for

disinfecting it.

The lining of the viewing aperture should be

replaced in case of intense soiling (cf.

Chapter 8.3).

Page 18

Page 18

Instruction Manual Mesotest II

___________________________________________________________________

8.2. Replacing the Viewing Aperture Lining

The lining of the viewing aperture consists of

an elastic material. There is a slot on its

outer edge which slips onto the front frame

of the unit's casing. The lining of the viewing

aperture is reinforced on the inside with a

wire clip spring to stabilize its shape.

The unit can be laid on its back in order to

replace the lining of the viewing aperture.

Caution! Disconnect the

mains plug before tipping

the unit.

Be sure to lay the unit on

a soft surface.

Caution! Be careful not to

damage the glass of the viewing aperture

when installing the new lining of the

viewing aperture.

In order to replace the lining of the viewing

aperture, first remove the clip spring (Figure

10 a).

To do this, grasp the clip spring successively

by both of its rounded ends and unhook the

ends of the spring upwards out of the rubber

holder. Then pull the clip spring completely

out of the upper guide slot.

Now press the lining of the viewing aperture

out of its guide slot and pull it out, starting on

one side (Figure 10 b).

The replacement is carried out in the

reverse order:

Compress the lining of the viewing aperture

vertically and insert it into the frame of the

casing. Beginning from either side, press the

slot of the viewing aperture lining into the

frame. Take care not to bend the small

ventilation openings at the back.

With the continuous spring uppermost, place

the clip spring into its guide slot (Figure 11).

Take care that the spring is completely in

the slot.

Then grasp both rounded ends of the clip

spring one after the other and hook them

again into the groove at the bottom.

Figure 10 a - Removing the clip spring

Figure 10 b - Removing the lining of the viewing

aperture

Figure 11 - Inserting the clip spring

Page 19

Instruction Manual Mesotest II

___________________________________________________________________

Page 19

8.3. Replacing Fuses

Figure 12 - Mains plug with fuse drawer

Disconnect the mains plug

before replacing the fuses!

Replace only with a fuse of

type T 400 mA. A repeated

blowing of the fuses indicate

an internal fault of the Mesotest II.

Please clearly mark the unit as nonoperational and contact our service

personnel.

The two fuses of the unit are located in a

small fuse drawer which is built into the

mains input connector.

To open the drawer, grasp the small grip on

its top and pull the drawer out towards the

back.

For replacements, use only the fuse type

given on the rating plate. Press the drawer

back into place until the grip of the drawer

snaps into place again.

8.4. Replacing the Work Area Light.

Figure 13 - Work area light.

The bulb of the work area light has a long

working life. Should it ever burn out,

however, replacement is very easy.

The bulb is replaced as a unit with its plastic

socket, which also serves as a light shade.

Simply remove the light by pulling it

upwards. Take care not to bend the contact

wires of the bulb when inserting the new

light.

Guide the contact wires of the bulb and the

plastic nipples of its mounting into their

holes and push in the light until it is seated.

Page 20

Page 20

Instruction Manual Mesotest II

___________________________________________________________________

8.5. Solving Problems and Malfunctions

If a problem occurs which you cannot solve

with the Troubleshooting Table below, label

Problem Possible cause Solution

the unit as "Out of Order" and contact our

service personnel.

No reaction when the mains

switch is turned on.

The control unit or the serial

The fuses of the unit are

The unit was switched off and on

The examinee says that he does

not recognize anything.

The examination room is too

The work area light fails to light

up.

R/L/BIN and - DPT. do not

function with correct minus lens

values but are nevertheless

displayed in the LCD.

The Mesotest II is not connected

to the power mains.

Power failure, or the power

outlet is inactivated.

cable of the PC is incorrectly

connected.

defective.

again too quickly.

The unit is in Stand-by Mode. Press any key of the control unit.

brightly illuminated.

The light bulb is defective. Replace it (cf. Chapter 8.4).

Optional equipment has not

been installed in the unit.

Insert the mains cable into the

power outlet or into the input

connector of the Mesotest II.

Contact your house electrician.

Check whether the plug is

connected correctly.

Exchange the fuses (cf.

Chapter 8.3).

Wait 5 seconds between

switching the unit off and on.

Darken the room or cover the

tinted window with the enclosed

metal cover.

8.6. Maintenance: Description and Intervals

The Mesotest II has been built in such a way

that no special maintenance is required.

9. Disposal

Have the packaging disposed of

as recyclable waste.

When the device has reached

the end of its service life it has

to be disposed of properly:

The metal parts of the device should go to

scrap yard.

Plastic components, electrical components and

circuit boards should be disposed of as scrap

electronics.

To be certain, however, we recommend an

inspection of the photometric values every 2

years. Contact your OCULUS service

personnel for this purpose

Batteries should be disposed of as special

waste.

Materials should be disposed of according to

the laws of your country.

Please use the services of suitable waste

disposal companies.

Ask your town or municipal administration for

information about local waste disposal

companies.

Page 21

Instruction Manual Mesotest II

___________________________________________________________________

Page 21

10. Terms of Warranty and Service

10.1. Terms of Warranty

With the purchase of this instrument you

have chosen a high-quality product from

OCULUS. Your instrument has been

manufactured with great care using highgrade materials and state-of-the-art

production technology. Any software

delivered with this product has been tested

by OCULUS and confirmed to comply with

current technical standards. Please be sure

to read the operating manual as well as all

safety instructions before initial use and to

observe them when using the instrument.

This instrument is provided with a warranty

in accordance with the legal regulations.

Any manipulation of the device by

unauthorized persons voids all warranty

claims, since improper alterations or

attempts at repair can create considerable

hazards for users as well as patients.

Any manipulation by unauthorized persons

of PC hardware or software included in the

delivery likewise voids all warranty claims.

Please report any transport damage to the

shipping agent immediately upon or after

delivery and have this confirmed on the

freight bill so that any claims can be duly

settled.

In general our General Business and

Delivery Terms as amended at the date of

purchase shall apply.

Page 22

Page 22

Instruction Manual Mesotest II

___________________________________________________________________

10.2. Liability for Malfunction or Damage

OCULUS considers itself responsible for the

safety, reliability and functionalism of the

unit only if the unit is used in accordance

with this Instruction Manual.

The unit contains no parts (except the light

bulb), which require maintenance or repair

by the user.

No liability whatever is possible on the part

of OCULUS if assembly work, additions to

the unit, readjustments, maintenance work,

alterations, or repairs are carried out on the

unit by non-authorized persons or if the unit

is improperly cared for or handled.

If the above-mentioned work is carried out

by authorized persons, these persons must

be requested to provide a certification of the

type and extent of their repair work,

including details on changes made in the

ratings or the capacities of the unit if

required. The certification must bear the

date on which the work was carried out as

well as the name of the service company

and must be signed.

If desired, OCULUS will provide authorized

persons with circuit diagrams, replacement

parts lists, additional descriptions, and

adjustment instructions for this purpose.

Use only original parts from OCULUS for

repairs.

10.3. Manufacturer's and Service Address

You can receive additional information from

our service department or from our

authorized representatives.

Manufacturer's and Service Address:

OCULUS Optikgeräte GmbH

Münchholzhäuser Str. 29

D - 35582 Wetzlar

Tel.:++49 / 641 / 2005-0

Fax:++49 / 641 / 2005-255

e-mail = sales@oculus.de

Page 23

Instruction Manual Mesotest II

___________________________________________________________________

Page 23

11. Appendix

11.1. Literature References

- Aulhorn, E. und Harms, H.: Über die

Untersuchung der Nachtfahreignung von

Kraftfahrern mit dem Mesoptometer

Klin.Mbl. für Augenheilkunde 157/1970,

843-873, F. Enke-Verlag, Stuttgart

- B. Lachenmayr, Annemarie Buser und

Susanne Müller:

Welche visuelle Information benötigt der

Kraftfahrer für die sichere Teilnahme am

Straßenverkehr?

Ophthalmologie (1994) 91: 383-394

© Springer-Verlag 1994

- Nolte, W., (1962), Die Leuchtdichteverhältnisse im Straßenverkehr als Grundlage für die Augenuntersuchung von

Kraftfahrern.

Ber Dtsch Ophthalmol Ges 64: 543-547

- Empfehlung der Deutschen Ophthalmologischen Gesellschaft zur Fahreignungsbegutachtung für den Straßenverkehr

DOG, Heidelberg 1996

- DIN 58220-T1; März 1988; Sehschärfebestimmung, Normsehzeichen,

Beuth-Verlag, Berlin

Page 24

Page 24

Instruction Manual Mesotest II

___________________________________________________________________

11.2. Declaration of Compliance

We hereby declare as sole proprietor that

this product complies with the following

norms or normative documents:

- EN 60601-1 Medical electrical equipment;

General requirements for the safety,

05/1994

- EN 60601-1-2 Collateral Standard:

Electromagnetic compatibility, 09/1994

in accordance with the directives of

Guideline 93/42/EWG for Medical Products.

Dipl.Ing. Rainer Kirchhübel

Managing Director

OCULUS Optikgeräte GmbH

11.3. Order Information, Accessories, Replacement Parts

62800 Mesotest II

62801 Mesotest II Type 62800

with 3 additional sets of minus lenses

and an eye cover

62802 Carrying bag

62855 Set of 10 test note pads

6280006004 Light (spare light bulb for workplace light)

6280000001 Dust cover

6280001003 Lining of the viewing aperture

6280001007 Clip spring (for the viewing aperture lining)

05100090 Fuse 0.4 AT

62803 Software module for IBM-compatible PCs for recording examinations and

controlling the Mesotest II, incl. interface cable.

Diverse electrically operated elevation platforms on request.

Page 25

Instruction Manual Mesotest II

___________________________________________________________________

Page 25

11.4. Technical Data

Mains connection

100 - 240 VAC

50 - 60 Hz

35 VA

Fuses

2 x T 0,4 A - 250 V

Weight

7.8 kg incl. control unit and mains cable

Light sources

White LED´s

One for surrounding and one for glare

Dimensions

WxDxH 246 x 377 x 464 mm

Control unit WxDxH 82 x 152 x 45 mm

37

377 246

464

82

152

Mode of operation:

Via an external control unit with LCD and

integrated work area lighting.

Connection via cable to a serial interface, all

adjustments are carried out by a motor.

Option: Operation via PC.

Test distance:

5 m

No. of tests:

8 tests (4 with and 4 without glare);

6 different, freely selectable Landolt ring

positions.

We reserve the right to make changes necessitated by ongoing technical development.

Optotype carrier:

Permanently installed glass disc.

Optotypes:

Landolt rings, visual acuity 0.1

4 contrast levels: 1:23 / 1:5 / 1:2,7 / 1:2

Fixation assistance:

Via 2 light diodes, can be turned on at any

time.

Unit viewing aperture:

Elastic lining to seal off distracting room

light, made of material which is pleasant to

the touch, with ventilation, appropriate for all

head sizes.

Window of the unit:

Via a semitransparent mirror through a

tinted window in free space, used to avoid

instrument myopia.

Photometric data:

Brightness of surroundings:

Without glare: 0.032 ±0.003 cd/m2

With glare: 0.10 ± 0.01 cd/m2

Glare light source: 0.35 ± 0.03 lux

Angle of glare: 3°

Minus lenses:

Optional, for ascertaining the presence of

night myopia, with 3 sets of minus lenses:

-0.5 D / -1.0 D / - 1.5 D

Can be swung into position by motor, with

integrated eye cover for monocular

examinations

IEC 601-1 Classification:

Type of protection against electrical shock:

Safety class 1

Degree of protection against electrical

shock: Type B

Degree of protection against entry of water:

IP 20

Operating conditions:

Temp.: +10°C to +40°C

Humidity: 30 % to 75 %

Air pressure: 700 hPa to 1060 hPa

Loading...

Loading...