Page 1

RobotEye VISION REV25

User Manual

Ocular Robotics Pty. Ltd.

Level 3, 12-14 Ormonde Pde

Hurstville NSW 2220

Australia

www.ocularrobotics.com

Page 2

ii

www.ocularrobotics.com Ocular Robotics Pty Ltd

Revision Table

Copyright Notice and Disclaimer

Copyright 2013 Ocular Robotics Pty. Ltd (“Ocular Robotics”). All rights reserved.

No parts of this manual may be reproduced in any form without the express

written permission of Ocular Robotics.

Ocular Robotics makes no representations or warranties in relation to this User

Manual or the information and materials provided herein. Every precaution has

been taken in the preparation of this manual to include accurate and up to date

information. Ocular Robotics does not warrant that the information in this User

Manual is complete, true, accurate or non-misleading. Information contained

herein are subject to change without notice.

Ocular Robotics assumes no responsibility for errors or omissions or any

damages resulting from the use of the information contained in this handbook.

Date

Notes

12/07/2011

10/04/2013

Initial Release

Revision 1

Page 3

Table of Contents iii

www.ocularrobotics.com Ocular Robotics Pty Ltd

Table of Contents

Revision Table ................................................................................................................................................. ii

Table of Contents .......................................................................................................................................... iii

1 Introduction ................................................................................................................................................. 1

2 Basics............................................................................................................................................................... 2

2.1 System Components .......................................................................................................................... 2

2.1.1 RobotEye VISION REV25 Unit ............................................................................................... 2

2.1.2 RobotEye VISION REV25 System ......................................................................................... 3

2.2 What You Need .................................................................................................................................... 4

2.3 Handling and Transportation ........................................................................................................ 4

2.4 Initial Setup ........................................................................................................................................... 5

2.4.1 RobotEye VISION REV25 Unit ............................................................................................... 5

2.4.2 RobotEye VISION REV25 System ......................................................................................... 7

2.5 Safety ..................................................................................................................................................... 10

2.6 Operation ............................................................................................................................................. 11

2.7 Cleaning and Maintenance ............................................................................................................ 12

2.7.1 Replacement Parts ................................................................................................................... 12

3 General Description ................................................................................................................................. 13

3.1 Electrical .............................................................................................................................................. 13

3.2 Power .................................................................................................................................................... 13

3.2.1 RobotEye VISION REV25 Unit ............................................................................................. 13

3.2.2 RobotEye VISION REV25 System ....................................................................................... 13

3.3 Mechanical .......................................................................................................................................... 15

3.4 Ethernet ............................................................................................................................................... 18

3.4.1 RobotEye VISION REV25 Unit ............................................................................................. 18

3.4.2 RobotEye VISION REV25 System ....................................................................................... 18

3.4.3 Network Topology ................................................................................................................... 19

3.5 Optical ................................................................................................................................................... 21

3.5.1 Field of View ............................................................................................................................... 21

3.5.2 Camera Mounting ..................................................................................................................... 22

3.5.3 Camera Focus and Aperture ................................................................................................. 23

3.5.4 Modulation Transfer Function ............................................................................................ 23

Page 4

Table of Contents iv

www.ocularrobotics.com Ocular Robotics Pty Ltd

4 Specifications ............................................................................................................................................. 24

Page 5

Introduction 1

www.ocularrobotics.com Ocular Robotics Pty Ltd

1 Introduction

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

The REV25 User Manual is provided as a guide to the connection, configuration and safe

use of the Ocular Robotics REV25 Vision System. For development of custom software

applications for use with the REV25 system see the RobotEye Network Interface

Manual, RobotEye API Reference Manual, or contact Ocular Robotics.

Chapter 2 Basics, describes the initial setup and basic use of the REV25 including

information on cleaning, maintenance and safety. Chapters 3 General Description

presents a system description in terms of the system’s Mechanical and Electrical

properties and its communication and power interfaces.

CAUTION - USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF

PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN

SIGNIFICANT RISK OF INJURY. IT WILL ALSO VOID YOUR WARRANTY

Page 6

Basics 2

www.ocularrobotics.com Ocular Robotics Pty Ltd

2 Basics

IMPORTANT – Before connecting the power to this system or

attempting to operate it in any way, read and follow all instructions

regarding safe operation of this system contained in section 2.5.

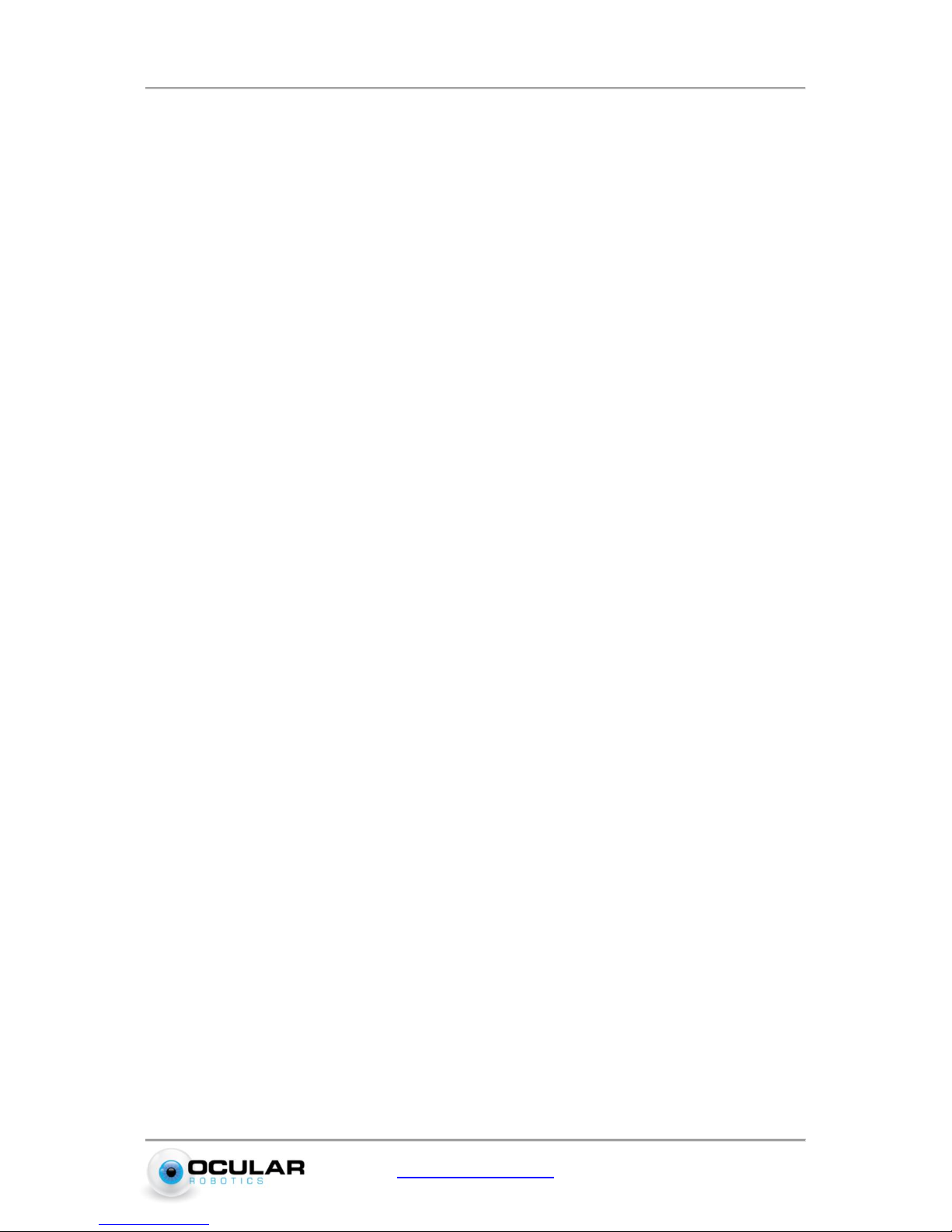

2.1 System Components

2.1.1 RobotEye VISION REV25 Unit

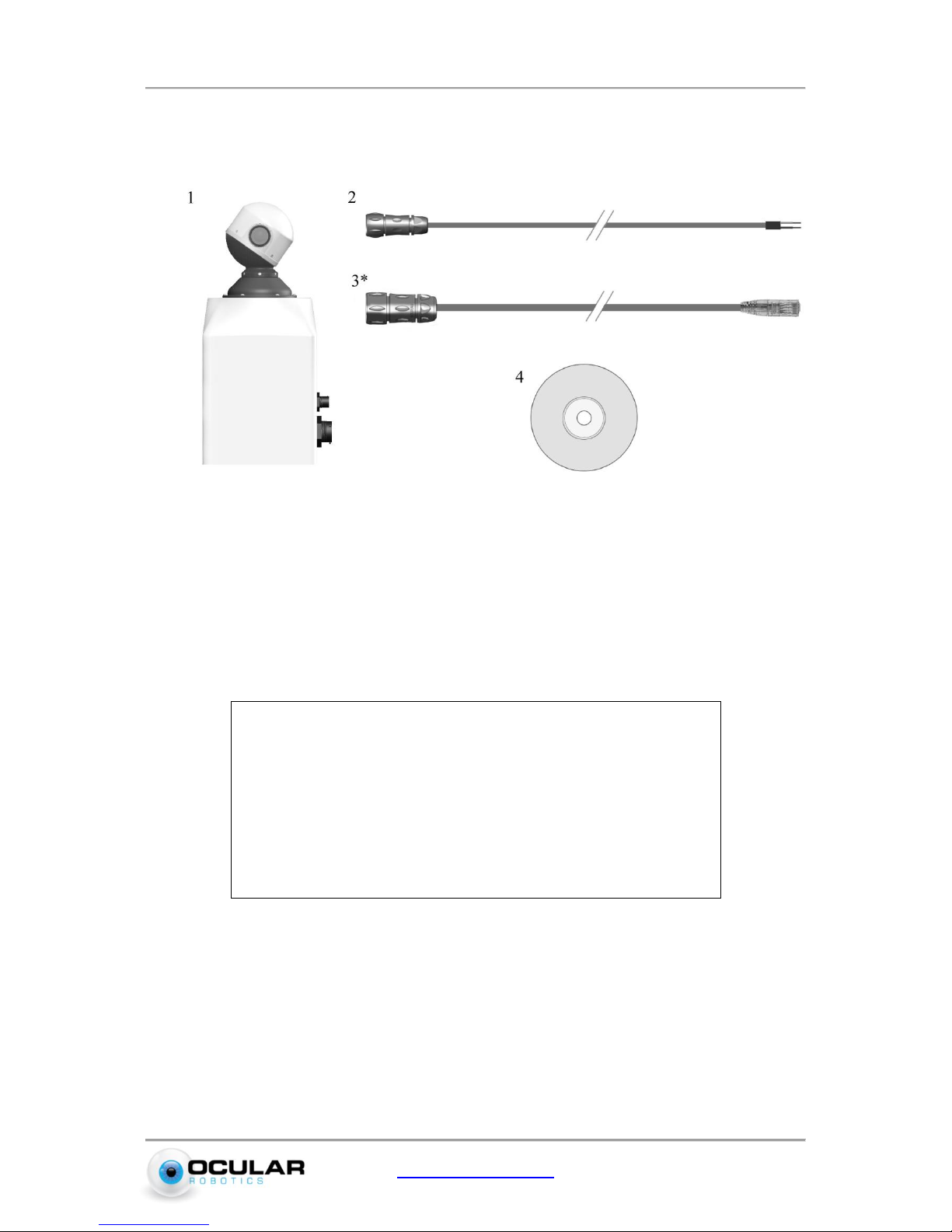

Figure 2.1 – RobotEye VISION REV25 Unit Packing List

The Ocular Robotics RobotEye VISION REV25 unit is supplied standard with the

following components, each of which can be seen in Figure 2.1:

1. The RobotEye VISION REV25 Unit.

2. Motor Power Amplifier Board.

3. 2-Axis Motion Controller Board.

4. Installation & documentation disk.

5. Cable Harness.

Page 7

Basics 3

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.1.2 RobotEye VISION REV25 System

Figure 2.2 – RobotEye VISION REV25 System Packing List

The Ocular Robotics RobotEye VISION REV25 System is an RobotEye VISION REV25

Unit mounted in an IP65* enclosure with power connector and dual Ethernet

connectors for RobotEye control and camera communication with the following

components, each of which can be seen in Figure 2.2:

1. The RobotEye VISION REV25 System.

2. REV25 power cable.

3. Cat-5e Ethernet cable (*optional).

4. Installation & documentation disk.

* To maintain the IP65 enclosure rating after installing or accessing the camera the base plate must be

replaced and base plate screws correctly tensioned

Page 8

Basics 4

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.2 What You Need

In order to operate the REV25 Vision unit and system, you will need:

1. Power supply – A 24 volt DC 10 Amp power supply with a continuous current

capacity of 10 Amps.

2. A suitable C-mount camera – Ocular Robotics can supply and mount a range of Allied

Vision Technologies GigE cameras, see the ordering info tab on the RobotEye VISION

REV25 product page of the Ocular Robotics website.

3. Ethernet cable – A standard Ethernet cable (Cat5e or Cat6) is needed for control and

communication with the REV25 system.

4. Camera communications cable – All cameras supplied by Ocular Robotics have a

GigE communications interface.

5. A computer with a Windows or Linux operating system with one free 100 Megabit

Ethernet port.

2.3 Handling and Transportation

Avoid handling the RobotEye using the scanning head. This may result in mechanical

damage and misalignment of the sensor.

When transporting, make sure the RobotEye head will not be subject to large external

loads and stresses.

Figure 2.3 – REV25 Handling Zones

Page 9

Basics 5

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.4 Initial Setup

NOTE – The robot eye head must be handled with extra care

during transport and installation. External loads exerted on the

head may result in damage.

2.4.1 RobotEye VISION REV25 Unit

Follow the steps below to set the REV25 unit up for use on a computer with a Windows

or Linux operating system. The library version number and system IP address shipped

with your system should be noted on the supplied Certificate.

Figure 2.4 Wiring and connections for the REV25 Unit

1. Connect Cable Harness (16 pin to 10/6 pin cable) between controller and amplifier

board.

Page 10

Basics 6

www.ocularrobotics.com Ocular Robotics Pty Ltd

2. Connect unit Encoder Sensor cable (14 pin connector) to black 2 Axis Motion

Controller board.

NOTE – Make sure the orientation of the connectors is correct.

Incorrect orientations may result in damage to the system.

3. Connect motor Hall Sensor cable (8 pin connector) from the unit to the black 2 Axis

Motion Controller board.

4. Connect motor power cables (4 pin white connectors) to the Motor Power Amplifier

board. Match the colour coding of the connectors to ensure correct operation,

incorrect connection of the motor power cables will result in uncontrolled motion of

the system on power up.

5. Connect both the 2 Axis Motion Controller board and Motor Power Amplifier board

to a 24 VDC power supply. Information on the polarity of the power connectors are

detailed in Section 3.2.

WARNING - Make sure the power supply is not powered before

connecting the cables.

6. Connect one end of the Ethernet cable to the network port on the PC or switch.

Connect the other end to the Ethernet port on the 2 Axis Motion Controller board.

7. Connect the chosen camera to the C-mount thread on the end of the REV25 unit. A

universal camera mount to suit all Allied Vision Technologies cameras

recommended for use with the REV25 product is supplied with the REV25 unit. If a

different camera is chosen and it can’t be used with the mount provided then

alternative mounting arrangements should be provided. DO NOT allow the camera

to be unsupported on the camera lens.

a) The camera lens should be rotated on the filter thread where it attaches to the

REV25 by the minimum amount required to align the body of the camera to one

of the two possible camera mount positions shown in Figure 3.12.

b) Remove two socket head screws in the base of the REV25 body in the chosen

position for the attachment of the camera mount (DO NOT have any more than

two screws removed from the base of the REV25 at any time). Place the camera

mount in position and replace the socket screws but do not tighten until the

mount is attached to the camera.

Page 11

Basics 7

www.ocularrobotics.com Ocular Robotics Pty Ltd

c) Use fasteners appropriate for your camera to fasten the camera to the mount and

then tighten the socket screws attaching the mount to the base of the REV25

(Note – The screws used to attach the camera to the mount will need to be

loosened to focus the camera).

8. Attach power and communications cables as appropriate for your camera.

2.4.2 RobotEye VISION REV25 System

Follow the steps below to set the REV25 system up for use on a computer with a

Windows or Linux operating system. The library version number and system IP address

shipped with your system should be noted on the supplied Certificate.

1. Connect one end of the Ethernet cable to the network port on the PC or Switch.

Connect the other end to the REV25 Control Ethernet port (right-side Ethernet

connector). Refer to Figure 2.5.

2. Connect another Ethernet cable to the REV25 Camera Ethernet port (left-side

Ethernet connector) and a PC or Switch.

Figure 2.5 Wiring and connections for the REV25 System

Page 12

Basics 8

www.ocularrobotics.com Ocular Robotics Pty Ltd

3. Make sure the 24 volt power supply is switched OFF. Connect the supplied power

cable to the 24 volt power supply. On the unterminated end of the cable you will find

two wires one black and one with a red sheath on it. The black wire should be

connected to the negative terminal on the power supply. The cable with the red

sheath should be connected to the positive terminal on the power supply. The green

and yellow cable should be connected to a ground reference.

WARNING - Make sure the power supply is not powered before

connecting the cables.

4. Connect the power supply cable to the corresponding plug on the REV25 system.

Ensure the correct orientation by aligning the polarisation keys on the panel

connector and the plug. If forced in the incorrect orientation, damage to the system

is likely to result. Refer to Section 3.2.2 - Power for further details.

5. If your REV25 Vision System was ordered complete with an Allied Vision

Technologies camera then your system should be ready to use. For adjusting the

Focus and Aperture of your camera see Section 3.5.3 - Camera Focus and Aperture.

Otherwise follow steps a) to i) to install your chosen camera.

a) Open the system enclosure by removing the eight countersunk socket screws

from the base.

b) Connect the chosen GigE camera to the C-mount thread on the end of the REV25

unit. A universal camera mount to suit all Allied Vision Technologies cameras

recommended for use with the REV25 Vision product is supplied with the REV25

Vision System. If a different camera is chosen and it can’t be used with the mount

provided then alternative mounting arrangements should be provided. DO NOT

allow the camera to be unsupported on the camera lens.

c) The camera lens should be rotated on the filter thread where it attaches to the

REV25 by the minimum amount required to align the body of the camera to one

of the two possible camera mount positions shown in Figure 3.12.

d) Remove two socket head screws in the base of the REV25 body in the chosen

position for the attachment of the camera mount (DO NOT have any more than

two screws removed from the base of the REV25 at any time). Place the camera

mount in position and replace the socket screws but do not tighten until the

mount is attached to the camera.

Page 13

Basics 9

www.ocularrobotics.com Ocular Robotics Pty Ltd

e) Use fasteners appropriate for your camera to fasten the camera to the mount and

then tighten the socket screws attaching the mount to the base of the REV25.

NOTE – The screws fastening the camera to the universal camera

mount must be loosened before adjusting the focus.

f) Attach the internal Ethernet cable from the enclosure camera Ethernet connector

to your GigE camera

g) The two pin connector shown in Figure 3.4 makes 24 VDC available for camera

power connection; a suitable converter from 24V to your camera’s required

voltage will need to be provided.

h) Follow the procedure in Section 3.5.3 to adjust the focus and aperture of the

camera.

i) Replace the base using the eight countersunk socket screws and tension

correctly to maintain the integrity of the seal.

6. Attach power and communications cables as appropriate for your camera.

Page 14

Basics 10

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.5 Safety

The RobotEye VISION REV25 System is a high speed device. All instructions regarding

safe operation of this system should be strictly followed.

Protection Class 3. The device operates with a separated extra low voltage

(SELV) of 24 Volts DC.

The device may only be operated as intended and in faultless condition. Safety

and warning signs must not be removed.

The REV25 Vision System is in accordance with Ingress Protection 65 (IP65).

The device is protected against dust and jet water.

All instructions regarding safe operation of this system should be strictly followed.

The user is responsible for the safe operation and maintenance of this system at all

times.

Installers of the sensor are responsible for ensuring their safe use in accordance

with all applicable regulations in the state, country or territory of use.

The device’s rotating head is not designed to accommodate for any alterations or

additions. High speed projectiles may result.

The device must be securely mounted during operation to prevent unstable motions

or vibrations.

Ensure that the Robot Eye head will not contact anything while operating in its full

range of movement.

Do not try to hold or touch the Robot Eye head while operating.

Do not attempt to disassemble the sensor. Improper disassembly will destroy the

optical alignment of the sensor and necessitate factory repairs. Tampering with any

enclosure will void warranty coverage.

The manufacturer will not accept liability for any resulting damages caused by the

non-observance of this manual or any unauthorised modification to the system.

Page 15

11

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.6 Operation

Special precautions for when operating the device.

The REV25 is NOT intended for use by children or inexperienced personnel.

DO NOT attempt to touch or impede the Robot Eye head during operation.

Avoid strands of fabric or long exposed hair from being in the vicinity of the Robot

Eye head during operation. Significant injury and/or mechanical damage may result.

The device must be protected from shock and impact.

Figure 2.6 Do not touch RE Head while in operation. Avoid impacts.

General considerations for when operating the device.

The REV25 should not be put into operation when the aperture is fogged or dirty.

The aperture should not be touched with bare hands. Refer to Section 2.7 for

cleaning the device.

The device must be protected against overheating. Persistent overheating of the

device will lead to reduced lifetime of the camera.

Additional protection is recommended when operating the device under extreme or

adverse environmental conditions. Rapid changes in temperature may lead to

humidity entering the device.

Page 16

12

www.ocularrobotics.com Ocular Robotics Pty Ltd

2.7 Cleaning and Maintenance

CAUTION – Power must be disconnected from the REV25 system

before any cleaning or maintenance is carried out.

User performable cleaning and maintenance of the RobotEye REV25 Vision System is

limited to cleaning of the exterior housing and the aperture window. For ANY other

maintenance or repair the unit should be returned to the factory. Unauthorised opening

of the system enclosure will void warranty. Use the following guidelines for cleaning of

the system enclosure and aperture window.

It is VERY important not to abrade or scratch the system window during cleaning or

at any other time as it has the potential to significantly degrade system performance.

Use a soft non-abrasive cloth to clean the window, make sure there are no foreign

abrasive particles on the window before performing cleaning, as this may damage

the window.

DO NOT use solvents. If a cloth alone is not sufficient, water or Isopropyl Alcohol

may be used.

The rest of the REV25 Vision System housing can be cleaned with a soft damp cloth.

2.7.1 Replacement Parts

Replacement parts can be ordered directly through Ocular Robotics.

1) RobotEye VISION REV25 System power cable.

a) The power cable comprises of a standard 3 core power cable rated for at least

10A.

b) The power cable has an IP68/IP69K UTS6JC103S Souriau connector attached to

interface with the mating UTS6JC103P receptacle on the enclosure.

2) Cat5e/Cat6 Ethernet cable (REV25 System).

a) The Cat5e or Cat6 Ethernet cable can optionally be fitted with an IP68/IP69K

Souriau UTS6JC18RJN connector.

3) 5mmx20mm 16A Fuse (REV25 System).

a) The fuse is located in the Schurter Fuseholder located above the left Souriau

Ethernet connector.

Page 17

General Description 13

www.ocularrobotics.com Ocular Robotics Pty Ltd

3 General Description

The RobotEye VISION REV25 System is a two-axis high performance vision system with

unprecedented motion bandwidth. The REV25 System is ideally suited for use on

ground vehicles, surface craft, aircraft and static installations.

The REV25’s embedded RobotEye technology allows applications such as inertial

stabilisation, object tracking, telepresence/teleoperation, environment mapping, rapid

disparate point data acquisition and persistent surveillance to be easily achieved.

3.1 Electrical

The REV25 Vision System requires a 24 Volt DC power supply that has a continuous

current capacity of 10 amps. The output voltage of the 24 VDC power supply used with

the REV25 System should not vary by more than ±15% from the nominal 24V under any

circumstances otherwise damage to the REV25 System may result.

3.2 Power

3.2.1 RobotEye VISION REV25 Unit

Power is supplied to the REV25 Unit via TE Connectivity Universal MATE-N-LOK

connectors as shown in Figure 3.1. Both the 2 Axis Motion Controller board and Power

Amplifier board need to be directly powered by the 24 VDC supply.

Figure 3.1 – Power connector on the controller and amplifier boards

3.2.2 RobotEye VISION REV25 System

Power is delivered to the REV25 System with the supplied 5 metre power cable. The

unterminated end of the power cable has two wires, one black and one with a red

sheath on it. The black wire should be connected to the negative terminal on the power

supply. The cable with the red sheath should be connected to the positive terminal on

the power supply.

Page 18

General Description 14

www.ocularrobotics.com Ocular Robotics Pty Ltd

Figure 3.2 – Power connector on the REV25 Enclosure

During connection of the power supply cable to the corresponding plug on the REV25

system, ensure the correct orientation by aligning the polarisation keys on the panel

connector and the plug. If forced in the incorrect orientation, damage to the system is

likely to result.

A 16A rated fuse is housed in the Schurter 3101-0110 fuseholder to prevent potential

damage to internal electrical components from power surges.

Figure 3.3 – Fuseholder on the REV25 Enclosure

Power to the camera inside the enclosure is provided via a Molex KK6471 two-way

connector. The red wire provides 24 VDC with respect to the black wire at 0 V. A

suitable voltage converter is required if the camera operates at a different voltage.

Figure 3.4 – Power connector for the camera

Page 19

General Description 15

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.3 Mechanical

The REV25 Vision System has an environmental protection rating of IP65 and can

operate in ambient temperatures of up to 70°C (The maximum operating temperature

of installed cameras may however be lower than this) making it suitable for use in a

wide range of industrial environments. The REV25 Vision Head enclosure has IP65

rating (when used with the cable socket and panel plug connectors mated).

The bounding dimensions and positions of mounting holes for the REV25 Unit and

System are shown in Figure 3.5 and Figure 3.6.

Page 20

General Description 16

www.ocularrobotics.com Ocular Robotics Pty Ltd

Figure 3.5 – REV25 Unit Mechanical Dimensions

Page 21

General Description 17

www.ocularrobotics.com Ocular Robotics Pty Ltd

Figure 3.6 – REV25 System Mechanical Dimensions

Page 22

General Description 18

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.4 Ethernet

3.4.1 RobotEye VISION REV25 Unit

The REV25 Vision Unit interfaces with a computer via a standard Ethernet cable. The

REV25 Control supports a 100 Megabit connection.

The Ethernet connection is located on the black 2 Axis Motor Controller Board.

Figure 3.7 – RJ45 Ethernet Connection located under the Serial No. label.

3.4.2 RobotEye VISION REV25 System

The REV25 Vision System interfaces with a computer via a standard Ethernet cable. The

REV25 Control supports a 100 Megabit connection.

The REV25 Vision System has two Ethernet connections located on the side of the

enclosure. The left Ethernet connector is for interfacing with the nominated imaging

camera. The right Ethernet connector is for controlling the REV25 Vision System.

Figure 3.8 – RJ45 Ethernet Connections on the REV25 System Enclosure

Page 23

General Description 19

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.4.3 Network Topology

It is recommended that the system be used on a private network to avoid large amounts

of (unwanted) data potentially being sent to all computers on the network (see Figure

3.9). Multiple REV25 Vision Units/Systems can be connected on a single network.

However this should be done using a switch to avoid data collisions on the network (see

Figure 3.10).

The REV25 is configured to allow any number of clients to receive data when in

broadcast mode. The REV25 will only accept commands from the Primary Client

however. This is to ensure that multiple clients cannot simultaneously send conflicting

commands to the sensor. The Primary Client is determined by the REV25 in a very

simple manner, it is the client that first sends data to the REV25 after it is powered up.

For a more detailed explanation of the network behaviour of the REV25 System see the

RobotEye UDP Communications Specification available for download from the Ocular

Robotics website.

In most situations use of a Cat5e Ethernet cable will be sufficient for operation of the

REV25 Vision Unit/System, however it is recommended that a Cat6 cable be used over

long distances to avoid packet loss due to the large volume of data.

The REV25 System enclosure has an IP68/69K rated (when used with the mating cable

plug) RJ45 connectors for use when environmental conditions require the use of extra

protection. The mating cable plug is a Souriau UTS6JC18RJN and can be purchased as an

Ethernet cable assembly from Ocular Robotics or through various suppliers of

electronic connectors.

Page 24

General Description 20

www.ocularrobotics.com Ocular Robotics Pty Ltd

Figure 3.9 – Network Schematic for Single Host PC to Single REV25

Figure 3.10 – Network Schematic for Single Host PC to Multiple REV25’s

Page 25

General Description 21

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.5 Optical

3.5.1 Field of View

The optical diagonal field of view for standard 4:3 aspect ratio CCD’s are listed in Table

1, with corresponding representations illustrated in Figure 3.11.

Table 1 – Approximate Diagonal Fields of Views for standard CCD’s

CCD Size

Diagonal FOV

1/4”

15°

1/3”

22°

1/2"

29°

2/3”

40°

Due to the nature of the optical path within the RobotEye, the 4:3 viewing rectangle will

rotate within the grey aperture circle depending on the RobotEye aperture’s azimuthal

position. The white circular mask inside the 4:3 viewing rectangle is a representation of

the effective field of view when a non-rotating video feed/image is desired.

NOTE – De-rotation of the video/image needs to be handled via

software.

Figure 3.11 – Field of View Representations for various CCD sizes (Not to Scale)

Page 26

General Description 22

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.5.2 Camera Mounting

The universal camera mount provided with the REV25 is designed to suit all Allied

Vision Technologies cameras recommended for use with the REV25 Vision Unit. If a

different camera is chosen and it can’t be used with the camera mount provided then

alternative mounting arrangements should be provided.

DO NOT allow the camera to be unsupported on the camera lens.

Unsupported cameras may result in mechanical damage.

The universal camera mount can be placed in two different orientations on the

mounting plate located at the bottom of the RobotEye unit as shown in Figure 3.5. The

recommended mounting orientations are illustrated in Figure 3.12 below. Note that the

RobotEye head in Figure 3.12 is facing the default home position (0 elevation, 0 azimuth)

and that the resulting camera view will be rotated 90° with respect to horizontal for

each orientation.

Figure 3.12 – Recommended Camera Mounting Orientations (Forward View)

Page 27

General Description 23

www.ocularrobotics.com Ocular Robotics Pty Ltd

3.5.3 Camera Focus and Aperture

A Fujinon HF50HA-1B lens is attached to the bottom of the REV25 unit. The focal length

is 50mm with an iris range of F2.3 to F22. The camera focus and aperture can be

adjusted by rotating the rings on the lens as shown in Figure 3.13. Release the locking

knobs to freely rotate the rings.

NOTE – The screws fastening the camera to the universal camera

mount must be loosened before adjusting the focus.

Figure 3.13 – Fujinon HF50HA-1B C-mount Lens

3.5.4 Modulation Transfer Function

The REV25 Vision optical system Modulation Transfer Function is provided below for

reference.

Figure 3.14 – Plot of the Modulation Transfer Function

Page 28

Specifications 24

www.ocularrobotics.com Ocular Robotics Pty Ltd

4 Specifications

Mechanical

Maximum Azimuth Rate

10,000°/s

Maximum Elevation Rate

4,000°/s

Maximum Aperture Acceleration

>50,000°/s

Azimuth Axis Resolution

0.010°

Elevation Axis Resolution

0.004°

Azimuth Range

360° Continuous

Elevation Range

70° (±35°)

Accuracy

0.05°

Weight

2.5 kg

Electrical

Communication (minimum 100 Megabit)

Ethernet

Supply Voltage

24 VDC

Power Consumption — Typical (average)

<1.5 A

— Maximum (peak)

10.0 A

Optical

Maximum optical field of view (diagonal)

40°

Optical port

C-Mount

Environmental

Operating Temperature Range

-20°C - +50°C

IP Class Rating (REV25 Vision System)

65

Note: IP Rating valid only when both supplied power &

optionally supplied Ethernet cable connectors are fitted.

Loading...

Loading...